1. Introduction

The important features of a nano- or micro-scale compensation stage are fast response, high positioning resolution, and excellent positioning repeatability. The two most common kinds of nano-scale compensation stage are

x-

y-yaw and

z-tilt. The

x-

y-yaw stage is like that proposed by Lee et al. [

1], and the

z-tilt stage is like another proposed by Liu et al. [

2]. The structure of

z-tilt stages is usually simpler than that of

x-

y-yaw stages. However, the shape of the flexure hinges in a

z-tilt stage influences stage bandwidth and coupling displacement more than in an

x-

y-yaw stage. Both types of nano-scale compensation stage can be of a coplanar design. Although, a coplanar stage has many advantages such as small size, a low center of gravity (which means a higher frequency response), low cumulative mechanical setup error and so on, coupling displacement is intensely influencing positioning accuracy [

3]. For example, when the stage is moved in the

y-direction, displacement in the

x-direction will not be zero. To decrease the coupling displacement, flexure hinges with reduced stiffness should be considered. However, lowering the stiffness of the flexure hinges can also lower the system bandwidth. Design of the flexure hinges should provide for an optimal coupling displacement to stage bandwidth ratio.

A Scott–Russell amplifying mechanism which was employed one-dimensional flexure hinges was analyzed by Chen et al. [

4]. Ahuett-Garza et al. conducted a study about large deflection planar compliant mechanisms constructed by one-dimensional flexure hinges which is similar to the Chen’s study [

5]. In Ahuett-Garza’s study, three kinds of one-dimensional flexure hinge were simulated. Tian et al. is using adaptive Simpson integration and polynomial approximation techniques to develop the dimensionless empirical equations for three kinds of one-dimensional flexure hinges [

6,

7]. The results show that the dimension and form of flexure hinges influence the stiffness and rotational precision. Although above research can analyze one-dimensional flexure hinges very well, there are too many parameters that are difficult for analyzing. The Taguchi method can be used to figure out the optimal parameters for such a system without a lot of experimentation and complex mathematical calculation being necessary. Some studies applied the Taguchi method to design the mechanics which are employed in one-dimensional flexure hinges [

8,

9,

10].

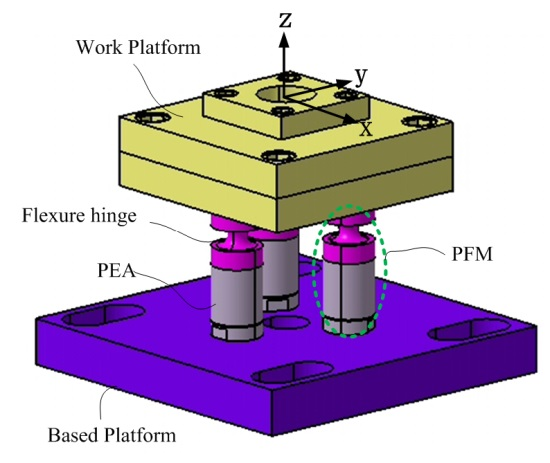

This study used Taguchi to find the optimal design parameters for a two-dimensional flexure hinges of a

z-tilt compensation stage. The three motions of the

z-tilt stage are the linear motion in the

z-axis, angular motion in the

x (θ

x) and

y (θ

y) axes. The easiest way to achieve

z-tilt motion is to use three piezoelectric-flexure-hinge modules (PFM) as shown in

