A New Method for Optimizing Water-Flooding Strategies in Multi-Layer Sandstone Reservoirs

Abstract

1. Introduction

2. Establishment and Validation of the Water-Injection Optimization Method

2.1. Establishment of the Water-Injection Optimization Method

2.1.1. Two-Phase Flow Theory of Water Flooding

2.1.2. Optimized Displacement in the Entire Water-Flooding Process

2.1.3. Optimized Displacement in a Given Water-Flooding Period

2.2. Establishment of the Water-Injection Optimization Method

2.2.1. Experimental Materials and Equipment

2.2.2. Experimental Scheme

2.2.3. Experimental Procedure

- The Berea cores with different permeability levels were saturated by formation water using a vacuum pump. The pore volume and the porosity of each core were measured.

- The flooding was conducted at a flow rate of 0.5 mL/min for 2 PV, 2.0 mL/min for 5 PV, and 10.0 mL/min for 30 PV sequentially until the residual oil saturation was reached.

- The flooding was conducted at a pressure of 0.25 MPa with water injection using the traditional method. The oil–water relative permeability of cores was given according to the national standard (GB/T 28912-2012 [33]).

- The Berea cores were placed in a Soxhlet extractor to conduct oil flooding using 120# gasoline until the extract in the upper part was clear enough, and the cores were then placed in an 80 °C drying oven to be dried to a constant weight, which makes sure that all experiments were conducted under the same relative permeability curve.

- We repeated experimental steps (i) to (ii) until all Berea cores reached the residual oil saturation.

- Optimized water flooding was conducted on each core with different flow rates. The water production and the oil production were recorded during the process.

