Advances in Meat Quality and Processing

A special issue of Applied Sciences (ISSN 2076-3417). This special issue belongs to the section "Food Science and Technology".

Deadline for manuscript submissions: 20 September 2024 | Viewed by 1661

Special Issue Editors

Interests: unit of food hygiene and technology; institute of food safety; food technology and veterinary public health

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

Meat quality determines the eating experience of consumers in terms of sensory quality and nutritional value, while also determining qualities such as food safety, animal welfare, and technological quality, with the latter being especially important in terms of further meat processing.

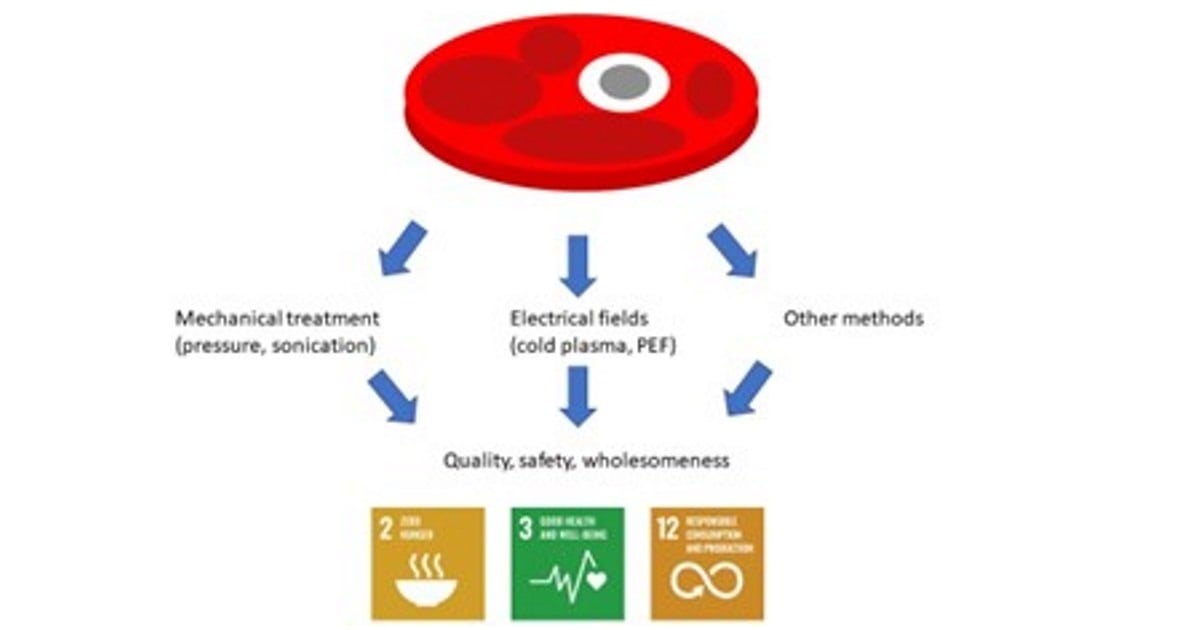

Traditional meat processing methods include heating, drying, smoking, salting, curing, fermentation, etc. New technologies include high-pressure treatment, shockwave technology, pulsed electric field, ohmic heating, cold plasma, ultrasound processing, electrical stimulation, and others. New technologies may help to improve food safety while often being more gentle than traditional meat processing methods. Furthermore, many of the new technologies may be considered green technologies, thus improving the sustainability of meat processing. The applications of new technologies also include new product development. However, drawbacks of the new technologies include their initial costs, and potentially unwanted chemical reactions.

This Special Issue welcomes original research papers as well as review papers regarding the subject of meat quality and processing, with a special focus on new technologies, green technologies, sustainable food production, and novel foods.

Dr. Kathrine Holmgaard Bak

Prof. Dr. Peter Paulsen

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Applied Sciences is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- new technologies

- meat quality

- meat processing

- food safety

- novel foods

- sustainable food production