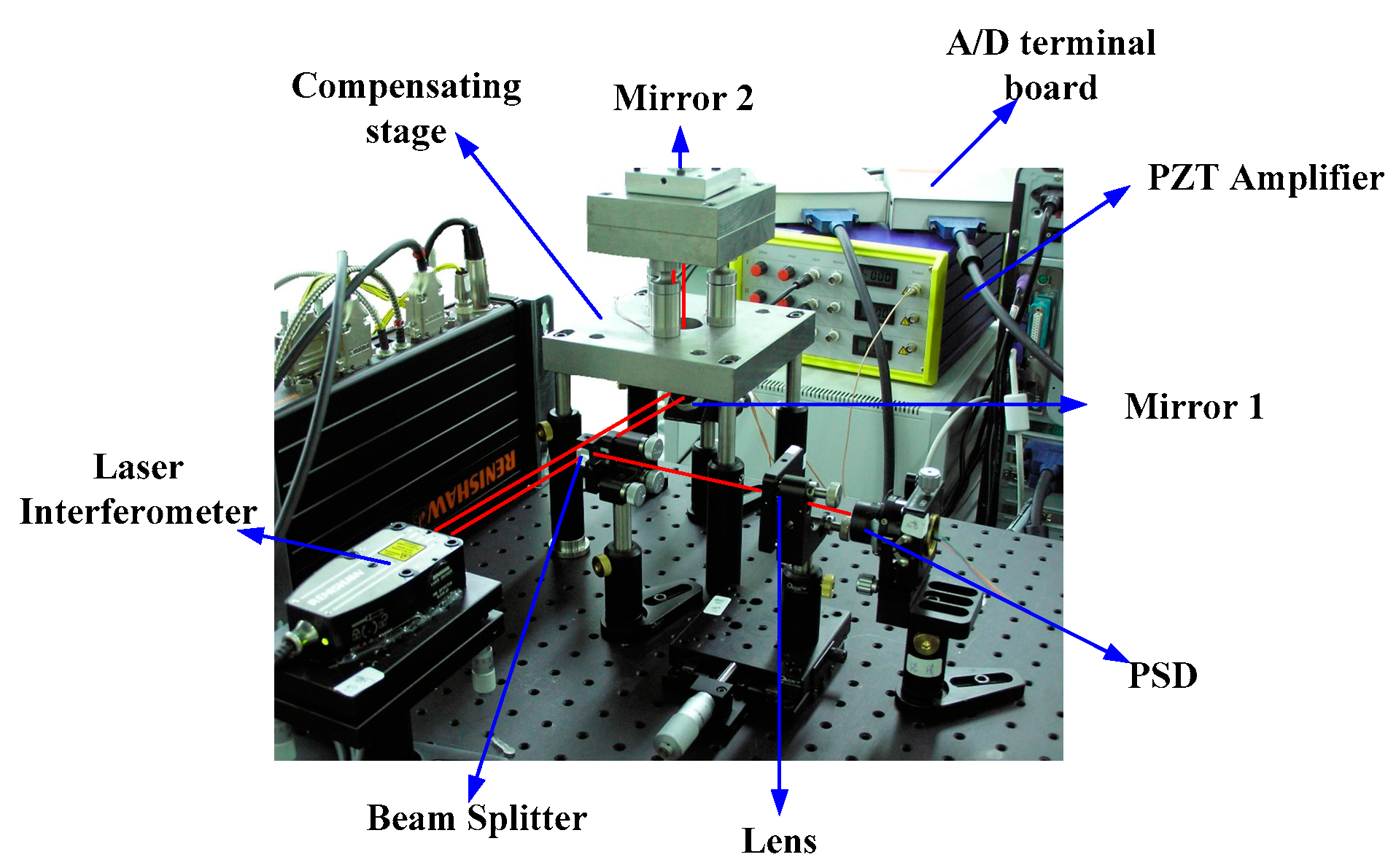

Figure 1. Here, each PFM consists of a flexure hinge and a piezoelectric actuator.

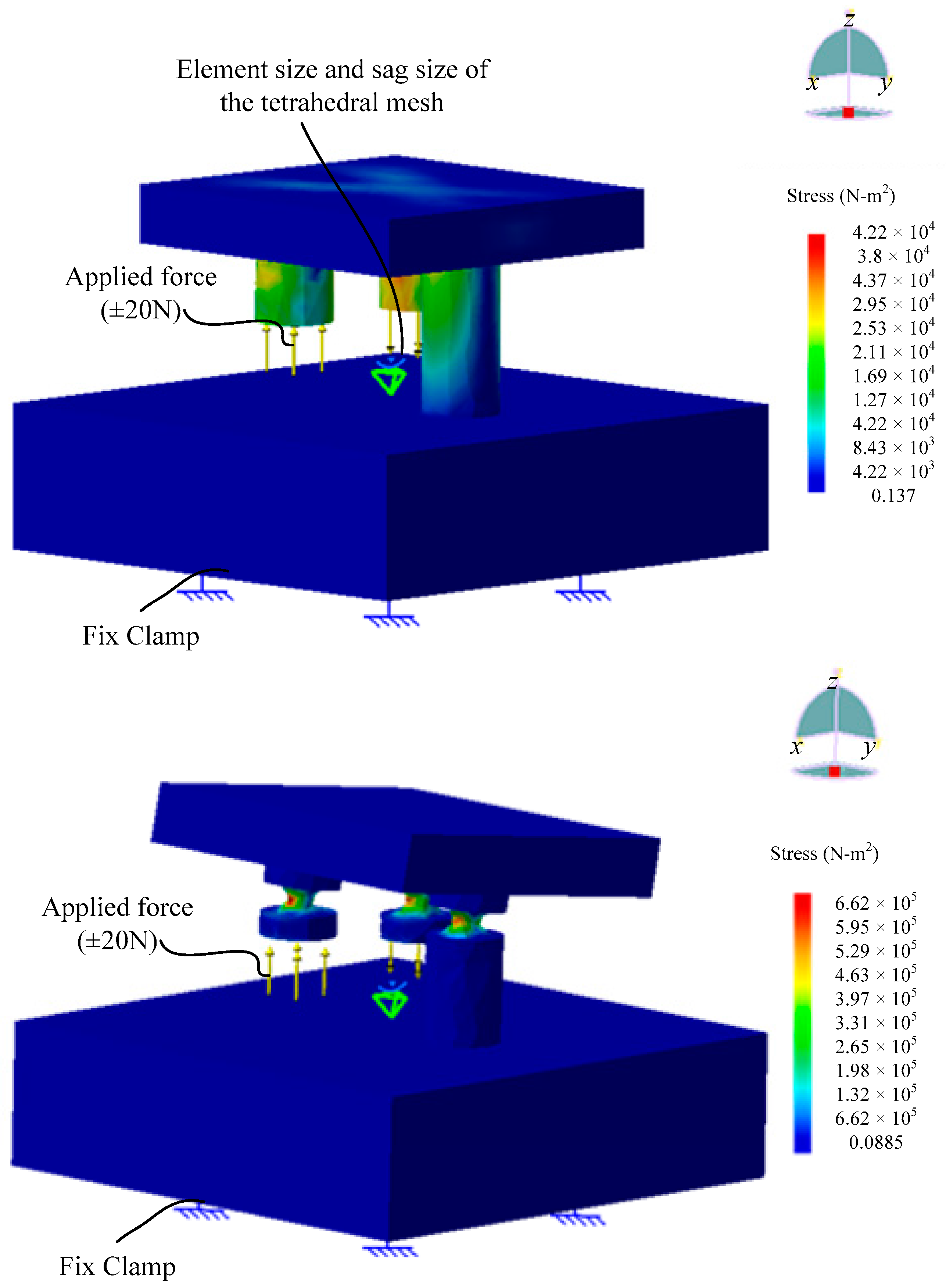

Figure 2 shows a simulation that explains why flexure hinges are needed for a

z-tilt stage. The upper one shows the stress concentrated on the piezoelectric actuator and deformation that occurs on the work platform if there is no flexure. This problem can be avoided by the use of flexure hinges. Two kinds of flexure hinge are commonly used, notched and circular [

