Comparative Study of Solid-Based and Liquid-Based Heat Transfer Enhancement Techniques in Liquid Piston Gas Compression

Abstract

:1. Introduction

1.1. Compressed Air Energy Storage and Importance of Isothermal Compression

1.2. Liquid Piston Gas Compressor and Heat Transfer Enhancement for Isothermal Compression

1.3. Objectives of the Present Work

2. Analytical Modeling

2.1. Mathematical Modeling of Liquid Piston Heat Transfer

2.2. Isothermal Compression Efficiency

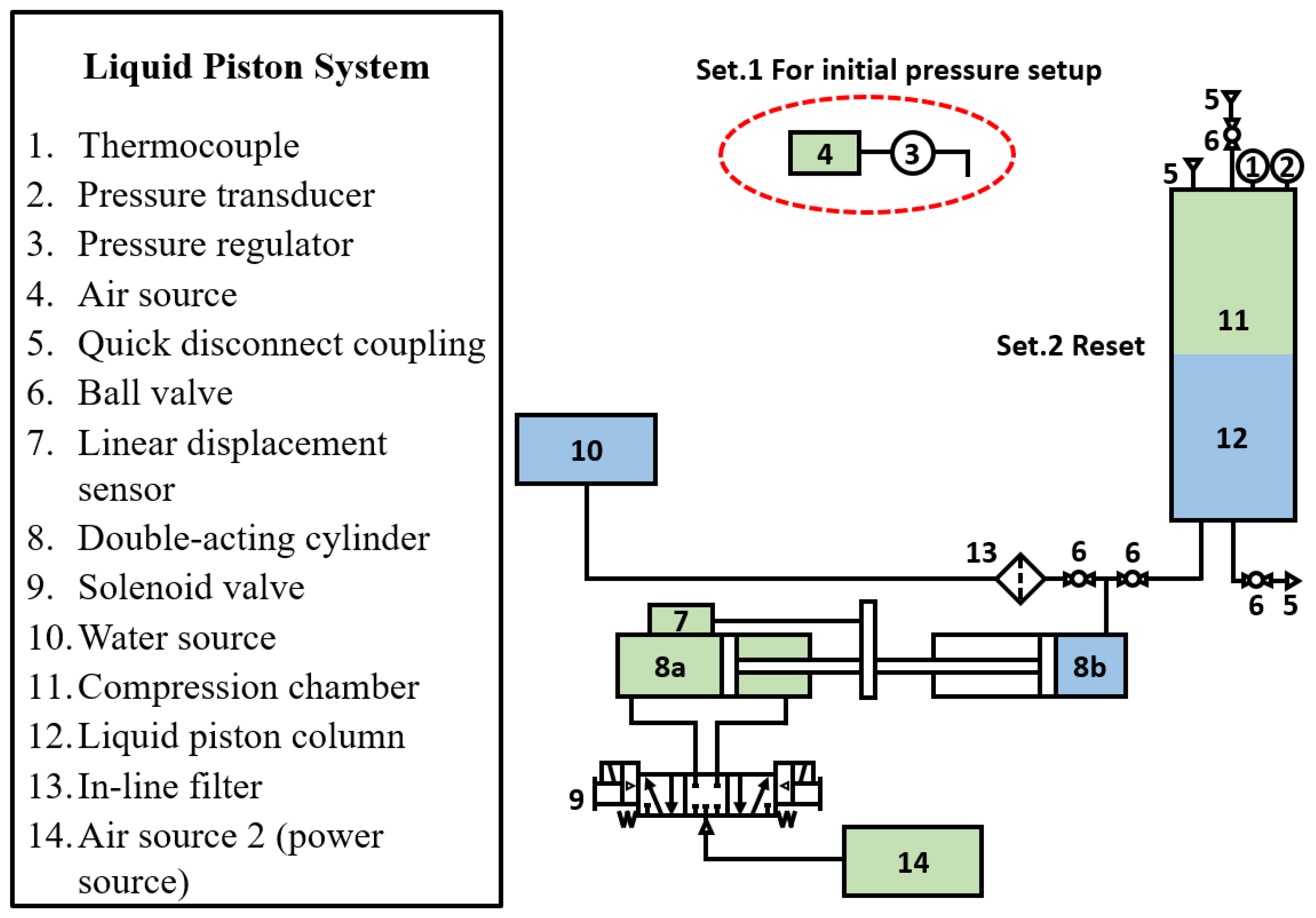

3. Materials and Methods

4. Results and Discussion

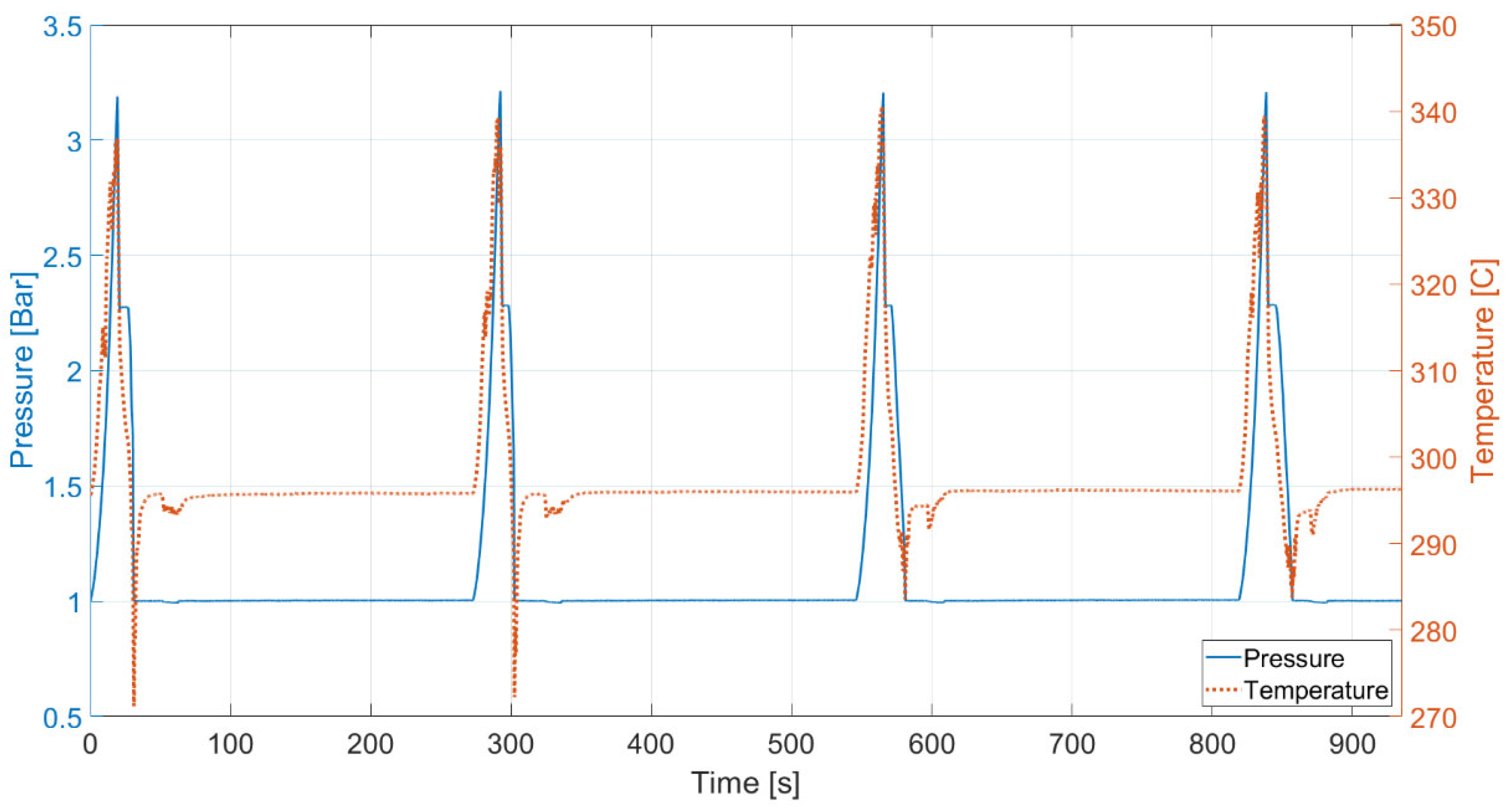

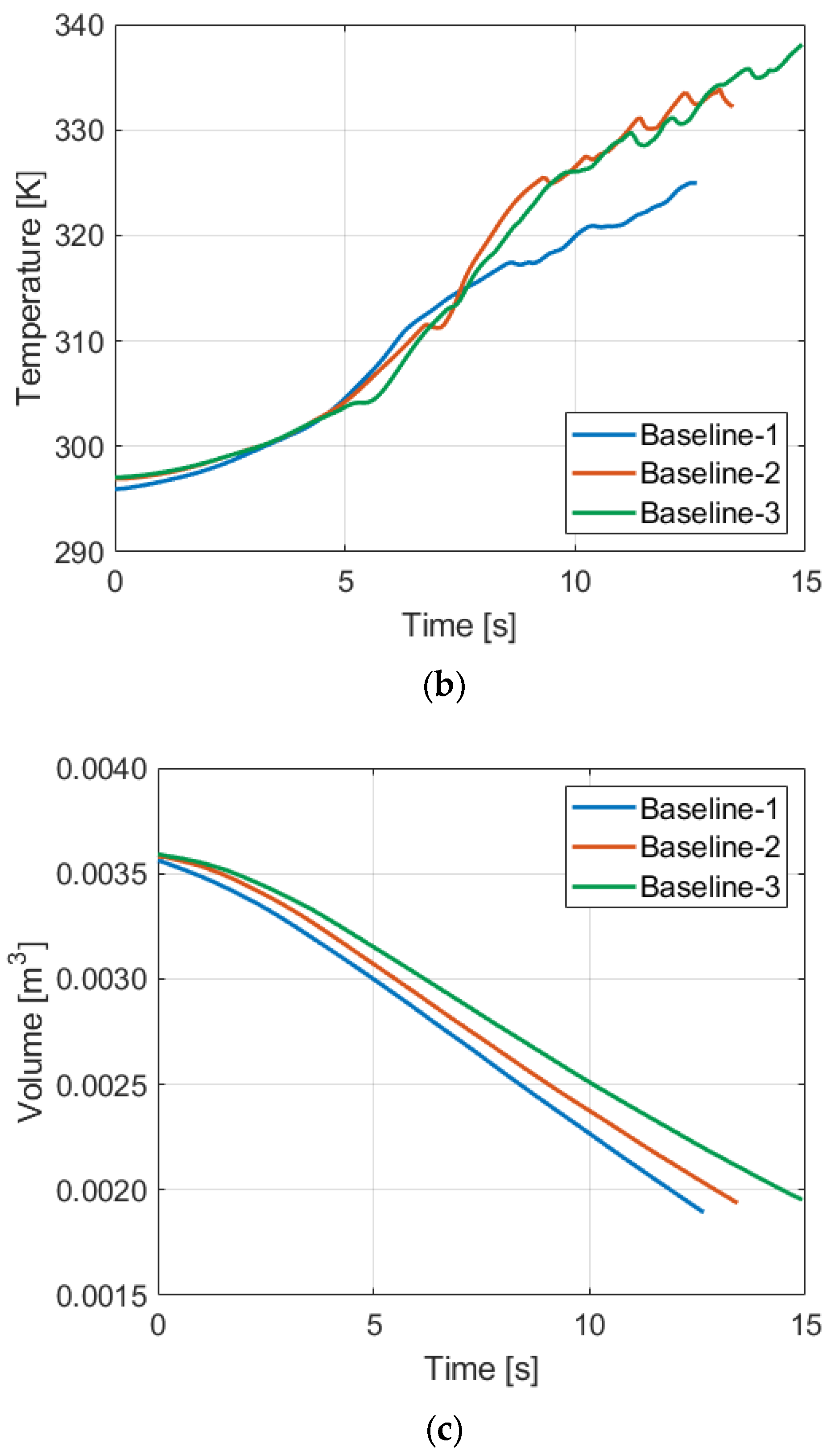

4.1. Baseline Compression

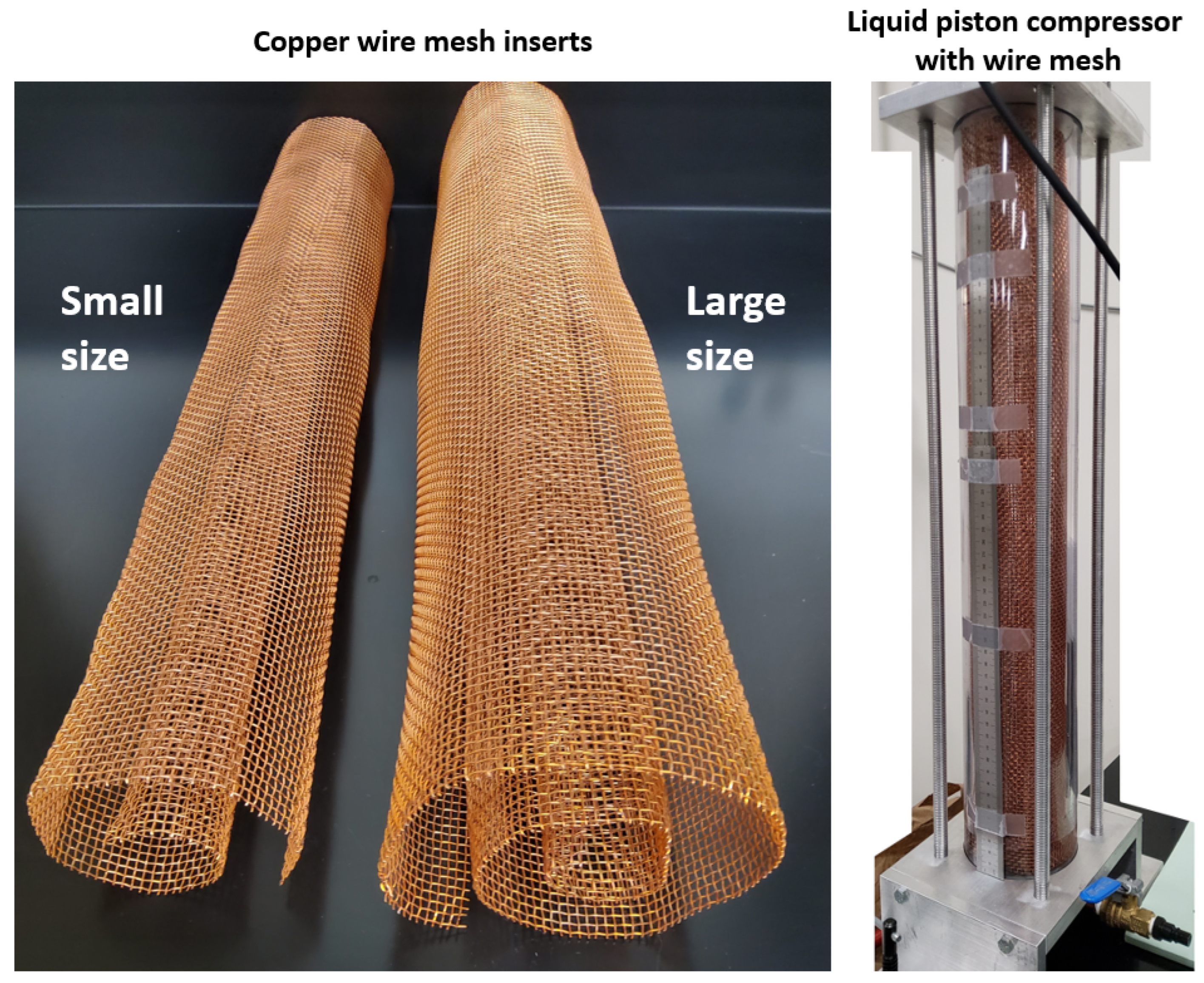

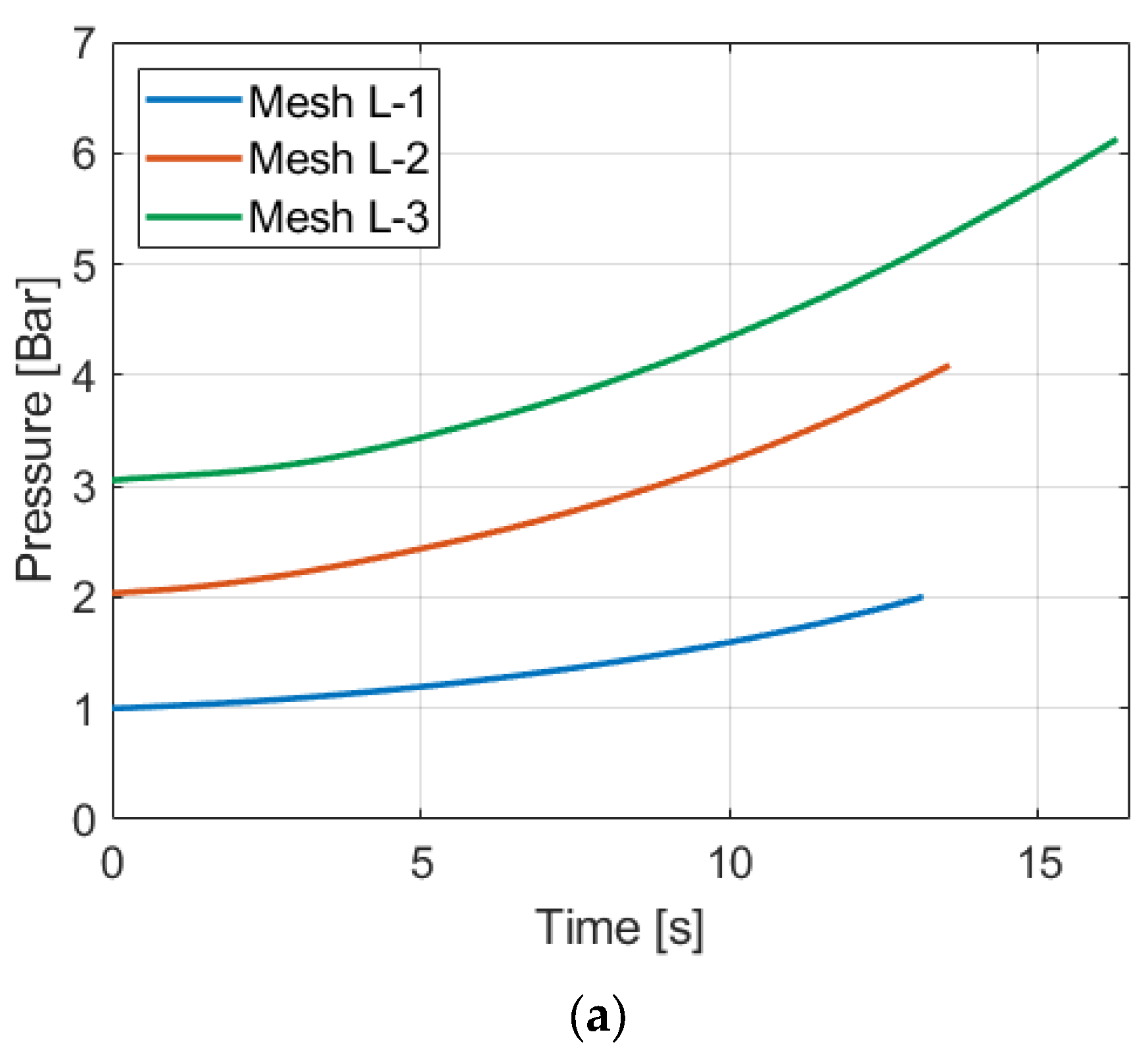

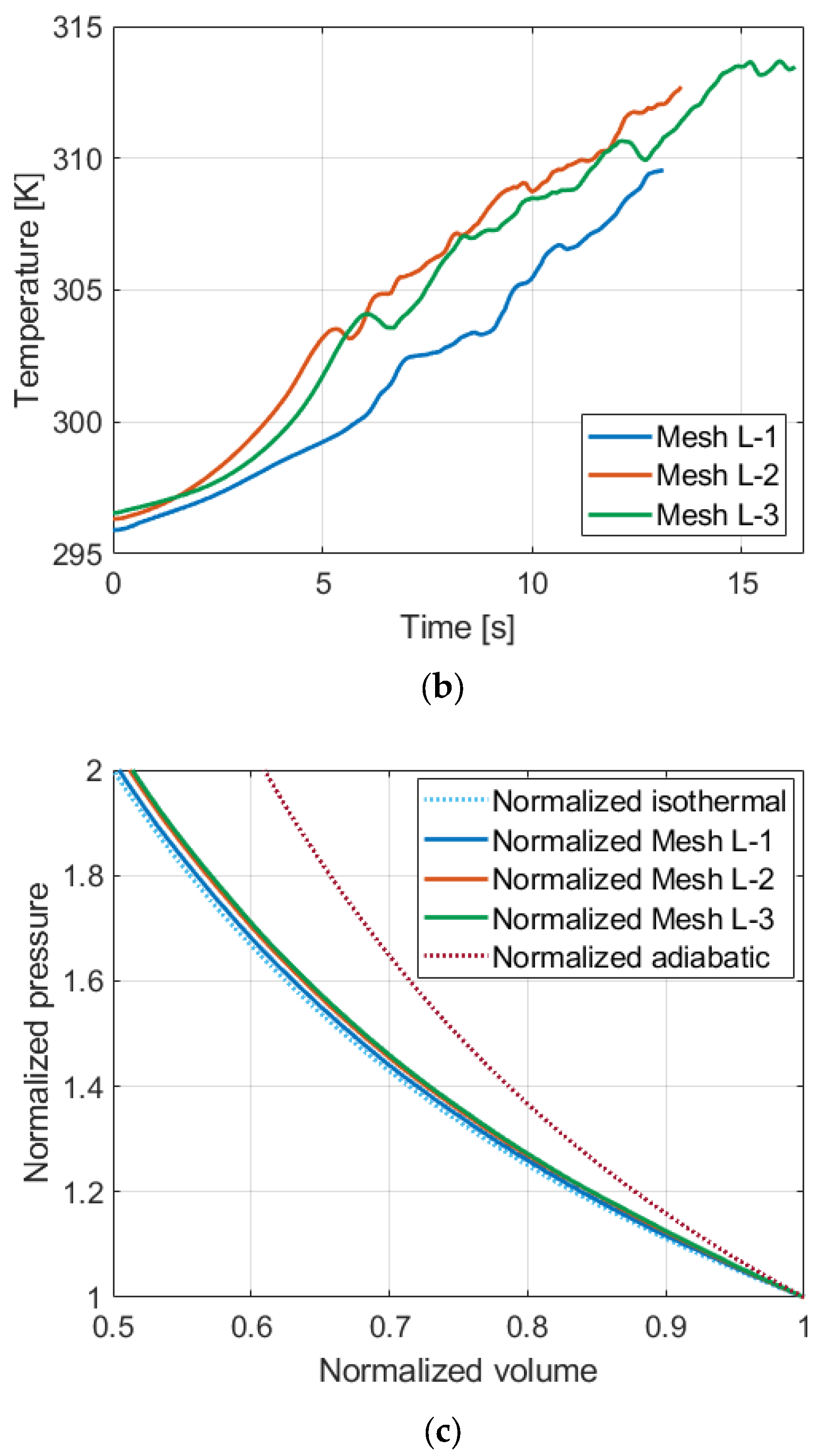

