1. Introduction

Recently, non-renewable energy sources have increasingly been causing environmental pollution, which is one of the most serious challenges worldwide. Over 70% of the energy used in industry is from non-renewable sources that have a serious impact on the environment and living organisms including humans [

1]. These factors contribute to renewable energy development. Wind is one of the renewable energy sources that provide a solution to the environmental pollution problem as it has a much smaller pollution impact on the environment than non-renewable energy sources such as burning fossil fuels. It can be considered a competitive alternative to other conventional sources of electricity generation [

2]. Wind energy has been attracting more attention in the world as it is a clean and sustainable energy source that is capable of keeping pace with the world’s ever-growing power needs.

Wind energy is leading the renewable energy market with installations that keep growing each year; 2021 was the second-best year ever for the global wind industry as it showed a year-over-year (YOY) growth of 12%, according to the Global Wind Energy Report of 2022. Almost 94 GW of wind power was installed, resulting in a global cumulative wind power capacity of up to 837 GW, with an increase of 153% compared to 2020 [

3]. However, more installations are needed in order to reach the net zero target, the balance between greenhouse gas emissions produced vs. those taken out from the atmosphere by 2050.

Harvesting energy coming from the flowing air and converting it to electricity is performed conventionally through the utilization of a WT system [

4]. WT converts the kinetic energy in the wind into mechanical energy by means of a rotor shaft connected to a generator that converts mechanical energy into electricity. The mechanical output power and torque of the WT depend on several factors such as wind speed, rotor swept area and the geometry of the turbine, blade pitch angle, turbine rotational speed, and turbine size. Equation (1) represents the output power of the WT.

where

Pm is the WT’s mechanical power,

ρ is the air density,

Vw is the wind velocity in meters per second, and

A is rotor area in meters. The power coefficient of the rotor or rotor efficiency (

Cp) in the equation can be defined as the ratio between the actual obtained power and the maximum power available in the wind. The maximum value of the power coefficient derived based on 1D momentum theory is called the Betz limit.

Cp varies with the TSR of the turbine (

λ), which is the ratio between the blade tip speed and wind speed, and the pitch angle of the blades (

β) and it is unique to each WT type. An example of a basic numerical model to show the relationship between various variables that affect the power coefficient of a wind turbine is shown in Equations (2)–(4) [

5,

6].

where

β is the blade pitch angle,

ωr is the rotational speed of the rotor in radians per second, and

R is the rotor’s radius in meters.

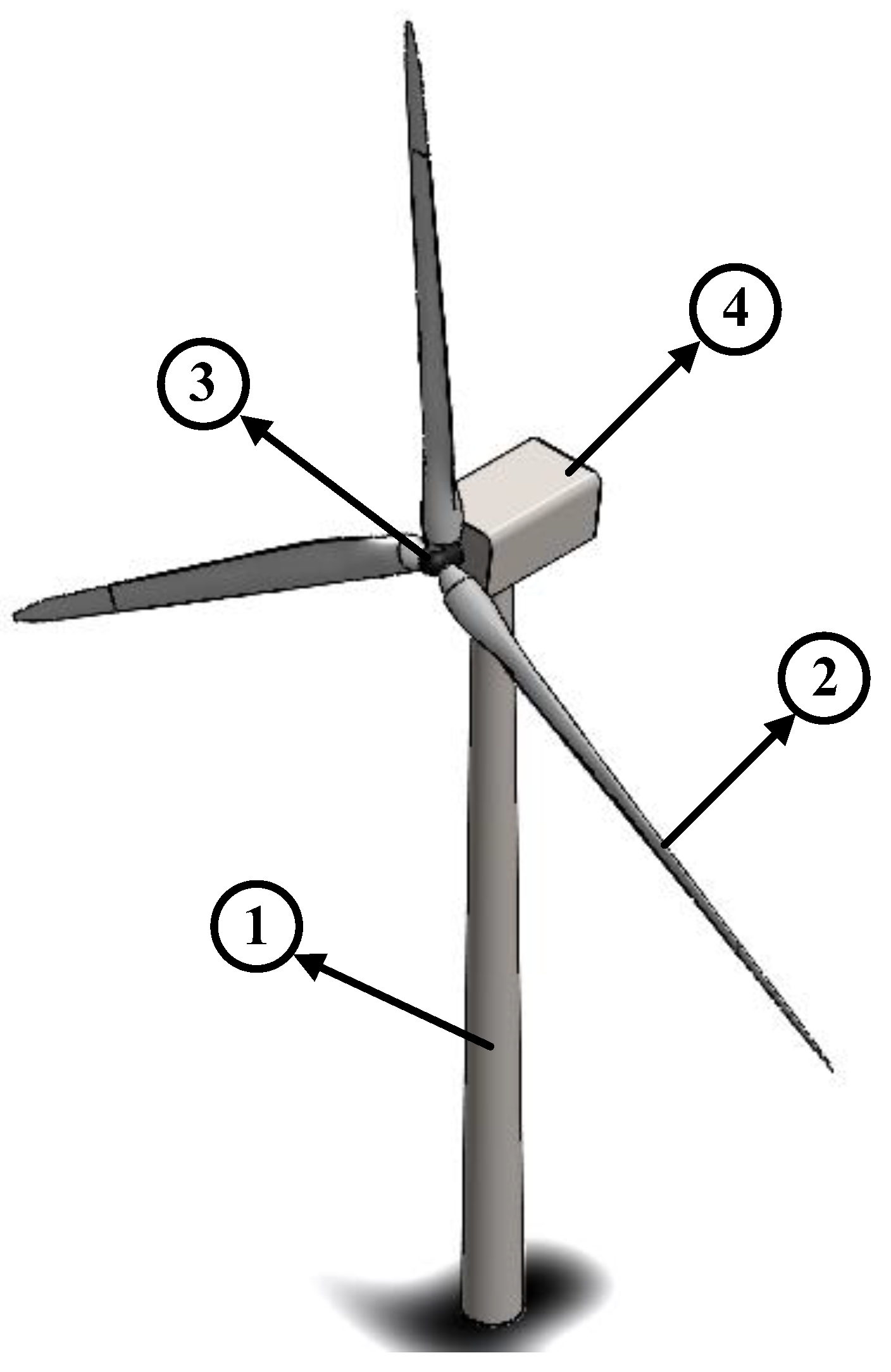

WTs are non-linear complex systems with flexible structures that are subjected to the wind that can vary dramatically in strength and direction, which in sequence effects the efficient harvesting of wind power. Modern horizontal axis wind turbines (HAWT) come in different sizes but generally, all types consist of several main components shown in

Figure 1, which are: (1) the tower, the wind turbine’s supporting structure made of tubular steel; (2) the blade, a long fiberglass piece which catches the wind at the top of the wind turbine to turn the turbine; (3) the hub, a cast structure into which the blades are fitted and that is connected to the turbine’s main shaft; (4) the nacelle, which is a cover that houses the gearbox and generator connecting the rotor and tower.

However, low wind speeds result in low output power, while high wind speeds may cause the failure of most of the WT’s mechanical components [

7]. Moreover, WTs are connected to a varying electrical grid with unpredictable voltage, frequency, and power flow fluctuations, hence the amount of power that can be executed from the wind, output power efficiency, cost, reliability, and availability strongly depend on the applied control strategy.

As WTs are becoming larger and more flexible, designing innovative control strategies to ensure the quality and stability of the power systems, besides decreasing wind energy cost by increasing the capture efficacy, becomes an explicit goal [

8,

9]. In addition, there are other main control objectives that need to be considered while designing a WT control system, such as energy capture maximization, mechanical load, and fatigue attenuation, providing damping, reliability, and availability that directly affect the cost and competitiveness of wind power technology [

10,

11]. Control can also be applied on the scale of wind farms to maximize power output through wake mitigation or other techniques [

12]. There are many review articles that also consider WT size and design, different operating regions and different platforms (onshore and offshore) [

13,

14,

15]. However, the scope of this work is control performed on the wind turbine components.

In a WT system, three types of controllers dominate, namely pitch angle control, torque control, and yaw alignment control. However, a study on the number of failures of turbines in a year has shown that the pitch control system is the first most common mechanical component contributing to an overall failure rate, followed by the yaw control system and then the torque control system [

16,

17].

