Sustainability Opportunities for Mediterranean Food Products through New Formulations Based on Carob Flour (Ceratonia siliqua L.)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material, Dough, and Bread Preparation

- C1: carob pod powder, only

- C2: carob seed powder, only

- C3: white wheat flour (WF)

- C4: carob pod powder 5% (+95% WF)

- C5: carob pod powder 10% (+90% WF)

- C6: carob pod powder 20% (+80% WF)

- C7: carob pod powder 30% (+70% WF)

- C8: carob seed powder 5% (+95% WF)

- C9: carob seed powder 10% (+90% WF)

- C10: blend of 10% carob pod powder/10% carob seed powder (+80% WF)

- C11: blend of 15% carob seed powder/5% carob pod powder (+80% WF)

- C1″ to C11″: baked cakes’ samples based on the corresponding blend formulation (as listed above).

2.2. Rheological Parameters Determination

2.3. Color Determination

2.4. Texture Determination (and Related Parameters)

2.5. Flour Composition

2.6. Aroma Volatile Compounds Analysis

2.7. Acceptance Test

2.8. Statistical Analysis

3. Results and Discussion

3.1. Rheological Properties of Flour (Wheat Flour, Carob Flour, Carob Seed Flour, and Flour Mixture)

3.2. Flour Composition

3.3. Textural Proprieties of Carob Enriched Bread Formulations

3.4. Color Properties of Carob-Enriched Bread Formulations

3.5. Aroma Compounds and Volatile Contaminants

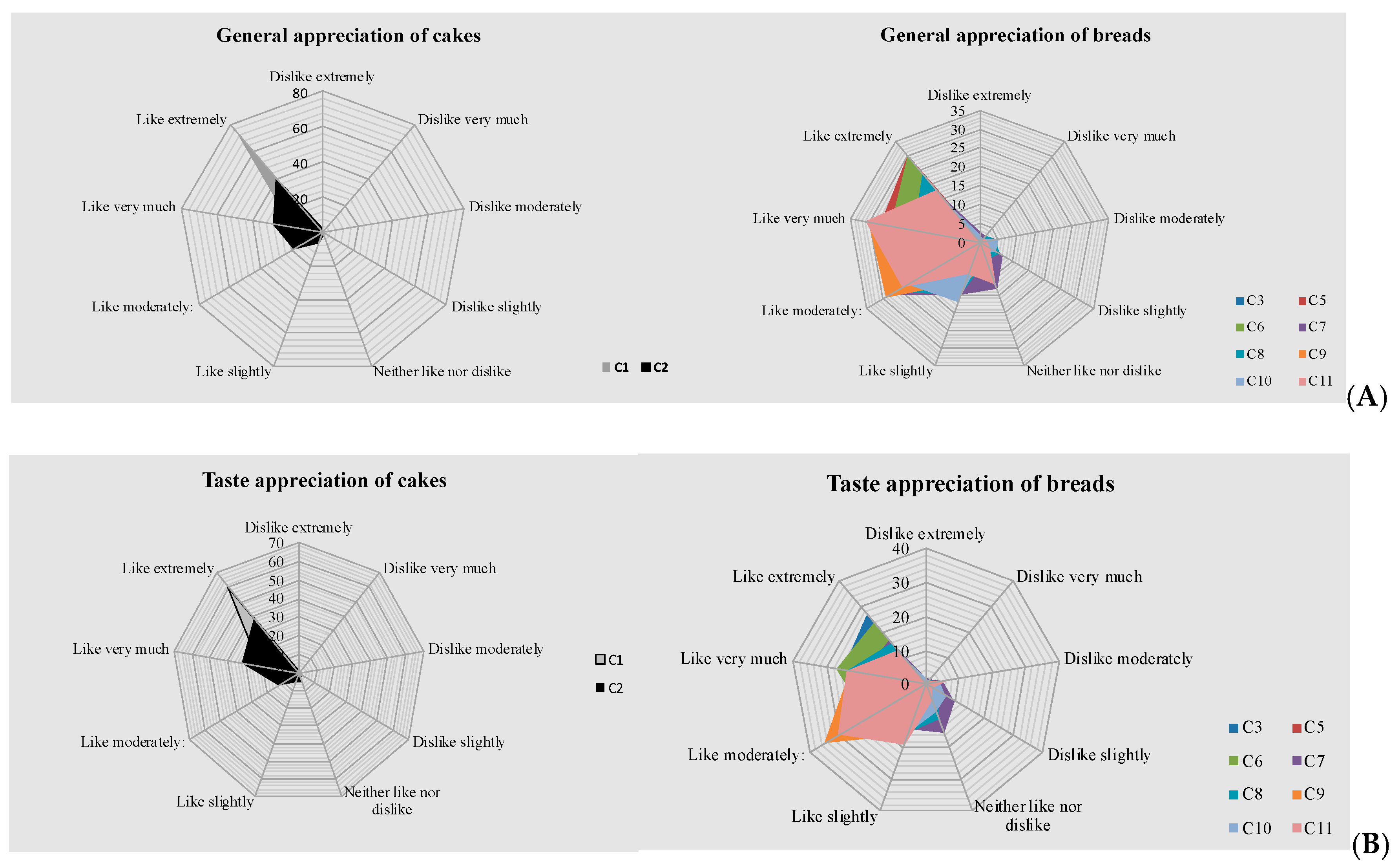

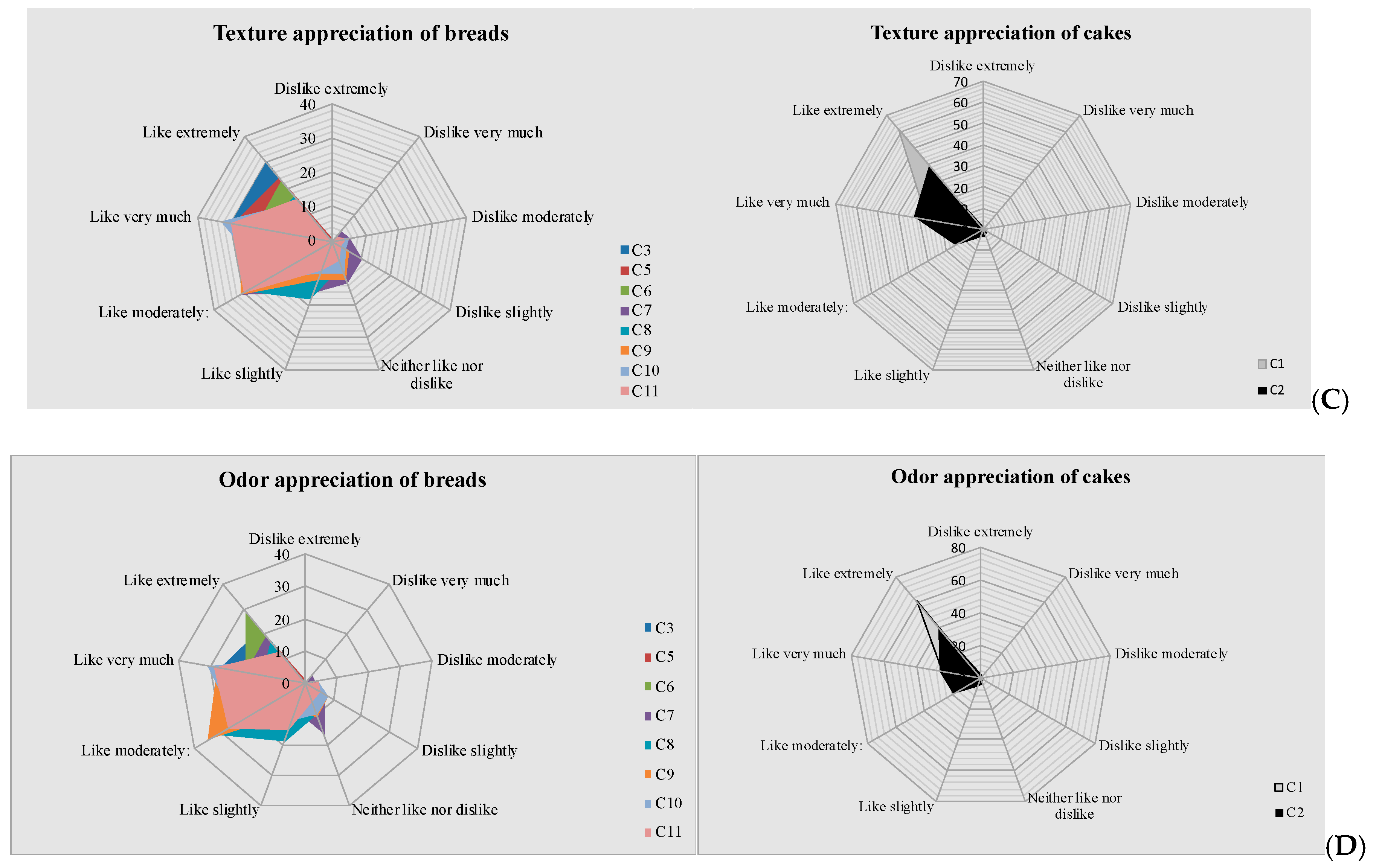

3.6. Hedonic Studies

4. Conclusions

- (a)

