Abstract

Currently, the transportation sector represents about one third of the total energy consumed in the world, most of this energy being obtained almost exclusively from oil. However, the world is changing, as well as the aviation industry. Since lignocellulosic biomass is a low-cost feedstock that does not compete with food, it has drawn great attention as one of the most attractive alternatives to replace fossil feedstocks for the production of fuels. Renewable jet fuels could have a significant impact on lowering greenhouse gas emissions and providing a long-term sustainable alternative to petroleum-derived fuels. However, the catalytic upgrading of lignocellulosic residues in industry still remains a big challenge and the development of highly integrated systems that allow the direct conversion of lignocellulosic wastes is essential to achieve that goal. The importance of renewable jet fuels and the potential of lignocellulosic biomass have already been extensively reviewed. However, this work presents a new perspective on the main catalytic routes and challenges for the sustainable production of aviation fuels from biomass wastes.

1. Introduction

The rapid consumption of non-renewable fossil fuels and consequent greenhouse gas emissions (GHG) have encouraged the pursuit of environmentally friendly renewable energy sources [1,2]. While natural gas and coal can be substituted by solar and wind for electricity production, petroleum can only be replaced by biomass since it is the only source of renewable carbon available on Earth. Biomass valorization achieves an effect on CO2 reduction because biomass grows by utilizing CO2 and sunlight through photosynthesis. Biomass is any hydrocarbon that mainly consists of carbon, hydrogen, oxygen and nitrogen, and its resources have a basic structure composed of cellulose, hemicelluloses, lignin and minor amounts of other organics [3]. Considering the availability of forestry and agricultural feedstocks, aquatic plants and algae, as well as municipal and industrial wastes, there is a great worldwide potential for producing fuels and chemicals from biomass. Thus, converting sustainable lignocellulosic biomass into fuels and valuable chemicals offers a promising approach to achieve the pressing global task of carbon footprint reduction, helping to reduce the dependence on fossil resources [4]. The global energy demand for transportation is expected to continue growing with economic expansion and evolution. As a result, the continued crude oil depletion, combined with the ever-growing need for renewable sources, strongly motivates the search for and development of advanced fuels [5,6].

2. Sustainable Aviation Fuels

Within the subject of sustainable drop-in fuel production, the field that shows both the greatest challenges and opportunities is sustainable aviation fuels (SAFs) [7]. As a main transportation mode, aviation supports the global economy with fast conveyance of products and people for tourism, commerce and many other socio-economic activities. In the next years, the world should witness a “drop-in” aviation fuel production upsurge due to renewable energy and economic developments [8]. Although the COVID-19 pandemic has affected the aviation sector’s emissions, it is expected that pre-COVID levels will be rapidly reached and that the global demand for SAF will increase to more than double the current level by 2050 [9]. These forewarnings urge the development of SAF from renewable sources (e.g., lignocellulosic biomass), not only to reduce the GHG emissions issue but also to prevent fuel shortage.

Sustainable fuels are fundamental for the transition to zero carbon, as planned by the European Green Deal (EGD) [10] and the UN Sustainable Development Goals (SDGs) [11,12], since their use cannot only decrease emissions but also the dependency on imported fossil fuels [13]. Additionally, the EGD has set the ambition to reduce GHG emissions in all the transportation sector by 90% by 2050 compared to 1990 [10], while the Renewable Energy Directive (RED) has encouraged SAF production in the European Union (EU), defining a target of achieving a 32% share of renewable energy in the EU by 2030 (in the latest RED II), with 14% in the transport sector [14]. Moreover, the White Paper 2011 Roadmap to a Single European Transport Area set the goal to achieve 40% use of SAF by 2050 and reduce the carbon emissions in transport by 60% by 2050 [15]. Hence, we urgently need the development of advanced sustainable technologies that allow us to maximize the fuel yield, optimize its properties and achieve price parity with fossil-based fuels [1,16]. However, a significant roadblock to the development of a new process for SAF production is related to the highly strict and rigorous approval process, together with the large quantities required for testing (>400 L) [7]. In fact, due to high safety standards and compatibility issues, only drop-in SAFs with excellent performance in aviation engines are approved by ASTM D7566 [17]. Furthermore, airplanes are much less flexible in terms of energy sources, unlike other transportation means that can use electricity, wind, hydrogen or solar energy as power. Thus, only one energy source can generate thrust in an aircraft and this fuel has more stringent standards and specifications [18].

Aviation fuel specifications are detailed in ASTM D1655-09 and include the freeze point, flash point, energy density, flammability, viscosity, combustion performance, sulphur content, density, acidity and others [19]. For example, jet fuels require high flash points to reduce fire hazards, high energy density to minimize storage space, low freezing points to ensure good cold flow properties at high altitudes, good sealing to avoid leakage, etc. [1,20]. In fact, only four hydrocarbon families can be accepted as alternatives to conventional jet fuel—namely, n-alkanes, iso-alkanes, cycloalkanes (naphthenes) and aromatics—while other molecular families (e.g., heteroatom-containing molecules, unsaturated hydrocarbons like olefins, oxygenated molecules and metals) are not acceptable due to their properties of poor thermal stability and freeze point, amongst others [7]. Therefore, oxygenate fuels like biodiesel and ethanol do not meet the strict specifications for jet fuel, so it is imperative to develop SAF from biomass feedstocks. Accordingly, linear alkanes are fundamental to increasing the fuel energy density. On the other hand, although iso-alkanes contain a high energy density, they are added to improve the fuel cold flow properties. Moreover, cyclo-alkanes allow the density of fuel to be increased while lowering its freezing point. Finally, a certain quantity of aromatics (e.g., 20%) is also important to ensure proper sealing, since they promote the swelling of elastomeric valves [18].

Currently, SAF blends like hydro-processed esters and fatty acids (HEFA) and Fischer–Tropsch (FT) contain no aromatics, so they must be blended with conventional petroleum-based jet fuel (up to 50%). The reason for this required blending is the fact that most SAF is composed of paraffins and, unlike traditional jet fuel, it does not contain aromatics, which are essential to ensuring seals swell in engines and prevent fuel leaks, as previously mentioned. In fact, the ASTM D7566 specifies that Jet A must contain between 8% and 25% aromatics to provide the necessary fuel properties and ensure proper fuel system operations [17]. However, aromatic hydrocarbons are currently viewed as a source of pollution and, therefore, are being removed as fast as possible (cf. Section 4). Since aromatics are a fundamental component to create a drop-in 100% SAF from biomass wastes, they would change the future of aviation; unfortunately, aromatics are also a stumbling block in the production of jet fuel from sustainable sources. Lignin comprises about 30% of lignocellulosic biomass but, due to its recalcitrance, and despite valiant efforts, an economically viable and scalable process for converting the lignin fraction to useful molecules such as aromatics has not been established yet. Transforming lignin to the targeted aromatic molecules requires three steps to occur in one-pot, to break the macromolecule into smaller pieces while getting rid of all the oxygen atoms; the three steps are as follows: (i) selectively break C–O bonds to free the oxygen atoms, (ii) avoid adding non-carbon atoms into the aromatic rings (e.g., atoms from H2) and (iii) preserve the molecule’s carbon backbone. Some studies have already been devoted to lignin conversion in SAF [21,22]. Yet, due to the difficulty of this process, lignin is usually left behind as a waste product, imposing a “blending wall” of SAF due to the amount of aliphatic hydrocarbons that can be used without varying the fuel properties.

The SAF carbon range distribution varies from C8 to C16, depending on the composition of the selected biomass feedstock and refining process, and they must have the exact same quality and characteristics as conventional jet fuel, to avoid the need to redesign engines, aircraft and fuel suppliers or to build new fuel supply airport systems [23]. The process proposed herein (cf. Section 3) will focus on the catalytic conversion of the cellulose and hemicellulose fractions of biomass.

3. Catalytic Production of SAF

There are several methods for producing fuels from biomass, such as (i) hydrodeoxygenation (HDO), hydrocracking and isomerization of lipids [24,25,26]; (ii) gasification-FT synthesis-HDO pathway [27,28,29], (iii) biomass pyrolysis-bio-oil hydrocracking/isomerization [30,31]; and (iv) depolymerization of biomass-platform chemical synthesis-fuel precursor design and synthesis-HDO [32,33,34]. Some processes have already been developed at a commercial scale and the fuels have been approved by ASTM D7566, but others, like fermentation and catalytic conversion to hydrocarbons, are still at research stage. Among these four routes, the latter is particularly promising for achieving high-energy-density jet fuel with the required specifications, due to its versatile process that tunes the fuel quality and properties [35]. This route of catalytic conversion from biomass to jet fuels is a highly complex process involving deep chemical changes through selective oxygen removal steps (e.g., dehydration, decarboxylation and hydrogenolysis), followed by molecular-weight and structural adjustments (e.g., aldol condensation and oligomerization) [36,37,38]. The oxygen removal steps are necessary to control the high reactivity of biomass and allow the production of less reactive intermediates, while C–C coupling reactions are essential to obtain fuels in the appropriate carbon range (higher than 6). These reactions are typically performed in the aqueous phase due to the high solubility in water of the molecules derived from sugar monomers [39]. Furthermore, besides being non-toxic, readily available, affordable and inflammable, water is known to have an amphoteric behaviour and to become more ionized (H2O → OH− + H3O+) with the increase of temperature, acting as an acid catalyst in hydrolysis reactions. Moreover, due to the reversible proton behaviour, the proton automatically disappears when the water is cooled down, solving the issue related to acid recovery and waste disposal. In addition, this process allows the use of a greater variety of biomass feedstocks, which is not limited to oil crops or fats compared to other processes like first-generation biofuel technology.

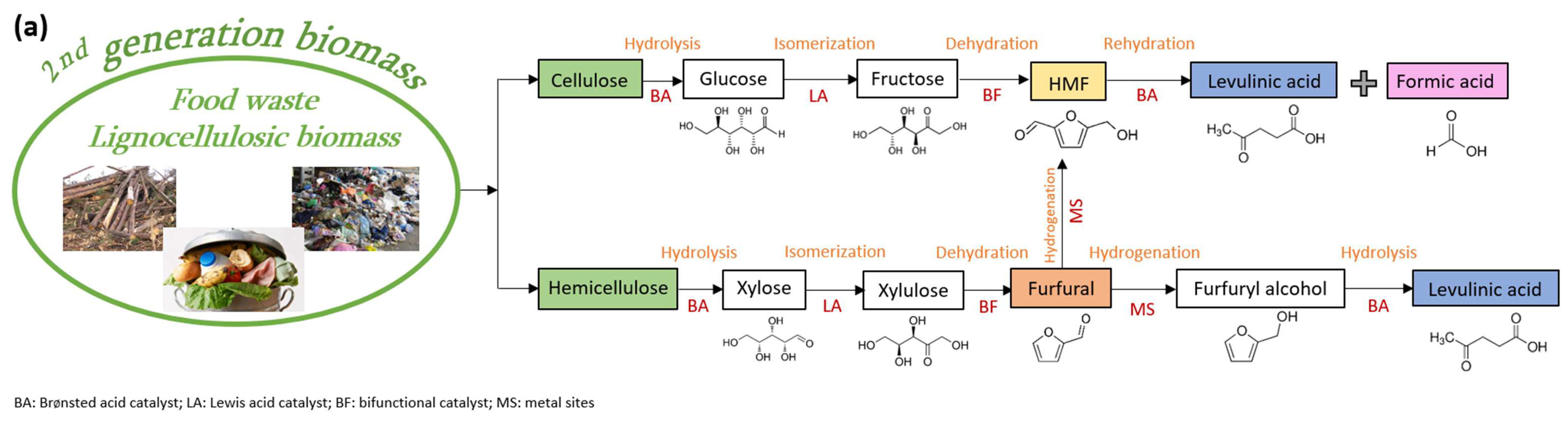

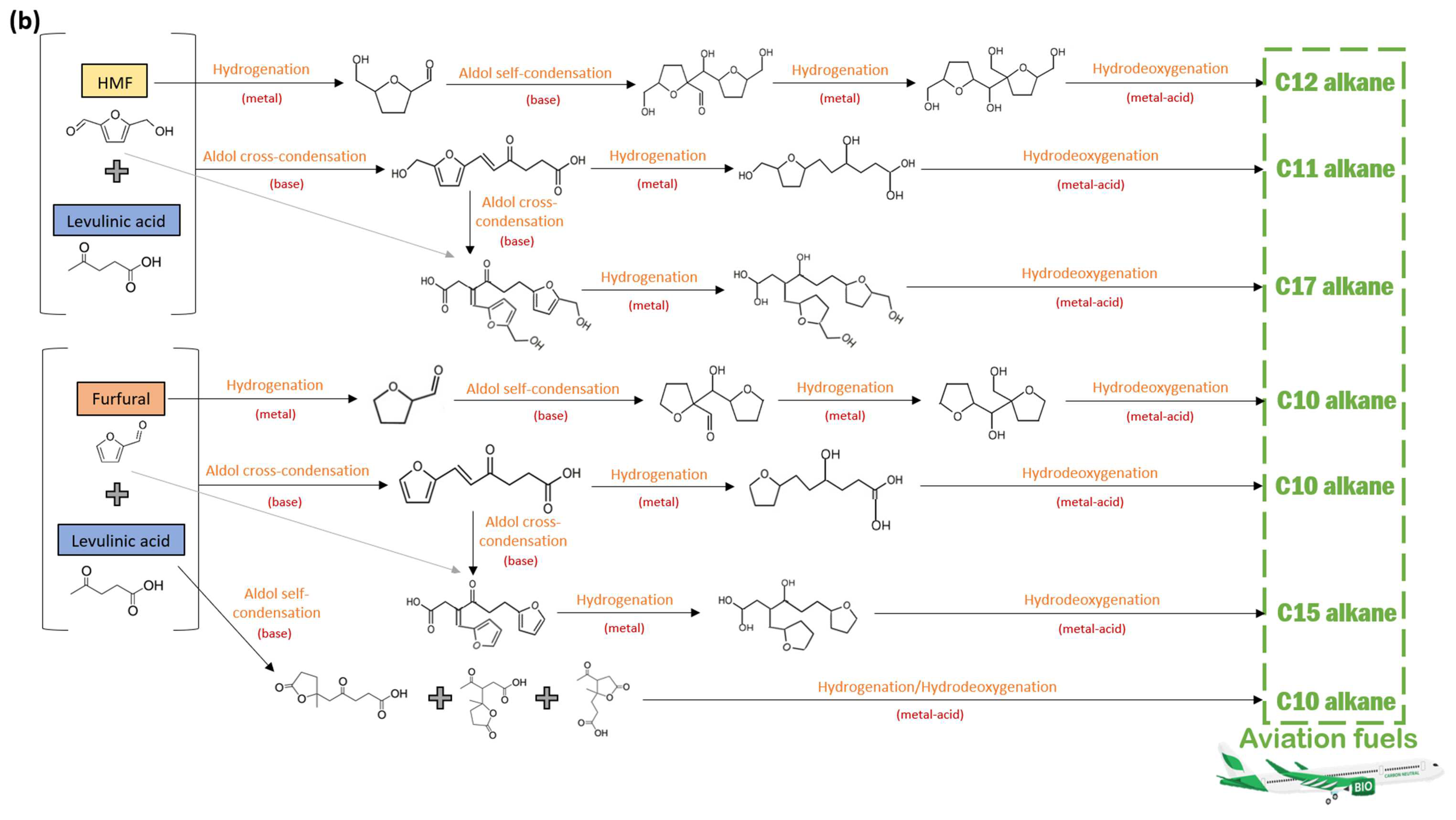

Accordingly, to obtain high-energy-density fuels, oxygen-abundant biomass requires an oxygen removal process, typically a catalytic hydrotreatment commonly known as HDO. In addition, since the conversion of biomass-derived compounds can only produce hydrocarbons with a carbon number up to 6, which is shorter than that of aviation fuel, the employment of C–C coupling reactions is necessary to obtain products with higher carbon numbers that can be further transformed into jet fuel (C8–C16 hydrocarbons). One process that could be considered is the conversion of biomass wastes to SAF via sugar alcohols intermediates, while another possibility would be to consider the process using furanics as intermediates [40]. However, this latter process has the advantage of eliminating hydrolysis as a separate step and reducing hydrogen consumption. Furfural, 5-hydroxymethylfurfural (HMF) and levulinic acid (LA) are the biomass-derived products that are most frequently used to obtain long-chain jet fuel precursors through hydroxyalkylation/alkylation [41,42], dimerization [43] and condensation processes [32,34,44]. Furanics like furfural and HMF are readily obtained from the dehydration of sugars over mineral acids [45,46]. Also, LA is an important biomass-derived compound that can be obtained from the acid hydrolysis of cellulosic wastes [47]. Following this route, the conversion of biomass feedstocks can be accomplished by the combination of multiple reactions that are often accelerated over different catalysts: (i) hydrolysis of polysaccharides to produce glucose (from cellulose) or xylose (from hemicellulose), commonly catalyzed by Brønsted acids; (ii) isomerization of glucose to fructose or xylose to xylulose, which is promoted by Lewis acids or Brønsted bases; (iii) acid-catalyzed dehydration to produce carbonyl-containing furan compounds like HMF (from fructose) and furfural (from xylulose); (iv) aldol/cross-condensation to form larger compounds (>C6) by forming C–C bonds; (v) hydrogenation of these aldol-products to large water-soluble molecules; and vi) dehydration/hydrogenation/HDO reactions to convert these molecules to C8–C16 alkanes over bifunctional acid–metal catalysts [39,48,49]. Figure 1 shows one possible process for SAF production, involving the cascade dehydration, aldol-condensation, hydrogenation and HDO reactions necessary to obtain the fuel with targeted molecular weights [50]. This process is divided into two parts in Figure 1: Figure 1a shows the possible routes for producing HMF, LA and furfural intermediates from food waste and biomass residues (through cellulose and hemicellulose), whereas Figure 1b shows for the first time a possible reaction between furfural/HMF and LA intermediates to produce aviation-ranged hydrocarbons. Therefore, one main challenge of this process for SAF production from biomass is reducing the number of reactors used to carry out all the required steps.

Figure 1.

Possible routes for jet-fuel-ranged hydrocarbon catalytic production from biomass: (a) production of HMF, furfural and LA intermediates and (b) reaction between intermediates to originate alkanes (the active sites for each reaction are written in red).

Aldol-condensation reactions have particular importance for the formation of large organic species from biomass. For instance, glucose and xylose, which can be directly obtained from the hydrolysis of cellulose and hemicellulose, do not undergo aldol-condensation since the carbonyl groups undergo intramolecular reactions to form ring structures. However, the dehydration of glucose and xylose produces HMF and furfural, respectively. Additionally, unlike LA, HMF and furfural cannot self-condensate, since they do not possess the α-H atom required for aldol-condensation reactions. Yet, HMF and furfural can be cross-condensed with other compounds like LA, acetone and others to form larger molecules [34,48]. The cross-condensation between HMF and acetone has already been reported [32,48], while Chen et al. have recently studied the cross-condensation between furfural and LA to obtain C10–C20 fuel precursors [34]. However, since LA can be readily obtained from HMF and furfural, it would be of particular interest to investigate the cross-condensation of LA with HMF and/or furfural to produce C10–C17 compounds that can be further converted to alkanes (Figure 1b). Despite excellent reviews that have already been published on the sustainable production of aviation fuels and the role of catalysis in it [1,9,48], this work proposes a route for producing aviation fuels from biomass, by combining HMF and furfural intermediates (obtained from cellulose and hemicellulose conversion, respectively) with LA that can be obtained in both cellulose and hemicellulose conversion processes. To better illustrate this herein newly proposed conversion process, Figure 1 is presented to help grasp the essence of SAF manufacturing. To produce jet-fuel-ranged hydrocarbons (C8–C16), these precursors are necessary to remove oxygen by catalytic HDO. The elimination of oxygen can occur via direct hydrogenolysis, dehydration, decarboxylation and decarbonylation, but in the case of biomass-derived substrates, HDO reactions are typically used to minimize the high oxygen content.

In recent years, the production of transportation fuels from lignocellulose has received large attention due to its advantages, including low-cost raw materials, mild operation conditions and high selectivity to the desired products [35,51,52,53,54,55,56,57,58,59,60]. Furthermore, some reviews have been published about the most important achievements of the last few years on alternative fuels for aviation [9,18,20,37,61,62,63,64,65]. Hence, continuous efforts must be considered for the improvement of the total hydrocarbon yields and also the development of efficient and cost-effective direct routes to produce economically-competitive jet fuels.

4. Feedstock Selection and Pre-Treatment

Selecting feedstock and technology for producing SAF is not straightforward, the main obstacles being the affordability and competitiveness in comparison to conventional jet fuel. For example, SAF can be about 2–8 times more expensive than fossil-based fuel, so technological advancement and improvement are essential. The first advantages of renewable feedstocks in comparison to the others are (i) sustainability, (ii) CO2 recycling, (iii) renewable materials, (iv) lower fossil-fuel dependency and (v) eco-friendly process.

Biomass feedstocks for fuel production are generally divided into three categories according to their ease of usage and sustainability: (i) first-generation feedstock relates to agricultural products like wheat, maize and vegetable oils; (ii) second generation refers to agricultural wastes (e.g., husks), non-food crops and municipal/industry residues; (iii) third-generation biofuels are relatively new and are obtained from algae. Among the most favorable sources are non-food energy crops like algae, municipal solid waste (MSW) and forestry/wood residues. The first generation has several drawbacks, such as competition with food, high total production costs, reliance on non-sustainable fertilizers that could limit GHG emissions, promotion of land deforestation and resulting biodiversity loss, as well as competition for clean water. Furthermore, algae has a disadvantage in that it must be separated from water due to the small algal cells, in addition to requiring lysis; this can be very challenging. On the other hand, using second-generation feedstocks allows us to reduce the amount of them that is continuously sent to landfill or incinerated. Although the production of second-generation biofuels has its own challenges associated with the complexity of biomass, they could have a substantial impact on cost reductions and increased productivity efficiency [66].

Until now, the great majority of SAF have been obtained from oleochemical/lipidic sources like vegetable oils, but the predicted upcoming demand will not only be fulfilled by these types of substrates, since lignocellulosic wastes can also contribute to SAF production. Non-edible forestry and agricultural residues might be considered, since they do not compete with food and are easily available. However, transporting these residues from remote areas might not be economically attractive, and they can be seasonal or have a limited time window for collection after harvesting, thus demanding extra storage space. On the other hand, MSW can be used to obtain high-value products, promoting waste diversion from its current management, which consists of landfilling or incineration [67]. MSW is a heterogeneous mixture of different residues, such as food waste, plastics, paper/cardboard, wood, textiles, etc. However, one difficulty associated with this process is the fact that MSW contains a high moisture content and contamination (ash, nitrogen and heavy metals), so it requires a pre-treatment and separation before processing. Furthermore, its characteristics and production rates are dependent on regionality, population, socio-economic conditions, dietary routines, seasonability, municipal sorting system, etc. Therefore, a potential climate change mitigation can be attained if its organic fraction (OFMSW) is applied as feedstock for biofuel production [68]. As a result, one of the biggest biomass sources that has been currently receiving increasing attention and research interest is non-edible OFMSW, which is composed of food waste, kitchen waste and leftovers from cafeterias, restaurants, residences and markets, as well as garden waste [68].

In addition, in the context of lignocellulosic biomass conversion, plant-cell deconstruction is a tedious process, since its recalcitrance is an intrinsic property given by lignocellulose to ensure protection from chemical and/or biological degradation. Furthermore, physical factors like crystallinity, assessable volume, particle size and surface area have a great impact on lignocellulose recalcitrance. Indeed, the particle size and crystallinity degree have already been shown to greatly affect the cellulose hydrolysis potential [69,70]. Therefore, the highly crystalline and recalcitrant lignocellulosic biomass structure demands a deconstruction that can be achieved through several pre-treatment methods, including chemical, physical (milling, grinding and extrusion), physicochemical (supercritical CO2 and steam explosion) and biological processes [37,71,72]. However, these pre-treatments have cost implications and their respective advantages and disadvantages, which need to be well thought out when choosing the feedstock for SAF production. For example, due to lignin’s nature, its conversion to jet-fuel-ranged hydrocarbons is extremely hard via aqueous conversion; so, in many cases, besides the structural deconstruction, delignification is crucial for further biomass processing (e.g., alkaline pre-treatment has been shown to digest the existing lignin, making cellulose and hemicellulose readily available).

5. Catalysts

Mineral acid catalysts have been widely used in lab-scale applications, but they bring huge challenges in large-scale ones; these relate to the obtaining of high-purity final products, recovering and recycling of the catalyst, and safety issues. On the other hand, heterogeneous catalysts solve those problems but tend to reach lower yields compared to homogenous catalysts. Despite that, the development of novel, non-toxic, inexpensive, high-performance and recyclable catalysts is promising. Carbon materials show excellent electrical conductivity and developed porosity [73]. Furthermore, these materials have the advantage of being full of functional groups with tunable properties that encompass them with acid active sites, where the acidities can be regulated by adjusting their surface properties [74]. However, not all materials are suitable to being introduced as support, due to the collapse of microstructure induced by kinetic energy [75]. The porosity of these materials provides reaction sites and eases reactant transportation, whereas the Brønsted acid sites facilitate the hydrolysis of cellulose; the hydrogenation can take place readily over Pt, Pd and Ru metals, and transition metals like W, Sn and Cu are beneficial to the catalysis of aldol-condensation reactions in cellulose/hemicellulose conversion [75].

Within the aim of synthesizing the fuel precursors through the condensation of LA and furfural/HMF, followed by the direct conversion of the condensation intermediates to liquid fuel without the need for separation, it is fundamental to control the reaction to obtain the desired weight-ranged products. Therefore, understanding the intermediates’ structure and solubility characteristics is an important aspect for effectively producing liquid alkane fuels. The direct conversion of precursor mixtures requires a catalyst with high activity or stepwise HDO. HDO reactions require high pressure and temperature and a specific catalyst to produce the desired species. Carbon-based solid acid catalysts are shown as potential candidates due to their high thermal stability and low cost [49]. Noble metal catalysts are usually used along with the Brønsted or Lewis acidic sites for C–O cleavage. The achievement of a suitable balance among these reactions is crucial to circumvent side reactions. In this case, a metal-acid multifunctional catalysis strategy can be promising for mildening the reaction conditions due to the contribution of multifunctional active sites capable of facilitating HDO reactions. As a result, a suitable multifunctional catalyst for this reaction is recommended, i.e., a system including Lewis acid or basic sites to facilitate isomerization, and Brønsted sites to catalyze, for example, the final fructose dehydration to HMF. Furthermore, heterogeneous catalysts may decrease equipment corrosion and bring advantages of catalyst recycling without separation and disposal problems, while concerns for heterogeneous catalytic reactions include long reaction times and expensive catalysts. Catalyst selection is crucial due to its role in controlling the yields, which in turn impacts the costs, so the development of a catalyst with high activity, selectivity and stability has significant importance.

6. Economic and Environmental Feasibility

The economic feasibility of a process for SAF production needs to be assessed based on techno-economic analysis and the environmental issues evaluated by a life-cycle analysis (LCA) [66]. In processes that use lignocellulosic biomass as feedstocks, the most influential factors to be considered in the LCA are biomass cultivation, harvesting and transportation. Hence, technologies that can use local biomass wastes, such as MSW, are far more economical and environmentally viable. In addition, biofuels generated from second-generation biomass are more sustainable than first generation since they have a larger potential to reduce GHG (50–100%) compared to first-generation fuels (50–90%) [66].

Two considerations that must be made when evaluating the feasibility of the process are the yield of SAF that can be attained from renewable sources and the life-cycle GHG emissions. Those analyses are beyond the scope of this work but have already been documented in the literature [20,76,77,78,79,80]. Pavlenko et al. have presented a study of the cost associated with alternative jet fuel production and concluded that the cost varies substantially according to the technology employed, as well as the feedstock [76]. For example, the costs can vary from 0.88 EUR/L for HEFA to 3.44 EUR/L for the direct conversion of sugar to jet fuels, whose values are 2–8 times the price of petroleum jet fuel. They also estimated that HEFA has a cost of approximately EUR 200 per ton of CO2 equivalents reduced, while gasification-FT has a cost of approximately EUR 400–500 per ton of CO2 reduced [76]. Regarding the yield (tons of total fuel production/ton of feedstock), it can vary from 0.3 (theoretical maximum) from sugars to fuel to 0.9 from HEFA [76].

Finally, it is fundamental to align the strategy with the SDG. Using the catalytic processing of biomass to SAF herein mentioned, the selected SGD aligned with this route include SDG 7 (affordable and clean energy), SGD 9 (industry, innovation and infrastructure), SDG 11 (sustainable cities and communities), SDG 12 (responsible consumption and production) and SDG 13 (climate action) [13].

7. Challenges and Future Work

Firstly, optimization is fundamental to reducing the overall number of reaction steps. Taking advantage of the analogous reaction conditions of two or more steps means they can be combined in one single reactor, minimizing the overall separation of reactions and reactors needed. However, it is important to note that each lignocellulosic biomass feedstock has different reaction characteristics (e.g., dehydration) in similar processing environments, so the development of a unified strategy for a wide range of feedstocks is a great challenge to be overcome. Moreover, preliminary studies must also be performed with the individual fractions (e.g., cellulose and hemicellulose) and model/intermediate compounds (e.g., glucose and fructose) to further understand the reaction pathways and explain the product portfolio. A proper study must also be executed on the change in product selectivity with time, productivity, catalytic stability and regenerability, which have a vital importance in the determination of the techno-economical potential of the developed process. Furthermore, the catalytic processing of lignocellulosic biomass in industry remains a tremendous challenge, in which one of the main obstacles is the absence of an economic process capable of competing with those existing for fossil-fuel feedstock. Therefore, new studies must be undertaken to accomplish the production of SAF from renewable biomass sources over cost-competitive processes.

Developing highly integrated methods that allow the one-pot catalytic conversion of the whole lignocellulose (including the lignin fraction) is essential. Besides this, the conversion of lignocellulosic residues to SAF is far more challenging compared to other fuels, due to its higher standards. Thus, several challenges must be overcome to unlock biomass’s full potential, such as selective C–C bond formation, efficient production of targeted hydrocarbons with minimum H2 consumption, and valorization of the lignin fraction. Considering the latter, since jet fuel must contain between 8% and 25% aromatics to comply with the ASTM D7566 standard, aromatics are fundamental to producing a drop-in 100% SAF from biomass. Therefore, future efforts must be centered on developing an economically viable and scalable process for converting the lignin fraction. This achievement would allow us to break down the current “blending wall” and be a game changer in the full replacement of petroleum-based fuel by SAF.

Finally, it is also imperative to develop sustainability metrics for SAF, including renewability, environmental impact, economic viability, energy security and others. SAF needs to be produced in large quantities, be cost-competitive and also have a well-established life-cycle GHG footprint. Future directions must include analysis of the life-cycle costs and the environmental side effects of the developed SAF, since life-cycle CO2 emissions vary significantly depending on the feedstock and process.

To pave the way for lignocellulosic biomass valorization to aviation fuels, these challenges must be overcome, and new methodologies must involve several required chemical transformations.

8. Concluding Remarks

Whereas the petrochemical refinery managed to reach its current efficiency by continuous improvement over the last 50 years, and biorefinery is still in its infancy, this catalytic processing could make a big step in the direction of transitioning towards a biomass-based economy. In fact, the future of SAF will rely on the balance between GHG emissions and production cost, so future research should be focused on new processes to further improve the process cost effectiveness through optimization, integration and scaling-up. More importantly, the cost of producing SAF from biomass residues must be competitive with current petroleum technology.

Technical challenges will exist, namely concerning process efficiency, catalyst design, product upgrading and cleaning, utilization of by-products, recycling, etc. However, it is essential to develop new catalytic systems that are economically and environmentally friendly, to produce SAF from biomass. Accordingly, here is presented for the first time a possible process for the catalytic conversion of biomass wastes into SAF, by combining LA (resultant from both hemicellulose and cellulose conversion) with furfural and/or HMF (resultant from hemicellulose and cellulose conversion, respectively), thus valorizing both cellulose and hemicellulose fractions of lignocellulosic biomass wastes.

Author Contributions

The manuscript was written through contributions of all authors. L.S.R.: conceptualization; writing—original draft; writing—review & editing. M.F.R.P.: conceptualization; resources; funding acquisition; writing—review & editing. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by national funds through FCT/MCTES (PIDDAC): LSRE-LCM, UIDB/50020/2020 (DOI: 10.54499/UIDB/50020/2020) and UIDP/50020/2020 (DOI: 10.54499/UIDP/50020/2020); ALiCE, LA/P/0045/2020 (DOI: 10.54499/LA/P/0045/2020).

Conflicts of Interest

The authors have no known competing financial interests or personal relationships that could influence this work.

Abbreviations

| EGD | European Green Deal |

| EU | European Union |

| FT | Fischer–Tropsch |

| GHG | greenhouse gas emissions |

| HDO | hydrodeoxygenation |

| HEFA | hydroprocessed esters and fatty acids |

| HMF | 5-hydroxymethylfurfural |

| LA | levulinic acid |

| LCA | life-cycle analysis |

| MSW | municipal solid waste |

| OFMSW | organic fraction of municipal solid waste |

| RED | Renewable Energy Directive |

| SAF | sustainable aviation fuels |

| SDG | Sustainable Development Goals |

References

- Wang, H.; Yang, B.; Zhang, Q.; Zhu, W. Catalytic routes for the conversion of lignocellulosic biomass to aviation fuel range hydrocarbons. Renew. Sustain. Energy Rev. 2020, 120, 109612. [Google Scholar] [CrossRef]

- Ryu, H.W.; Kim, D.H.; Jae, J.; Lam, S.S.; Park, E.D.; Park, Y. Recent advances in catalytic co-pyrolysis of biomass and plastic waste for the production of petroleum-like hydrocarbons. Bioresour. Technol. 2020, 310, 123473. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Yan, B.; Chen, G. Technical review on jet fuel production. Renew. Sustain. Energy Rev. 2013, 25, 59–70. [Google Scholar] [CrossRef]

- Yang, L.; Luo, W.; Li, H.W.; Wang, H.Y.; Zhang, A.; Wu, Z.; Liu, Q.; Wang, Z.; Lv, P.; Yuan, Z. Catalytic oleic acid hydrotreating to bio-aviation fuel over highly dispersed Ni/SAPO-11 catalysts prepared by citric acid and ethylene glycol co-assistance impregnation. J. Environ. Chem. Eng. 2022, 10, 107220. [Google Scholar] [CrossRef]

- Park, C.; Choi, H.; Lin, K.A.; Kwon, E.E.; Lee, J. COVID-19 mask waste to energy via thermochemical pathway: Effect of Co-Feeding food waste. Energy 2021, 230, 120876. [Google Scholar] [CrossRef]

- Lin, X.; Lei, H.; Huo, E.; Qian, M.; Mateo, W.; Zhang, Q.; Zhao, Y.; Wang, C.; Villota, E. Enhancing jet fuel range hydrocarbons production from catalytic co-pyrolysis of Douglas fir and low-density polyethylene over bifunctional activated carbon catalysts. Energy Conv. Manag. 2020, 211, 112757. [Google Scholar] [CrossRef]

- Cronin, D.J.; Subramaniam, S.; Brady, C.; Cooper, A.; Yang, Z.; Heyne, J.; Drennan, C.; Ramasamy, K.K.; Thorson, M.R. Sustainable Aviation Fuel from Hydrothermal Liquefaction of Wet Wastes. Energies 2022, 15, 1306. [Google Scholar] [CrossRef]

- Ng, K.S.; Farooq, D.; Yang, A. Global biorenewable development strategies for sustainable aviation fuel production. Renew. Sustain. Energy Rev. 2021, 150, 111502. [Google Scholar] [CrossRef]

- Emmanouilidou, E.; Mitkidou, S.; Agapiou, A.; Kokkinos, N.C. Solid waste biomass as a potential feedstock for producing sustainable aviation fuel: A systematic review. Renew. Energy 2023, 206, 897–907. [Google Scholar] [CrossRef]

- EUR-Lex. Access to European Union Law: The European Green Deal. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1576150542719&uri=COM%3A2019%3A640%3AFIN (accessed on 23 August 2023).

- Spencer, T.; Pierfederici, R.; Sartor, O.; Berghmans, N.; Samadi, S.; Fischedick, M.; Knoop, K.; Pye, S.; Criqui, P.; Mathy, S.; et al. Tracking sectoral progress in the deep decarbonisation of energy systems in Europe. Energy Policy 2017, 110, 509–517. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: https://sdgs.un.org/2030agenda (accessed on 5 April 2023).

- Panoutsou, C.; Germer, S.; Karka, P.; Papadokostantakis, S.; Kroyan, Y.; Wokcieszyk, M.; Maniatis, K.; Marchand, P.; Landalv, I. Advanced biofuels to decarbonise European transport by 2030: Markets, challenges, and policies that impact their successful market uptake. Energy Strat. Rev. 2021, 34, 100633. [Google Scholar] [CrossRef]

- EUR-Lex. Access to European Union Law: Directive 2018/2001/EU of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG&toc=OJ:L:2018:328:TOC (accessed on 10 June 2023).

- EUR-Lex. Access to European Union Law: White Paper Roadmap to a Single European Transport Area—Towards a Competitive and Resource Efficient Transport System (COM/2011/0144 Final). Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52011DC0144 (accessed on 25 November 2023).

- Knopf, B.; Nahmmacher, P.; Schmid, E. The European renewable energy target for 2030—An impact assessment of the electricity sector. Energy Policy 2015, 85, 50–60. [Google Scholar] [CrossRef]

- ASTM D7566-22a; A Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons. ASTM International: West Conshohocken, PA, USA. Available online: https://www.astm.org/d7566-22a.html#:%7E:text=Specification%20D7566%20is%20directed%20at%20civil%20applications%2C%20and,aviation%20turbine%20fuel%20from%20production%20to%20the%20aircraft (accessed on 23 August 2023).

- Díaz-Pérez, M.A.; Serrano-Ruiz, J.C. Catalytic Production of Jet Fuels from Biomass. Molecules 2020, 25, 802. [Google Scholar] [CrossRef] [PubMed]

- ASTM D1655-21c; Standard Specification for Aviation Turbine Fuels. ASTM International: West Conshohocken, PA, USA. Available online: https://www.astm.org/d1655-21c.html (accessed on 23 August 2023).

- Zhang, C.; Hui, X.; Lin, Y.; Sung, C. Recent development in studies of alternative jet fuel combustion: Progress, challenges, and opportunities. Renew. Sustain. Energy Rev. 2016, 54, 120–138. [Google Scholar] [CrossRef]

- Yang, Z.; Xu, Z.; Feng, M.; Cort, J.R.; Gieleciak, R.; Heyne, J.; Yang, B. Lignin-based jet fuel and its blending effect with conventional jet fuel. Fuel 2022, 321, 124040. [Google Scholar] [CrossRef]

- Stone, M.L.; Webber, M.S.; Mounfield, W.P., III; Bell, D.C.; Christensen, E.; Morais, A.R.C.; Li, Y.; Anderson, E.M.; Heyne, J.S.; Beckham, G.T.; et al. Continuous hydrogeoxygenation of lignin to jet-ranged aromatic hydrocarbons. Joule 2022, 6, 2324–2337. [Google Scholar] [CrossRef]

- Abrantes, I.; Ferreira, A.F.; Silva, A.; Costa, M. Sustainable aviation fuels and imminent technologies—CO2 emissions evolution towards 2050. J. Cleaner Prod. 2021, 313, 127937. [Google Scholar] [CrossRef]

- Wang, J.; Singer, S.D.; Souto, B.A.; Asomaning, J.; Ullah, A.; Bressler, D.C.; Chen, G. Current progress in lipid-based biofuels: Feedstocks and production technologies. Bioresour. Technol. 2022, 351, 127020. [Google Scholar] [CrossRef] [PubMed]

- Xing, S.; Liu, Y.; Liu, X.; Li, M.; Fu, J.; Liu, P.; Lv, P.; Wang, Z. Solvent-free hydrodeoxygenation of bio-lipids into renewable alkanes over NiW bimetallic catalyst under mild conditions. Appl. Catal. B Environ. 2020, 269, 118718. [Google Scholar] [CrossRef]

- Zula, M.; Grilc, M.; Likozar, B. Hydrocracking, hydrogenation and hydro-deoxygenation of fatty acids, esters and glycerides: Mechanisms, kinetics and transport phenomena. Chem. Eng. J. 2022, 444, 136564. [Google Scholar] [CrossRef]

- Yan, Q.; Yu, F.; Liu, J.; Street, J.; Gao, J.; Cai, Z.; Zhang, J. Catalytic conversion wood syngas to synthetic aviation turbine fuels over a multifunctional catalyst. Bioresour. Technol. 2013, 127, 281–290. [Google Scholar] [CrossRef] [PubMed]

- Shahabuddin, M.; Alam, M.T.; Krishma, B.B.; Bhaskar, T.; Perkins, G. A review on the production of renewable aviation fuels from the gasification of biomass and residual wastes. Bioresour. Technol. 2020, 312, 123596. [Google Scholar] [CrossRef] [PubMed]

- Leibbrandt, N.H.; Aboyade, A.O.; Knoetze, J.H.; Görgens, J.F. Process efficiency of biofuel production via gasification and Fischer–Tropsch synthesis. Fuel 2013, 109, 484–492. [Google Scholar] [CrossRef]

- Shao, S.; Ye, Z.; Liu, C.; Hu, X.; Sun, J.; Li, X.; Zhang, H.; Xiao, R. Catalytic pyrolysis of holocellulose followed by integrated aldol condensation and hydrogenation to produce aviation fuel. Energy Conver. Manag. 2022, 264, 115644. [Google Scholar] [CrossRef]

- Kannapu, P.R.H.; Pyo, S.; Lam, S.S.; Jae, J.; Rhee, G.H.; Khan, M.A.; Jeon, B.; Park, Y. MgO-modified activated biochar for biojet fuels from pyrolysis of sawdust on a simple tandem micro-pyrolyzer. Bioresour. Technol. 2022, 359, 127500. [Google Scholar]

- Huber, G.W.; Chheda, J.N.; Barrett, C.J.; Dumesic, J.A. Production of Liquid Alkanes by Aqueous-Phase Processing of Biomass-Derived Carbohydrates. Science 2005, 308, 1446–1450. [Google Scholar] [CrossRef]

- Corma, A.; Torre, O.; Renz, M.; Villandier, N. Production of High-Quality Diesel from Biomass Waste Products. Angew. Chem. Int. Ed. 2011, 50, 2375–2378. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Y.; Zhang, X.; Liu, J.; Zhang, Q.; Ma, L. Catalytic production of long-chain hydrocarbons suitable for aviation turbine fuel from biomass-derived levulinic acid and furfural. Fuel 2023, 334, 126665. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, L.; Chen, Y.; Zhang, X.; Liu, J.; Liu, Q.; Li, Y.; Wang, C.; Zhang, Q.; Ma, L. Pilot study on production of aviation fuel from catalytic conversion of corn stover. Bioresour. Technol. 2023, 372, 128653. [Google Scholar] [CrossRef]

- Saleem, M. Possibility of utilizing agriculture biomass as a renewable and sustainable future energy source. Heliyon 2022, 8, e08905. [Google Scholar] [CrossRef]

- Saravanan, A.; Kumar, P.S.; Jeevanantham, S.; Karishma, S.; Vo, D.N. Recent advances and sustainable development of biofuels production from lignocellulosic biomass. Bioresour. Technol. 2022, 344, 126203. [Google Scholar] [CrossRef] [PubMed]

- Okolie, J.A.; Epelle, E.I.; Tabat, M.E.; Orivri, U.; Amenaghawon, A.N.; Okoye, P.U.; Gunes, B. Waste biomass valorization for the production of biofuels and value-added products: A comprehensive review of thermochemical, biological and integrated processes. Process Saf. Environ. Prot. 2022, 159, 323–344. [Google Scholar] [CrossRef]

- Hao, J.; Xiao, J.; Song, G.; Zhang, Q. Energy and exergy analysis of bio-jet fuel production from lignocellulosic biomass via aqueous conversion. Case Stud. Therm. Eng. 2021, 26, 101006. [Google Scholar] [CrossRef]

- Jiang, Z.; Hu, D.; Zhao, Z.; Yi, Z.; Chen, Z.; Yan, K. Mini-Review on the Synthesis of Furfural and Levulinic Acid from Lignocellulosic Biomass. Processes 2021, 9, 1234. [Google Scholar] [CrossRef]

- Climent, M.J.; Corma, A.; Iborra, S. Conversion of biomass platform molecules into fuel additives and liquid hydrocarbon fuels. Green Chem. 2014, 16, 516–547. [Google Scholar] [CrossRef]

- Li, G.; Li, N.; Wang, Z.; Li, C.; Wang, A.; Wang, X.; Cong, Y.; Zhang, T. Synthesis of High-Quality Diesel with Furfural and 2-Methylfuran from Hemicellulose. ChemSusChem 2012, 5, 1958–1966. [Google Scholar] [CrossRef]

- Shang, X.; Yang, Y.; Sun, Y. Electrohydrodimerization of biomass-derived furfural generates a jet fuel precursor. Green Chem. 2020, 22, 5395–5401. [Google Scholar] [CrossRef]

- Faba, L.; Díaz, E.; Ordóñez, S. Base-Catalyzed Condensation of Levulinic Acid: A New Biorefinery Upgrading Approach. ChemCatChem 2016, 8, 1490–1494. [Google Scholar] [CrossRef]

- Chheda, J.N.; Román-Leshkov, Y.; Dumesic, J.A. Production of 5-hydroxymethylfurfural and furfural by dehydration of biomass-derived mono- and poly-saccharides. Green Chem. 2007, 9, 342–350. [Google Scholar] [CrossRef]

- Zeitsch, K.J. The Chemistry and Technology of Furfural and Its Many By-Products, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Fritzpatrick, S.W. Production of Levulinic Acid from Carbohydrate-Containing Materials. Eur. Pat. Appl. EP0873294, 17 May 1996. [Google Scholar]

- Chheda, J.N.; Dumesic, J.A. An overview of dehydration, aldol-condensation and hydrogenation processes for production of liquid alkanes from biomass-derived carbohydrates. Catal. Today 2007, 123, 59–70. [Google Scholar] [CrossRef]

- Xiong, X.; Yu, I.K.M.; Dutta, S.; Masek, O.; Tsang, D.C.W. Valorization of humins from food waste biorefinery for synthesis of biochar-supported Lewis acid catalysts. Sci. Totald Environ. 2021, 775, 145851. [Google Scholar] [CrossRef] [PubMed]

- West, R.M.; Liu, Z.Y.; Peter, M.; Dumesic, J.A. Liquid Alkanes with Targeted Molecular Weights from Biomass-Derived Carbohydrates. ChemSusChem 2008, 1, 417–424. [Google Scholar] [CrossRef] [PubMed]

- Bayu, A.; Abudula, A.; Guan, G. Reaction pathways and selectivity in chemo-catalytic conversion of biomass-derived carbohydrates to high-value chemicals: A review. Fuel Process. Technol. 2019, 196, 106162. [Google Scholar] [CrossRef]

- Han, X.; Guo, Y.; Liu, X.; Xia, Q.; Wang, Y. Catalytic conversion of lignocellulosic biomass into hydrocarbons: A mini review. Catal. Today 2019, 319, 2–13. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, L.; Wang, T.; Zhang, X.; Long, J.; Zhang, Q.; Ma, L. High yield of renewable hexanes by direct hydrolysis–hydrodeoxygenation of cellulose in an aqueous phase catalytic system. RSC Adv. 2015, 5, 11649–11657. [Google Scholar] [CrossRef]

- Liu, S.; Okuyama, Y.; Tamura, M.; Nakagawa, Y.; Imai, A.; Tomishige, K. Selective transformation of hemicellulose (xylan) into n-pentane, pentanols or xylitol over a rhenium-modified iridium catalyst combined with acids. Green Chem. 2016, 18, 165–175. [Google Scholar] [CrossRef]

- Beeck, B.O.; Dusselier, M.; Geboers, J.; Holsbeek, J.; Morré, E.; Oswald, S.; Giebeler, L.; Sels, B.F. Direct catalytic conversion of cellulose to liquid straight-chain alkanes. Energy Environ. Sci. 2015, 8, 230–240. [Google Scholar] [CrossRef]

- Xia, Q.; Chen, Z.; Shao, Y.; Gong, X.; Wang, H.; Liu, X.; Parker, S.F.; Han, X.; Yang, S.; Wang, Y. Direct hydrodeoxygenation of raw woody biomass into liquid alkanes. Nat. Commun. 2016, 7, 11162. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Bi, P.; Wang, J.; Jiang, P.; Wu, X.; Xue, H.; Liu, J.; Zhou, X.; Li, Q. Production of jet and diesel biofuels from renewable lignocellulosic biomass. Appl. Energy 2015, 150, 128–137. [Google Scholar] [CrossRef]

- Serrano-Ruiz, J.C.; Braden, D.J.; West, R.M.; Dumesic, J.A. Conversion of cellulose to hydrocarbon fuels by progressive removal of oxygen. Appl. Catal. B Environ. 2010, 100, 184–189. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, L.; Wang, T.; Zhang, Q.; Wang, C.; Yan, J.; Ma, L. One-Pot Catalytic Conversion of Raw Lignocellulosic Biomass into Gasoline Alkanes and Chemicals over LiTaMoO6 and Ru/C in Aqueous Phosphoric Acid. ACS Sustain. Chem. Eng. 2015, 3, 1745–1755. [Google Scholar] [CrossRef]

- Liu, S.; Tamura, M.; Nakagawa, Y.; Tomishige, K. One-Pot Conversion of Cellulose into n-Hexane over the Ir-ReOx/SiO2 Catalyst Combined with HZSM-5. ACS Sustain. Chem. Eng. 2014, 2, 1819–1827. [Google Scholar] [CrossRef]

- Rodionova, M.V.; Bozieva, A.M.; Zharmukhamedov, S.K.; Leong, Y.K.; Lan, J.C.; Veziroglu, A.; Veziroglu, T.N.; Tomo, T.; Chang, J.; Allakhverdiev, S.I. A comprehensive review on lignocellulosic biomass biorefinery for sustainable biofuel production. Int. J. Hydrog. Energy 2022, 47, 1481–1498. [Google Scholar] [CrossRef]

- Velvizhi, G.; Balakumar, K.; Shetti, N.P.; Ahmad, E.; Pant, K.K.; Aminabhavi, T.M. Integrated biorefinery processes for conversion of lignocellulosic biomass to value added materials: Paving a path towards circular economy. Bioresour. Technol. 2022, 343, 126151. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Li, H. Water-mediated catalytic hydrodeoxygenation of biomass. Fuel 2022, 310, 122242. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, X.; Liu, Q.; Zhang, Q.; Chen, L.; Ma, L. A review of conversion of lignocellulose biomass to liquid transport fuels by integrated refining strategies. Fuel Process. Technol. 2020, 208, 106485. [Google Scholar] [CrossRef]

- Perkins, G.; Batalha, N.; Kumar, A.; Bhaskar, T.; Konarova, M. Recent advances in liquefaction technologies for production of liquid hydrocarbon fuels from biomass and carbonaceous wastes. Renew. Sustain. Energy Rev. 2019, 115, 109400. [Google Scholar] [CrossRef]

- Kargbo, H.; Harris, J.S.; Phan, A.N. “Drop-in” fuel production from biomass: Critical review on techno-economic feasibility and sustainability. Renew. Sustain. Energy Rev. 2021, 135, 110168. [Google Scholar] [CrossRef]

- Aracil, C.; Haro, P.; Giuntoli, J.; Ollero, P. Proving the climate benefit in the production of biofuels from municipal solid waste refuse in Europe. J. Clean. Prod. 2017, 142, 2887–2900. [Google Scholar] [CrossRef]

- Barampouti, E.M.; Mai, S.; Malamis, D.; Moustakas, K.; Loizidou, M. Liquid biofuels from the organic fraction of municipal solid waste: A review. Renew. Sustain. Energy Rev. 2019, 110, 298–314. [Google Scholar] [CrossRef]

- Ribeiro, L.S.; Órfão, J.J.M.; Pereira, M.F.R. Enhanced direct production of sorbitol by cellulose ball-milling. Green Chem. 2015, 17, 2973–2980. [Google Scholar] [CrossRef]

- Barakat, A.; Mayer-Laigle, C.; Solhy, A.; Arancon, R.A.D.; Vries, H.; Luque, R. Mechanical pretreatments of lignocellulosic biomass: Towards facile and environmentally sound technologies for biofuels production. RSC Adv. 2014, 4, 48109–48127. [Google Scholar] [CrossRef]

- Puligundla, P.; Oh, S.; Mok, C. Microwave-Assisted Pretreatment Technologies for the Conversion of Lignocellulosic Biomass to Sugars and Ethanol: A Review. Carbon Lett. 2016, 17, 1–10. [Google Scholar] [CrossRef]

- Peng, H.; Li, H.; Luo, H.; Xu, J. A novel combined pretreatment of ball milling and microwave irradiation for enhancing enzymatic hydrolysis of microcrystalline cellulose. Bioresour. Technol. 2013, 130, 81–87. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Tong, L.; Ding, Y.; Zhang, W.; Liang, H. Synthesis of hierarchically porous carbon materials by zinc salts-assisted carbonization of biomass and organic solid wastes. Particuology 2024, 84, 45–52. [Google Scholar] [CrossRef]

- Gao, M.; Li, Z.; Zhao, B.; Yu, S.; Huang, L.; Wu, Q. Nickel-tungsten co-doped carbon-based catalyst for high selective production of ethylene glycol from cellulose hydrogenolysis. Fuel Process. Technol. 2023, 247, 107816. [Google Scholar] [CrossRef]

- Xiao, Z.; Li, J.; Wang, H.; Ge, Q.; Xing, C.; Huang, J.; Ji, J.; Mao, J. New fabrication of nonmodel supported catalysts for cellulose to low carbon chemicals with the assistance of mechanochemical abrading. Biomass Bioenergy 2023, 170, 106722. [Google Scholar] [CrossRef]

- Pavlenko, N.; Searle, S.; Christensen, A. The Cost of Supporting Alternative Jet Fuels in the European Union; The International Council of Clean Transportation: Washington, DC, USA, 2019; pp. 1–20. [Google Scholar]

- O’Malley, J.; Pavlenklo, N.; Searle, S. Estimating Sustainable Aviation Fuel Feedstock Availability to Meet Growing European Union Demand; The international Council of Clean Transportation: Washington DC, USA, 2021; pp. 1–19. [Google Scholar]

- Elhaj, H.F.A.; Lang, A. The Worldwide Production of Bio-Jet Fuels—The Current Developments Regarding Technologies and Feedstocks, and Innovative New R & D Developments; Technical Report SD-ARC-WBA; World Bioenergy Association (WBA): Stockholm, Sweden, 2014. [Google Scholar] [CrossRef]

- Schmidt, P.; Weindorf, W. Power-to-Liquids: Potentials and Perspectives for the Future Supply of Renewable Aviation Fuel; German Environment Agency: Neuglobsow, Germany, 2016. [Google Scholar]

- Doliente, S.S.; Narayan, A.; Tapia, J.F.D.; Samsatli, N.J.; Zhao, Y.; Samsatli, S. Bio-aviation Fuel: A Comprehensive Review and Analysis of the Supply Chain Components. Front. Energy Res. 2020, 8, 110. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).