Compaction Curves and Strength of Clayey Soil Modified with Micro and Nano Silica

Abstract

:1. Introduction

2. Materials and Methods

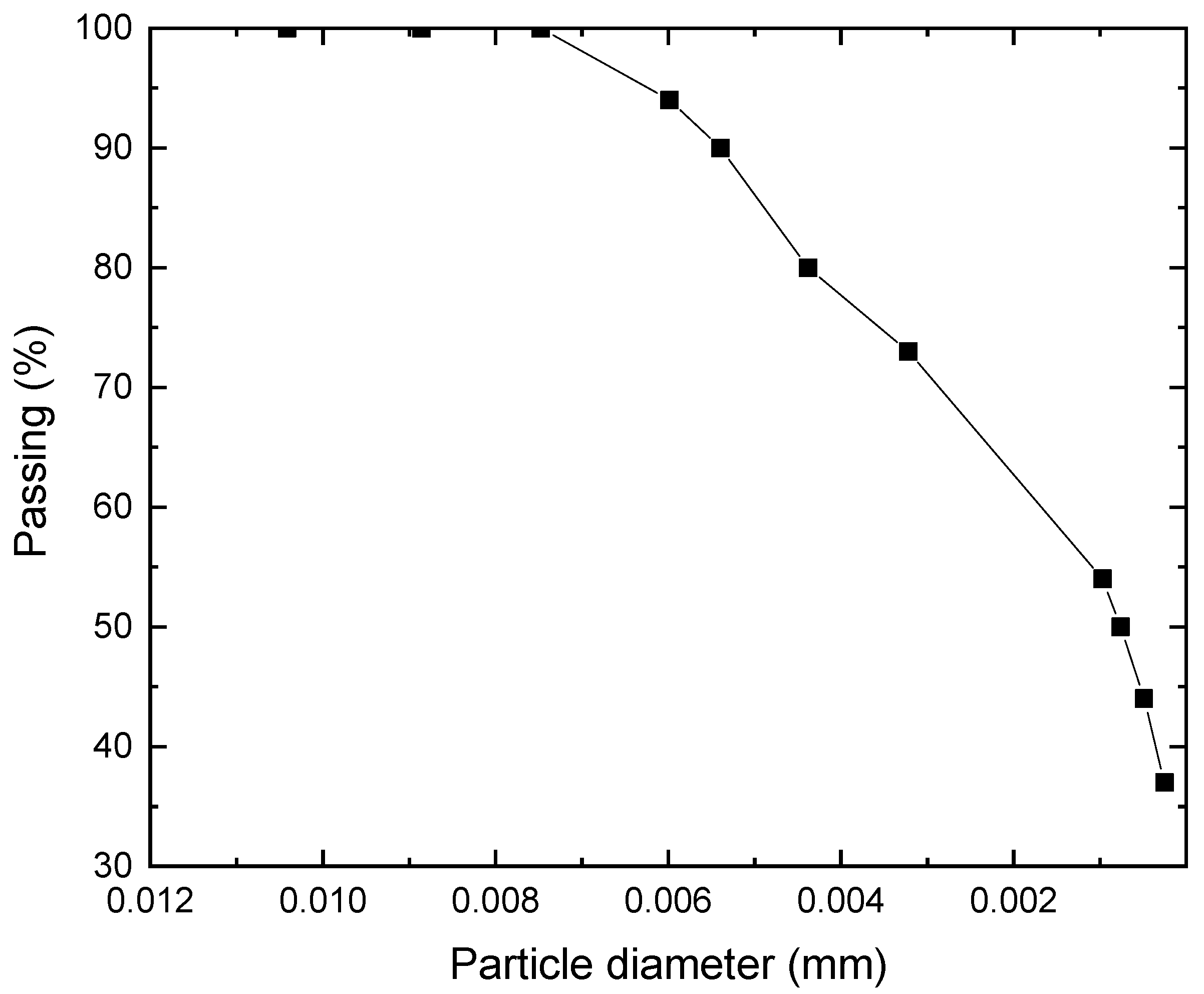

2.1. Clayey Soil

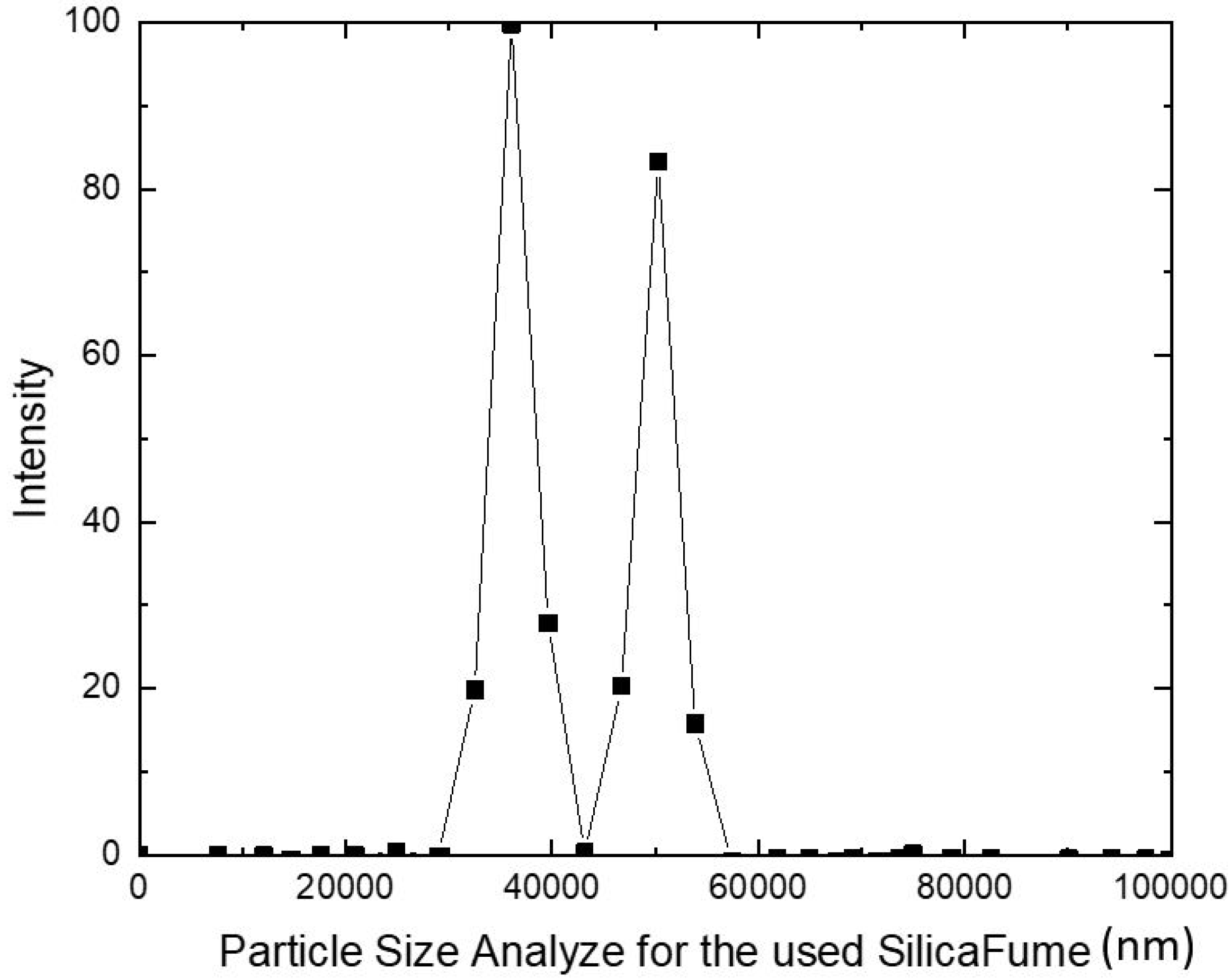

2.2. Silica-Fume

2.3. Preparation of Nano-Materials

2.4. Test Methods

2.4.1. Atterberg Tests (Consistency Limits)

2.4.2. Compaction Tests

2.4.3. Unconfined Compressive Strength Tests

2.5. Results and Discussion

2.5.1. Atterberg Limits

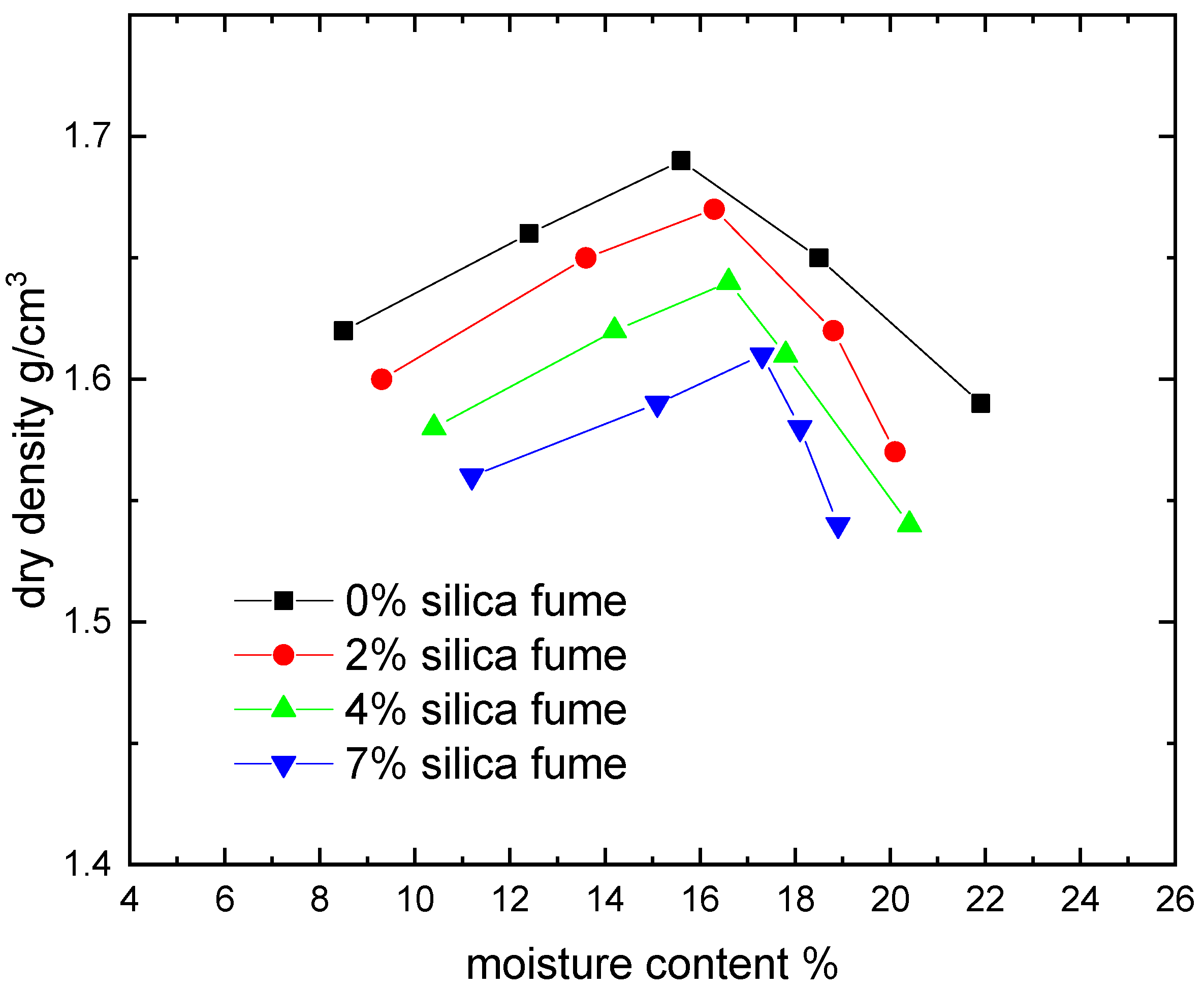

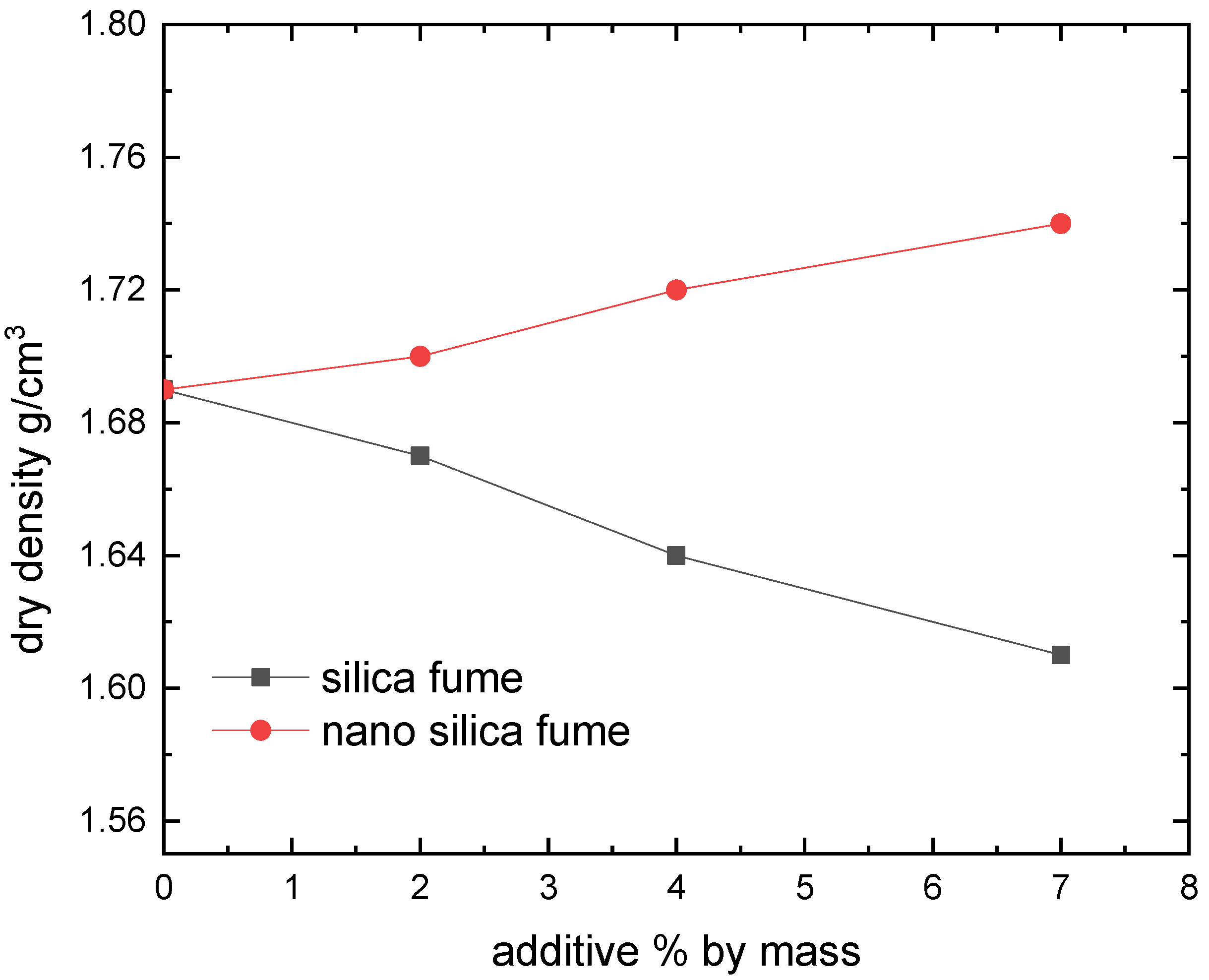

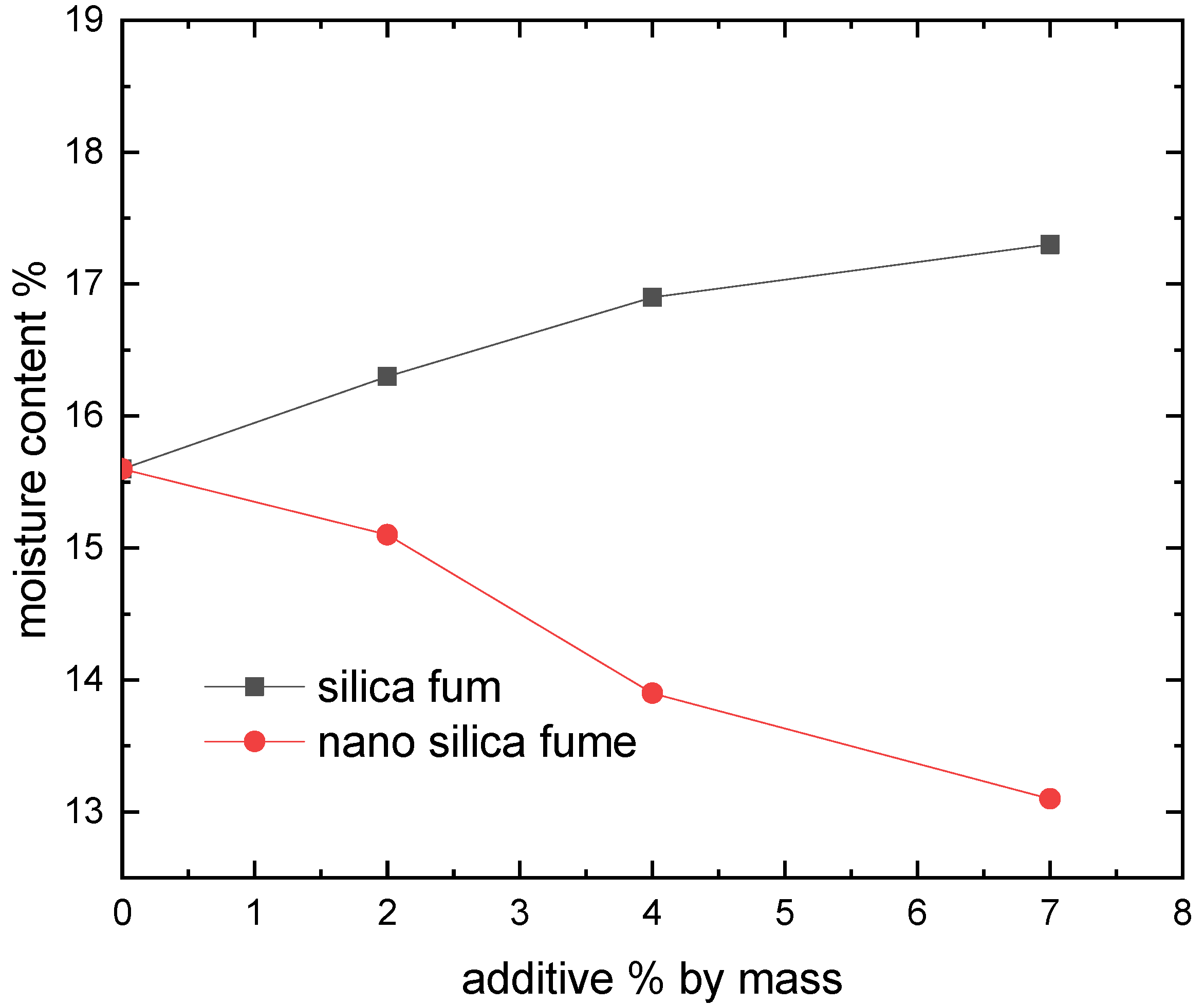