11]. Circular flexure hinges are usually employed on

z-tilt stages because motion is two-dimensional. Other kinds of flexure hinges with special shapes have been proposed by Jywe [

12]. Flexure hinges are not limited to use on nano-scale stages, but can also be used in such applications as tool compensation as proposed by Andrew Woronko et al. [

13]. The main problem of piezoelectric actuator usage is hysteresis which causes low positioning accuracy. For increased positioning accuracy, Lin et al. adopted a hysteresis observed control method [

14]. Banning et al. built a hysteresis model for hysteresis displacement compensation [

15]. There are some different models are used for hysteresis compensation such as the classical Preisach model [

16], Inverse Preisach Model [

17], Bouc–Wen model [

18], and so on. The improvement of mathematical model compensation methods is limited. Thus, some studies using a compensator with a PID (proportional–integral–derivative) controller to improve the steady state error and dynamic tracking performance like Ru et al. proposed [

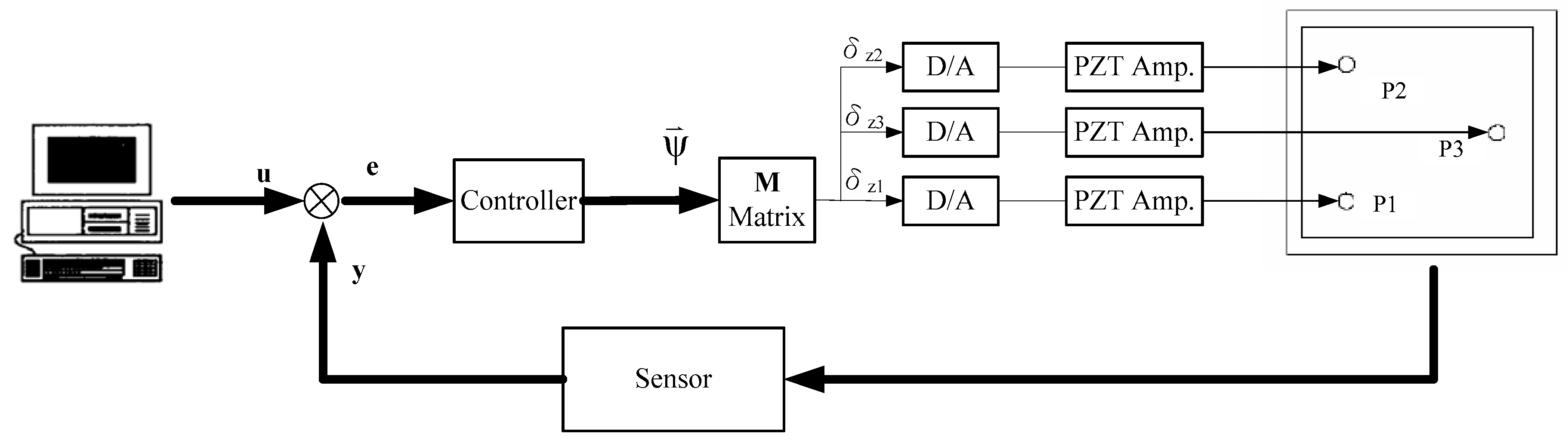

19]. Beside mathematical compensation methods (e.g., feed-forward compensator), Liu et al. employed a capacitor in the piezoelectric driving circuit for hysteresis reduction and the method is called capacitor insertion method [

2]. This study was concerned with positioning accuracy. Thus, only a PI (proportional–integral) controller was used.