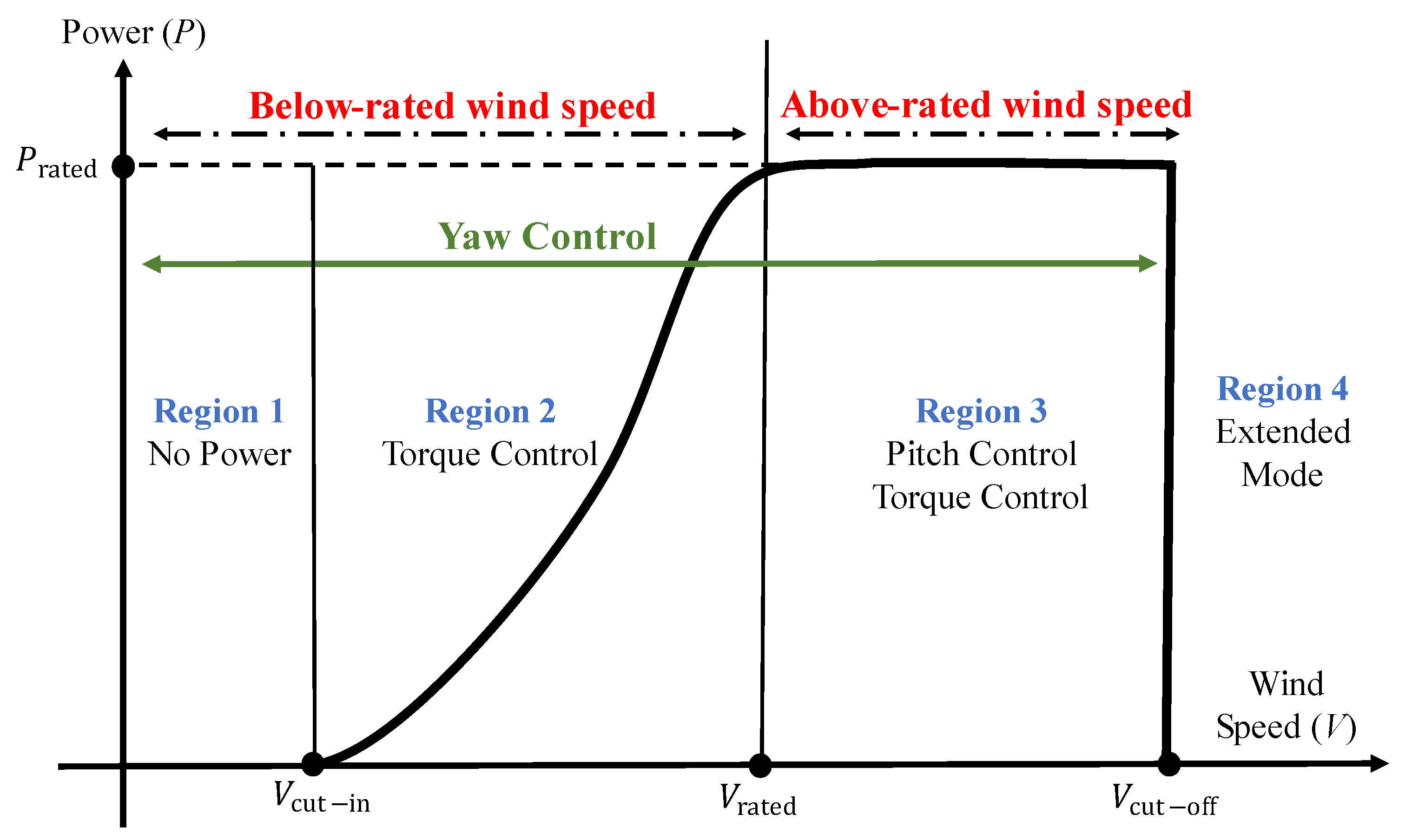

Based on a WT’s power curve, shown in

Figure 2, there are four main regions enclosed in two main areas. The actual power supplied to the WT grid is responsible for dividing the curve into two main areas, which are the above- and below-rated power areas. The main objective of the below-rated power area, where the wind speed is below the rated wind speed, is to maximize power capture, while in the above-rated power area, where the wind speed exceeds the rated wind speed, the objective is to maintain power at its rated value to avoid power fluctuations.

Typically, the power curve of a utility-scale WT is divided to four operating regions depending on the wind speed value. In region 1, as the wind speed is less than the cut-in wind speed value (

, there is not sufficient torque exerted on the turbine rotor to make it rotate with enough rotational speed to produce power. In region 2, also known as the transition region, the wind speed is between the cut-in speed and the rated speed value (

). The objective is to obtain maximum aerodynamic efficiency through a torque controller that controls the generator’s synchronous speed so that the power produced grows rapidly reaching the rated/maximum power. In region 3, the rated power is maintained at a constant until the wind speed reaches the cut-off speed value (

, in this region the pitch angle control is needed to limit the incoming power or apply a braking mode to prevent WT structure fatigue by controlling the blade’s angle, which affects the rotor’s rotational speed (i.e., increasing the blade’s angle results in decreasing the rotational speed). Region 4, also known as the extended mode region, is where the wind speed exceeds the cut-off speed, so the rotor speed has to be controlled so as not to fatigue the WT’s components [

18]. However, yaw control is applicable in all 4 regions, as it considers the wind direction change, so it is also applied to keep constant rated power output as it does not depend on the wind speed.

In this paper, state-of-the-art control techniques for wind turbine rotors adopted by researchers are viewed and categorized according to the three types of controllers for WTs: pitch control, yaw control, and torque control.

2. Pitch Control Technique

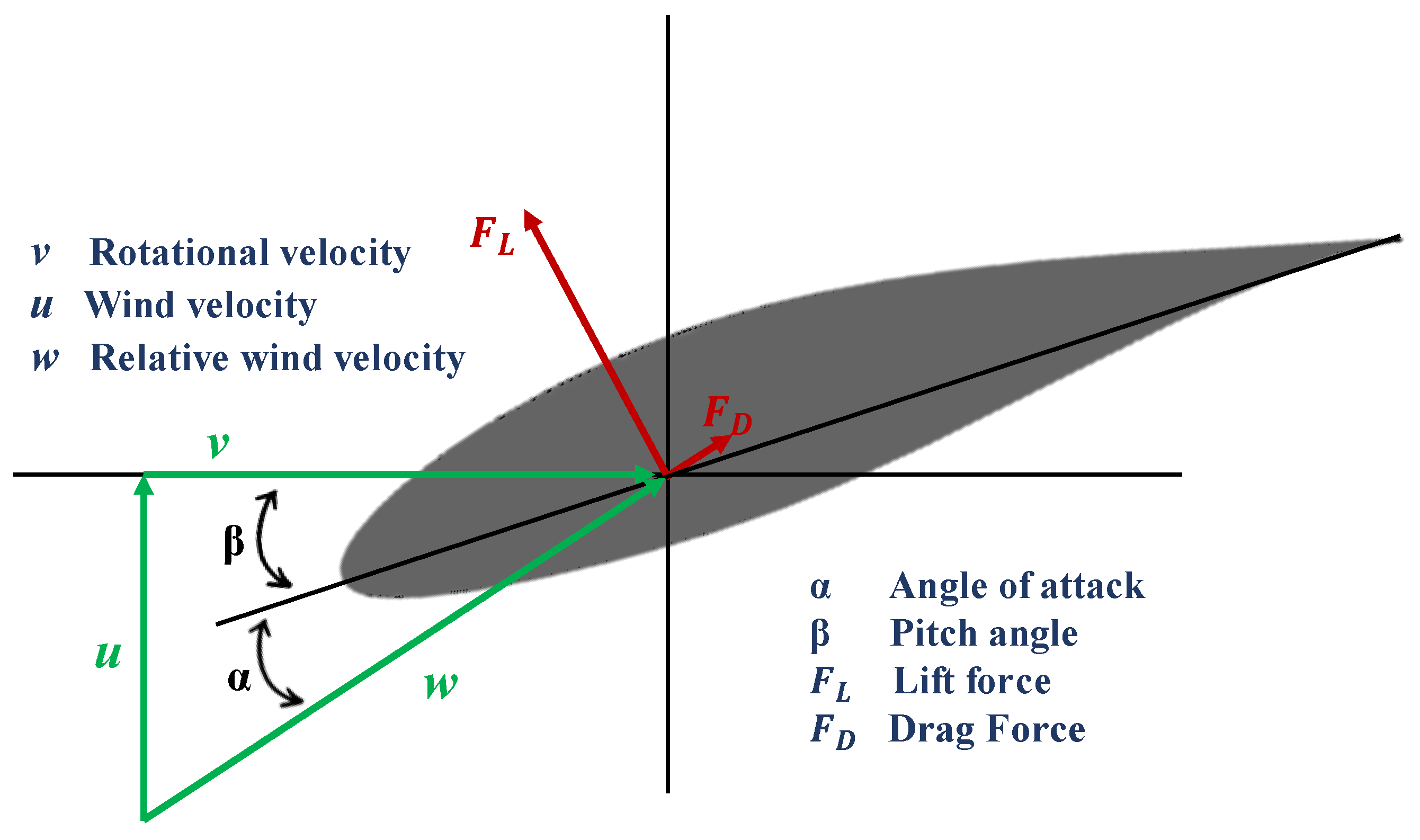

Pitch control is a system that operates and controls the pitch angle (β) of a WT blade by changing the aerodynamic forces on the blade at high wind speeds to limit rotor speed. The pitch control system, shown in

Figure 3, is a closed loop control system that consists of the main controller that calculates the required pitch angle (

) considering a set of conditions, transfers it to the pitch actuator system, which is made up either of gears and electric motors a or power supply system with hydraulic cylinders, and a wind speed sensor to give a feedback signal for the current wind conditions (

). In the low wind speed region, the maximum power extraction mode is adapted, and the pitch angle is kept at its optimum operation, while in the high wind speed region, the rotor speed is accelerated so the pitch angle is adjusted to control the rotor speed to keep it within the controllable limit in order to produce stable power as well as keep the wind turbine in a safe operating environment.

