Bubble Effect Phenomenon in Modern Transformer Insulation Systems Using Aramid-Based Materials and Alternative Insulating Liquids

Abstract

1. Introduction

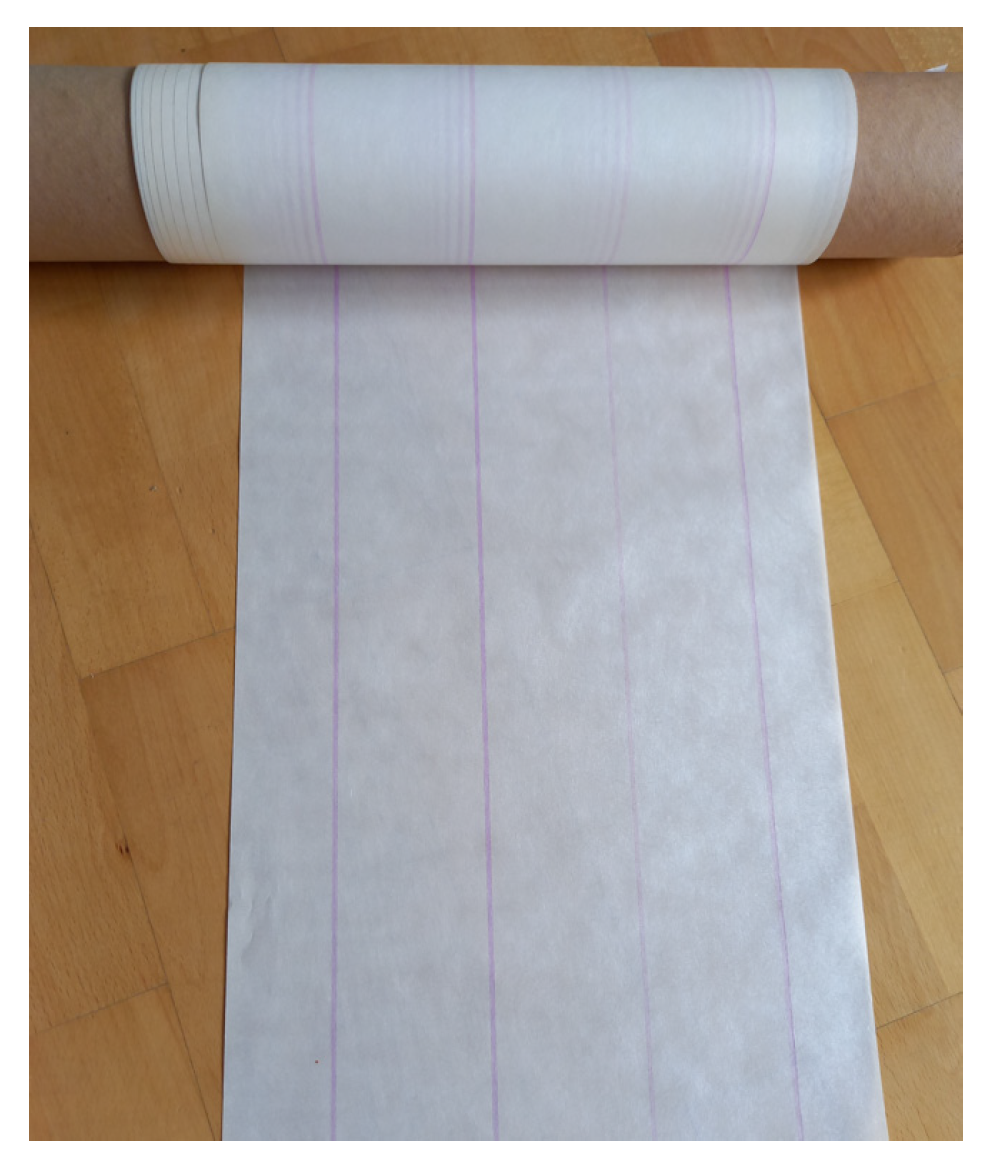

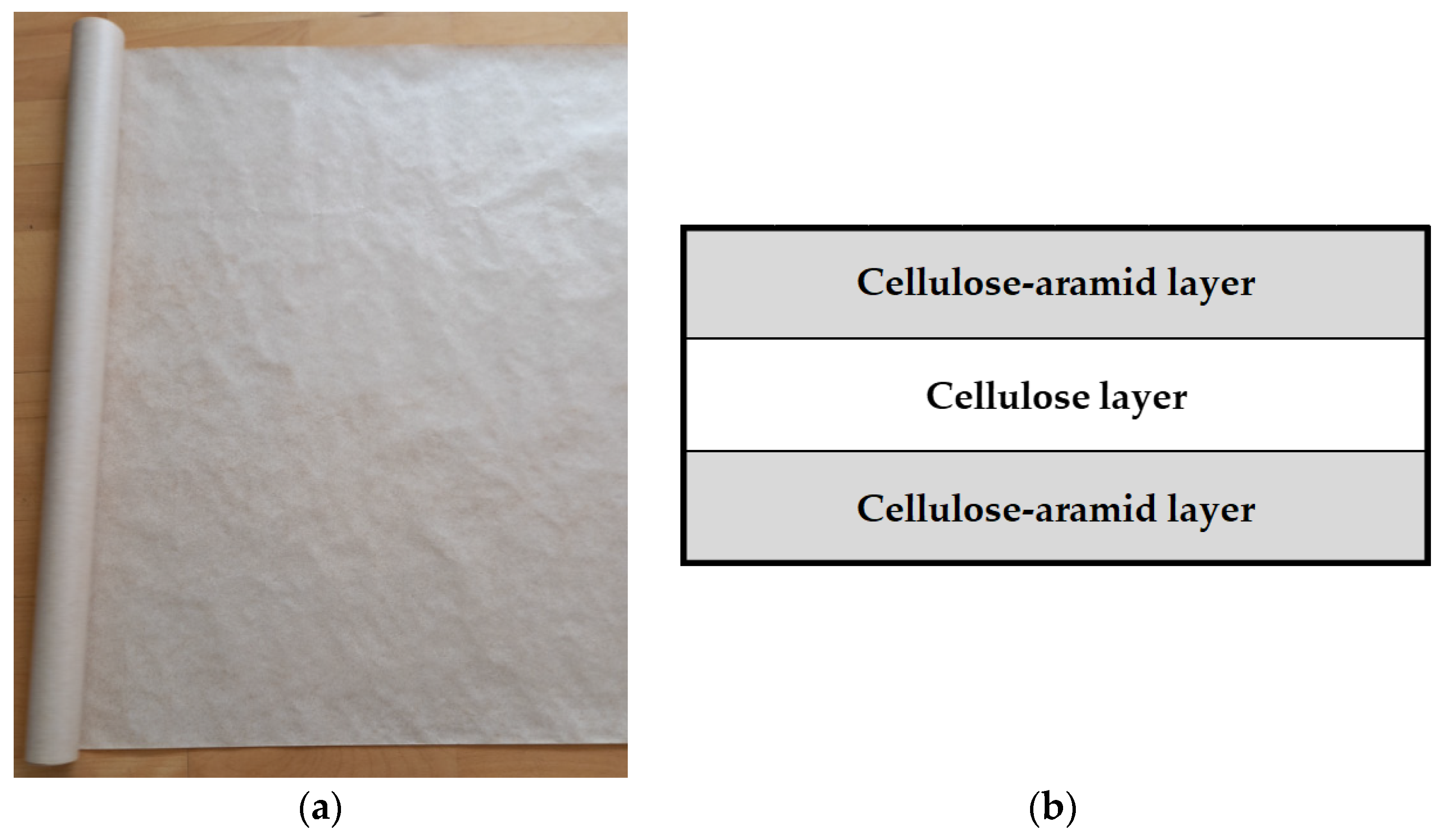

2. Solid and Liquid Insulation Materials Used in Experiment

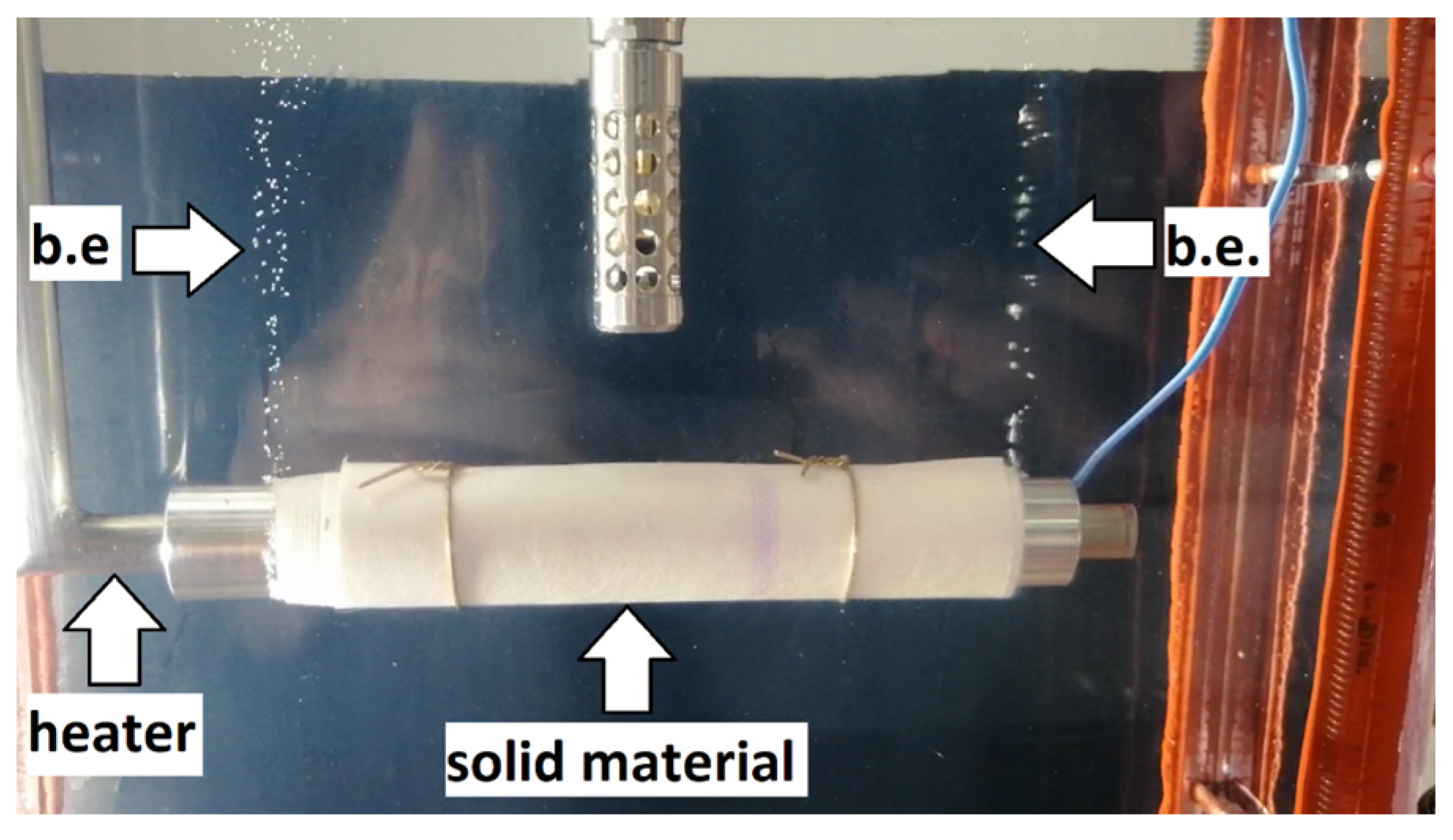

| Parameter | Unit | Midel 7131 | Orlen Oil Trafo En |

|---|---|---|---|

| Density at 20 °C | kg/m3 | 970 | 870 |

| Kinematic viscosity at 40 °C | mm2/s | 29.5 | 9.6 |

| Pour point | °C | −60 | −51 |

| Flash point | °C | 260 | 146 |

| Fire classification in accordance with IEC 61100/IEC 61039 [28,29] | – | K3 | 0 |

| Biodegradability | % | 89 | 10 |

| Breakdown voltage | kV | >75 | 69 |

| Dielectric loss factor at 90 °C | – | <0.0080 | 0.0015 |

3. Bubble Effect

- —bubble effect initiation temperature [K],

- —water content of cellulose paper [%],

- —total pressure affecting on the bubble [Torr],

- —dissolved gas content in the oil [%].

4. Experiment

- —moisture content in solid insulation [%],

- —mass of the test sample [g],

- —mass of the material after drying [g].

| Moisture of Cellulose Paper (in Oil) [%] | Moisture of Cellulose Paper (in Midel 7131) [%] | Moisture of Nomex® 910 (in Oil) [%] | Moisture of Nomex® 910 (in Midel 7131) [%] | Moisture of Nomex® 926 (in Oil) [%] | Moisture of Nomex® 926 (in Midel 7131) [%] |