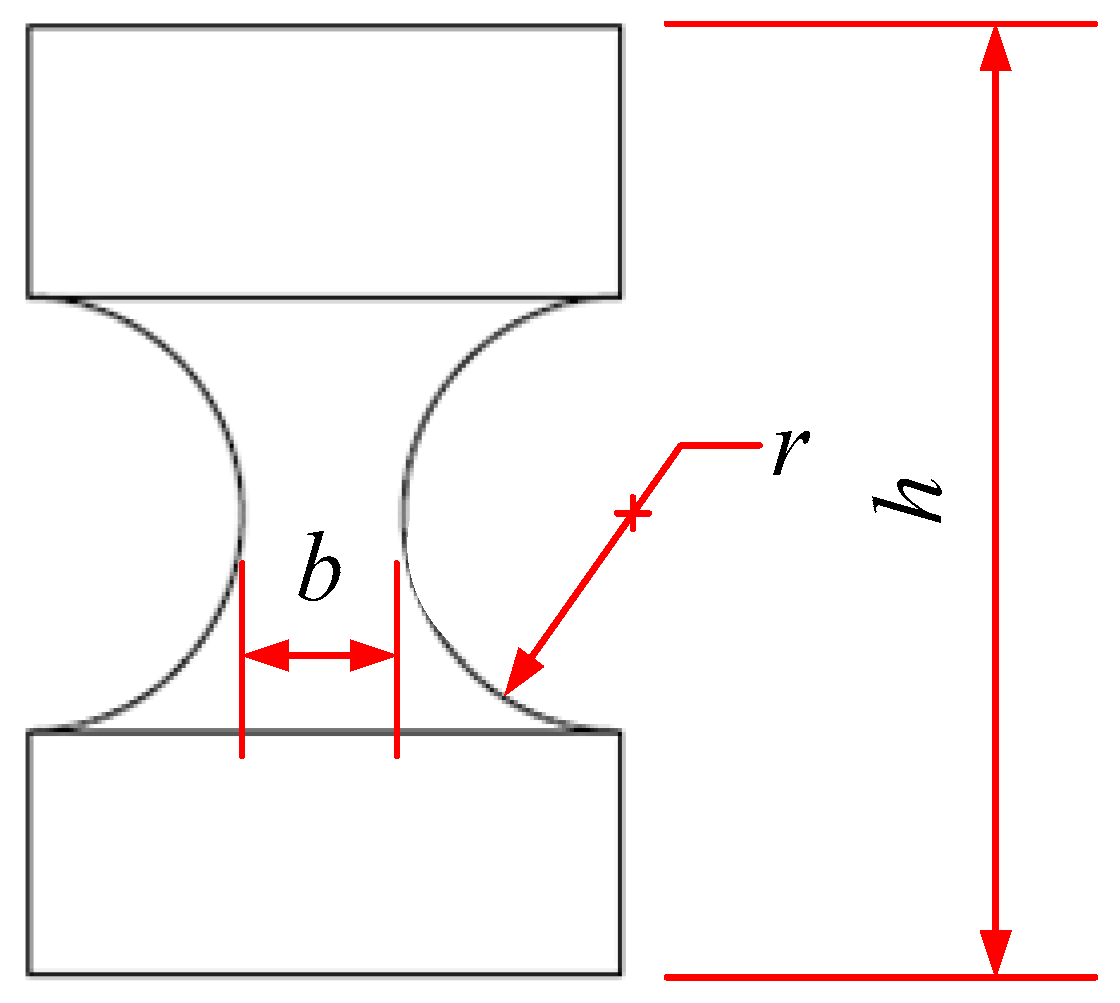

There are three parameters which need to be taken into account in the design of a 2D circular flexure hinge: the minimum diameter (

b); the body height (

h); and the notch radius (

r), as shown in

Figure 3. Estimating of the static performance of a

z-tilt stage, such as coupling displacement and stage stiffness, can be made using simulation and stepwise displacement experiments. The dynamic performance of a

z-tilt stage can be tested by a tracking experiment [

2,

20]. The first part of this study describes the use of the Taguchi method to optimize design of the circular flexure hinges. The second part is a description of dynamic performance tests of the proposed

z-tilt stage. At the last in this study, some experiments were performed to check whether the results achieved the design intent.

2. Flexure Hinge Optimal Design

The S/N (signal-to-noise) ratio η is used as a performance evaluation index for optimal design results obtained by the Taguchi method. In this study, quality characteristics include: (1) the smaller the better (STB), the ideal value being zero, such as the poisoning error of a machine tool; (2) the larger the better (LTB), the ideal value here being infinity, such as the lifetime of a device; and (3) nominally the best (NTB), the special value of a target, such as the wavelength of a laser interferometer. In this study, eight steps were followed to arrive at an optimal design for the 2D circular flexure hinges.

Step 1. Deciding the design parameters:

As previously mentioned, the three parameters this study is concerned with are the minimum diameter (

b), the body height (

h), and the notch radius (

r), as shown in

Figure 3.

Step 2. Setting the parameter levels:

All parameters were set at three levels, as listed in

Table 1, according to the required dimension of the stage, design experience, heuristics, machining rationality, notch sensitivity, and research results [

8,

21]. Please note, the optimal results based on level belong to local optimization, and are not global.

Step 3. Building an orthogonal array:

In this study an OA

9(3

3) orthogonal array (OA) was used in the simulation as shown in

Table 2 where each level (A1, A2, A3, B1, …, C2, and C3) appears three times. The OA is balanced and there is no repeated permutation.

Step 4. Defining the output response:

Two output responses were defined for the evaluation index:

- (1)

Natural frequency (η

1): The natural frequencies of the

z-tilt stage with no load and when loaded. For such a stage, the system bandwidth is usually proportional to the natural frequency and so the LTB equation was used for performance evaluation:

- (2)

Coupling angular displacement (η

2): The ideal value of coupling displacement is zero, so the STB equation was used for evaluation:

In Equations (1) and (2), yi represents the simulation output value, for example, the natural frequency (units can be ignored); n represents the number of output response (n = 1 for η1; n = 1 for η2).