- SDG2, zero hunger, by tackling obesity, allergies, and nutritional deficiencies if consumers prefer nutrient-dense wheat and carob bread, instead of the ultra-processed types (nutritionally poor and deleterious to health). On the other hand, environmental impact can be simultaneously minimized while valuing local biodiversity and local food traditions, which are concerns of today’s consumers;

- (b)

- SDG 12, responsible consumption, and production, because partially replacing wheat by carob, decreases are expected in production-based nitrogen emissions and nitrogen emissions embodied in imports, given the low requirements of carob trees when compared to cereals;

- (c)

- SDG 13, climate action, by adopting simpler formulations (e.g., removing palm oil), significant reductions in CO2 emissions embodied in imports can be achieved; lower energy-related CO₂ emissions are to expect in consequence of the partial replacement of wheat flour (obtained from energy-intensive processes) by carob flour (requiring less energy). When artisanal breadmaking and less processed bakery products are adopted, local distribution and shorter supply chains become more adequate, and thus transportation-related CO2 emissions are also expected to be lower;

- (d)

- SDG 15, life on land, improvements are expected for the same reasons, since promoting sustainable breadmaking over ultra-processed versions (encompassing the elimination of palm oil) will halt the permanent deforestation, also decreasing the contribution to terrestrial and freshwater biodiversity threats embodied in imports.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dasgupta, P. The Economics of Biodiversity: The Dasgupta Review, Abridge version; HM Treasury: London, UK, 2021. [Google Scholar]

- TEEB. TEEB for Agriculture & Food: Scientific and Economic Foundations; UN Environment: Geneva, Switzerland, 2018. [Google Scholar]

- UNEP (United Nations Environment Programme). Emissions Gap Report 2019. Available online: http://www.unenvironment.org/emissionsgap (accessed on 20 January 2021).

- Keairns, D.L.; Darton, R.C.; Irabien, A. The Energy-Water-Food Nexus. Annu. Rev. Chem. Biomol. Eng. 2016, 7, 239–262. [Google Scholar] [CrossRef]

- Lange, L.; Connor, K.O.; Arason, S.; Bundgård-Jørgensen, U.; Canalis, A.; Carrez, D.; Gallagher, J.; Gøtke, N.; Huyghe, C.; Jarry, B.; et al. Developing a Sustainable and Circular Bio-Based Economy in EU: By Partnering across Sectors, Upscaling and Using New Knowledge Faster, and for the Benefit of Climate, Environment & Biodiversity, and People & Business. Front. Bioeng. Biotechnol. 2021, 8, 1456. [Google Scholar] [CrossRef]

- Rippin, H.L.; Wickramasinghe, K.; Halloran, A.; Whiting, S.; Williams, J.; Hetz, K.; Pinedo, A.; Breda, J.J. Disrupted food systems in the WHO European region—A threat or opportunity for healthy and sustainable food and nutrition? Food Secur. 2020, 23, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Serres, A.; Murtin, F.; Nicoletti, G. A Framework for Assessing Green Growth Policies. In OECD Economics Department Working Papers; No. 774; OECD Publishing: Paris, France, 2010. [Google Scholar] [CrossRef]

- Clark, M.A.; Domingo, N.; Colgan, K.; Thakrar, S.K.; Tilman, D.; Lynch, J.; Azevedo, I.L.; Hill, J.D. Global food system emissions could preclude achieving the 1.5 °C and 2 °C climate change targets. Science 2020, 370, 705–708. [Google Scholar] [CrossRef] [PubMed]

- Kok, K.P.W.; Boer, A.C.L.; Cesuroglu, T.; Meij, M.G.; Wildt-Liesveld, R.; Regeer, B.J.; Broerse, J.E.W. Transforming Research and Innovation for Sustainable Food Systems—A Coupled-Systems Perspective. Sustainability 2019, 11, 7176. [Google Scholar] [CrossRef] [Green Version]

- Food and Agriculture Organization of the United Nations. Livestock’s Long Shadow–Environmental Issues and Options; FAO: Rome, Italy, 2006. [Google Scholar]

- Clark, M.; Tilman, D. Comparative analysis of environmental impacts of agricultural production systems, agricultural input efficiency, and food choice. Environ. Res. Lett. 2017, 12, 064016. [Google Scholar] [CrossRef]

- FAO & CIHEAM. FAO-CIHEAM Partnership—Advancing Sustainable Rural Development in the Mediterranean; FAO: Rome, Italy, 2020. [Google Scholar]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2019, 363, eaaw9908, Erratum in 2018, 360, 987–992. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Willett, W.; Rockström, J.; Loken, B.; Springmann, M.; Lang, T.; Vermeulen, S.; Garnett, T.; Tilman, D.; DeClerck, F.; Wood, A.; et al. Food in the Anthropocene: The EAT-Lancet Commission on healthy diets from sustainable food systems. Lancet 2019, 393, 447–492. [Google Scholar] [CrossRef]

