The Analysis of Plastic Forming in the Rolling Process of Difficult-to-Deform Ti + Ni Layered Composites

Abstract

:1. Introduction

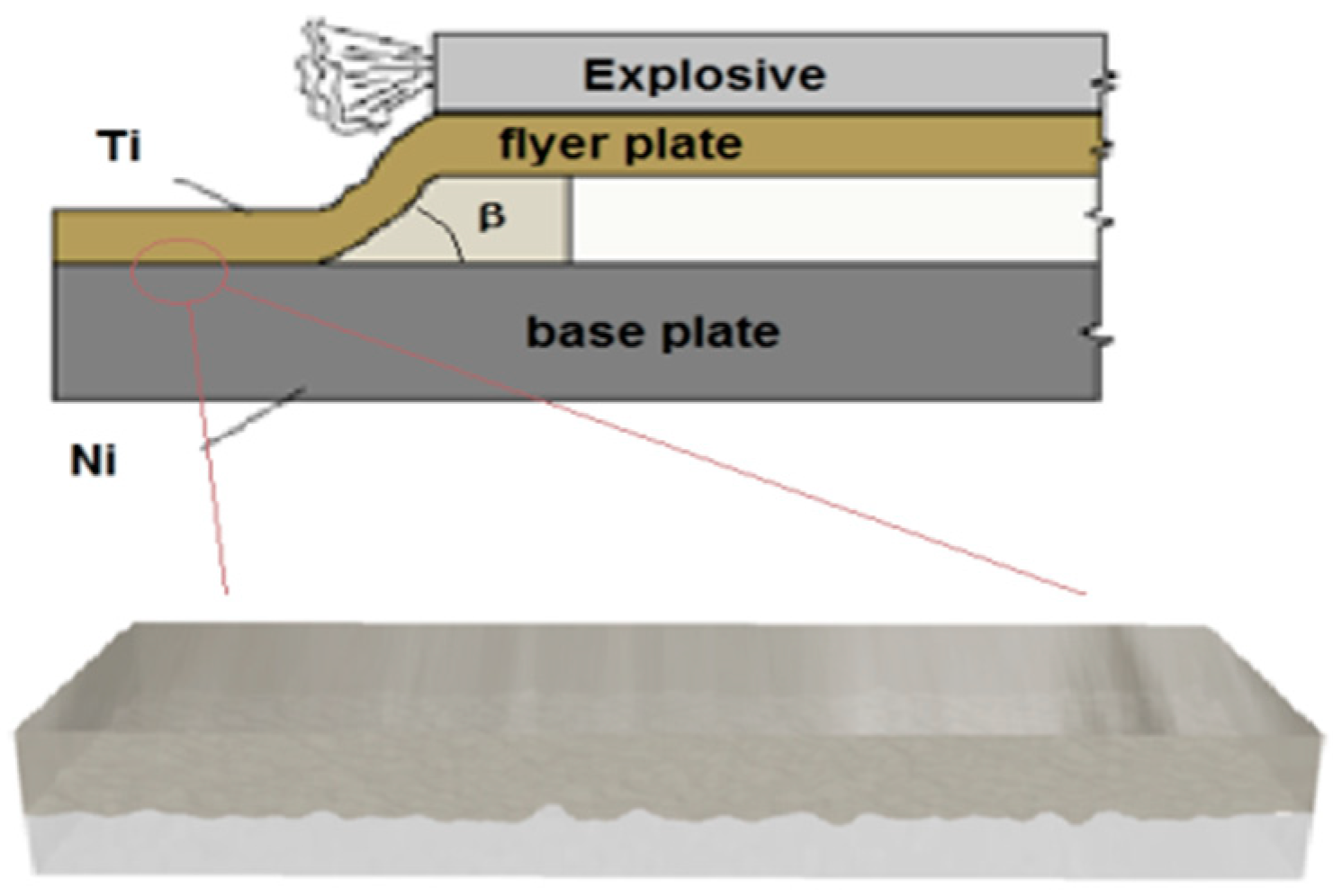

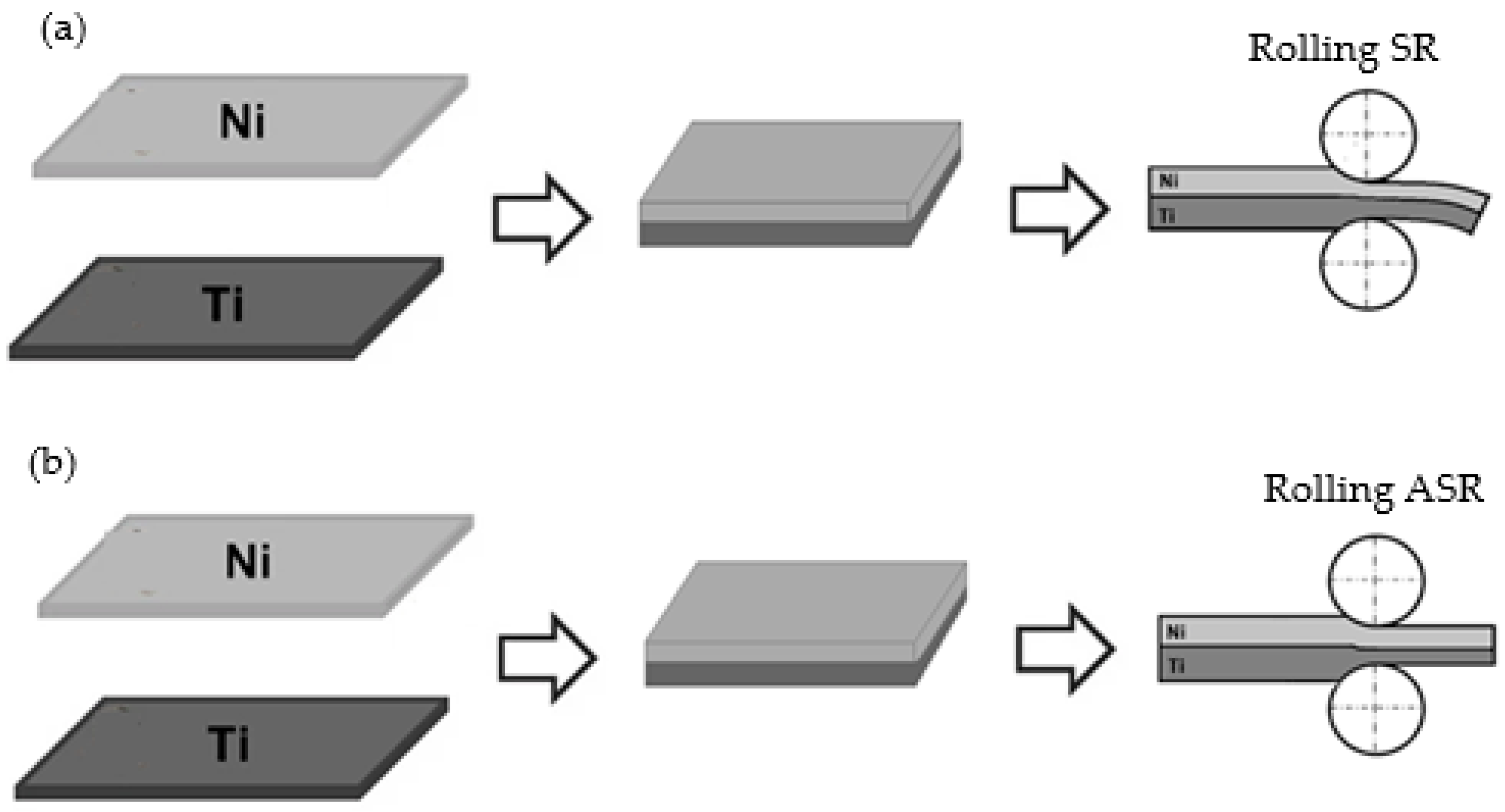

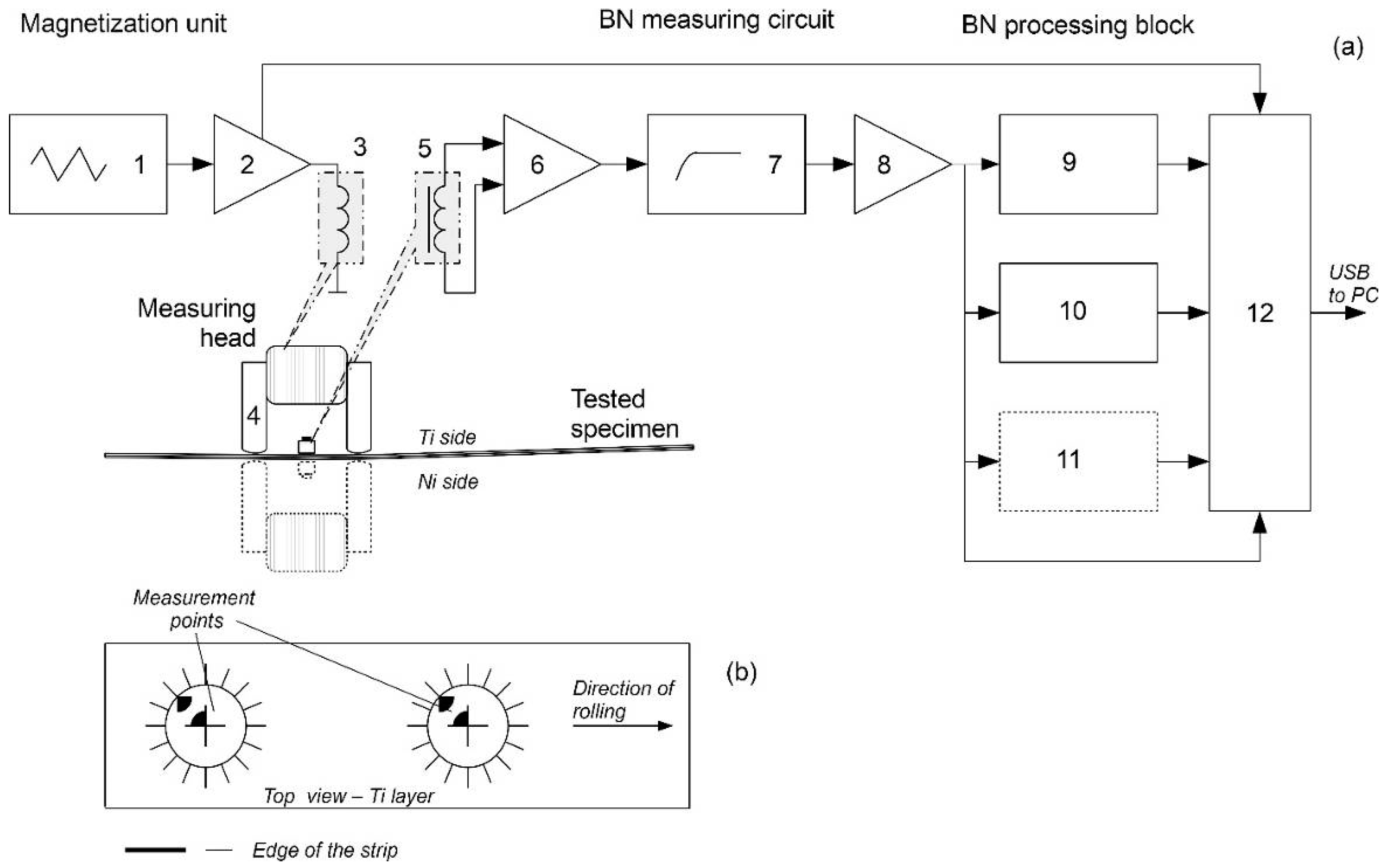

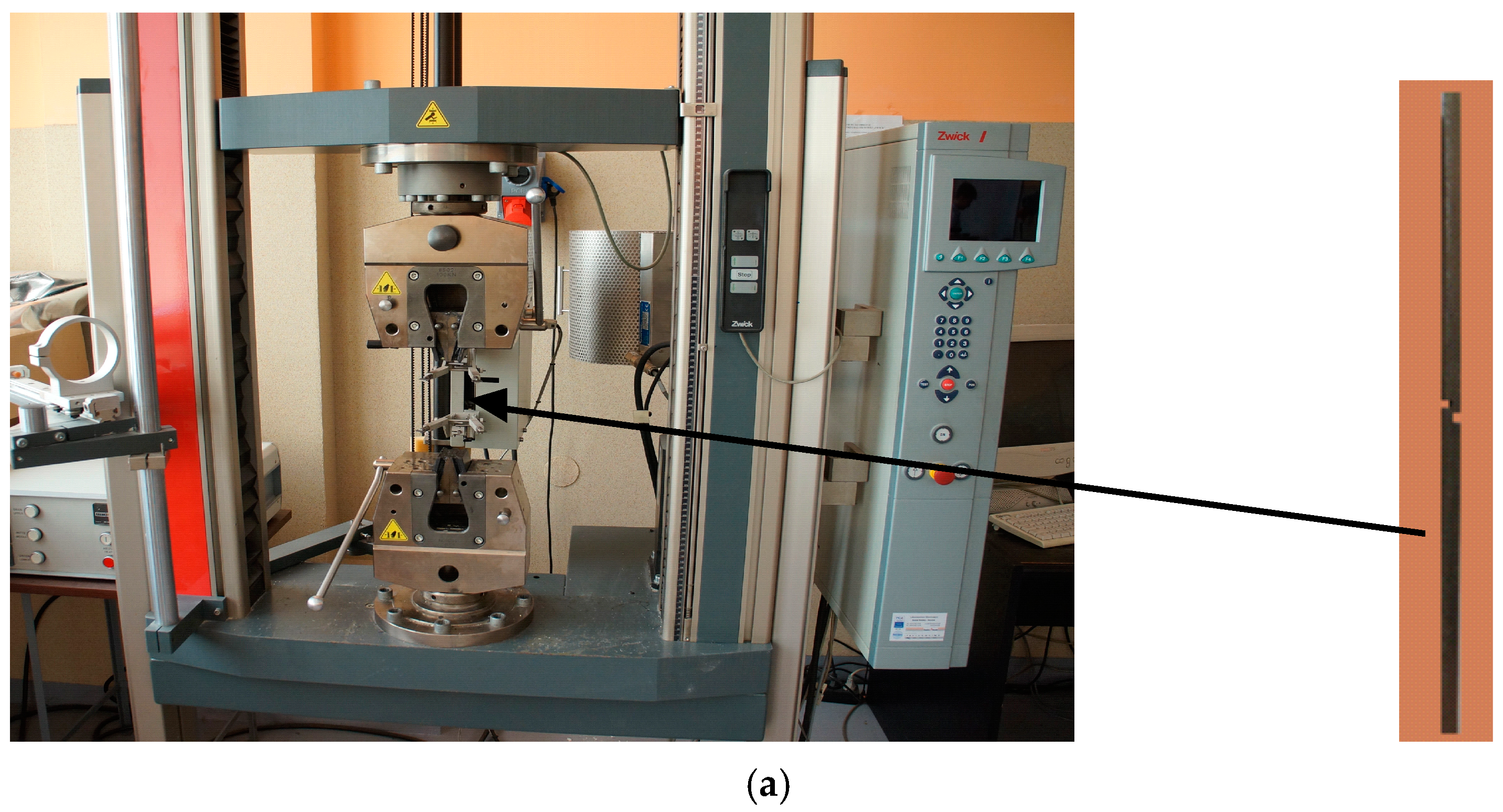

2. Materials and Methods

- shear strength of the joint for materials before the rolling process;

- cold rolling;

- the residual stress analysis with the use of the non-destructive method using the Barkhausen noise (BN) technique,

- analysis of microstructure.

- VU—peripheral speed of the upper roll,

- VL—peripheral speed of the lower roll.

3. Results and Discussion

4. Conclusions

- After the explosive welding process, a permanent connection was obtained with a shear strength more than three times higher than the requirements provided for by the standard—150 MPa.