4.2. With-Copper Wire Mesh Insert Compression

4.3. Comparative Study with Liquid-Based Heat Transfer Enhancement Techniques

4.4. Future Work and Suggestions

5. Conclusions

- Pros: it showed excellent isothermal performance, second to the spray method. This was achieved with a relatively small reduction in the volume of the compression chamber. No extra work input is required to be employed, and it can be simply incorporated into the system.

- Cons: when the system is scaled up to a utility scale, the cost of the materials can be substantial. The existence of inserts in the chamber compromises air volume.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature and Abbreviations

| Surface area of bubble | |

| Surface area of chamber | |

| Surface area of a droplet | |

| Surface area of mesh insert | |

| Specific heat | |

| Heat transfer coefficient of a droplet | |

| Overall heat transfer coefficient of mesh insert | |

| Thermal conductivity of bubble | |

| Bubble wall thickness | |

| Mass of air | |

| Pressure | |

| Initial pressure | |

| Pressure of air | |

| Final pressure | |

| Pressure profile of isothermal process | |

| Pressure ratio | |

| Rate of heat transfer | |

| Rate of aqueous foam heat transfer | |

| Rate of mesh insert heat transfer | |

| Rate of spray heat transfer | |

| Temperature of air | |

| Temperature of bubble | |

| Temperature of droplet | |

| Temperature of mesh insert | |

| Temperature of surroundings | |

| Temperature change of air | |

| Time | |

| Internal energy | |

| Overall heat transfer coefficient | |

| Volume | |

| Initial volume | |

| Temperature of air | |

| Final volume | |