- Serra-Majem, L.; Tomaino, L.; Dernini, S.; Berry, E.M.; Lairon, D.; Ngo de la Cruz, J.; Bach-Faig, A.; Donini, L.M.; Medina, F.X.; Belahsen, R.; et al. Updating the Mediterranean Diet Pyramid towards Sustainability: Focus on Environmental Concerns. Int. J. Environ. Res. Public Health 2020, 17, 8758. [Google Scholar] [CrossRef]

- Tarsitano, E.; Calvano, G.; Cavalcanti, E. The Mediterranean Way a model to achieve the 2030 Agenda Sustainable Development Goals (SDGs). J. Sustain. 2019, 12, 108–119. [Google Scholar] [CrossRef]

- UNESCO. Intangible Cultural Heritage, Mediterranean Diet. Available online: https://ich.unesco.org/en/RL/mediterranean-diet-00884 (accessed on 20 January 2021).

- Food and Agriculture Organization of the United Nations. FAO. FAOSTAT. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 11 July 2020).

- Özcan, M.M.; Arslan, D.; Gökçalik, H. Some compositional properties and mineral contents of carob (Ceratonia siliqua) fruit, flour and syrup. Int. J. Food Sci. Nutr. 2007, 58, 652–658. [Google Scholar] [CrossRef]

- Papaefstathiou, E.; Agapiou, A.; Giannopoulos, S.; Kokkinofta, R. Nutritional characterization of carobs and traditional carob products. Food Sci. Nutr. 2018, 6, 2151–2161. [Google Scholar] [CrossRef] [PubMed]

- Lal, R. Home gardening and urban agriculture for advancing food and nutritional security in response to the COVID-19 pandemic. Food Secur. 2020, 23, 1–6. [Google Scholar] [CrossRef]

- Vanham, D.; Mak, T.N.; Gawlik, B.M. Urban food consumption and associated water resources: The example of Dutch cities. Sci. Total Environ. 2016, 565, 232–239. [Google Scholar] [CrossRef]

- Correia, P.J.; Pestana, M. Exploratory Analysis of the Productivity of Carob Tree (Ceratonia siliqua) Orchards Conducted under Dry-Farming Conditions. Sustainability 2018, 10, 2250. [Google Scholar] [CrossRef] [Green Version]

- Barak, S.; Mudgil, D. Locust bean gum: Processing, properties and food applications—A review. Int. J. Biol. Macromol. 2014, 66, 74–80. [Google Scholar] [CrossRef]

- Papageorgiou, M.; Paraskevopoulou, A.; Pantazi, F.; Skendi, A. Cake Perception, Texture and Aroma Profile as Affected by Wheat Flour and Cocoa Replacement with Carob Flour. Foods 2020, 9, 1586. [Google Scholar] [CrossRef]

- Goulas, V.; Stylos, E.; Chatziathanasiadou, M.V.; Mavromoustakos, T.; Tzakos, A.G. Functional Components of Carob Fruit: Linking the Chemical and Biological Space. Int. J. Mol. Sci. 2016, 17, 1875. [Google Scholar] [CrossRef] [PubMed]

- Tsatsaragkou, K.; Gounaropoulos, G.; Mandala, I. Development of gluten free bread containing carob flour and resistant starch. LWT Food Sci. Technol. 2014, 58, 124–129. [Google Scholar] [CrossRef]

- Rodríguez-Solana, R.; Coelho, N.; Santos-Rufo, A.; Gonçalves, S.; Pérez-Santín, E.; Romano, A. The Influence of In Vitro Gastrointestinal Digestion on the Chemical Composition and Antioxidant and Enzyme Inhibitory Capacities of Carob Liqueurs Obtained with Different Elaboration Techniques. Antioxidants 2019, 8, 563. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ISO 712:2009. Cereals and Cereal Products—Determination of Water Content—Reference Method; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- AACC. Alveograph Method for Soft and Hard Wheat Flour. In Approved Methods of Analysis, 11th ed.; AACC Method 54-30.02; Cereals & Grains Association: St. Paul, MN, USA, 1999. [Google Scholar]

- ISO 2171:2007. Cereals, Pulses and By-Products—Determination of Ash Yield by Incineration; International Organization for Standardization: Geneva, Switzerland, 2007. [Google Scholar]

- ISO 21415-2:2015. Wheat and Wheat Flour—Gluten Content—Part 2: Determination of Wet Gluten and Gluten Index by Mechanical Means; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Peryam, D.R.; Girardot, N.F. Advanced taste method. J. Food Eng. 1952, 24, 58–61. [Google Scholar]