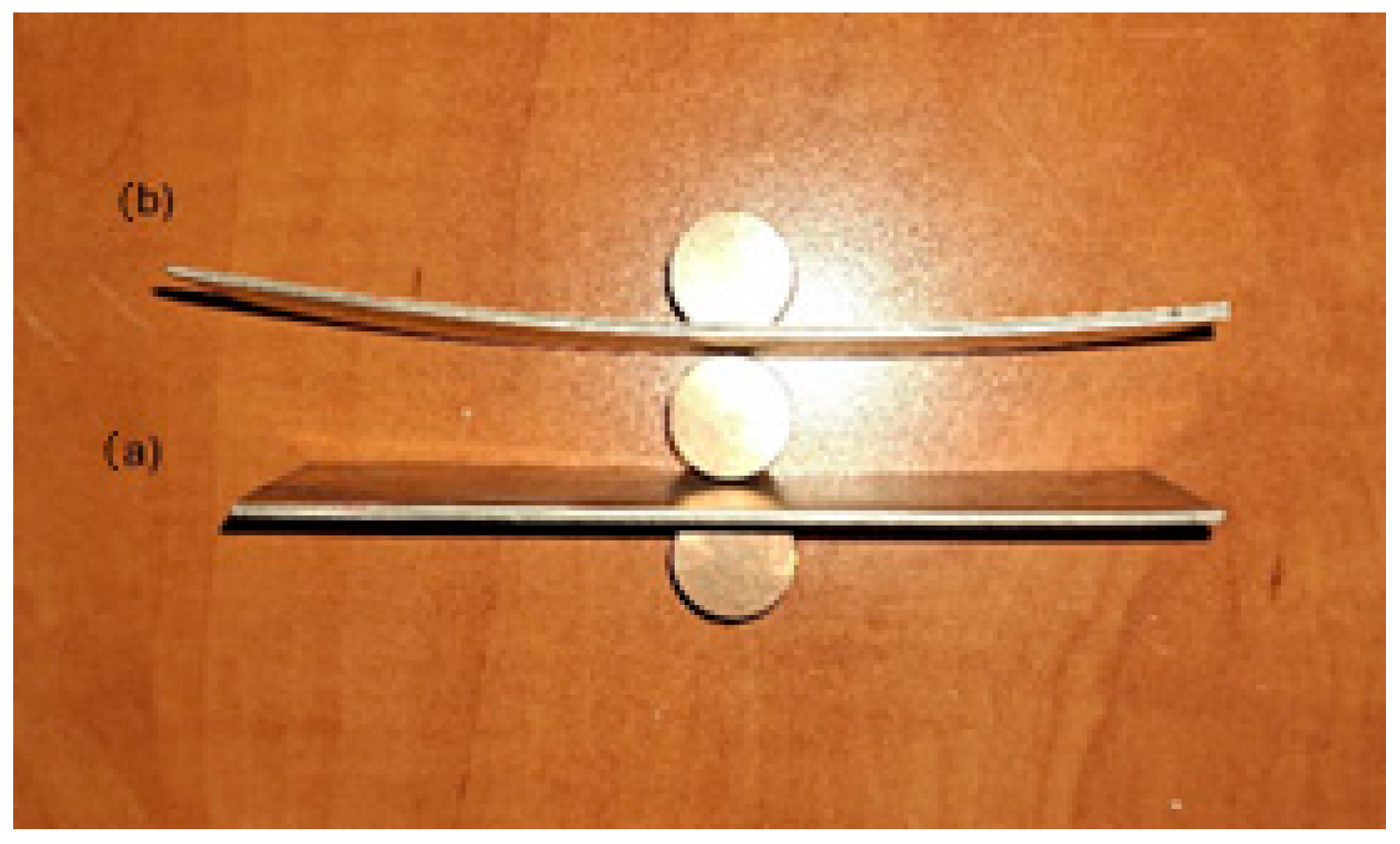

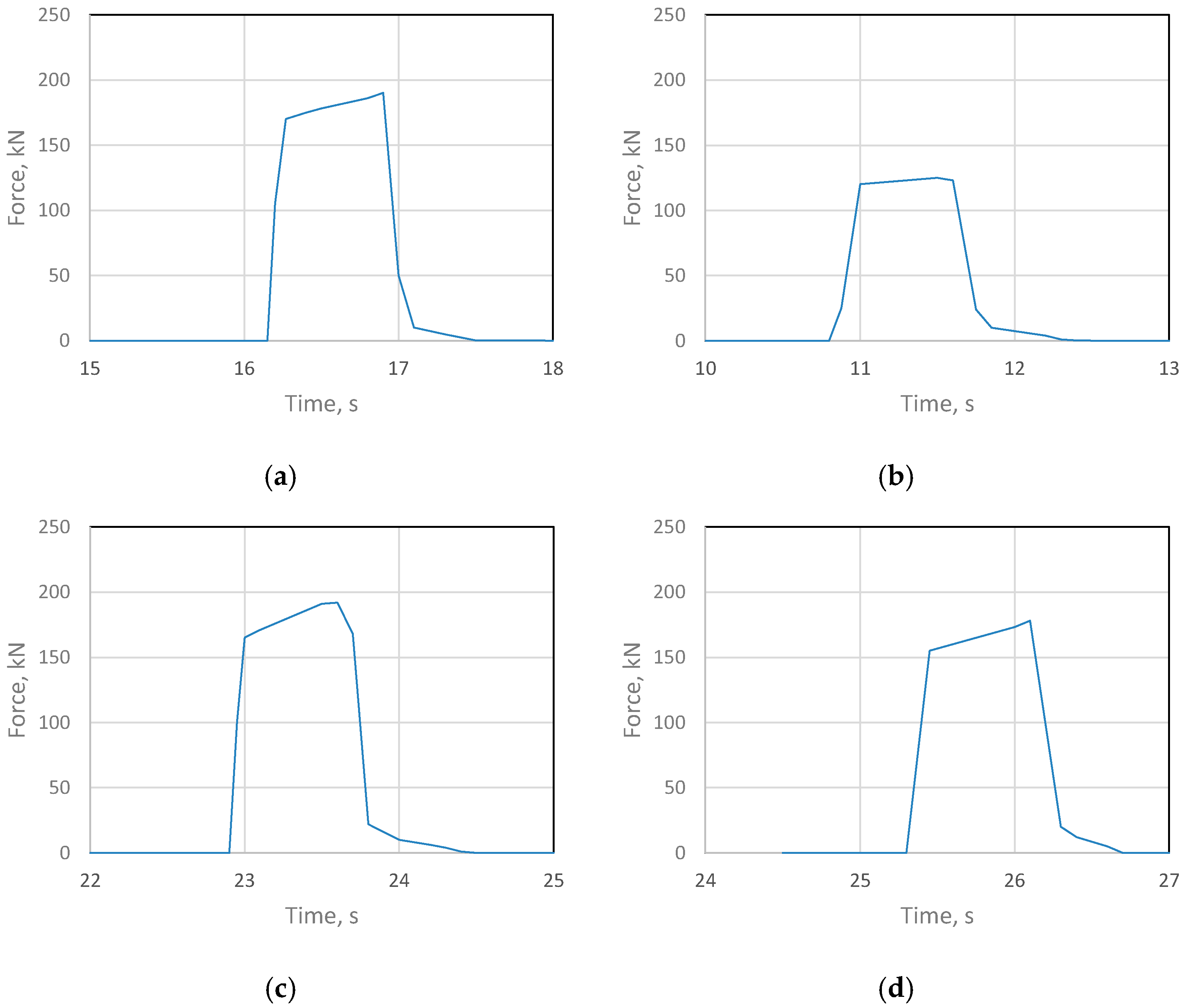

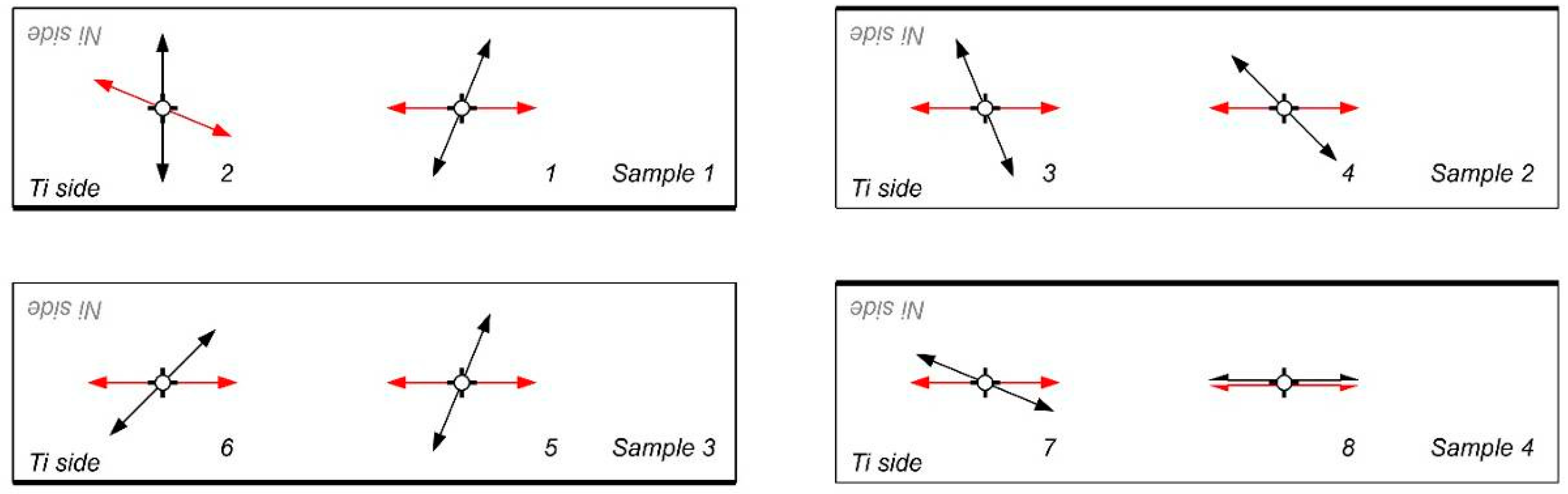

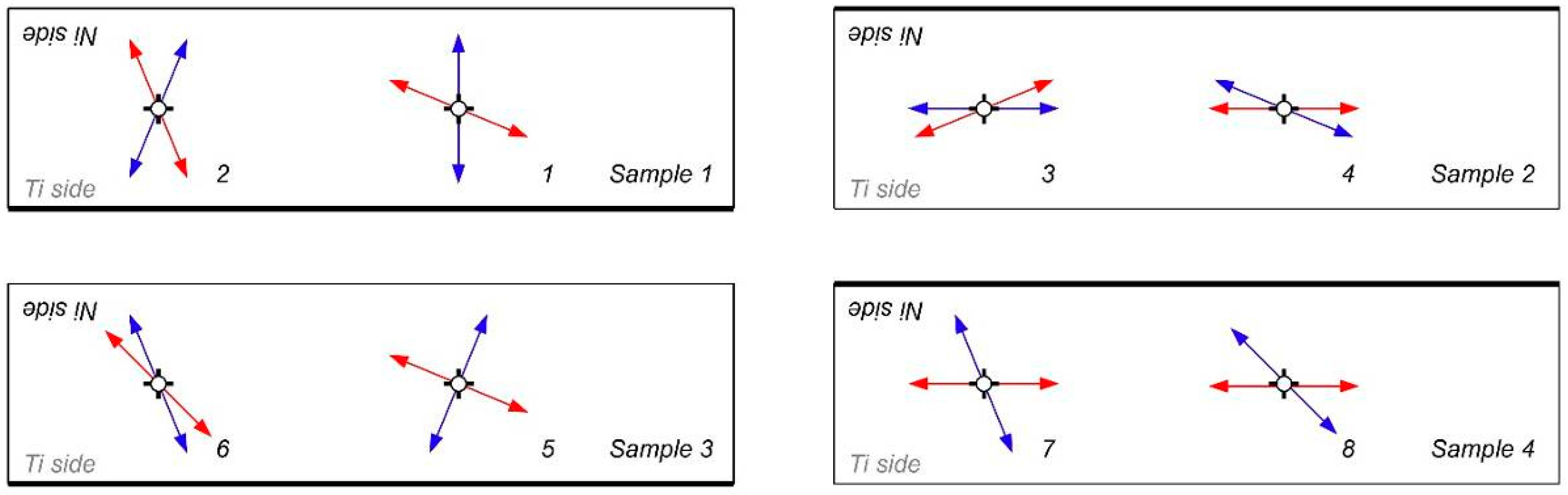

- During the rolling process, however, the problem is the selection of optimal process parameters for pairs of difficult-to-deform materials. The carried-out tests show that plastic deformation of Ti-Ni composite sandwich sheets were conducted properly. The introduction of asymmetry in the peripheral speed of the work rolls for rolling composite Ti-Ni sheets had a positive effect on their bending after the plastic forming process (Figure 6 and Figure 7). The macroscopic observation revealed that no cracks or delamination were observed in the area of the joint.

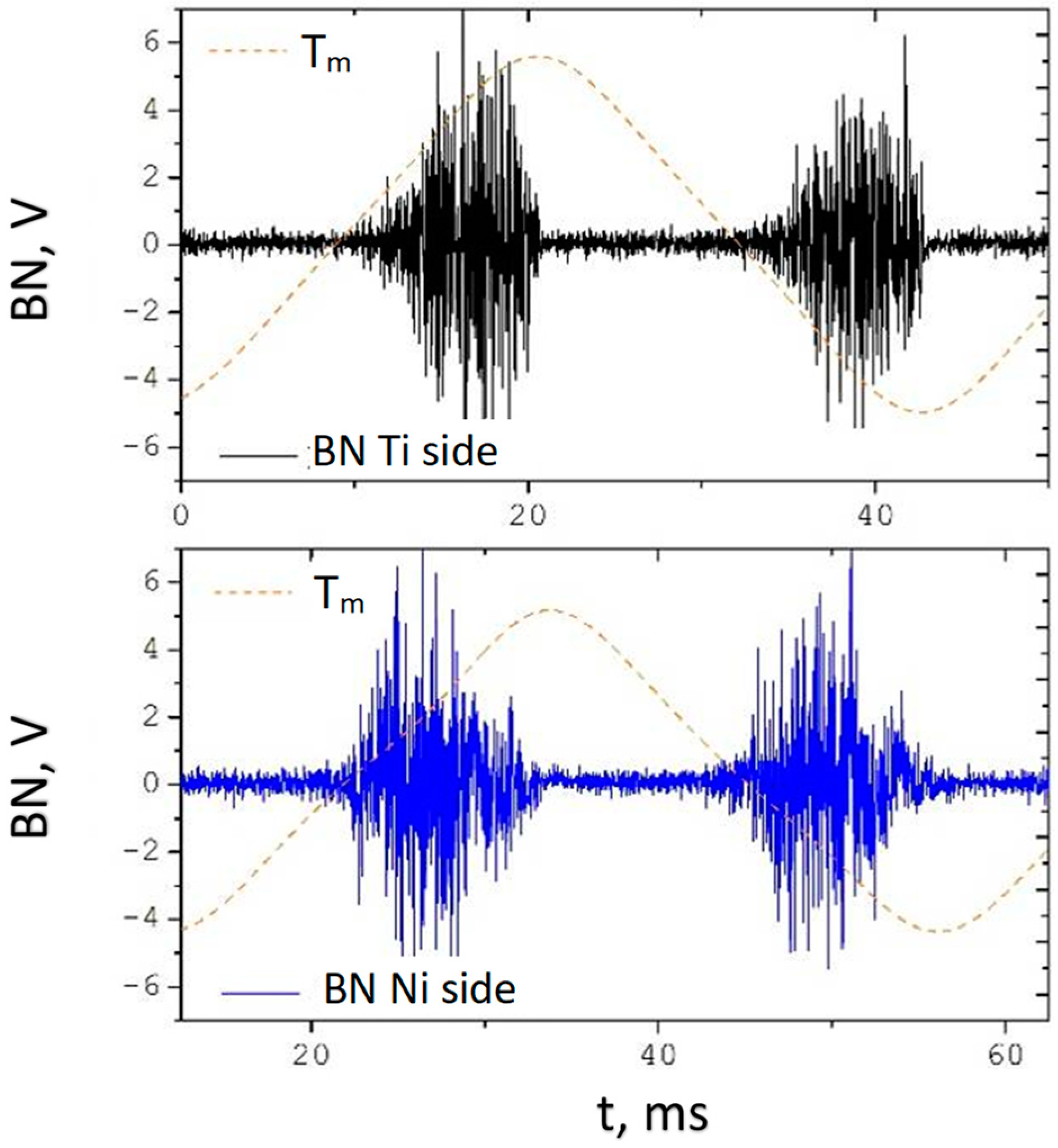

- Obtained results have confirmed the possibility of the stress determination in the nickel layer of thin composite by the Barkhausen method. It can be a new, additional, or supplementary testing tool for Ti-Ni sheets alongside existing ultrasound NDT of composite joint quality.