3. Results and Discussion

3.1. Analysis of Influencing Factors on the Optimized Water-Injection Rate

3.2. Influence of Reservoir and Fluid Properties

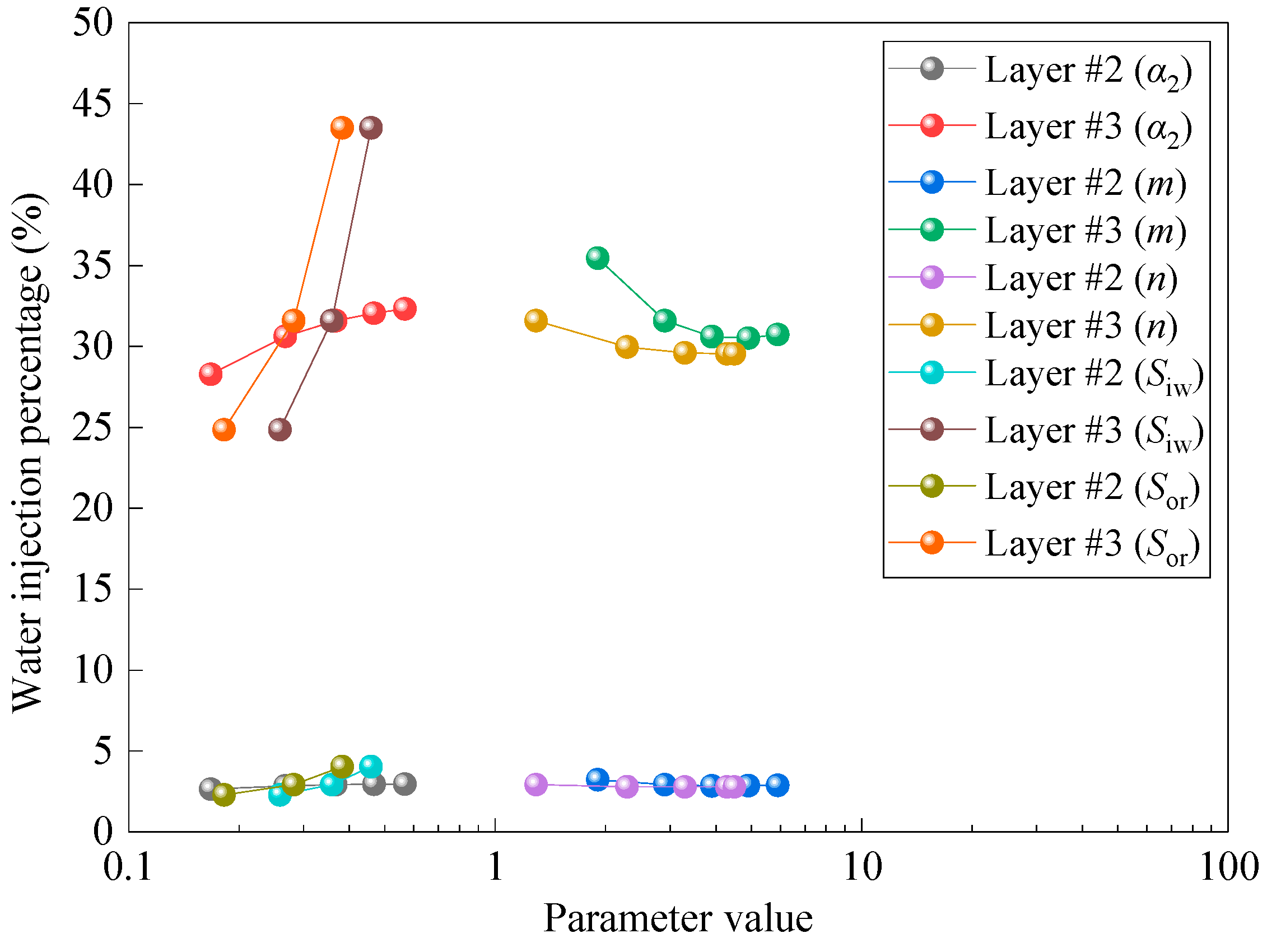

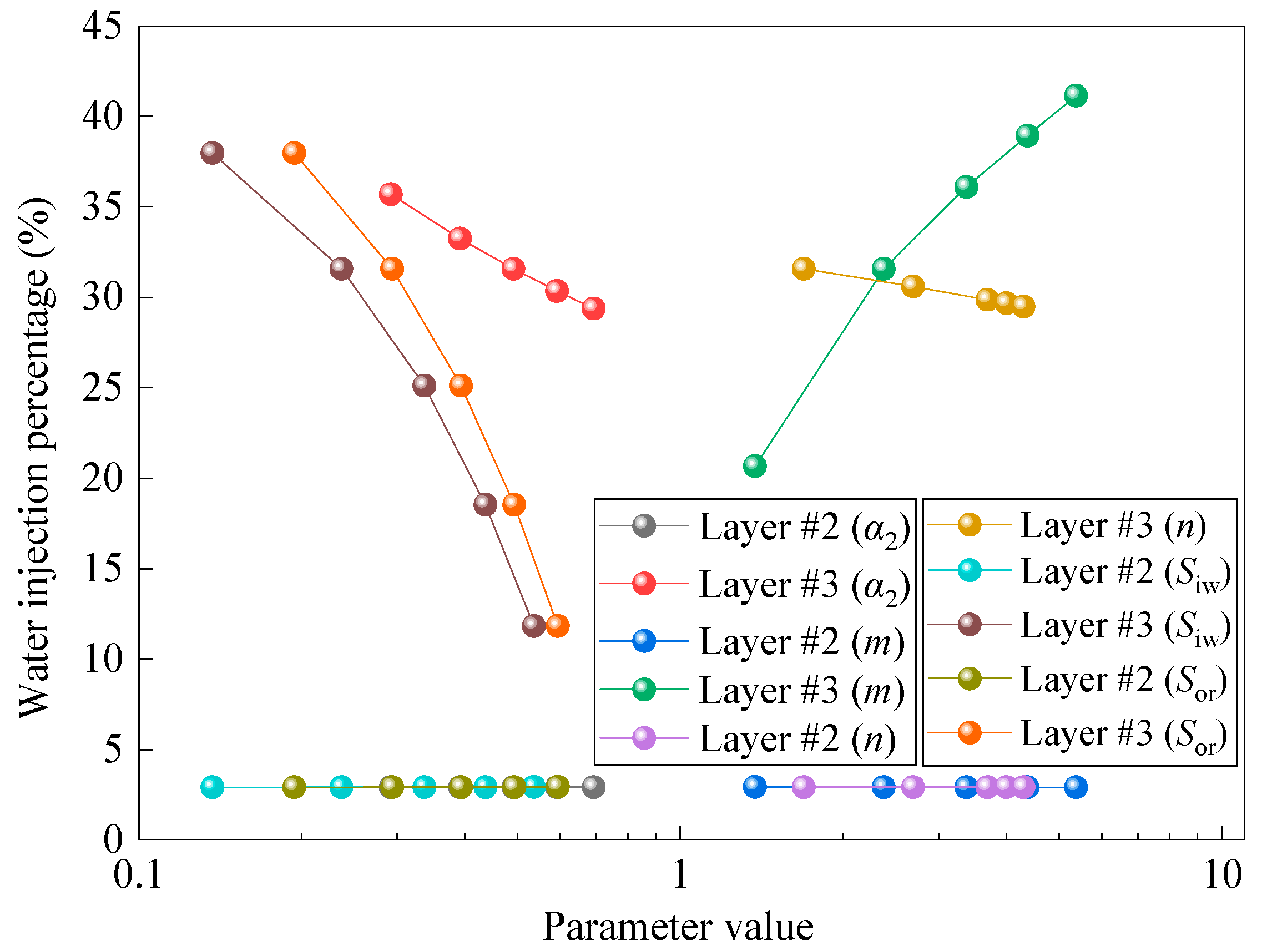

3.3. Influence of Relatively Permeability Curve

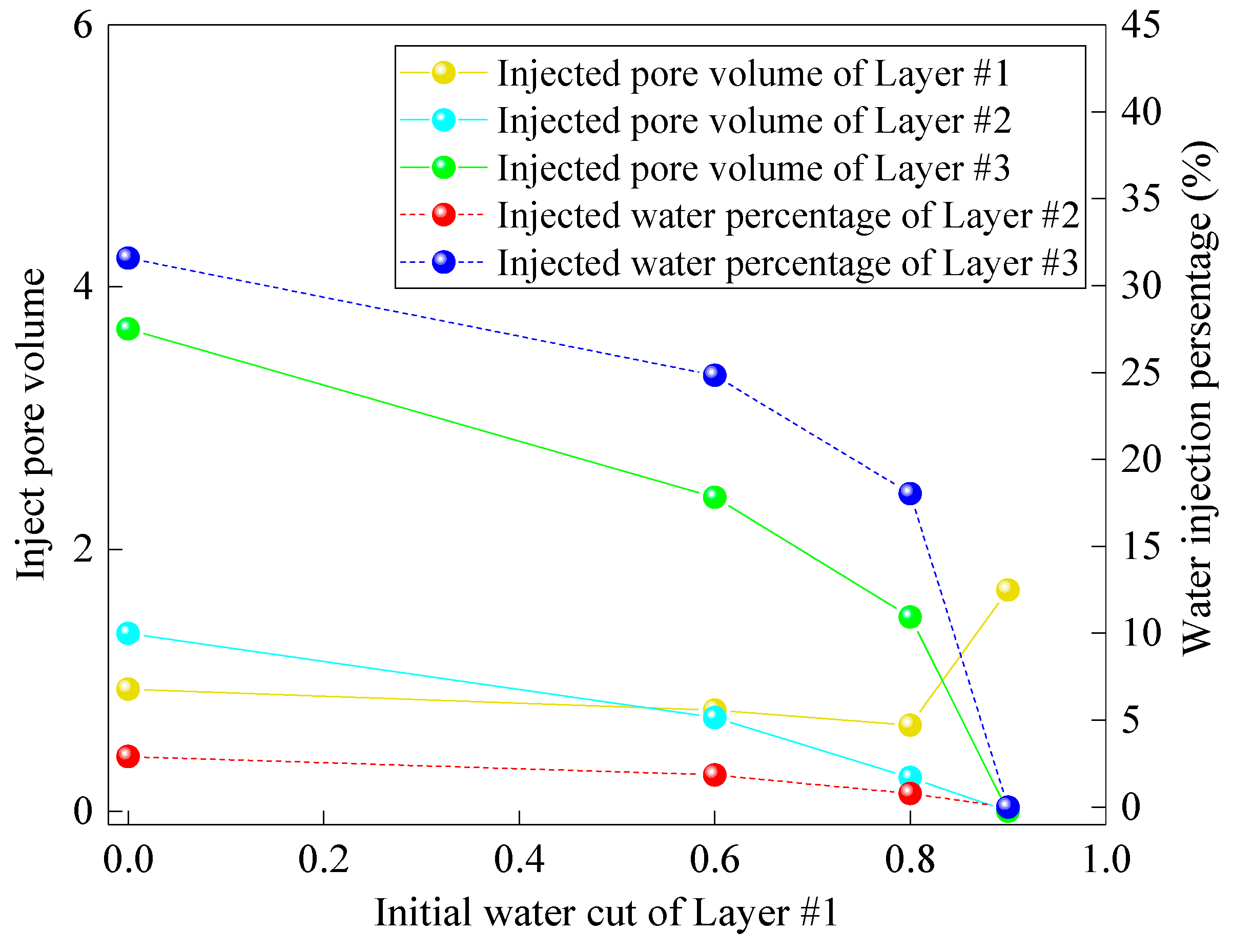

3.4. Influence of the Optimization Timing

3.5. Result Analysis of the Experimental Verification

3.5.1. Generalized Water-Flooding Experimental Results

3.5.2. Optimized Water-Flooding Experimental Results

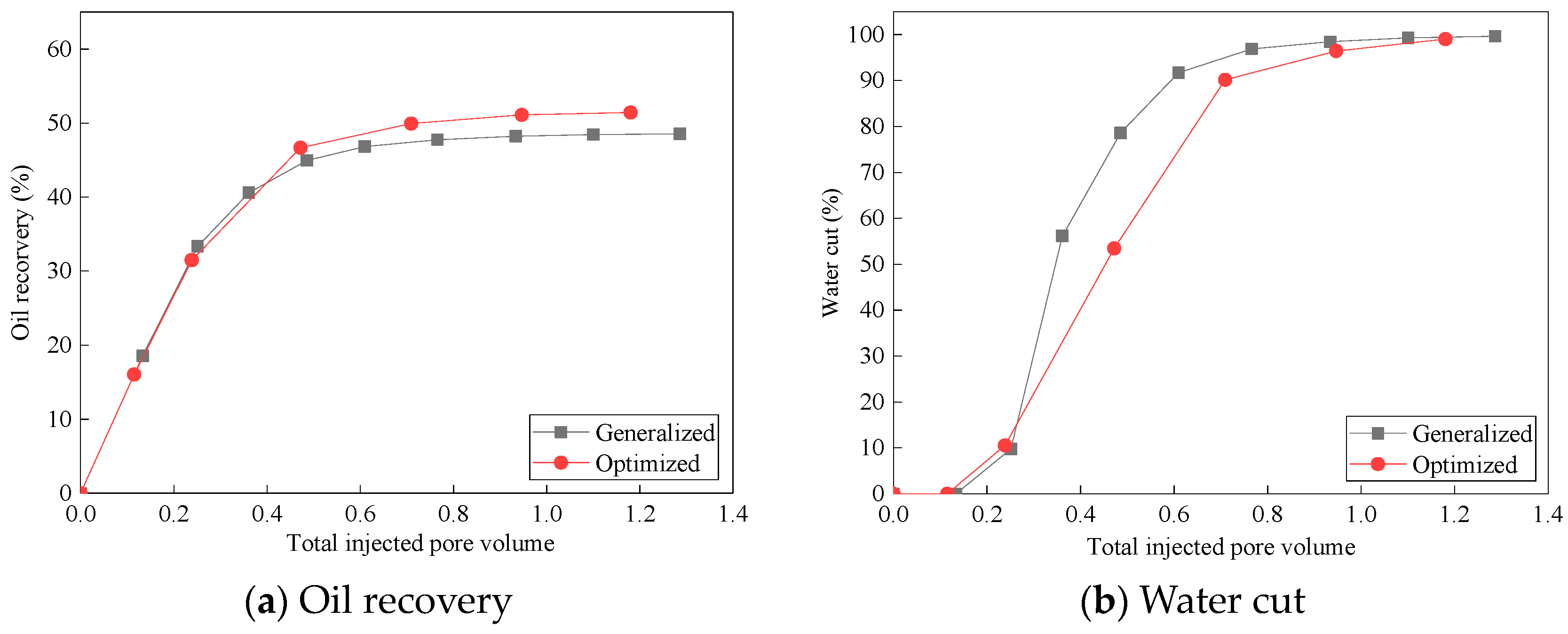

3.5.3. Comparison of the Traditional and the Optimized Results

4. Conclusions

- A new method of optimizing water flooding in multi-layer sandstone oilfields in the entire water-flooding process and in a given water-flooding period is proposed based on reservoir engineering theory and optimization technology. Optimization mathematical models for maximizing oil recovery and NPV are