| Final volume of isothermal compression | |

| Volume profile of isothermal process | |

| Compression work | |

| Cooling work | |

| Isothermal compression work | |

| Rate of compression work | |

| Isothermal compression efficiency | |

| Baseline-N | Baseline compression starting at N bar(s) |

| Mesh L-N | Compression with large mesh insert starting at N bar(s) |

| Mesh S-N | Compression with small mesh insert starting at N bar(s) |

| Spray-N | Compression with spray injection starting at N bar(s) |

| Foam-N | Compression with aqueous foam starting at N bar(s) |

| CAES | Compressed air energy storage |

| ICAES | Isothermal compressed air energy storage |

References

- Renewable Energy Explained—U.S. Energy Information Administration (EIA). Available online: https://www.eia.gov/energyexplained/renewable-sources/ (accessed on 8 December 2023).

- Yekini Suberu, M.; Wazir Mustafa, M.; Bashir, N. Energy Storage Systems for Renewable Energy Power Sector Integration and Mitigation of Intermittency. Renew. Sustain. Energy Rev. 2014, 35, 499–514. [Google Scholar] [CrossRef]

- Qin, C.; Loth, E. Isothermal Compressed Wind Energy Storage Using Abandoned Oil/Gas Wells or Coal Mines. Appl. Energy 2021, 292, 116867. [Google Scholar] [CrossRef]

- Qin, C.; Loth, E.; Li, P.; Simon, T.; Van de Ven, J. Spray-Cooling Concept for Wind-Based Compressed Air Energy Storage. J. Renew. Sustain. Energy 2014, 6, 043125. [Google Scholar] [CrossRef]

- Crotogino, F.; Mohmeyer, K.-U.; Scharf, R. Huntorf CAES: More than 20 Years of Successful Operation. In Proceedings of the SMRI Spring Meeting, Orlando, FL, USA, 15–18 April 2001. [Google Scholar]