Figure 4 shows the forces and wind effect on the blade’s airfoil. There are two methods to achieve zero rotor speed acceleration, which are pitch-to-feather, controlling the aerodynamic power captured by the blade (

Pcaptured), and pitch-to-stall, controlling the output power of the generator (

Pelectrical). The pitch-to-feather method is a common way to reduce the aerodynamic power resulting from very high wind speeds [

18].

In [

19], slow and fast pitching control rates at high wind speeds were investigated. The simulation results showed that if the pitch angle control is performed instantaneously, the speed can be kept constant by adjusting the difference between the captured power (

Pcaptured) and electrical power (

Pelectrical) to zero. Most large WTs use proportional–integral–differentiation (PID) or proportional–integral (PI) control for pitch angle control and power regulation. PID controllers are mostly used in industry to control a system, as they are feasible and easy to implement. They use closed-loop control feedback to keep the actual system’s output as close to the setpoint output as possible. To use PI/PID controllers, the parameters should be found, adjusted, and tuned according to the system’s behavior.

R. Karthik et al. implemented several methods for tuning a PID controller’s parameters, these are KP, KI, and KD, to study their impact on the system [

20]. The performance of each method is represented in terms of the time domain performance index term and the parameters of interest are delay time (

Td), peak time (

Tp), rise time (

Tr), settling time (

Ts), peak overshoot (M

p in %), and steady-state error (ess). Evaluating the response efficacy of each method was based on giving/producing the lower values for the mentioned parameters. Simulation results showed that among all the PID parameters tuning methods, the Zeigler–Nicholas method gives better performance in terms of time delay, settling time, and peak overshoot compared to the other methods, hence is the use of this method is recommended for tuning the PID controller’s parameters in WT application.

Clemens Jauch et al. designed a PID pitch angle controller for a fixed speed active-stall WT, which has only a pitch system to control the output power, by deriving the transfer function (TF) of the WT system from its step response using the root locus method [

21]. The TF of the WT was of a very high order due to the system’s non-linearities so it has been defined as sets of 2nd-order TFs. Steady-state error was avoided by adding an integrator to the system. A pole was added at the origin of the s-plane to deform the locus, preventing the root locus from crossing the previously found point for the dynamic response, so the WT’s performance became significantly better despite the limitations of the pitch system.

Richie Gao and Zhiwei Gao designed an effective PI pitch controller to overcome the effect of delays caused by hydraulic pressure-driven units that affect the pitch control systems [

22]. In order to estimate the PI controller parameters, a direct search optimization technique was applied to assume no delays in the WT. The input and output of the controlled system are used to design a delay estimator to estimate the disturbances caused by the delay, then subtract this estimated delay from the WT’s output to give compensated output used for feedback loop control, to remove the effect of the delays. The applied controller showed reliable improvement of the WT control system without the need for prior knowledge of the system delays.

Since PID parameters are unknown and calculated by numerous complex techniques, Atif Iqbal et al. have proposed a developed particle swarm optimization (PSO) algorithm with fminsearch in order to provide optimal parameters for the PID pitch controller to stabilize the WT’s power output [

23]. The developed PSO algorithm showed improvement in the system’s stabilization in different aspects from rising time to settling time. By comparing the proposed algorithm to conventional PSO, the simulation results indicated a higher output power and a limit on the rotor speed, along with mechanical torque. Also, Sachin Goyal et al. developed a neuro-fuzzy (NF) tuned PID pitch controller for an individual pitch controller–variable speed wind turbine (IPC–VSWT) to quickly maintain the output power in line with wind speed fluctuations [

24]. Comparison between untuned PID and NF-tuned PID showed a performance improvement for the proposed algorithm regarding overshoot percentage and settling time by 15% and 37%, respectively, compared to untuned PID.

There are recent optimization methods that have been used for PI/PID controller parameter tuning. Shi-Jie Jiang et al. proposed a recent Archimedes optimization algorithm (AOA) based on the Taguchi parallel method (TPAOA), which has few parameters to solve, is easy to implement, and has an easy-to-understand interface for PID parameter tuning [

25]. Using the parallel mechanism and Taguchi orthogonal solved the drawbacks of the optimization algorithm and showed competitive optimization results compared to other algorithms represented in the CEC2017 test suite and also smoothed the WT’s output power by reducing the impact of wind speed fluctuations on the system.

In [

26], the firefly algorithm (FA) for PID pitch control parameter tuning was proposed. The FA was improved by applying a hybrid parallel compact technique that helps in finding better solutions with minimum errors and saves more operation memory. The parallel compact firefly algorithm (PCFA) was compared to the original FA and the results showed the superiority of the PCFA in smoothing the output power in a shorter calculation time and using less operation memory. Also, in [

27] the grey wolf optimization (GWO) algorithm for the PI-MPPT controller gains tuning was proposed by considering integral time-multiplied square error (ITSE) minimizing, which is developed from SCIG power error regarding region 3. The GWO algorithm provided optimal performance for PI tuning compared to the genetic algorithm (GA) and PSO algorithms.

Soft computing techniques are algorithms that deal with imprecision, approximation, and uncertainty as they can provide an approximate solution for complex and non-linear systems with non-exact models effectively. The maximum power point tracking (MPPT) technique is considered to be a soft computing method as it deals with a non-exact system model and it relies on achieving the best control action that investigate the best performance, so choosing the appropriate MPPT algorithm is an important factor for system performance enhancement [

28].

Fuzzy logic control (FLC) is a soft computing technique and mathematical based system that converts and analyzes analog data in terms of logical variables by assigning a specific output according to the state of the input, so it can deal with complex nonlinear control situations. FLC is easier, cheaper, and more robust than a PID controller in that it can cover a wide range of operation points for a dynamic system. Tan Luong Van et al. presented an FLC Sugeno-type application to improve the wind energy captured by a 2-MW wind turbine at rated wind speed for a variable speed variable pitch (VSVP) WT [

29]. The controller is implemented by taking the generator output power and generator speed instead of wind speed as inputs to the controller, while the output is the reference pitch angle β

ref. In the partial-load region,

Pref is determined by the MPPT control strategy, while in the full-load region,

Pref is set to

Prated, the FLC finds β

ref by determining inputs, setting up rules, and converts the results into output signals. Experiments and simulation showed that FLC gives 5.097%, 2.043%, and 3.065% higher output power than that of PI controllers with and without gain scheduling, and PID controllers, respectively, and also could maintain output power and speed at high wind speeds.

FLC showed an improved performance also for small WTs, M.A.M. Prats et al. presented a computational fuzzy pitch controller model for 600 kW VSVP wind turbines to improve the captured energy at low, rated, and high wind speeds and compared its performance to the PI linear controller [

30]. The simulation results at rated wind speed showed a 1.9% increase in energy capture with the fuzzy controller compared to the PI controller and better speed and blade pitch control was observed compared to the conventional linear controller. These results declare an improved transition between power limitation in the full-load region and power optimization in the partial-load region. F. Scherillo et al. also designed a fuzzy logic-based pitch control for a 60 kW mini wind turbine and investigated its performance for different turbulence and wind intensities [

31]. The simulation showed good results in terms of rotor speed and power production variability compared to the PID controller based on the Ziegler–Nichols rule.

For FLC optimization, Zafer Civelek proposed an advanced intelligent genetic algorithm (AIGA) with new features that enhance the algorithm’s performance such as the addition of an acceptable error concept (AEC) [

32]. In order to adjust the coefficient of normalization, denormalization, and FLC values, the conversion from decimal to binary and from binary to decimal is determined based on this acceptable error. For better performance, the selection of crossover which enables the production of new individuals from two individuals with high fitness values and also affects the time that the GA reaches the goal was 90%. Benchmark functions are used for performance analysis and comparison between GA, IGA, and AIGA and the results showed that AIGA reaches the desired results in iterations equal to 75 while the GA and IGA iterations number is 1000, and also reaches 1000 optimum results for all of the test functions, which will helps to increase the WT’s output power stability.

FLC can provide an alternative approach to tune and adjust PID controller parameters by utilizing a set of if–then rules to overcome the problem of PI/PID controller and handle the dynamically changing operating points of the WT system and also increase the power system stability of the WT. Minh Quan Duong et al. have presented a hybrid controller of PI and FLC techniques in order to smooth wind power fluctuations and drop output power at high wind speeds [

33]. The conventional PI controller’s purpose was to linearize the model by regulating the output according to a relative error between mechanical power (

Pmech) and nominal power (

Pnom), where the ε = (

Pmech −

Pnom)/

Pnom and its parameter gain are chosen based on Ziegler–Nicholas equations. In order to improve the generator’s disturbance and damping characteristics, a fuzzy logic technique was proposed. The power error was represented by three linguistic variables, negative (N), zero (Z), and positive (P), and for the output, nine memberships were used. After the fuzzy sets are defined, the control strategy is defined by a set of if–then rules. The simulation results showed an improvement in power quality rather than using a PI controller only.

