Abstract

Recently, the use of plant-origin materials has become especially important due to the aggravation of environmental problems and the shortage and high cost of synthetic materials. One of the potential candidates among natural organic compounds is polysaccharides, characterized by a number of advantages over synthetic polymers. In recent years, natural polysaccharides have been used to design composite catalysts for various organic syntheses. This review is devoted to the current state of application of polysaccharides (chitosan, starch, pectin, cellulose, and hydroxyethylcellulose) and composites based on their catalysis. The article is divided into four main sections based on the type of polysaccharide: (1) chitosan-based nanocomposites; (2) pectin-based nanocomposites; (3) cellulose (hydroxyethylcellulose)-based nanocomposites; and (4) starch-based nanocomposites. Each section describes and summarizes recent studies on the preparation and application of polysaccharide-containing composites in various chemical transformations. It is shown that by modifying polysaccharides, polymers with special properties can be obtained, thus expanding the range of biocomposites for catalytic applications.

1. Introduction

The current requirements for cleaner technologies represent the most important challenge on the journey toward more sustainable and environmentally friendly chemistry. In order to achieve progress in the development of clean technologies, attempts are being made to avoid the use of toxic and hazardous substances and replace fossil resources with alternative natural raw materials. Polysaccharides, as one of the most widespread natural organic compounds possessing several advantages over synthetic polymers, attract much attention. They are safe, economical, stable, biocompatible, and biodegradable, and they easily interact with metals due to their high functionality [1,2,3]. Numerous hydroxyl (–OH), carboxyl (–COOH), or amine (–NH2) groups covalently anchored to the periphery of the polysaccharide glucose units provide them with a versatile ability for modification and functionalization to obtain materials with useful properties. Recently, they have been successfully used to design novel green materials for application in different fields such as pharmacology, medicine, the food sector, cosmetics, the chemical industry, catalysis, and remediation [3,4,5,6,7,8,9,10,11,12,13,14]. Each of the existing areas is currently being developed intensively and therefore requires separate detailed analyses and summaries regarding the results.

Catalysis plays a key role in the development of green technologies for chemicals and materials. One of the potential applications of polysaccharides is the development of biocomposite catalysts for various organic syntheses.

In recent decades, the number of publications (including reviews [13,14,15]) on the design and application of such catalysts has increased significantly [14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34]. The presence of the abovementioned functional groups in polysaccharides is a unique opportunity for the physicochemical binding of metal ions to form metal nanoparticles. The strong affinity of these biopolymers to interact with metal nanoparticles leads to stabilization and prevents metal leaching, which is an important factor in catalysis. Today, many chemical processes are tested using different types of metal–polysaccharide catalysts [14,15,16]. For example, chitosan-supported palladium catalysts have shown high activity, good reusability, and long life in the selective hydrogenation of different aromatic compounds, including aldehydes [17,18,19,32], nitroarenes into corresponding amines [20,21], and acetylenic compounds [22,23].

A comprehensive analysis of oxidation syntheses of nanocatalysts containing different types of polysaccharides is presented in [24]. Chitosan-based metal catalysts have been used successfully for the oxidation of organic compounds [24,25,26,27], the “click” cycloaddition of azides with terminal alkynes [28,29], and the cyclopropanation of olefins [29].

Cross-coupling reactions have gathered much attention over the past few decades as a simple and mild way to synthesize organic compounds. Palladium is one of the most effective catalysts for these syntheses. Various renewable polysaccharides have been used to support palladium catalysts for cross-coupling reactions [30,31,32,33,34,35,36]. The most commonly used is chitosan. The other polysaccharides used as components of catalytic systems are starch, pectin, cellulose and its derivatives, alginate, gum, etc. [36].

One of the main challenges in the field of catalysis is the preparation of new materials to replace traditional catalysts quickly, cheaply, and efficiently. From this point of view, polysaccharide-based catalysts are very promising. According to recent reviews [13,15,24,36], many approaches are used for the preparation of catalysts based on polysaccharides because various heterogeneous catalysts are prepared with a variety of polysaccharides using different techniques, and their performances are tested in different reactions. However, to our knowledge, there are no reviews dedicated to the classification of catalysts from the point of view of the chemical properties of each polysaccharide to allow for the design of various types of heterogeneous catalysts based on them.

It is difficult to discuss all the varieties of natural polysaccharides used in the development of novel catalytic systems and to analyze and classify the methods of their preparation and application in one review. We have focused on the analysis of the use of chitosan, cellulose, and their derivatives as the most abundant naturally occurring and commonly considered biopolymers in the design of catalysts. There is increasing interest in the study of starch and pectin as catalyst components due to the widespread methods for their extraction from plant waste and the possibility of forming physicochemical bonds with metal ions and inorganic supports.

In this review, we present some results on the application of these polysaccharides as components of catalysts for different organic processes, classify the composite catalysts into several types based on the chemical properties of each polysaccharide, and partly discuss the advantages and disadvantages of methods for their preparation and future trends.

2. Chitosan-Based Nanocomposites

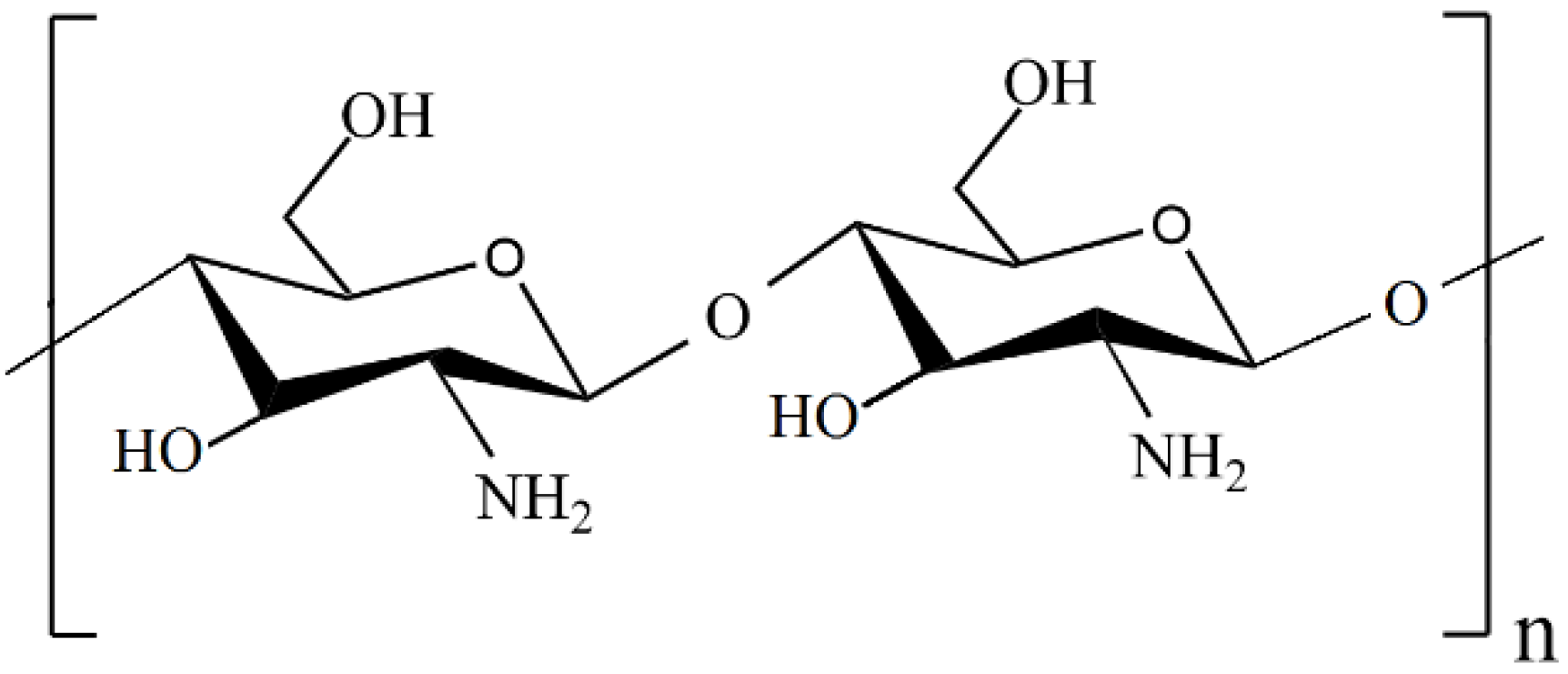

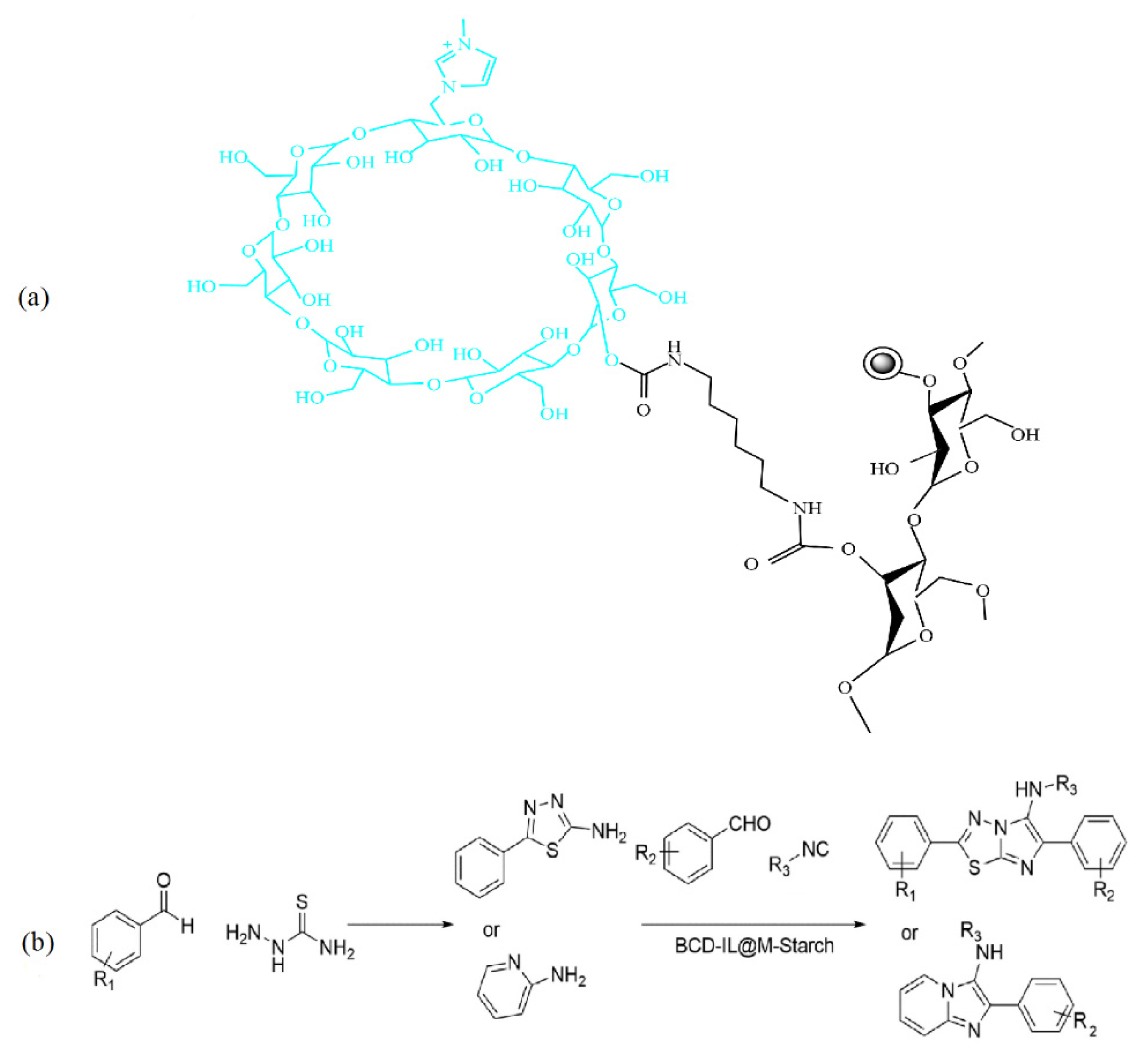

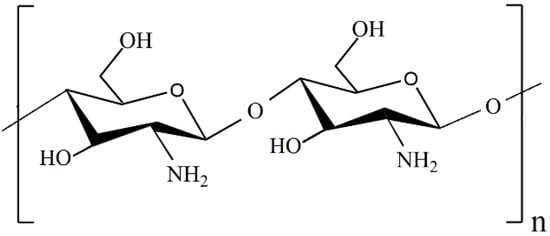

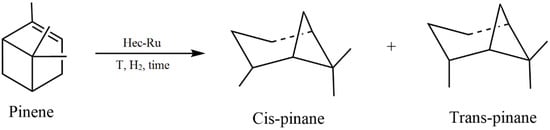

Recently, chitosan-based composites have attracted much attention due to the unique properties of chitosan, such as nontoxicity, renewability, and high availability [37,38]. Chitosan (CS or Chit) is a linear random copolymer of N-acetyl-D-glucosamine and deacetylated D-glucosamine units connected by β-1,4 glycosidic linkages (Figure 1), obtained from the chemical alkaline deacetylation of chitin [39,40].

Figure 1.

Structure of a chitosan molecule.

Chitin is the second-most prevalent natural polysaccharide after cellulose [41,42], meaning that chitosan (CS) is also a very abundant biopolymer. Chitosan has three types of reactive functional groups, i.e., an amino/acetamido group and both primary and secondary hydroxyl groups at the C-2, C-3, and C-6 positions, respectively [39,43]. The degree of deacetylation is one of the most important parameters affecting the properties of chitosan, such as its solubility in aqueous acidic solutions, the degree of swelling in water, crystallinity, average molecular weight, susceptibility to biodegradation, biological activity, and biocompatibility [41]. The free amine groups (–NH2), located at C-2 on the rings of the D-glucosamine repeated units, may be pronated under acidic conditions [39]. At pH < 6.3, the free amino groups are protonated and positively charged, and chitosan is a water-soluble cationic polyelectrolyte. At pH > 6.3, the free amino groups become deprotonated, and the chitosan loses its charge and becomes insoluble [44]. Due to the presence of free amino and hydroxyl groups, chitosan is more reactive, which means that it is susceptible to chemical modifications. For example, chitosan forms chelate complexes with metal ions. The free amino groups in chitosan are considered to be much more effective for metal ion complexation than the acetyl groups in chitin [41]. Thus, chitosan exhibits cationic behavior in acidic solutions and a strong affinity for metal ions; therefore, it has received increased attention for the preparation of heterogeneous catalysts as both chelating and stabilizing agents [45,46].

2.1. Chitosan as a Catalyst Support or Stabilizing Agent

Due to the presence of reactive amino groups, chitosan’s thermal stability and insolubility in organic solvents hold great potential, representing a versatile platform for supporting metal ions (or nanoparticles) [46]. Transition metal ions, such as palladium, ruthenium, gold, silver, copper, cobalt, and iron, immobilized on chitosan have found applications as catalysts for hydrogenation, coupling, oxidation, and other organic synthesis reactions [29,46]. There are various methods for the preparation of transition metal catalysts supported on chitosan.

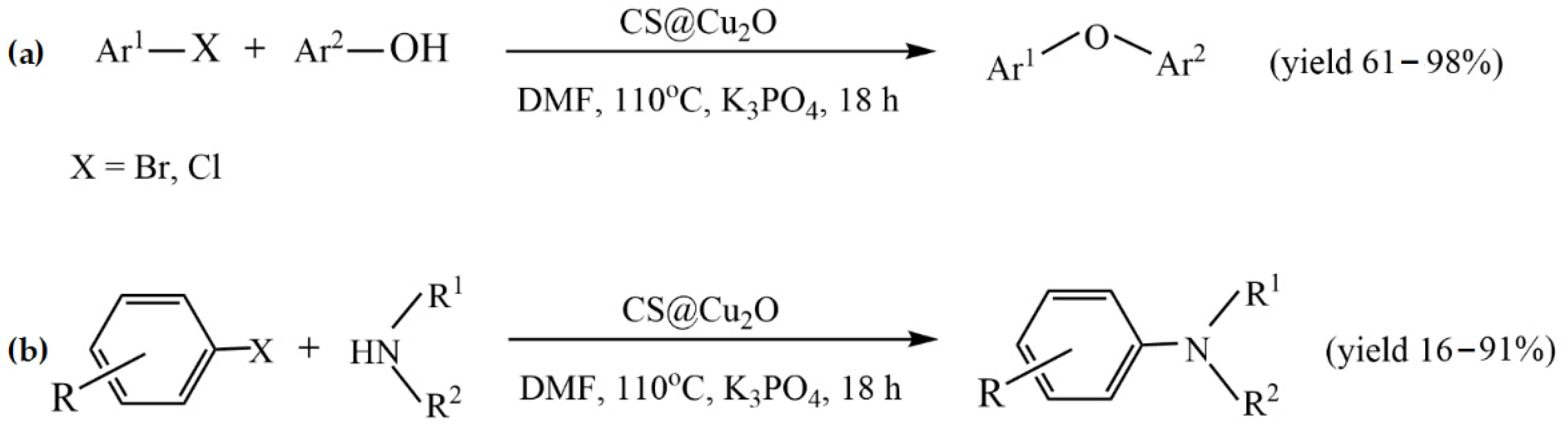

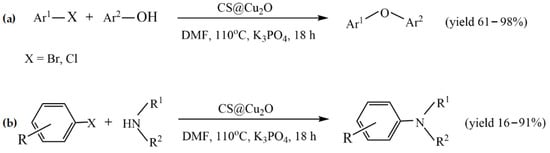

The simplest method to prepare chitosan-based metal catalysts is to mix a slurry of chitosan with a solution of the metal precursor, resulting in the adsorption of metal ions. Cunwei et al. [47] used this approach to prepare a series of chitosan-supported Cu catalysts for ligand-free C-O and C-N coupling reactions. The catalysts differ according to the metal precursor and solvent used for their preparation. Chitosan (CS)-supported copper salts (CS@CuSO4 and CS@Cu(OAc)2) were prepared by suspending CS in an aqueous solution of CuSO4 and Cu(OAc)2. A CS@CuI catalyst was prepared via the adsorption of CuSO4 on chitosan in methanol media, followed by treating the resulting blue solid with NaI. The ultrasonic stirring of Cu2O nanoparticles and chitosan in toluene resulted in CS@Cu2O, which showed better catalytic potency in the coupling of bromobenzene with phenol than other Cu catalysts. The best yield (95%) for this catalyst was achieved at the following reaction conditions: 2.0 mmol of phenol, 1.0 mmol of ArBr, 0.5 mol% CS@Cu2O, 3.0 mmol of K3PO4, 0.5 mL of anhydrous DMF under an Ar atmosphere for 18 h. This catalyst was also studied in other C-O and C-N coupling reactions, providing good and excellent yields under the same reaction conditions (Figure 2). In addition, the catalyst was reused in the coupling reaction of phenol with chlorobenzene during four runs without a significant decrease in its catalytic activity, and no leaching of copper was observed [47].

Figure 2.

CS@Cu2O-catalyzed coupling reactions of (a) aryl bromide/chloride with phenols and (b) of N-heterocyclic amines with aryl bromide/iodides. Reprinted with permission from ref. [47]. Copyright 2019 Science China Press.

Another simple method to prepare chitosan-based metal catalysts is the physical mixing of chitosan and metal salts. In [20], Pd/Chit catalysts were prepared via the physical mixing of chitosan (Chit), PdCl2, NaOH, and ascorbic acid (AA) using a mortar and pestle. The AA served as a mild reducing agent in the conversion of PdCl2 to Pd nanoparticles (NPs), and the NaOH was crucial in anchoring the resulting Pd NPs to the chitosan support during solid grinding. The resulting catalyst demonstrated a higher available surface area and a larger number of accessible active sites than other Pd NP catalysts reported using solution methods. As a result, in the presence of NaBH4 (10 mmol) as a hydrogen source, Pd/Chit (150 mg) demonstrated enhanced catalytic activity (TOF = 8498 h−1; yield = 96%) for the reduction of p-nitrophenol (1 mmol) to p-aminophenol in water (10 mL) at 300 K. The catalyst was reused four to ten times without a significant decrease in its catalytic activity. Furthermore, a kinetics investigation of the reduction of nitroarene under optimal reaction conditions showed that Pd/Chit has a substantially lower activation energy than other reported Pd NP catalysts.

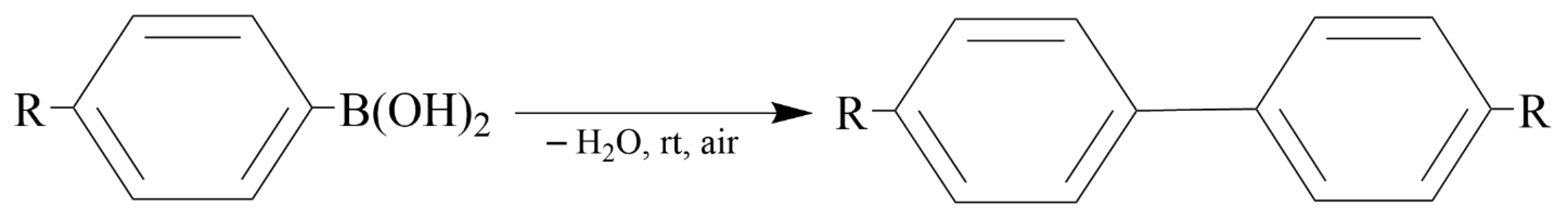

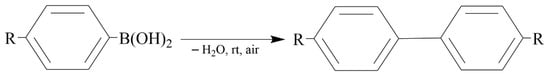

Reddy et al. [48] used a solid-grinding approach for the synthesis of gram-scale quantities of solid chitosan-supported gold NPs using sodium borohydride (NaBH4) as the reducing agent (Figure 3). It was found that gold NP sizes could be modulated (2.8–9.5 nm) by varying the amount of gold NPs (0.47–12.5 wt.%) loaded onto the solid chitosan support. These solid chitosan-supported gold NPs were used as heterogeneous catalysts for the oxidative homocoupling of arylboronic acids (0.25 mmol) into biphenyls and the aerobic oxidation of benzyl alcohols (0.25 mmol) into the corresponding aldehydes and acids in water (15 mL) at room temperature and under open air. The catalysts showed higher activity and selectivity for the homocoupling of arylboronic acid reactions, yielding 94–99% biphenyls, when compared with those of other well-known hydrophilic polymer-stabilized colloidal nanogold catalysts prepared using conventional solution-based methods.

Figure 3.

The homocoupling of arylboronic acid reaction.

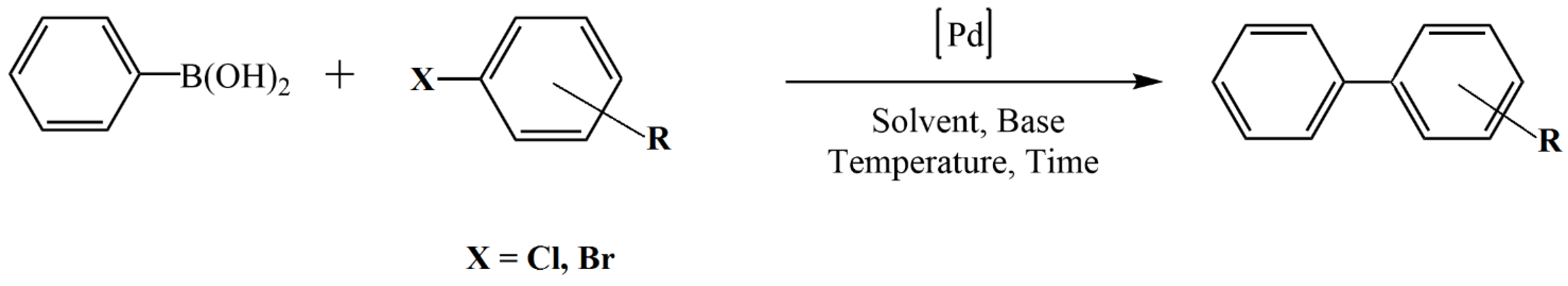

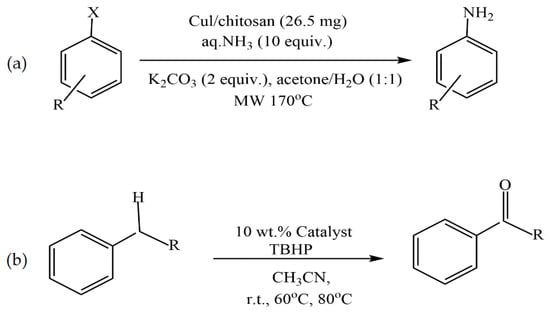

However, the preparation of chitosan-based metal catalysts from a biopolymer dilute acidic solution is still the preferred and more common approach. Chitosan is capable of adsorbing and stabilizing large amounts of metal ions. Furthermore, chitosan has an intrinsic ability to reduce metal ions to metal particles. Catalyst materials may also be fabricated by mixing chitosan with preformed metal particles [29]. Grandini et al. [49] prepared palladium nanoparticles supported on a chitosan/cellulose film by stirring microgranular cellulose and previously prepared Pd NPs in a viscous acetic acid aqueous solution of chitosan, followed by drying the obtained homogenous mixture in a glass Petri plate. The resulting fibrous catalyst employed an adequate palladium load (0.5 mol%) and provided a very good to high product yield (78–98%) in the Suzuki–Miyaura cross-coupling of phenylboronic acid (1.5 mmol) with different aryl iodides/bromides (1 mmol) in presence of K2CO3 (2 mmol) as a base in ethanol (3 mL) at 100 °C (Figure 4). In addition, the catalyst demonstrated excellent recyclability in the cross-coupling of phenylboronic acid with 4-iodoanisole. The catalyst was reused during 10 runs without a decrease in catalytic activity.

Figure 4.

Suzuki–Miyaura cross-coupling of phenylboronic acid with different aryl iodides/bromides.

The chemical properties of chitosan allow for the fabrication of catalysts in various forms, such as gels, spheres, fibers, etc. The preparation of such catalysts is accompanied by the precipitation of chitosan with an alkali or its interaction with cross-linking agents. It should be noted that the precipitation of chitosan in the presence of transition metal salts or nonmetal/metal oxides (SiO2, Al2O3, Fe3O4, etc.) results in the formation of metal (or nonmetal) oxides stabilized/functionalized with the polymer, where an inorganic component is responsible for any catalytic functions or serves as the core hybrid support material for the separation of a catalyst (transition metal ions or NPs, enzymes, etc.) immobilized on the polymer shell (see Section 2.2 and Section 2.3). Schiff’s base reaction between the amino groups of chitosan and aldehydes improves the mechanical properties of catalytic microspheres due to the cross-linking of the polymer and results in the formation of new functional groups with a better affinity for metal ions; this can decrease the leaching of metal ions from the cross-linked polymer matrix and increase the lifetime of a catalyst. For this reason, chitosan can also be modified with other organic molecules (see Section 2.3).

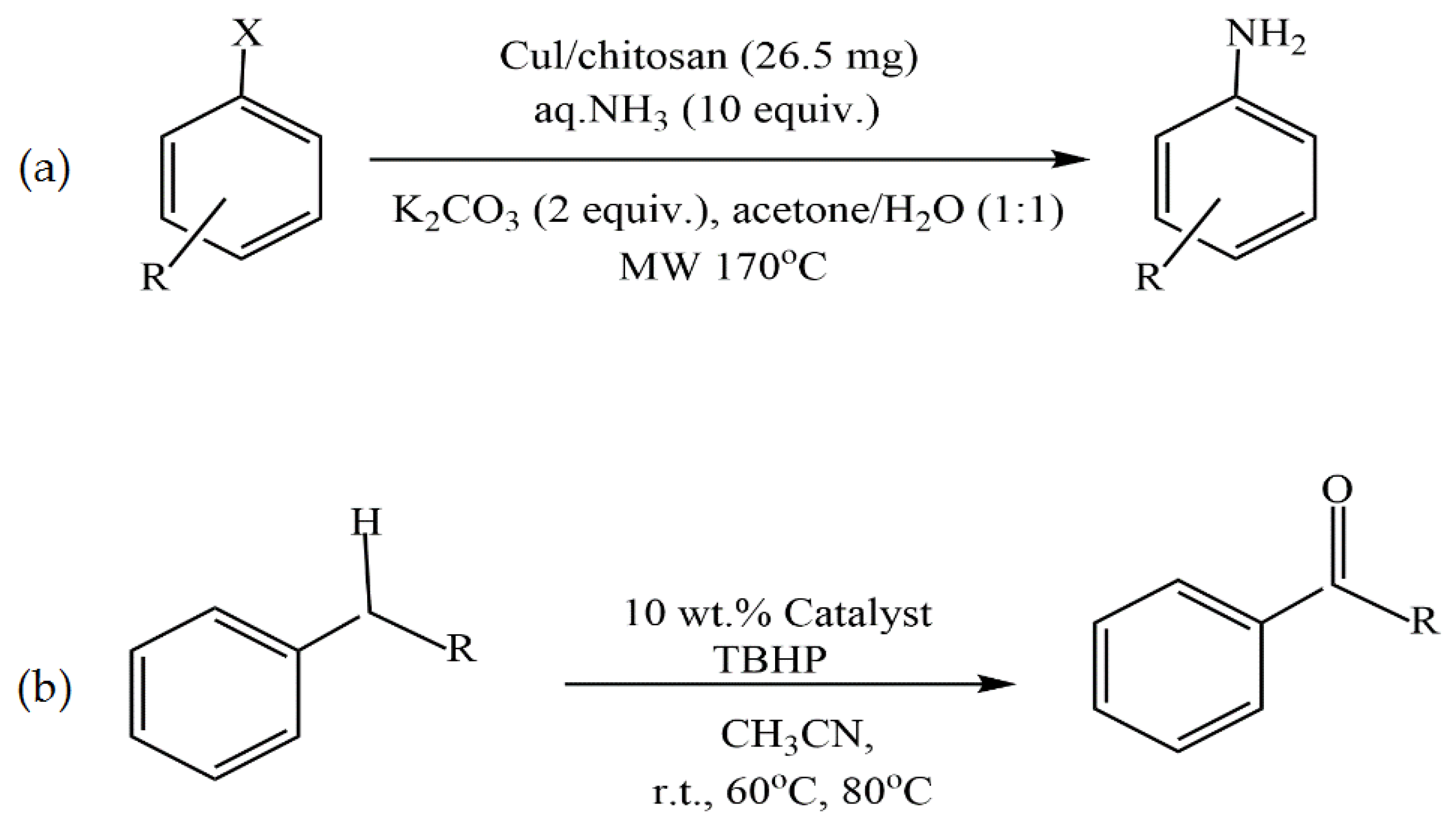

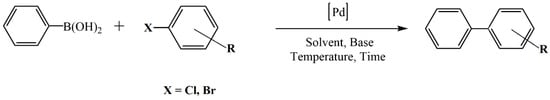

Kanarat et al. [50] reported that the dropwise addition of a solution containing chitosan and copper salt (Cu(OAc)2 or CuI) into a NaOH solution resulted in spherical granules of Cu/chitosan catalysts for the C-H oxidation of alkylarenes to ketones with tert-butyl hydroperoxide (TBHP) and the C-X amination of aryl halides with ammonia (Figure 5). These catalysts were compatible with various substrates, resulting in 2–97% and 39–99% yields for the oxidation and amination reactions, respectively. Moreover, chitosan served as both a versatile support to enhance the catalytic performance of copper-active species and a base to promote the catalytic reactions.