developed. The stratified water-injection rate for each layer could then be optimized based on the overall water-flooding performance rather than reservoir permeability and thickness.

- The new method is verified by water-flooding experiments using Berea cores. This method is also compared with the traditional method based on reservoir permeability and thickness. The total oil recovery using the new method is increased approximately by 3 percent after the injection of the same PV of water, which is consistent with the theoretical analysis.

- The results show that the overall water-flooding performance can be significantly improved by optimized water injection in a multi-layer sandstone oilfield. The geological reserves of each layer and the endpoints of the relative permeability curves have the greatest influence on the optimized water-injection rate, rather than the reservoir permeability and thickness, which are the primary considerations in traditional water-injection-rate optimization.

- The method proposed in this paper could not only be implemented in a multi-layer sandstone oilfield developing from beginning to end but also could be used in an oilfield that has been developed for years. This study also shows that the earlier the optimized water injection is conducted, the better the water-flooding performance will be.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Steven, W.P.; Marcelo, L. Practical Aspects of Waterflooding; SPE: Kuala Lumpur, Malaysia, 2023. [Google Scholar]

- Wang, Y.P.; Liu, Y.K.; Deng, Q.J. Current Status and Countermeasures of Development of Continental Sandstone Oilfields in Ultra-High Water Cut Stage in China. J. Northeast. Pet. Univ. 2014, 28, 1–9. [Google Scholar]

- Zhu, L.H.; Du, Q.L.; Jiang, X.Y.; Guo, J.H.; Wei, L.Y.; Jin, Y.X. Characteristics and Countermeasures of Three Major Conflicts during Ultra-High Water Cut Stage in Continental Multi-layer Sandstone Reservoirs. Acta Pet. Sin. 2015, 36, 210–216. [Google Scholar]

- Cui, C.Z.; Li, S.; Yang, Y.; Wang, J.; Huang, Y.S.; Wu, Z.W. Zonal Regulation Method for Reservoirs in Ultra-High Water Cut Stage. Acta Pet. Sin. 2018, 39, 1155–1161. [Google Scholar]

- Lu, F.M.; Cai, M.J.; Zhang, Y.; Xiao, X.H. Discussion on Classification Scheme and Research Method for Clastic Reservoir Architectures. Lithol. Reserv. 2020, 32, 1–11. [Google Scholar]

- Liu, H.; Pei, X.H.; Luo, K.; Sun, F.C.; Zheng, L.C.; Yang, Q.H. Current Status and Development Trend of Layered Water Injection Technology in Chinese Oil and Gas Fields. Pet. Explor. Dev. 2013, 40, 733–737. [Google Scholar] [CrossRef]

- Liu, H.; Li, Y.C.; Jia, D.L.; Wang, S.L.; Qiao, M.X.; Qu, R.Y.; Wen, P.Y.; Ren, Z.H. Current Status and Prospects of the Application of Artificial Intelligence in the Fine Adjustment of Water Injection Development Schemes. Acta Pet. Sin. 2023, 44, 1574–1586. [Google Scholar]