- Cavallo, A. Controllable and Affordable Utility-Scale Electricity from Intermittent Wind Resources and Compressed Air Energy Storage (CAES). Energy 2007, 32, 120–127. [Google Scholar] [CrossRef]

- Cavallo, A.J. Energy Storage Technologies for Utility Scale Intermittent Renewable Energy Systems. J. Sol. Energy Eng. 2001, 123, 387–389. [Google Scholar] [CrossRef]

- Bennett, J.A.; Simpson, J.G.; Qin, C.; Fittro, R.; Koenig, G.M.; Clarens, A.F.; Loth, E. Techno-Economic Analysis of Offshore Isothermal Compressed Air Energy Storage in Saline Aquifers Co-Located with Wind Power. Appl. Energy 2021, 303, 117587. [Google Scholar] [CrossRef]

- Hunt, J.D.; Zakeri, B.; Nascimento, A.; de Jesus Pacheco, D.A.; Patro, E.R.; Đurin, B.; Pereira, M.G.; Filho, W.L.; Wada, Y. Isothermal Deep Ocean Compressed Air Energy Storage: An Affordable Solution for Seasonal Energy Storage. Energies 2023, 16, 3118. [Google Scholar] [CrossRef]

- Maisonnave, O.; Moreau, L.; Aubrée, R.; Benkhoris, M.-F.; Neu, T.; Guyomarc’h, D. Optimal Energy Management of an Underwater Compressed Air Energy Storage Station Using Pumping Systems. Energy Convers. Manag. 2018, 165, 771–782. [Google Scholar] [CrossRef]

- Wang, Z.; Ting, D.S.-K.; Carriveau, R.; Xiong, W.; Wang, Z. Design and Thermodynamic Analysis of a Multi-Level Underwater Compressed Air Energy Storage System. J. Energy Storage 2016, 5, 203–211. [Google Scholar] [CrossRef]

- Wolf, D. Methods for Design and Application of Adiabatic Compressed Air Energy Storage Based on Dynamic Modeling; Laufen: Oberhausen, Germany, 2011. [Google Scholar]

- Tec-Science. Why Do Pressure and Temperature Increase During the Compression of a Gas? Tec-Science: New Delhi, India, 2021. [Google Scholar]

- Budt, M.; Wolf, D.; Span, R.; Yan, J. Compressed Air Energy Storage—An Option for Medium to Large Scale Electrical-Energy Storage. Energy Procedia 2016, 88, 698–702. [Google Scholar] [CrossRef]

- Kim, Y.-M.; Lee, J.-H.; Kim, S.-J.; Favrat, D. Potential and Evolution of Compressed Air Energy Storage: Energy and Exergy Analyses. Entropy 2012, 14, 1501–1521. [Google Scholar] [CrossRef]

- Van de Ven, J.D.; Li, P.Y. Liquid Piston Gas Compression. Appl. Energy 2009, 86, 2183–2191. [Google Scholar] [CrossRef]

- Qin, C.; Loth, E. Liquid Piston Compression Efficiency with Droplet Heat Transfer. Appl. Energy 2014, 114, 539–550. [Google Scholar] [CrossRef]

- Zhang, C.; Saadat, M.; Li, P.Y.; Simon, T.W. Heat Transfer in a Long, Thin Tube Section of an Air Compressor: An Empirical Correlation From CFD and a Thermodynamic Modeling; American Society of Mechanical Engineers Digital Collection; ASME: Houston, TX, USA, 2013; pp. 1601–1607. [Google Scholar]

- Hu, S.; Xu, W.; Jia, G.; Cai, M.; Li, J.; Lu, Y.; Ren, T. Efficiency Analysis of an Arrayed Liquid Piston Isothermal Air Compression System for Compressed Air Energy Storage. J. Therm. Sci. 2023, 32, 17–29. [Google Scholar] [CrossRef]

- Zhang, C.; Li, P.Y.; Van de Ven, J.D.; Simon, T.W. Design Analysis of a Liquid-Piston Compression Chamber with Application to Compressed Air Energy Storage. Appl. Therm. Eng. 2016, 101, 704–709. [Google Scholar] [CrossRef]

- Wieberdink, J.; Li, P.Y.; Simon, T.W.; Van de Ven, J.D. Effects of Porous Media Insert on the Efficiency and Power Density of a High Pressure (210 bar) Liquid Piston Air Compressor/Expander—An Experimental Study. Appl. Energy 2018, 212, 1025–1037. [Google Scholar] [CrossRef]

- Yan, B.; Wieberdink, J.; Shirazi, F.; Li, P.Y.; Simon, T.W.; Van de Ven, J.D. Experimental Study of Heat Transfer Enhancement in a Liquid Piston Compressor/Expander Using Porous Media Inserts. Appl. Energy 2015, 154, 40–50. [Google Scholar] [CrossRef]

- Haney, L.; Prosser, R.; Lanzon, A.; Mahmoudi, Y. Modelling of near Isothermal Liquid Piston Gas Compressor Employing Porous Media for Compressed Air Energy Storage Systems. Int. J. Therm. Sci. 2025, 212, 109775. [Google Scholar] [CrossRef]

- Patil, V.C.; Liu, J.; Ro, P.I. Efficiency Improvement of Liquid Piston Compressor Using Metal Wire Mesh for Near-Isothermal Compressed Air Energy Storage Application. J. Energy Storage 2020, 28, 101226. [Google Scholar] [CrossRef]