Figure 5.

C-X amination of aryl halides with ammonia (a) and C-H oxidation of alkylarenes to ketones with tert-butyl hydroperoxide (TBHP) (b).

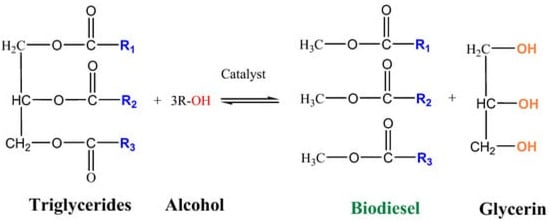

Correia et al. prepared calcium/chitosan spheres via the dropwise addition of a chitosan and calcium nitrate solution into an aqueous ammonia solution [51]. Then, these calcium-incorporated chitosan spheres were calcined in order to obtain a porous calcium catalyst without organic material. Afterward, the calcined calcium/chitosan spheres were used in the transesterification reaction of sunflower oil with methanol. The conversion of sunflower oil to methyl esters under optimized reaction conditions (oil/methanol ratio—1:9; catalyst amount—3 wt.%; time—4 h; temperature—60 °C; magnetic stirring—1000 rpm), which were determined by a factorial experimental design, was 56.12 ± 0.32 wt.%. These results show that chitosan can be used as a structuring agent in the fabrication of porous alkaline catalysts for biodiesel production.

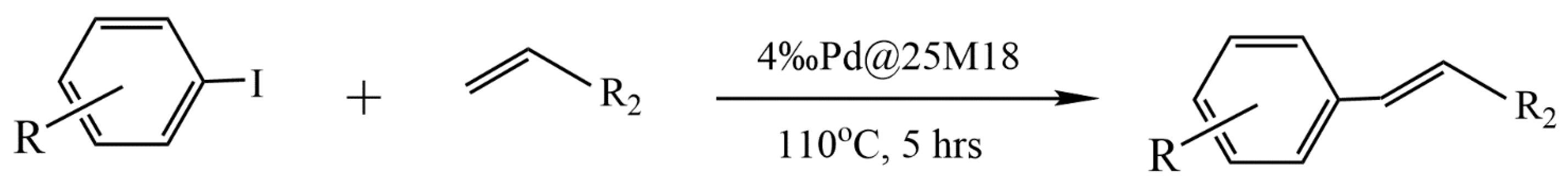

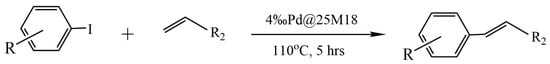

In [52], chitosan microsphere-supported palladium catalysts (Pd@CM) for a Mizoroki–Heck reaction were successfully prepared by electrospraying a PdCl2/chitosan mixture in a trifluoracetic acid (TFA) aqueous solution into a NaOH aqueous solution, followed by cross-linking the obtained polymer microspheres with glutaraldehyde. This novel heterogeneous palladium catalyst has been demonstrated to be an efficient catalyst for the Mizoroki–Heck reaction of aromatic iodides with olefins (Figure 6). The reaction yield in the presence of triethylamine in N,N-dimethylacetamide at 110 °C reached 82–98%. The high catalytic activity of Pd@CM has been attributed to the high dispersion of palladium species and the small size of chitosan microspheres, and the remarkable stability and recyclability can be ascribed to the chelation of palladium with the abundant amine and hydroxyl groups on the chitosan chain and the entrapment of palladium species in the cross-linked chitosan chain. It should be noted that Pd@CM was even more active than the catalyst with palladium species adsorbed on the surface of chitosan microspheres (Pd-CM).

Figure 6.

Pd@25M18-catalyzed Mizoroki–Heck reaction of aromatic iodides with olefins.

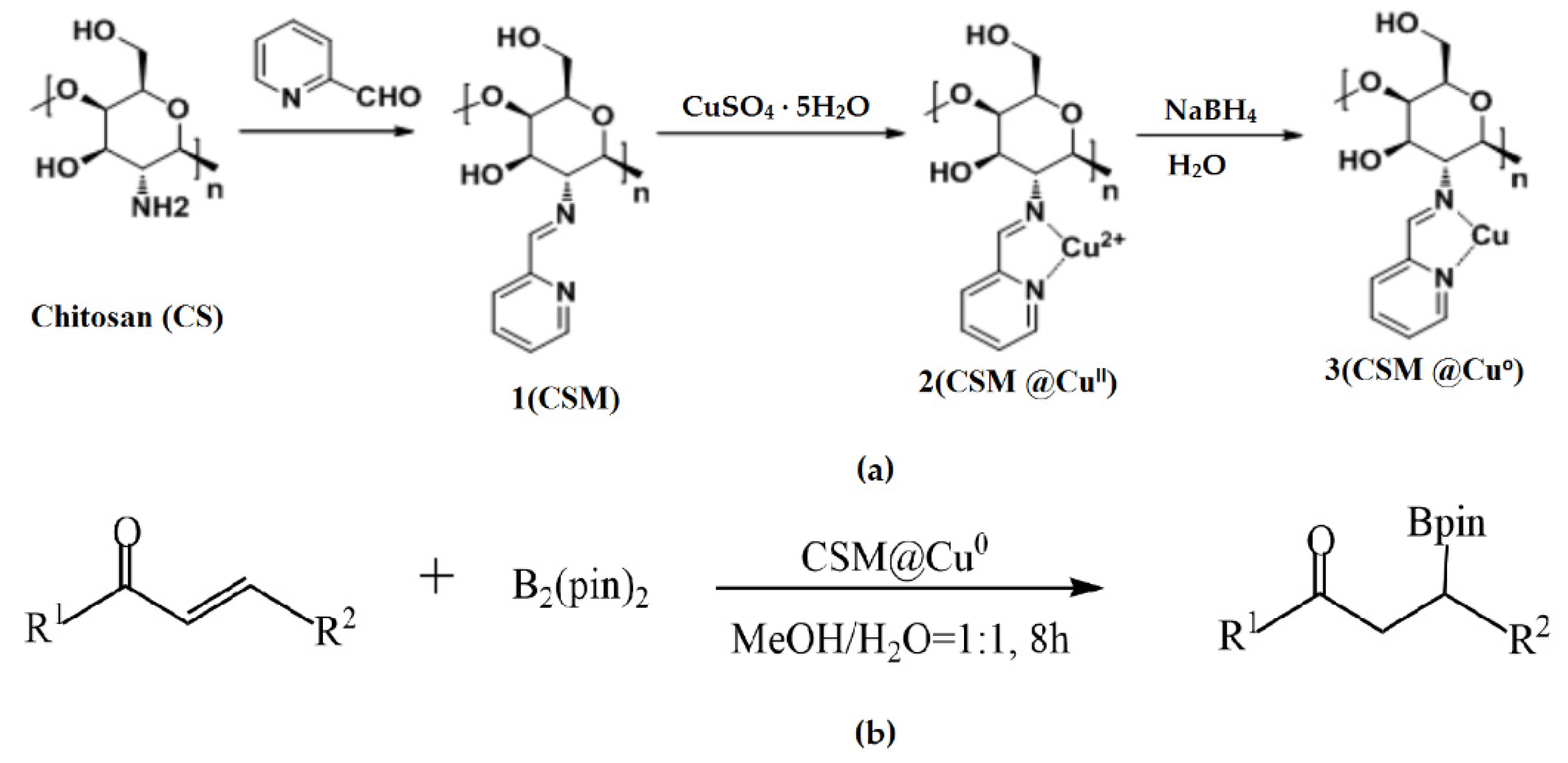

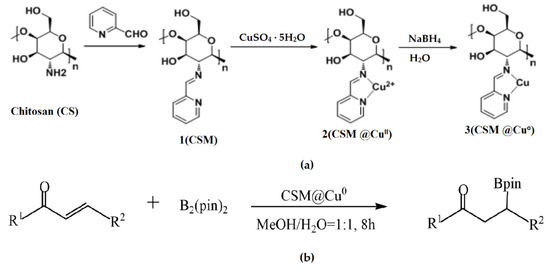

Wang et al. used modified chitosan microspheres (CSMs) prepared by cross-linking a polymer with 2-pyridinecarboxaldehyde in a water/oil emulsion in the construction of a heterogeneous catalyst loaded with nano-Cu prepared using a reduction reaction (Figure 7a) [53]. Under mild conditions, such as no ligand at room temperature, the CSM@Cu0 catalyst was successfully applied to catalyze the borylation of α,β-unsaturated receptors in a water–methanol medium, yielding 17–100% of the corresponding β-hydroxy product (Figure 7b). Even after being repeatedly used five times, the catalyst still exhibited excellent catalytic activity.

Figure 7.

Preparation of the CSM@Cu0 catalyst (a) and its application to the boron addition reactions (b). Reprinted from ref. [53].

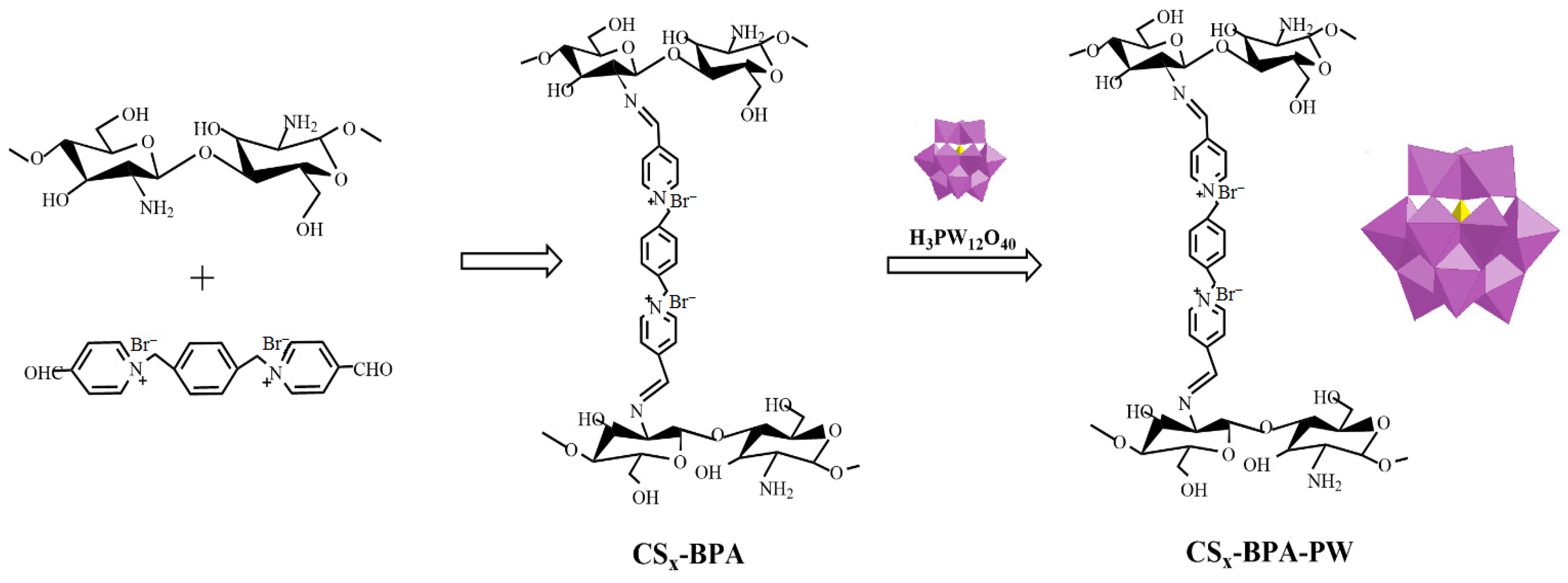

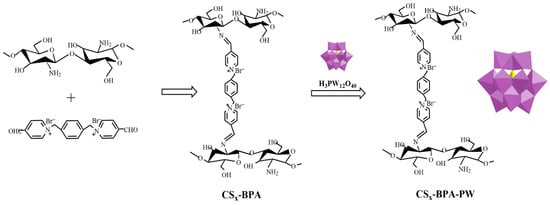

Li et al. [54] demonstrated that cross-linked chitosan (CS) bearing –NH2 functional groups obtained by cross-linking CS with a dicationic pyridine ionic compound (BPA) acted as a promising support to produce heterogeneous H3PW12O40 catalysts (Figure 8). The redox properties of polyoxometalate (PW) anions could be controlled by varying the amount of CS in CSx-BPA-PW. The resulting hybrid, CS1.5-BPA-PW (0.01 mmol), performed as an efficient solid catalyst in the epoxidation of cyclooctene (5 mmol substrate; 10 mmol H2O2; 5 mL acetonitrile; 70 °C; 1 h; conversion: 100%; selectivity for the cyclooctene oxide: 100%) and the oxidation of benzyl alcohol (5 mmol substrate; 6 mmol H2O2; 5 mL acetonitrile; 90 °C; 4 h; conversion: 88%; selectivity for the benzaldehyde: 97%) with H2O2.

Figure 8.

Schematic illustration outlining the preparation and structure of the CSx-BPA-PW catalysts [54].

2.2. Chitosan-Modified Catalysts on Inorganic Supports

The immobilization and stabilization of metal nanoparticles on chitosan (CS or Chit) lead to the formation of two-component composites with tunable catalytic properties due to the effect of the polymer on the size, shape, morphology, and other physicochemical characteristics of active species. At the same time, the use of chitosan as a support in catalysis is troubled by problems such as insufficient resistance to attrition and the small specific surface area of the polymer. One of the approaches for overcoming these problems is using inorganic materials (SiO2, metal oxides, and clays) modified with chitosan as a catalytic support. Such composite supports can combine the advantages of both chitosan (the chelation and stabilization of metal species) and inorganic material (high surface area and mechanical and thermal stability). There are various methods to obtain three-component metal–chitosan–inorganic material catalysts.

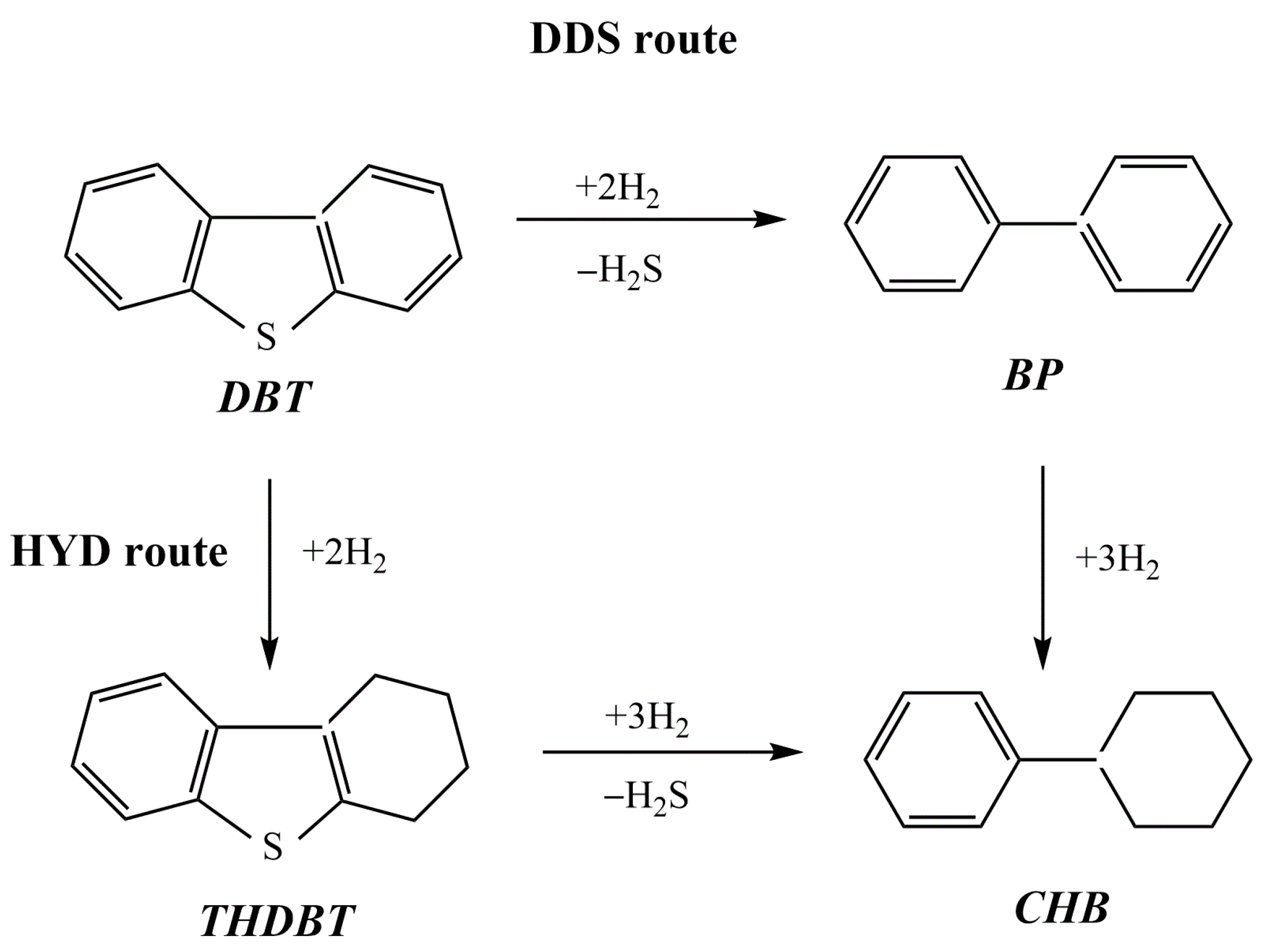

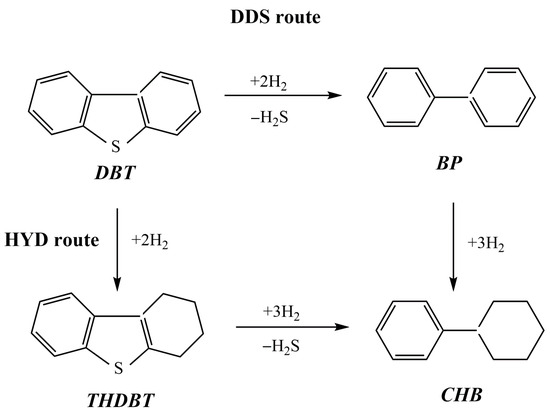

In [55], two series of NiMoP catalysts supported on chitosan-modified alumina (A) and alumina titania (AT) were prepared by using a sequential pore-filling impregnation procedure. In each series, the order of chitosan and metal precursor impregnation was varied in the same way. The catalysts were studied in the hydrodesulfurization (HDS) of dibenzothiophene (DBT, 0.3 g) in a batch reactor using n-hexadecane (100 mL) as the solvent at 320 °C, 72.4 kg cm−2, and 1000 rpm. The HDS reaction can occur through both the direct desulfurization (DDS) and hydrogenation (HYD) pathways, with the formation of the following products: biphenyl (BP), cyclohexylbenzene (CHB), tetrahydrodibenzothiophene (THDBT), and bicyclohexane (BCH) (Figure 9). The series of catalysts supported on alumina presented the most remarkable effect of chitosan, in which the –OH and –NH groups of the organic molecule interacted with the acid sites of the support, weakening the interaction between alumina and the deposited metal phases. In all cases, DBT was converted mainly through direct sulfur removal. The catalysts ChP3/A (alumina support impregnated with chitosan in phosphoric acid solution prior to NiMoP deposition) and ChP4/AT (alumina titania support impregnated with NiMoP solution prior to contact with a solution comprising chitosan and phosphorus) exhibited the best performance in HDS reactions and also showed the highest selectivity in biphenyl formation (81.4% and 88.6%, respectively). The presence of carbonaceous residuals on the catalyst’s surface, as shown via XPS, could enhance the HDS activity from the ChP4/AT sample.

Figure 9.

Reaction network of the dibenzothiophene (DBT) hydrodesulfurization process.

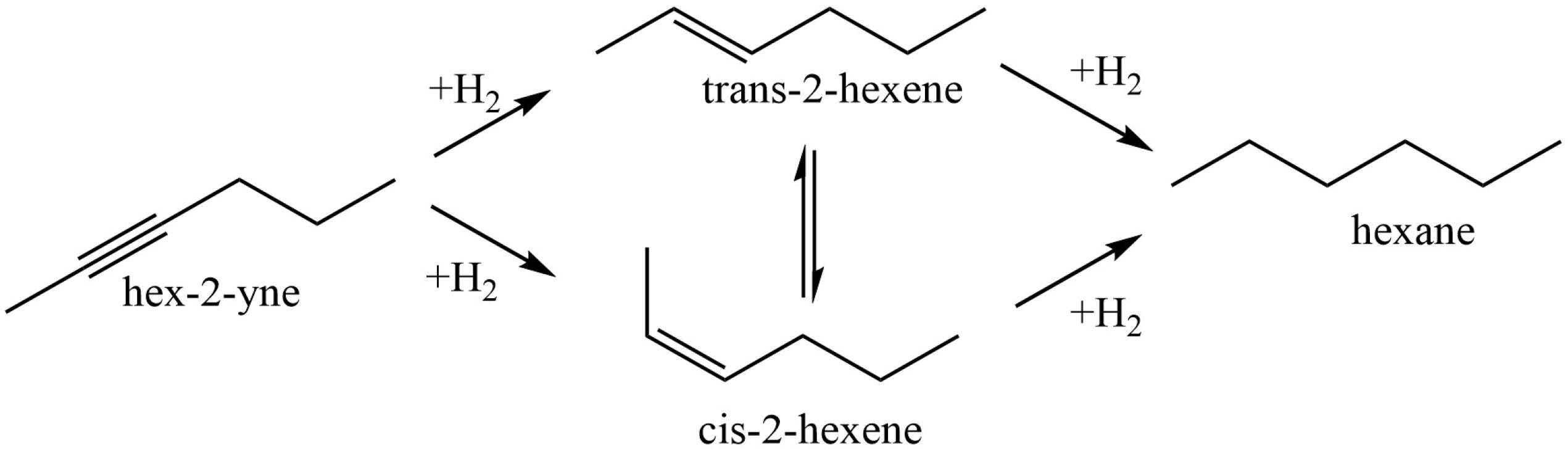

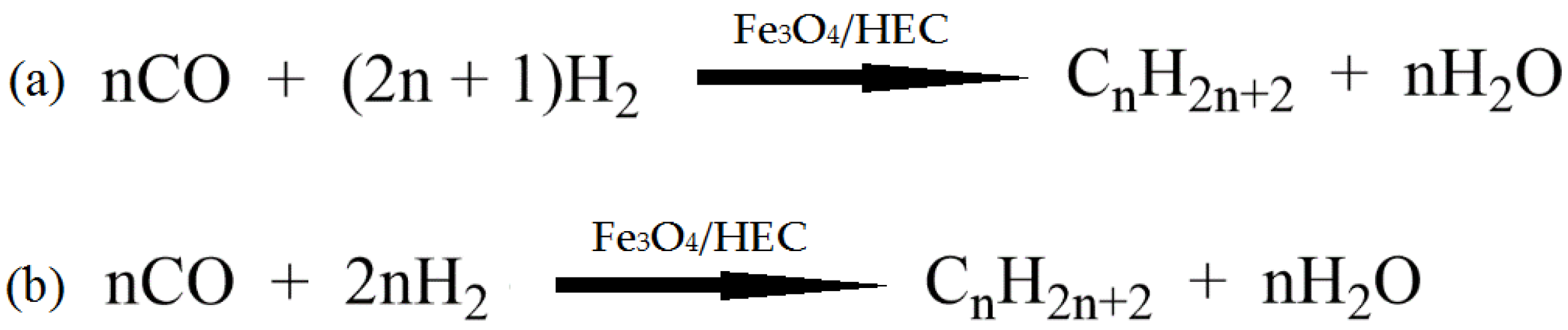

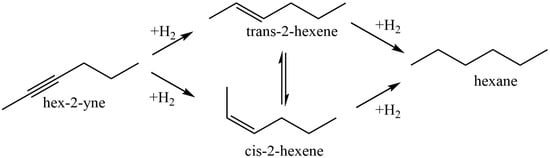

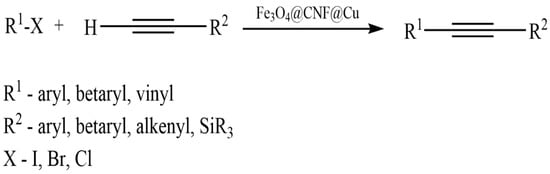

Sun et al. [56] used chitosan (CS) and polyvinyl pyrrolidinone (PVP) in order to stabilize Pd nanoparticles on the surface of modified montmorillonite clay (AlMn-PM). The preparation of Pd@CS/AlMn-PM and Pd@PVP/AlMn-PM catalysts was accomplished via the sequential adsorption of a polymer (CS or PVP) and palladium ions on pillared montmorillonite clay with further heat treatment of the resulting three-component composites at 200 °C. The resultant Pd@polymer/AlMn-PM heterogeneous catalytic nanocomposites (2.3 µmol of Pd) showed highly competitive catalytic performances in Sonogashira coupling reactions with various aryl iodides (1 mmol) and phenylacetylene (1.2 mmol) at 90 °C for 1 h (yield 92–100%). Pd@CS/AlMn-PM showed better comprehensive catalytic performance than Pd@PVP/AlMn-PM. This was mainly attributed to its higher specific area, stronger chelation of Pd species, and better solvent resistance. In [57], Pd and PdAg catalysts supported on chitosan (Chit)-modified zinc oxide were prepared using the same method (sequential adsorption), except that the resulting Pd-Chit/ZnO and PdAg-Chit/ZnO composites were not heat treated and were studied in n-hex-2-yne hydrogenation at 40 °C and P = 0.1 MPa (Figure 10). A comparison of the catalysts in the hydrogenation process indicated that the catalytic properties of such composites could be tuned by varying the chitosan content and adding a second metal. A monometallic 1% Pd-Chit/ZnO catalyst with 2 wt.% chitosan content ([Pd]:[Chit] = 1:1.3 mol/mol) showed the highest activity in the n-hex-2-yne hydrogenation, with a hydrogen uptake rate of 21 × 10−6 mol/s. A further increase in the polymer content ([Pd]:[Chit] = 1:3.3 mol/mol) or the addition of silver with a reduction in the palladium content promoted an increase in the yield of the target product (selectivity to cis-2-hexene increased from 82% to 91–96%), and, at the same time, the activity of the catalysts was reduced.

Figure 10.

Reaction network of n-hex-2-yne hydrogenation.

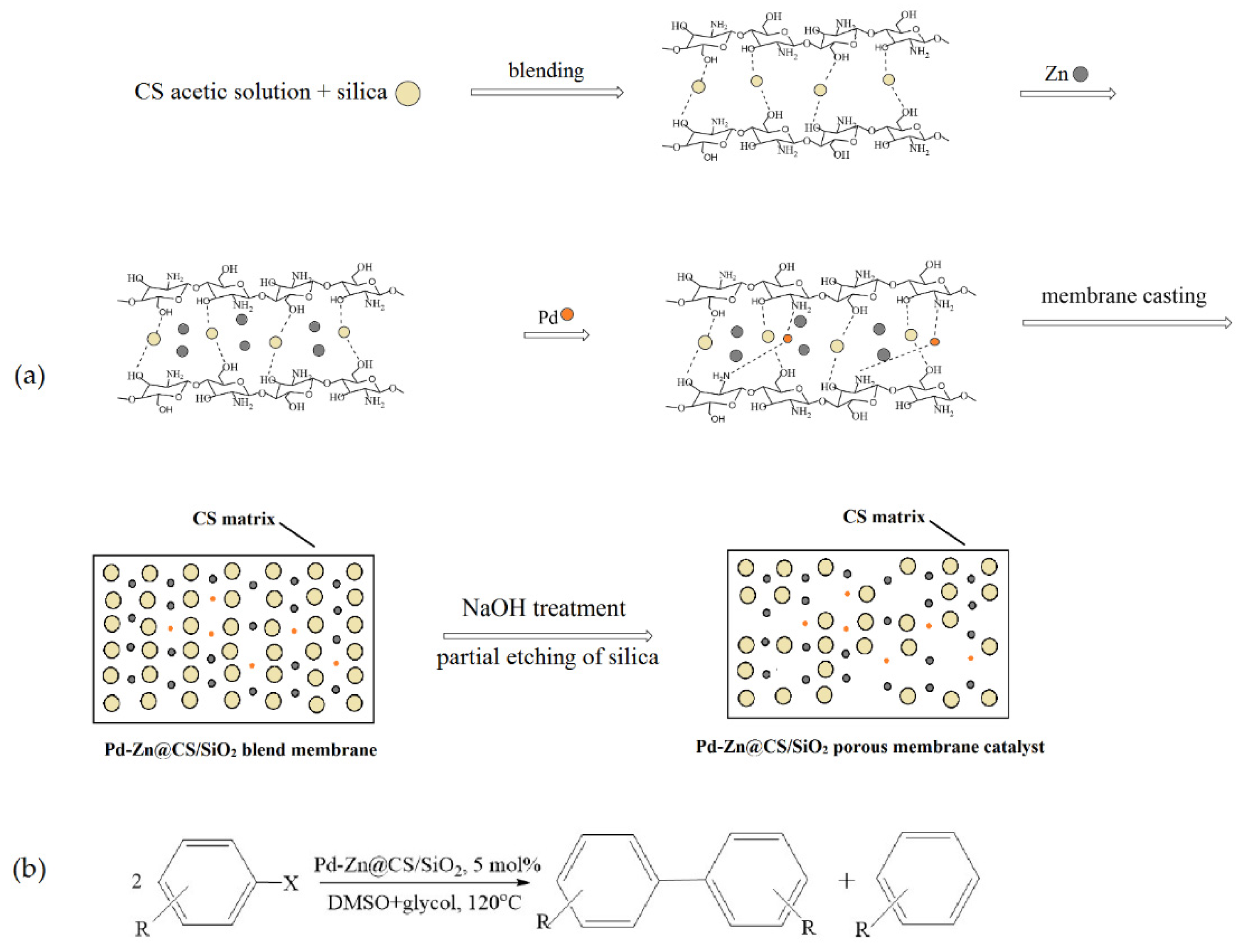

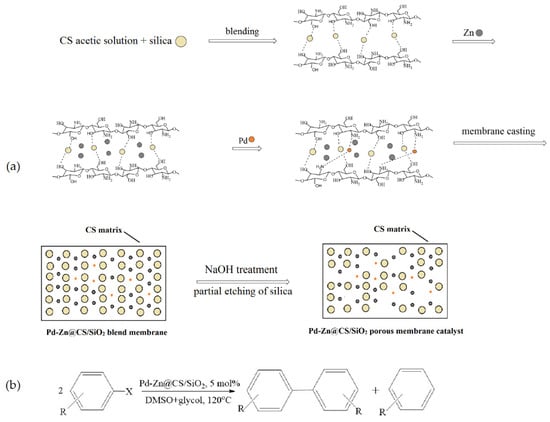

Liu et al. [58] synthesized an efficient heterogeneous catalyst, which included palladium and zinc nanoparticles supported on a chitosan/silica (CS/SiO2) composite membrane. The catalyst was prepared by casting a mixture containing chitosan in an acetic acid aqueous solution, silica colloids (40 wt.%), Zn powder, and a Na2PdCl4 solution, followed by partially etching SiO2 from the resulting membrane (Figure 11a). The high-resolution transmission electron microscopy and X-ray photoelectron spectroscopy characterization of this catalyst showed that the Pd0 nanoparticles (below 5 nm) and Zn0 aggregates (about 10–15 nm) were dispersed well in the CS/SiO2 matrix. The prepared Pd-Zn@CS/SiO2 membrane catalyst was highly active for the Ullmann reductive homocoupling reactions of various aryl halides (41.8–100% conversion), and the selectivity for biphenyls reached 54–98% (Figure 11b). The catalyst could be recycled five times without significant loss of activity.