|---|---|---|---|---|---|

| 0.66 | 0.65 | 0.56 | 0.56 | 0.50 | 0.50 |

| 1.85 | 1.85 | 1.21 | 1.25 | 0.95 | 0.95 |

| 1.85 | 1.85 | 1.95 | 2.04 | 1.03 | 1.17 |

| 2.37 | 2.38 | 2.05 | 2.70 | 1.56 | 1.66 |

| 2.80 | 2.70 | 2.71 | 2.88 | 1.58 | 1.66 |

| 3.66 | 3.73 | 2.90 | 3.30 | 1.97 | 1.95 |

| 3.78 | 3.74 | 3.30 | 3.80 | 2.50 | 2.56 |

| 4.30 | 4.30 | 3.30 | 4.90 | 2.58 | 2.60 |

| 4.30 | 5.50 | 3.80 | - | 2.95 | 2.95 |

| 5.50 | 5.50 | 3.80 | - | 2.95 | 3.50 |

| 5.50 | 6.14 | 4.87 | - | 3.50 | 3.50 |

| 6.17 | - | - | - | 3.50 | 3.84 |

| - | - | - | - | 4.04 | - |

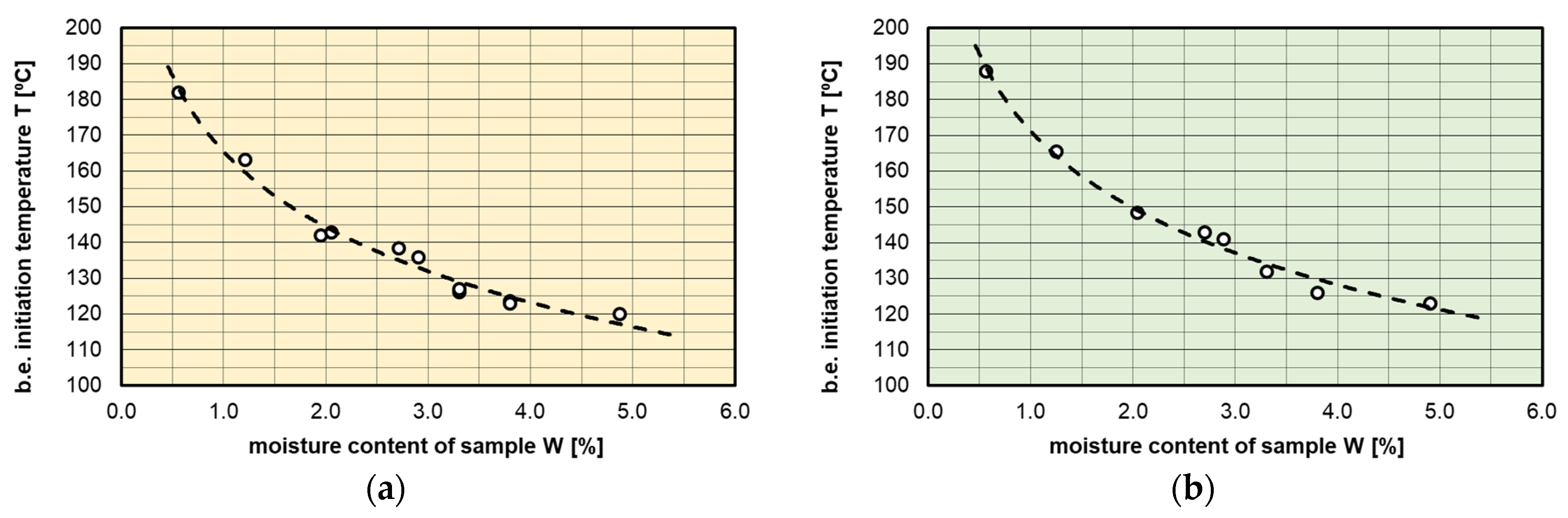

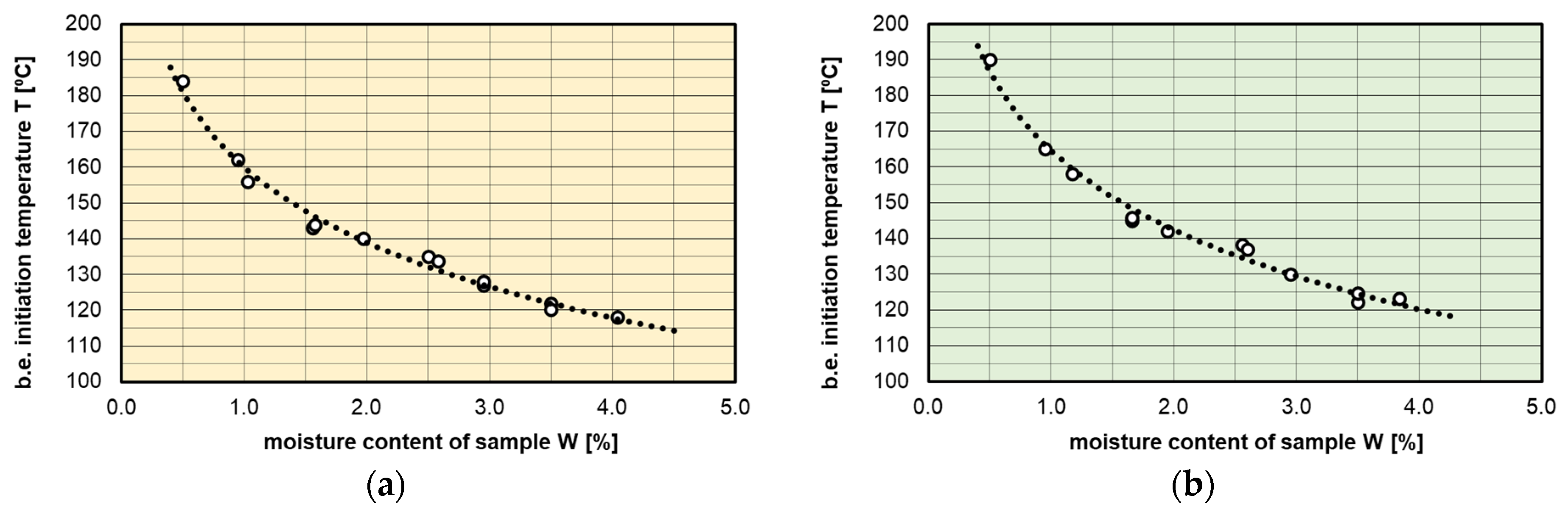

5. Results and Discussion

5.1. Presentation of Research Results

5.2. Bubble Effect Initiation Temperature Comparison of Electro-Insulating Liquids

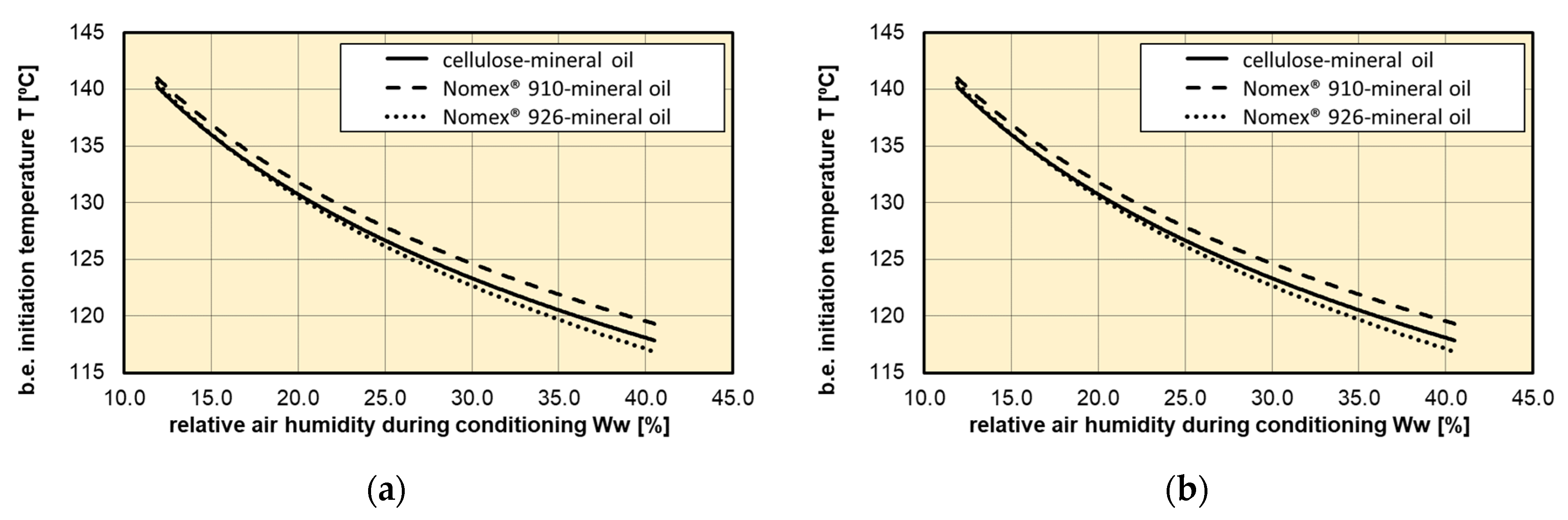

5.3. Bubble Effect Initiation Temperature Comparison of Solid Materials

6. Conclusions

- (1)

- All the tested materials were characterized with similar values of the bubble initiation temperature. However, the Nomex® 910 material had a slightly higher b.e. initiation temperature, while Nomex® 926 had slightly lower values. Although, the observed differences in the range of 2–3 °C can be considered negligible from the perspective of application in an operating transformer.

- (2)

- All tested materials have a slightly lower initiation temperature of the bubble phenomenon when they are immersed in mineral oil, and higher when immersed in synthetic ester.

- (3)

- The difference in the temperature of the bubble effect initiation of the tested materials decreases with their relative humidity. Aramid-based materials obtain less moisture than cellulose-based materials, which partially eliminates the differences in the bubble effect initiation temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sikorski, W.; Walczak, K.; Przybylek, P. Moisture Migration in an Oil-Paper Insulation System in Relation to Online Partial Discharge Monitoring of Power Transformers. Energies 2016, 9, 1082. [Google Scholar] [CrossRef]

- Feng, J.; Wang, W.; Ma, X.; Wang, N.; Ma, H.; Wei, J. Insulation Breakdown Failure Analysis of a 500kV Power Transformer in Lightning Impulse Test. In Proceedings of the IEEE 5th Conference on Energy Internet and Energy System Integration (EI2), Taiyuan, China, 22–24 October 2021. [Google Scholar]