- Khaljani, M.; Vennard, A.; Harrison, J.; Surplus, D.; Murphy, A.; Mahmoudi, Y. Experimental and Modelling Analysis of Efficiency Enhancement in a Liquid Piston Gas Compressor Using Metal Plate Inserts for Compressed Air Energy Storage Application. J. Energy Storage 2021, 43, 103240. [Google Scholar] [CrossRef]

- Ren, T.; Xu, W.; Jia, G.-W.; Cai, M. A Novel Isothermal Compression Method for Energy Conservation in Fluid Power Systems. Entropy 2020, 22, 1015. [Google Scholar] [CrossRef] [PubMed]

- Ren, T.; Xu, W.; Cai, M.; Wang, X.; Li, M. Experiments on Air Compression with an Isothermal Piston for Energy Storage. Energies 2019, 12, 3730. [Google Scholar] [CrossRef]

- Patil, V.C.; Acharya, P.; Ro, P.I. Experimental Investigation of Water Spray Injection in Liquid Piston for Near-Isothermal Compression. Appl. Energy 2020, 259, 114182. [Google Scholar] [CrossRef]

- Patil, V.C.; Ro, P.I. Experimental Study of Heat Transfer Enhancement in Liquid Piston Compressor Using Aqueous Foam. Appl. Therm. Eng. 2020, 164, 114441. [Google Scholar] [CrossRef]

- Patil, V.C. Efficiency Improvement Techniques in Liquid Piston Compressor for Ocean Compressed Air Energy Storage Application. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2019. [Google Scholar]

- Single vs. Multi-Stage Compressors. Available online: https://cascousa.com/compressed-air-101/types-of-compressors/single-versus-multi-stage-compressors/ (accessed on 8 April 2022).

- Pollak, R. History of First U.S. Compressed-Air Energy Storage (CAES) Plant (110 MW 26 h): Volume 2: Construction; EPRI: Palo Alto, CA, USA, 1994. [Google Scholar]

- Budt, M.; Wolf, D.; Span, R.; Yan, J. A Review on Compressed Air Energy Storage: Basic Principles, Past Milestones and Recent Developments. Appl. Energy 2016, 170, 250–268. [Google Scholar] [CrossRef]

- Zhang, C.; Yan, B.; Wieberdink, J.; Li, P.Y.; Van de Ven, J.D.; Loth, E.; Simon, T.W. Thermal Analysis of a Compressor for Application to Compressed Air Energy Storage. Appl. Therm. Eng. 2014, 73, 1402–1411. [Google Scholar] [CrossRef]

- Ahn, B.; Ro, P.I. Experimental Investigation of Impacts of Initial Pressure Levels on Compression Efficiency and Dissolution in Liquid Piston Gas Compression. Energies 2023, 16, 1921. [Google Scholar] [CrossRef]

- Ahn, B. Comprehensive Experimental Investigation of Liquid Piston Gas Compression for Energy Storage Applications. Ph.D. Thesis, Baylor University, Waco, TX, USA, 2023. [Google Scholar]

- Ahn, B.; Ro, P.I. Spray Cooling Technique in Liquid Piston Gas Compression and Impact of Air Dissolution on Efficiency Evaluation at Different Pressure Levels. J. Energy Storage 2024, 81, 110460. [Google Scholar] [CrossRef]

- Ahn, B.; Patil, V.C.; Ro, P.I. Effect of Integrating Metal Wire Mesh with Spray Injection for Liquid Piston Gas Compression. Energies 2021, 14, 3723. [Google Scholar] [CrossRef]

- Li, C.; Wang, H.; He, X.; Zhang, Y. Experimental and Thermodynamic Investigation on Isothermal Performance of Large-Scaled Liquid Piston. Energy 2022, 249, 123731. [Google Scholar] [CrossRef]

- Çengel, Y.; Boles, M. Thermodynamics An Engineering Approach, 2nd ed.; McGraw-Hill, Inc.: Chicago, IL, USA, 1994; ISBN 0-07-911652-3. [Google Scholar]

| Sensor | Model | Accuracy |

|---|---|---|

| Pressure transducer | Omega Engineering PX409-250A10V (Norwalk, CT, USA) | ±0.08% BSL accuracy |