Figure 11.

Preparation of the Pd-Zn@CS/SiO2 membrane catalyst (a) and its application for the reductive homocoupling of various aryl halides (b). Adapted from [58].

In [59], monometallic Cu and bimetallic Cu-M (M = Co, Zn, Fe, Ni) catalysts were prepared using the NaOH-assisted precipitation of chitosan (CS) on silica (SiO2) and the further immobilization of metal ions on the resulting CS-SiO2 composite. The Cu@CS-SiO2 and Cu-M@CS-SiO2 catalysts demonstrated high efficiency in the process of catalytic wet peroxide oxidation for the degradation of 1,1-dimethyl hydrazine wastewater with H2O2 (100% in 10 min) at 65 °C. The Cu-Zn@CS-SiO2 catalyst activity was minimally affected within six reaction cycles.

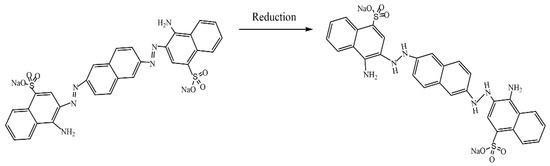

Ali et al. [60] also used the ability of chitosan to precipitate at pH > 6.3 in order to obtain a chitosan–silica (CH-SiO2) nanocomposite fiber as a support material for metal nanoparticles (Cu, Co, Ag, and Ni). The CH-SiO2 nanocomposite fiber was prepared by adding a mixture of SiO2 nanoparticles dispersed in a chitosan solution to a concentrated aqueous solution of NaOH using a clean disposable syringe. Metal nanoparticles (NPs) templated on chitosan–silica nanocomposite fiber were prepared via the treatment of CH-SiO2 with a metal salt solution and NaBH4. The catalysts were studied in both the reduction of 4-nitroaniline (4-NA) and the decolorization of Congo red (CR) (Figure 12) using NaBH4 as a reductive agent under ambient conditions. The Cu nanoparticle (NP)-loaded CH-SiO2 (Cu/CH-SiO2) showed high catalytic efficiency in the reduction of 4-NA and CR when compared to other loaded metal NPs. Apparent rate constants of 6.17 × 10−3 s−1 and 1.68 × 10−2 s−1 and turnover frequencies (TOFs) of 4.693 h−1 and 3.965 h−1 were observed for the reduction of 4-NA and CR, respectively. In addition, the catalytic activity of the Cu/CH-SiO2 catalyst was also examined and found to be efficient in the reduction of nitrophenols (2-NP, 3-NP, and 4-NP) and other dyes.

Figure 12.

Reductive decolorization of Congo red using NaBH4 as a reductive agent in ambient conditions.

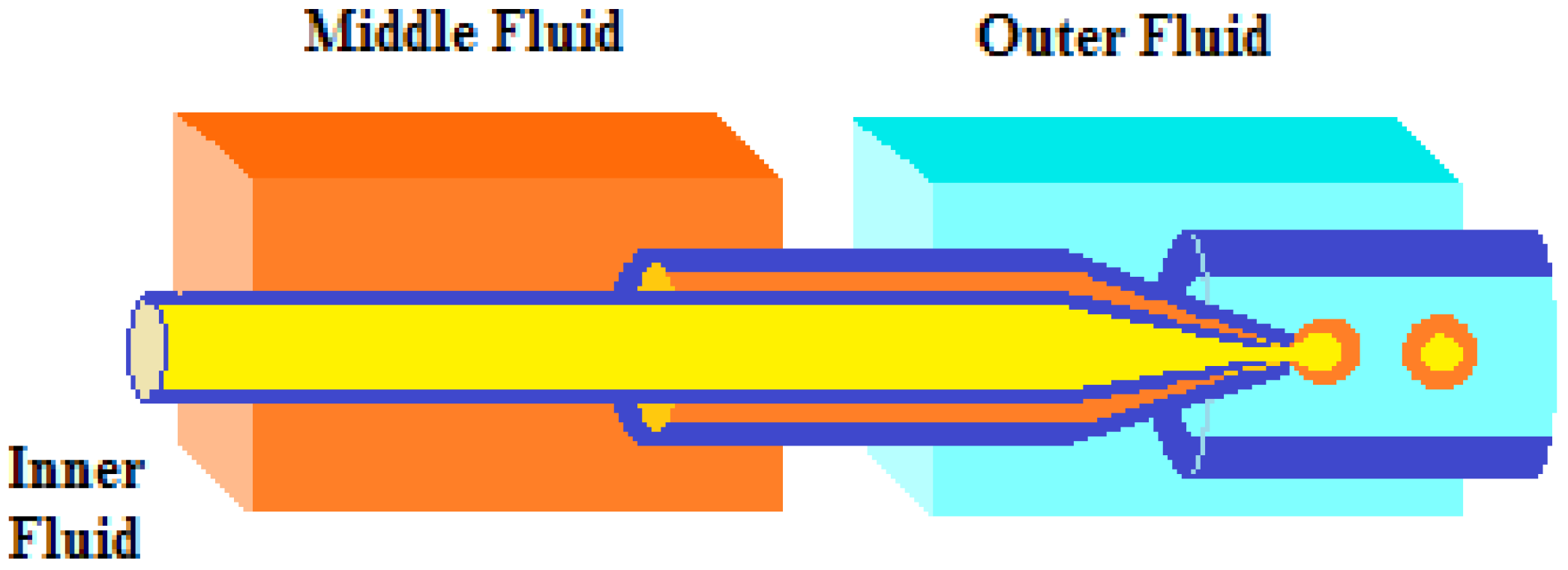

Ma et al. [61] proposed a simple microfluidic method to prepare monodispersed palladium nanoparticles (NPs) supported on silica/chitosan core–shell hybrid microspheres (Figure 13). In order to prepare the silica/chitosan core–shell hybrid microspheres, the inner (SiO2 sol) and middle (chitosan aqueous solution with acetic acid) fluids were injected (in the dispersed phase) into the microchannel and broken into monodispersed droplets under the shearing force of the continuous flow at the intersection. The droplets (a droplet of SiO2 sol inside a droplet of chitosan solution) were formed in a Teflon tube and collected in a solidification bath, where Schiff’s base reaction between chitosan and glutaraldehyde and the extraction of water from droplets in n-octanol were used to presolidify the droplets. In order to obtain the catalyst, palladium ions were adsorbed onto the shell layer of the microspheres via chelation and were then reduced to Pd(0) using NaBH4 at room temperature. Because a large amount of the –NH2 provided by chitosan has a strong force with metal ions, the Pd nanoparticles loaded on the microspheres remained monodispersed and had a mean diameter of only 2–3 nm. In addition, the core–shell structure indicated that chitosan had mainly been distributed on the shell of the microspheres, indicating that palladium was mainly loaded on the shell, too, which can effectively reduce the mass transfer distance between the reactant and catalyst. Therefore, the supported Pd catalyst showed superb catalytic performance in the hydrogenation of cyclohexene (TOF 5.89 min−1) under the optimal conditions of a H2/liquid ratio of 25, a Pd loading amount of 30 mg/g, 300 K, and P = 0.1 MPa. Furthermore, the silica/chitosan-supported catalyst showed excellent stability, with relatively high catalytic performance for 7 days without an obvious decrease in its activity.

Figure 13.

Schematic diagram of a micro fluidic device [61].

2.3. Chitosan-Based Magnetic Catalysts

Magnetic iron oxide nanoparticles (MNPs) represent a promising material for catalytic applications due to their inherent unique properties, such as a high specific surface area, ordered mesopore structures, high loading of complex immobilization, relative chemical inertness, easy dispersibility in solutions, and magnetic properties [62,63]. Immobilizing a catalyst on the surface of MNPs allows for the simple separation of the magnetic catalyst without the need for centrifugation, filtration, or other tedious methods [64]. However, magnetic nanoparticles (MNPs) themselves have some disadvantages, such as being prone to self-oxidation and agglomeration, having intrinsic instability, and exhibiting magnetic dipole interactions, resulting in the significant deterioration of inherent unique nanoparticle properties [65]. Therefore, coating MNPs with the appropriate agents before using the immobilizing catalyst is required to overcome these disadvantages. Chitosan is one of the most promising coating agents that can provide a number of benefits in the design of magnetic catalysts. More specifically, the unique chemical properties of chitosan allow for the simple functionalization of MNPs, and diverse types of catalysts for various reactions can be obtained.

2.3.1. Chitosan as a Catalyst

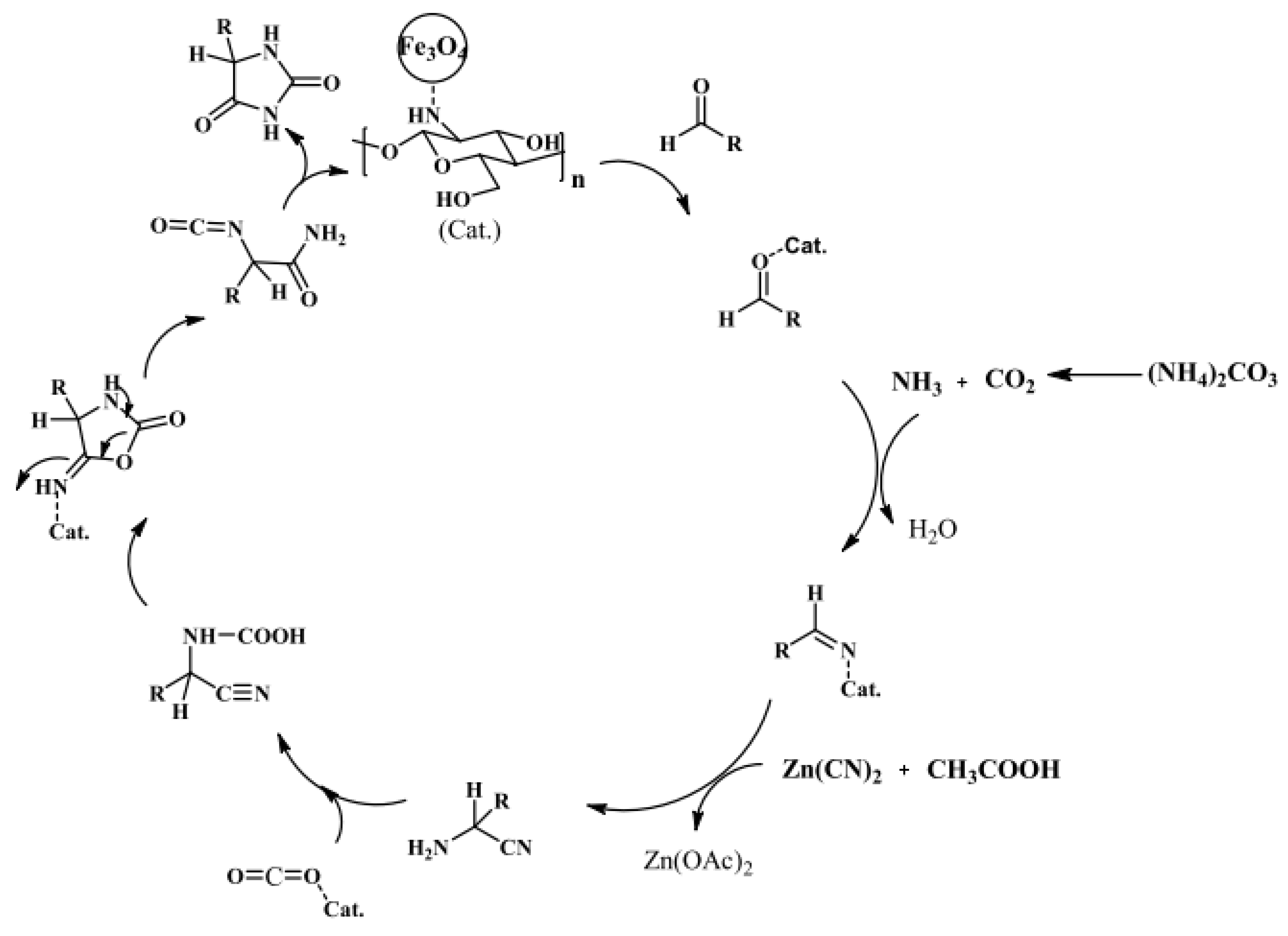

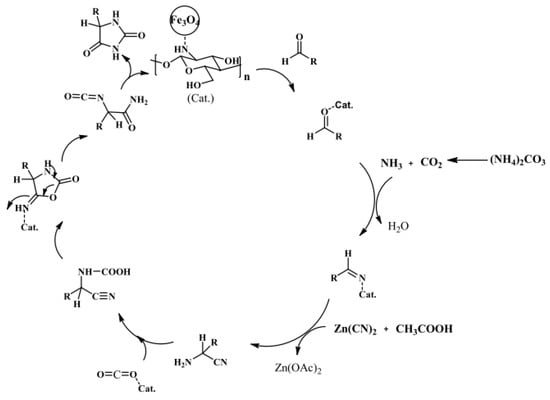

A chitosan shell on the surface of the MNP core can act as an efficient catalyst. Safari and Javadian proposed an easy method for the synthesis of 5-substituted hydantoins with high yields (80–97%) and short reaction times (12–25 min) by using a robust and magnet-recoverable catalyst, prepared via the simple adsorption of chitosan on the surface of Fe3O4 nanoparticles (Figure 14) [64].

Figure 14.

Plausible mechanism for the synthesis of 5-substituted hydantoins using Fe3O4-chitosan as a magnetic catalyst. Reaction conditions: aldehyde (1 mmol), ammonium carbonate (5 mmol), Zn(CN)2 (1 mmol), catalyst (20 mg), and 60 °C. Reprinted with permission from ref. [64]. Copyright 2016 Oxford International Collaboration Centre Press.

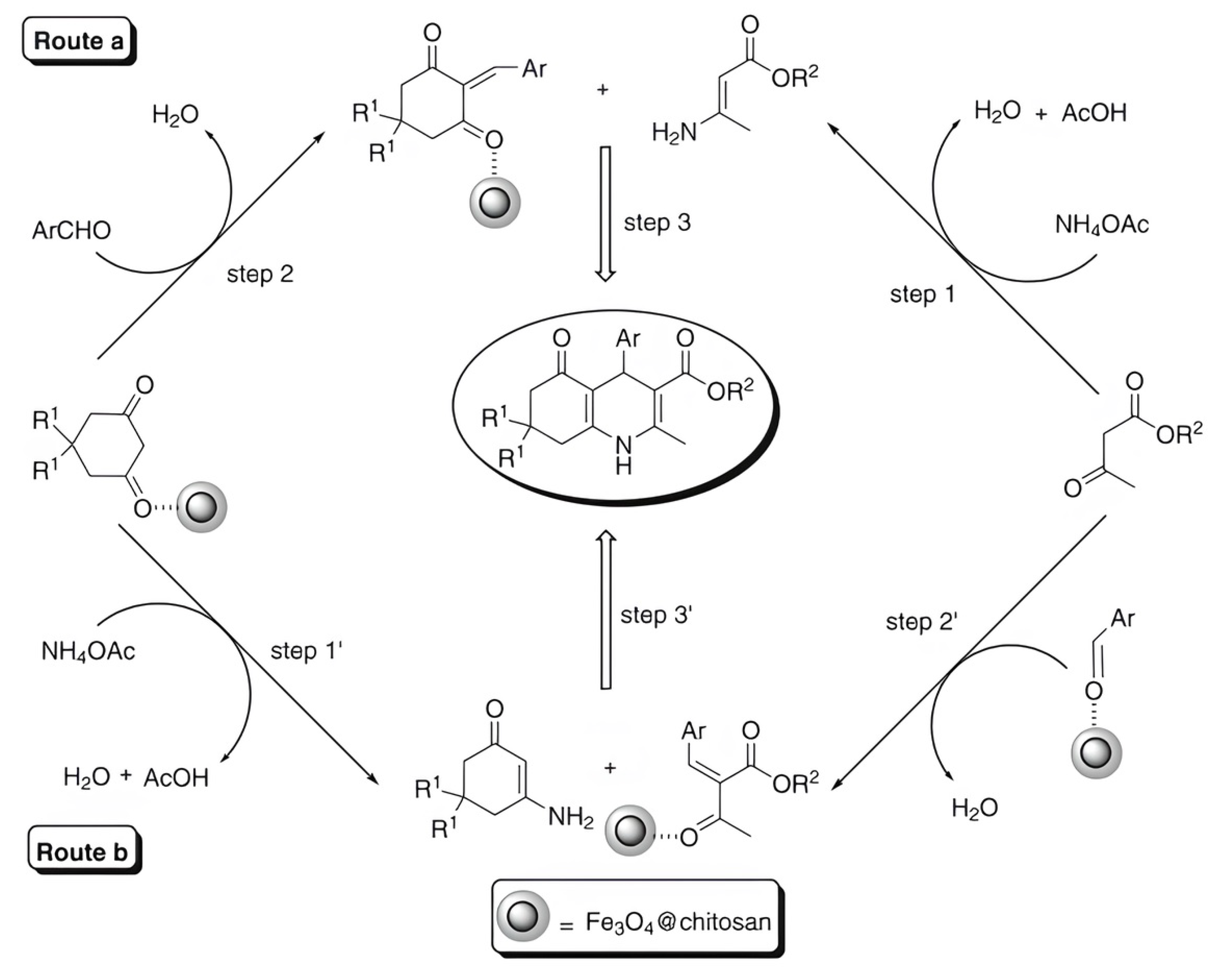

In [66], a Fe3O4@chitosan nanocomposite was prepared by coating Fe3O4 nanoparticles with chitosan–glycolic acid gel; this was used as a green, magnetically recyclable, and efficient catalyst for the synthesis of chemically and biologically important dihydropyridine derivatives at room temperature under mild reaction conditions (Figure 15). This process allows for the easy and efficient synthesis of 1,4-dihydropyridine derivatives at high yields (87–95%). The catalyst is recovered via filtration and can be reused at least five times without a significant loss in catalytic activity.

Figure 15.

Two proposed mechanistic routes for the synthesis of 1,4-dihydropyridine derivatives using Fe3O4@chitosan as a catalyst. The first proposed mechanism: step 1; step 2; step 3. The second proposed mechanism: step 1′; step 2′; step 3′. Reprinted with permission from ref. [66]. Copyright 2016 Springer Nature.

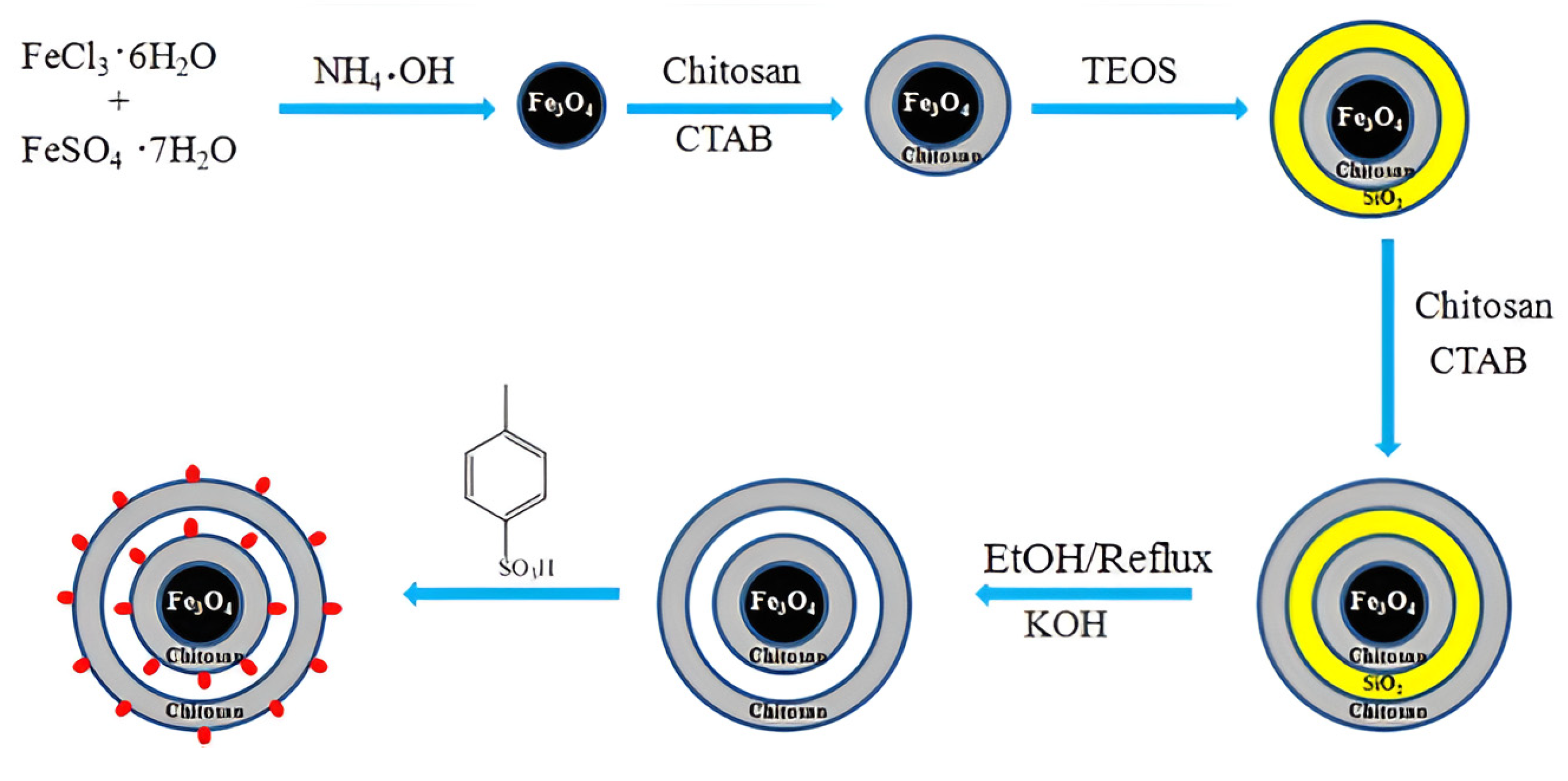

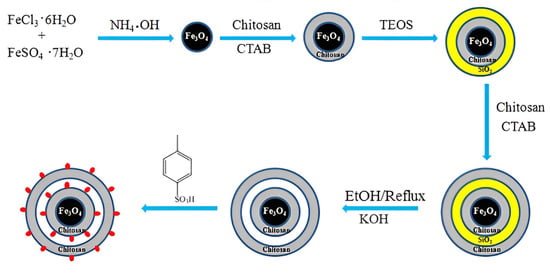

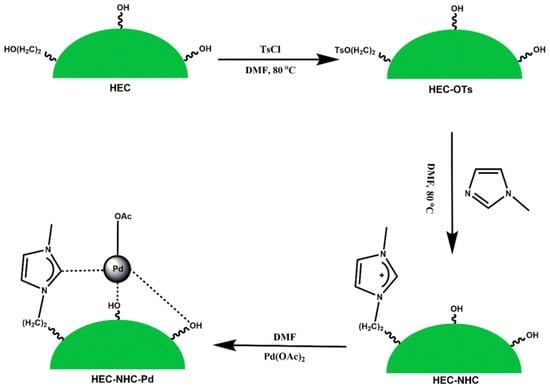

Wang et al. [67] proposed an interesting way to prepare a magnetic chitosan acidic catalyst for the esterification of oleic acid with methanol. The synthesis of the catalyst includes the subsequent coating of Fe3O4 nanoparticles with chitosan or silica and chitosan and the further etching of the SiO2 middle layer from the triple shell. Finally, magnetic microspheres with a double chitosan shell structure were sulfonated to produce the Fe3O4@Chitosan-Hollow-Chitosan-SO3H (FCHC-SO3H) acidic catalyst (Figure 16). A novel FCHC-SO3H magnetic catalyst was found to show predominant catalytic performance in producing biodiesel. Under the optimum reaction conditions (a 15:1 methanol/oleic acid mole ratio and a 4 wt.% catalyst dosage at 80 °C for 3 h), a high biodiesel yield of 96.7% was obtained over FCHC-SO3H.

Figure 16.

Schematic illustration of the synthesis of the mesoporous magnetic biomass-based acidic FCHC-SO3H catalyst [67].

2.3.2. Metal Catalysts on Magnetic Chitosan

The functionalization of MNPs with chitosan (CS) can provide a large number of hydroxyl, primary amino, and acetylamino groups on their surface. Furthermore, these groups can be converted easily to another coordinating ligand by using a chemical reaction with varieties of organic molecules, such as carbonyl compounds, esters, nitriles, etc. This affords a variety of metal complexes for various catalytic organic syntheses, such as coupling reactions, reductions, cycloadditions, and multicomponent reactions [65].

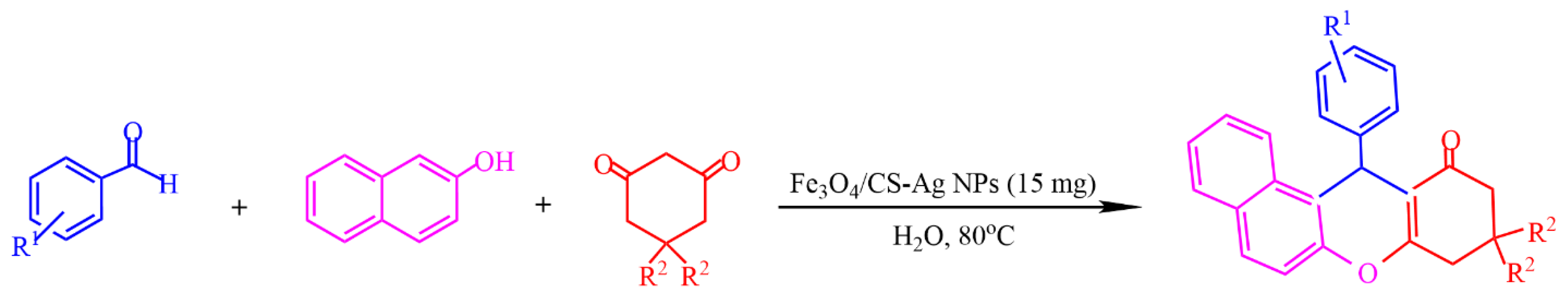

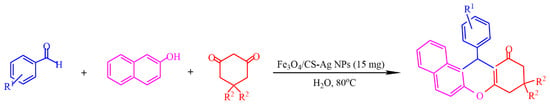

In [68], Fe3O4 nanoparticles were modified using –NH2 groups via the in situ coprecipitation of Fe3+ and Fe2+ ions in the presence of chitosan (CS) using NH4OH in an aqueous solution, resulting in a magnetic Fe3O4/CS composite. The adsorption of Ag+ ions on the surface of the latter, followed by the green reduction of Ag+ via ascorbic acid, yielded Fe3O4/CS-Ag NPs, which showed an excellent catalytic activity (85–96%) toward the one-pot, three-component synthesis of 12-aryl-8,9,10,12-tetrahydrobenzo[α]xanthene-11-one derivatives (Figure 17).

Figure 17.

One-pot, three-component synthesis of 12-aryl-8,9,10,12-tetrahydrobenzo-[α]xanthene-11-one derivatives. Adapted from [68].

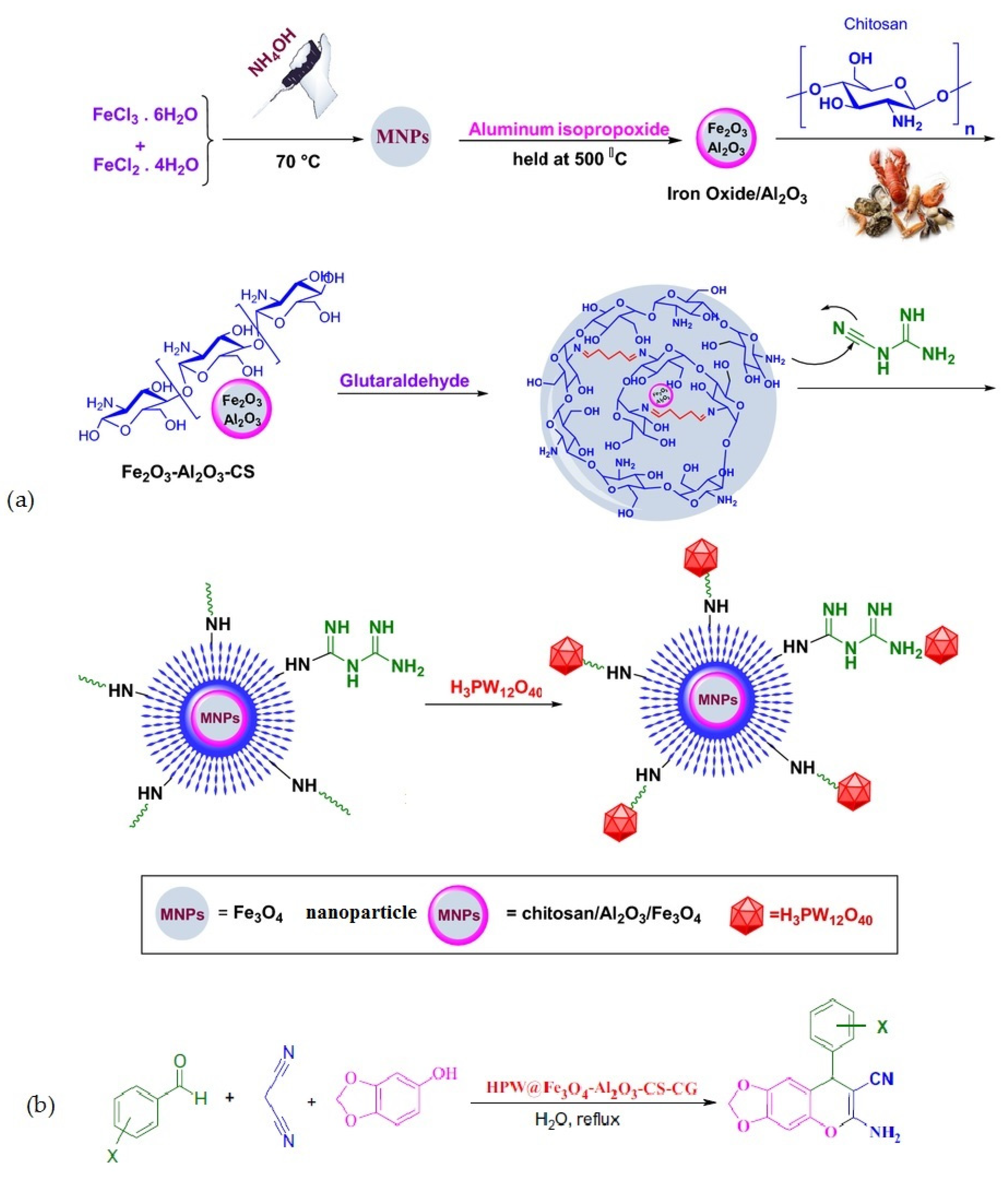

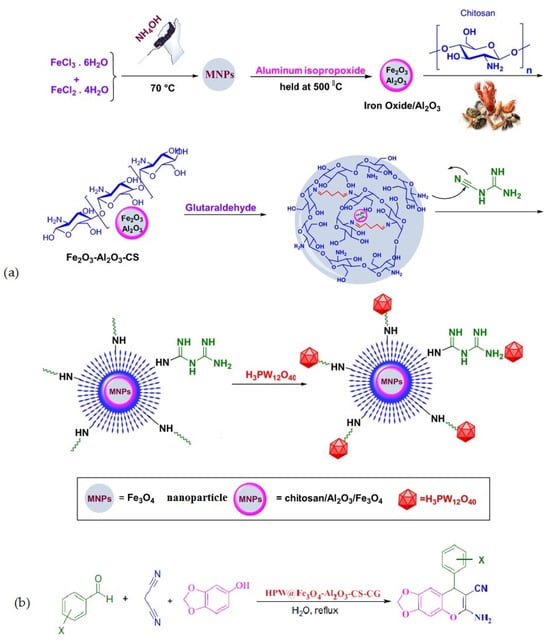

Rahimzadeh et al. [69] used Al2O3/Fe3O4 nanoparticles coated with chitosan–cyanoguanidine as a support material to create a phosphotungstic acid catalyst. The catalytic activity of the fabricated composite (Figure 18a) was examined in a one-pot, three-component reaction involving diverse active methylene compounds, various aryl aldehydes, and malononitrile in water (Figure 18b). The results revealed that the composite showed efficient catalytic performance, and all reactions proceeded smoothly and led to the formation of the corresponding pyranochromene derivatives with high to excellent yields (80–97%).

Figure 18.

Preparation of HPA@Fe3O4-Al2O3/CS-CG (a) and its application in the synthesis of 6-amino-8-aryl-7-cyano-8H-[1,3] dioxolo-[4,5-g]-chromene (b). Reprinted from ref. [69].

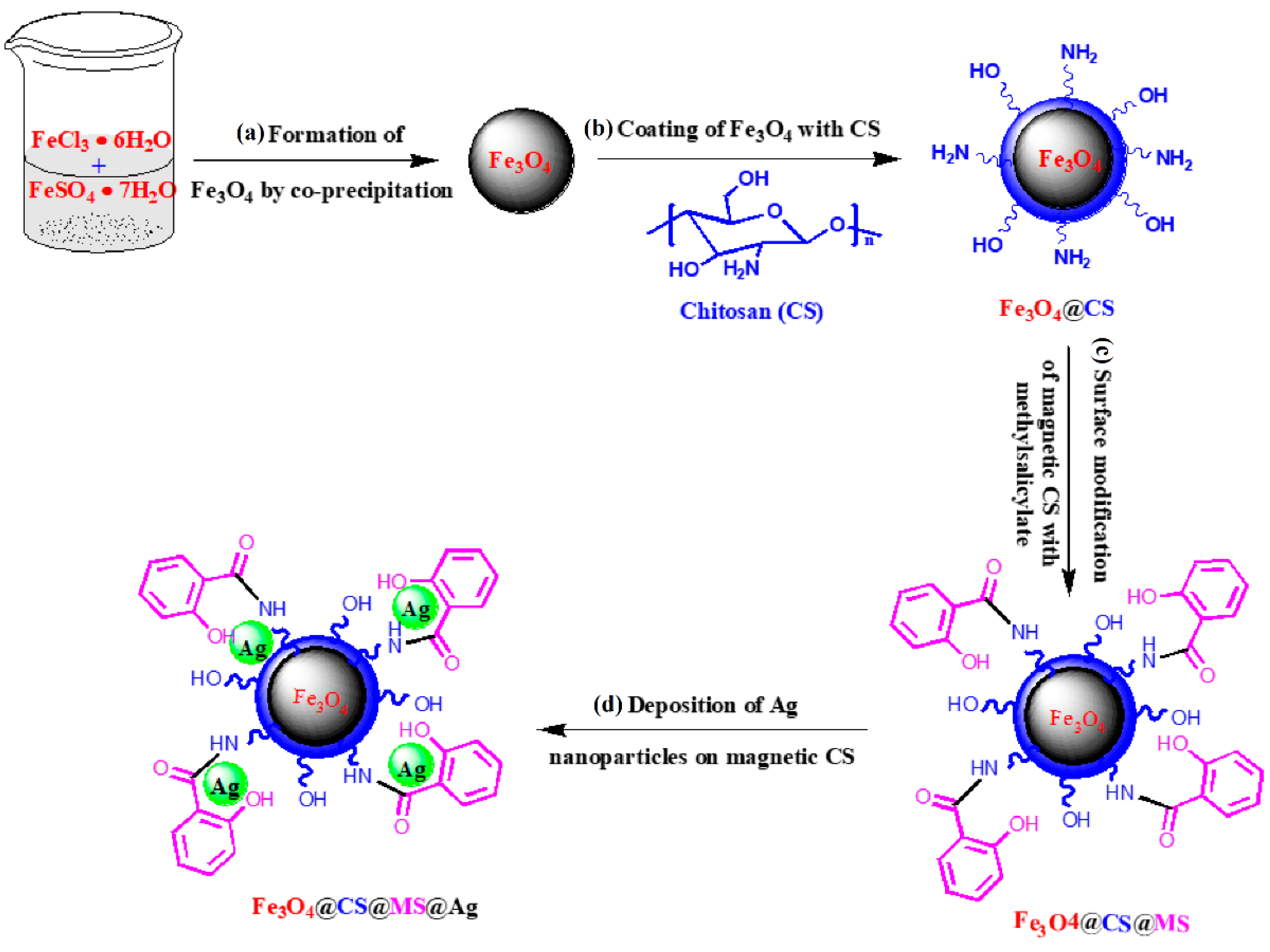

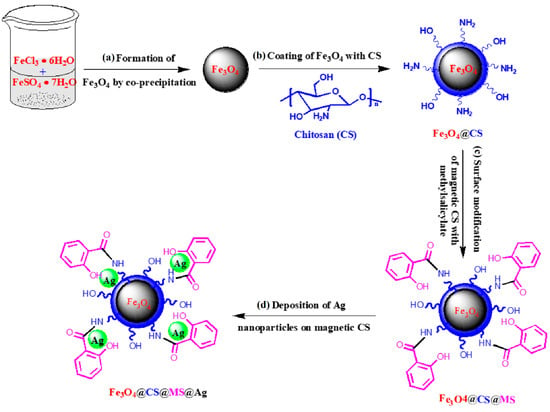

In [70], a heterogeneous catalyst (denoted as Fe3O4@CS@MS@Ag) was fabricated using the deposition of silver nanoparticles on magnetic chitosan via an easy and facile modification of its surface using methyl salicylate (MS) (Figure 19). The catalyst (0.8 mg) showed excellent catalytic activity in the reduction of 4-nitrophenol (6 mL of 10.0 mg/L 4-NP aqueous solution) to 4-aminophenol in the presence of NaBH4 (1.0 mL of freshly prepared 1.0 mM NaBH4 aqueous solution) under ambient conditions. The catalyst was separated using an external magnet after each cycle of catalytic reaction and was reused effectively five times with almost 90% efficiency.

Figure 19.

Synthetic procedure for the fabrication of Fe3O4@CS@MS@Ag as a catalyst. Reprinted from ref. [70].

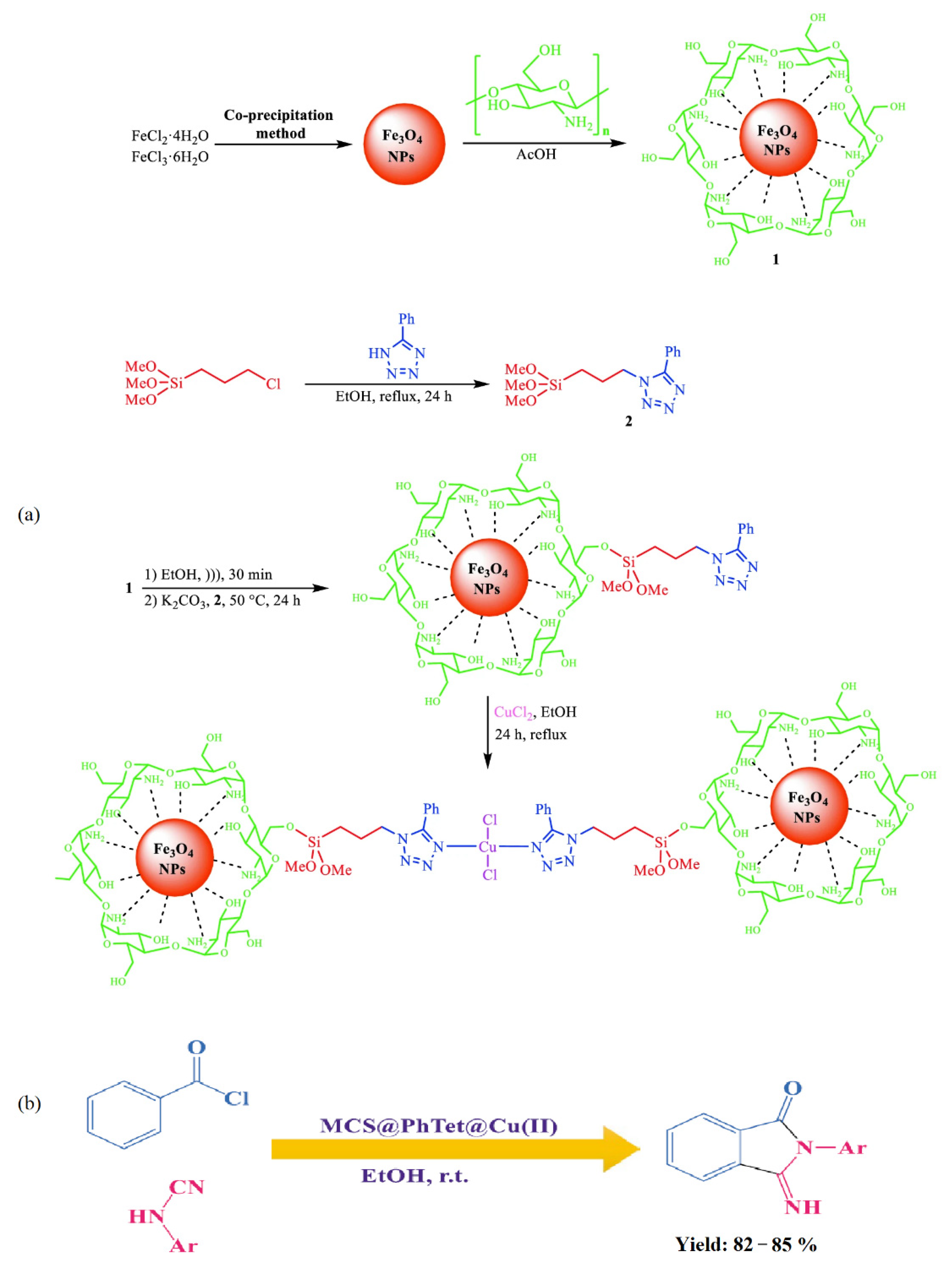

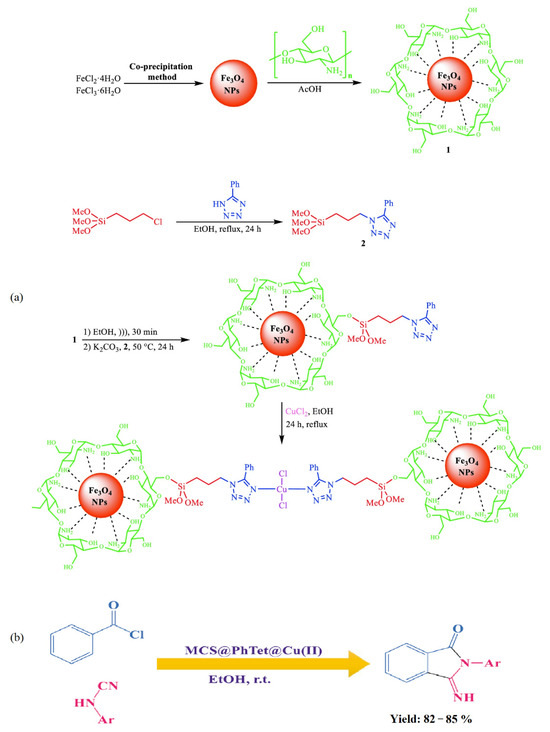

Nasrollahzadeh et al. [71] synthesized a novel copper (II) complex of 5 phenyl 1H tetrazole immobilized on magnetic chitosan (MCS@PhTet@Cu(II)) (Figure 20a) as an effective catalyst. The catalytic activity of MCS@PhTet@Cu(II) was evaluated in the ultrasound-assisted synthesis of 3-imino-2-phenylisoindolin-1-one derivatives via the reaction between benzoyl chloride and arylcyanamides in ethanol under ambient temperature (Figure 20b). The catalyst showed high efficiency and recyclability even after five cycles with no significant loss of its efficiency.

Figure 20.

Preparation of MCS@PhTet@Cu(II) (a) and its application in the synthesis of 3-imino-2-phenylisoindolin-1-one derivatives (b). Reprinted from ref. [71].

2.3.3. Enzymatic Catalysts on Magnetic Chitosan

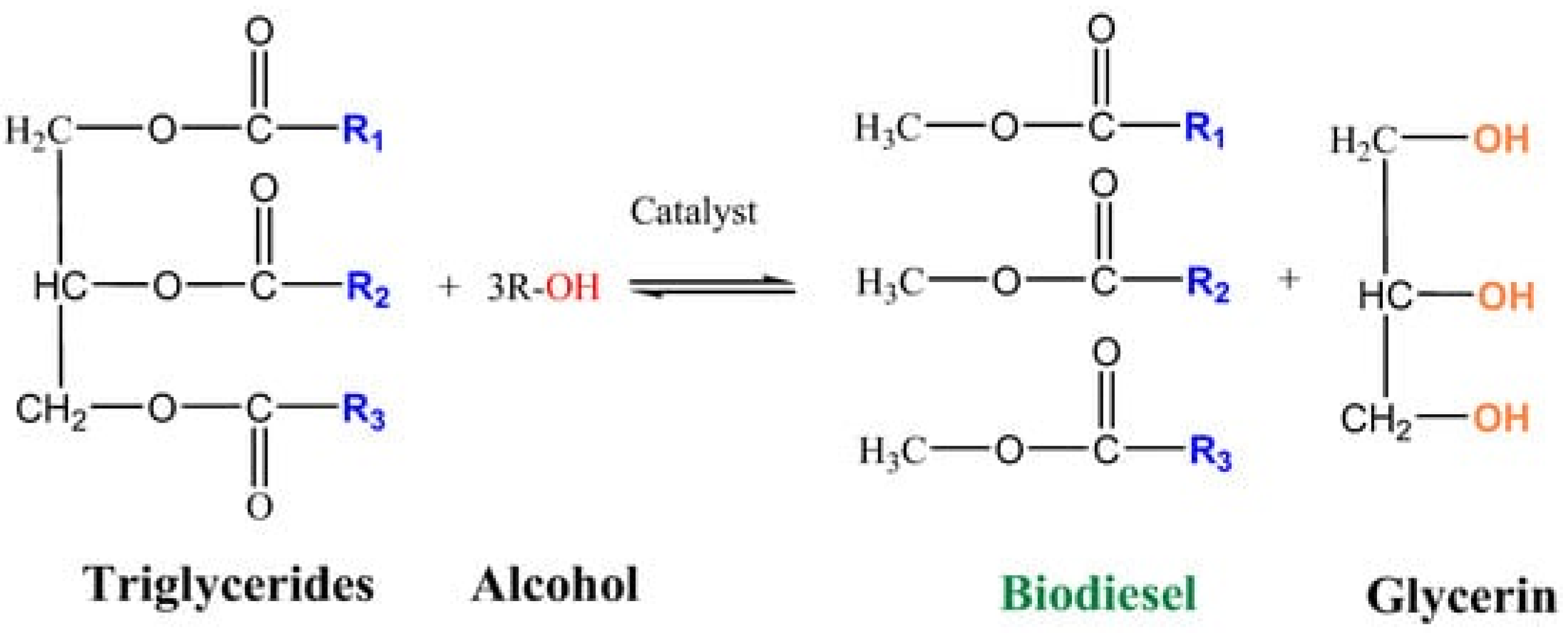

Chitosan-coated MNPs have become attractive as carriers for the immobilization of enzyme catalysts due to the ability of the polysaccharide to adsorb organic molecules. The immobilization of soluble enzymes on a chitosan shell can improve the stability of enzymes over a wide range of operating conditions [72]. On the other hand, the magnetic core makes it possible to recover these enzymatic catalysts from a reaction mixture for their fast and easy reuse. All of this can facilitate the widespread application of soluble enzymes in industrial processes. For example, such catalysts can be used in biofuel production via the transesterification of vegetable oils (Figure 21).

Figure 21.

Transesterification reaction [73].

In [74], the enzymatic synthesis of ethyl esters from coconut oil (Cocos nucifera) and ethanol was evaluated in a bioreactor assisted by an electromagnetic field using lipase from Pseudomonas fluorescens immobilized on chitosan/magnetite beads. The attained results suggest that the synthesis of ethyl esters in this unconventional bioreactor assisted by a magnetic field was positively influenced by molar ratio and temperature, while magnetic induction was important for the establishment of the magnetically stabilized bed; in addition, this helped retain/separate the magnetic biocatalysts for further reuse. The transesterification reaction in the presence of the catalyst achieved a maximum conversion of around 12% under the optimal reaction parameters of 12 h, an oil/alcohol molar ratio of 1:11.25, 47.5 °C, and a magnetic induction of 9.7 mT.

Chen et al. [75] prepared magnetic whole-cell biocatalysts (MWCBs) by immobilizing Pseudomonas mendocina cells within Fe3O4–chitosan microspheres. The MWCBs were applied to the conversion of soybean oil into biodiesel, with a yield of 87.32% obtained under the optimum operating conditions of 48 h, a MWCB concentration of 10 wt.%, a water content of 10 wt.%, 35 °C, a methanol/oil molar ratio of 4:1, and a four-step addition of methanol. In addition, the MWCBs had excellent reusability and still produced a biodiesel yield of 83.57% after 10 cycles, which was higher than that of Fe3O4-uncontained whole-cell biocatalysts (74.06%).

Enzymatic catalysts immobilized on magnetic chitosan can also be used to degrade organic pollutants to CO2 and H2O for soil and wastewater treatment. In [76], cold-active crude enzymes from a psychrophile (xylene monooxygenase (XMO) and catechol 1,2-dioxygenase (C1,2D)) were immobilized on magnetic chitosan microparticles using glutaraldehyde as a linker. The optimization of the amount of each compound involved in immobilization (chitosan, glutaraldehyde, magnetic microparticles, and enzymes) showed that the highest immobilization yield was up to 98%. The immobilized enzymes showed improved pH tolerance ranging from 4.0 to 9.0, better temperature stability ranging from 5 °C to 50 °C, higher storage stability (~70% activity after 30 days of storage), and, more importantly, greater reusability (~40% activity after 10 repetitive cycles of usage) compared to their free form. Moreover, the immobilization of enzymes provided a two-fold increase in the p-xylene degradation rate in soil (10,000 mg/kg) and water (200 mg/L) samples.

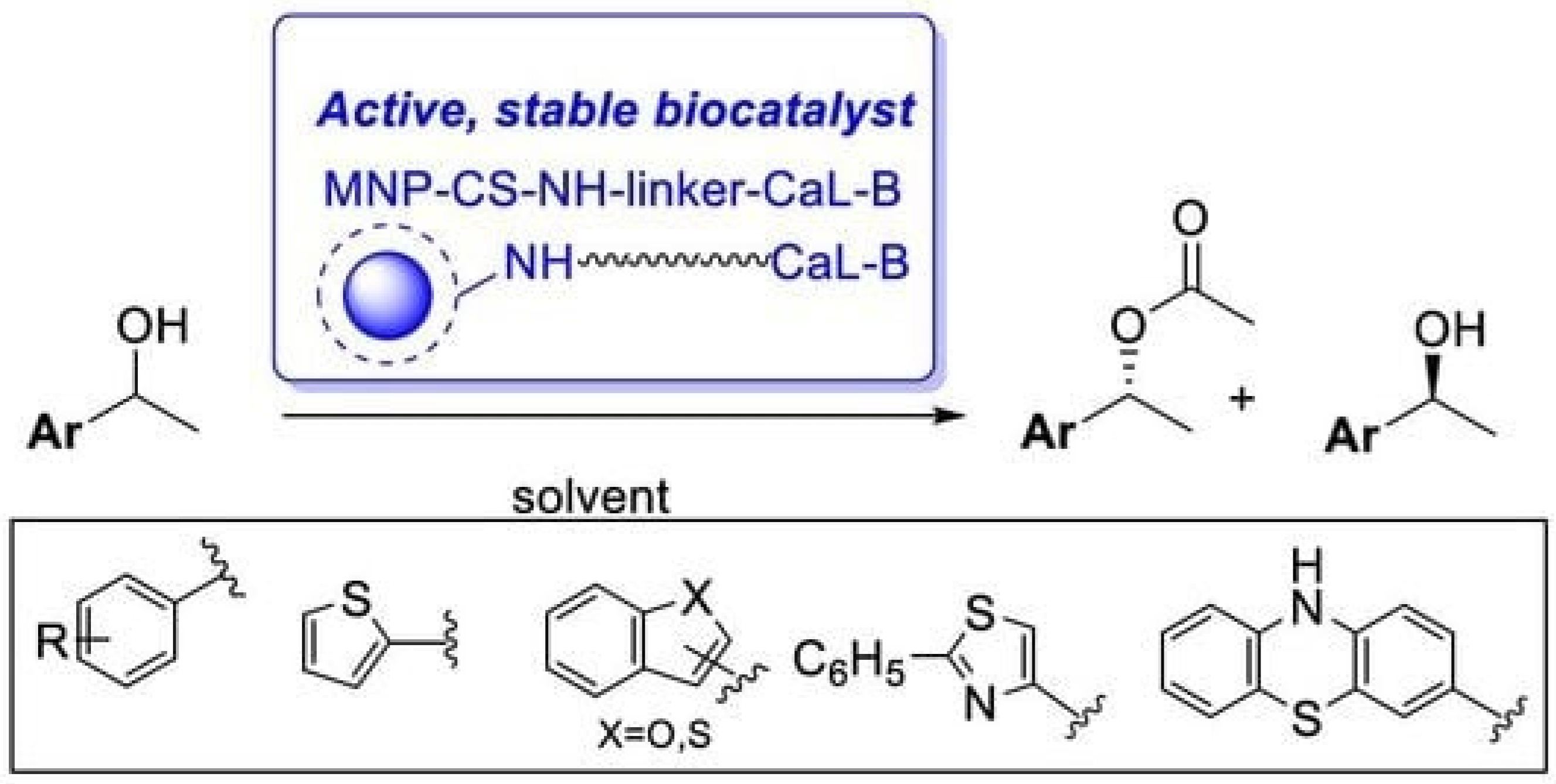

Another application of magnetic chitosan–enzyme catalysts is the synthesis of valuable chemicals or their precursors. For example, lipase B from Candida antarctica (CaL-B) immobilized by covalent binding on sebacoyl-activated chitosan-coated magnetic nanoparticles (MNPs) proved to be an efficient biocatalyst (49.2–50% conversion in 3–16 h and >96% enantiomeric excess) for the enzymatic kinetic resolution of some racemic heteroarylethanols via transesterification with vinyl acetate (Figure 22). Under optimal conditions (vinyl acetate, n-hexane, 45 °C), the biocatalyst remained active after 10 cycles [77].

Figure 22.

Enantiomer-selective transesterification of racemic ethanols mediated by immobilized CaL-B.

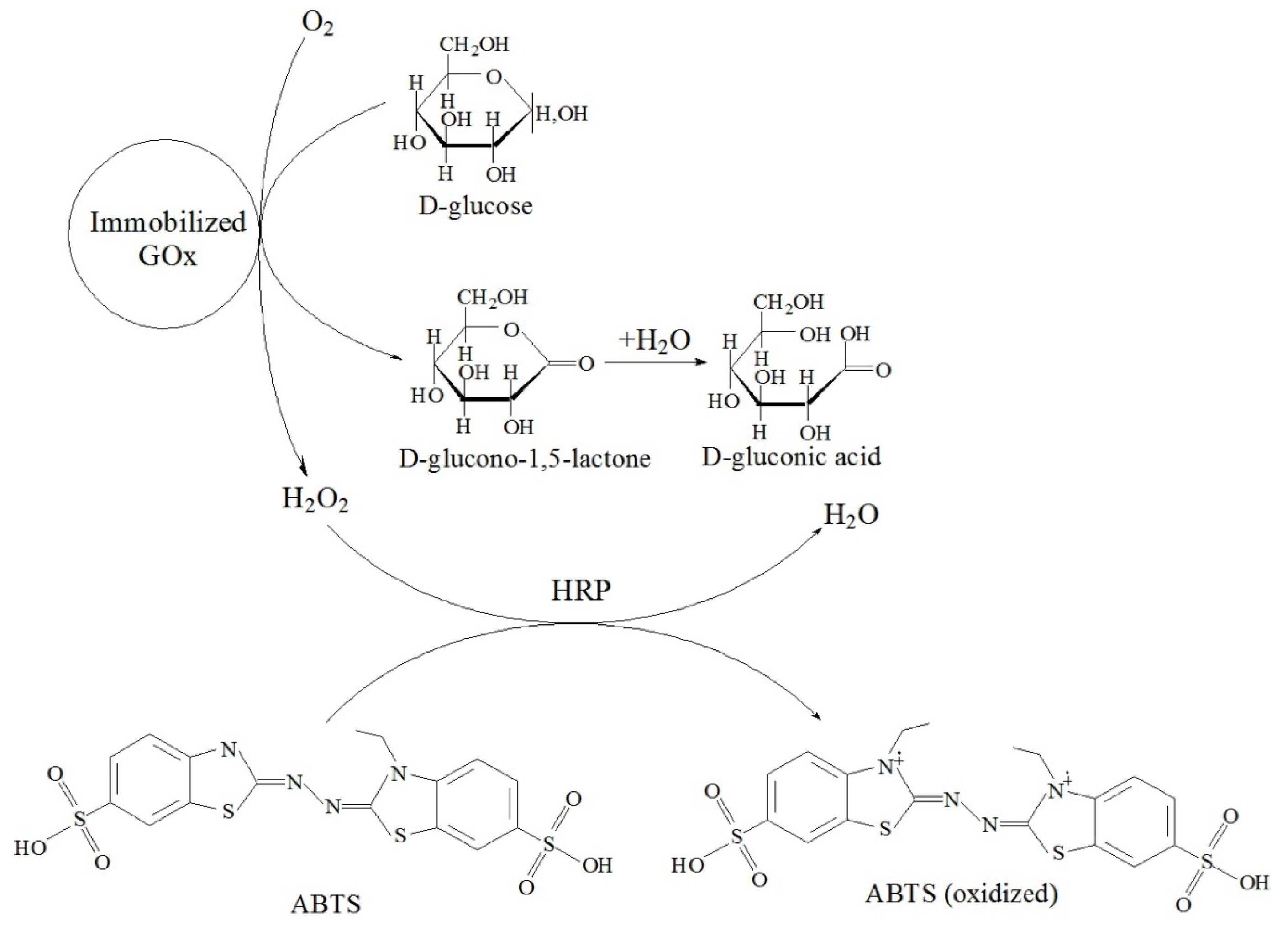

Tikhonov B B et al. [78] developed magnetically recoverable biocatalysts based on magnetite nanoparticles (MNAs) coated with an ultra-thin layer (about 0.9 nm) of chitosan (CS) ionically cross-linked with sodium tripolyphosphate (TPP). Excessive CS amounts were removed by multiple washings combined with magnetic separation. Glucose oxidase (GOx) was attached to the magnetic support via the interaction with N-hydroxysuccinimide (NHS) in the presence of carbodiimide (EDC), leading to a covalent amide bond. These steps resulted in the formation of the biocatalyst for D-glucose oxidation to D-gluconic acid (Figure 23), which can be used in the preparation of pharmaceuticals due to the benign character of the biocatalyst components. In order to choose the catalyst with the best catalytic performance, the amounts of all biocatalyst components were varied. The optimal biocatalyst—prepared using 0.1 g of CS, 0.05 g of TPP, 0.1 g of NHS, 0.04 g of EDC, and 0.01 g of GOx per 1 g of MNAs—showed 100% relative catalytic activity at pH 6 and 35 °C. The immobilization of GOx and the magnetic character of the support prevents GOx and biocatalyst loss and allows for repeated use.

Figure 23.

Schematic representation of D-glucose oxidation to D-gluconic acid in the presence of peroxidase (HRP) and 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt (ABTS).

2.4. Chitosan/Metal–Organic Framework Catalysts

In the past few years, metal–organic frameworks (MOFs) formed via the self-assembly of metal ions with organic ligands via strong coordination bonds have attracted massive attention. The major characteristic features of MOFs are their phenomenal surface area and porosity, high density of transition metals, and good chemical, mechanical, and thermal stability. These properties make MOFs perfect materials for catalytic application [79]. Among them, bio-based MOFs seem to be very promising due to the abundance, nontoxicity, and chemical properties of the renewable material sources (polysaccharides, amino acids, and peptides) used for their preparation [80]. Chitosan-based MOFs are no exception and can also be used as effective catalysts in various reactions.