- Shi, W.; Ma, Y.; Tao, L.; Zhang, N.; Ma, C.; Bai, J.; Xu, Z.; Zhu, Q.; Zhong, Y. Study of the Enhanced Oil Recovery Mechanism and Remaining Oil State of Heavy Oil after Viscosity-Reducer-Assisted CO2 Foam Flooding: 2D Microvisualization Experimental Case. Energy Fuels 2023, 37, 18620–18631. [Google Scholar] [CrossRef]

- Shi, W.; Xu, L.; Tao, L.; Zhu, Q.; Bai, J. Flow behaviors and residual oil characteristics of water flooding assisted by multi-effect viscosity reducer in extra heavy oil reservoir. Pet. Sci. Technol. 2023, 41, 1231–1249. [Google Scholar] [CrossRef]

- Tao, L.; Liu, X.; Shang, H.; Zhang, N.; Shi, W.; Bai, J.; Xu, Z.; Zhu, Q.; Zhong, Y. Effects Evaluation on Multiround Injection of a N2 Foam & Viscosity Reducer to Improve the Recovery of Fault-Block Heavy Oil Reservoir with Edge-Bottom Water: A Two-Dimensional Visualization Experimental Study. Energy Fuels 2023, 37, 18785–18800. [Google Scholar]

- Zhai, X.; Wen, T.; Matringe, S. Estimation of Inter-Well Connections in Waterflood under Uncertainty for Application to Continuous Waterflood Optimization of Large Middle-Eastern Carbonate Reservoirs; SPE 182450; SPE: Kuala Lumpur, Malaysia, 2016. [Google Scholar]

- Ibrahima, F.; Maqui, A.; Negreira, A.S.; Liang, C.; Olalotiti, F.; Khebzegga, O.; Matringe, S.; Zhai, X. Reduced-Physics Modeling and Optimization of Mature Waterfloods; SPE 188313; SPE: Kuala Lumpur, Malaysia, 2017. [Google Scholar]

- Naderi, F.; Siavashi, M.; Nakhaee, A. A Novel Streamline-Based Objective Function for Well Placement Optimization in Waterfloods. ASME J. Energy Resour. Technol. 2021, 143, 102104. [Google Scholar] [CrossRef]

- Azamipour, V.; Assareh, M.; Mittermeir, G.M. An improved optimization procedure for production and injection scheduling using a hybrid genetic algorithm. Chem. Eng. Res. Des. 2018, 131, 557–570. [Google Scholar] [CrossRef]

- Azamipour, V.; Assareh, M.; Eshraghi, R. Development of an effective completion schedule for a petroleum reservoir with strong aquifer to control water production. J. Petrol. Explor. Prod. Technol. 2023, 13, 365–380. [Google Scholar] [CrossRef]

- Yousef, A.A.; Gentil, P.; Jensen, J.L.; Lake, L.W. A capacitance model to infer inter well connectivity from production and injection rate fluctuations. SPE Reserv. Eval. Eng. 2006, 9, 630–646. [Google Scholar] [CrossRef]

- Soroush, M.; Kaviani, D.; Jerry; Jensen, L. Interwell Connectivity Evaluation in Cases of Changing Skin and Frequent Production Interruptions. J. Pet. Sci. Eng. 2014, 122, 616–630. [Google Scholar]

- Yousefi, S.H.; Rashidi, F.; Sharifi, M.; Soroush, M.; Ghahfarokhi, A.J. Interwell connectivity identification in immiscible gas-oil systems using statistical method and modified capacitance-resistance model: A comparative study. J. Pet. Sci. Eng. 2020, 198, 108175. [Google Scholar] [CrossRef]

- Huang, Z.Q.; Wang, Z.X.; Hu, H.F.; Zhang, S.M.; Liang, Y.X.; Guo, Q.; Yao, J. Dynamic interwell connectivity analysis of multi-layer waterflooding reservoirs based on an improved graph neural network. Pet. Sci. 2023, in press. [CrossRef]

- Guo, J.H.; Wei, L.Y.; Sun, L.; Wang, H.T.; Dong, C.; Yin, S.M.; Yi, Z.L. Estimation of Interwell Connectivity of a Single Layer in a Stratified Reservoir Based on Physical Constraints. In Proceedings of the International Field Exploration and Development Conference 2023, Wuhan, China, 20–22 September 2023. IFEDC-202315564. [Google Scholar]