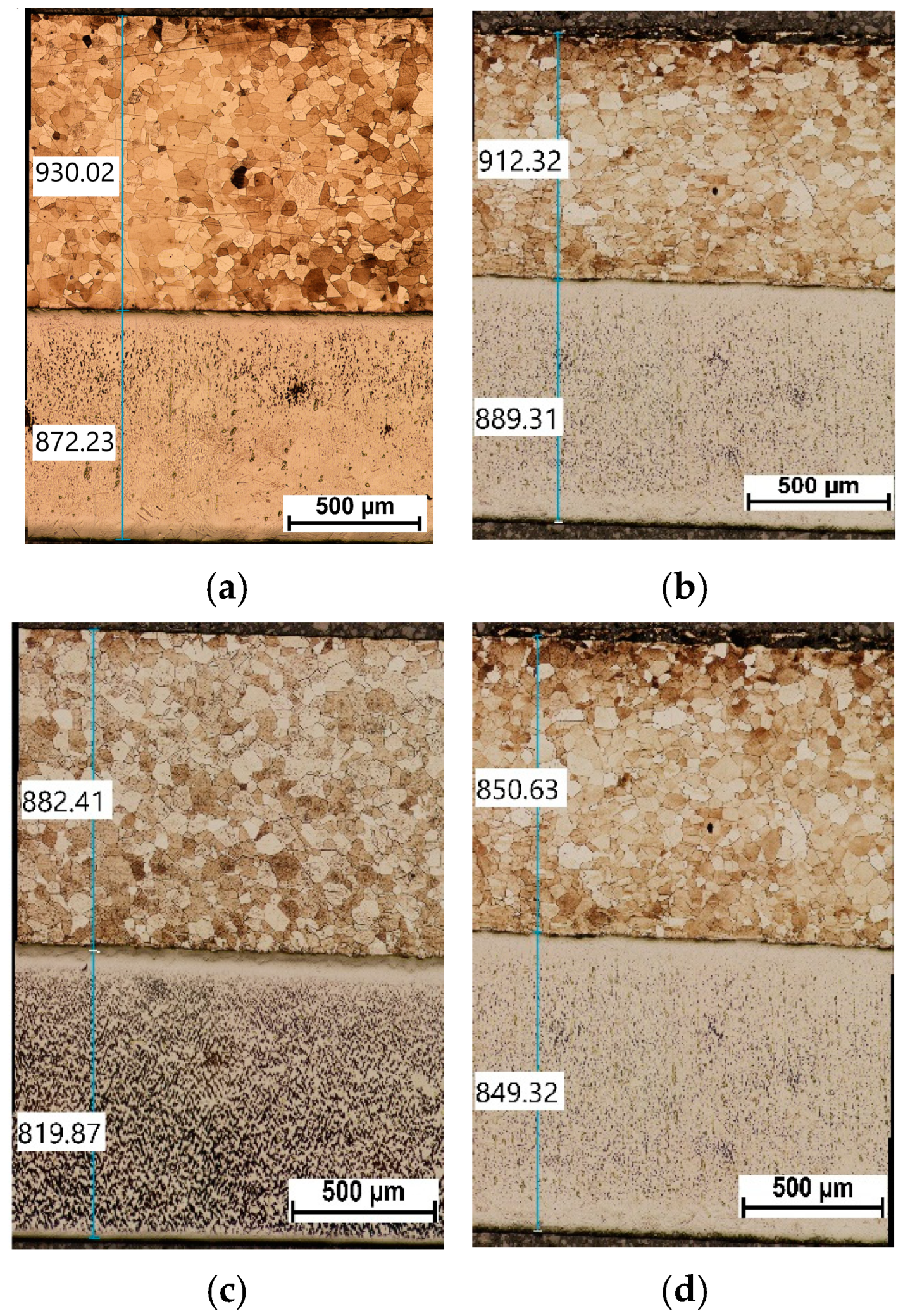

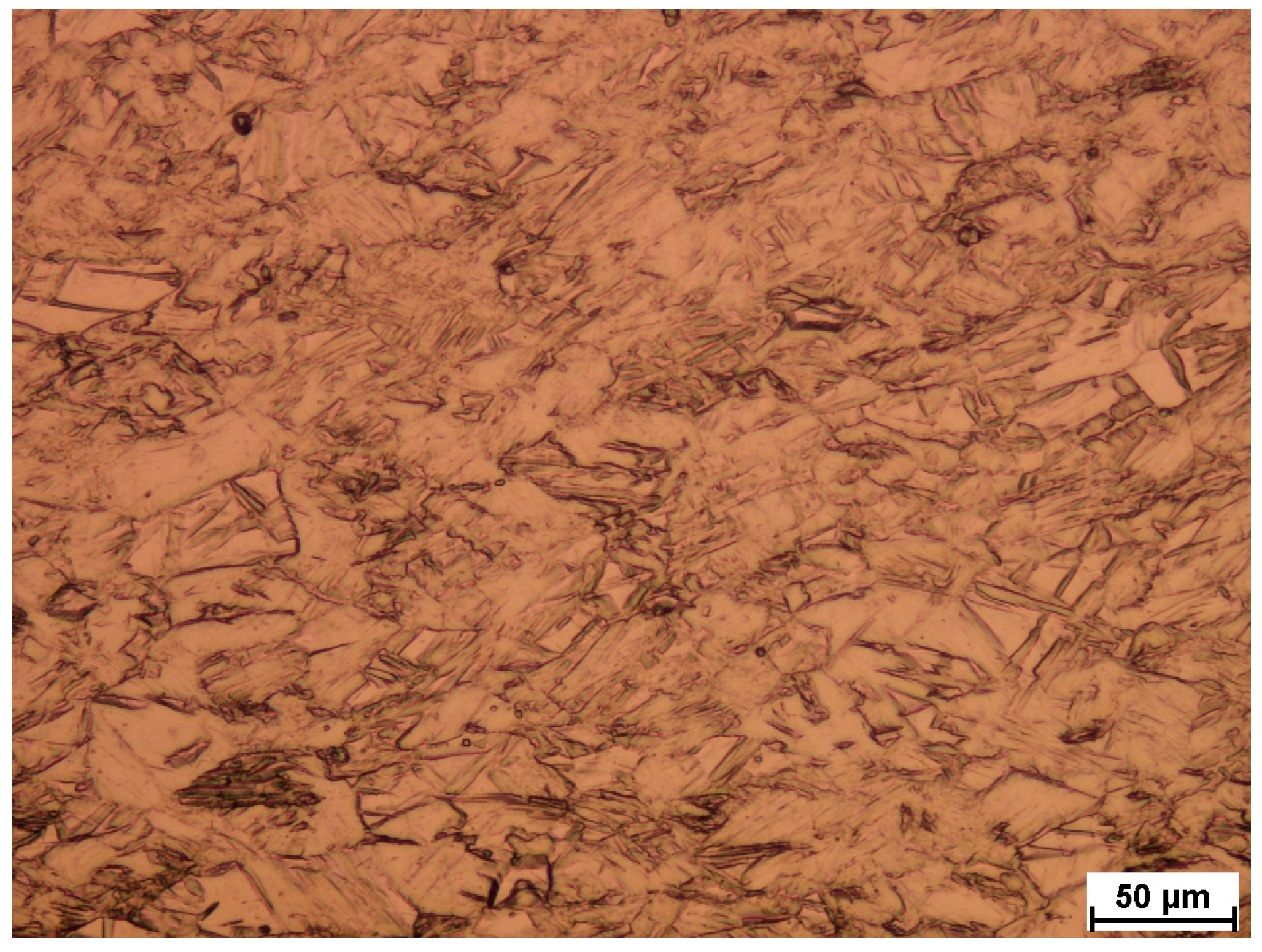

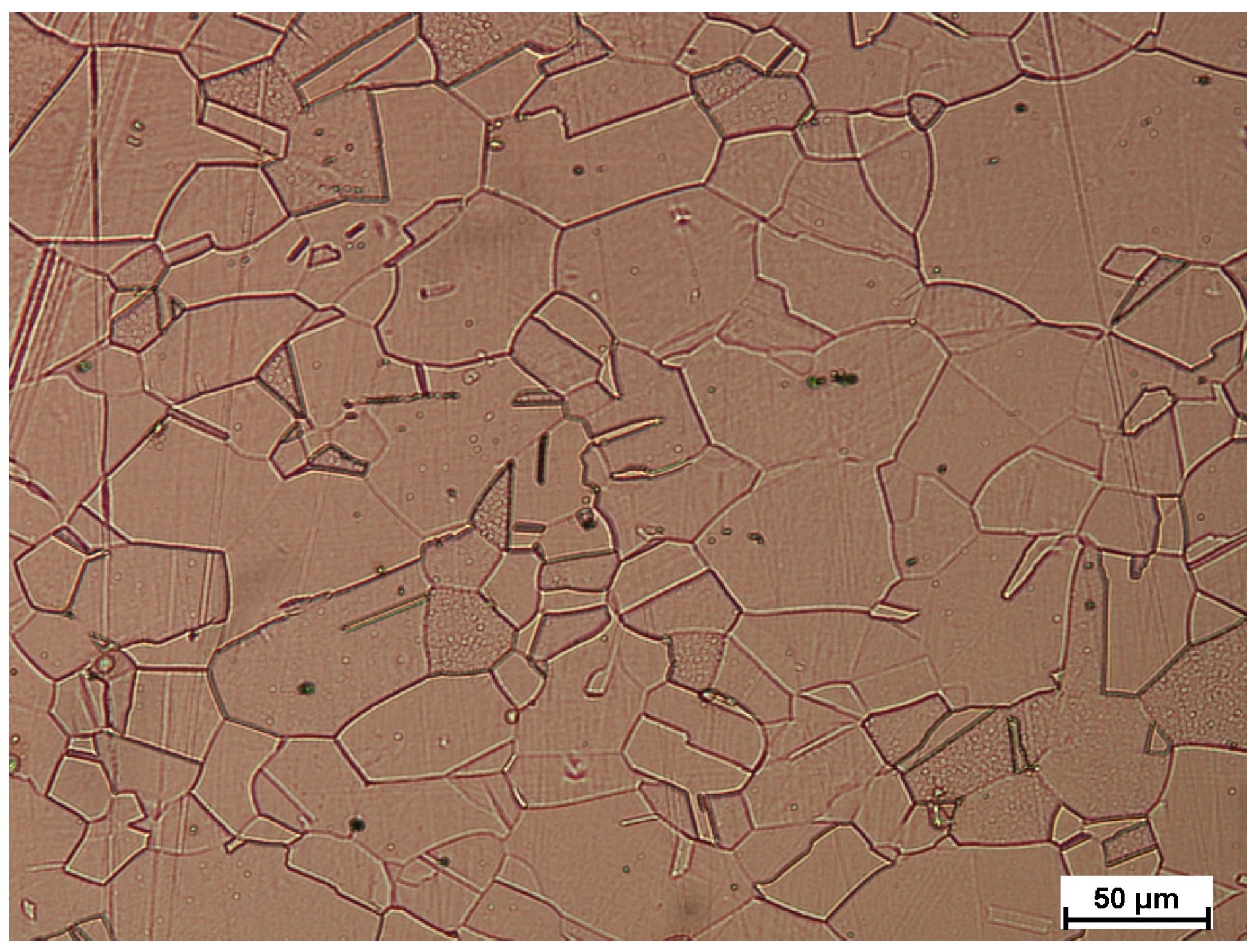

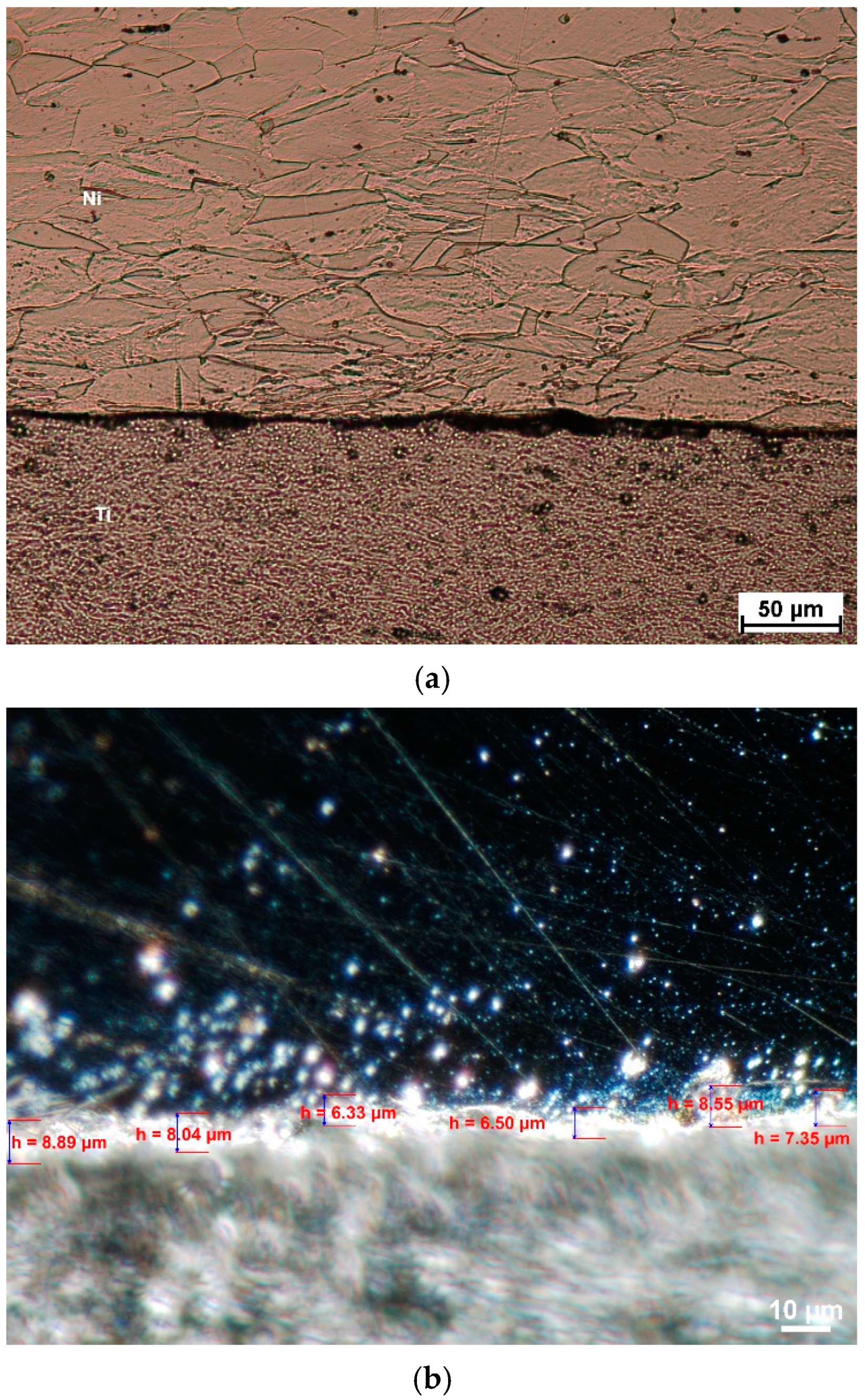

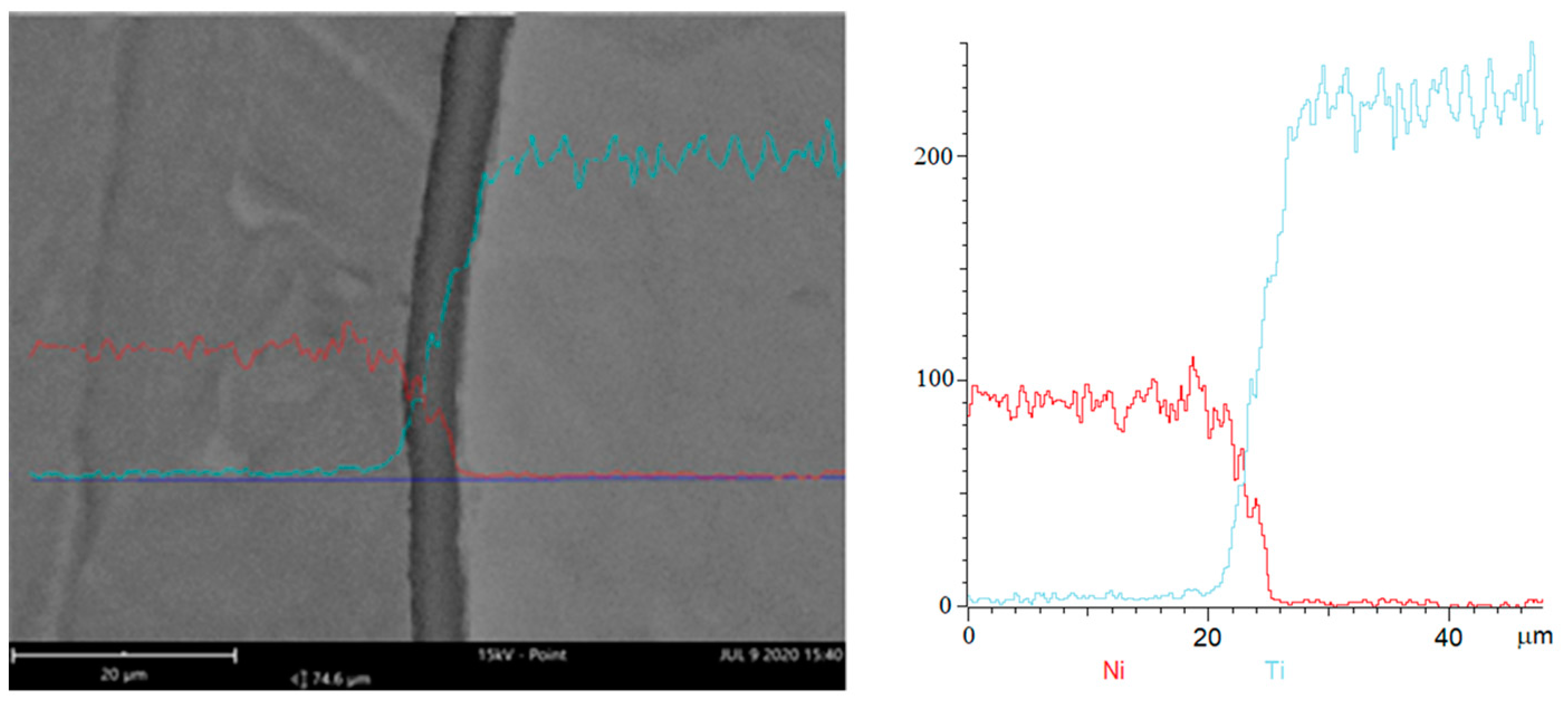

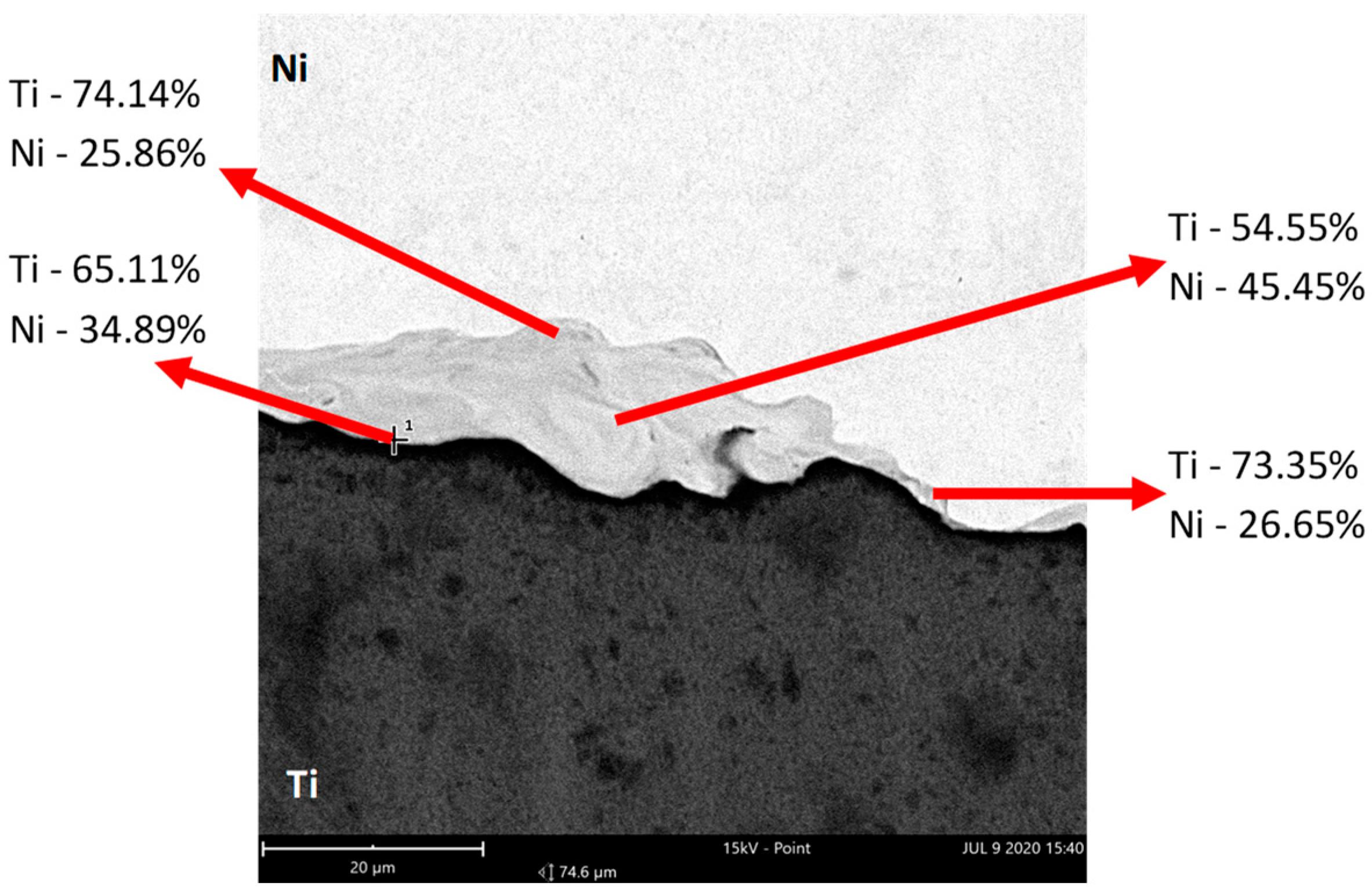

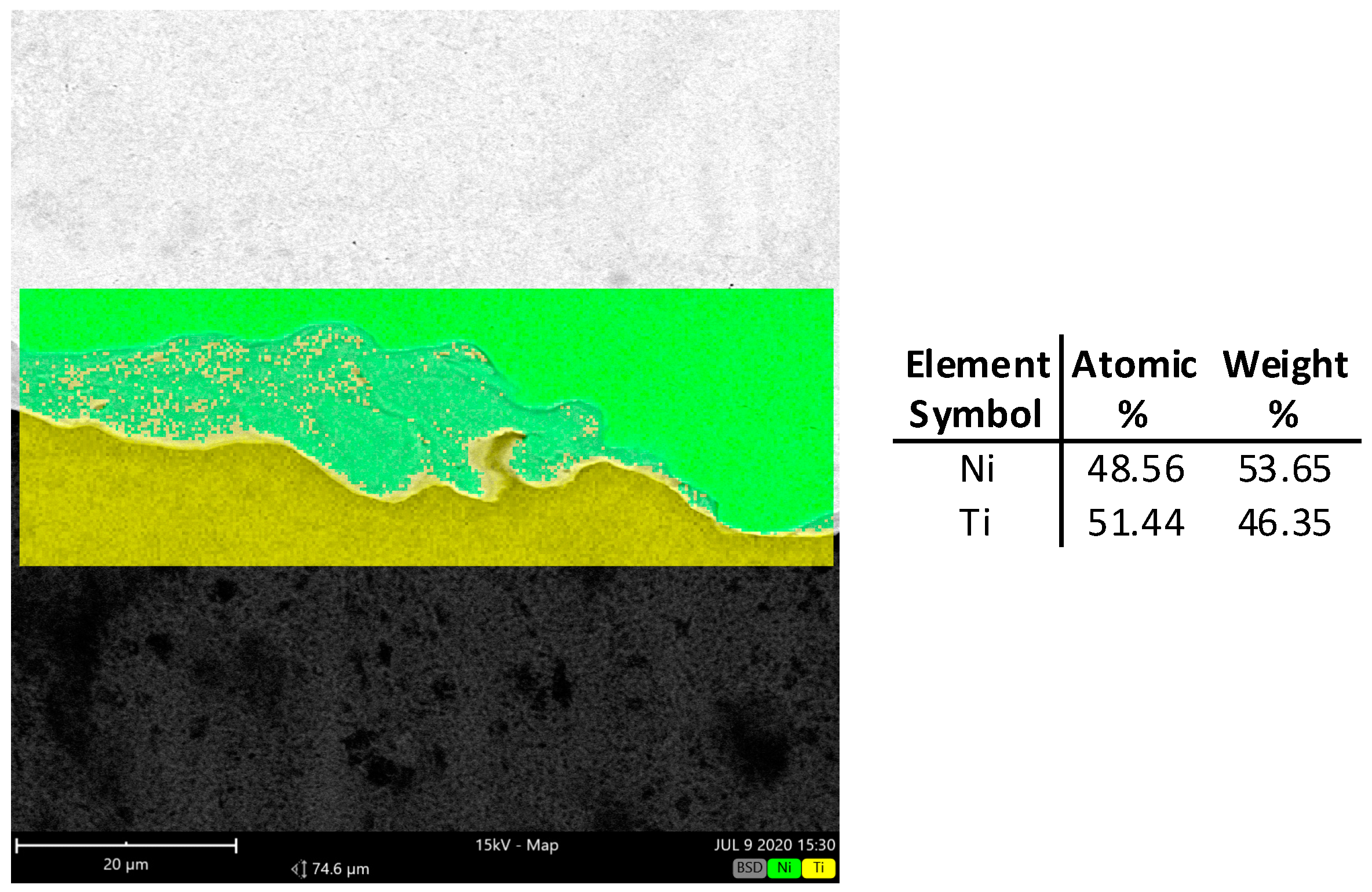

- The microstructure analysis of the joining area shows that cold deformation with the use of the symmetrical and asymmetrical rolling does not generate cracks. It was confirmed that the intermetallic layer is non-uniform. The chemical composition changes in volume. In the central part it is composed of a mixture of about 50% Ti and Ni.