Lin Pan and Xudong Wang also proposed a repetitive control combined with a Takagi–Sugeno fuzzy PID pitch controller in order to stabilize the output power [

34]. However, in [

35] a comparison between three control schemes for the WT pitch control system was proposed, which are PID, fuzzy, and fuzzy–PID regarding generator power, torsional torque, and generator speed in the above-rated wind speed region. The PID controller had a higher deviation in the three comparison aspects, while fuzzy and fuzzy–PID showed remarkable power fluctuation reduction and also a reduction in torsional torque. However, fuzzy–PID gave the best results in improving the system’s performance.

Asif Rashid and Deng Ying developed logical fuzzy control inference (FCI) which is a non-linear method that uses if–then fuzzy rules set along with “OR” or “AND” connectors [

36]. This control model automatically adjusts the β angle to measure rotor speed so as to increase power production. So, by applying the FCI control method based on Mamdani rules with a PI(D) controller which controls the variation in rotor speed by correcting the error between the output and the desired input, a promising result of maximizing captured power and economically efficient energy performance have been achieved.

In [

37], a novel approach for pitch control based on an adaptive neuro-fuzzy inference system for obtaining effective wind velocity with no need for a sensor and sliding mode observer to estimate the aerodynamic torque was proposed. This approach aimed to control output power and rotor speed optimally in the over-rate wind speed region which increases the life of the WT. Simulations for fore–aft tip displacement showed a decrease in its STD value by 50%.

Since modern WT control systems depend mainly on their actuators, there are some constraints that should be considered like actuator limitations, system constraints due to system non-linearities, and the intermittency of integrating wind power into the electric grid. It is important to recognize that both the generator torque and the blade pitch angle have limitations in absolute values and change rates, but the limitation of blade pitch actuators is the more critical one of these. The prediction control technique can analyze current and historical data to make a prediction about the future output knowing the system’s input and constraints. Several forecasting techniques considering different time scales were reviewed and discussed in [

38] showing the major challenges associated with wind power prediction and the different mechanisms to determine the best available. Since wind turbine operation has a periodic nature, the direct inclusion of the constraints in the control algorithm for individual pitch control shows a non-continuity optimization problem, so Vlaho Petrovic et al. proposed a constraints inclusion method by transforming wind turbine constraints into a d-q coordinate system to ensure the continuity of the constraints in the system model [

39].

Ahmed Lasheen and Abdel Latif Elshafei designed a model predictive control (MPC) algorithm that depends on the system model for predicting the future output over a selected horizon. The MPC algorithm was designed based on a Takagi-Sugeno fuzzy model for its ability to control multivariable systems subjected to constraints [

40]. Linearized models have been produced by the open-source software FAST at determined operating points depending on wind speed variation, each produced model represents a fuzzy rule, so in order to reduce the number of fuzzy rules to ease calculations, the gap metric concept was applied resulting in a total of six linearized models at wind speed range from 12 to 22 m/s with 2 m/s step. A fuzzy MPC algorithm was also used in [

41] to reduce the blades’ flip-wise deflections and regulate the output power of the WT in region 3, considering the generator fluctuations. Compared to the gain scheduled PI (GSPI) baseline controller, FMPC showed better performance regarding less settling time and overshoot, less computational time, and mechanical load reduction. The overall fuzzy model, after blending all rules, is a time-varying linear model that can predict the future output and states by applying MPC to it.

Another prediction algorithm is the feedforward technique which considers solutions for improving the situation in the future rather than considering positive or negative feedback. P. Venkaiah and Bikash K. Sarkar proposed a fuzzy feedforward PID pitch controller developed through an electrohydraulic pitch actuation system which has merits of high power-to-weight ratio, self-lubricating, etc. [

42]. The feedforward technique estimates the output of the WT system from the PID control algorithm, which minimizes the error between the desired and current state of the system without waiting for the PID response.

In [

43], a hybrid artificial intelligence and advanced control technique for the VSWT pitch control system is introduced. Wind speed prediction based on support vector regression (SVR) was developed and the predicted wind speed is used as an input for a novel feedforward mechanism designed to develop a non-linear relationship between pitch angle and wind speed. Also, they implemented an uncertainty and disturbance estimator (UDE) based feedback controller to build an external disturbance model to deal with it and provide system stability.

Mohamed Abdelkarim et al. proposed a partial offline quasi-min-max fuzzy model-predictive pitch controller considering WT nonlinearities, unstructured model dynamics, pitch angle constraints, and wind speed variations [

44]. Fuzzy modeling combined with the MPC algorithm together can achieve optimal system operation by taking into account the pitch angle constraints and WT non-linearities. The quasi-min-max technique incorporated with the fuzzy model guarantees the system’s closed-loop stability by transforming the stability and pitch angle constraints into linear matrix inequality (LMI) problems as it is the optimal tool to solve multi-constrained system problems. In partial offline strategy, offline design is followed by online synthesis, in the offline design, sets of data including pitch angle constraints are computed and the online synthesis includes a simplified optimization problem solved to ensure the stability of the WT closed loop system. Controller validation using FAST simulator showed the effectiveness of the proposed controller over the conventional scheduled PI controller in terms of electrical power, generator speed, and mechanical load reduction, and also reduces the computational burden problem through the partial offline strategy.

H.M. Hassan et al. also proposed an LMI technique to design a robust collective pitch controller (CPC) for large WTs [

45]. Due to the uncertainties of the WT model, the controller design constraints have included the H∞ problem for better speed regulation, the H

2 problem for optimizing control action with performance, H

∞/H

2 trade-off criteria to overcome these problems, and also pole clustering to improve transient response by specifying regions representing system’s eigenvalue limits. The CPC controller was first designed based on a single operating point model but it showed drawbacks because it did not meet the designed constraints at all operating points, so a poly-topic model has been considered to overcome these drawbacks by selecting different operating points (six wind speeds). The CPC has been integrated with IPC to cancel the mechanical loads. A performance comparison between the proposed controller and classical collective pitch controller has shown six-fold improvement in speed regulation and a four-fold reduction in fatigue loads but it exerts control effort slightly more than the PI controller, within the permissible limits, which is necessary for mitigating fatigue loads.

Reducing the loading effect on WTs while achieving maximal power output at the same time is an important objective in order to increase the lifetime of the equipment and extract the maximum power. Atif Iqbal et al. designed a fuzzy-based model predictive controller to control pitch angle in region 3 to minimize the load effect and maximize the extracted power [

46]. The fuzzy model is designed based on Mamdani’s method by using 49 rules. The MPC has mainly 2 inputs which are rotor speed and output power, while the output variable is feeding to the actuator. The MPC uses output power to predict the system’s behavior. From the simulation and by comparing the proposed method and the conventional PI controller, the proposed controller could reduce the rotor speed and so the mechanical torque as well as extracting maximal power. In comparison to conventional linear controllers, fuzzy controllers provide nonlinear control actions, rely less heavily on mathematical models, and are also better able to reject noise, disturbances, and parameter variations.

Also, for load reduction, Sungsu Park and Yoonsu Nam proposed a separate set of individual and collective pitch control algorithms using a linear–quadratic regulator (LQR) with augmented rotor speed integration (LQRI) to cancel the steady-state error, and the Kalman filter was also designed in order to estimate system states and wind speeds [

47]. Although the centralized pitch controller has the advantage of handling multi-control objectives, separate individual and collective pitch controllers are better for controlling rotor speed and bending moments on the blade since the individual pitch controller is considered as secondary controller that acts as on-off mechanism. The proposed pitch controller consists of three control loops: generation torque control, which is kept constant at above-rated speed; collective pitch control that controls rotor speed and improves trade-offs between rotor speed regulation and load reduction; and an individual pitch controller, which is designed as an additional loop around the system to reduce the fluctuating loads on the blades. The simulation showed very good rotor speed regulation and a noticeable reduction in blade bending moments.

Due to the drawbacks of a non-linear MPC (NMPC) based on a conventional structure, which includes complicated implementation and a heavy computational burden, Dongran Song et al. proposed a novel NMPC that uses a discrete prediction model with large time steps, which reduces the number of time discrete points so the solution set becomes numerable and implementation complexity and computational burden are decreased [

48]. An iterative algorithm is performed after solution sets are defined from the previewed wind speeds to search the optimal sequence of generator torque and set the first element of it as a controller output. Simulation has been conducted on two models of WT, 1.5 MW and 5 MW wind turbines, and compared with the base controller. The results showed that the proposed NMPC increased the energy extraction efficiency by about 1% for the 1.5 MW WT and 1.28–1.95% for the 5 MW WT.