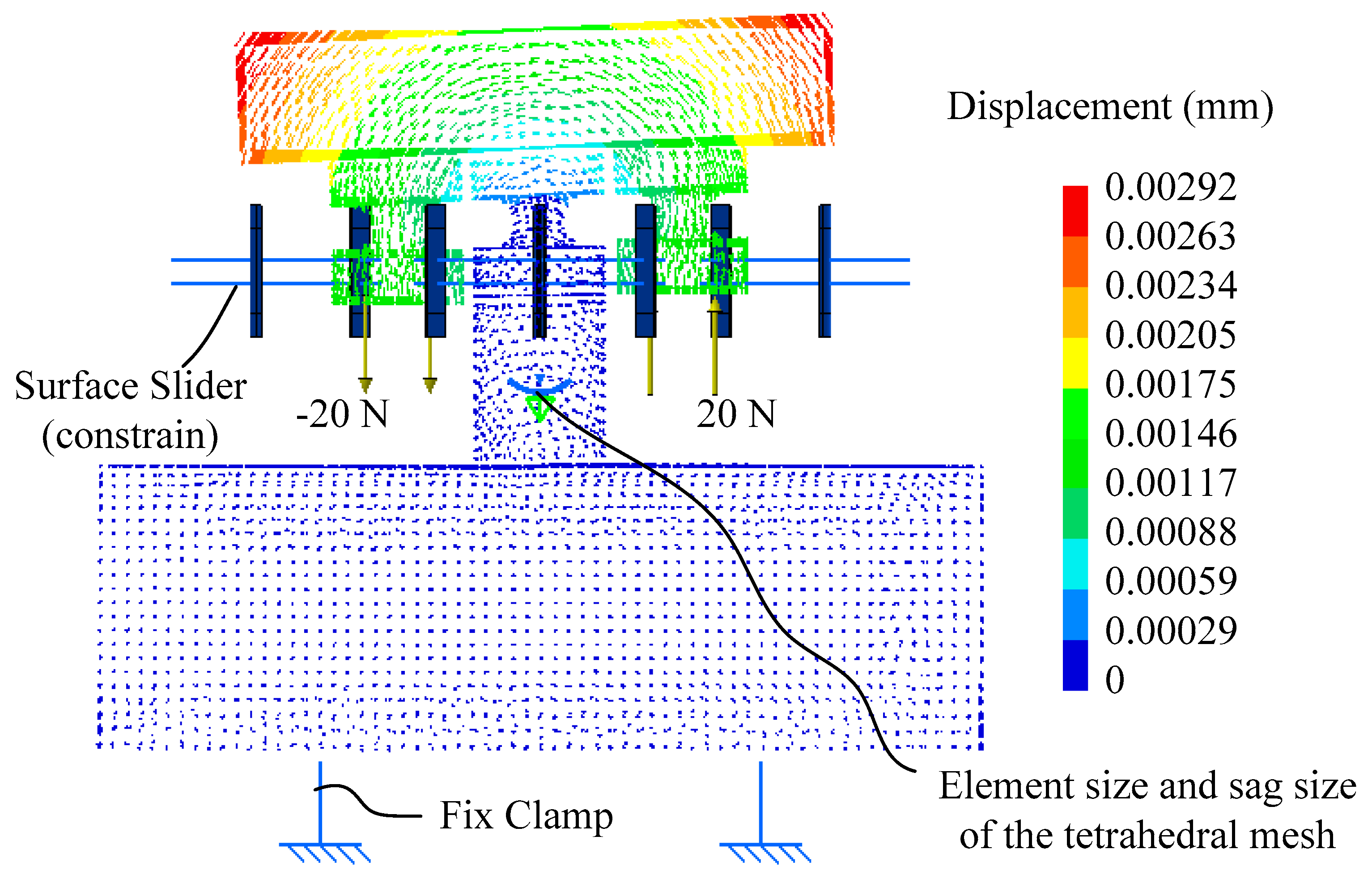

Step 5. Performing simulation:

Dassault Systèmes CATIA V5R15 was used for simulation in this study. For natural frequency simulation, this study used a

z-tilt stage loading of zero and 5 kg. For coupling angular displacement simulation, the

z-tilt stage was rotated on the

y-axis (θ

y) and observed the angular displacement of

x-axis (θ

x). Please note that, for a

z-tilt stage, coupling displacement for the

z-direction motion is zero.