- It has to be stated that the intermetallic layer is not continuous; it can be seen that there are areas of intermetallics. The joining area after explosive welding is wavy; after the applied rolling process, the wave peaks slightly decrease. What is interesting is that the intermetallics after explosive welding are wider than after the rolling process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Q.; Hu, X.; Liu, X. Analysis of Mechanical Parameters in Multi-Pass Asymmetrical Rolling of Strip by Slab Method. Materials 2023, 16, 6286. [Google Scholar] [CrossRef] [PubMed]

- Rydz, D. The Influence of Asymmetry Factor and Deformation on the Criterion Optimizing the Relative Flow Rate of St3S+0H13J Bimetallic Strip. Metalurgija 2005, 44, 91–95. [Google Scholar]

- Grudzień, J.; Grochała, D.; Grzejda, R.; Kochmański, P. Testing The Effectiveness of Hybrid Milling and Surface Burnishing in Improving the Wear Resistance of Machine Parts Made of Structural Steel. Lubricants 2024, 12, 458. [Google Scholar] [CrossRef]

- Grochała, D.; Grzejda, R.; Parus, A.; Berczyński, S. The Wavelet Transform For Feature Extraction And Surface Roughness Evaluation After Micromachining. Coatings 2024, 14, 210. [Google Scholar] [CrossRef]

- Krajewski, S.J.; Grochała, D.; Tomków, J.; Grzejda, R. Analysis of the Surface Stereometry of Alloyed Austenitic Steel After Fibre Laser Cutting Using Confocal Microscopy. Coatings 2023, 13, 15. [Google Scholar] [CrossRef]

- Strzelecki, G.W.; Nowakowska-Langier, K.; Namyślak, K.; Mulewska, K.; Wilczopolska, M.; Minikayev, R.; Nadolski, M.; Okrasa, S.; Romaniuk, S.; Zdunek, K. Shannon Entropy Characterization of High-Entropy Thin Films Synthesized by Pulsed Magnetron Sputtering: The Influence of Modulation Frequency. Metall. Mater. Trans. A 2025, 56, 518–531. [Google Scholar] [CrossRef]

- Hawryluk, M.; Janik, M.; Zwierzchowski, M.; Lachowicz, M.M.; Krawczyk, J. Possibilities of Increasing the Durability of Dies Used in the Extrusion Process of Valve Forgings from Chrome-Nickel Steel by Using Alternative Materials from Hot-Work Tool Steels. Materials 2024, 17, 346. [Google Scholar] [CrossRef]

- Krawczyk, J.; Łukaszek-Sołek, A.; Lisiecki, Ł.; Śleboda, T.; Hawryluk, M. Wear Mechanisms of the Forging Tool Used in Pre-Forming in a Double Forging System of Truck Parts. Materials 2023, 16, 351. [Google Scholar] [CrossRef]

- Wang, H.; Chen, N.; Cheng, H.; Wang, Y.; Zhao, D. Tensile Deformation Mechanism of an In Situ Formed Ti-Based Bulk Metallic Glass Composites. Materials 2024, 17, 4486. [Google Scholar] [CrossRef]

- Eizadjou, M.; Kazemi Talachi, A.; Danesh Manesh, H.; Shakur Shahabi, H.; Janghorban, K. Investigation of Structure and Mechanical Properties of Multi-Layered Al/Cu Composite Produced by Accumulative Roll Bonding (ARB) Process. Compos. Sci. Technol. 2008, 68, 2003–2009. [Google Scholar] [CrossRef]

- Paul, H.; Faryna, M.; Prazmowski, M.; Banski, R. Changes in the Bonding Zone of Explosively Welded Sheets. Arch. Metall. Mater. 2011, 56, 463–474. [Google Scholar] [CrossRef]

- Zhao, K.; Xu, D.; Song, X.; Ma, Y.; Li, H.; Zhang, J.; Chen, D. Reducing Yield Asymmetry between Tension and Compression by Fabricating ZK60/WE43 Bimetal Composites. Materials 2020, 13, 249. [Google Scholar] [CrossRef] [PubMed]

- Rydz, D.; Stradomski, G.; Pałęga, M.; Salwin, M.; Opydo, M.; Szarek, A.; Fik, J.; Chmielewski, T. Analysis of Plastic Forming During Rolling of Al1050-AZ31-Al1050 Layered Composites for Transport Purposes. Adv. Sci. Technol. Res. J. 2024, 18, 234–244. [Google Scholar] [CrossRef] [PubMed]

- Sang, C.; Cai, X.; Zhu, L.; Ren, X.; Niu, G.; Wang, X.; Feng, P. Interfacial Microstructure of Ti/Ni Joints with Ti–Al Interlayer by Rapid Thermal Explosion Bonding in Vacuum. Vacuum 2020, 171, 109028. [Google Scholar] [CrossRef]

- Nayanathara Thathsarani Pilapitiya, P.; Ratnayake, A.S. The World of Plastic Waste: A review. Clean. Mater. 2024, 11, 100220. [Google Scholar] [CrossRef]

- Luo, J.; Aco, V.L. Using cold roll bonding and annealing to process Ti/Al multi-layered composites from elemental foils. Mater. Sci. Eng. A 2004, 379, 164–172. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Vivekanandhan, S.; Tripathi, N.; Roy, P.; Snowdon, M.R.; Drzal, L.T.; Misra, M. Sustainable Composites for Lightweight and Flame Retardant Parts for Electric Vehicles to Boost Climate Benefits: A perspective. Compos. Part C Open Access 2023, 12, 100380. [Google Scholar] [CrossRef]

- Fronczek, D.M.; Chulist, R.; Litynska-Dobrzynska, L.; Kac, S.; Schell, N.; Kania, Z.; Szulc, Z.; Wojewoda-Budka, J. Microstructure and Kinetics of Intermetallic Phase Growth of Three-Layered A1050/AZ31/A1050 Clads Prepared by Explosive Welding Combined With Subsequent Annealing. Mater. Des. 2017, 130, 120–130. [Google Scholar] [CrossRef]

- Tavoosi, M. The Kirkendall Void Formation in Al/Ti Interface During Solid-State Reactive Diffusion Between Al and Ti. Surf. Interfaces 2017, 9, 96–200. [Google Scholar] [CrossRef]

- Wachowski, M.; Kosturek, R.; Śniezek, L.; Mróz, S.; Stefanik, A.; Szota, P. The Effect of Post-Weld Hot-Rolling on the Properties of Explosively Welded Mg/Al/Ti Multilayer Composite. Materials 2020, 13, 1930. [Google Scholar] [CrossRef]

- Topolski, K.; Wieciński, P.; Szulc, Z.; Gałka, A.; Garbacz, H. Progress in the Characterization of Explosively Joined Ti/Ni Bimetals. Mater. Des. 2014, 63, 479–487. [Google Scholar] [CrossRef]

- Karolczuk, A.; Kluger, K.; Derda, S.; Prazmowski, M.; Paul, H. Influence of Impact Velocity on the Residual Stress, Tensile Strength, and Structural Properties of an Explosively Welded Composite Plate. Materials 2020, 13, 2686. [Google Scholar] [CrossRef] [PubMed]

- Buque, C.; Tirschler, W.; Holste, C. Analysis of Local Variations of Internal Stresses in Cyclically Deformed Nickel Crystal by Barkhausen Noise Measurements. Mat. Sc. Eng. A 1966, 215, 168–174. [Google Scholar] [CrossRef]

- Garstka, T.; Rydz, D. Explosively Welded Ti-Ni Bimetallic Plate Characterization Using Barkhausen Noise. J. Electr. Eng. 2015, 66, 186–189. [Google Scholar]

- Rydz, D.; Dyja, H.; Berski, S. The Prediction of Curvature of Bimetallic Plate Al-Cu During Asymmetrical Cold Rolling. Metalurgija 2003, 42, 261–264. [Google Scholar]

- Mozaari, A.; Hosseini, M.; Manesh, H.D. Al/Ni Metal Intermetallic Composite Produced by Accumulative Roll Bonding and Reaction Annealing. J. Alloys Compd. 2011, 509, 9938–9945. [Google Scholar] [CrossRef]

- Gronostajski, Z.; Pater, Z.; Madej, L.; Gontarz, A.; Lisiecki, L.; Łukaszek-Sołek, A.; Łuksza, J.; Mróz, S.; Muskalski, Z.; Muzykiewicz, W.; et al. Recent Development Trends in Metal Forming. Arch. Civ. Mech. Eng. 2019, 19, 898–941. [Google Scholar] [CrossRef]

- Roberts, I.; Mynors, D. Optimal Selection of Machine Parameters in Tension Leveling of Sheet Metals. Eng. Mater. Sci. 2012, 212671857. [Google Scholar]

- Mihara-Narita, M.; Asai, K.; Sato, H.; Watanabe, Y.; Nakatsugawa, I.; Saito, N.; Chino, Y. Dissimilar Welding of Magnesium Alloys and Aluminum Alloys by Explosive Welding. Materials 2025, 18, 1013. [Google Scholar] [CrossRef]