Controlling each blade’s angle individually is a challenge in variable speed variable pitch wind turbines at the full region, so Mahmood Mirzaei et al. proposed a linear MPC that takes the future values of wind speed measured by LIDAR as a scheduling variable [

49]. In order to avoid the complex optimization problem of an MPC, the system has been linearized around an equilibrium point. Two controllers are implemented, the first is a collective pitch controller and the second is an individual pitch controller, which reduces fatigue loads on the blades by adjusting the pitch angle. For the LIDAR uncertainty, the extended Kalman filter algorithm has been used to estimate the effective wind speed on the rotor and then compare it against the filtered information that comes from the LIDAR.

Since the linear model at a specific operating point is not suitable for representing a non-linear WT model leading to plant–model mismatch producing a reference tracking error, which results in errors between the predicted and measured output is a problem that faces predictive controllers. D. Q. Dang et al. proposed an offset predictive controller (OF-PC) for speed control of VSWTs to obtain the zero-offset predictive result by estimating the mismatch between measured and predicted outputs so as to guarantee maximum power [

50]. The generator torque can be considered as a control input in order to regulate generator speed to track the optimal speed trajectory, while the rotor speed is the state variable. From simulation and comparison between the proposed and conventional PC controller, in a 240 s simulation, OF-PC showed the highest efficiency of 99.50% with respect to ideal optimal power and also maintained the tip speed ratio at its optimal value which is seven.

Finite control set model predictive control (FCS-MPC) is a discrete model used to predict system behavior for every admissible control set and the one that minimizes the predefined function is finally selected. Dongran Song et al. developed an MPC method by using a finite control set for pitch angle control [

51], the wind turbine’s nonlinear model was linearized by a non-standard extended Kalman filter then a discrete-time linear model of the system is used to predict the future value of the state variable for possible control sets. Two quality functions (QF) have been defined to represent the control system’s multi-objectives by making variables follow a reference. The results showed faster action of the pitch actuator and optimal tracking for rotor speed under MPC than under a conventional control system.

Demanded power point tracking (DPPT) control algorithms are integrated into conventional generator torque and blade pitch controllers with a mode switch by Kwansu Kim et al. [

52]. Both algorithms use power demanded from higher-level wind farm controllers as reference power to track it. The first algorithm is torque-based control represented as KNU1, it uses two modes switches, one is to turn on DPPT by torque control only when the power demand is lower than the available/measured power and the generator speed is lower than the rated speed. The other mode switch is to turn on the collective pitch controller when the power demand is lower than that measured but the generator speed is higher than the rated speed. The second algorithm is pitch-based control represented by a KNU2 and it uses only one mode switch which turns on and off both DPPT control and collective pitch control at the same time in the cases of region 3 winds. Simulation tests showed that KNU1 has faster control ability but keeps a high tip speed ratio (TSR), which increases the torque coefficient that may increase the wake effect, while KNU2 showed advantages with respect to load.

Another technique that is used today in electric drive system speed control is sliding mode control (SMC), which can provide a fast dynamic response and the ability to deal with the system’s external disturbances and parameter variation while reducing mechanical and drive train loads. The SMC technique switches the desired control action smoothly to attain the preferable performance regarding the system’s parameters and signals. A sliding surface is created to switch the signal smoothly within its limits hence decrease the chattering signals resulting in better system performance [

53]. L. Colombo et al. proposed an SMC to regulate rotor speed to its rated speed which corresponds to the rated aerodynamic power of the WT by tracking the rated power [

54]. The designed controller considers several uncertainties in the WT model and is based on a unique pitch controller. For controlling speed in region 3, the pitch angle is used as a control input so that the output speed follows the desired speed by considering a pre-defined table containing the aerodynamic power-rated values and the corresponding rated angular speeds. In order to evaluate the proposed controller’s performance, a comparison was made between it and PI control. The absolute tracking error value with respect to rated power has been computed for both controllers and the proposed controller has shown an 11% improvement in reducing the error.

Mehrnoosh and Mohammad Hossein also presented SMC for pitch angle using the PSO-SVM method to calculate its coefficients [

55]. However, in [

56], a hybrid control algorithm of sliding mode and PI controllers along with an observer which reduces the change in power coefficient parameter errors was proposed. This hybrid algorithm could remove wind speed controller parameters from the designed control algorithm so that the uncertainties and disturbances caused by wind speed change are eliminated. They also discussed the robustness of the proposed algorithm regarding the uncertainties of the WT structure. The simulations declared that the proposed controller algorithm’s root mean square (RMS) error has been improved by 65% compared to the sliding mode control algorithm alone proposed in [

55].

Increasing WT size causes interaction between the tower and drive train aerodynamics which results in introducing right half-plane zeros (RHPZ) in the dynamics that link blade pitch angle and generator speed, limiting the control system’s ability to regulate the generator speed through pitch control. So, William E. Leithead and Sergio Dominguez proposed a coordinated controller design (CCD) to overcome this limitation [

57]. The controller structure considers one aspect which is the accommodation of aerodynamic non-linearity. The CCD is based on parallel path modification, using both generator and blade pitch, which enables RHPZ to be counteracted and decouple the tower fatigue loads from the generator speed control. In addition, a PI controller is combined in order to achieve the same bandwidth as the conventional controller and make it easily tuned for different WT systems.

Due to WT system uncertainties that cannot be avoided in the mathematical model, the WT’s behavior cannot be exactly presented, meanwhile the pitch control system requires accurate information about the system’s mathematical model or complex equations analysis. Artificial intelligence (AI) control can be a solution for such a problem as it only needs a system’s input and output data without the need for a dynamic model, it only depends on artificial networks which are the computing systems that use the obtained dataset to calculate the considered output. As mentioned before, a PI/PID controller’s gains are difficult to tune precisely in such a complex system like a WT system, so combining artificial intelligence algorithms with a PI/PID controller in order to adjust the controller’s parameters has been proposed in [

58,

59,

60]. Jing Du and Bo Wang implemented a back-propagation neural network (BP-NN) PI controller in order to adjust PI controller parameters through self-learning by the network system [

58]. Each neuron in BP neural network has a weight that is adjusted online by taking rated speed, measured speed, and speed difference as inputs to the network system. Simulation analysis using Simpack software was manipulated to compare between PI control with gain-scheduling and a BP neural network PI strategy which showed its improved control effects on maintaining the stability of output power at rated wind speeds since the standard deviation of PI with gain-scheduling was 2.207 while that of a BP neural network PI control was 1.92.

Iman Poultangari et al. also proposed the radial basis function (RBF) neural network to obtain optimal PI gains to construct a CPC [

59]. The RBF neural network must be trained with an optimal training dataset to give optimal PI gains. The PSO algorithm was used to obtain the optimal dataset by using some constant speeds above-rated speed to obtain an optimal pair of PI gains for each wind speed value. The constant wind speeds are used as inputs and their corresponding optimal gains as outputs for training the RBF neural network. The proposed method does not need knowledge about the non-linearities and uncertainties of the system. The results showed a favorable performance for the proposed method rather than the conventional PI controller in terms of keeping both generator speed and torque within their rated value with fewer variations and also less usage of pitch actuation.

Wei Jie et al. developed a predictive model for the important parameter variables to control a WT based on analyzing input and output data of wind farms [

61]. The model is based on using an extreme learning machine (ELM) algorithm to target the output which reduces the information loss in the transmission process and uses it as reference data for pitch control, which is based on the RBF, while deep LEM (DLEM) has been used to simplify the higher order non-linear mode. The simulation showed a reduction in model computational complexity and computing resource consumption.

Yarong Zou et al. proposed the linear active disturbance rejection control (LADRC)-PI optimization algorithm based on the extremum seeking (ES) algorithm in order to improve disturbance rejection and track the optimal and extreme value working state [

62]. The LADRC control design was first evaluated for three different WTs, 50 kW, 275 kW, and 1.5 MW, and they all gave a consistent response. Compared to the traditional PI and PID controllers, the proposed LADRC-ES algorithm showed better setpoint tracking performance and the rise time was reduced to half.

Also, Chengzhen Jia et al. proposed an intelligent adaptive pitch control approach combining feedforward RBF-NN and a finite impulse response (FIR) filter based on LiDAR measurements and LADRC controller variable bandwidth to reduce disturbances and mechanical load, and hence result in system performance enhancement [

63]. The hybrid control algorithm can adaptively adjust the control coefficients according to wind speed fluctuations measured 50 m in front of the WT’s blade by a LiDAR sensor. Simulation results showed a remarkable reduction in generator speed fluctuations by 40.8% and blade root load moment by 13.1% compared to a PI controller.

Peng Chen et al. proposed an adaptive dynamic program (ADP) based on reinforcement learning using the system’s data [

64]. The ADP can guarantee rotor speed stability around the rated value by controlling/changing pitch angle in the full-load area to indirectly improve the efficiency of wind energy and achieve real-time online learning. The variation in pitch angle to reduce the consumed energy of the pitch actuator is relatively gradual. The controller is based on the Markov decision process (MDP) framework. The simulation results showed better performance than other traditional controllers but it also has some problems which need to be solved by improving the training of neural networks to increase the success rate and speed up learning.