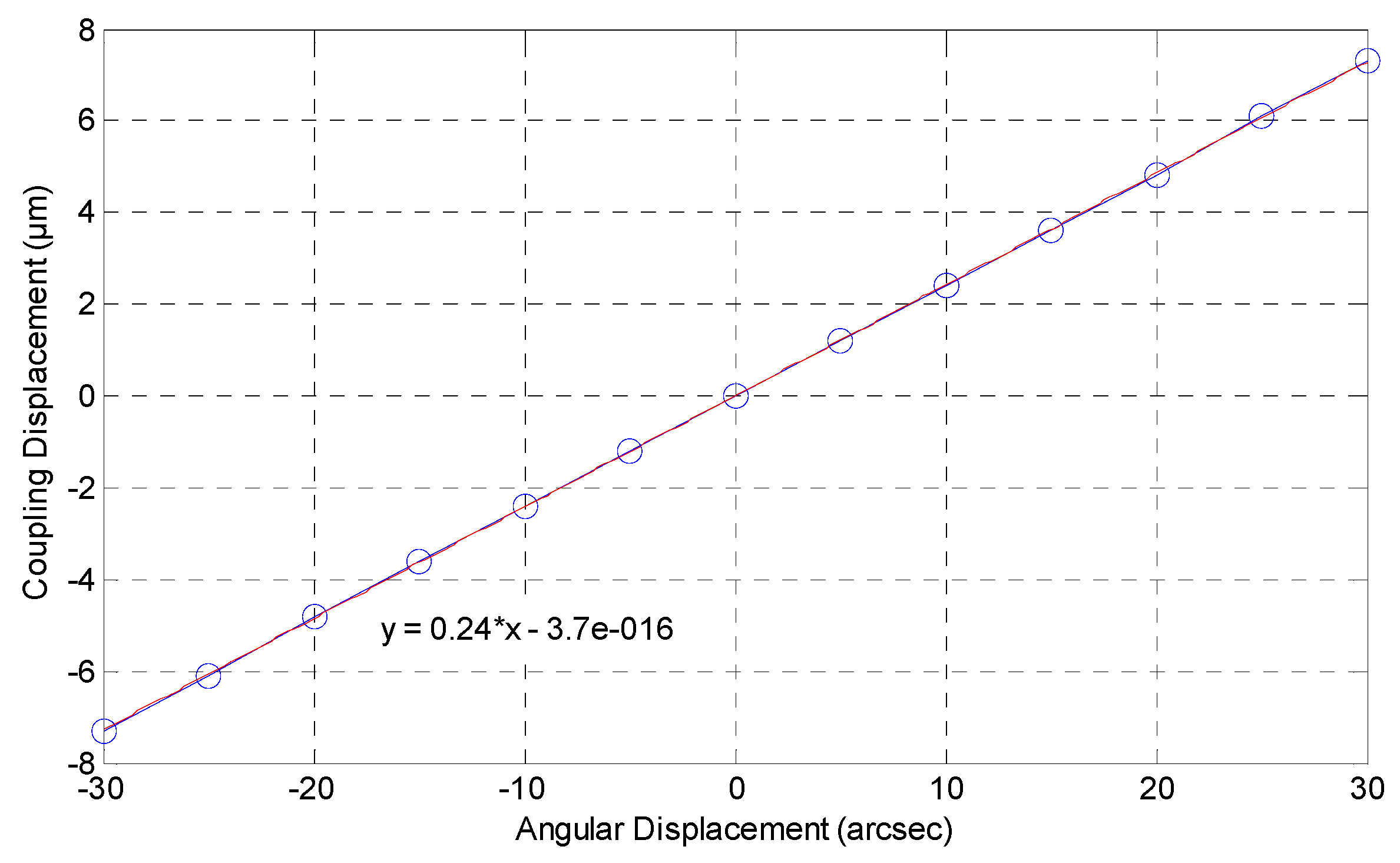

Figure 4 shows the simulation setup and result, in which the applied force is ±20 N. The simulation results are shown in

Table 3 and

Table 4. Note that, since the stage is moved by constant force while simulation, displacement θ

y for each trail is different. This study is employed percentage for judging the simulation result.

Step 6. To compute the S/N ratio:

According to Equations (1) and (2) and

Table 3, the S/N ratio for each trial can be computed as shown in

Table 5. The average S/N ratio denoted of

, for example, for A1 and B2 are:

After computation,

Table 6 and

Table 7 were built. In the tables, δ represents the maximum variation of average S/N Ratio of a single influencing parameter, which can be computed using the following equation:

The value of δ also represents the degree of influence. A large value for δ means the parameter has more influence than others. For example, for a

z-tilt stage the natural frequency and minimum diameter are the most important.

Table 7 were constructed and ranking was made according to the degree of influence.

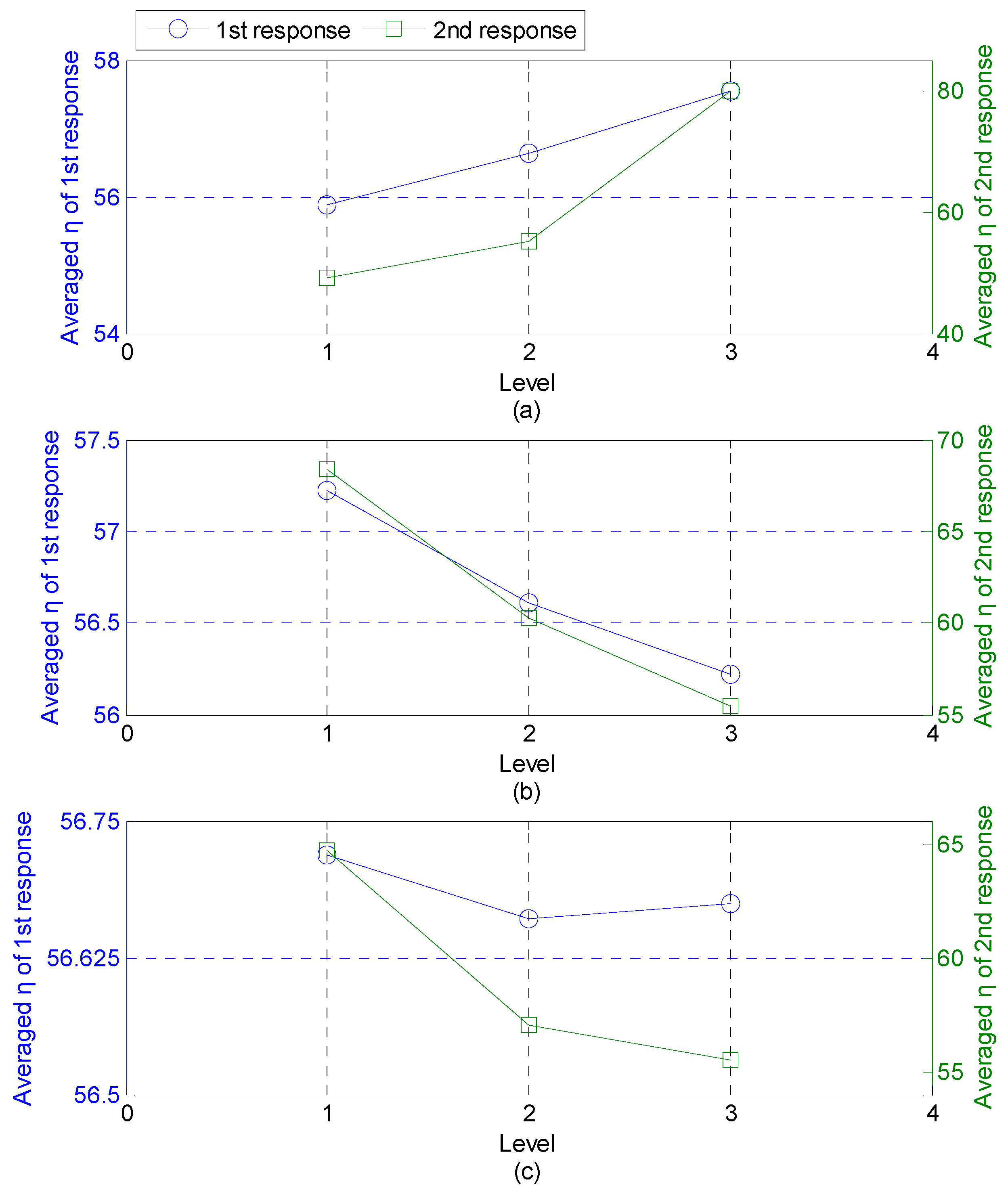

Step 7. Deciding the optimal parameters:

From

Table 6 and

Table 7, the optimal value of each parameter of the flexure hinge can be decided based on the following principium:

If the output responses of the experiments have the same trend, select the level with the highest S/N ratio.