Catalysts containing chitosan and MOFs can be used in wastewater treatment. Vigneswaran et al. reported [81] that a combination of a hetero-structured metal–organic framework of copper (II) benzene-1,3,5-tricarboxylate (Cu-BTC) with a Fe2O3 nano-photocatalyst using chitosan (CS) as a tethering agent resulted in the formation of a hybrid mesoporous nanocomposite (CS-Fe@Cu-BTC). The CS-Fe@Cu-BTC photocatalyst demonstrated 91% removal of paraquat within 60 min at pH 5. The durability of the CS-Fe@Cu-BTC nanocomposite was also established after four cycling processes.

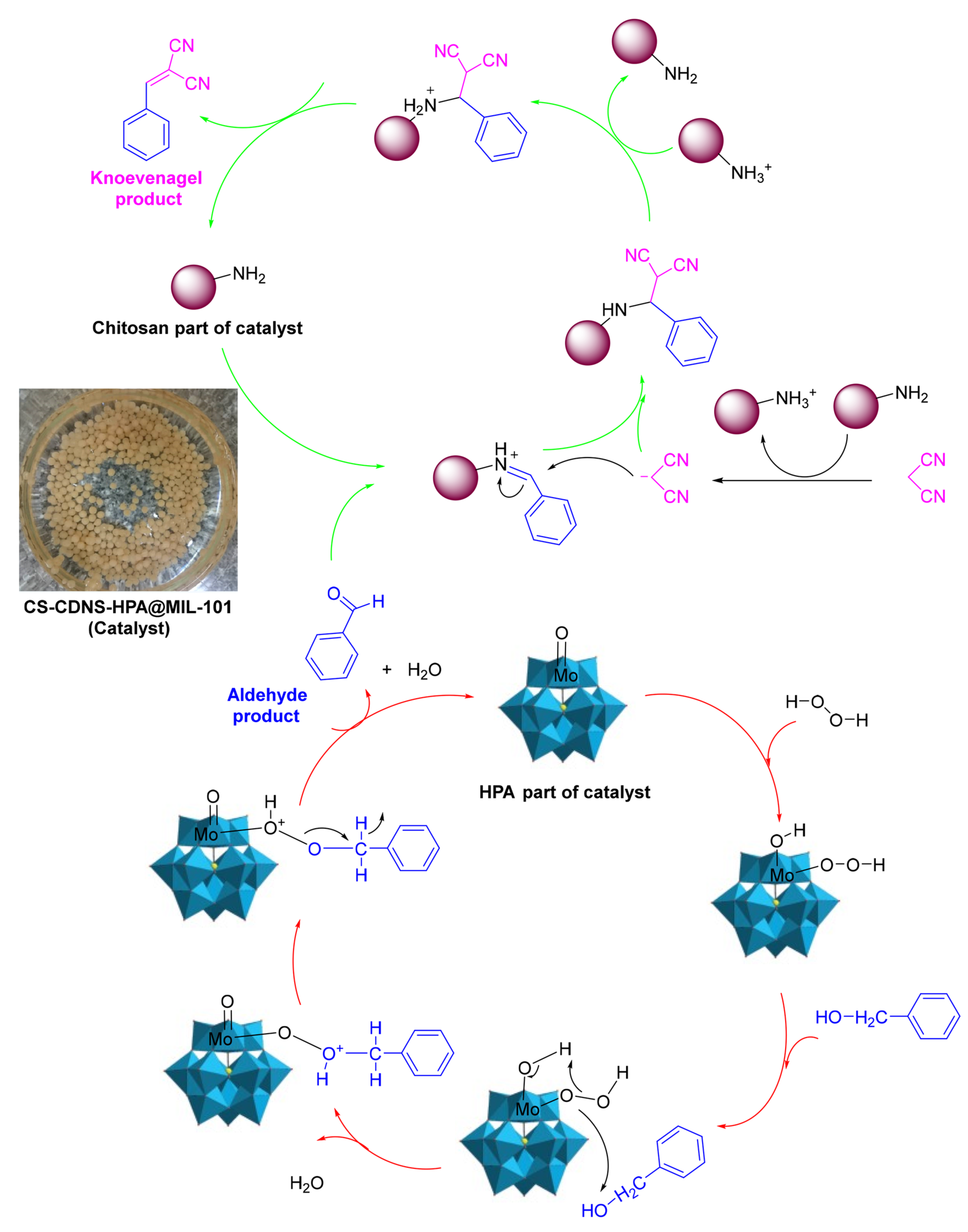

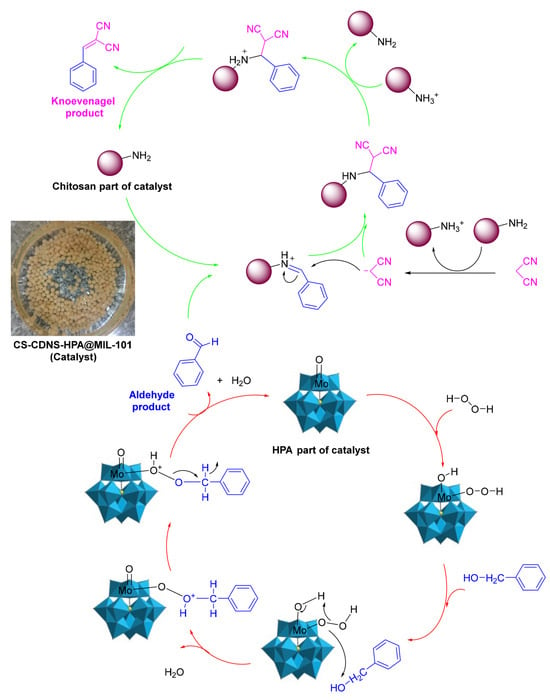

Another application of chitosan/MOF catalysts is tandem reactions, in which bonds are developed without isolating the intermediates by altering the reaction conditions or through the inclusion of chemical reagents [80]. Sadjadi et al. [82] described the synthesis of a novel bi-functional catalytic composite, in which a MIL-101(Fe) metal–organic framework modified with phosphomolybdic acid (HPA) and cyclodextrin-based nanosponges (CDNS) was incorporated into chitosan (CS) beads. CS-CDNS-HPA@MIL-101 was examined in alcohol oxidation and the cascade alcohol oxidation–Knoevenagel condensation reaction. It was found that the designed catalyst possessed both an acidic feature and redox potential, which could promote both reactions in aqueous media at 55 °C, and various substrates with different electronic features could tolerate the aforementioned reactions to furnish the products, with a 75–95% yield. That is, the amino groups on the chitosan served as catalysts for the Knoevenagel condensation reaction, and phosphomolybdic acid (HPA) catalyzed the oxidation process (Figure 24). The cyclodextrin nanosponge mainly acted as a phase transfer agent. The catalyst could be readily recovered and recycled for five runs with a slight loss in catalytic activity. Moreover, the measurement of phosphomolybdic acid leaching showed that its incorporation in a metal–organic framework and bead structure could suppress its leaching, which is considered a drawback for this compound.

Figure 24.

The plausible mechanism for the cascade alcohol oxidation–Knoevenagel condensation reaction, highlighting the catalyst effect. Reprinted from ref. [82].

Chitosan/MOF composites can also be used as a support material for metal catalysts. Wang et al. [83] discussed the preparation of chitosan (CS) microspheres coated with a ZIF-8 metal–organic framework using polydopamine (PDA) as a connecting material. A CS/PDA@ZIF-8 core–shell composite, which possessed regular morphology, uniform size, and a large surface area (353.1 m2/g), was used as a support material for the immobilization and stabilization of palladium nanoparticles (NPs). The CS/PDA@ZIF-8@Pd catalyst performed well in an array of reactions at room temperature. For example, the Kapp value of the p-nitrophenol reduction reaction reached 0.0426 s−1, and the TOF of the Suzuki coupling reaction reached 128 h−1 (99% yield of biphenyl products). The prepared catalyst demonstrated a reusability of six cycles in the Suzuki reaction with a slight loss in catalytic activity.

Thus, the chemical properties of chitosan make it possible to obtain effective catalysts for various organic transformations (coupling reactions, reduction of nitroaromatics, transesterification, hydrogenation, oxidation, multicomponent reactions, cascade reactions, decomposition of organic molecules, etc.) using different approaches. The simplest one is based on the binding affinity of the –NH2 and –OH functional groups of the polysaccharide toward transition metal ions. The ability of chitosan macromolecules, when dissolved in an acidic medium, to be precipitated at pH > 6.3 is used in the preparation of catalytic microspheres, where chitosan serves as a support for metal catalysts. This ability is also used to functionalize inorganic materials (alumina, silica, magnetite, etc.) and obtain core–shell composites, in which the chitosan shell can act as both a catalyst and a linker to immobilize metal or nonmetal catalysts (enzymes and sulfonic acids) on their surface. The cross-linking of the polysaccharide macromolecules with aldehydes is used to improve the mechanical strength of chitosan microspheres, promote the strong fixation of the chitosan shell to the surface of an inorganic support, and also reduce the probability of metal NP leaching. Chitosan can also be modified to form chelate ligands (Schiff bases, etc.) with better affinity for transition metal ions, which also affects their behavior in catalytic processes. Of particular interest is the combination of chitosan with organometallic frameworks (MOFs), where the biopolymer can act as a binding agent between MOFs and active particles or as a support for MOF-based catalysts. Studies on the immobilization of soluble enzymes on magnetic chitosan, which can allow for the widespread application of enzymatic catalysts in industrial processes, also show promise.

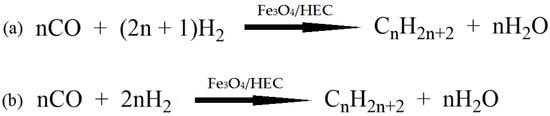

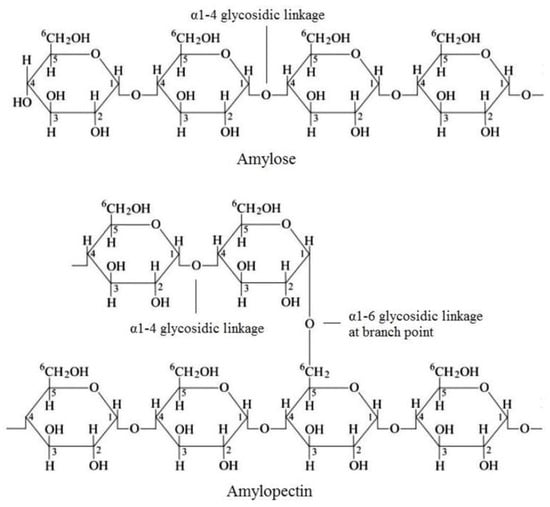

3. Pectin-Based Nanocomposites

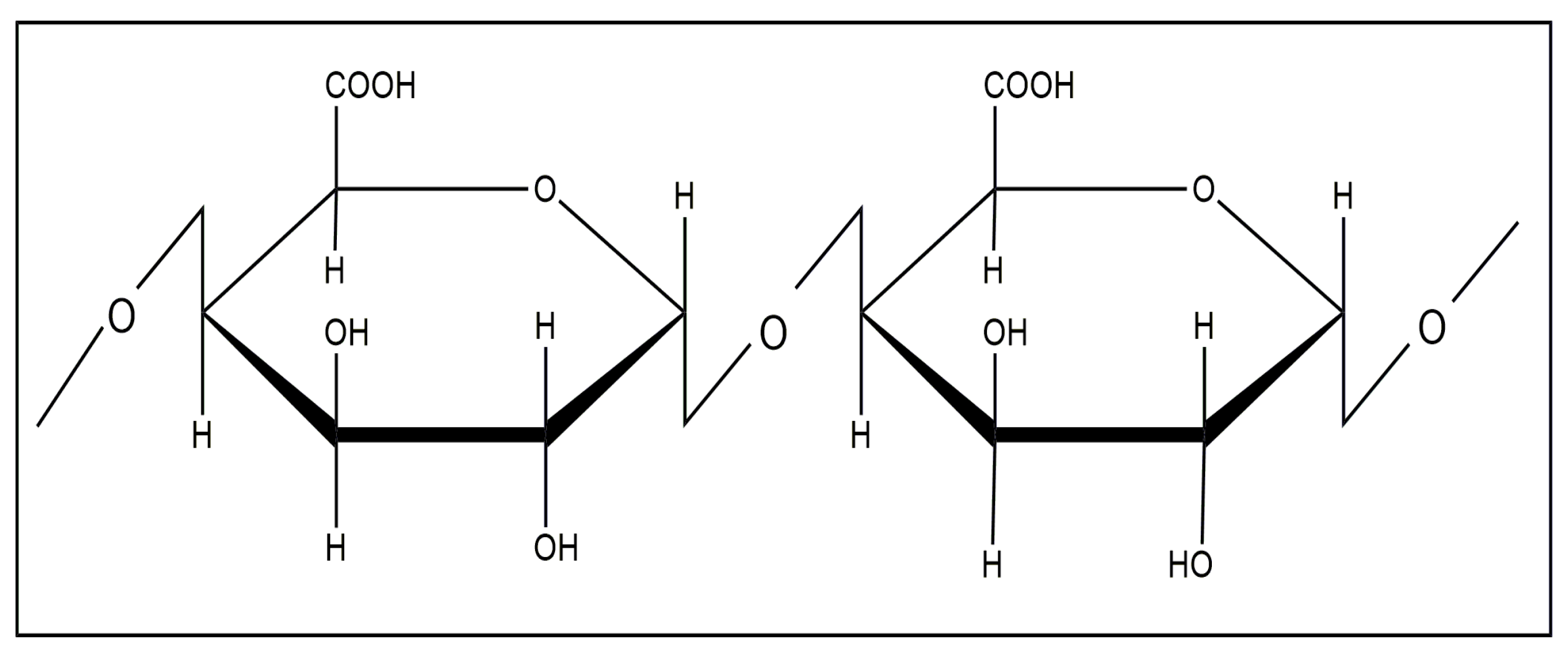

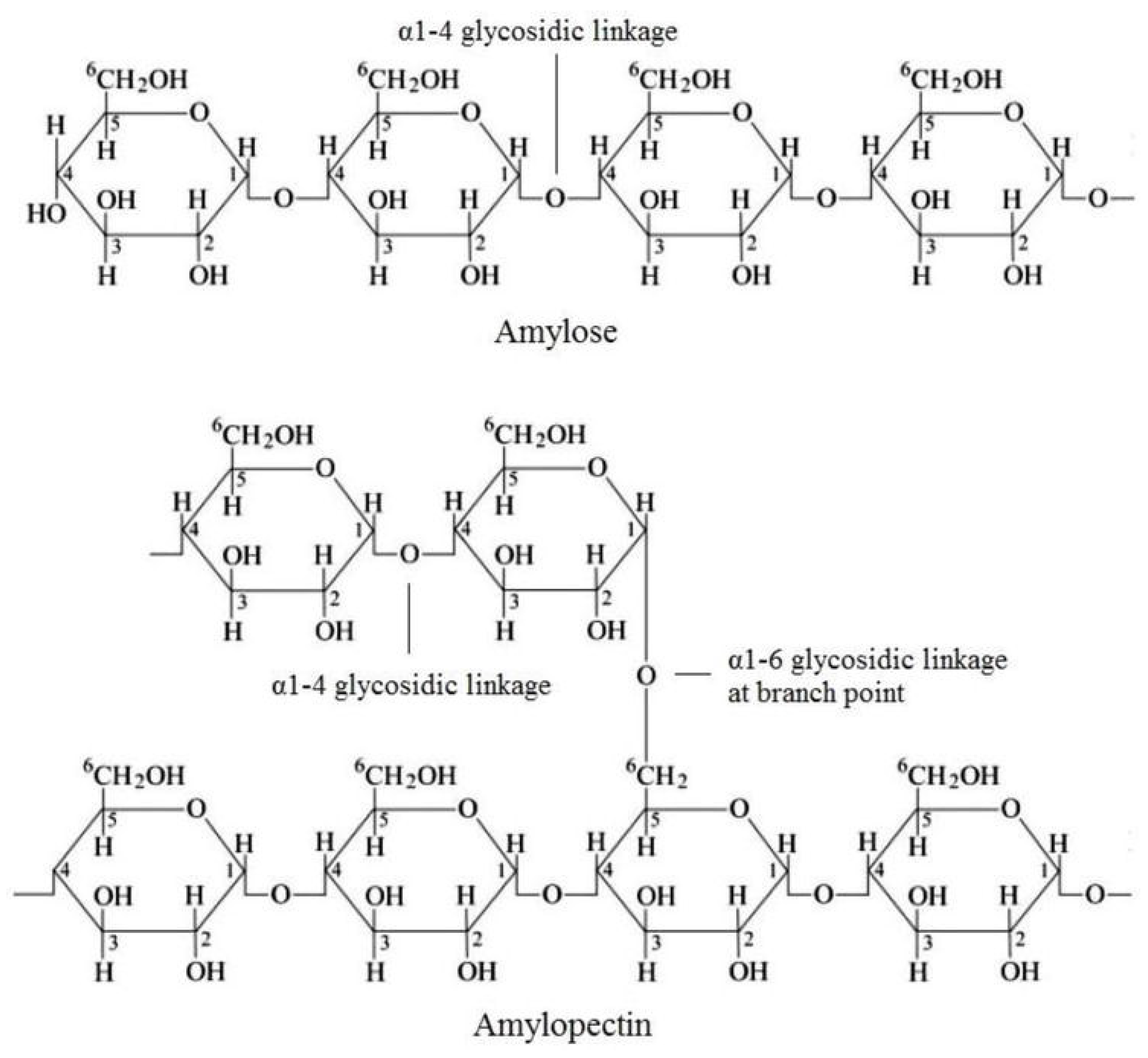

Pectins are heteropolysaccharides that are widely used in the medical, food, and cosmetic industries due to their emulsifying, gelling, thickening, and stabilizing properties [84,85]. The structure of pectin mainly consists of D-galacturonic acid residues connected through an α-1,4-glycosidic bond to a polymer chain (Figure 25).

Figure 25.

Structural formula of pectin.

The presence of a large number of functional groups in the structure provides unique properties and a wide range of pectin applications [84,85,86,87]. Pectin is considered a safe, non-toxic, inexpensive product to produce and represents an easily accessible polysaccharide [88,89].

Pectins are separated by the degree of methoxylation—the ratio of the number of methoxyl groups (O-CH3) to all the acid residues in the molecule. According to the degree of esterification, all industrial pectin species are classified as high methoxyl (with an esterification degree that is equal to or more than 50%) or low methoxyl (with an esterification degree of less than 50%) [90]. The degree of esterification is an important parameter that determines the special properties and functionality of pectin (stability, viscosity, gelation, strength, etc.) [91,92,93,94,95].

Pectins are contained in plant cell walls and are abundant in plant waste [96,97]. Their composition and structure strongly depend on the source of pectin, extraction stages, conditions, etc. [96]. On an industrial scale, about 85% of pectin is extracted from citrus peels and apple pomace, which are characterized by a high pectin content (18–30%) and are accessible as agricultural waste [88]. Sugar beet pulp, sunflower seeds, mangoes, bananas, grapefruit, etc., are considered alternative sources of pectin [90,98,99].

Traditional methods of pectin extraction involve the use of hot water (60–100 °C) in an acidic medium for several hours [96,100,101]. In recent years, various alternative methods, such as enzymatic [102], microwave [96,103], and ultrasonic [102,103,104,105] methods, have been used to increase the yield of pectin, which can improve process efficiency and are more environmentally friendly and cost-effective [97,101,104].

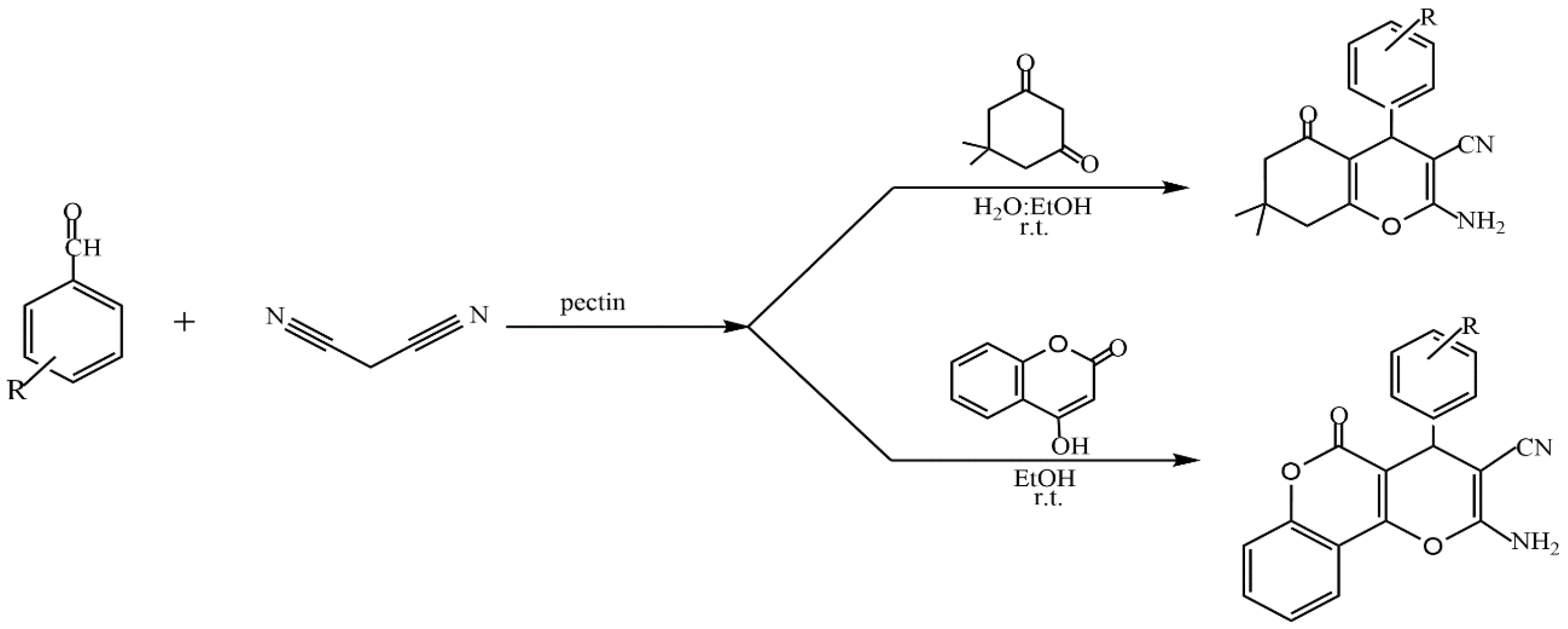

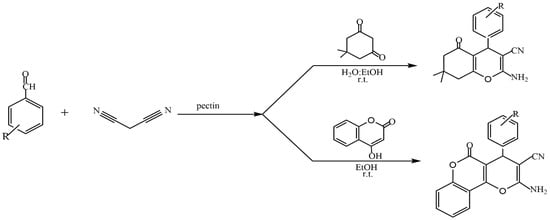

3.1. Pectin and Pectin–Inorganic Composites as Catalysts

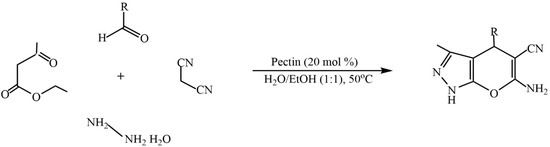

The presence of a large number of carboxyl and hydroxyl groups in the molecules allows pectins to be used to design various materials such as sorbents for wastewater treatment [106,107], organic–inorganic hybrid composites [108,109,110,111], and catalysts [24]. The study of the catalytic properties of pectin and pectin-containing nanocomposites has been described in [112,113,114,115,116,117,118,119,120,121]. In several reviews [24,36,112,114], the authors discuss the prospect of applying the most common polysaccharides, including pectin, to catalytic processes (oxidation, Heck, Suzuki–Miyaura, cross-coupling reactions, etc.). Kangani et al. reported the green synthesis of tetrahydrobenzo[b]pyran and pyrano[c]chromene derivatives (Figure 26) in the presence of natural pectin in water–ethanol and ethanol media at room temperature [112].

Figure 26.

Synthesis of tetrahydrobenzo[b]pyran and 3,4-dihydropyrano[c]chromene derivatives in the presence of pectin.

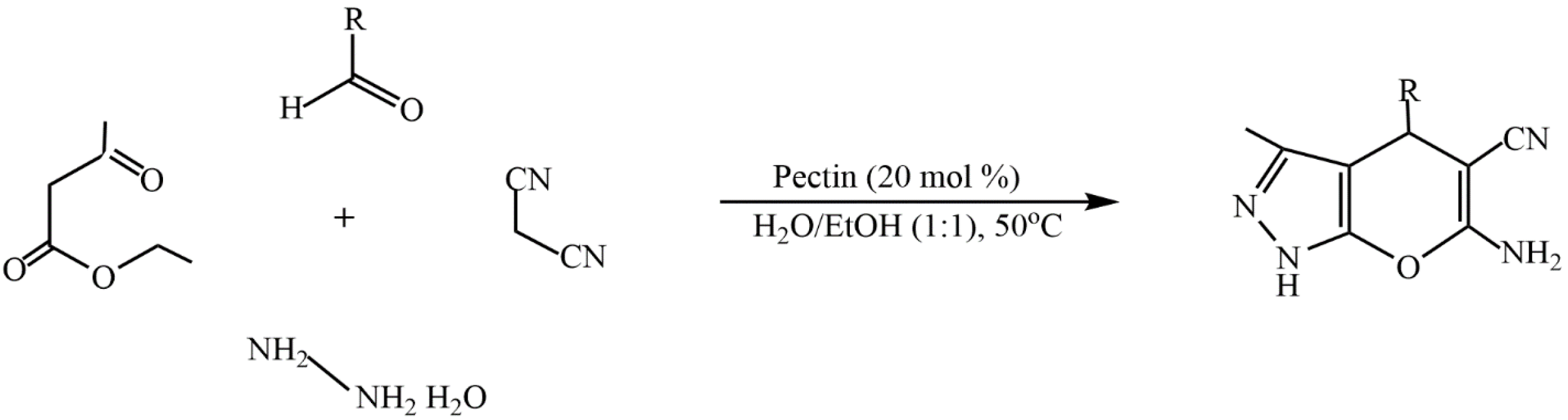

The advantages of such types of synthesis are high product yields, short reaction times, mild synthesis conditions, and the use of natural, easily accessible, and inexpensive pectin as a catalyst. The catalytic properties of pectin are comparable to those of other catalysts. The environmentally friendly synthesis of biologically valuable heterocyclic compounds (dihydropyrano[2,3-c]pyrazole derivatives) by using the one-pot method is proposed in [113]. In this study, pectin was used as a biopolymer catalyst to rapidly access dihydropyrano[2,3-c]pyrazole derivatives in an aqueous ethanol medium over a short period of time. Comparative studies on the catalytic properties of the developed catalyst using known catalytic systems for the synthesis of dihydropyrano[2,3-c]pyrazole derivatives were carried out (Figure 27).

Figure 27.

Synthesis of dihydropyrano[2,3-c]pyrazole derivatives.

The results showed that pectin is an effective green catalyst for the production of biologically active compounds. Acosta et al. used the cation-binding capacity of pectin to reduce the amount of calcium ions leached into biodiesel [119]. The main disadvantage of biodiesel production via the reaction of vegetable oil transesterification using an efficient CaO catalyst is the presence of a large amount of calcium ions in the obtained biodiesel. The calcium content exceeds the permissible concentration (ASTM D6751) [119,122]. In this work, a CaO-based catalyst was prepared using a precipitation method with Na2CO3 and Ca(NO3)2 in the presence of pectin, followed by calcination. The most active catalyst, CaP-600, was prepared at a temperature of 600 °C. The synthesized catalysts showed high activity in the reaction of soybean oil transesterification to obtain biodiesel.

The design of pectin–inorganic composites for catalysis applications is of great interest [115,116,117,118]. When designing this type of material, the combination of the advantages of both components determines the specific properties of these nanocomposites. The strong synergetic interaction between them leads to the formation of composites with desired properties that positively affect the physicochemical properties of nanocomposite materials.

It should be noted that the proposed syntheses of pectin-based catalysts are generally considered environmentally friendly. Attallah et al. developed a pectin/chitosan/zinc oxide (Pec/CS/ZnO) nanocomposite for the removal of carbamazepine (CBZ) from aqueous solutions under direct sunlight [115]. In the organo-inorganic composite, chitosan and pectin act as the adsorbent for carbamazepine. Zinc oxide is responsible for the photocatalytic degradation of CBZ. The addition of zinc oxide to pectin and chitosan, according to the authors, will bring new and unique functional properties and increase the efficiency of the synthesized nanocomposites in carbamazepine reduction. The optimal conditions for CBZ reduction were 0.5 g/L Pec/CS/ZnO nanocomposite, pH 4, and an experimental time of 3 h. Under these conditions, the degradation efficiency of 10 mg/L CBZ was 69.5%, with a rate constant (k) of 0.00737 min−1 and a half-life of 94 min. Pectin has the ability to improve the dispersion of the developed material and also acts as a stabilizer of nanoparticles (NPs) during their synthesis [116].

Nazeri and coworkers used pectin as a support for the preparation of a heterogeneous catalyst based on metal phthalocyanines [118]. Before the immobilization of copper tetra-aminophthalocyanine, pectin was oxidized with periodate. The catalytic activity of the developed catalysts was investigated in the reaction of CO2 fixation to obtain cyclic carbonates.