Ahmet Serdar Yilmaz and Zafer Özer have proposed two types of neural networks as pitch angle controllers, multi perceptron with backpropagation (MLP) and RBF [

65]. The RBF algorithm was used as a second/alternative controller to MLP. Both neural networks were trained online at variable speeds in a short period of time. MLP-NN has two inputs and one output with five neurons in the hidden layer while RBF-NN has three inputs and one output with 10 neurons in the hidden layer. Both of them have a non-linear activation function in the hidden layer and a linear activation function in the output layer. From the simulation, the RBF-based controller gave better results as it has a smaller settling time.

Different control algorithms were used for the WT pitch control system, considering the system’s nonlinearity. Classical control systems showed simplicity and adaptive response for pitch control, but they showed difficulty in measuring the wind speed precisely while modern and soft computing control techniques showed rapid response and ability to solve the system’s nonlinearity and complexity but also needed rules updating with the change in the system’s parameters variations. Artificial intelligence algorithms have the ability to automatically train and update their variables so they showed a smooth transition between the operating regions, which decreases pitch actuation usage.

3. Torque Control Technique

At the below-rated wind speed region, the objective is to optimize the maximum output power at this low wind speed by controlling the generator’s synchronous speed. Here the control deals with the WT’s electrical subsystem or, one might say, the electronic converter connected to the generator. This operation considers maximizing aerodynamic efficiency by changing the generator’s electrical torque to achieve the optimum tip speed ratio (defined as a function of rotor radius and rotor and wind speeds) between the rotor and wind speeds to achieve the maximum aerodynamic power coefficient while keeping the pitch angle fixed. The change in electrical/generator torque (

Tg) against mechanical torque I produces acceleration torque, making the rotor speed follow the wind speed changes and keep the tip speed ratio at its optimum value [

18].

The torque control system, shown in

Figure 5, is associated with rotor speed control either in the below-rated wind speed region by increasing the generator synchronous speed while keeping the pitch angle constant or the above-rated wind speed region by maintaining the generator torque at its rated value while varying the pitch control and this can be called multivariable control that aims to continuously regulate the rotor speed along with the electrical power in order to avoid the drawbacks of using the pitch angle as the only control input signal while keeping the generator torque at its rated value [

66]. In the previous section, various pitch control techniques were reviewed, so in this section, some of the torque control techniques are presented.

Adel Merabet et al. proposed a multivariable control strategy that operates in both below- and above-rated wind speeds. Regarding the torque control, it was designed based on the zero speed-tracking error technique in order to follow wind speed trajectory, which is represented by a WT’s rotational speed reference that was carried out from a wind speed measurement, allowing the turbine to operate at the optimum tip speed ratio and, as a result, achieve maximum power extraction in the below-rated wind speed region while keeping pitch angle constant [

67]. Turbine torque was considered to be an unknown, and it was estimated by a torque estimator to guarantee the control’s robustness, then PI torque control was designed to control the d-q components of generator current and so control its speed. Simulation results showed the robustness of the proposed multivariable control strategy and that it overcame the drawbacks of using the pitch angle only as a control input.

Boubekeur and Houria proposed a nonlinear dynamic feedback torque control approach considering no wind speed measurement aims to maximize the power extracted from the wind in the below-rated wind speed region and reducing the mechanical loads [

68]. Simulation results showed a 10% improvement in WT efficiency using the dynamic state feedback with estimator compared to an indirect speed controller, and a reduction of 1.18 kNm of the low-speed shaft torsional torque standard deviation. They also proposed the combined control strategy’s principle between the fast nonlinear dynamic state feedback torque control strategy, but without considering WT dynamics, and a slow linear PID pitch controller in order to minimize the actuator control loads [

69]. Simulation using FAST showed that the nonlinearity in torque control alone could realize improved electric power regulation, the standard deviation of the electric power was 1 kW while it was 45 kW for PID torque control, but it could not maintain the rotor speed at its nominal value so the slow PID pitch angle controller was incorporated to regulate the rotor speed. Compared to a monovariable controller, the proposed strategy showed great performance in regulating rotor speed fluctuations and electrical power regulation.

Direct torque control (DTC) is a technique based on controlling generator torque and flux directly by selecting a voltage vector and there are three modes of operation which are sub, super, and synchronous generator speed. The synchronous speed mode particularly was adopted in a few studies [

70,

71] while the three modes have been considered separately in [

72,

73]. Zhe Zhang et al. proposed a sensorless MPPT space vector modulation-based direct torque control (SVM-DTC) with a quasi-sliding-mode-observer (QSMO) operated with low sampling frequency to estimate rotor position and flux linkage of the permanent magnet synchronous generator (PMSG) since the accuracy of such control depends strongly on the exact rotor speed information [

70]. Optimal torque that relies on optimal shaft speed is then obtained for DTC and so MPPT control is achieved without measuring wind speed. In [

71], the DTC technique was also proposed to optimize captured wind energy to extract maximum power using the MPPT algorithm by operating particularly on synchronous mode, while in [

72] the wind randomness was considered by operating in the three modes of operation, sub, super, and synchronous speed, separately and the results showed the effectiveness of the control in the three operation modes.

Huo Dongdong applied DTC based on two methods for controlling WT generator torque, which are SVM and matrix converter methods and compared them with respect to different criteria like complexity, dynamic response, and switching frequency [

74]. The simulation showed the superiority of SVM, especially in switching frequency and reducing torque ripples. For power performance enhancement, Eial Awwad proposed a 12-section polygonal DTC of 30° and compared it to the conventional 60° 6-section DTC for a PMSG machine side converter and grid side converter to solve the drawbacks of conventional DTC such as inaccurate switching frequency and high torque ripples [

75]. The simulation showed satisfactory dynamic performance with torque and flux ripple reduction resulting in enhanced output characteristics.

Optimal torque control (OTC) is a control method that allows the generator to operate at the optimal speed so that the MPPT strategy can be applied to track the maximum power production regarding delivering only active power into the grid [

76]. K. Palanimuthu compared the performance of PMSGs and permanent magnet vernier generators (PMVG) in wind turbine systems using MPPT control [

77]. Both traditional and improved OTCs were employed to analyze and validate both generators’ dynamic performance under various wind conditions.

Robust adaptive control was proposed by Srikanth Bashetty et al. for torque and pitch control in order to maximize the power extraction at different wind speeds operating regions by maintaining the rotor angular speed at its optimum value through switching between torque and pitch control depending on the wind speed [

78]. The inputs of the system’s transfer function are the thrust force on the rotor blades applied by the wind, aerodynamic torque exerted on WT’s rotor (whose coefficients are a function of pitch angle), and electrical torque applied by the generator. The reference model has the nominal rotor speed as the input reference and angular speed as the output from the model and an input for the controller so that the controller can track the optimal angular speed by varying the generator torque according to the error value between them. The simulation results verified that the rotor speed was maintained to track to the optimal speed value at all regions, which means this adaptive controller can be applied for any uncertainties giving efficient rotor angular speed tracking performance.

Btissam Majout proposed a novel smooth continuous switching control for SMC in order to solve the problem of the chattering phenomenon that causes extreme fluctuations for the WECS [

79]. The proposed approach was compared to the conventional SMC by simulation under random wind speed fluctuations and the results showed the effectiveness and robustness of the proposed algorithm regarding the system’s stability and output current ripple control. In [

80,

81] an integral SMC (ISMC) was proposed which has the benefits of providing robust performance regardless of the system’s uncertainty and adapts the power supply dependently during critical partial load. The simulations declared the robustness of the proposed ISMC according to better energy extraction and dynamic response as it has the ability of fast error convergence.

M. Abdelrahem et al. proposed a predictive torque control with no weighting factor based on calculating the d-axis reference current directly from the reference torque, obtaining the q-axis current to be the second controller variable to regulate the power change between the DFIG stator and the grid. The voltage vector reference is then computed based on those current references [

82]. According to the location of the reference voltage vector, the cost function is evaluated to achieve the best switching action and then the new cost function is presented by voltage error so no weighting factor is needed, hence the computational load is significantly reduced compared to classical predictive control.

Another approach for controlling rotor speed to maximize the captured wind energy at different wind speed operating regions is by employing wind speed estimation. Wind speed information could be provided by using sensors like LiDAR [

49,

73]. Fanzhong Meng et al. proposed an ES control algorithm based on LiDAR information to track the optimal power coefficient value, hence increasing and optimizing power production [

83]. However, wind speed measuring using a wind sensor such as LiDAR or mostly using a mechanical anemometer greatly increases the system’s cost regarding installation and maintenance costs and reduce the system’s performance. So, replacing the wind speed instrument with an effective wind estimator based on a soft computing technique would provide sufficient wind information needed for the controller algorithm and also solve the cost and system performance problem [

84].

Various soft computing techniques have been used for wind speed estimation such as the fuzzy logic model in [

85] used for estimating the wind speed based on fuzzy rules deduced from the WT’s typical power curve, which represents the behavior of the relationship between the extracted power, rotor speed, and wind speed. An artificial neural network model like in [

86], an estimation algorithm based on unknown input disturbance and extreme learning machine (UIDOB-ELM) is presented, as is a support vector machine in [

87,

88], which is suitable for problems defined by a small sample, nonlinearity, local minima, and has high generalization and deep neural networks (DNNs) which showed a robustness performance in a real time domain despite the system’s uncertainties and actuator faults [

89].