- Fasano, A.; Sapone, A.; Zevallos, V.; Schuppan, D. Nonceliac gluten sensitivity. Gastroenterology 2015, 148, 1195–1204. [Google Scholar] [CrossRef]

- Ford, R.P.K. The gluten syndrome: A neurological disease. Med. Hypotheses 2009, 73, 438–440. [Google Scholar] [CrossRef] [PubMed]

- Lebwohl, B.; Sanders, D.S.; Green, P. Coeliac disease. Lancet 2018, 391, 70–81. [Google Scholar] [CrossRef]

- Fardet, A. Wheat-based foods and non celiac gluten/wheat sensitivity: Is drastic processing the main key issue? Med. Hypotheses 2015, 85, 934–939. [Google Scholar] [CrossRef]

- European Commission—Directorate for Health and Food Safety. Guidelines Relating to the Provision of Information on Substances or Products Causing Allergies or Intolerances as Listed in Annex II of Regulation (EU) No 1169/2011 on the Provision of Food Information to Consumers; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Pali-Schöll, I.; Untersmayr, E.; Klems, M.; Jensen-Jarolim, E. The Effect of Digestion and Digestibility on Allergenicity of Food. Nutrients 2018, 10, 1129. [Google Scholar] [CrossRef] [Green Version]

- Boublenza, I.; Lazouni, H.A.; Ghaffari, L.; Ruiz, K.; Fabiano-Tixier, A.S.; Chemat, F. Influence of roasting on sensory, antioxidant, aromas, and physicochemical properties of carob pod powder (Ceratonia siliqua L.). J. Food Qual. 2017, 2017, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Krokou, A.; Stylianou, M.; Agapiou, A. Assessing the volatile profile of carob tree (Ceratonia siliqua L.). Environ. Sci. Pollut. Res. Int. 2019, 26, 35365–35374. [Google Scholar] [CrossRef]

- Niccolai, E.; Baldi, S.; Ricci, F.; Russo, E.; Nannini, G.; Menicatti, M.; Poli, G.; Taddei, A.; Bartolucci, G.; Calabrò, A.S.; et al. Evaluation and comparison of short chain fatty acids composition in gut diseases. World J. Gastroenterol. 2019, 25, 5543–5558. [Google Scholar] [CrossRef]

- Rios-Covian, D.; González, S.; Nogacka, A.M.; Arboleya, S.; Salazar, N.; Gueimonde, M.; de Los Reyes-Gavilán, C.G. An Overview on Fecal Branched Short-Chain Fatty Acids Along Human Life and as Related with Body Mass Index: Associated Dietary and Anthropometric Factors. Front. Microbiol. 2020, 11, 973. [Google Scholar] [CrossRef] [PubMed]

- Farag, M.A.; El-Kersh, D.M. Volatiles profiling in Ceratonia siliqua (carob bean) from Egypt and in response to roasting as analyzed via solid-phase microextraction coupled to chemometrics. J. Adv. Res. 2017, 8, 379–385. [Google Scholar] [CrossRef]

- Racolta, E.; Tofana, M.; Muresan, C.C.; Socaci, C.; Florin, G.G.; Vlad, M. Volatile compounds and sensory evaluation of spreadable creams based on roasted sunflower kernels and cocoa or carob powder. Bull. UASVM Food Sci. Technol. 2014, 71, 107–113. [Google Scholar] [CrossRef]

- Issaoui, M.; Nesrine, M.; Flamini, G.; Delgado, A. Enrichment of white flour with spices positively impacts safety and consumer acceptance of bread. Int. J. Food Sci. Technol. 2020, 14834, 1–13. [Google Scholar] [CrossRef]

- European Food Safety Authority (EFSA). Furan in Food—EFSA Confirms Health Concerns. 2017. Available online: https://www.efsa.europa.eu/en/press/news/171025 (accessed on 10 December 2020).

- FAO/WHO; Commission du Codex Alimentarius; Programme Mixte FAO/OMS sur les Normes Alimentaires; Comité du CODEX sur les Contaminants dans L’Alimentation. 5eme Session, CX/CF 11/5/13, Document de Travail sur le Furane; FAO/WHO: Hague, the Netherlands, 2011. [Google Scholar]

- Schieberle, P.; Grosch, W. Potent odorants of rye bread crust—Differences from the crumb and from wheat bread crust. Z. Lebensm. Unters. Forsch. 1994, 198, 292–296. [Google Scholar] [CrossRef]

- Martins, S.I.F.S.; Jongen, W.M.F.; van Boekel, M.A.J.S. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Technol. 2000, 11, 364–373. [Google Scholar] [CrossRef]

- Hodge, J.E. Dehydrated foods–Chemistry of browning reactions in model systems. J. Agric. Food Chem. 1953, 1, 928–943. [Google Scholar] [CrossRef]