- Wierzba, A.; Mróz, S.; Szota, P.; Stefanik, A.; Mola, R. The Influence of the Asymmetric ARB Process on the Properties of Al-Mg-Al Multi-Layer Sheets. Arch. Metall. Mater. 2015, 60, 2821–2825. [Google Scholar] [CrossRef]

- Sun, H.; Li, Q.; Chan, Y.C. A Study Of Ag Additive Methods by Comparing Mechanical Properties Between Sn57.6Bi0.4Ag and 0.4wt% Nano-Ag-Doped Sn58Bi BGA Solder Joints. J. Mater. Sci. Mater. Electron. 2014, 25, 4380–4390. [Google Scholar] [CrossRef]

- Cao, J.; Li, C.; Qi, J.; Shi, Y.; Feng, J. Combustion joining of carbon–carbon composites to TiAl intermetallics using a Ti–Al–C powder composite interlayer. Compos. Sci. Technol. 2015, 115, 72–79. [Google Scholar] [CrossRef]

- Zdrodowska, K.; Wojsyk, K.; Szala, M. The Microstructural Properties of Explosion Welded Ni/Ti Joint. Adv. Sci. Technol. Res. J. 2014, 8, 71–74. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, Z.; Zhao, T.; Zhang, D.; Cheng, J.; Wang, W.; Qiao, K.; Yang, Y.; Wang, K. Effect of Temperature on the Interfacial Evolution of Ti/Ni Multilayered Composites Fabricated by ARB. J. Alloys Comp. 2019, 803, 265–276. [Google Scholar] [CrossRef]

- Shen, T.D.; Quan, M.X.; Wang, J.T. Solid State Amorphization Reactions in Ni/Ti Multilayer Composites Prepared by Cold Rolling. J. Mat. Sc. 1993, 28, 394–398. [Google Scholar] [CrossRef]

- Gavalec, M.; Barenyi, I.; Krbata, M.; Kohutiar, M.; Balos, S.; Pecanac, M. The Effect of Rotary Friction Welding Conditions on the Microstructure and Mechanical Properties of Ti6Al4V Titanium Alloy Welds. Materials 2023, 16, 6492. [Google Scholar] [CrossRef]

- Grassino, J.; Vedani, M.; Vimercati, G.; Zanella, G. Effects of Skin Pass Rolling Parameters on Mechanical Properties of Steels. Int. J. Precis. Eng. Mnanuf. 2017, 13, 2017–2026. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.; Yang, Q.; Wang, Q.; Wang, Y.; Li, W. Mechanism of Lateral Metal Flow on Residual Stress Distribution During Hot Strip Rolling. J. Mater. Proces. Tech. 2021, 288, 116838. [Google Scholar] [CrossRef]

- Mróz, S.; Szota, P.; Stefanik, A. The Theoretical and Experimental Analysis of the Possibility of Employing the Groove Rolling Process for the Manufacture of Mg/Al Bimetallic Bars. Metalurgija 2016, 55, 628–630. [Google Scholar]

- Abvabi, A. Effect of Residual Stresses in Roll Forming Process of Metal Sheets. Ph.D. Thesis, Deakin University, Melbourne, Australia, 2014. [Google Scholar]

- Skripalenko, M.M.; Galkin, S.P.; Karpov, B.V.; Romantsev, B.A.; Kaputkina, L.M.; Danilin, A.V.; Skripalenko, M.N.; Patrin, P.V. Forming Features and Properties of Titanium Alloy Billets After Radial-Shear Rolling. Materials 2019, 12, 3179. [Google Scholar] [CrossRef]

- Naizabekov, A.; Lezhnev, S.; Arbuz, A.; Panin, E. The Effect of Radial-Shear Rolling on Microstructure and Mechanical Properties of Stainless Austenitic Steel AISI-321. MATEC Web Conf. 2018, 190, 11003. [Google Scholar] [CrossRef]

- Garstka, T. The Complex System for Residual Stress Determination Based on Barkhausen Noise Measurement. In Proceedings of the 5th International Conference on Barkhausen Noise and Micromagnetic Testing, Petten, The Netherlands, 2–3 June 2005; pp. 219–226. [Google Scholar]

- Pitoňák, M.; Mičietová, A.; Moravec, J.; Čapek, J.; Neslušan, M.; Ganev, N. Influence of Strain Rate on Barkhausen Noise in Trip Steel. Materials 2024, 17, 5330. [Google Scholar] [CrossRef] [PubMed]

- Sheng, H.; Wang, P.; Yang, Y.; Tang, C. Stress and Microstructures Characterization Based on Magnetic Incremental Permeability and Magnetic Barkhausen Noise Techniques. Materials 2024, 17, 2657. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Ziman, J.A.; Raghuraman, S.R.; Nebel, J.-E.; Weber, F.; Starke, P. Short-Time Fatigue Life Estimation for Heat Treated Low Carbon Steels by Applying Electrical Resistance and Magnetic Barkhausen Noise. Materials 2023, 16, 32. [Google Scholar] [CrossRef]

- Nishihara, H.; Taniguchi, S.; Maeda, H.; Oguro, I.; Harada, M.; Ogino, T.; Matsumoto, S.; Shindo, Y.; Ohtsuka, S. The effect of mechanical stress on Barkhausen noises from heat-treated nickel plates. In Proceedings of the 12th Asia-Pacific Conference on NDT, Auckland, New Zealand, 5–10 November 2006. [Google Scholar]

- Vengrinovich, V.; Tsukerman, V.L. Stress and Texture Measurement Using Barkhausen Noise and Angular Scanning of Driving Magnetic Field. In Proceedings of the 15th WCDNT—World Conference on Nondestructive Testing, Montreal, QC, Canada, 31 August–3 September 2004. [Google Scholar]

- Piotrowski, L.; Chmielewski, M.; Augustyniak, M.; Maciakowski, P.; Prokop, K. Stress Anisotropy Characterisation with Help of Barkhausen Effect Detector with Adjustable Magnetic Field Direction. Int. J. Ap. Electr. Mech. 2015, 48, 163–170. [Google Scholar] [CrossRef]

- Silva, S.; Mansur, T.; Palma, E. Determining Residual Stress in Ferromagnetic Materials by Barkhausen Noise Measurement. In Proceedings of the 15th World Conference on Nondestructive Testing, Rome, Italy, 15–21 October 2000. [Google Scholar]

- Augustyniak, B. Magnetomechanical Effects and Their Applications at Non-Destructive Evaluation of Materials. Ph.D. Thesis, Gdańsk University of Technology, Gdańsk, Poland, 2003. (In Polish). [Google Scholar]

| Material | Ti | Ni | Fe | N | C | Mn | Si | O |

|---|---|---|---|---|---|---|---|---|

| Ti (Grade 1) | balance | - | 0.02 | 0.008 | 0.01 | - | - | 0.01 |

| Ni (N0221) | - | balance | 0.14 | - | 0.01 | 0.21 | 0.11 | - |

| Materials | UTS, Mpa | YS0.2, Mpa | HV01 | A, % |

|---|---|---|---|---|

| Ti Grade 1 | 324 | 215 | 115 | 43 |

| Ni N0221 | 390 | 170 | 95 | 48 |

| Sample | H mm | Dimensions of the Shear Area | Comments | ||||

|---|---|---|---|---|---|---|---|

| L mm | B mm | S mm2 | Fmax kN | Rs Mpa | |||

| 1 | 2 | 1.02 | 20 | 20.4 | 9.2 | 450.8 | rupture in the joining area |

| 2 | 2 | 0.98 | 19.6 | 19.2 | 8.62 | 448.96 | rupture in the joining area |

| 3 | 1.8 | 0.95 | 20.2 | 19.19 | 8.37 | 436.16 | rupture in the joining area for av = 1.0 |

| 4 | 1.8 | 1.07 | 20.1 | 21.51 | 9.64 | 446.92 | rupture in the joining area for av = 1.1 |

| No. | HTi0/HNi0 mm/mm | HTi/HNi mm/mm | H1 mm | ε % | εTi % | εNi % | av | 1/R 1/m |

|---|---|---|---|---|---|---|---|---|

| 1 | 1/1 | 0.87/0.93 | 1.8 | 10 | 13 | 7 | 1.0 | 1.18 |

| 2 | 1/1 | 0.89/0.91 | 1.8 | 10 | 11 | 9 | 1.1 | 0.1 |

| 3 | 1/1 | 0.82/0.88 | 1.7 | 15 | 18 | 12 | 1.0 | 0.98 |

| 4 | 1/1 | 0.85/0.85 | 1.7 | 15 | 15 | 15 | 1.1 | 0.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rydz, D.; Mróz, S.; Szota, P.; Stradomski, G.; Garstka, T.; Dyl, T.C. The Analysis of Plastic Forming in the Rolling Process of Difficult-to-Deform Ti + Ni Layered Composites. Materials 2025, 18, 1926. https://doi.org/10.3390/ma18091926

Rydz D, Mróz S, Szota P, Stradomski G, Garstka T, Dyl TC. The Analysis of Plastic Forming in the Rolling Process of Difficult-to-Deform Ti + Ni Layered Composites. Materials. 2025; 18(9):1926. https://doi.org/10.3390/ma18091926

Chicago/Turabian StyleRydz, Dariusz, Sebastian Mróz, Piotr Szota, Grzegorz Stradomski, Tomasz Garstka, and Tomasz Cyryl Dyl. 2025. "The Analysis of Plastic Forming in the Rolling Process of Difficult-to-Deform Ti + Ni Layered Composites" Materials 18, no. 9: 1926. https://doi.org/10.3390/ma18091926

APA StyleRydz, D., Mróz, S., Szota, P., Stradomski, G., Garstka, T., & Dyl, T. C. (2025). The Analysis of Plastic Forming in the Rolling Process of Difficult-to-Deform Ti + Ni Layered Composites. Materials, 18(9), 1926. https://doi.org/10.3390/ma18091926