- Liu, F.L.; Mendel, J.M.; Nejad, A.M. Forecasting injector/producer relationships from production and injection rates using an extended Kalman filter. SPE J. 2009, 14, 653–664. [Google Scholar] [CrossRef]

- Zhao, H.; Kang, Z.J.; Zhang, Y.; Sun, H.T.; Li, Y. Connectivity Calculation Method for Characterizing Inter-Well Formation Parameters and Oil-Water Dynamics. Acta Pet. Sin. 2014, 35, 922–927. [Google Scholar]

- Zhao, H.; Kang, Z.J.; Sun, H.T.; Zhang, X.S.; Li, Y. An interwell connectivity inversion model for waterflooded multilayer reservoirs. Pet. Explor. Dev. 2016, 43, 106–114. [Google Scholar] [CrossRef]

- Zhao, H.; Xu, L.F.; Guo, Z.Y.; Liu, W.; Zhang, Q.; Ning, X.W.; Li, G.H.; Shi, L.H. A new and fast waterflooding optimization workflow based on INSIM-derived injection efficiency with a field application. J. Pet. Sci. Eng. 2019, 179, 1186–1200. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, W.; Rao, X. Connection element method for reservoir numerical simulation. Sci. Sin. Technol. 2022, 52, 1869–1886. [Google Scholar] [CrossRef]

- Du, Q.L.; Zhu, L.H. New Method for Studying Layered Utilization Status of Oil and Water Wells. Pet. Explor. Dev. 2004, 31, 96–98. [Google Scholar]

- Song, K.P.; Wang, L.J.; He, X.; Wang, Y.; Liu, S.M. Dynamic Splitting Method for Predicting Distribution and Dynamic Indicators of Remaining Oil in Single Layers. Acta Pet. Sin. 2000, 21, 122–126. [Google Scholar]

- Li, C.L.; Li, L.M. Study on Well Spacing Design in Anisotropic Formations. Xinjiang Pet. Geol. 2003, 24, 559–561. [Google Scholar]

- Feng, Q.H.; Wang, X.; Wang, D.P.; Huang, Y.S. Argumentation of Development Effectiveness of Balanced Displacement in Waterflood Reservoirs. Oil Gas Geol. Recovery Effic. 2016, 23, 83–88. [Google Scholar]

- Cui, C.Z.; Liu, L.J.; Feng, Y.; Wu, G.H.; Chen, H.L.; Jin, C.L.; Feng, Y.; Wu, G.H.; Chen, H.L.; Jin, C.L. Zonal Water Injection and Rational Allocation Method Based on Balanced Displacement. Oil Gas Geol. Recovery Effic. 2017, 24, 67–71. [Google Scholar]

- Chang, H.J.; Sun, G.Y.; Chen, X.M.; Zhai, S.Q.; Zhang, Y.H. Research and Application of Plane Injection-Production Optimization Based on Balanced Displacement. Spec. Oil Gas Reserv. 2019, 26, 120–124. [Google Scholar]

- Chen, C.L. Development of Multi-layer Reservoirs Based on the Minimum Water Consumption Rate for Balanced Displacement. J. Xi’an Shiyou Univ. Nat. Sci. Ed. 2020, 35, 63–67. [Google Scholar]

- GB/T 28912-2012; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; Standardization Administration of the People’s Republic of China. Determination Method of Two-Phase Fluid Relative Permeability in Rocks. Standards Press of China: Beijing, China, 2013.