- Kaminski, E.; Przybilski, R.; Gruchala, L. Thermal degradation of precursors and formation of flavour compounds during heating of cereal products. Part I. Changes of amino acids and sugars. Food Nahr. 1981, 25, 507–518. [Google Scholar] [CrossRef]

- Pico, J.; Bernal, J.; Gómez, M. Wheat bread aroma compounds in crumb and crust: A review. Food Res. Int. 2015, 75, 200–215. [Google Scholar] [CrossRef] [PubMed]

- Espinoza-Orias, N.; Stichnothe, H.; Azapagic, A. The carbon footprint of bread. Int. J. Life Cycle Assess. 2011, 16, 351–365. [Google Scholar] [CrossRef]

- Kulak, M.; Nemecek, T.; Frossard, E.; Chable, V.; Gaillard, G. Life cycle assessment of bread from several alternative food networks in Europe. J. Clean. Prod. 2015, 90, 104–113. [Google Scholar] [CrossRef]

- Correia, P.J.; Guerreiro, J.F.; Pestana, M.; Martins-Loução, M.A. Management of carob tree orchards in Mediterranean ecosystems: Strategies for a carbon economy implementation. Agrofor. Syst. 2017, 91, 295–306. [Google Scholar] [CrossRef]

- Medici, M.; Canavari, M.; Toselli, M. Interpreting Environmental Impacts Resulting from Fruit Cultivation in a Business Innovation Perspective. Sustainability 2020, 12, 9793. [Google Scholar] [CrossRef]

- Mukherjee, S.; Asthana, A.; Howarth, M.; Chowdhury, J.I. Techno-Economic Assessment of Waste Heat Recovery Technologies for the Food Processing Industry. Energies 2020, 13, 6446. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M. Theoretical investigation of hot box solar cookers having conventional and finned absorber plates. Int. J. Low Carbon Technol. 2015, 10, 238–245. [Google Scholar] [CrossRef] [Green Version]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. State of the art of solar cooking: An overview. Renew. Sustain. Energy Rev. 2012, 16, 3776–3785. [Google Scholar] [CrossRef]

- Turfani, V.; Narducci, V.; Durazzo, A.; Galli, V.; Carcea, M. Technological, nutritional and functional properties of wheat bread enriched with lentil or carob flours. LWT 2017, 78, 361–366. [Google Scholar] [CrossRef]

| WF | Carob Pulp Powder (%) | Carob Seed Powder (%) | Mixture | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C3 | C1 | C7 | C6 | C5 | C2 | C9 | C8 | C10 | C11 | |

| H (%) | 14.80 a ± 0.11 | 13.53 ± 0.75 | 13.40 b ± 0.75 | 13.50 b ± 0.11 | 13.70 b ± 0.00 | 5.90 c ± 0.50 | 14.0 a ± 0.00 | 14.20 a ± 0.11 | 13.60 b ± 0.23 | 13.20 b ± 0.00 |

| p(mmH2O) | 71.20 c ± 4.26 | nd | 69.00 c ± 1.73 | 89.60 c ± 6.87 | 55.40 c ± 2.60 | nd | 276.7 a ± 4.99 | 134.60 b ± 5.94 | 253.40 a ± 3.48 | 164.0 b ± 1.54 |

| L (mm) | 60.60 a ± 2.39 | nd | 20.20 b ± 3.11 | 30.80 b ± 5.58 | 53.4 a ± 7.63 | nd | 15.75 c ± 2.36 | 30.80 b ± 4.81 | 14.80 c ± 0.00 | 14.40 c ± 3.57 |

| G (cm³) | 17.08 a ± 2.85 | nd | 9.96 c ± 0.75 | 12.28 b ± 1.12 | 16.18 a ± 1.15 | nd | 8.80 c ± 0.66 | 12.26 b ± 0.96 | 8.54 c ± 0.25 | 8.40 c ± 1.04 |

| W (10−4j) | 152.0 ab ± 2.95 | nd | 58.00 c ± 1.81 | 119.4 b ± 9.50 | 103.6 b ± 13.39 | nd | 186.7 a ± 4.80 | 178.2 a ± 2.52 | 160.4 ab ± 15.93 | 97.20 b ± 7.93 |

| p/L | 1.28 d ± 0.43 | nd | 3.55 c ± 1.36 | 2.82 ± 0.70 | 1.05 d ± 0.14 | nd | 17.57 a ± 1.65 | 4.45 c ± 0.65 | 17.15 a ± 2.50 | 12.63 b ± 9.97 |