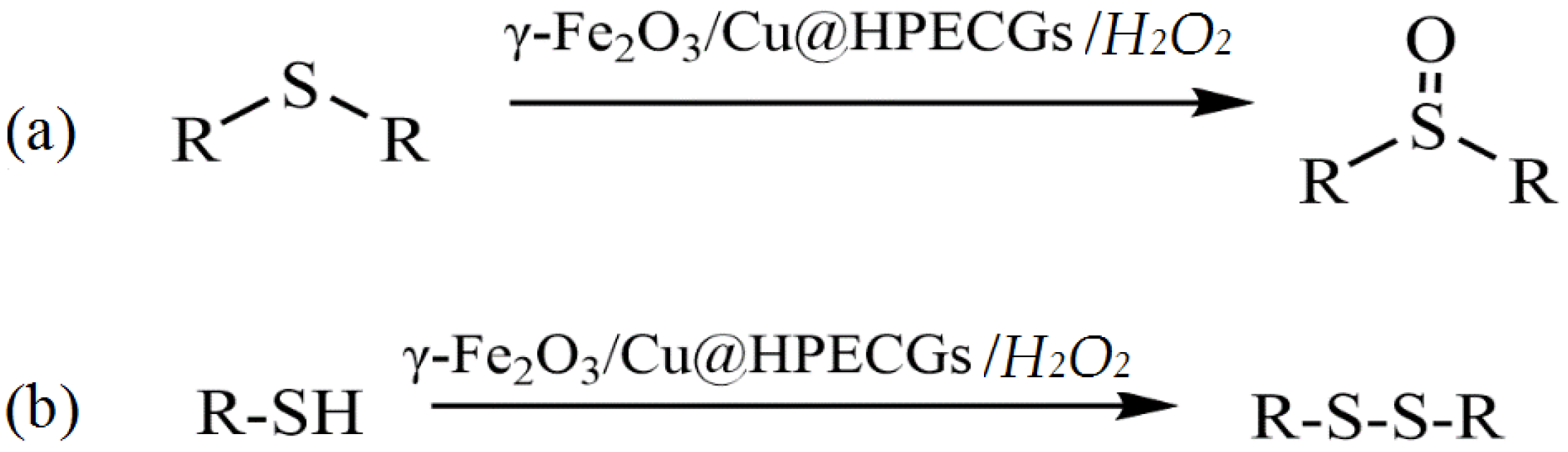

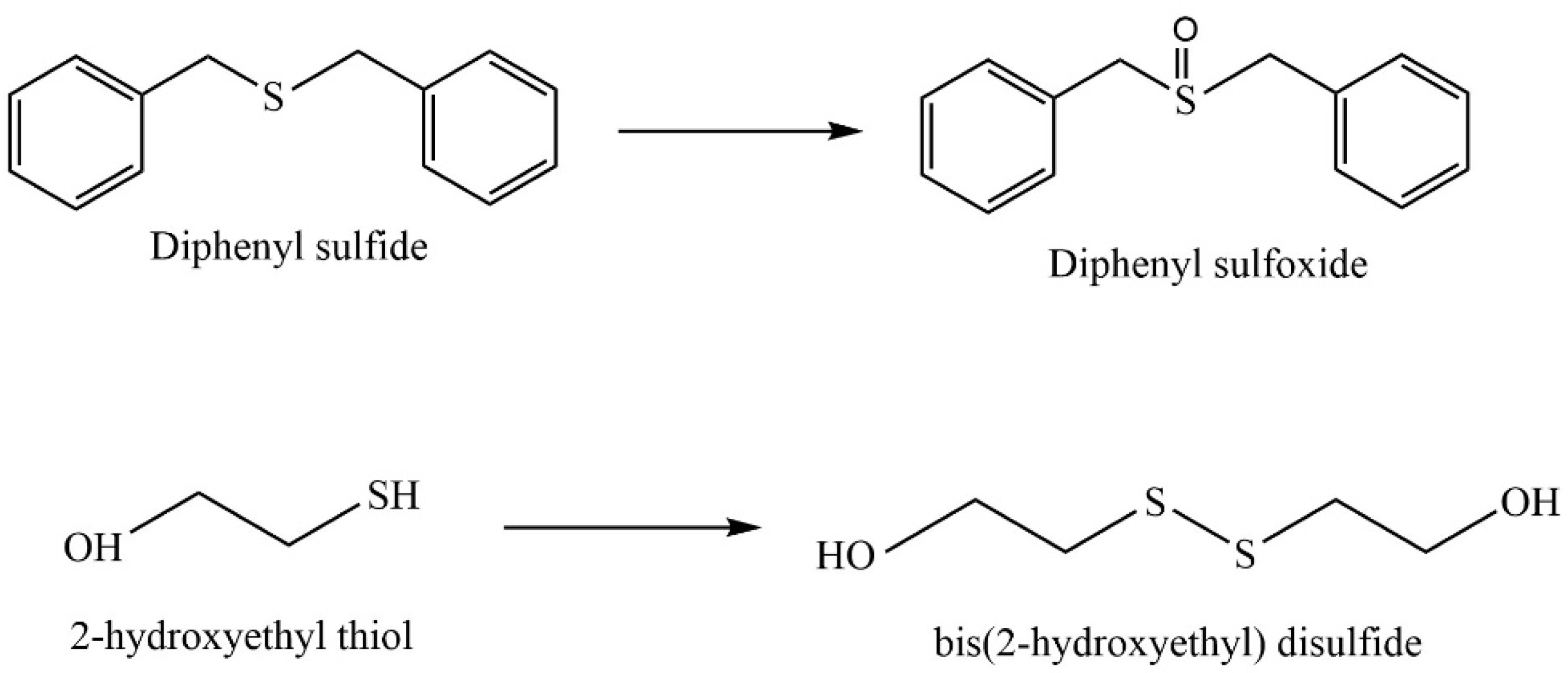

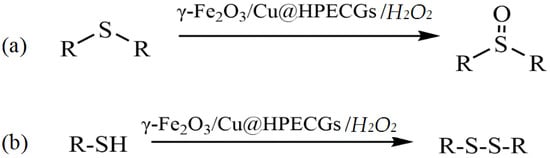

The development of catalytic systems based on non-platinum metals is the most reasonable compared to that of catalysts based on noble metals. Yarmohammadi et al. developed a method for obtaining iron and copper nanoparticles embedded in a pectin hydrogel matrix [123]. The pectin hydrogel was prepared in the presence of calcium chloride by using a physical cross-linking method. Then, iron and copper nanoparticles were deposited on the surface of the hydrogel matrix. The synthesized composite demonstrated high activity, selectivity, and stability in the oxidative coupling of thiols with disulfides in the presence of the green oxidant hydrogen peroxide (Figure 28).

Figure 28.

Chemoselectivity in the oxidation of sulfides and the oxidative coupling of thiols (a), as well as the oxidative coupling of thiols by using γ-Fe2O3/Cu@HPECGs with H2O2 (b).

Thus, the preparation of polymer–inorganic composites by modifying the surface of inorganic materials with a polymer has a number of advantages, which include the improvement of their catalytic properties, multifunctionality, the widening of application possibilities for inorganic materials (metals, oxides, and sorbents), etc. It should be noted that pectin itself can act as a catalyst and a binding agent for metals (e.g., calcium ions in biodiesel production).

3.2. Metal Nanoparticles Stabilized with Pectin

In recent years, polysaccharides have been used to stabilize, microencapsulate, and modify the active phase of the nanoparticles (NPs) in catalytic systems. There are some works devoted to the preparation and application of pectin-stabilized metal nanoparticles in catalysis.

The stabilizing role of pectin was confirmed by Baran [120]. The agar/pectin composite (APC), which is characterized by high thermal stability, high active surface area, and strong covalent bonds, was used as a stabilizer of palladium nanoparticles. No toxic reducing agents were used to immobilize the nanoparticles on the composite surface. SEM micrographs showed that the palladium nanoparticles had a spherical morphology and were homogeneously distributed on the APC surface; the average size of the PdNPs was 34–54 nm. The synthesized catalysts showed high efficiency in Suzuki–Miyaura cross-coupling reactions and the reduction of o-nitroaniline at room temperature in an aqueous medium. The results indicate that biopolymer-containing composites can be used as stabilizers for nanoparticles of various noble metals. Thus, Baran T developed a promising support for the fixation of metal ions—pectin modified with a Schiff base (Pct) [124]. The obtained material has a good adsorption capacity in relation to Pd ions. The catalytic properties of the synthesized Pct-Pd catalyst were investigated in the Suzuki–Miyaura reaction. High conversion and reproducibility values were obtained. The conversion reached 91% after 12 consecutive portions of the substrate, and no significant leaching of Pd ions from the surface of the modified support was observed. The synthesized pectin-based catalyst is promising for industrial application.

In [117], an environmentally friendly method for the preparation of pectin-stabilized palladium nanoparticles obtained by exposing an aqueous solution of PdCl2 (100 mL, 1 mM) to pectin without an additional reducing agent was presented. The synthesized nanoparticles were investigated in the Mizoroki–Heck reaction between various aryl halides and n-butyl acrylate under solvent-free conditions. The catalyst can be reused for six cycles without a significant loss of catalytic activity.

A method for obtaining Pt, Pd, Au, and Ag nanoparticles by reducing their ions in pectin in the absence of additional reducing agents was shown in [125]. Their electrocatalytic activity was investigated in the electro-oxidation of glucose. Ponce et al. showed the promising application of catalysts prepared in the presence of pectin in the production of biodiesel (biodiesel yield was about 95%) [126]. The disadvantage of the synthesis was the use of high-temperature calcination stages (600 °C).

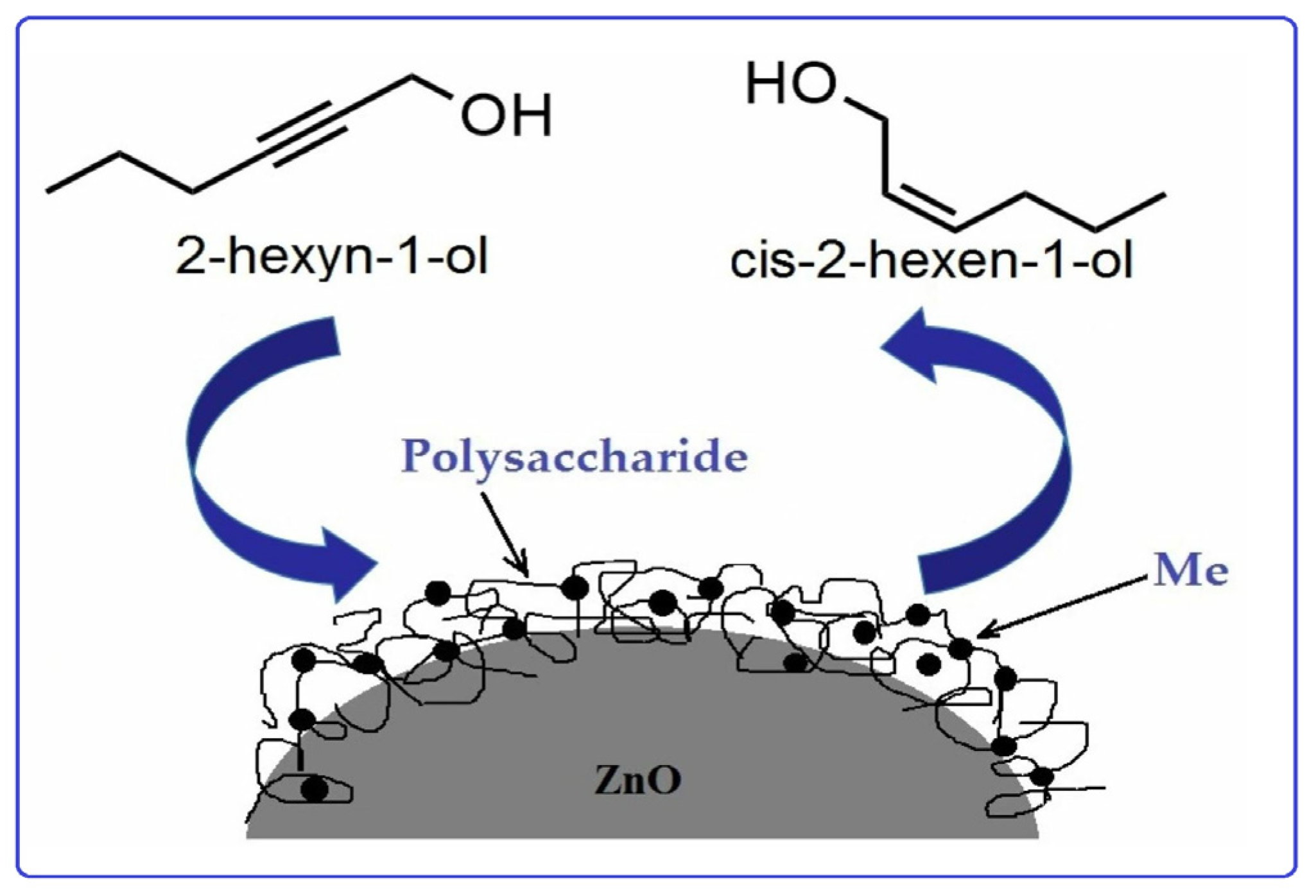

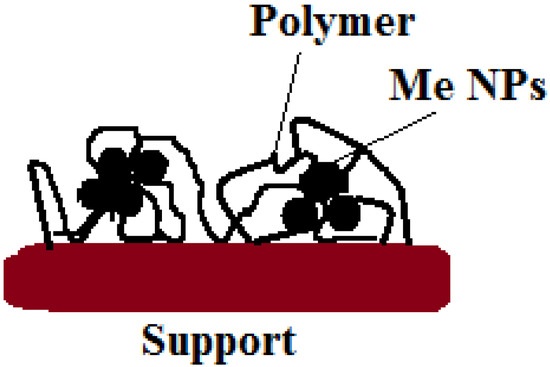

In the development of heterogeneous catalysts, the leaching of the active phase is one of the most challenging tasks. In order to solve this problem, various approaches are used. A simple method for obtaining pectin- and PEG-stabilized palladium catalysts deposited on a solid support was proposed by Zharmagambetova A et al. [127]. The synthesis of catalysts involves the low-temperature stages of the sequential deposition of polymer and metal ions (Pd, Pt, etc.) on inorganic supports. The catalysts have shown activity, selectivity, and stability in the hydrogenation of n-hexyn-2 and phenylacetylene. It should be noted that the catalytic properties (activity and selectivity) of the polysaccharide-based catalyst were comparable to those of the catalysts based on synthetic polymers. The same approach to the synthesis of catalysts was used in [22,23,128]. In all cases, the modification of a traditional support material with polymers led to an increase in its affinity for transition metal ions. Moreover, the modification with polymers provides the formation of stabilized metal nanoparticles (NPs) on the surface of support materials (Figure 29). The polymer “layer” promotes the uniform distribution of the active phase (metal NPs) and prevents its agglomeration, while the inorganic support provides the easy separation of the catalyst from the reaction products and resistance to the action of the solvent. The developed method allows for an increase in the efficiency of catalysts in low-temperature hydrogenation processes and for carrying out the process under the atmospheric pressure of hydrogen.

Figure 29.

Scheme of the formation of a polymer-stabilized palladium catalyst deposited on a solid support for the process of acetylene compound hydrogenation.

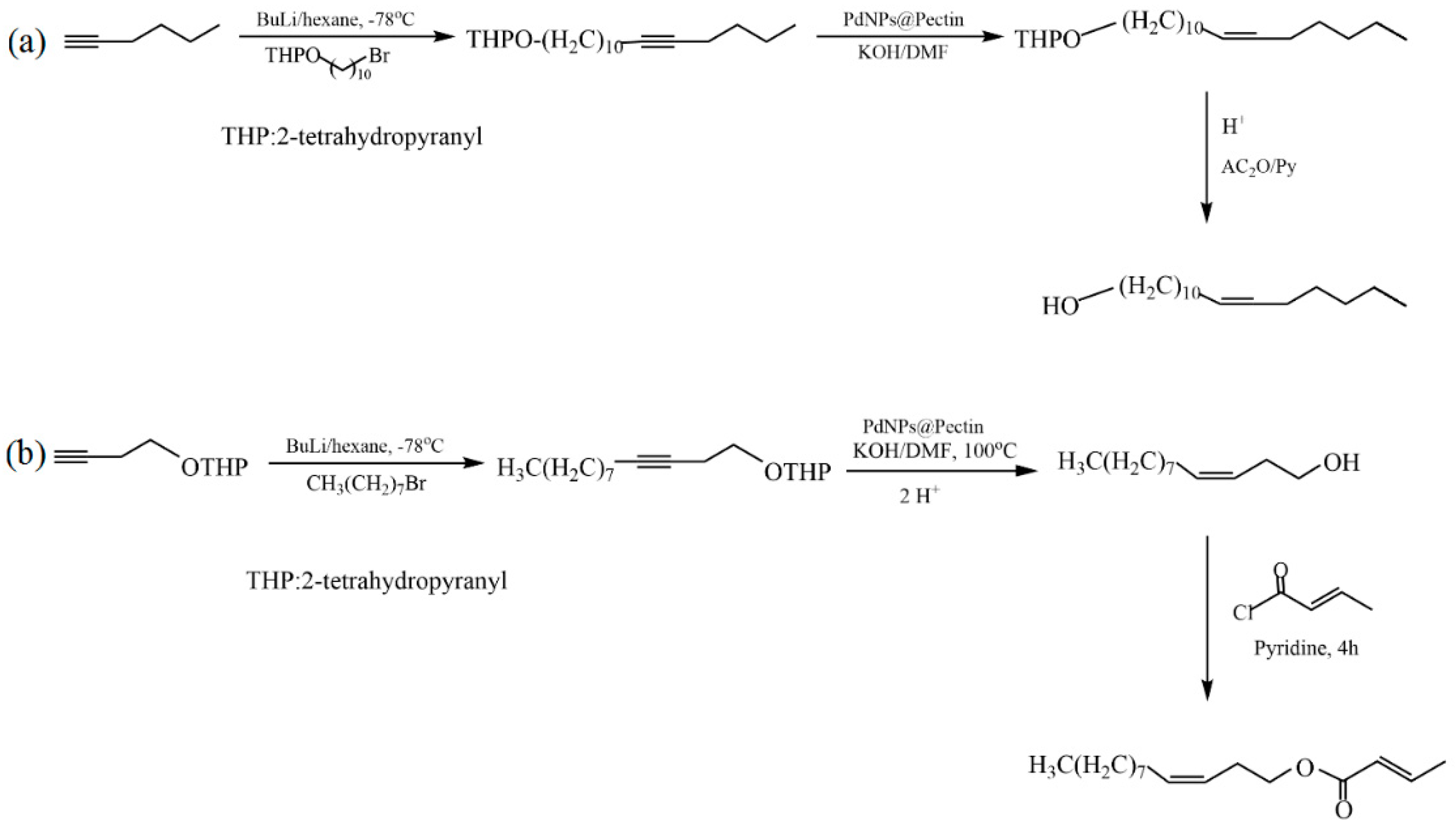

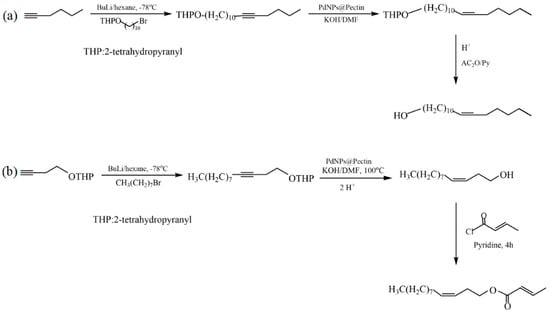

Le et al. proposed an in situ synthesis of palladium nanoparticles (PdNPs) using pectin extracted from the leaves of Cyclea barbata (a species of flowering plant) as a green reducing and stabilizing reagent [33]. The developed PdNP@pectin catalyst showed high catalytic activity in the Heck reaction in an aqueous medium. The synthesized catalysts were investigated in the hydrogenation of alkynes to cis-alkenes and in the synthesis of the sex pheromones of Plutella xylostella ((Z)-11-hexadecen-1-yl acetate) and Cylas formicarius ((Z)-3-dodecen-1-yl(E)-2-butenoate) (Figure 30). The yields of (Z)-11-hexadecen-1-yl acetate and (Z)-3-dodecen-1-yl(E)-2-butenoate were 70% and 68%, respectively.

Figure 30.

Synthesis of Plutella xylostella (a) and Cylas formicarius (b) pheromones.

Thus, in the formation of catalytic systems based on metal nanoparticles, pectin is a potential stabilizing agent that prevents the leaching and aggregation of the active phase of nanoparticles.

3.3. Pectin-Based Magnetic Catalysts

Magnetic catalysts have attracted much attention because of their ability to be separated from the reaction mixture using a magnetic field, which is a more efficient, less energy-consuming, and faster way to separate small particles compared to filtration and centrifugation [129]. Polysaccharides containing functional groups can be used for modifying magnetic nanoparticles [121,130].

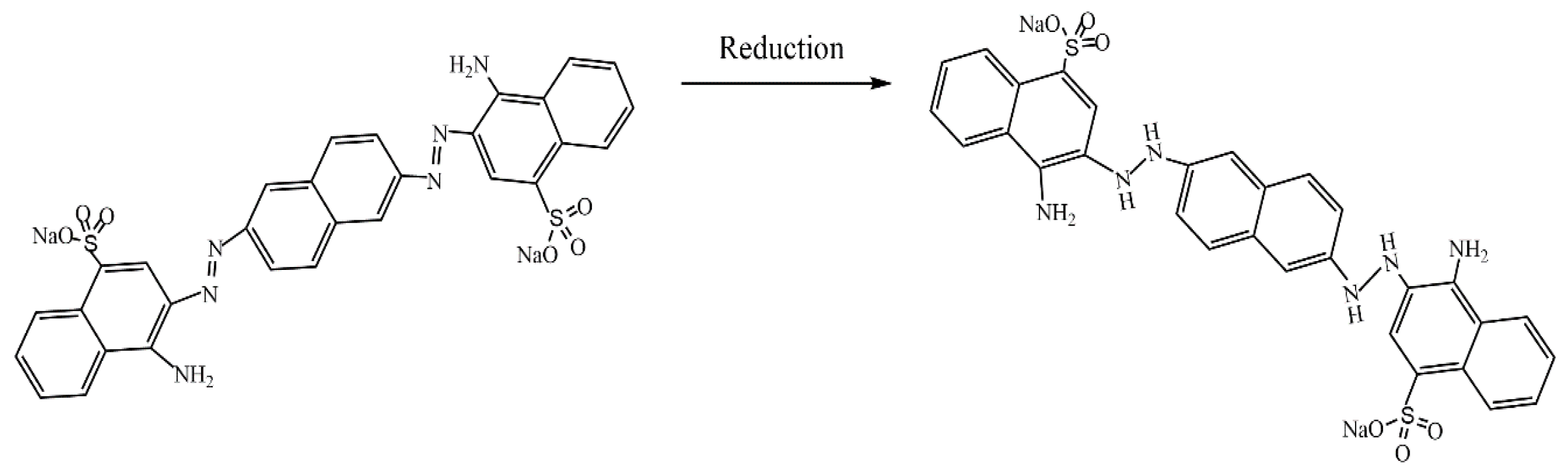

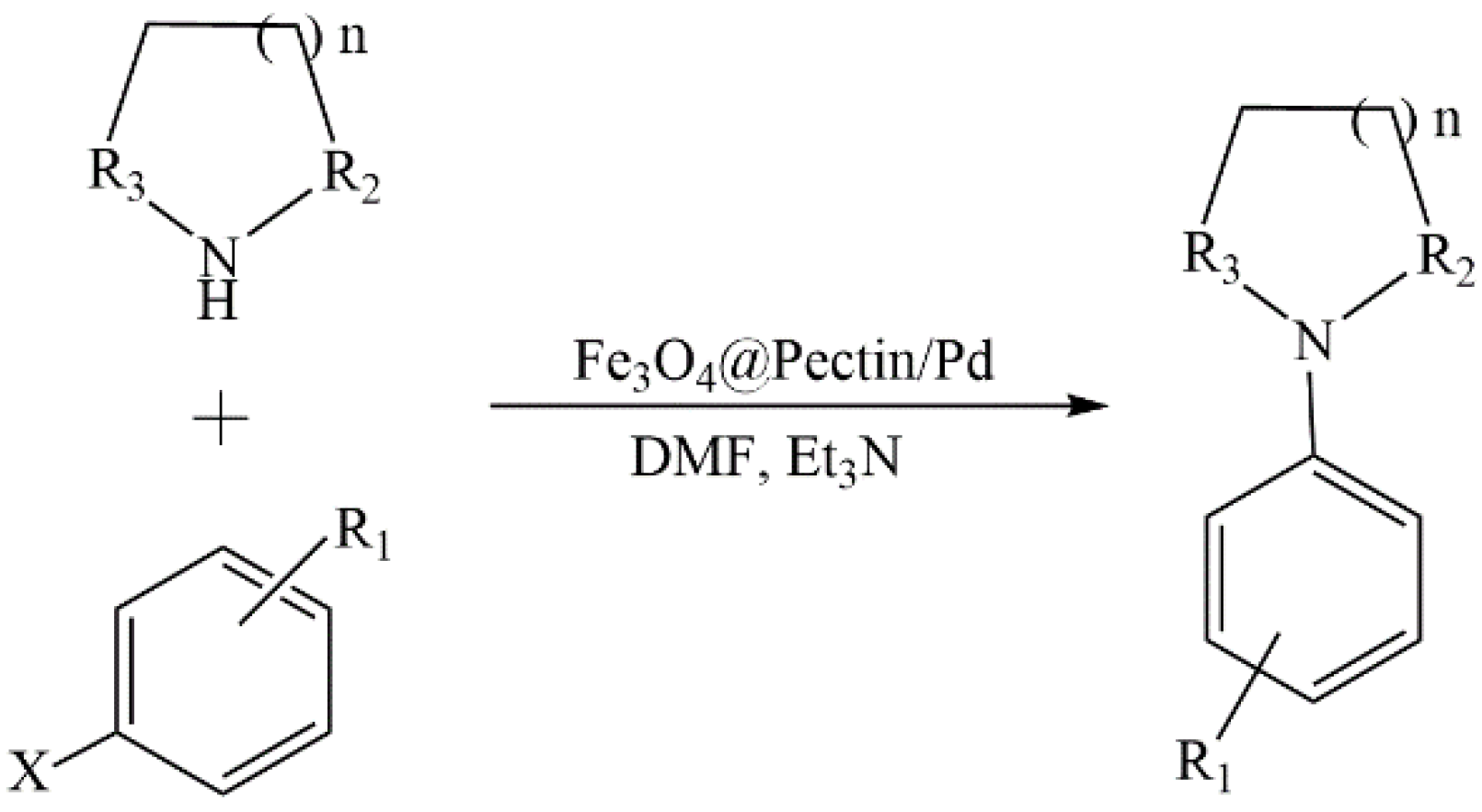

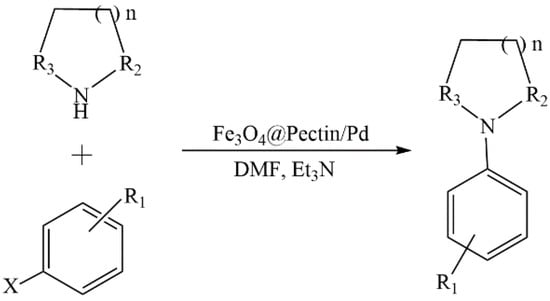

Li et al. synthesized new magnetic Au nanoparticles modified with pectin (Fe3O4/pectin/Au) [121]. The developed composite was investigated in the catalytic reduction of nitroarenes in a water–ethanol medium without any promoters or ligands. Due to its strong paramagnetism, the catalyst was easily recovered and reused for 11 cycles without a significant loss of reactivity. Similar composites based on pectin and Fe3O4 were used to synthesize a Pd nanocatalyst (Fe3O4@pectin/Pd) [130]. The catalyst showed high reactivity in the C-C and C-N cross-coupling reactions of Suzuki and Buchwald–Hartwig reactions, respectively (Figure 31). The catalyst was easily extracted using an external magnet and then reused. The slight leaching of palladium was observed over several tests.

Figure 31.

Buchwald–Hartwig cross-coupling reaction.

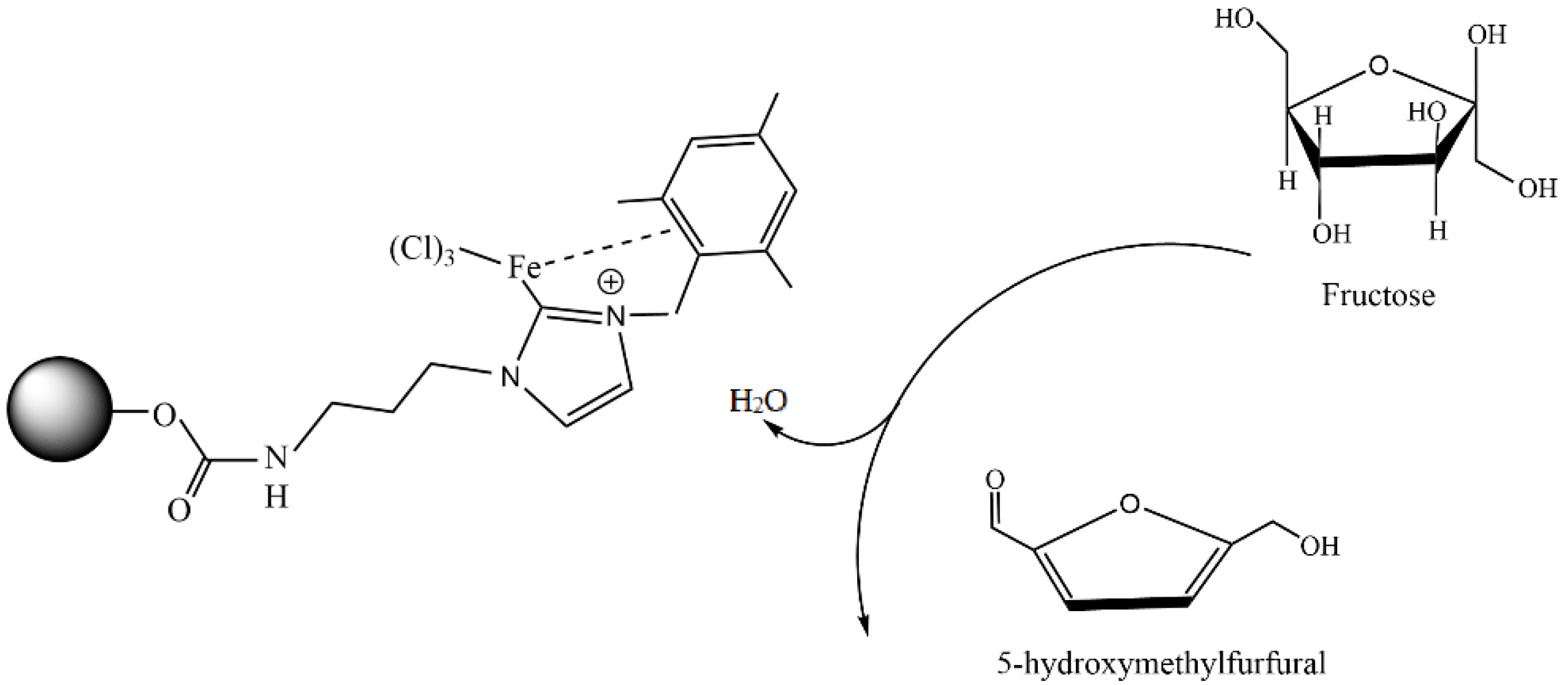

Ghamari Kargar et al. proposed an approach for the development of a magnetic catalyst based on pectin (Fe3O4@PectinImidazole SO3H-Cu(II)) for the oxidation of benzyl alcohols to aldehydes [131]. The advantages of this method are low catalyst loading, obtaining pure products, using inexpensive metals, the absence of solvents, using a biodegradable and environmentally friendly support, and the stability of the catalyst.