- Przybylek, P.; Moranda, H.; Walczak, K.; Moscicka-Grzesiak, H. Can the bubble effect occur in an oil impregnated paper bushing? IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1879–1883. [Google Scholar] [CrossRef]

- Perkasa, C.Y.; Wijaya, J.; Lelekakis, N.; Martin, D. Preliminary study of bubble formation in vegetable oil filled power transformer. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Chenzhen, China, 20–23 October 2013. [Google Scholar]

- Arumugam, S. Failure Diagnosis and Root-Cause Analysis of In-Service and Defective Distribution Transformers. Energies 2021, 14, 4997. [Google Scholar] [CrossRef]

- Bagheri, M.; Phung, B.T.; Blackburn, T. Influence of temperature and moisture content on frequency response analysis of transformer winding. IEEE trans. Dielectr. Electr. Insul. 2014, 21, 1393–1404. [Google Scholar] [CrossRef]

- Lewandowski, K.; Moranda, H. Analysis of possibility of shorted coil localization in power transformer on the basis of its frequency response (SFRA). ITM Web. Conf. 2019, 28, 01029. [Google Scholar] [CrossRef]

- Lewandowski, K.; Moranda, H. Detection of windings short-circuits in a power transformer using the SFRA method. Prz. Elektrotechniczny 2018, 94, 118–121. (In Polish) [Google Scholar]

- Pradhan, M.K.; Yew, K.J.H. Experimental investigation of insulation parameters affecting power transformer condition assessment using frequency domain spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1851–1859. [Google Scholar] [CrossRef]

- Mishra, D.; Baral, A.; Haque, N.; Chakravorti, S. Condition Assessment of Power Transformer Insulation Using Short-Duration Time-Domain Dielectric Spectroscopy Measurement Data. IEEE Trans. Instrum. Meas. 2020, 69, 4404–4411. [Google Scholar] [CrossRef]

- Przybylek, P. A comparison of bubble evolution temperature in aramid and cellulose paper. In Proceedings of the 2013 IEEE International Conference on Solid Dielectrics, Bologna, Italy, 30 June–4 July 2013. [Google Scholar]

- Arshad, M.; Islam, S.M. Significance of Cellulose Power Transformer Condition Assessment. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1597–1598. [Google Scholar] [CrossRef]

- Brancato, E.L. Insulation Aging a Historical and Critical Review. IEEE Trans. Dielectr. Electr. Insul. 1978, EI-13, 308–317. [Google Scholar] [CrossRef]

- 1276-2020; IEEE Guide for the Application of High-Temperature Insulation Materials in Liquid-Immersed Distribution, Power and Regulating Transformers. IEEE Standard: Piscataway, NJ, USA, 2020.

- Marek, R.P.; Calil, W.; Galhardo, L.; Souza, A. Practical verification of a high temperature insulation system for power transformers. In Proceedings of the IX International Workshop on Power Transformers, Equipment, Substation and Materials, Foz Do Iguacu, Brazil, 29 October 2018. [Google Scholar]

- Szewczyk, R. Papier izolacyjny wzmocniony aramidem—Wlasciwosci i zastosowania. Urządzenia Dla Energetyki 2019, 2, 47–54. (In Polish) [Google Scholar]

- Szewczyk, R.; Duart, J.-C.; Trifigny, P. Mitigation of lock-in effect for compact substations with transformers meeting future EU efficiency regulations. In Proceedings of the 25th International Conference on Electricity Distribution, Paper No. 2089. Madrid, Spain, 3–6 June 2019. [Google Scholar]

- Szewczyk, R.; Marek, R.; Ballard, R.C.; Duart, J.-C.; Vercesi, G. Innovative insulation materials helping in cost reduction of modern transformers. In Proceedings of the 25th International Conference on Electricity Distribution, Paper No. 2108. Madrid, Spain, 3–6 June 2019. [Google Scholar]

- DuPont Nomex® 926 Technical Data Sheet, 04.2016. Available online: https://www.dupont.com/content/dam/dupont/amer/us/en/safety/public/documents/en/DPT16_21668_Nomex_926_Tech_Data_Sheet_me01_Reference.pdf (accessed on 6 July 2023).

- DuPont Nomex® 910 Technical Data Sheet, 01.2017. Available online: https://www.dupont.com/content/dam/dupont/amer/us/en/safety/public/documents/en/DPT16_21921_Nomex_910_Tech_Data_Sheet_me06.pdf (accessed on 6 July 2023).