| I.e | 47.9 a ± 1.33 | nd | nd | nd | 41.12 a ± 3.19 | nd | nd | nd | nd | nd |

| Hardness (g) | 446.7 f ± 6.00 | 410.8 f ± 14.6 | 1404.3 b ± 5.20 | 879.6 c ± 9.95 | 646.9 d ± 4.40 | 541.8 e ± 25.35 | 668.3 d ± 6.08 | 512.1 e ± 34.04 | 671.9 d ± 74.64 | 2062.3 a ± 87.10 |

| Elasticity (mm) | 0.45 b ± 0.00 | 0.45 b ± 0.00 | 0.44 b ± 0.01 | 0.41 b ± 0.01 | 0.42 b ± 0.01 | 0.51 a ± 0.01 | 0.49 a ± 0.01 | 0.49 a ± 0.01 | 0.48 ab ± 0.01 | 0.45 b ± 0.00 |

| Weight (g) | 44.48 d ± 1.90 | 64 b ± 5.99 | 58 bc.0 ± 2.64 | 61 b.0 ± 1.73 | 55.0 c ± 1.00 | 84 a ± 5.56 | 67.0 b ± 3.60 | 66 b.0 ± 1.73 | 63 b.0 ± 2.00 | 56 c ± 1.73 |

| Height (mm) | 65.00 a ± 2.64 | 40.58 b ± 0.69 | 27.89 d ± 0.90 | 36.37 c ± 0.33 | 35.44 c ± 0.48 | 42.78 b ± 0.31 | 33.77 c ± 0.30 | 39.77 bc ± 0.07 | 36.45 c ± 0.09 | 22.91 d ± 0.11 |

| Wheat Flour | Flour Enriched with Different % of Carob Pulp Powder | Flour Enriched with Different % of Carob Seed Powder | Flour Enriched with Mixture (Seed & Pulp) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C3 | C1 | C7 | C6 | C5 | C2 | C9 | C8 | C10 | C11 | |

| Ash (%) | 0.33 e ± 0.00 | 1.99 b ± 0.00 | 0.66 d ±0.00 | 0.66 d ± 0.00 | 0.66 d ±0.00 | 4.16 a ±0.23 | 1.00 c ± 0.00 | 0.66 d ± 0.00 | 0.99 bc ± 0.00 | 1.00 c ± 0.00 |

| Gluten hydration (%) | 65.84 b ± 0.21 | nd | 53.90 c ± 3.26 | 61.84 b ± 0.84 | 65.92 b ± 0.23 | nd | 70.35 a ± 3.10 | 65.69 b ± 6.22 | 23.34 d ± 2.41 | 23.25 d ± 2.01 |

| Gluten, humid (g) | 35.86 b ± 4.30 | nd | 18.45 d ± 4.58 | 36.3 b ± 0.63 | 30.69 b ± 1.14 | nd | 26.19 c ± 5.34 | 34.71 b ± 8.35 | 54.41 a ± 6.54 | 54.83 a ± 8.01 |

| Gluten, dry (g) | 12.25 a ± 1.54 | nd | 8.58 c ± 2.71 | 13.84 a ± 0.06 | 10.45 b ± 0.31 | nd | 7.84 c ± 2.39 | 12.16 a ± 5.02 | 10.56 b ± 0.42 | 10.50 b ± 2.54 |

| Volatile Compounds (%) | Retention indices | White Wheat Flour | Carob Pulp Enriched Flour | Carob Seed Enriched Flour | Blend (Carob Pulp & Seed) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C3″ C3 | C1″ | C6 | C5 | C2″ | C9 | C8 | C10 | C11 | |||

| Cake | Bread | Cake | Bread | Bread | Cake | Bread | Bread | Bread | Bread | ||

| Acetic acid | 603 | nd | nd | 2.70 ± 0.14 | nd | nd | 2.5 ± 0.21 | 4.1 ± 0.14 | 4.3 ± 0.21 | 6.9 ± 0.28 | 2.5 ± 0.21 |

| Isovaleraldehyde | 654 | 13.8 ± 0.28 | nd | 1.40 ± 0.14 | nd | nd | nd | nd | nd | nd | nd |

| 2-methylbutanal | 657 | 13.7 ± 0.28 | nd | nd | nd | nd | nd | nd | nd | nd | nd |

| 2-pentanone | 697 | nd | nd | nd | nd | 40.0 ± 1.06 | 2.3 ± 0.14 | nd | nd | 0.3 ± 0.00 | 0.7 ± 0.07 |

| n-heptane | 700 | nd | nd | nd | nd | 10.2 ± 0.35 | nd | 1.1 ± 0.14 | nd | 0.9 ± 0.07 | 0.4 ± 0.07 |

| Methyl isobutyrate | 693 | 4.30 ± 0.21 | nd | nd | nd | nd | nd | nd | nd | nd | nd |