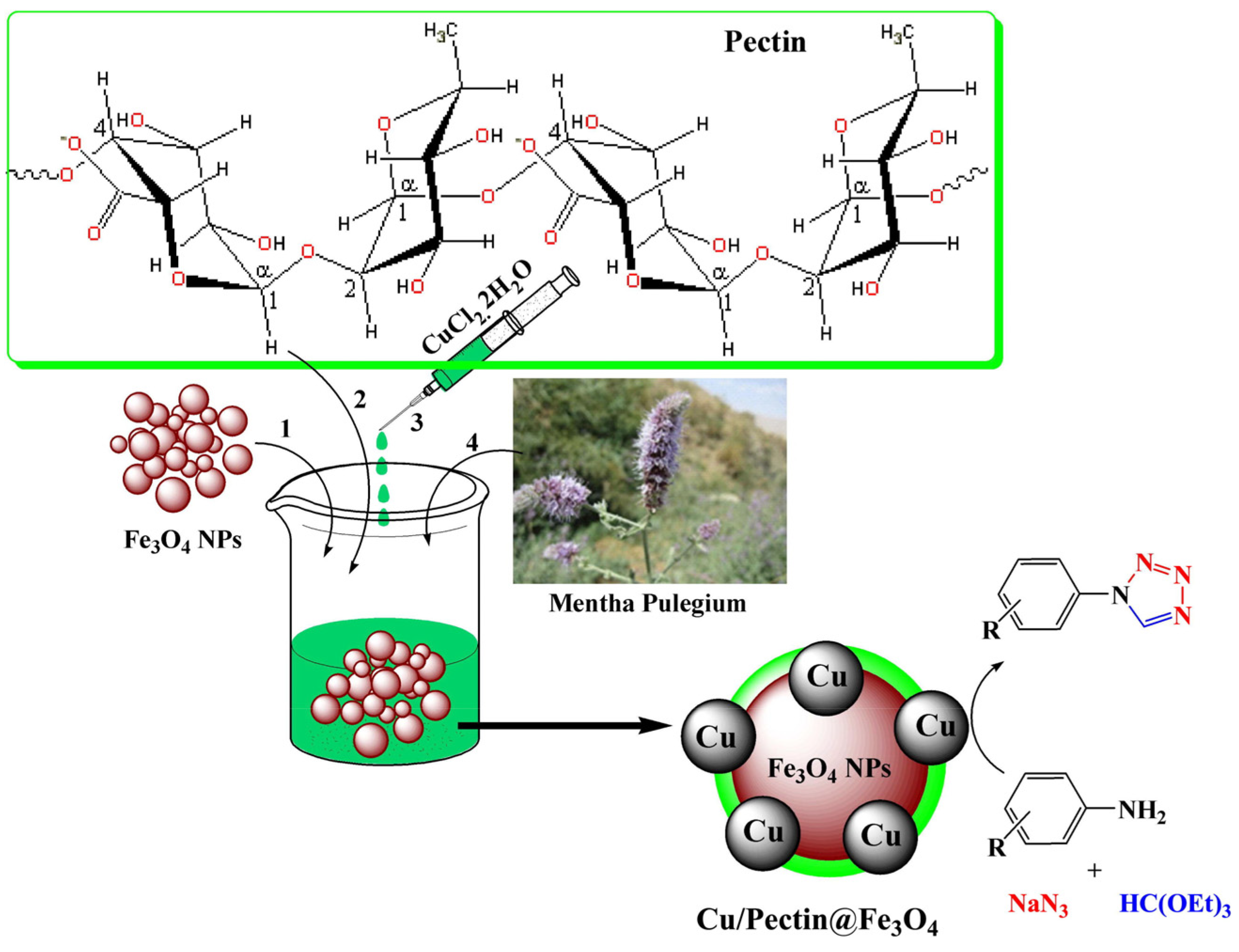

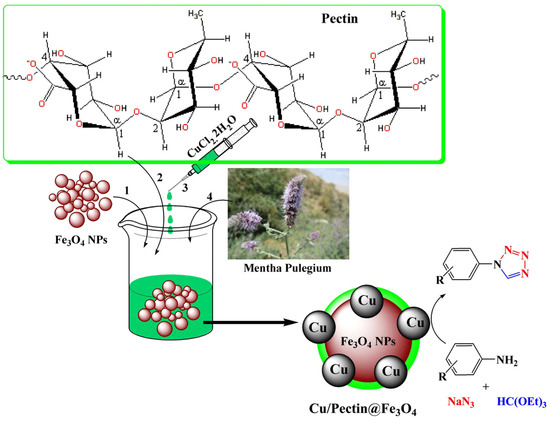

Xue et al. developed a Cu/pectin@Fe3O4 nanocomposite (Figure 32) [132]. The synthesized nanocomposite was thoroughly characterized using a wide range of physicochemical methods such as FT-IR, FESEM, TEM, and ED. The catalyst was investigated in the solvent-free synthesis of variously substituted 1H-tetrazoles. The nanocomposite also showed biological activity.

Figure 32.

Preparation of a Cu/Pectin@Fe3O4 nanocomposite and its application for the synthesis of 1-substituted-1H tetrazoles. Reprinted from ref. [132].

Khashei Siuki et al. tested a magnetic catalyst based on pectin and nickel (Fe3O4@Pectin@Ni (II)) in the oxidation reaction of alcohols [133]. The developed catalysts showed high stability. The simplification and cost reduction of the preparation of xanthine analogs were achieved.

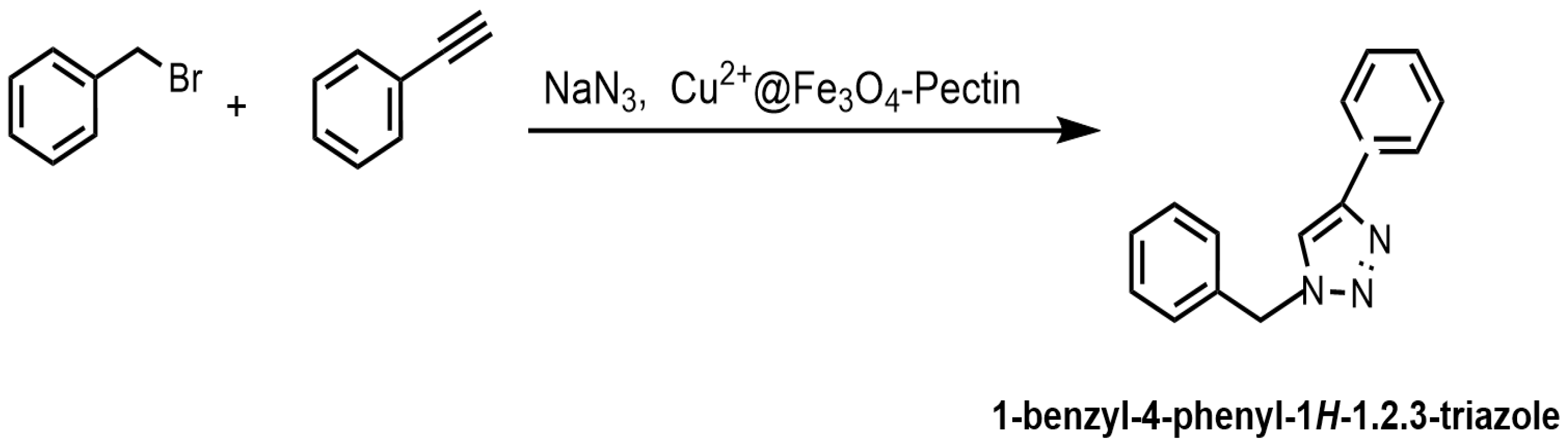

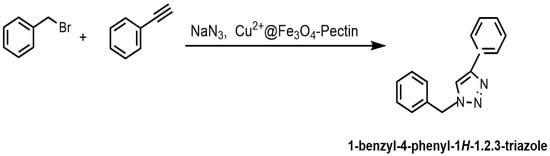

Doustkhah et al. reported that Fe3O4 nanoparticles encapsulated in apple pectin (Fe3O4–pectin) can be used as a magnetic support material for a copper catalyst [134]. The developed Cu2+@Fe3O4–pectin nanocomposite was prepared via the coprecipitation of Fe(II/(III) ions in an alkaline solution, followed by the adsorption of copper(II) ions (Figure 33). The formation of magnetic nanoparticles in the pectin network was established. Pectin also served as a chelating agent to fix copper ions. The developed catalyst was then used in regioselective three-component triazole synthesis (Figure 33); the reaction conditions were benzyl bromide—1 mmol; NaN3—1.2 mmol; phenylacetylene—1 mmol; H2O—1 mL; and stirring the reaction for 4 h at room temperature.

Figure 33.

Preparation of Cu2+@Fe3O4–pectin and its application in regioselective three-component triazole synthesis.

Thus, magnetic catalysts based on pectin are characterized by improved catalytic properties, low catalyst loading, lower costs, and a biodegradable component used in the synthesis.

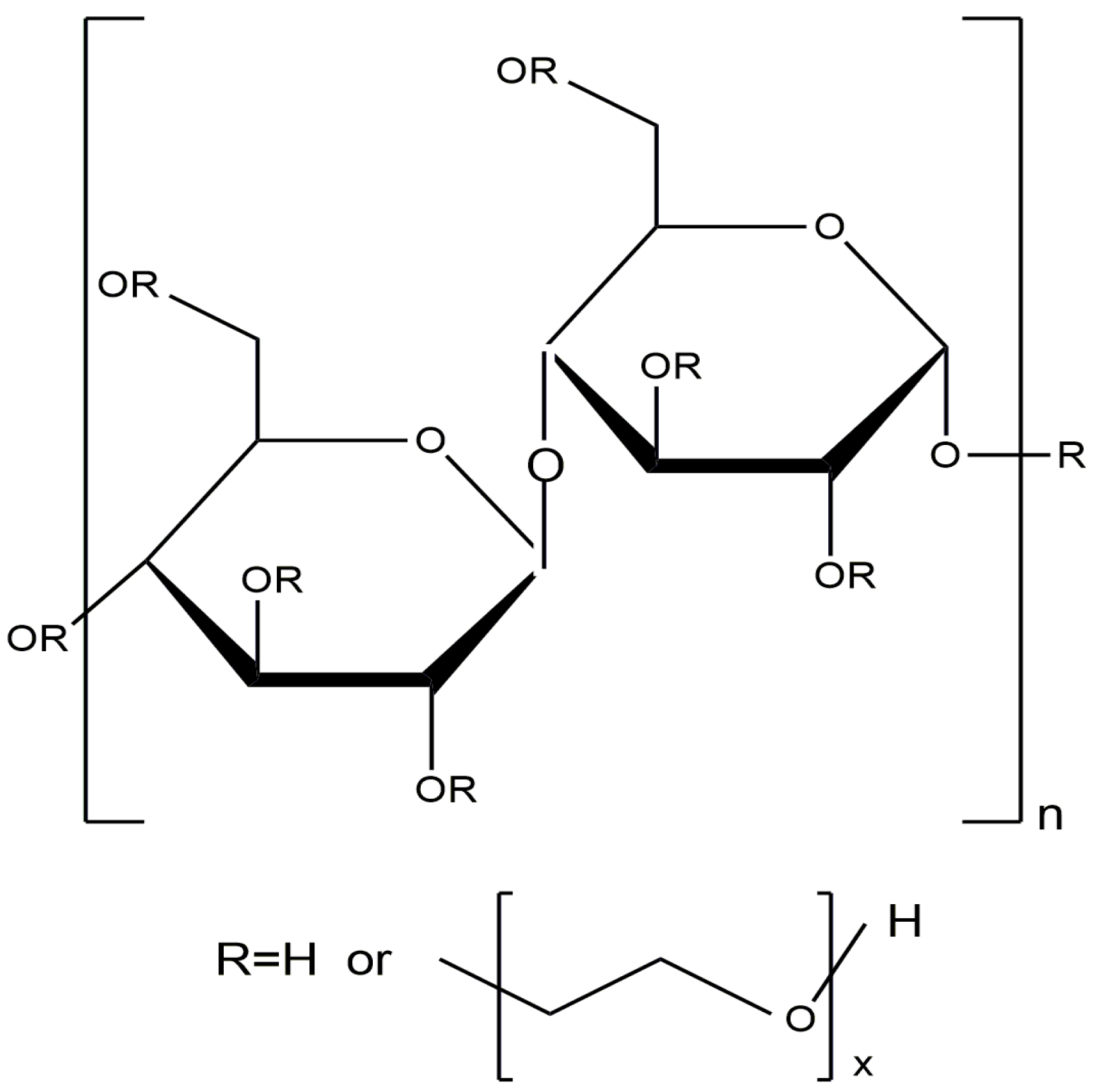

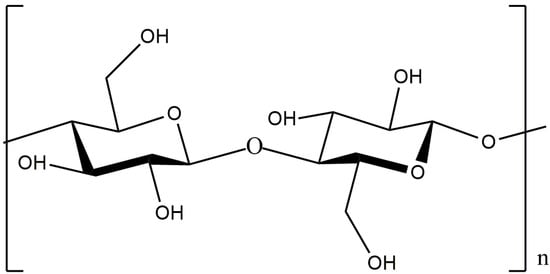

4. Cellulose-Based Nanocomposites

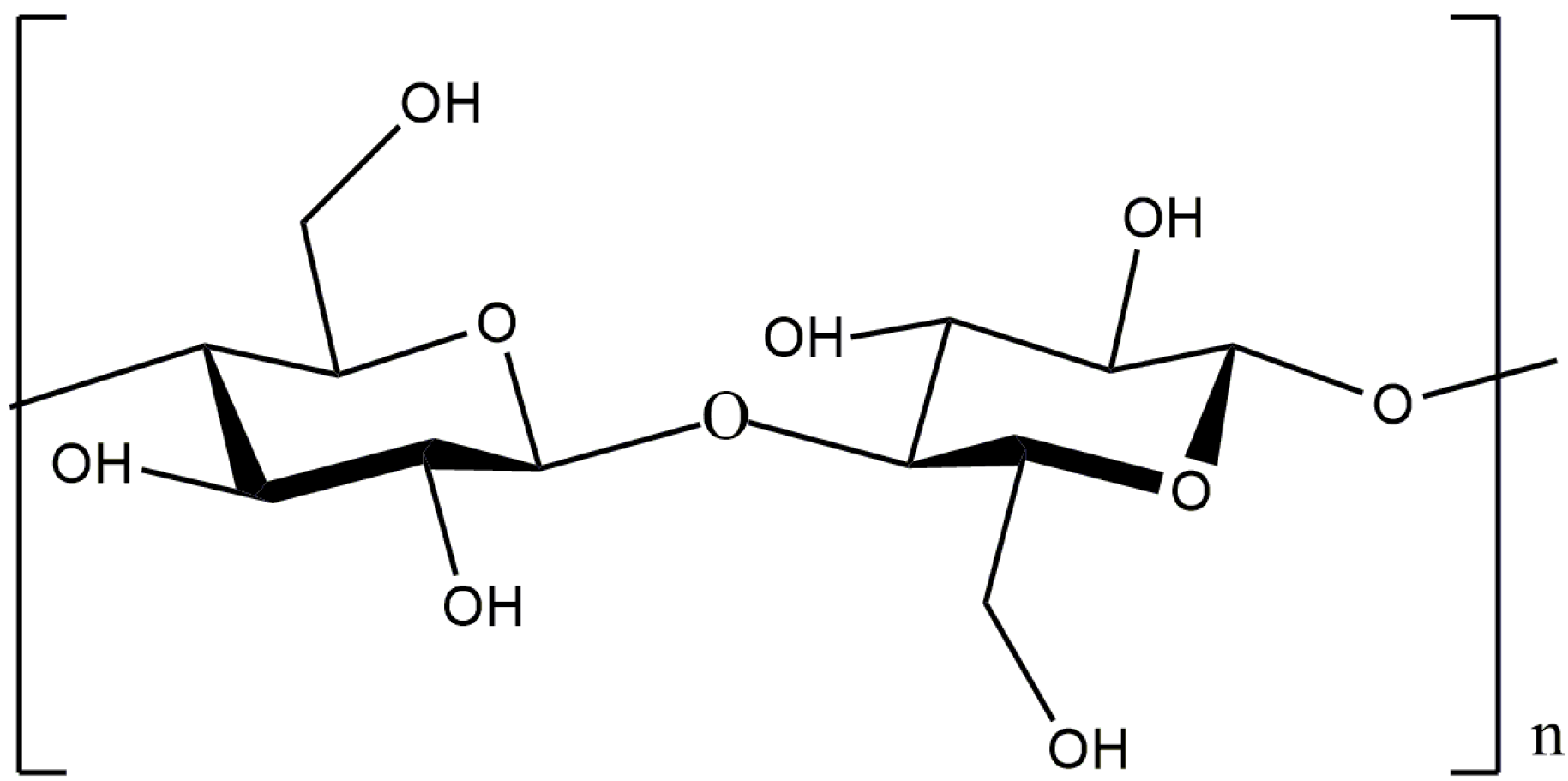

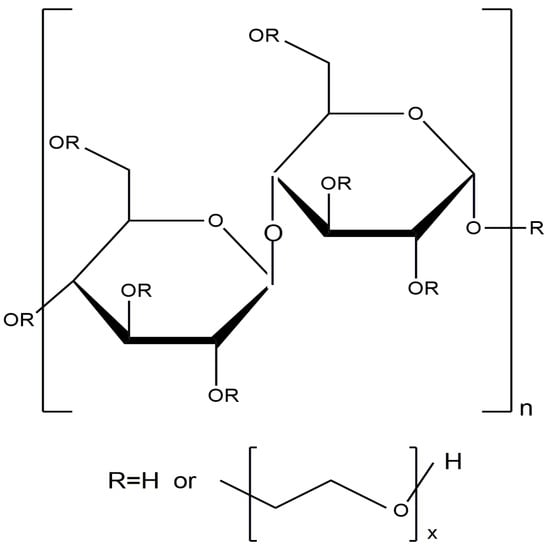

Cellulose is one of the most widespread natural polysaccharides. Natural cellulose is a linear polymer consisting of consecutive β-D-glucopyranose links and is characterized by a large number of OH- groups in the polymer chain, which determines the excellent chemical activity of cellulose (Figure 34).

Figure 34.

Structural formula of cellulose.

Due to its unique characteristics (high biocompatibility, biodegradability, low toxicity, and ability for chemical modification), cellulose is actively used in the food, medicine, construction, and textile industries [135,136]. Many studies have been devoted to the development and application of cellulose-based catalysts [135,136,137,138,139,140,141,142,143].

4.1. Cellulose as a Catalyst Support and Stabilizing Agent

Due to its unique architectural structure, cellulose is considered an ideal support for fixing nanoparticles and stabilizing them for the creation of nanocatalysts.

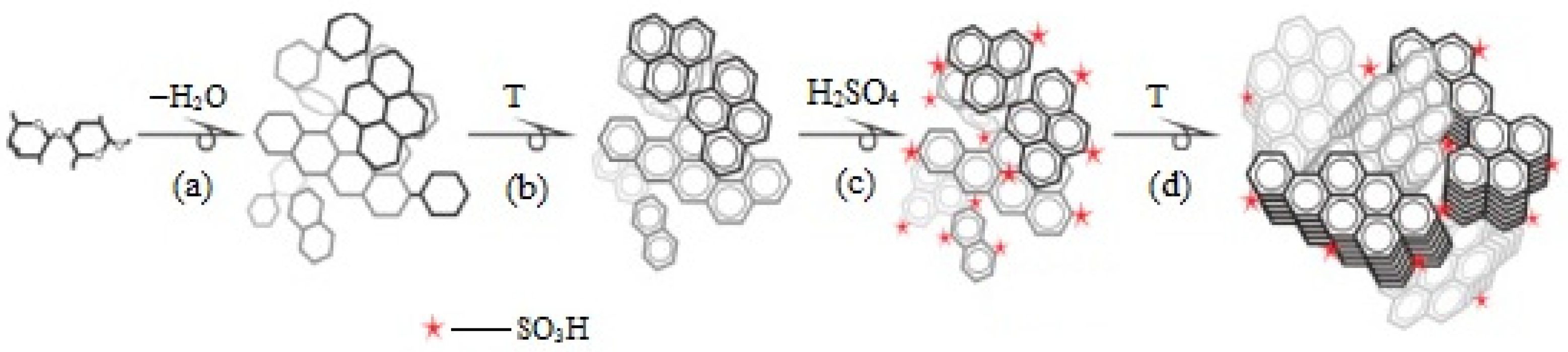

Li et al. provided a description of various cellulose-based nanocatalysts prepared using the layer-by-layer (LbL) self-assembly method [135]. The synthesized nanocatalysts are three-dimensional porous structures with a high specific surface area. They demonstrated strong catalytic properties in photocatalysis processes (photodegradation of organic dyes and photocatalytic hydrogen production).

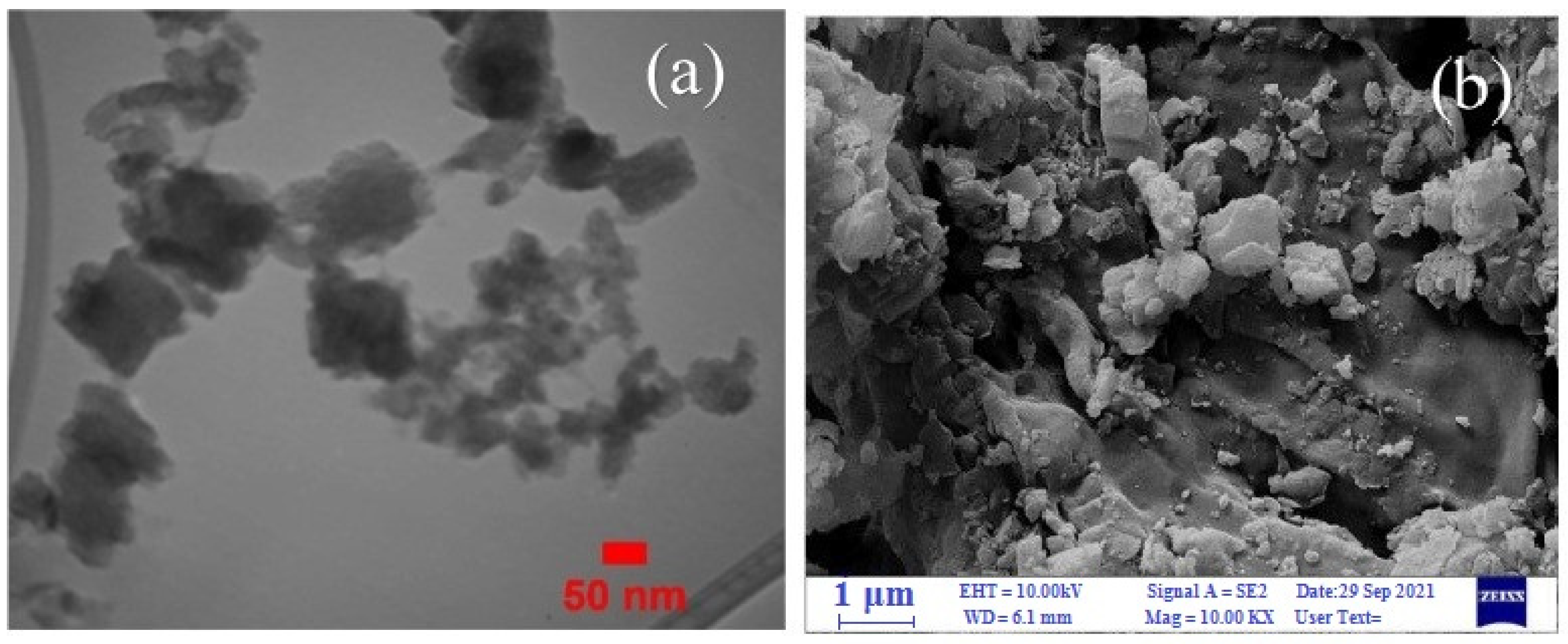

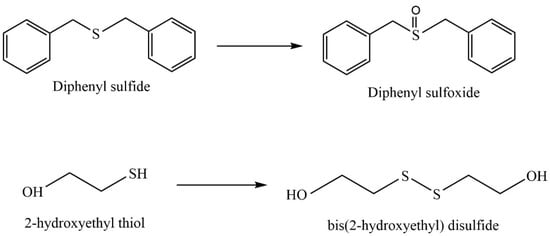

Naeimi et al. [137] synthesized a nanocatalyst based on bentonite clay (natural bentonite), cellulose extracted from wheat waste, and a vanadium complex for use as a catalyst in the oxidation of sulfides and thiols (Figure 35); the sulfide oxidation conditions were Cel/Ben/V nanocomposite—20 mg; 30% H2O2—0.33 mL; sulfide—1 mmol; EtOH—2 mL; T—25 °C; and magnetically stirred for 2 h or under ultrasonic irradiation within 1 h; the thiol oxidation conditions were Cel/Ben/V nanocomposite—20 mg; 30% thiol—1 mmol; CH3CN—2 mL; T—25 °C; and magnetically stirred for 2 h or under ultrasonic irradiation within 1 h.

Figure 35.

Oxidation of sulfides and thiols.

The developed catalysts showed high efficiency in the oxidation of various substrates. During the preparation of the composites, ultrasonic treatment was used instead of the usual mixing. A reduction in composite preparation time was achieved, and a high yield of reaction products was obtained. TEM images of the Cel/Ben/V nanocatalyst indicated the formation of 18–105.5 nm particles (Figure 36a). The SEM image clearly showed the morphology of the nanocatalyst (Figure 36b); the polymer matrix, bentonite, and the vanadium complex were detected.

Figure 36.

TEM (a) and SEM images (b) of Cel/Ben/V. Reprinted from ref. [137].

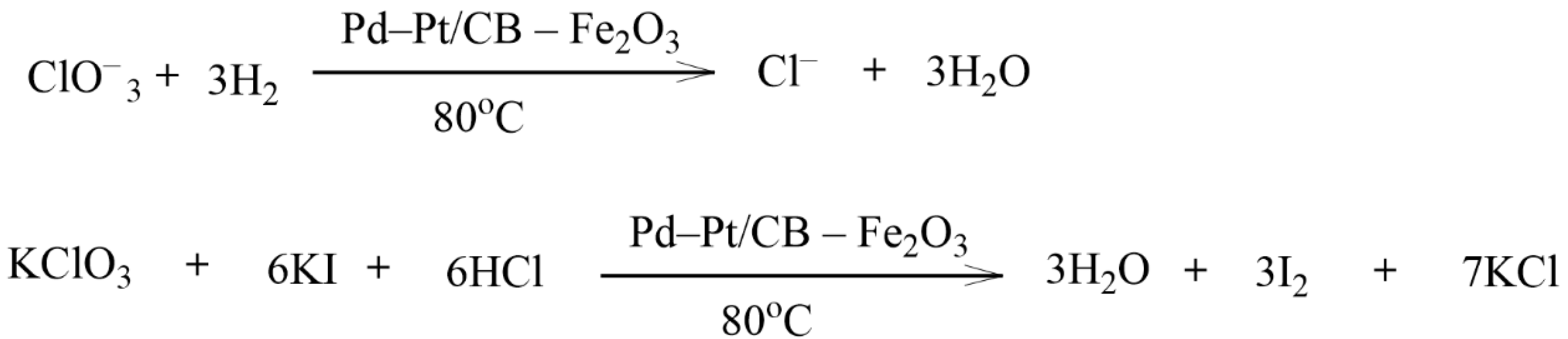

Sikora et al. used CB as a support for the synthesis of Pd and Pt catalysts for the catalytic hydrogenation of chlorate (Figure 37) [139]. The advantage of this study was the low content of noble metals (<0.6 wt.%) in the catalyst. Fe2O3 was used as the catalyst promoter. The degree of substrate transformation reached 92.5%. The continuous hydrogenation of chlorate in the Pd-Pt/CB-Fe2O3 catalytic system was carried out. The developed catalyst showed good results. Over 160 min in the presence of this catalyst, the chlorate content in the reaction mixture reached a zero value.

Figure 37.

Hydrogenation of chlorate on a Pd-Pt/CB-Fe2O3 support.

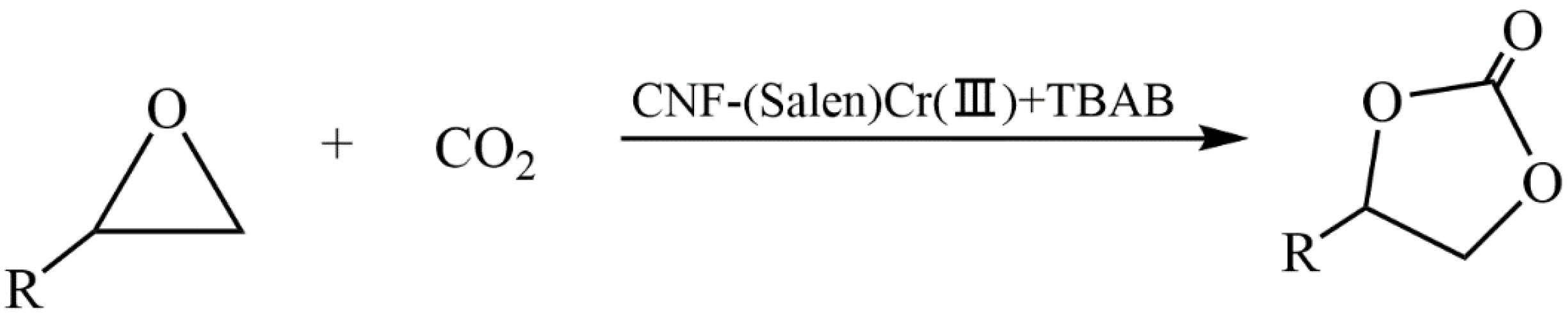

Liu et al. developed a new heterogeneous catalyst based on cellulose nanofibers (CNF) and a (Salen)Cr(III) complex to produce cyclic carbonates via a CO2 cycloaddition reaction with epoxides (Figure 38) [140]. The method of preparing the catalyst included the modification of CNFs with (3-aminopropyl)triethoxysilane (APTES), the synthesis of a Schiff base with salicylaldehyde, and a subsequent treatment with chromium chloride. The developed heterogeneous catalyst CNF-(Salen)Cr(III) showed high efficiency in the cycloaddition reaction of CO2 to epichlorohydrin under mild conditions with the participation of the co-catalyst TBAB. The yield of chloropropene carbonate was 97.8%. The catalyst based on cellulose nanofibers (CNFs) and the (Salen)Cr(III) complex retained its catalytic activity after recycling tests.

Figure 38.

Synthesis of cyclic carbonate using various epoxides.

Gia-Thien Ho et al. proposed an environmentally friendly method to obtain silver nanoparticles on cellulose aerogel (CA) extracted from water hyacinth for the hydrogenation of nitrophenol in the presence of NaBH4 in an aqueous medium [141]. The obtained results showed that at room temperature, in the presence of a 1.5Ag/CA2.0 catalyst, the reaction was completed within 10 min. After five recycling tests, the catalyst did not lose its activity.