- Marek, R.P.; Wicks, R.C.; Galhardo, L.; Szewczyk, R. New cellulose paper enhanced with aramid—Practical example of material thermal evaluation acc. to IEEE Std C57. In Proceedings of the SCD1 Colloquium Trends in Technology, Materials, Testing and Diagnostics Applied to Electric Power Systems, Rio de Janeiro, Brazil, 13–18 September 2015. [Google Scholar]

- Lalik, M.; Maleska, M.; Zdanowski, M. Badania podstawowych wlasciwosci fizycznych i elektrycznych estru Midel 7131® (Research on the basic physical and electrical properties of Midel 7131® ester). Pozn. Univ. Techonology Acad. J. Electr. Eng. 2018. (In Polish) [Google Scholar]

- Available online: https://www.orlenoil.pl/ (accessed on 4 November 2022).

- Rozga, P. Electrical strength of transformer insulating liquids based on synthetic and natural esters. Prz. Elektrotechniczny 2014. (In Polish) [Google Scholar]

- Przybylek, P.; Moranda, H.; Moscicka-Grzesiak, H.; Cybulski, M. Laboratory Model Studies on the Drying Efficiency of Transformer Cellulose Insulation Using Synthetic Ester. Energies 2020, 13, 3467. [Google Scholar] [CrossRef]

- Przybylek, P.; Moranda, H.; Moscicka-Grzesiak, H.; Szczesniak, D. Application of Synthetic Ester for Drying Distribution Transformer Insulation—The Influence of Cellulose Thickness on Drying Efficiency. Energies 2019, 12, 3874. [Google Scholar] [CrossRef]

- Przybylek, P. Water saturation limit of insulating liquids and hygroscopicity of cellulose in aspect of moisture determination in oil-paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1886–1893. [Google Scholar] [CrossRef]

- IEC 61100; Classification of Insulating Liquids According to Fire Point and Net Calorific Value. International Electrotechnical Commission: Geneva, Switzerland, 1992.

- IEC Standard 61039; Classification of Insulating Liquids. 2nd ed. International Electrotechnical Commission: Geneva, Switzerland, 2008.

- Przybylek, P. The Influence of Cellulose Insulation Aging Degree on its Water Sorption Properties and Bubble Evolution. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 906–912. [Google Scholar] [CrossRef]

- Oommen, T.V.; Lindgren, S.R. Bubble evolution from transformer load. In Proceedings of the IEEE/PES Transmission and Distribution Conference Exposition, Atlanta, GA, USA, 2 November 2001; Volume 1, pp. 137–142. [Google Scholar]

- Przybylek, P.; Moranda, H.; Moscicka-Grzesiak, H. Zjawisko “bubble effect” w izolacji papierowo-olejowej o różnym stopniu zawilgocenia i zestarzenia. Pomiary Autom. Kontrola 2009, 55, 44–46. [Google Scholar]

- Qin, C.; He, Y.; Shi, B.; Zhao, T.; Lv, F.; Cheng, X. Experimental Study on Breakdown Characteristics of Transformer Oil Influenced by Bubbles. Energies 2018, 11, 634. [Google Scholar] [CrossRef]

- Hill, J.; Wang, Z.; Liu, Q.; Krause, C.; Wilson, G. Analysing the power transformer temperature limitation for avoidance of bubble formation. High Volt. 2019, 4, 210–216. [Google Scholar] [CrossRef]

- IEC 60076-14:2013; Power transformers—Part 14: Liquid-Immersed Power Transformers Using High-Insulation Materials. International Standard, IEC: Geneva, Switzerland, 2013.

- Perkasa, C.Y.; Czaszejko, T.; Lelekakis, N.; Wijaya, J. A Comparison of the Formation of Bubbles and Water Droplets in Vegetable and Mineral Oil Impregnated Transformer Paper. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2111–2118. [Google Scholar] [CrossRef]

- Perkasa, C.Y.; Wijaya, J.; Lelekakis, N.; Martin, D. Investigating bubble formation in vegetable and mineral oil impregnated transformer paper insulation systems. In Proceedings of the 2012 22nd Australasian Universities Power Engineering Conference (AUPEC), Bali, Indonesia, 26–29 September 2012. [Google Scholar]

- Poessniker, C. Bubble Formation in Power Transformers—A Potential Risk of the Future Network Reliability? CIGRE Power Syst. Expert. 2022, A2, 11139. [Google Scholar]