| Thermocouple | Omega Engineering 5TC-TT-K-40 (Norwalk, CT, USA) | 2.2 °C |

| Linear position sensor | TE SPD-50-3 (Galway, Ireland) | 0.25% |

(Bar) | Baseline | Mesh L | Mesh S | |||

|---|---|---|---|---|---|---|

| (K) | (%) | (K) | (%) | (K) | (%) | |

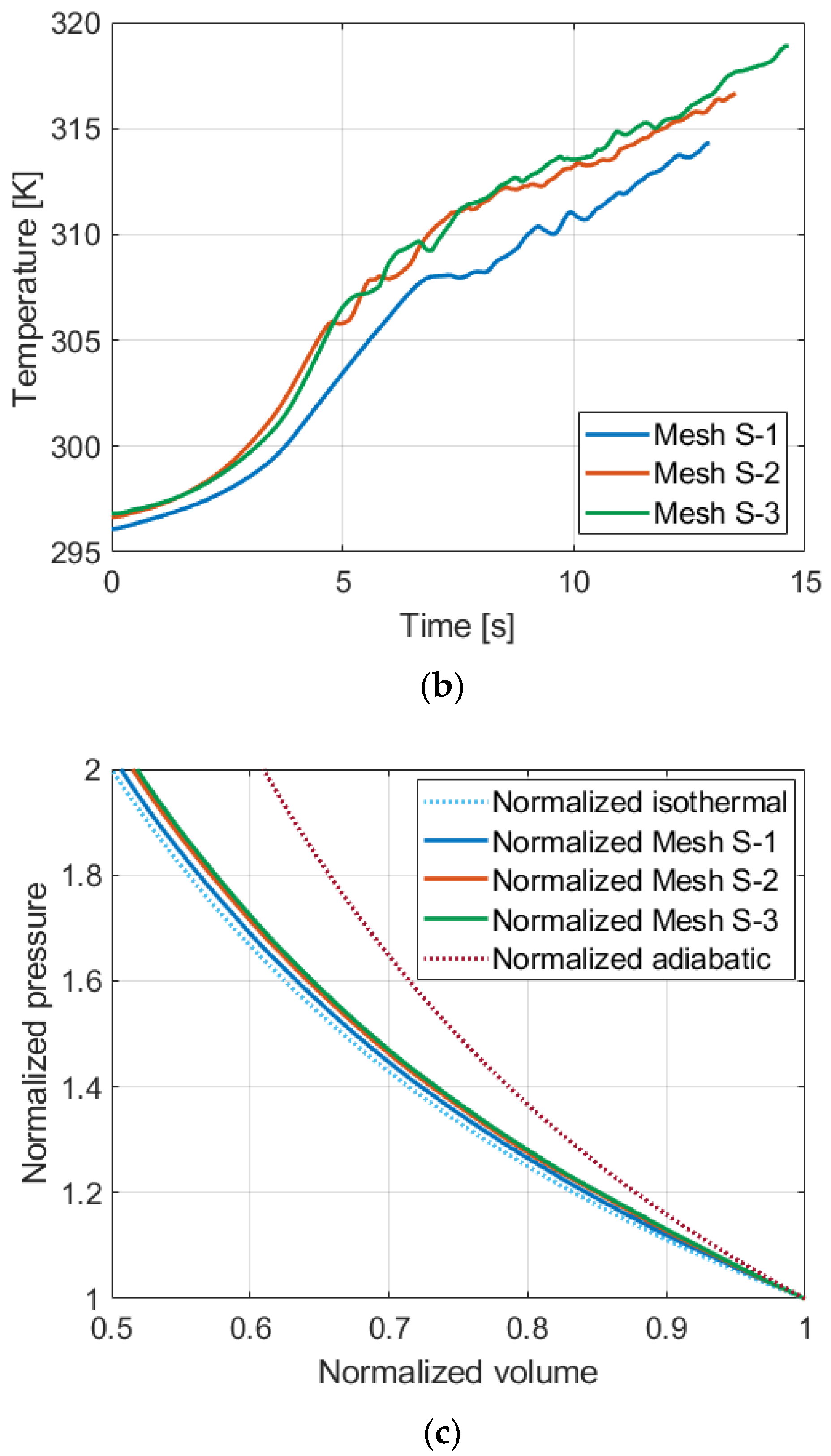

| 1 | 29.03 | 87.4 | 13.65 | 97.4 | 18.24 | 96.1 |

| 2 | 35.24 | 84.2 | 16.39 | 94.3 | 19.99 | 92.7 |

| 3 | 41.03 | 83.0 | 16.91 | 93.4 | 22.08 | 91.5 |

| Project | Compression | (%) | Compression | (%) | (%) |

|---|---|---|---|---|---|

| Spray | Baseline-1 | 87.8 | Spray-1 | 98.5 | +10.7 |

| Baseline-2 | 84.2 | Spray-2 | 98.0 | +13.8 | |

| Baseline-3 | 83.3 | Spray-3 | 98.5 | +15.2 | |

| Aqueous foam | Baseline-1 | 89.2 | Foam-1 | 91.4 | +2.2 |

| Baseline-2 | 86.1 | Foam-2 | 88.2 | +2.1 | |

| Baseline-3 | 85.3 | Foam-3 | 86.6 | +1.3 | |

| Wire mesh | Baseline-1 | 87.4 | Mesh L/S-1 | 97.4/96.1 | +10/+8.7 |

| Baseline-2 | 84.2 | Mesh L/S-2 | 94.3/92.7 | +10.1/+8.5 | |

| Baseline-3 | 83.0 | Mesh L/S-3 | 93.4/91.5 | +10.4/+8.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, B.; Schmetzer, M.; Ro, P.I. Comparative Study of Solid-Based and Liquid-Based Heat Transfer Enhancement Techniques in Liquid Piston Gas Compression. Energies 2025, 18, 2032. https://doi.org/10.3390/en18082032

Ahn B, Schmetzer M, Ro PI. Comparative Study of Solid-Based and Liquid-Based Heat Transfer Enhancement Techniques in Liquid Piston Gas Compression. Energies. 2025; 18(8):2032. https://doi.org/10.3390/en18082032

Chicago/Turabian StyleAhn, Barah, Macey Schmetzer, and Paul I. Ro. 2025. "Comparative Study of Solid-Based and Liquid-Based Heat Transfer Enhancement Techniques in Liquid Piston Gas Compression" Energies 18, no. 8: 2032. https://doi.org/10.3390/en18082032

APA StyleAhn, B., Schmetzer, M., & Ro, P. I. (2025). Comparative Study of Solid-Based and Liquid-Based Heat Transfer Enhancement Techniques in Liquid Piston Gas Compression. Energies, 18(8), 2032. https://doi.org/10.3390/en18082032