El Idrissi et al. synthesized a heterogeneous cobalt catalyst supported on a TEMPO–cellulose aerogel [142]. The catalyst preparation method involved the reduction of cobalt sulfate with NaBH4 in the presence of an aqueous suspension of TEMPO–cellulose at room temperature. TEMPO–cellulose prevents the connection of cobalt ions with boron. The results of the catalyst physicochemical study (SEM, XRD, EDX, et al.) confirmed the formation of cobalt nanoparticles uniformly distributed on the aerogel. The synthesized catalyst showed high efficiency in the reduction reactions of 4-nitroaniline, 4-nitrophenol, and 2-nitrophenol in water in the presence of sodium borohydride.

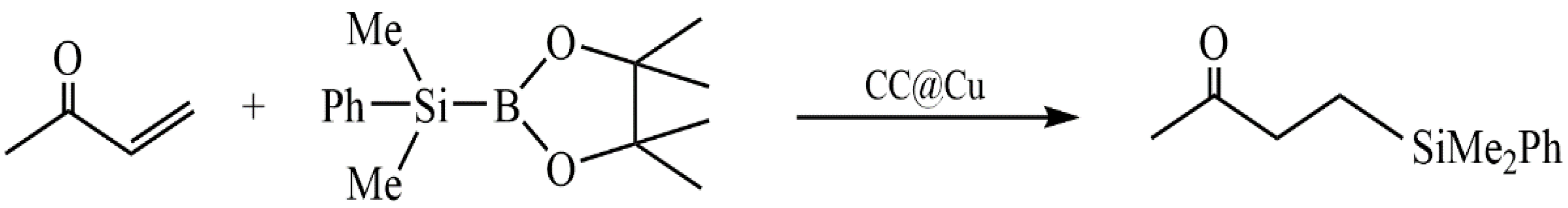

Zhang et al. developed a green heterogeneous copper catalyst based on a chitosan/cellulose composite using a cross-linking method [143]. The developed catalyst was tested in the silylation reaction of α,β-unsaturated compounds in an aqueous medium (Figure 39). The advantages of the proposed technology include no need for bases, ease of use, availability, and the reusability of the catalyst.

Figure 39.

Reaction of α,β-unsaturated compounds in the presence of a catalyst.

In [144], the simple synthesis of palladium nanoparticles fixed to nanoporous microspheres of cellulose was proposed. The obtained catalyst was tested in the Suzuki–Miyaura coupling reaction and showed high catalytic activity and stability. The TOF was 2126 h−1. The catalyst remained active for six continuous cycles.

Shi et al. used cellulose fibers as templates for the synthesis of copper catalysts based on zinc oxide [145]. The catalysts are characterized by a three-dimensional structure and high activity in photocatalytic CO2 conversion into energy and chemicals. The effect of different valence states of Cu on the photocatalytic activity of the synthesized composite was investigated. CuZnOCell-T showed higher activity than CuO-ZnOCell-T. The use of cellulose significantly improved the catalytic properties of the developed composites.

Li et al. synthesized Pd nanoparticles supported on perfluoroalkyl-modified cellulose using the solid-state method [146]. The developed palladium nanocatalyst was successfully tested in the reduction reaction of nitrobenzene to N-phenylhydroxylamine under mild conditions (at room temperature and in an aqueous medium). The authors of the study explained that the high efficiency of the palladium catalyst is due to the small size of palladium nanoparticles (1.0 and 2.5 nm) and the presence of F-containing groups. The surface modified with F-containing groups is highly hydrophobic, which is favorable for organic reactions in an aqueous environment. Modified cellulose with a more hydrophobic surface can lead to the adsorption of nitrobenzene on N-phenylhydroxylamine, thus preventing its complete hydrogenation to aniline.

Bahsis et al. used cellulose extracted from date palm as a support for the immobilization of copper (II) and copper (I) ions [147]. The developed copper catalysts demonstrated high efficiency in the synthesis of 1,4-disubstituted-1,2,3-triazoles at room temperature in an aqueous medium. Biocatalysts are easily separated from the reaction mixture and can be reused at least five times without a significant decrease in catalytic properties.

Prekob et al. immobilized palladium nanoparticles on carbonized cellulose by using the impregnation method [148]. The results of the catalyst physicochemical study confirmed the formation of Pd nanoparticles. The nanocatalyst was studied in the hydrogenation reaction of nitrobenzene in a methanol medium. The hydrogenation reaction was carried out at different temperatures (283–323 K) and constant hydrogen pressure (20 bar). The optimum process conditions were 303 K and 20 bar pressure. The maximum conversion of the substrate reached >99%.

Dohendou et al. presented a review on the use of biopolymers—including cellulose—as supports in the design of catalysts for the Heck cross-coupling reaction [36]. It was shown that catalytic systems based on natural polysaccharides are characterized by high sorption capacity, activity, and stability, which makes it possible to use natural polymers as supports in the synthesis of Heck cross-coupling reaction catalysts.

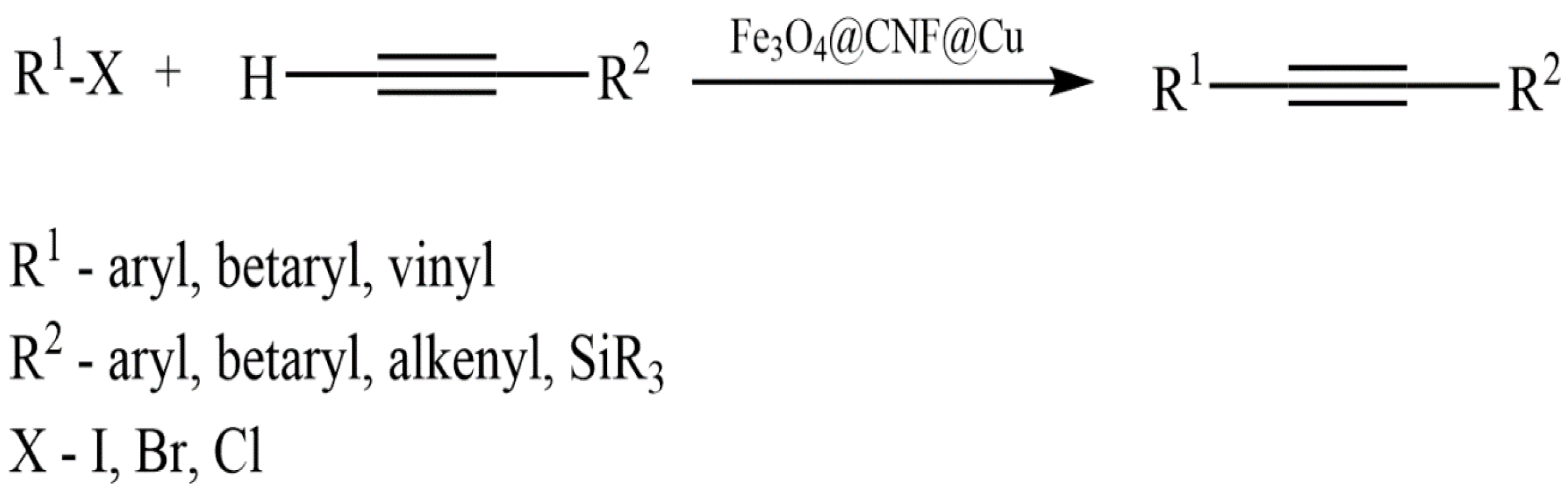

Fan et al. developed new bimetallic catalysts for the Sonogashira reaction by attaching polyethyleneimine (PEI) to the end of the PAMAM dendrimer grafted to cellulose, followed by the sorption of Pd(II) and Cu(II) ions [149]. Tree-shaped PAMAM was chosen as a support for the introduction of palladium and copper ions. PEI and cellulose with a large number of reactive OH- groups were used to increase the copper content in the catalyst. The synthesized bimetallic catalyst showed high efficiency in the synthesis of alkynes and benzofurans via the Sonogashira reaction and could be reused for up to seven consecutive cycles without significant loss of activity. The activity of the obtained catalyst was comparable to that of already-known catalytic systems.

Dewan et al. proposed the use of cellulose extracted from pomegranate peel waste as a support for Pd(0) nanoparticles [150]. This nanocatalyst was investigated in Suzuki–Miyaura and Sonogashira cross-coupling processes under mild conditions. The presence of sites in the cellulose matrix appropriate for interaction favored the uniform distribution of palladium nanoparticles on the support surface. The catalyst could be easily separated from the reaction mixture.

In summarizing the above, the use of cellulose in the design of nanocatalysts as a support and stabilizing agent brings a number of advantages: the increased dispersion of active phase nanoparticles, stability, reusability, etc.

4.2. Cellulose-Based Magnetic Catalysts

The functionalization of magnetic nanoparticles using polymers provides magnetic catalysts with improved characteristics by varying the nature of the polymer and reducing agent, the ratio of components, etc. Cellulose has a clear morphology, high specific surface area, and chelating ability, which makes it attractive for the functionalization of magnetic particles. The studies presented in [151,152,153,154] are devoted to the use of cellulose in the synthesis of magnetic nanocatalysts.

Zhang et al. [151] developed magnetic CuFe2O4@Ag@ZIF-8 nanospheres deposited on cellulose nanocrystals (CNCs). The catalyst included a paramagnetic core (CuFe2O4@Ag) and a porous shell in the form of a zeolite framework (ZIF-8). CuFe2O4 NPs were prepared in the presence of dispersant and cellulose nanocrystals. Ag NPs were deposited on CuFe2O4/CNC via in situ reduction. While investigating the catalytic properties of the synthesized composites in the reduction of 4-nitrophenol, the cellulose-supported composites were found to have higher reactivity than the nanocomposite without polysaccharide and a zeolite framework (CuFe2O4@Ag). Due to the combined properties of ZIF-8 and the CuFe2O4/CNC@Ag components, the nanocatalysts exhibited high activity.

Almajidi et al. [152] synthesized nanocomposites based on cellulose, β-cyclodextrin (BCD), graphene oxide (GO), and copper and iron oxides (Cu2O and Fe3O4). The Fe3O4 magnetic NLCs were prepared using an in situ method. The catalytic ability of the developed nanocomposite was demonstrated in a Hantzsch reaction, with a high yield of 1,4-dihydropyridine derivatives under mild conditions. According to the authors of the work, the advantages of the new nanocatalytic system are high catalytic properties, environmental friendliness, and easy recovery.

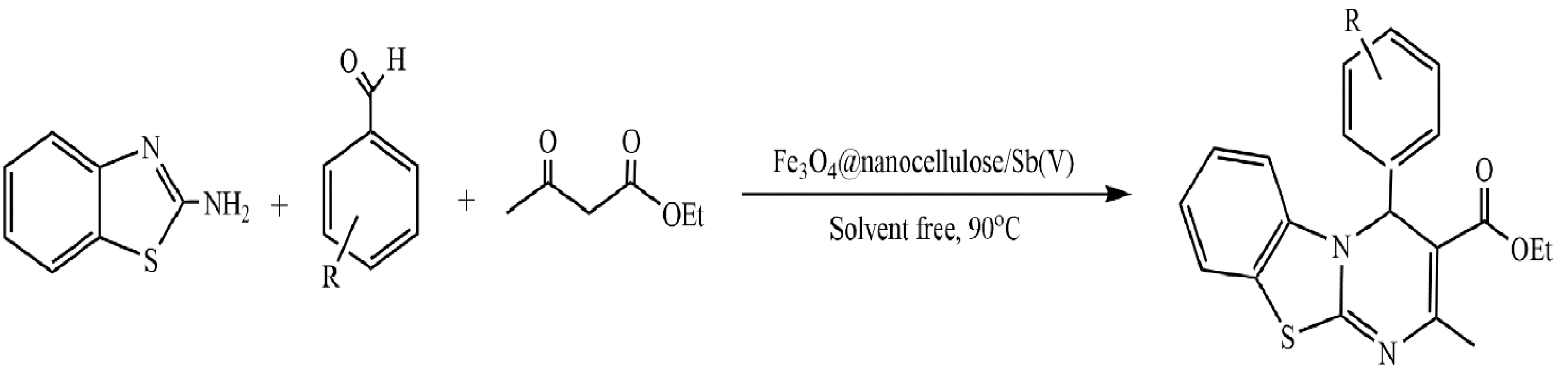

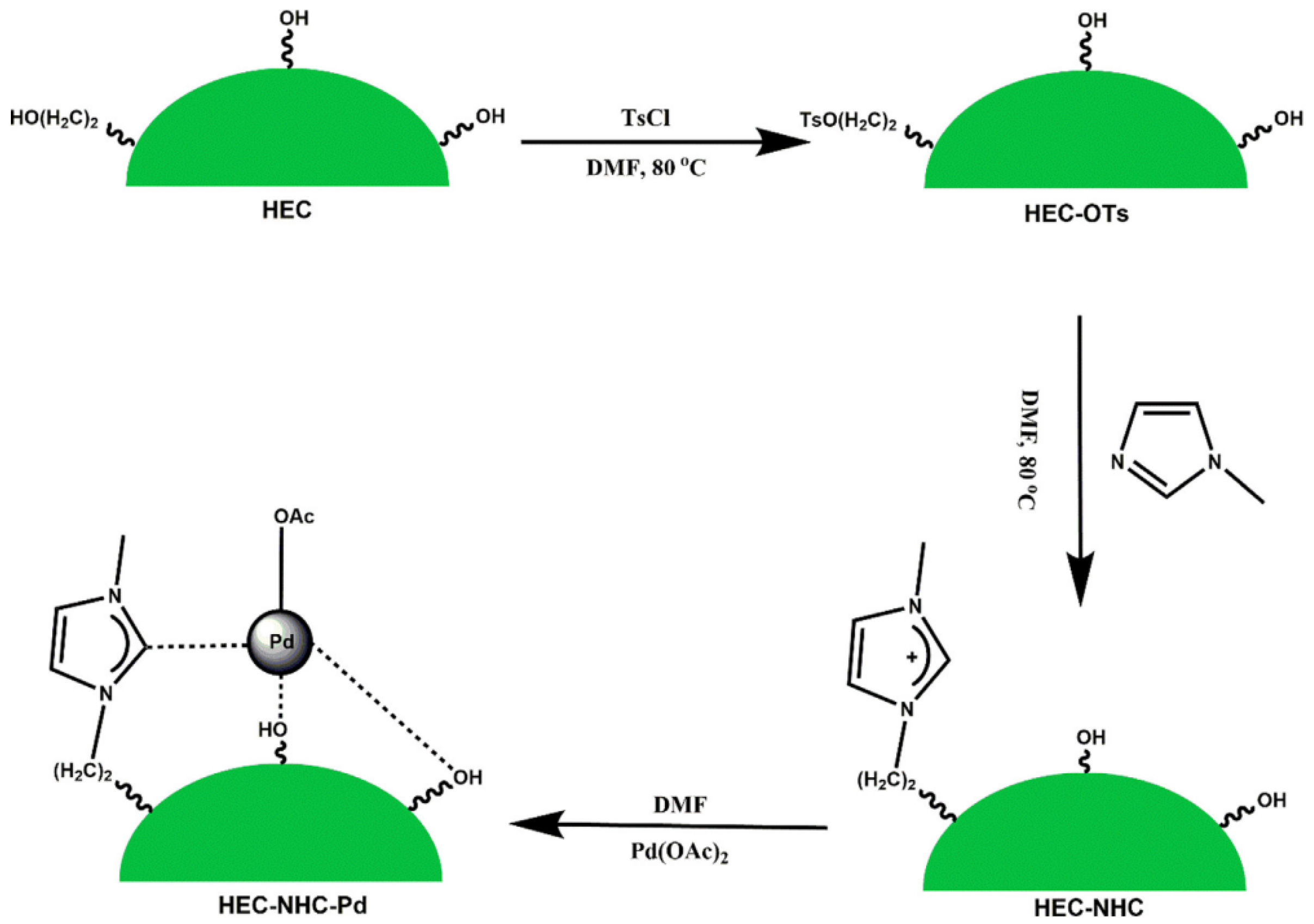

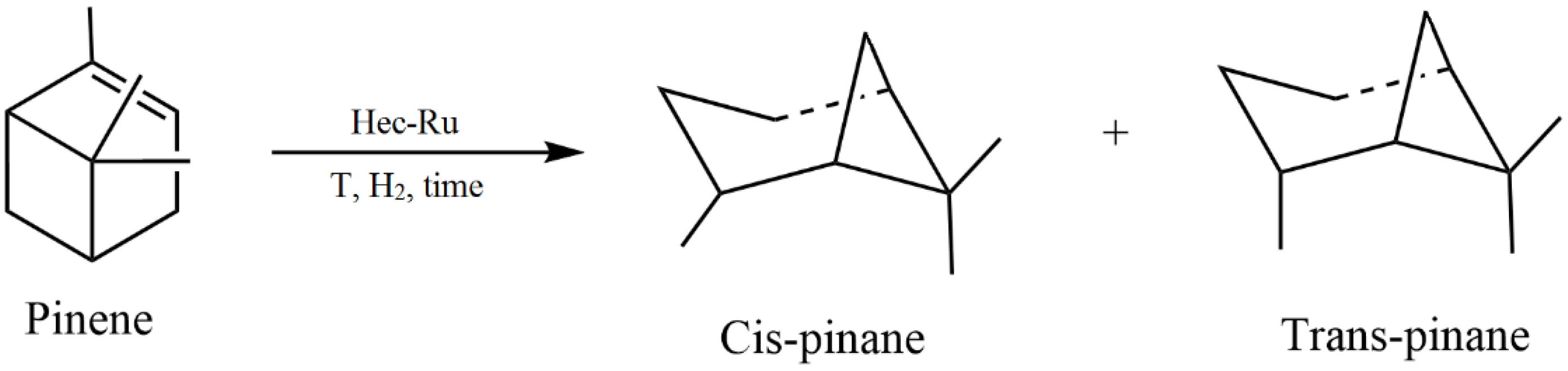

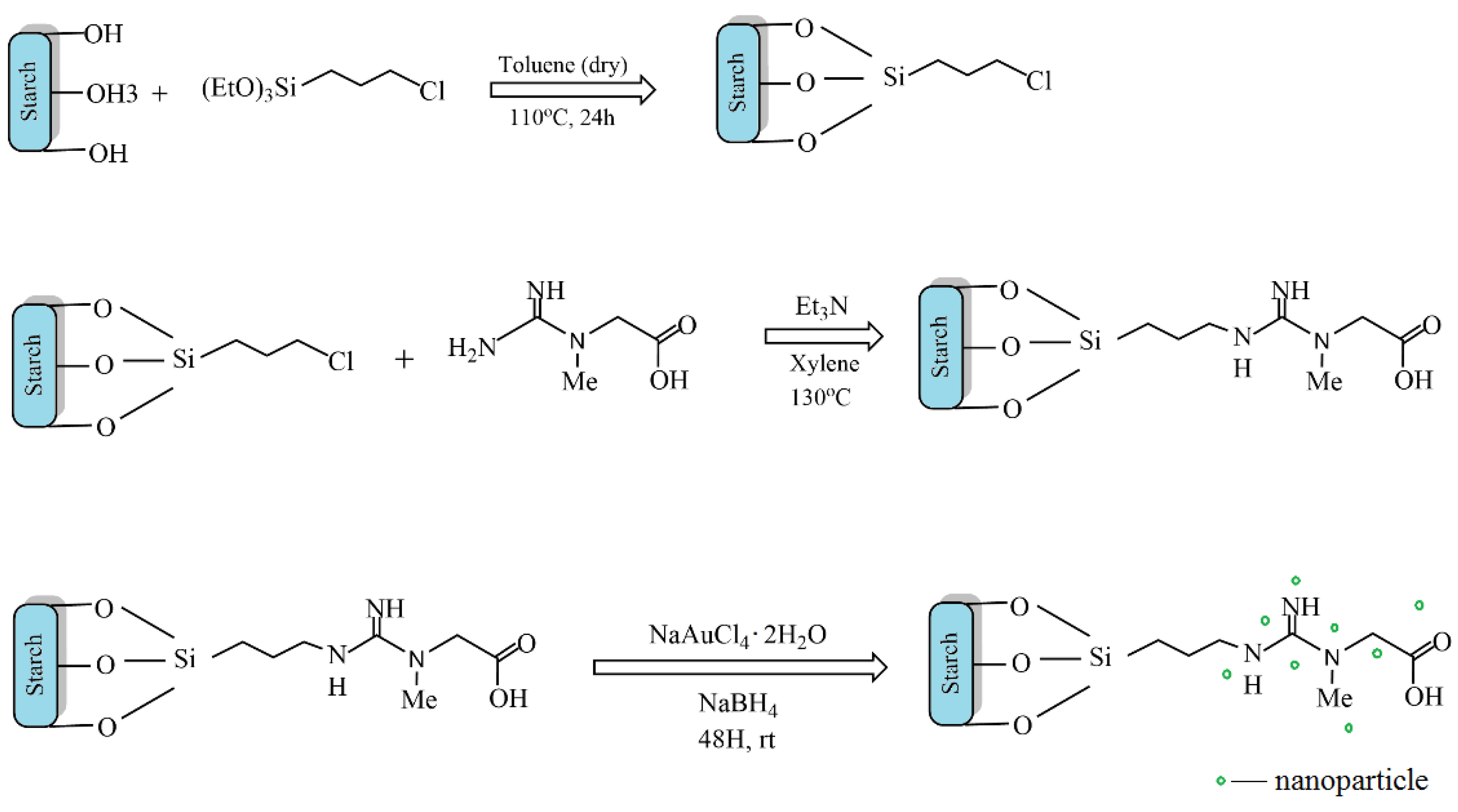

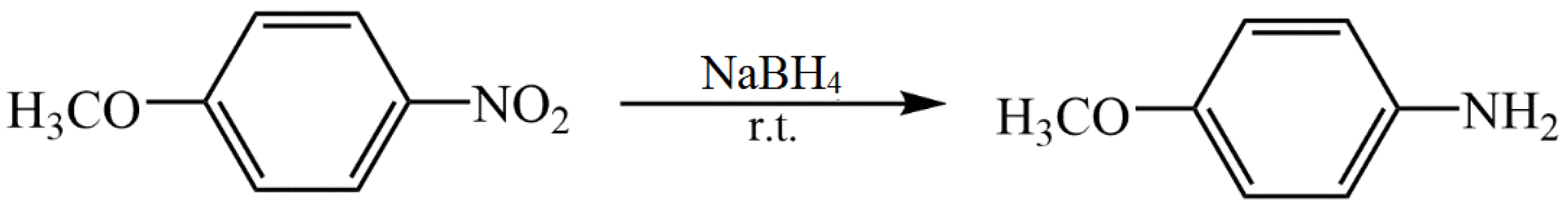

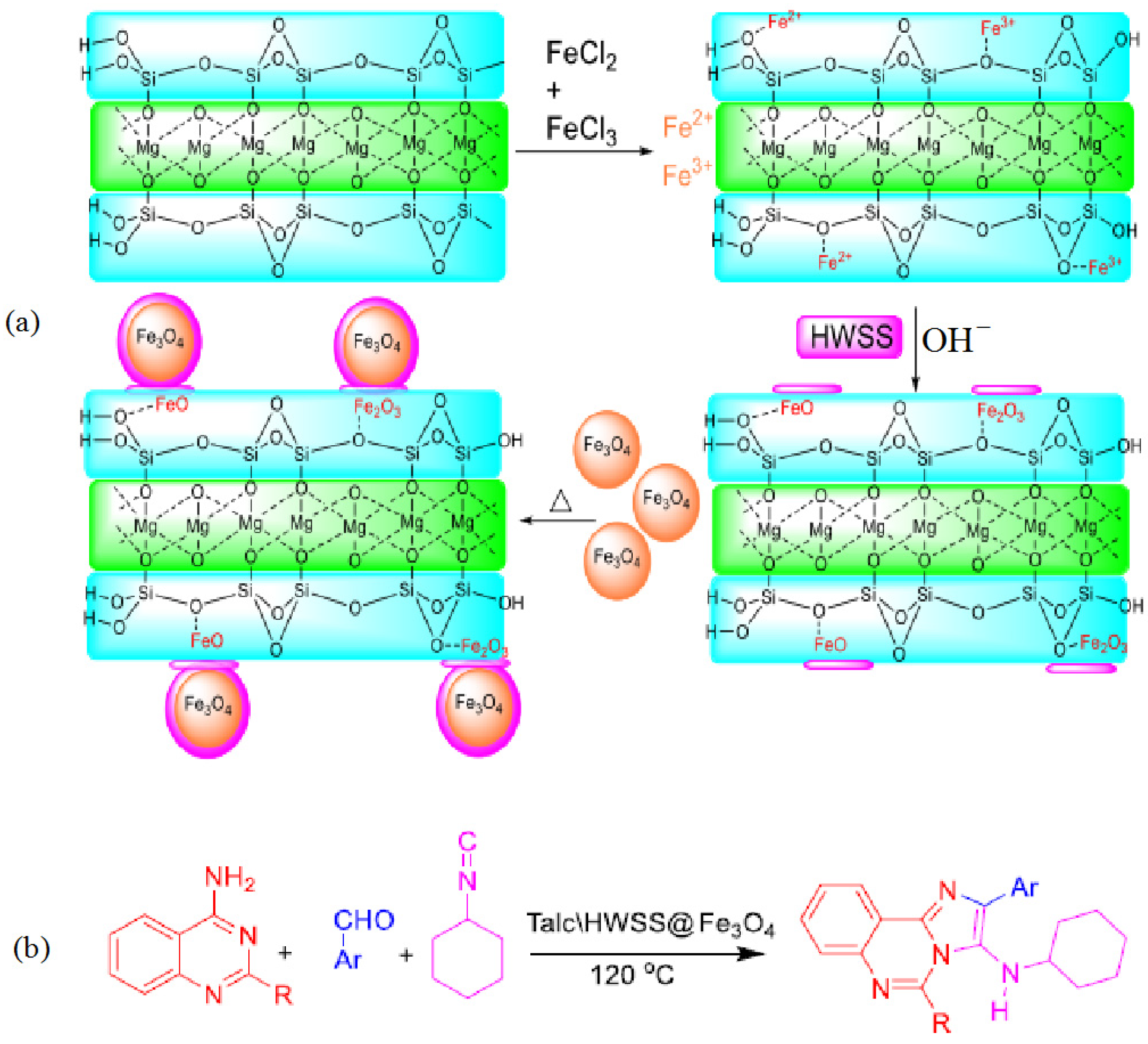

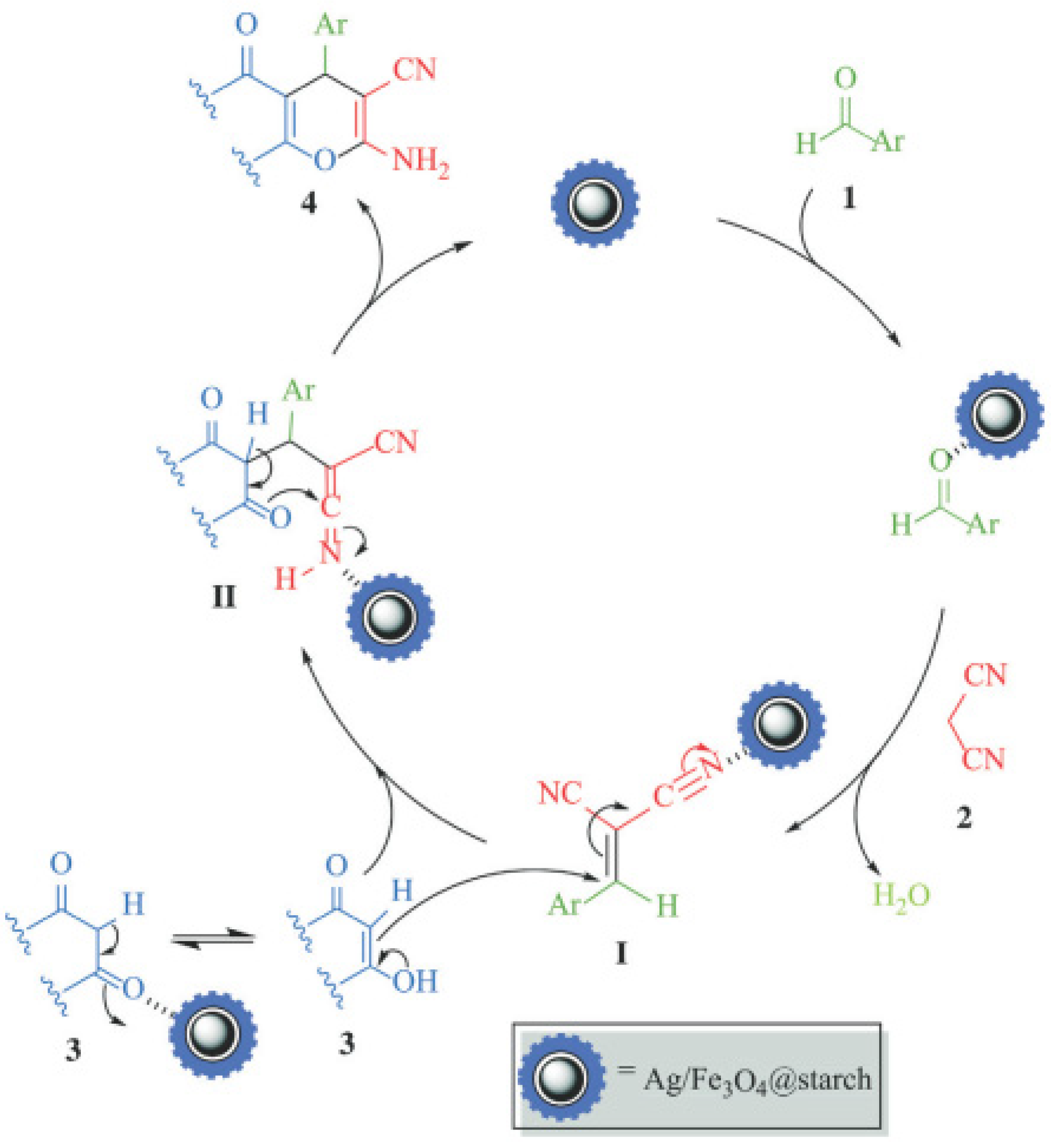

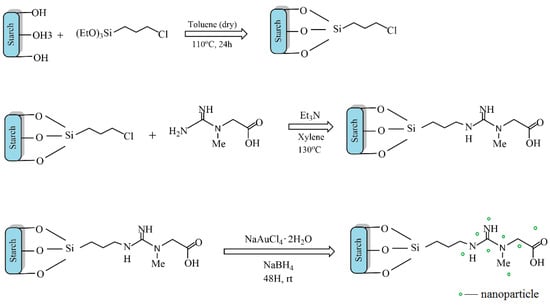

El Allaoui et al. used a coprecipitation method to synthesize new heterogeneous catalysts based on cellulose beads (CBs) and cobalt ferrite nanoparticles (CoFe2O4 NPs) for the degradation of rhodamine B (RhB) [138]. The degradation rate of rhodamine B reached 98.51% at 25 °C. The developed CoFe2O4@CB catalyst showed high stability and the possibility for reuse. The obtained results indicate the promising application of mechanically obtained CoFe2O4@CB catalysts in wastewater treatment.