FLC also showed its effectiveness in updating the weight coefficient automatically by setting heuristic rules based on training and experience regarding different wind speeds and generator torque ripples. An adaptive fuzzy PI speed controller was proposed for producing optimal power [

90,

91]. The simulations showed reduction in torque fluctuations and enhancement in power production at different wind speeds with no steady state error under disturbance. Also, as in [

48], the authors designed a basic fuzzy regulator to adjust the control NMPC weight coefficient and employed an improved multi-objective marine predator algorithm (IMMPA) to optimize fuzzy regulator membership functions for the generator’s torque fluctuation control and hence power production enhancement [

92]. The simulation showed a 1.77% increase in power production and a reduction in the generator’s toque fluctuations by 0.126% compared to the fixed weight coefficient.

Hybrid techniques such as the NF algorithm and particle swarm optimization based on support vector regression have shown high accuracy in effective wind speed estimation and WT variable adjustment [

93,

94,

95]. In [

96], a multi–adaptive neuro-fuzzy inference system (ANFIS), combining a neural network and fuzzy inference controller, was proposed in order to reduce power output and generator speed oscillations by adapting both generator torque and pitch angle simultaneously. The proposed ANFIS controller was compared to PI and MPC controllers by simulations at the same wind conditions and the results showed that the drive-train torsional torque, generator torque and output power perfectly track 1 pu without any overshoots or undershoots at the start time. Hence the WT’s power was improved, and the lifetime of the mechanical parts increased.

Amir Farrokh et al. presented a nonlinear control based on linear input–output feedback for a fed-doubly induction generator using two layers of ANN [

97]. This control technique showed perfect tracking performance for torque and rotor flux instead of rotor and stator resistance uncertainties. Also in [

98], nonlinear MLP mapping to estimate the effective wind speed was used to design an extended optimal torque controller for tracking the calculated optimal torque command, the accuracy of the proposed method was improved by 2–7% compared to an unknown input disturbance observer and the extreme learning machine (UIDOB-ELM) estimator.

Similar to a pitch control system, torque control considers the change in wind torque due to wind speed change, so that controlling the generator torque can take the WT dynamic system to the optimal operating point. Classic and modern control techniques showed low losses and high efficiency, but had poor dynamic response and difficulty in calculating the torque estimator. On the other hand, AI and soft computing techniques showed high tracking efficiency for the optimal speed value so they can transition smoothly between operating regions with no need for exact wind measurements.

4. Yaw Control Technique

Natural wind has a direction randomicity characteristic, i.e., it continuously changes direction from time to time. Nonetheless, wind turbines have been designed to most efficiently generate power when the wind is perpendicular to the rotor plane since, when the nacelle is not aligned with the wind direction, yaw misalignment occurs causing potential loss of energy, which is a function of the rotor area projection on the perpendicular plane of the wind speed [

18] so the yaw control system (YCS) is activated whenever the nacelle of the WT is not aligned with the incident wind direction. It gives a signal to the yaw mechanism, which consists of electrical motors, gears, and bearings to rotate the nacelle about the tower’s vertical axis so that the angle between the nacelle axis and the incidental wind, called the yaw angle (

ψ), is almost zero [

99], as shown in

Figure 6. So, in order to enhance the utilization of wind energy, the yaw control system is designed to ensure that the WT is constantly facing the wind incident by following the wind direction to maximize the rotor effective area and so the captured power. In addition to maximizing captured power, the yaw control system has other objectives, which are to unsnap tangled cable when necessary and avoid any oscillatory behavior or dangerous gyroscopic effect [

18].

There are two types of yaw misalignments, which are yaw motion error (YME), the deviation between the mean value of the measured yaw angle (

μ) and zero, and zero-point shifting error (ZPSE), when the zero point of wind vane sensor is not aligned with the rotor shaft due to poor installation or after long-term use [

100]. Directing the WT’s nacelle windward can be carried out by two techniques, one uses the wind force to direct the nacelle, which is called passive yaw and is mostly used for small WTs. The other is to use electric motors to adjust the nacelle windward according to automatic signals from wind direction sensors, it avoids frequent rotation and reduces mechanism wear and it is used for medium and large WTs due to larger applied torque and it is called active yaw [

101,

102].

In order to improve yaw alignment, the yaw error angle must be measured precisely, either by measurements instrument, analytic methods, or soft computing measurement, to be calibrated in order to reach the minimum yaw error. An advanced measurement instrument such as LiDAR for estimating the yaw error to be corrected was applied in [

103,

104,

105,

106]. The proposed control algorithms depend on correcting the yaw angle by analyzing empirical data and developing a correction scheme through comparison between measurements from the nacelle wind vane to that of a met-mast wind vane using LiDAR. In [

103], the updated controller aims to correct the yaw error depending on rotor speed, so the data extracted from the original and updated systems were limited to a 30–35 RPM rotor speed. The results declared that the yaw correction has an obvious effect on decreasing the mean yaw error and increasing the power captured below the rated domain by 1–5%. Similarly, a LiDAR-assisted yaw control system that measures the yaw error and builds a 3D table based on recorded power segments and yaw azimuth on SCADA was proposed in [

107]. This method could automatically correct the yaw angle error based on different power and yaw azimuth intervals.

With regard to analytical methods, Solomin et al. proposed an analytic solution for reducing periodical yawing error, called differential error of yawing, caused by deviation of the flowing wind [

108]. Experimental data for the vane’s angle fluctuation were collected to build a yaw error compensator model by using regression analysis. Several simulation experiments showed that using a compensator could reduce yaw differential error and increase power production by 3.37%. Also, Peng Guo et al. studied wind direction fluctuations in terms of fluctuation period T and amplitude A [

109]. Weibull distribution was applied to fit marginal probability density of these wind direction fluctuation measurements and a mixed copula was employed to connect these marginal distributions for extracting indicators that can accurately determine the wind direction fluctuation characteristics and hence help in the optimization of yaw control system parameters. Moreover, a combination between a feedforward neural network [

110] and K-nearest neighbor (KNN) [

111] with the Weibull distribution results in better wind measurement forecasting and accurate description of wind direction change.

Chenzhi Qu et al. proposed a data-driven calibration method to determine the value and direction of yaw misalignment by using historical data for six 2 MW WTs [

112]. The consistency of this method was verified by comparing the proposed calibration method with the same flow direction and acceptable deviation as LiDAR measurements.

Feifei Bu et al. designed a yaw control system using a digital signal processor (DSP) controller to improve wind turbine rapidity and accuracy and it was developed based on micro-stepping control to overcome problems of out-of-step and low frequency oscillations [

113]. A wind sensor was attached to a conductive plastic potentiometer, which generate resistance output voltage transformed to voltage from 0 to 3.3 V to represent angle from 0 to 360°. The wind turbine turns in the shortest path in order to reach the optimal acceptable accuracy of the system. However, great real-time performance and fast data processing and automatic wind direction tracking have been achieved.

Since the yaw system is a non-linear system that has time-varying parameters and it is too complex to be mathematically modelled, classical control techniques will not give the expected output results. From many years, a yaw classical PD controller and fuzzy self-adaptive controller were used separately to make comparisons between their performances [

114]. The comparisons showed the effectiveness of a fuzzy controller in following the wind direction changes and so improving wind energy efficacy while the PD controller parameters’ tuning as a wind condition dependent process showed less sufficient results compared to the fuzzy logic controller.

Liu Wenzhou et al. also proposed a PID controller combined with a fuzzy adaptive yaw controller and complete wind wheel position adjustment to track the wind direction. The simulation results showed the effectiveness of the fuzzy self-adaptive control to calibrate the PID gains online to give better real-time wind direction tracking [

115]. Fuzzy control has also been used as a fatigue-oriented yaw control strategy to optimize the yaw speed at each stage of yaw operation [

116]. Due to the long run operation of the yaw system, the yaw bearing is exposed to the accumulation of fatigue loads, so this proposed yaw control strategy could reduce the fatigue load on the yaw bearing in different yawing scenarios.

Stefanos Theodoropoulos et al. have developed a fuzzy controller by considering FIS based on the Takagi–Sugeno model [

117]. The inputs to the controller are yaw zero, yaw error change, and wind velocity while the output is a constant or linear signal to the motor’s driver, which then converts it into synchronized pulses for the motor. MATlab has been used to simulate the model’s output power at each specified yaw error angle and wind velocity. The simulation results declare that the advanced fuzzy controller has the ability to retain the nominal output power despite the increase of yaw error angle, taking into consideration both the direction and velocity of the wind. In ref. [

118], Ramaswamy Bharani et al. designed a simple, low cost, and accurate yaw positioning fuzzy logic controller equipped with a wind turbine sensor and an angle position sensor on the tower top in order to track the maximum wind velocity. The accuracy of the controller of ±1.5° has been validated using a real-time dataset.