| Pentanal | 701 | 3.50 ± 0.14 | nd | nd | nd | nd | nd | nd | nd | nd | nd |

| Acetoin | 707 | nd | 55.0 ± 0.64 | 0.6 ± 0.14 | 6.2 ± 0.28 | 1.1 ± 0.07 | 48.9 ± 0.64 | 38.5 ± 0.49 | 51.8 ± 0.57 | 4.7 ± 0.14 | 25.5 ± 0.28 |

| Isopentyl alcohol | 736 | 1.90 ± 0.07 | 9.50 ± 0.35 | 0.5 ± 0.00 | 3.5 ± 0.14 | 5.7 ± 0.21 | nd | nd | nd | 6.2± 0.21 | nd |

| Isobutyric acid | 773 | nd | nd | 74.4 ± 1.13 | 68.5 ± 0.71 | nd | nd | nd | nd | 46.1 ± 0.64 | nd |

| 1-ethoxy-2-propanol | 748 | 3.3 ± 0.14 | nd | nd | nd | nd | nd | nd | nd | nd | nd |

| 1,3-butanediol | 788 | nd | 15.20 ± 0.35 | nd | nd | 7.8 ± 0.21 | 15.0 ± 0.28 | 26.3 ± 0.35 | 16.6 ± 0.35 | nd | 27.0 ± 0.42 |

| 2,3-butanediol | 790 | nd | 6.90 ± 0.14 | nd | nd | 5.8 ± 0.14 | 15.3 ± 0.35 | 16.6 ± 0.28 | 8.2 ± 0.21 | nd | 14.8 ± 0.35 |

| Butyric acid | 801 | nd | nd | 4.4 ± 0.21 | 4.0 ± 0.21 | nd | nd | nd | nd | 2.6 ± 0.14 | nd |

| Hexanal | 802 | 11.9 ± 0.28 | nd | nd | nd | nd | nd | nd | nd | nd | nd |

| 2-methylbutyric acid | 863 | nd | nd | 1.7 ± 0.07 | 3.7 ± 0.14 | nd | nd | nd | nd | nd | nd |

| 1-hexanol | 869 | 7.2 ± 0.21 | nd | nd | nd | nd | nd | 0.3 ± 0.00 | nd | nd | nd |

| Anisole | 920 | nd | nd | nd | nd | nd | nd | nd | nd | nd | 14.7 ± 0.35 |

| Hexanoic acid | 989 | nd | nd | 4.1 ± 0.28 | nd | nd | nd | nd | nd | nd | nd |

| Butyl butyrate | 996 | 2.4 ± 0.07 | nd | nd | nd | nd | nd | nd | nd | nd | nd |

| 3-ethyl-1-hexanol | 1031 | 0.5 ± 0.07 | 2.80 ± 0.14 | nd | nd | 4.0 ± 0.14 | nd | 2.1 ± 0.07 | 0.6 ± 0.07 | 0.4 ± 0.07 | nd |

| Limonene | 1032 | 7.50 ± 0.14 | 3.60 ± 0.21 | nd | 1.2 ± 0.14 | 6.6 ± 0.28 | nd | 1.3 ± 0.14 | 1.8 ± 0.07 | 1.8 ± 0.07 | 1.1 ± 0.14 |

| Phenylethyl alcohol | 1111 | nd | 1.40 ± 0.07 | nd | nd | nd | nd | nd | nd | nd | nd |

| Veratrole | 1149 | nd | nd | nd | nd | nd | nd | nd | nd | nd | 3.1 ± 0.28 |

| p-vinylanisole | 1154 | nd | nd | nd | nd | nd | nd | nd | nd | nd | 3.6 ± 0.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Issaoui, M.; Flamini, G.; Delgado, A. Sustainability Opportunities for Mediterranean Food Products through New Formulations Based on Carob Flour (Ceratonia siliqua L.). Sustainability 2021, 13, 8026. https://doi.org/10.3390/su13148026

Issaoui M, Flamini G, Delgado A. Sustainability Opportunities for Mediterranean Food Products through New Formulations Based on Carob Flour (Ceratonia siliqua L.). Sustainability. 2021; 13(14):8026. https://doi.org/10.3390/su13148026

Chicago/Turabian StyleIssaoui, Manel, Guido Flamini, and Amélia Delgado. 2021. "Sustainability Opportunities for Mediterranean Food Products through New Formulations Based on Carob Flour (Ceratonia siliqua L.)" Sustainability 13, no. 14: 8026. https://doi.org/10.3390/su13148026

APA StyleIssaoui, M., Flamini, G., & Delgado, A. (2021). Sustainability Opportunities for Mediterranean Food Products through New Formulations Based on Carob Flour (Ceratonia siliqua L.). Sustainability, 13(14), 8026. https://doi.org/10.3390/su13148026