If the output responses of the experiments have no similar trend and have different ranking, select that with the lowest ranking.

If the output responses of the experiments have no similar trend and have same ranking, select the level with the highest S/N ratio.

First, draw a cross-correlation chart from

Table 6 and

Table 7 as shown in

Figure 5. From this chart, find the optimal value for each parameter according to the above principium. For parameter A, the result satisfies principium 1, therefore, the optimization result of the minimum diameter is A3. For parameter B, the result also satisfies principium 1, thus, the optimization result of body height is B1. For parameter C, the result does not satisfy principium 1 or 2, thus, principium 3 is used to select the optimal notch radius, in this study the choosing was C3. The optimal design parameters are listed in

Table 8.

Step 8. Checking correctness of the results.

The optimal results of each parameter are A3, B1, and C3, which agrees exactly with trial 7 of the OA table. From

Table 3, we can see that the natural frequency is highest and coupling angular displacement is the smallest of all the values in the OA table. Thus, the stage clearly complies with the required specifications and the output responses list in

Table 9.

3. Kinematic Analysis

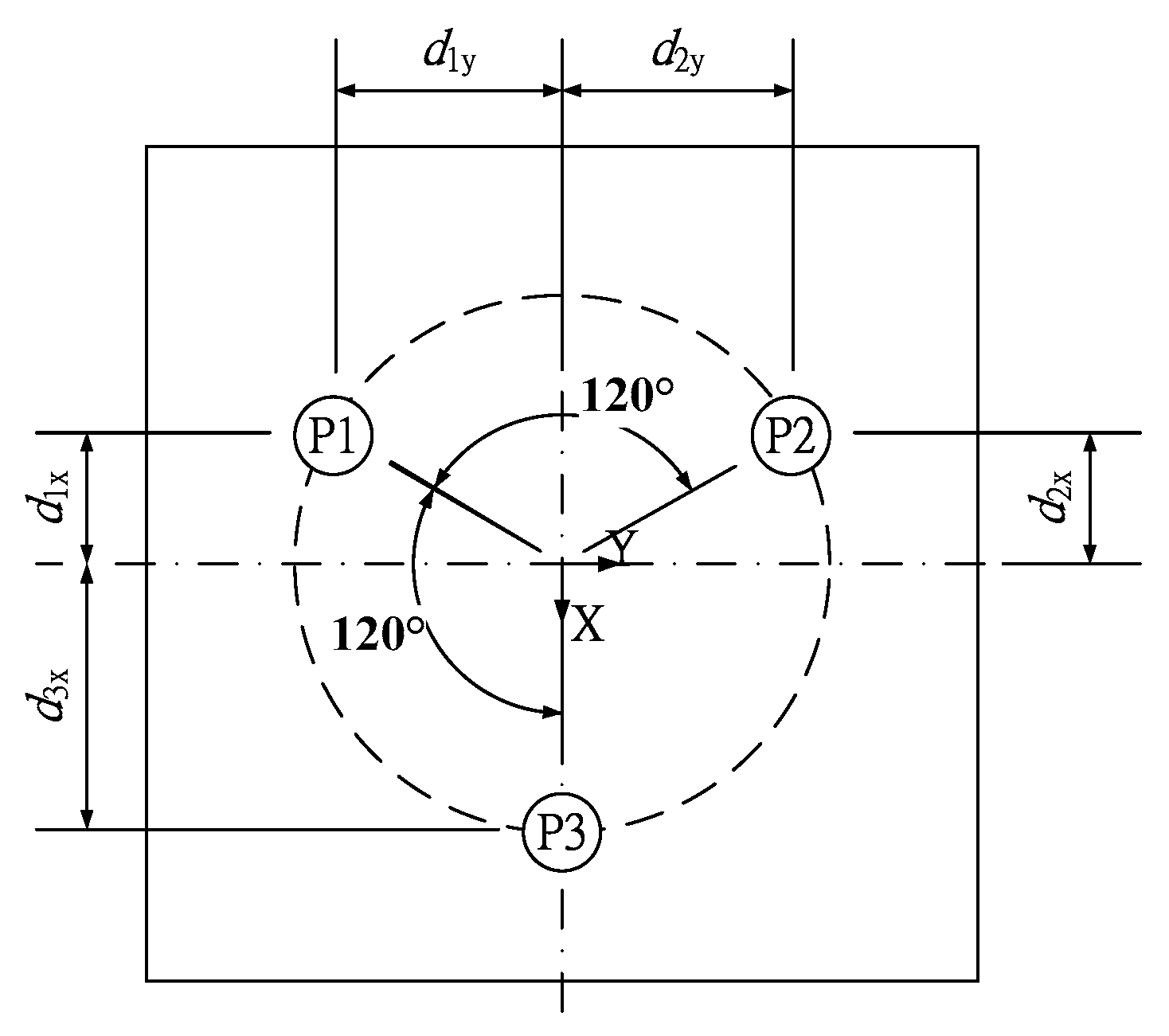

The positions of the PFMs are shown in

Figure 6. The mathematical model of the stage movement shows in

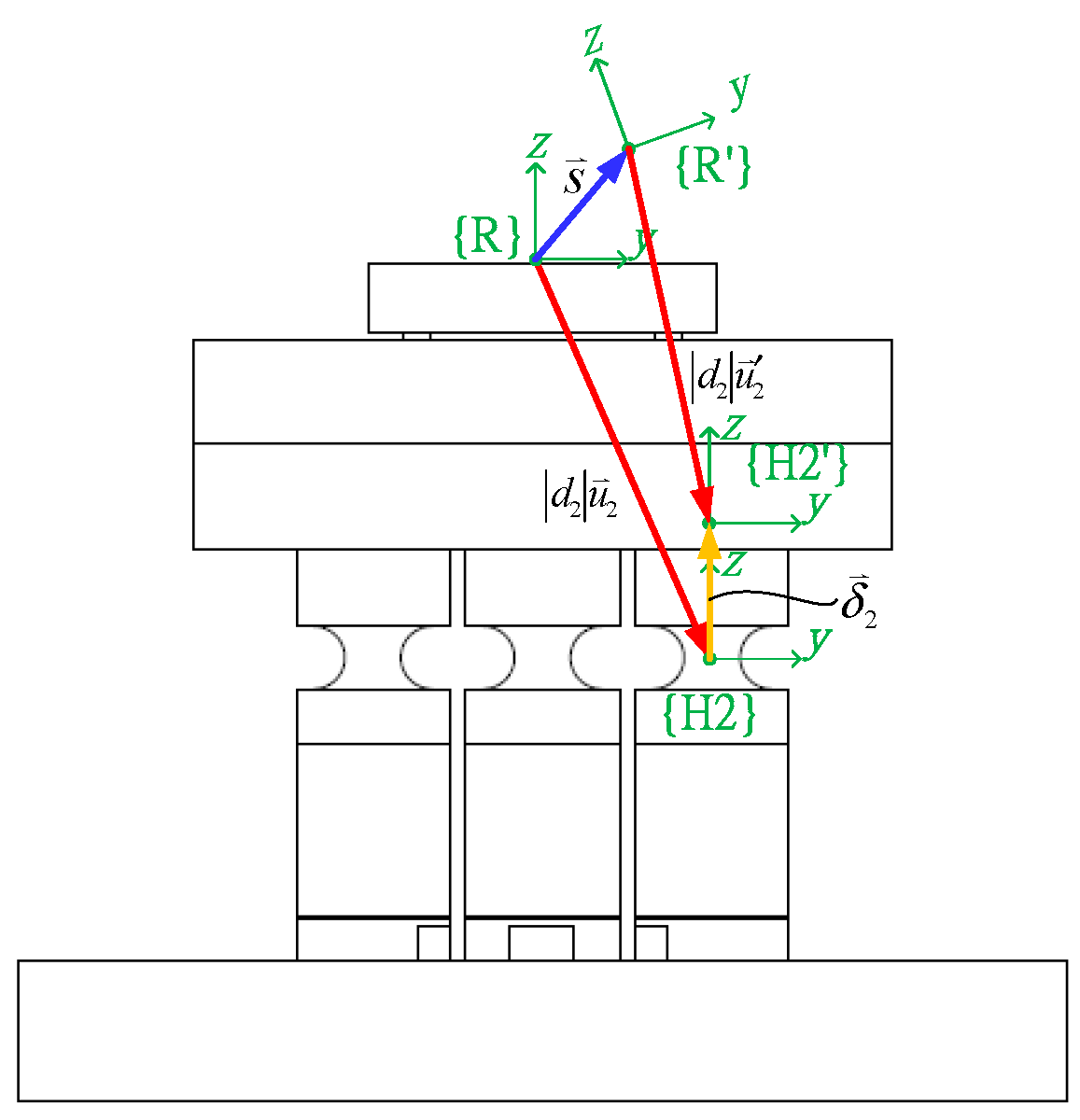

Figure 7. The coordinate systems as seen in

Figure 7 include: {R} the reference coordinate system of the stage (the origin, or reference point), located at the center of the work platform; {H

i} represents the center position of the flexure hinge of the PFM, where