Prediction of wind direction over a specific time horizon to be used as an input for a yawing control system could be the proper solution as it allows the WT to begin yawing earlier than it would, which reduces structural load mitigation as well as maximizing power production extraction efficiency. Martin Spencer et al. proposed two yaw controllers, one was created by modifying the feedback yaw controller considering wind direction prediction, and the other was based on MPC [

119]. The baseline controller was similar to that used for the Dutch offshore wind energy converter (DOWEC) 6 MW WT, which was used to determine the yawing rate of NREL 5 MW and it was modified to use the wind direction average over a future period of time instead of a past one. Online optimization was carried out by qpOASES (a general-purpose quadratic program solver) for a preview time of 60 s. Since the optimization is based on the yaw rate, the output will always be continuously varying, which will cause increases in yaw actuation, so this problem is solved by modifying the MPC controller to activate the yaw drive at discrete intervals with specific conditions and the results reveal an 8% increase in power capture during extreme direction change and 0.5% increase during turbulent wind and also several fatigue loads were reduced.

In [

120,

121], a stochastic model predictive yaw control (SMPYC) technique was presented, based on intelligent scenario generation (ISG) to generate characterized scenarios for wind direction prediction, and then the yaw action is optimized by the proposed SMPYC. Compared to the conventional MPYC, the power captured efficiency was improved by 0.26–0.43%.

In [

122], Nikola Hure et al. described the design of an optimal yaw control system based on very-short-term wind direction predictions that resulted in maximizing the power production by 0.6% and minimizing structural loads by taking actuator limits into consideration using the model predictive control paradigm discussed in [

123]. The aforementioned objectives can lead to optimal power production performance and a long lifetime to obtain maximum profit. Also, in light of period-term wind prediction, Chen et al. proposed a LiDAR-assisted long-short term-neural network (LSTM-NN) yaw control strategy to solve the accurate measurement data lag in the yaw control system [

124]. The predicted wind speed data are used to plan for the number of yaw actuations in both medium- and low-speed regions to achieve power enhancement without increasing yaw duty. The results showed an improvement in power production by 3.5% and a reduction in yaw actuations by 3.9%. Likewise, a two-level economic model predictive control (TL-EMPC) yaw strategy based on real wind measurements using LiDAR was presented [

125]. This strategy considered the power loss during the yawing process, fatigue of WT parts, and a limited load of the yaw actuator so as to obtain the best yaw speed at different wind speeds. The simulations declared a 1.8% increase in average power.

Dongran Song et al. presented two methods for wind direction prediction based on time series models, the first one used an auto-regressive integrated moving average (ARIMA) model, while the second was a hybrid ARIMA method-based Kalman filter (ARIMA-KF) [

126]. The prediction and statistical results of the ARIMA-KF model showed effectiveness in providing good forecast results compared to the ARIMA model and so it is better applicable to optimal yaw control in WTs. Then, they developed and tested a novel yaw control structure that consists of a wind direction predictive model based on a hybrid ARIMA-KF model and two novel yaw control methods aiming to decrease yaw error, yaw action time, and yaw action count [

127]. The ARIMA model was initially defined by choosing three sampling periods (10 s, 30 s, 60 s) and then letting the model start training by model identification, parameter estimation, and diagnostic checking. While the two yaw control methods included one using the predicted wind direction as the tracking reference, and the other was based on model predictive control (MPC) using a finite control set in order to decrease yaw error by tracking the predicted wind direction and avoid yaw actuator over-usage. The simulation results showed the capability of the two yaw controllers to increase the extracted wind power by reducing the yaw error and the effect of the MPC to minimize the yaw actuation.

Another prediction algorithm was presented in [

128,

129] by Dongran Song et al. It was developed by MPC using a multi-step prediction horizon and finite control set that includes the yaw actuator variables and yaw system’s hardware constraints, the optimal solution was then effectively found by using the exhaustive search (ES) method that depends on suggesting each and every variable in the control set domain, selecting the ones that satisfy the system’s constraints and then finding the optimal variable that optimizes the control objective. Three MPC controllers with one-step, three-step, and six-step prediction were developed and simulated on MATlab software and the results showed the effectiveness and superiority of the proposed multi-step prediction algorithm in tracking the wind direction. And in [

130], Dongran Song proposed a novel adaptive MPC (AMPC) for the yaw system to determine the best control horizon and yaw rate that results in the minimum value of the system’s QF. The simulation results based on real-time data showed an improvement in the predictive control-based yaw system performance with different wind direction data.

Dongran Song et al. also developed two control systems in order to optimize the power extraction efficiency (PEE) from wind. The first one is a direct measurement-based conventional logic control (control system 1), and the second is a soft measurement-based advanced model predictive control (control system 2) [

131]. The main objectives of the YCS are minimization of the power reduction factor and minimization yaw actuator usage so a multi objective pareto swarm optimization (MOPSO) algorithm is proposed to solve the two-objective issue. The results of the simulation and analysis of the two YCSs were compared to each other and they declared that at actuator usage > 4.9%, the PEE of control system 2 is higher than that of control system 1. Nevertheless, as the actuator usage decreases, the PEE of the two control systems becomes worse but that of control system 2 decreases faster.

In contrast to the yaw control techniques that consider following the direction of the wind to aim the WT’s rotor windward to maximize the power extracted, an inverse approach was adopted that calculates the maximum power point then tracks it rather than dealing with the wind direction. Felix Alberto et al. developed an active yaw control algorithm based on the hill climbing control (HCC) algorithm that takes the maximum generated power as an indication to determine maximum wind speed direction without using a vane [

102]. HCC is an artificial intelligence method used to search maximum point of function by manipulating the control variables. In this model, it takes the change in output power as a continuous reference. The simulation was carried out on Matlab considering three cases which are constant wind intensity, constant wind direction, and both variations. The motor was turned on whenever there was change in output power due to a change in wind intensity and/or direction, immediately after the motor was turned on, the generated power does not change making the motor turn off again. While Haiguo Piao and Zhixin Wang proposed a vane-hill climbing (V-HC) algorithm which is applicable for large WT systems to ease the process of wind direction tracking for the HCC algorithm [

132].

In [

133,

134,

135], MPPT control combined with a full power converter system and fast alignment of the nacelle to the wind direction was developed. This technique is based on aligning the rotor to the wind direction through estimating the error between the optimum wind turbine rotational speed, calculated from the tip speed ratio and the real wind turbine rotational speed, while it is not dependent on wind direction methods so as to decrease inaccuracies that may be caused due to vortex flow downstream of the blades.

Bo Jing et al. applied a new simulation method that simulates the output power at different yaw states and a detailed analysis of the effect of yaw misalignment on WT power generation. MPC control can be applied to calibrate yaw misalignment, specially of the ZPSE type that have a more serious impact on WT performance, so as to achieve maximum power extraction. The proposed method succeeds in detecting and calibrating ZPSE online without the need of additional detection equipment [

100]. In [

136], an identification and compensation scheme for yaw control strategy based on the SCADA system of data mining approach was proposed. The SCADA data are divided into portions in terms of yaw error and the power curve is set for each portion by an outlier detection algorithm to detect the best system performance and automatically compensate the yaw misalignment. This approach showed cost reduction compared to traditional calibration methods as there is no need for additional hardware.

Yan et al. have analyzed and optimized the yaw error through the three important links of a yaw control system, namely wind measurement, restart control strategy, and yaw execution [

137]. Based on the wind measurement study, using laser radar wind instead of mechanical crosswind instruments showed a 2.04% increase in power production and effectively reduced the yaw error. For the restart strategy, the delay threshold and yaw error angle could be adjusted by different wind speed segments and for the execution strategy, variable universe fuzzy control has been used for yaw error optimization. This optimization method showed effectiveness in improving wind turbine power generation.

Regarding WT system performance enhancement, machine learning algorithms as advanced control strategies that adjust themselves to perform way better while exposed to more data can provide additional features for wind turbine control systems and also consider the system’s constraints. Nida et al. developed SVR as a yaw error estimation approach [

138]. This method is a kind of machine learning technique that forms a number of learning methods from 2 variables which are variance and relaxation parameters (σ, c). SVR is applied to sets of data and root mean square error (RMSE) is calculated. The method with the least RMSE is conserved by saving the optimal σ and c, which are then used in SVR regression to obtain support vectors.

An advanced yaw control strategy using an artificial neural network (ANN) based reinforcement learning (RL) algorithm was designed by Aitor et al. and verified in a simulation environment to minimize the mechanical moment on yaw bearing while maximizing power gain [

139]. Such an algorithm considers self-learning during the operation in real environment conditions and multivariable states and actions in addition to the external mechanical loads. The algorithm builds matrix functions for each wind scenario, which are then analyzed with FAST to obtain multi-possible states and actions. The PSO and Pareto optimal dront (PSO-PoF) algorithm is then executed to find the optimal actions that satisfy the compromise between power gain and mechanical loads due to yaw rotation. The results have declared a reduction in mechanical moment compared to the system presented in [

140] while the value of the power gain has been kept similar.

An enhanced ANN has been implemented to generate a predicted wind direction input signal for the WT yaw control system [