- Li, J.; Zhang, S.Y. Oil Layer Classification for Lasaxing Oilfields at High Water cut Stage. Pet. Geol. Oilfield Dev. Daqing 2007, 86–90. [Google Scholar]

- Wu, J.Y.; Wang, Z.Q.; Wang, Q.Y.; Shao, S.; Sun, S.T. Reservoir Evaluating Method Based on the Strong-permeating Capacities and Assemble-scatter Degrees of the Sandbodies. Pet. Geol. Oilfield Dev. Daqing 2018, 37, 65–70. [Google Scholar]

| Ion Type | Na+ | Mg2+ | Ca2+ | Cl− | HCO3− | SO42− | TDS |

|---|---|---|---|---|---|---|---|

| on Concentration (mg/L) | 2316.4 | 11.6 | 10.1 | 2464.7 | 1913.0 | 62.9 | 6778.7 |

| Displacement Scheme | Displacement Condition | Low Permeability (0.1 μm2) | Medium Permeability (0.5 μm2) | High Permeability (1.2 μm2) |

|---|---|---|---|---|

| Traditional | Constant Pressure (MPa) | 0.25 | ||

| Optimized | Constant Flow Rate (cm3/min) | 3.8 | 6.1 | 8.4 |

| Reservoir Layer Number | Permeability (μm2) | Pore Volume (m3) | Connate Water Saturation (%) | Residual Oil Saturation (%) | m | n | ||

|---|---|---|---|---|---|---|---|---|

| #1 | 0.1 | 269 | 35.85 | 28.22 | 1.0 | 0.3675 | 2.9049 | 1.2931 |

| #2 | 0.4 | 538 | 31.30 | 29.76 | 1.0 | 0.4033 | 2.2010 | 1.4317 |

| #3 | 0.8 | 2152 | 23.68 | 29.38 | 1.0 | 0.4919 | 2.3739 | 1.6903 |

| Layer #1 | Layer #2 | Layer #3 | |

|---|---|---|---|

| Water Cut | 0.9534 | 0.9645 | 0.9883 |

| Recovery of OOIP | 0.3683 | 0.4336 | 0.5043 |

| Injected PV of Water | 0.9324 | 1.3581 | 3.6809 |

| Water-Injected Ratio | 1.0 | 2.9 | 31.6 |

| No. | Layer #1 | Layer #2 | Layer #3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Water Cut | Average Water Saturation | Water-Injection Volume | Water Cut | Average Water Saturation | Water-Injection Volume | Water Cut | Average Water Saturation | Water-Injection Volume | |

| 1 | 0.00 | 0.3585 | 0.0000 | 0.0000 | 0.3130 | 0 | 0 | 0.2368 | 0 |

| 2 | 0.60 | 0.5033 | 0.1605 | 0.9082 | 0.5122 | 0.6421 | 0.9552 | 0.5121 | 1.2842 |

| 3 | 0.80 | 0.5346 | 0.2748 | 0.9552 | 0.5504 | 1.0993 | 0.9769 | 0.5476 | 2.1987 |

| 4 | 0.90 | 0.5649 | 0.4932 | 0.9788 | 0.5861 | 1.9730 | 0.9892 | 0.5829 | 3.9460 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Yang, E.; Zhao, Y.; Fu, H.; Dong, C.; Du, Q.; Zheng, X.; Wang, Z.; Yang, B.; Zhu, J. A New Method for Optimizing Water-Flooding Strategies in Multi-Layer Sandstone Reservoirs. Energies 2024, 17, 1828. https://doi.org/10.3390/en17081828

Guo J, Yang E, Zhao Y, Fu H, Dong C, Du Q, Zheng X, Wang Z, Yang B, Zhu J. A New Method for Optimizing Water-Flooding Strategies in Multi-Layer Sandstone Reservoirs. Energies. 2024; 17(8):1828. https://doi.org/10.3390/en17081828

Chicago/Turabian StyleGuo, Junhui, Erlong Yang, Yu Zhao, Hongtao Fu, Chi Dong, Qinglong Du, Xianbao Zheng, Zhiguo Wang, Bingbing Yang, and Jianjun Zhu. 2024. "A New Method for Optimizing Water-Flooding Strategies in Multi-Layer Sandstone Reservoirs" Energies 17, no. 8: 1828. https://doi.org/10.3390/en17081828

APA StyleGuo, J., Yang, E., Zhao, Y., Fu, H., Dong, C., Du, Q., Zheng, X., Wang, Z., Yang, B., & Zhu, J. (2024). A New Method for Optimizing Water-Flooding Strategies in Multi-Layer Sandstone Reservoirs. Energies, 17(8), 1828. https://doi.org/10.3390/en17081828