- Wilhelm, H.; Fernandes, P.; Dill, L.; Moscon, K.; Steffens, C.; Peres, S.; Bender, V.; Marchesan, T.; Neto, J.F. Development of methodologies to predict incipient faults in power transformers related to particle contamination and bubble formation. CIGRE Power Syst. Expert. 2022, D1, 10178. [Google Scholar]

| Insulating Material | Relative Permittivity at 25 °C [–] |

|---|---|

| Mineral oil | 2.2 |

| Synthetic ester | 3.2 |

| Cellulose paper in mineral oil | 3.3–4.1 |

| Aramid paper in mineral oil | 2.94 |

| Sample Moisture [%] | B.e. Initiation Temperature for Cellulose in Oil [°C] | B.e. Initiation Temperature for Cellulose in Ester [°C] | Difference Between b.e. Initiation Temperature in Ester and Oil [°C] | Percentage Difference Between b.e. Initiation Temperature in Ester and Oil [%] |

|---|---|---|---|---|

| 1 | 172.5 | 180.7 | 8.2 | 4.8 |

| 1.5 | 160.3 | 167.7 | 7.4 | 4.6 |

| 2.0 | 151.7 | 158.5 | 6.7 | 4.4 |

| 2.5 | 145.1 | 151.3 | 6.3 | 4.3 |

| 3.0 | 139.6 | 145.5 | 5.9 | 4.2 |

| 3.5 | 135.0 | 140.6 | 5.6 | 4.1 |

| 4.0 | 131.0 | 136.3 | 5.3 | 4.0 |

| 4.5 | 127.5 | 132.5 | 5.0 | 3.9 |

| 5.0 | 124.3 | 129.1 | 4.8 | 3.9 |

| 5.5 | 121.5 | 126.1 | 4.6 | 3.8 |

| 6.0 | 118.9 | 123.3 | 4.4 | 3.7 |

| 6.5 | 116.5 | 120.7 | 4.2 | 3.6 |

| Average: | 5.7 | 4.1 |

| Sample Moisture [%] | B.e. Initiation Temperature for Cellulose in Oil [°C] | B.e. Initiation Temperature for Cellulose in Ester [°C] | Difference Between b.e. Initiation Temperature in Ester and Oil [°C] | Percentage Difference Between b.e. Initiation Temperature in Ester and Oil [%] |

|---|---|---|---|---|

| 0.5 | 186.9 | 192.3 | 5.4 | 2.9 |

| 1.0 | 166.1 | 170.3 | 4.3 | 2.6 |

| 1.5 | 153.9 | 157.5 | 3.6 | 2.3 |

| 2.0 | 145.2 | 148.4 | 3.1 | 2.1 |

| 2.5 | 138.5 | 141.3 | 2.8 | 2.0 |

| 3.0 | 133.1 | 135.5 | 2.5 | 1.8 |

| 3.5 | 128.4 | 130.6 | 2.2 | 1.7 |

| 4.0 | 124.4 | 126.4 | 2.0 | 1.6 |

| 4.5 | 120.9 | 122.7 | 1.8 | 1.5 |

| 5.0 | 117.7 | 119.4 | 1.6 | 1.4 |

| Average: | 2.9 | 2.0 |

| Sample Moisture [%] | B.e. Initiation Temperature for Cellulose in Oil [°C] | B.e. Initiation Temperature for Cellulose in Ester [°C] | Difference Between b.e. Initiation Temperature in Ester and Oil [°C] | Percentage Difference Between b.e. Initiation Temperature in Ester and Oil [%] |

|---|---|---|---|---|

| 0.5 | 181.1 | 186.7 | 5.7 | 3.1 |

| 1.0 | 160.0 | 164.6 | 4.6 | 2.9 |

| 1.5 | 147.7 | 151.6 | 3.9 | 2.7 |

| 2.0 | 138.9 | 142.4 | 3.5 | 2.5 |

| 2.5 | 132.1 | 135.2 | 3.1 | 2.3 |

| 3.0 | 126.6 | 129.4 | 2.8 | 2.2 |

| 3.5 | 121.9 | 124.5 | 2.6 | 2.1 |

| 4.0 | 117.8 | 120.2 | 2.4 | 2.0 |

| 4.5 | 114.2 | 116.4 | 2.2 | 1.9 |

| Average: | 3.4 | 2.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lewandowski, K.; Moranda, H.; Szewczyk, R. Bubble Effect Phenomenon in Modern Transformer Insulation Systems Using Aramid-Based Materials and Alternative Insulating Liquids. Energies 2023, 16, 5297. https://doi.org/10.3390/en16145297

Lewandowski K, Moranda H, Szewczyk R. Bubble Effect Phenomenon in Modern Transformer Insulation Systems Using Aramid-Based Materials and Alternative Insulating Liquids. Energies. 2023; 16(14):5297. https://doi.org/10.3390/en16145297

Chicago/Turabian StyleLewandowski, Kamil, Hubert Moranda, and Radoslaw Szewczyk. 2023. "Bubble Effect Phenomenon in Modern Transformer Insulation Systems Using Aramid-Based Materials and Alternative Insulating Liquids" Energies 16, no. 14: 5297. https://doi.org/10.3390/en16145297

APA StyleLewandowski, K., Moranda, H., & Szewczyk, R. (2023). Bubble Effect Phenomenon in Modern Transformer Insulation Systems Using Aramid-Based Materials and Alternative Insulating Liquids. Energies, 16(14), 5297. https://doi.org/10.3390/en16145297