2.5.2. Compaction Parameters

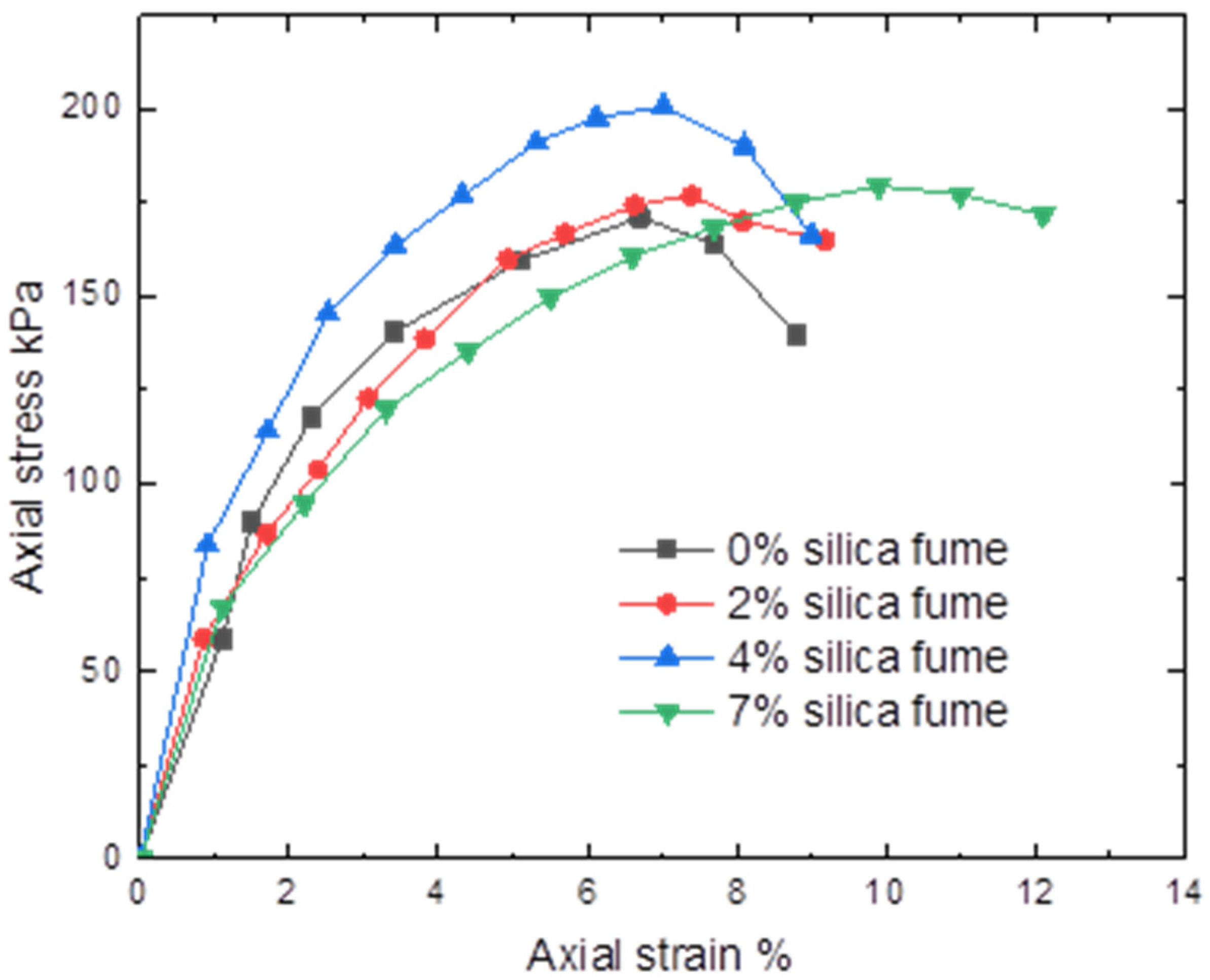

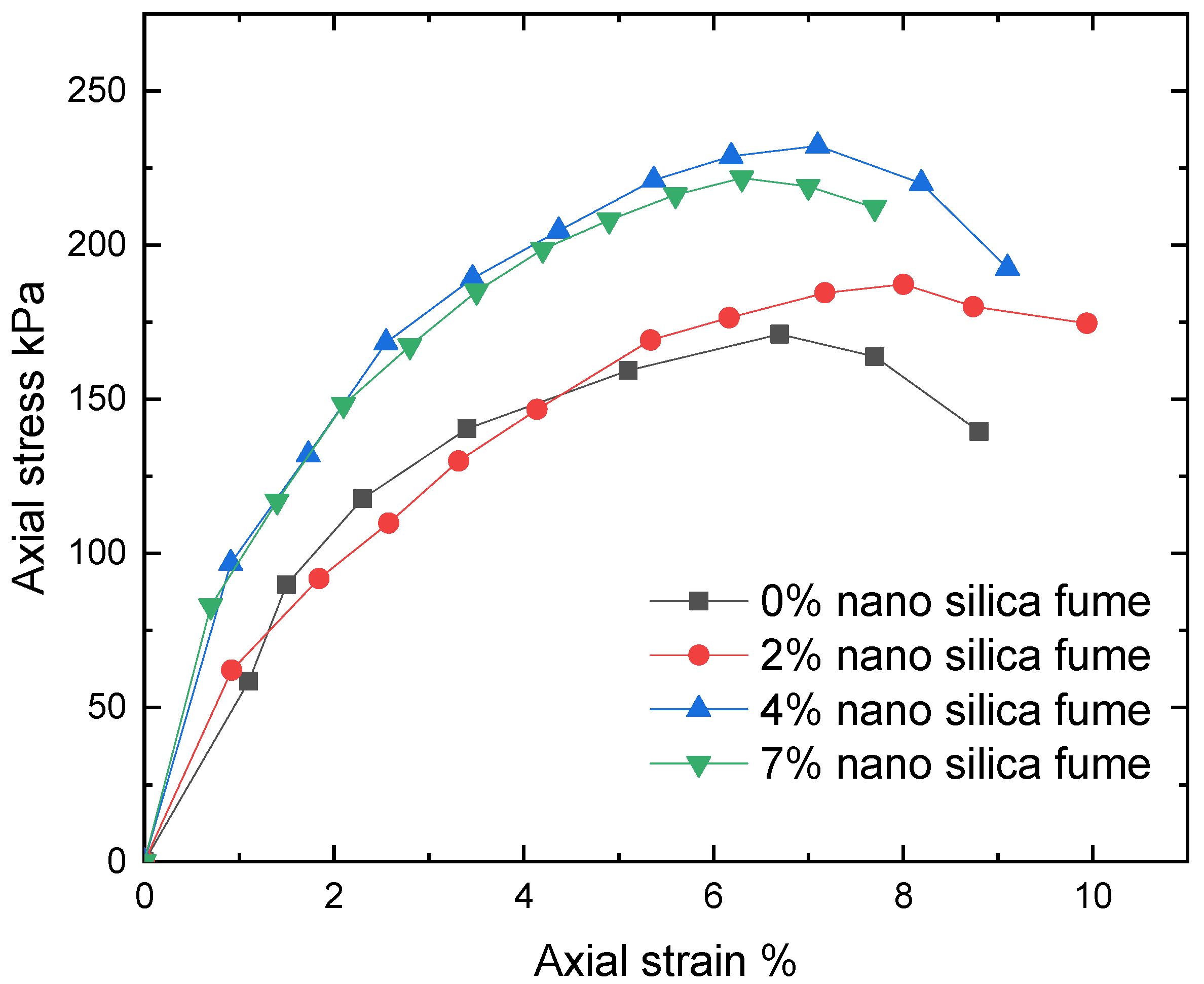

2.5.3. Unconfined Compressive Strength

3. Conclusions

- The Atterberg limits test results show that the addition of silica fume decreases the plasticity index of the treated soil while the latter increases with the addition of nano silica fume.

- Silica fume addition lowers the maximum dry density and increases optimum moisture content, whereas nano-silica addition increases maximum dry density and decreases optimal moisture content for the studied samples.

- The addition of 4% silica fume or nano silica lead to increasing the unconfined compressive strength of the tested samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ismael, B.; Lombardi, D.; Bhattacharya, S.; Ahmad, S.M. Use of instability curves for the assessment of post-liquefaction stability and deformation of sloping grounds. Eng. Geol. 2020, 265, 105347. [Google Scholar] [CrossRef]

- Ismael, B.; Lombardi, D. Effect of Liquefaction on the Seismic Response of Port Facilities in Reclaimed Islands: A Case Study from the 2016 Kumamoto Earthquake Sequence; CRC Press: Boca Raton, FL, USA, 2016; pp. 2016–2018. [Google Scholar]

- Goda, K.; Campbell, G.; Hulme, L.; Ismael, B.; Ke, L.; Marsh, R.; Sammonds, P.; So, E.; Okumura, Y.; Kishi, N.; et al. The 2016 Kumamoto Earthquakes: Cascading Geological Hazards and Compounding Risks. Front. Built Environ. 2016, 2, 19. [Google Scholar] [CrossRef] [Green Version]

- Ismael, B.; Lombardi, D.; Ahmad, S.M.; Arturo, J.; Ulloa, M. Liquefaction-Induced Lateral Spreading at Kamiezu Lake: A Case Study from the 2016 Kumamoto Earthquake Sequence. In Proceedings of the The Young Geotechnical Engineers Symposium (YGES 2018), Guildford, UK, 2–3 July 2018; pp. 31–32. [Google Scholar]

- Ismael, B.; Lombardi, D.; Ahmad, S.M. Post-cyclic stress-strain response of liquefied sand: A case study from the 2016 Kumamoto earthquake sequence. In Proceedings of the 2nd International Conference on Natural Hazards & Infrastructure, Chania, Greece, 23–26 June 2019. [Google Scholar]

- Ismael, B.; Lombardi, D.; Bhattacharya, S.; Ahmad, S.M. A state-dependent procedure to determine the post-liquefaction deformation of liquefied sand. Eng. Geol. 2015, 1–7. [Google Scholar]

- Bhattacharya, S.; Hyodo, M.; Nikitas, G.; Ismael, B.; Suzuki, H.; Lombardi, D.; Egami, S.; Watanabe, G.; Goda, K. Geotechnical and infrastructural damage due to the 2016 Kumamoto earthquake sequence. Soil Dyn. Earthq. Eng. 2018, 104, 390–394. [Google Scholar] [CrossRef]

- Ismael, B.; Lombardi, D. Evaluation of liquefaction potential for two sites due to the 2016 Kumamoto earthquake sequence. In Conference of the Arabian Journal of Geosciences; Springer: Cham, Switzerland, 2016; pp. 4–8. [Google Scholar]

- Ismael, B.; Lombardi, D. Analysis of Observed Liquefaction during the 2016 Kumamoto Earthquake; CRC Press: Boca Raton, FL, USA, 2018; Volume 8, p. 2018. [Google Scholar]

- Kolias, S.; Kasselouri-Rigopoulou, V.; Karahalios, A. Stabilisation of clayey soils with high calcium fly ash and cement. Cem. Concr. Compos. 2005, 27, 301–313. [Google Scholar] [CrossRef]

- Basha, E.A.; Hashim, R.; Mahmud, H.B.; Muntohar, A.S. Stabilization of residual soil with rice husk ash and cement. Constr. Build. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef] [Green Version]

- Yoder, E.J.; Witczak, M.W. Principles of Pavement Design; John Wiley & Sons: Hoboken, NJ, USA, 1991. [Google Scholar]

- Rezaei, A. Effect of Silica Fume and Curing Time on Volume Change Characteristics of Rice Husk Ash Stabilized Expansive Soil. Ph.D. Thesis, Eastern Mediterranean University (EMU)-Doğu Akdeniz Üniversitesi (DAÜ), İsmet İnönü Bulvarı, Gazimağusa, Turkey, 2014; p. 56. [Google Scholar]

- Kalkan, E.; Akbulut, S. The positive effects of silica fume on the permeability, swelling pressure and compressive strength of natural clay liners. Eng. Geol. 2004, 73, 145–156. [Google Scholar] [CrossRef]

- Ismael, B. Effect of Silica-Fume on the Strength and Swelling of Expansive Clays. Ph.D. Thesis, Civil Engineering Department, Al-Nahrain University, Baghdad, Iraq, 2013. [Google Scholar]

- Vakili, A.H.; Selamat, M.R.; Moayedi, H.; Amani, H. Stabilization of dispersive soils by pozzolan. In Forensic Engineering 2012: Gateway to a Safer Tomorrow; American Society of Civil Engineers: Reston, VI, USA, 2013; pp. 726–735. [Google Scholar]

- Arya, A.; Jain, A. A Review of Geotechnical Characteristics of Nano Additives Treated Soils. Int. J. Adv. Res. Sci. Eng. 2017, 6, 838–843. [Google Scholar]

- Ghasabkolaei, N.; Choobbasti, A.J.; Roshan, N.; Ghasemi, S.E. Geotechnical properties of the soils modified with nanomaterials: A comprehensive review. Arch. Civ. Mech. Eng. 2017, 17, 639–650. [Google Scholar] [CrossRef]

- Khanzada, F.A.; Nazir, K.; Ishtiaq, M.; Javed, M.F.; Kashif-Ur-Rehman, S.; Aslam, F.; Musarat, M.A.; Usanova, K.I. Concrete by Preplaced Aggregate Method Using Silica Fume and Polypropylene Fibres. Materials 2022, 15, 1997. [Google Scholar] [CrossRef] [PubMed]

- Yun, K.K.; Kim, J.B.; Song, C.S.; Hossain, M.S.; Han, S. Rheological Behavior of High-Performance Shotcrete Mixtures Containing Colloidal Silica and Silica Fume Using the Bingham Model. Materials 2022, 15, 428. [Google Scholar] [CrossRef] [PubMed]

- Xiong, G.; Wang, C.; Zhou, S.; Zheng, Y. Study on dispersion uniformity and performance improvement of steel fibre reinforced lightweight aggregate concrete by vibrational mixing. Case Stud. Constr. Mater. 2022, 16, e01093. [Google Scholar] [CrossRef]

- Taresh, N.M.; Shammeri, A. Improvement of Some Geotechnical Properties of Soft Soil Using Nanomaterial. 2012. [Google Scholar]

- Goodarzi, S.H.; Akbari, H.R. Assessing Geo-Mechanical and Micro-Structural Performance. Iran. J. Sci. Technol. Trans. Civ. Eng. 2015, 39, 333–350. [Google Scholar]

- Fattah, M.Y.; Al-Saidi, À.A.; Jaber, M.M. Characteristics of clays stabilized with lime-silica fume mix. Ital. J. Geosci. 2015, 134, 104–113. [Google Scholar] [CrossRef]

- Bahmani, S.H.; Farzadnia, N.; Asadi, A.; Huat, B.B.K. The effect of size and replacement content of nanosilica on strength development of cement treated residual soil. Constr. Build. Mater. 2016, 118, 294–306. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Taha, M.R. Geotechnical Properties of Soil-Ball Milled Soil Mixtures. Nanotechnol. Constr. 2009, 3, 377–382. [Google Scholar]

| Property | Clayey Soil |

|---|---|

| Unconfined compressive strength (kPa) | 171 |

| Liquid Limit LL (%) | 52.6 |

| Plastic limit (%) | 35.3 |

| Plasticity Index (%) | 17.3 |

| Specific Gravity, GS | 2.72 |

| Sand Content (%) | 0 |

| Silt Content (%) | 37 |

| Clay Content (%) | 63 |

| Max. Dry density (g/cm3) | 1.69 |

| Optimum Moisture Content (%) | 15.6 |

| Property | Composition (%) |

|---|---|

| SiO2 | 94.3 |

| Al2O3 | 0.31 |

| Fe2O3 | 0.82 |

| SO3 | 0.91 |

| CaO | 0.29 |

| MgO | 0.133 |

| K2O | 0.442 |

| Na2O | 0.081 |

| Tio2 | <0.02 |

| Loss on ignition | 3.38 |

| Oxide Composition | Pozzolan Class N |

|---|---|

| SiO2 + Al2O3 + Fe2O3 (min. percent) | 70 |

| SO3 (max. percent) | 4 |

| Moisture content (max. percent) | 3 |

| Loss on ignition max. | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshami, A.W.; Ismael, B.H.; Aswad, M.F.; Majdi, A.; Alshijlawi, M.; Aljumaily, M.M.; AlOmar, M.K.; Aidan, I.A.; Hameed, M.M. Compaction Curves and Strength of Clayey Soil Modified with Micro and Nano Silica. Materials 2022, 15, 7148. https://doi.org/10.3390/ma15207148

Alshami AW, Ismael BH, Aswad MF, Majdi A, Alshijlawi M, Aljumaily MM, AlOmar MK, Aidan IA, Hameed MM. Compaction Curves and Strength of Clayey Soil Modified with Micro and Nano Silica. Materials. 2022; 15(20):7148. https://doi.org/10.3390/ma15207148

Chicago/Turabian StyleAlshami, Abeer W., Bashar H. Ismael, Mohammed F. Aswad, Ali Majdi, Murtatha Alshijlawi, Mustafa Mohammed Aljumaily, Mohamed Khalid AlOmar, Ibraheem A. Aidan, and Mohammed Majeed Hameed. 2022. "Compaction Curves and Strength of Clayey Soil Modified with Micro and Nano Silica" Materials 15, no. 20: 7148. https://doi.org/10.3390/ma15207148

APA StyleAlshami, A. W., Ismael, B. H., Aswad, M. F., Majdi, A., Alshijlawi, M., Aljumaily, M. M., AlOmar, M. K., Aidan, I. A., & Hameed, M. M. (2022). Compaction Curves and Strength of Clayey Soil Modified with Micro and Nano Silica. Materials, 15(20), 7148. https://doi.org/10.3390/ma15207148