i = 1, 2 and 3; and {R'} represents the position of the reference point after the stage has moved. Let

be the displacement vector of the

z-tilt stage along the

x-,

y- and

z-axes, as well as θ

x and θ

y to be the angular displacement of the

z-tilt stage. After the stage has moved, the center of the flexure hinge is moved to a new position and the coordinate system is denoted as {H

i'}. For example, (see

Figure 8) when the reference point is moved from {R} to {R’}, the center position of the second flexure hinge is moved from {H2} to {H2’}, in which

represents the displacement vector of

i-th piezoelectric actuator. Note that since the PFMs can only move along their

z-axes, the vector components of the

x- and

y-axes are both zero. Assuming the distance and unity vector

di from {H

i} to {R} is known, and

, vector from {H

i} to {R} is

, when the stage is rotated along the

x- and

y-axes, the new unity vector denoted

can be computed by the following equation:

From

Figure 8, the movement equation of the

z-tilt stage can be derived as:

where the unity vectors are:

After expanding, Equation (6) can be written as:

For a nano-scale

z-tilt compensation stage, the angular displacement is much smaller than one degree, thus Equation (8) can be linearized and simplified as below:

From Equation (9), it can be seen that when the stage is rotated along

x- and

y-axes, coupling displacement will occur in the

z-axis. In this study,

is much smaller than 1 meter (57.306 mm), the angular displacements of θ

x and θ

y are much smaller than 1 degree as well as

being smaller than 1. In other words, the coupling displacements of

sx and

sy are very small and can be ignored. This means the relationship between the actuators and the stage displacements can be written as:

Because of

, Equation (10) can be rewritten as: