Abstract

The rapid development of digitalization, the Internet of Things (IoT), and Industry 4.0 has led to the emergence of the digital twin concept. IoT is an important pillar of the digital twin. The digital twin serves as a crucial link, merging the physical and digital territories of Industry 4.0. Digital twins are beneficial to numerous industries, providing the capability to perform advanced analytics, create detailed simulations, and facilitate informed decision-making that IoT supports. This paper presents a review of the literature on digital twins, discussing its concepts, definitions, frameworks, application methods, and challenges. The review spans various domains, including manufacturing, energy, agriculture, maintenance, construction, transportation, and smart cities in Industry 4.0. The present study suggests that the terminology “3 dimensional (3D) digital twin” is a more fitting descriptor for digital twin technology assisted by IoT. The aforementioned statement serves as the central argument of the study. This article advocates for a shift in terminology, replacing “digital twin” with “3D digital twin” to more accurately depict the technology’s innate potential and capabilities in Industry 4.0. We aim to establish that “3D digital twin” offers a more precise and holistic representation of the technology. By doing so, we underline the digital twin’s analytical ability and capacity to offer an intuitive understanding of systems, which can significantly streamline decision-making processes using the digital twin.

1. Introduction: Origins of Digital Twin and Its Development

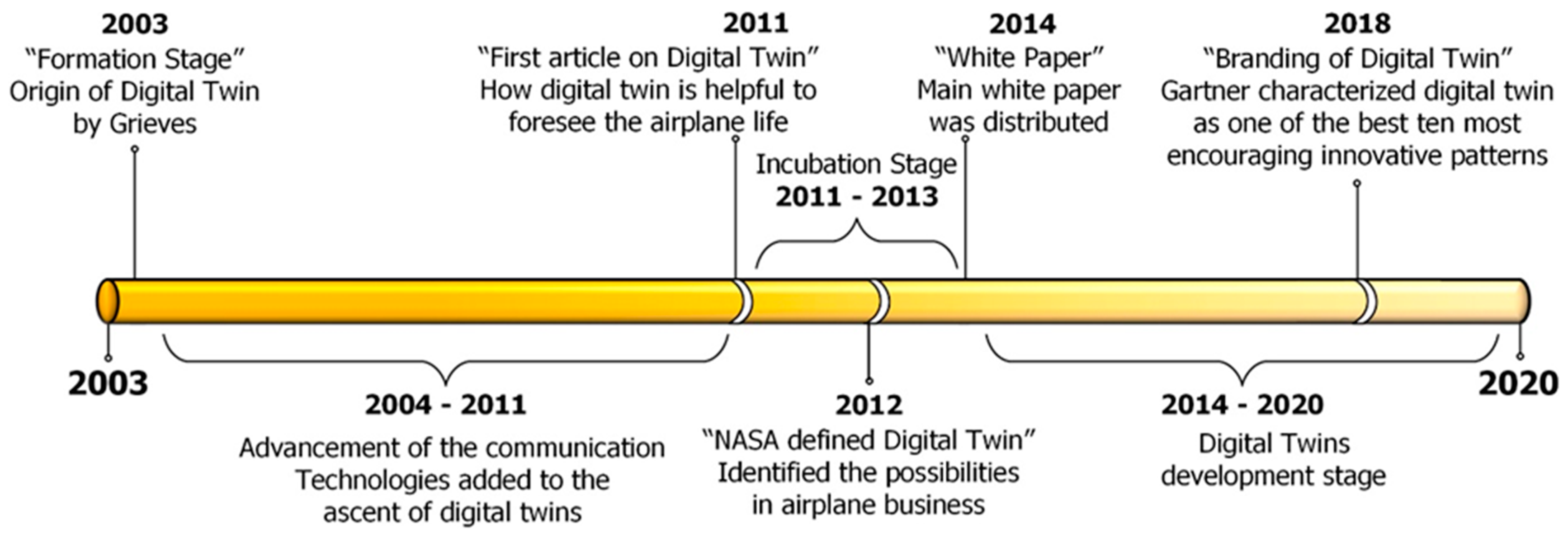

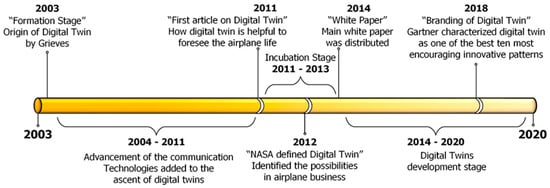

The history of the digital twin is relatively brief, primarily due to technological constraints during its early stages. The evolution of digital twins is divided into three different stages: (1) formation, (2) incubation, and (3) growth. This advancement and the significant key events are depicted in Figure 1.

Figure 1.

History of digital twin. Reused with permission from Bhatti et al. [1].

The first emergence of the digital twin concept can be traced back to Grieves in 2003. During this formative period, there were very few references to digital twin technology. However, until 2011, rapid advancements in communication sectors contributed to the rise of digital twins, as reported by Bhatti et al. [1]. In 2011, the first paper on digital twins was published, explaining by what method digital twins can assist in estimating aircraft operational lifespan. In 2012, NASA officially started the concept of digital twins and explored potential applications in the aerospace industry, as reported by Grieves [2]. Following this formal definition, a surge in academic research on digital twins was observed. The year 2014 saw the expansion of digital twins beyond their aviation-centric origins to a variety of practical applications.

Grieves [2] reported in 2018 that Gartner identified digital twins as among the top promising innovations affecting various industries in the future. As Yang et al. [3] stated, a digital twin is a unique simulation system based on professional knowledge and data in real time to create an accurate replica across various time and space scales. Glaessgen and Stargel [4] explained that digital twins technology is an advanced representation to describe the performance of a product. A number of interpretations of digital twin technology exist. Some experts believe that digital twin research should concentrate on simulation. Other professionals argue that it should comprise three components, which include physical, virtual, and connecting components as reported by Gabor, et al. [5].

In recent times, the concept of digital twins has attracted considerable attention from scholars and experts across several scientific and engineering fields. A particularly promising prospective use of the digital twin concept involves the ability to perform real-time optimization of control and operations through data-driven simulations [6]. The capabilities of optimization in real-time refer to the ability of digital twins to continuously analyze incoming data and make immediate adjustments to improve performance or efficiency. This concept is often discussed in the academic literature on digital twins, which explores the implementation of real-time optimization algorithms within digital twin frameworks for agriculture [7], predictive simulation [6], manufacturing systems [8], oil and gas industry [9], and petrochemical industry [10].

Regarding the use of digital twins, the term ‘local’ digital twin represents a specific, individual object, system, or process, which typically focuses on a particular asset or entity and simulates its behavior, characteristics, and interactions within its immediate environment. Local digital twins are often used for detailed monitoring, diagnostics, and predictive maintenance of specific assets or components. While local digital twins focus on individual entities or assets, ‘global’ digital twins provide a comprehensive view of larger-scale systems or environments by integrating data from multiple local digital twins. Both concepts are essential in leveraging digital twin technology for monitoring, analysis, and optimization across different levels of complexity [11,12].

Numerous studies have reviewed the digital twin issues in the last three years with a wide domain span. Semeraro et al. [13] tried to answer the digital twins paradigm’s basic questions (4W-1H), including scholarly studies, methodologies, and technological aspects across various application fields. Sjarov et al. [14] concentrated on identifying precise definitions of the phrase “Digital Twin” and establishing models that describe the idea of Digital Twin. By expanding the theoretical framework, they established a platform for the future modeling of augmented Digital Twins. Jones et al. [15] reviewed and analyzed digital twin publications from the past decade and provided a characterization of the digital twin by identifying the concept, terminology, and related processes. Like Jones et al. [15], Liu et al. [16] conducted a comprehensive and detailed study of multiple digital twin publications, analyzing them from numerous perspectives, including concepts, technology, and industrial applications. In a specific industry, Opoku et al. [17] reviewed and analyzed comprehensively the digital twin concept, technologies, and applications in the construction field. In a similar field, Madubuike, et al. [18] conducted a comprehensive review of the progress and application of digital twin technology in the construction sector and compared its utilization with other industries. Botín-Sanabria et al. [19] reviewed digital twin technology in-depth, examining its implementation issues and limitations across several domains and applications in engineering and other fields. Shahat, et al. [20] examined the existing and future possibilities and difficulties of digital twin cities and provided guidance for further research on the concept of city digital twin. Errandonea et al. [21] reviewed digital twins in maintenance applications and highlighted future research pathways and open issues. Lo et al. [22] conducted a study to examine the current status of digital twin research, with a specific focus on product design and development. They achieved this by describing typical industrial scenarios. The discussion also covered the challenges and potential applications of digital twins, with the aim of inspiring future research. Melesse et al. [23] examined the utilization of Digital Twins in the manufacturing industry. The authors offered valuable perspectives to many industrial sectors, practitioners, researchers, and specialists in the field about the distinct functions of Digital Twin models and the difficulties encountered in the domains of production, predictive maintenance, and after-sale services. In their study, Soori et al. [24] reviewed the utilization of digital twin technology in smart manufacturing systems. They specifically focused on examining the benefits and obstacles associated with modifying part production through the implementation of digital twin technology. Similar to Soori et al. [24], Psarommatis and May [25] also examined the concept of digital twins in the manufacturing industry. They thoroughly analyzed the existing literature on the use of digital twins in zero-defect manufacturing. They proposed a standardised design process to assist researchers and practitioners in developing digital twins, regardless of the specific field.

However, few papers still address the more fundamental concept of digital twins in various applications. This study contributes a review of the literature on digital twins, discussing its concepts, definitions, frameworks, application methods, and challenges. Moreover, the article could be of use in collaborative robotics. Digital twins play a crucial role in advancing collaborative robotics by providing simulation, monitoring, predictive capabilities, adaptive behavior, and training support. They enable stakeholders to design, deploy, and optimize collaborative workflows that enhance productivity, safety, and adaptability in various industrial and service sectors.

The outline structure of this study consists of seven sections, as follows: the basics of digital twin, which explore the concepts, definitions, and frameworks literature review methodology is described in Section 2; digital twin concept, definition, and frameworks are elaborated in section Section 3, the application of digital twin in Industry 4.0 in Section 4, the challenges and solution of digital twin technology in Section 5. The limitation of the term “Digital Twin” in Section 6 is the importance and significance of 3D digital twins in Section 7. The last section is the conclusion and future research.

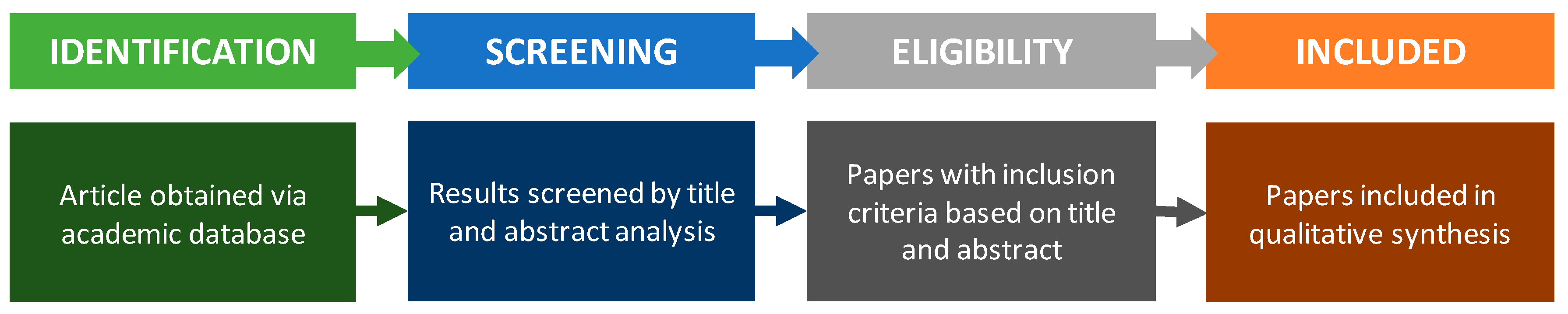

2. Methodology

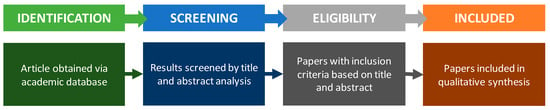

This literature review follows a systematic approach to comprehensively examine the existing literature on digital twins across diverse disciplines. The methodology encompasses several key steps to ensure rigor and transparency in the review process, as shown in Figure 2. First, an extensive literature identification was conducted using Scopus academic databases. This step was conducted to map the landscape of the research. Initially, the search was performed using relevant keywords such as “digital twin”, “digital twin technology”, and “digital twin applications” in the Scopus database. These keywords produced tens of thousands of articles with wide-span fields of discussion. Publications within a specified timeframe were considered to capture the most recent developments in the field, mostly the five last year’s publications. Duplicate and irrelevant articles were excluded from the review. Then, the article was screened using digital twins’ field applications, such as manufacturing, energy, agriculture, maintenance, construction, transportation, and smart cities. All of these fields involve intricate physical systems that can considerably benefit from digital representation and analysis. The authors selected this field as a representation of an application that has many contributions to advancing digitalization. Moreover, these fields all deal with complex physical systems that can benefit greatly from digital representation and analysis.

Figure 2.

Systematic review methodology.

Following the literature search, articles were screened by reviewing their titles, abstracts, and brief reviews to find potentially relevant studies. Subsequently, the text was comprehensively evaluated to determine suitability according to predetermined criteria for inclusion and exclusion. Review articles and conference papers were considered if they offered valuable information on the concept, definition, applications, frameworks, techniques, problems, limitations, or breakthroughs of digital twin technology in different fields.

Data and information were compiled and synthesized systematically, with relevant information from selected articles organized according to predetermined criteria into the paper’s outline. Content analysis was employed to identify recurring themes, trends, and patterns across the literature. The quality of selected articles was also assessed based on criteria such as rigor of concepts, definitions, frameworks, applications, challenges, and limitations to the review objectives. Finally, the review process was documented in detail to facilitate critical issues. This systematic methodology aims to provide a comprehensive review of the current knowledge of digital twin technology, its concepts, definitions, frameworks, applications, challenges, limitations, and future research.

3. Digital Twin: Concepts, Definitions, and Frameworks

Digital Twin technology, supporting digital transformation and decision-making across various industries, has evolved significantly over the past 20 years, leading to a multitude of definitions that risk diluting the concept and causing ineffective implementations. VanDerHorn and Mahadevan [26] review 46 Digital Twin definitions from the past decade, proposing a generalized definition encompassing the diverse range of applications and offering a detailed characterization to differentiate Digital Twins from other digital technologies.

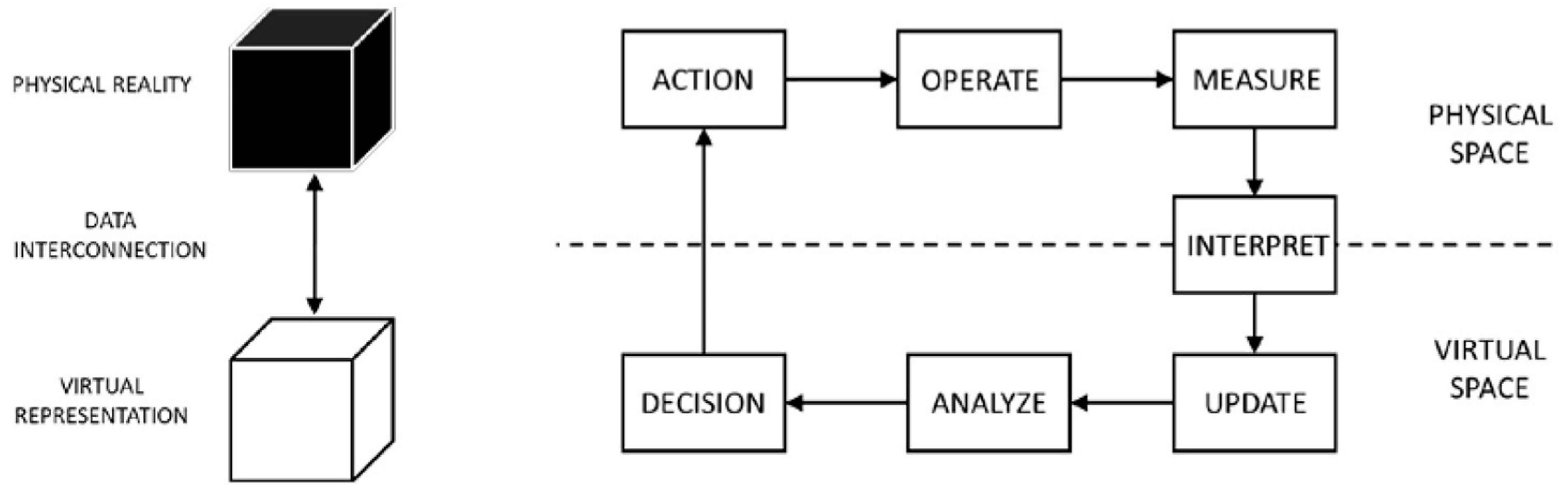

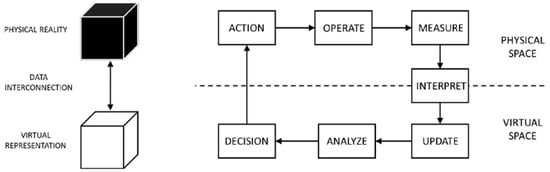

Numerous definitions in the literature tend to blend a definition with distinct characterizations of Digital Twins that are specific to the use cases they describe. A significant portion of the confusion surrounding the Digital Twin concept seems to stem from the qualifiers placed on certain characterizations to determine what is considered a Digital Twin and what is not. The study by VanDerHorn and Mahadevan [26] mentioned above identified Digital Twin by three main elements: (1) A physical existence, (2) a digital representation, and (3) connections that facilitate information exchange between the physical existence and digital representation, as depicted in Figure 3.

Figure 3.

Components and high-level processes of Digital Twin. Reused with permission from VanDerHorn and Mahadevan [26].

3.1. Digital Twin Reference Models

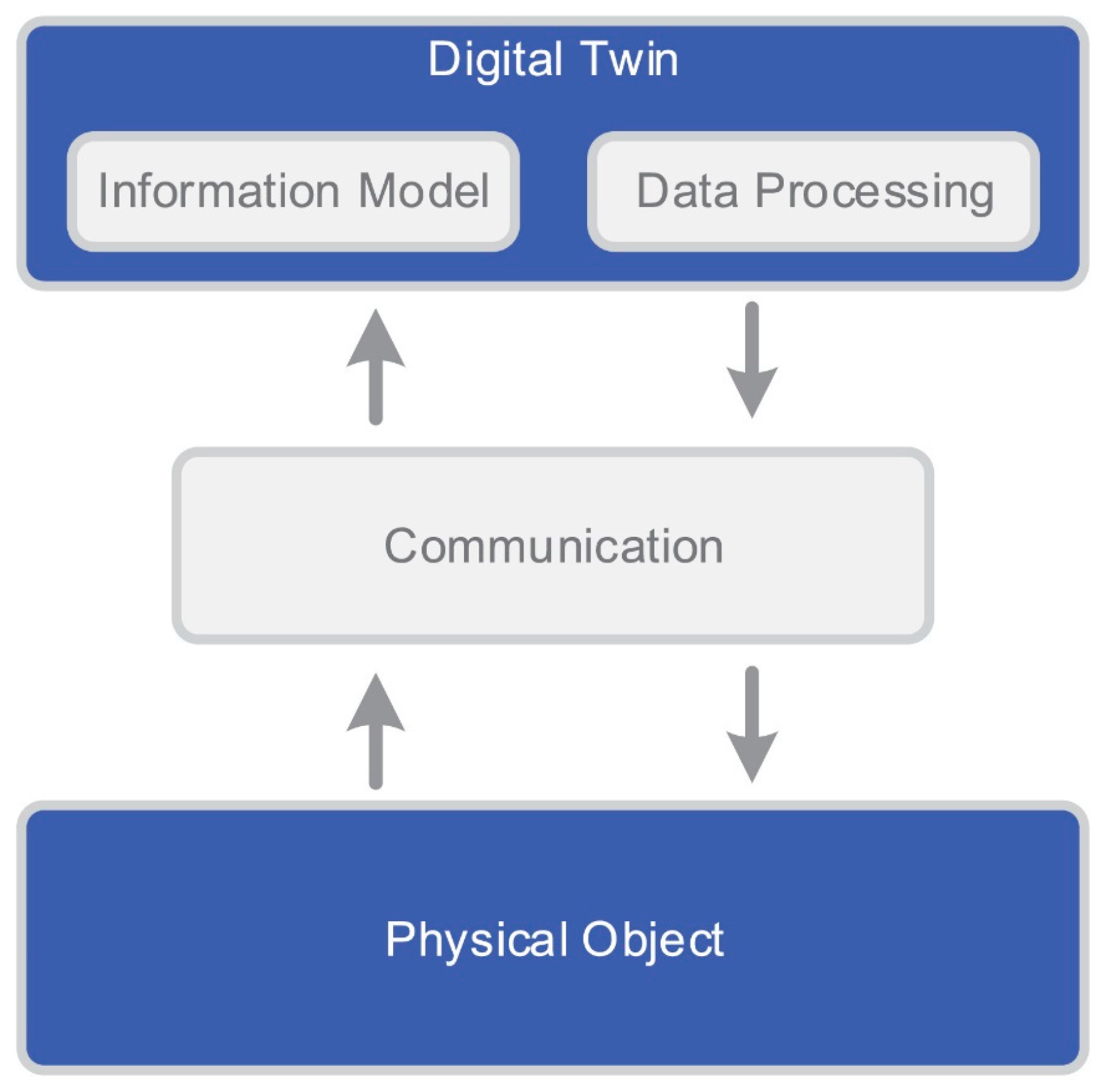

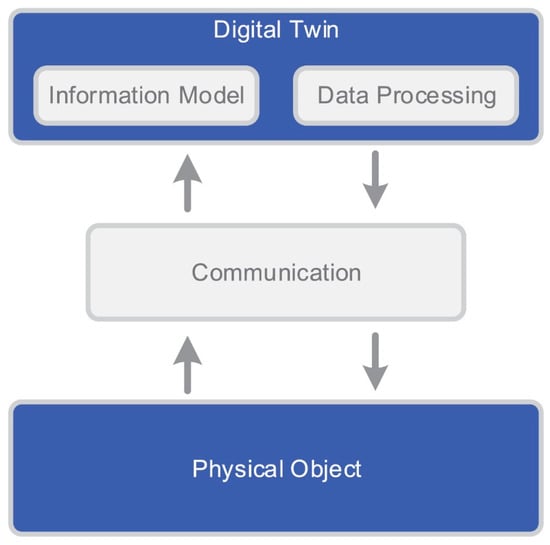

Lu et al. [27] examine the recent progress of Digital Twin technologies within manufacturing systems and processes from an Industry 4.0 point of view. It offers a detailed summary of Digital Twin definitions and state-of-the-art developments while organizing existing technologies under a reference model to systematize the Digital Twin development methodology. The study emphasizes representative applications aligned with the proposed reference model and concludes by identifying key research challenges for the future development of Digital Twins in smart manufacturing. Figure 4 displays a Digital Twin reference model. The creation of a Digital Twin hinges on three vital elements. First, we need an information model that takes the complexities of a physical object and simplifies it. Next, we need a way for the Digital Twin and the real-world object to ‘talk’ to each other, swapping data back and forth. Lastly, we have a data processing unit that takes data from numerous sources, reads it, and uses this information to create a digital representation of the physical object. These three components must collaborate to successfully construct a Digital Twin.

Figure 4.

A reference model of Digital Twin. Reused with permission from Lu et al. [27].

Aheleroff et al. [28] address the challenges in developing a comprehensive Digital Twin reference architecture that balances scope and scale, emphasizing the need for appropriate Industry 4.0 technologies and business models. The study highlights the lack of empirical research on the relationship between Digital Twin technology and mass individualization. A new Digital Twin reference architecture is proposed and applied to an industrial case study while also introducing the concept of Digital Twin as a Service (DTaaS) for digital transformation in unique wetlands. The results demonstrate a significant relationship between DTaaS capabilities and mass individualization, emphasizing the potential benefits of smart maintenance and predictive functionalities.

Aheleroff et al. [29] discuss the potential of using Digital Twin capabilities for mass personalization in the context of the Fourth Industrial Revolution (Industry 4.0). The study provides insights into new industrial applications for Digital Twin integration levels, contributing to a better understanding of the potential of Digital Twin in meeting the high customer demands and market competition of today’s business sectors. Erkoyuncu et al. [30] introduce a novel design framework for Digital Twin. Addressing the limitations of connecting existing brownfield systems and their data, the framework has been successfully tested on a helicopter gearbox demonstrator and a mobile robotic system, showcasing Digital Twin’s adaptiveness without the need for modifications to the data architecture.

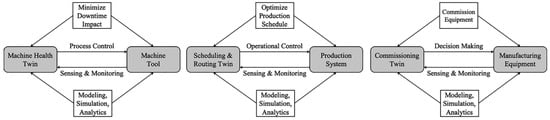

3.2. Scope and Requirements of Digital Twin in Manufacturing

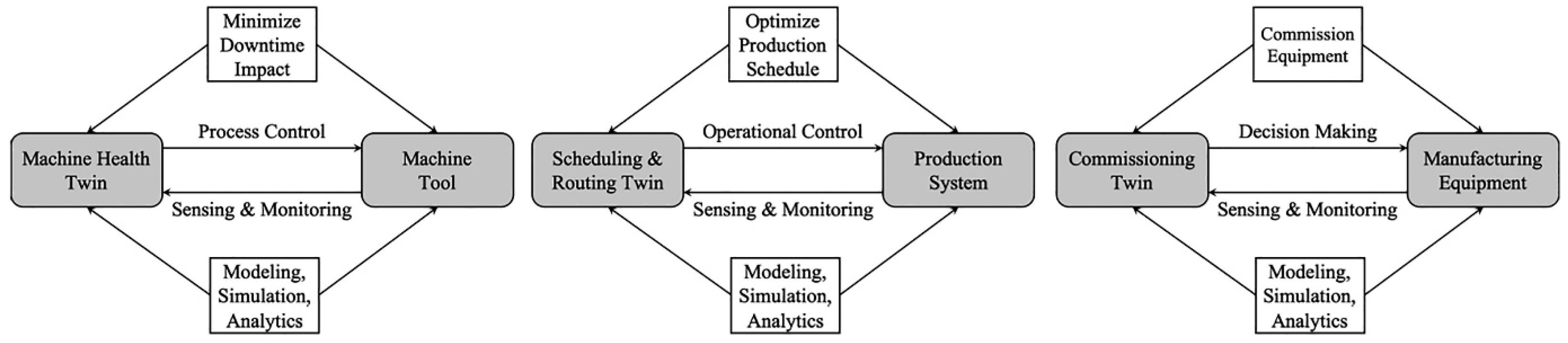

The digital twin concept holds significant potential for enabling smart manufacturing, but confusion persists regarding its implementation, particularly among small-to-medium-sized enterprises. Shao and Helu [31] consolidate various perspectives on digital twins to identify key characteristics for developing use case-specific digital twins, offering example applications and emphasizing the need for a standardized framework like ISO 23247. It enables context-reliant implementations, fostering composability and reusability of digital twin components to optimize manufacturing processes. Figure 5 illustrates three potential applications of digital twins at various manufacturing levels (e.g., machine, cell, line, facility, or supply chain):

Figure 5.

Three instances of digital twin utilization in manufacturing processes. Reused with permission from Shao and Helu [31].

Kritzinger et al. [32] provide a literature review of Digital Twin in manufacturing, aiming to establish a common understanding of the term. The review categorizes publications according to their level of Digital Twin integration, including Digital Model, Digital Shadow, and Digital Twin. It was found that in the highest development stage literature, Digital Twin is not as frequent as Digital Model and Digital Shadow.

3.3. Integrated Frameworks for Digital Twin

A multi-dimensional conceptual modeling approach is needed as digital twin technology expands into various engineering domains. Wu et al. [33] introduce a conceptual modeling method according to a 5D framework of Digital Twin, capturing complicated relationships between Digital Twin objects and their characteristics. This method was applied to model the digital twin of an intelligent vehicle at the conceptual level. Lee et al. [34] present an integrated digital twin and blockchain framework to improve information sharing among fragmented stakeholders in construction projects.

D’Amico et al. [35] propose a digital twin framework for the purpose of degradation assessment of complex engineering systems (CES) caused by wear, corrosion, and fracture. The digital twin continuously monitors the CES and updates a virtual model to make real-time predictions about future functionality, providing data-driven approaches to predict degradation evolution over time. The study introduces the conceptual framework and discusses its potential applications for the management of CES.

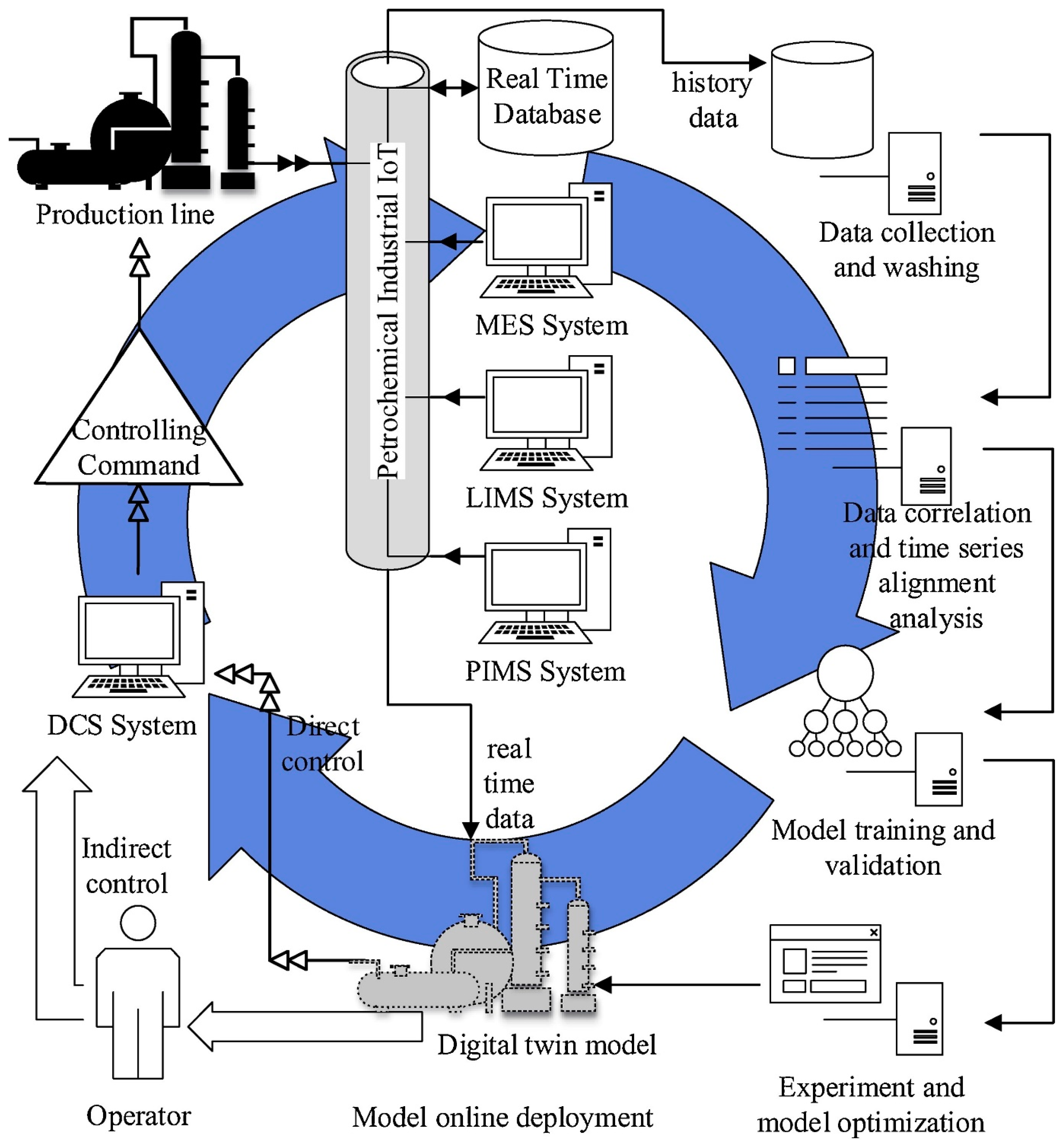

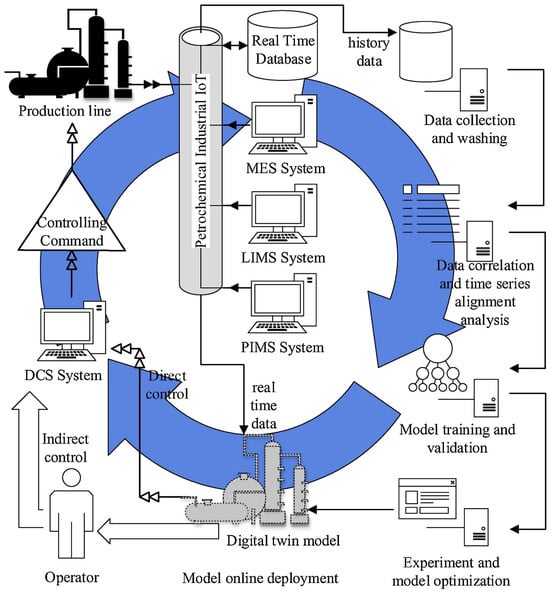

Leveraging digital twins, IoT, data mining, and machine learning, Min et al. [10] present a framework for intelligent manufacturing in the petrochemical industry, emphasizing agile and smart production controls. The proposed method integrates AI tools with real-time big data from industries for training and optimizes Digital Twin models, enabling dynamic adaptation to changing environments and enhancing economic benefits. Addressing industry-specific challenges, such as high data dimensions, time lags, and immediacy demands, the study demonstrates the effectiveness of the proposed method through a successful case study at a petrochemical factory.

The digital twin practice loop, designed for the petrochemical production line, involves a continuous cycle of control and optimization, as depicted in Figure 6. While the first iteration of the loop requires significant manual effort for preparation and business understanding, subsequent iterations are expected to be executed automatically by computers connecting the physical IoT and cyber-network. The repetition frequency depends on both business requirements and computing performance.

Figure 6.

Digital twin practice loop using machine learning techniques. Reused with permission from Min et al. [10].

The Industrial Internet of Things (IIoT) has emerged as a vital component of Industry 4.0, adding value to traditional devices through the integration of digital twin technology. Jiang et al. [36] examine digital twin concepts and influential framework models, concluding that successful digital twin implementation relies on a data, models, and services (DMS) framework. By applying this framework to both device acquisition and remote system layers within the IIoT, devices can be logically organized through the construction of partial digital twins with varying functions. This “device-digital twin-application” approach has been successfully demonstrated in the IoT of Gas-insulated Switchgear (GIS) systems, offering a unified architecture that supports internal digital twin expansion and multi-digital twin connections for improved mapping of complex systems. Furthermore, this method isolates direct business access to equipment, strengthens local-cloud collaboration, and fosters virtual-real integration and synchronization. The study also offers insights into the development of a collaborative framework between edge and cloud computing.

In short, the concept of Digital Twin has evolved over the years, leading to various definitions and frameworks that aim to capture its diverse applications. However, the multitude of definitions has caused confusion and ineffective implementations. Researchers have proposed a generalized definition that includes three main elements: a physical existence, a digital representation, and connections facilitating information exchange between the physical and digital counterparts. Reference models highlight the essential components required for constructing a Digital Twin, including an information model, a communication mechanism, and a data processing module. The development of comprehensive Digital Twin reference architectures is also crucial for effectively leveraging Industry 4.0 technologies and achieving mass individualization. The potential of Digital Twins for meeting the demands of today’s business sectors and enabling mass personalization under Industry 4.0 has been explored by several researchers. Furthermore, novel frameworks utilize ontologies for co-evolution with CES, showcasing the adaptiveness of Digital Twins without the need for extensive modifications. Overall, Digital Twin technology holds significant promise for supporting digital transformation and decision-making across industries, but further research and standardization efforts are needed to fully unlock its potential and ensure effective implementation.

3.4. Evaluation of Digital Twins Performance

Evaluating performance is crucial in enhancing or overseeing any process or system within a business. Evaluating the performance of digital twins helps determine how effectively they are fulfilling their intended objectives. Similar to the common business, digital twins require an evaluation approach to identify the maturity of the process. Moreover, performance evaluation ensures quality and reliability. By assessing its accuracy, robustness, and consistency, stakeholders can identify any discrepancies or shortcomings that may compromise its usefulness. It allows stakeholders to assess whether the digital twin is accurately representing the physical system, providing valuable insights and facilitating decision-making. Hence, the approach evaluation plays a significant role in guiding practitioners, experts, or researchers to improve more effective processes in digital twins.

Generally, the phrase “maturity” denotes a “condition of being complete, perfect, or ready” and suggests progression in the growth of a system [37]. As systems mature, they gradually improve their capacities to reach a desired future condition. During the evaluation process, the level of maturity can be assessed either using qualitative or quantitative methods, and it can be measured in a discrete or continuous manner [38]. The initial concepts of digital twins evaluation were outlined in [39], which presented a four-step implementation approach for digital technology (external inspiration, in-house impact analysis, shortlisting and assessment, and prototyping and implementation). Additional literature evaluations on Industry 4.0 maturity models are available in references [40,41]. However, the design and implementation of digital twins vary widely due to the numerous possibilities they offer. Therefore, the evaluation of digital twins is also wide-ranging in implementation.

Uhlenkamp et al. [42] organized and classified the maturity model, which formed the central part. The model’s validity was confirmed by its application to five use cases in production and logistics, representing various domains. The maturity model evaluates digital twins based on seven categories (context, data, computing capabilities, model, integration, control, human–machine interface) using a ranking system that includes 31 features. This marks the initial phase in conducting a methodical assessment, enhancing the organized advancement of such applications. The article presented a valuable framework for evaluating digital twins. However, the evaluation method’s scalability to highly complex digital twins with numerous functionalities needs to be addressed.

Psarommatis and May [43] introduced a systematic approach for evaluating the performance and flexibility of digital twins by presenting a step-by-step process for quantitatively monitoring the performance of digital twins using four key performance indicators (KPIs). In addition, the study suggested a novel KPI called DTflex to assess the level of flexibility exhibited by digital twins. The performance of DTflex was assessed as a KPI to showcase its use as a straightforward tool for designers and practitioners to efficiently compare various digital twin approaches.

4. Applications of Digital Twin in Industry 4.0

The profound influence of Digital Twin technology has been increasingly recognized across various sectors in Industry 4.0, reshaping the landscape of traditional operations and opening doors to significant improvements in efficiency, productivity, and innovation. This section delves into diverse applications of Digital Twins, exploring their implementation and potential impact in the manufacturing realm—specifically in cutting tools, 3D printing, additive manufacturing, dynamic scheduling, and data management—as well as in energy, agriculture, maintenance, construction, transportation, and the creation of smart cities. Through a detailed examination of these applications, we aim to provide a comprehensive understanding of the transformative role Digital Twin technology plays in the Fourth Industrial Revolution.

4.1. Manufacturing

4.1.1. Cutting Tool

The advancement of digital twin technology continues to revolutionize various aspects of manufacturing, with cutting tools being one notable example. By creating virtual counterparts for these tools, businesses can capture precise data throughout the production lifecycle, allowing for insightful analysis, optimized process planning, and continuous improvement. This is largely facilitated through standardizations like ISO 13399. Digital twin-driven data frameworks provide unique insights into tool wear, which is crucial for maintaining the efficiency and quality of manufacturing processes.

Botkina et al. [44] investigate the digital twin of a cutting tool, examining its data format, structure, information flows, data management, and potential applications for productivity analysis. Leveraging the international ISO 13399 standard and the event-driven line information system architecture (LISA) with IoT functionality, data is accurately collected throughout the production lifecycle. The digital twin is then stored, refined, and incorporated into process planning to achieve optimized machining solutions, demonstrating the value of digital twins in contemporary manufacturing processes.

Xie et al. [45] present a digital twin-driven data flow framework for cutting tools aimed at enhancing manufacturing digitalization and enabling continuous improvement of processes and tools throughout their life cycle. The framework offers two service modes for manufacturers to cater to customer needs and proposes a virtual cutting tool test platform that combines physical tool wear data with virtual tool wear data to provide valuable insights for the future of intelligent manufacturing. Additionally, the study discusses development prospects and challenges related to data analysis, fusion, mining, and service within this context.

Overall, digital twins of cutting tools showcase the transformative potential of this technology in manufacturing. By integrating real-time data from the physical world with a virtual model, it is possible to optimize machining solutions, enhance manufacturing digitalization, and provide valuable insights for future intelligent manufacturing. While development prospects and challenges remain, the strategic implementation of digital twin technology in cutting tools promises significant advancements in modern manufacturing operations.

4.1.2. 3D Printing and Additive Manufacturing

Digital twin technology has garnered significant attention in various sectors, including manufacturing, due to its potential to enhance process efficiency and product quality. Particularly in the fields of 3D printing and additive manufacturing, this technology offers promising solutions to persistent challenges such as material limitations, structural complexity, and high defect rates. The application of digital twins in these areas aims to reduce the traditionally time-consuming and costly trial-and-error processes and enable faster and more cost-effective part qualification. The following research summaries delve into the specific applications of digital twin technology in 3D printing and additive manufacturing, highlighting the latest developments and key findings in this evolving domain.

The 3D printing has the potential to transform manufacturing in various industries, but its current market value remains small due to limited material options, structural diversity, and susceptibility to defects. The existing trial-and-error qualification process is costly and time-consuming, restricting 3D printing to niche markets. A paper by Mukherjee and DebRoy [46] proposes a digital twin of the printing machine to lower the number of trial-and-error checks and expedite part qualification, making 3D-printed components more cost-effective. A comprehensive digital twin, incorporating mechanistic, control, and 3D printing statistical models, as well as machine learning and big data, can minimize defects and decrease the time between design and production.

The geometry, microstructure, and defects of additively manufactured components significantly affect their properties and serviceability. However, the selection of necessary process variables could not be based on scientific theories, and optimization is currently done through trial and error. The concept of a digital twin of additive manufacturing has been introduced to overcome this challenge. Knapp et al. [47] present a computationally efficient first-generation digital twin of laser-based directed energy deposition additive manufacturing using a transient, three-dimensional model that calculates temperature and velocity fields, cooling rates, solidification parameters, and deposit geometry. The measured profiles of stainless steel 316L and Alloy 800H deposits and metallurgical parameters were employed for verification.

Overall, the implementation of digital twins in 3D printing and additive manufacturing presents a significant opportunity to overcome current limitations. By reducing trial-and-error tests, these digital replicas can expedite part qualification, making the process more cost-effective and leading to wider adoption of 3D printing across various industries. Furthermore, digital twins can predict the complex spatial as well as temporal differences of metallurgical parameters affecting the components, contributing to more precise and efficient production. The higher prediction accuracy highlights the transformative potential of digital twin technology in these areas.

4.1.3. Dynamic Scheduling

In the dynamic and complex landscape of modern manufacturing, the integration of digital twin technology has proven to be a key enabler in streamlining job-shop scheduling and enhancing overall manufacturing processes. This section examines how digital twins, through their real-time simulation and analysis capabilities, contribute to the continuous digital monitoring and functional improvement of interconnected systems in manufacturing.

Zhang et al. [48] address common bottlenecks in dynamic scheduling for job-shops. Digital twin facilitates convergence between the physical job-shop and its virtual models, enhancing dynamic scheduling by fusing real and simulated data for machine availability prediction and real-time disturbance detection through comparison with its digital counterpart.

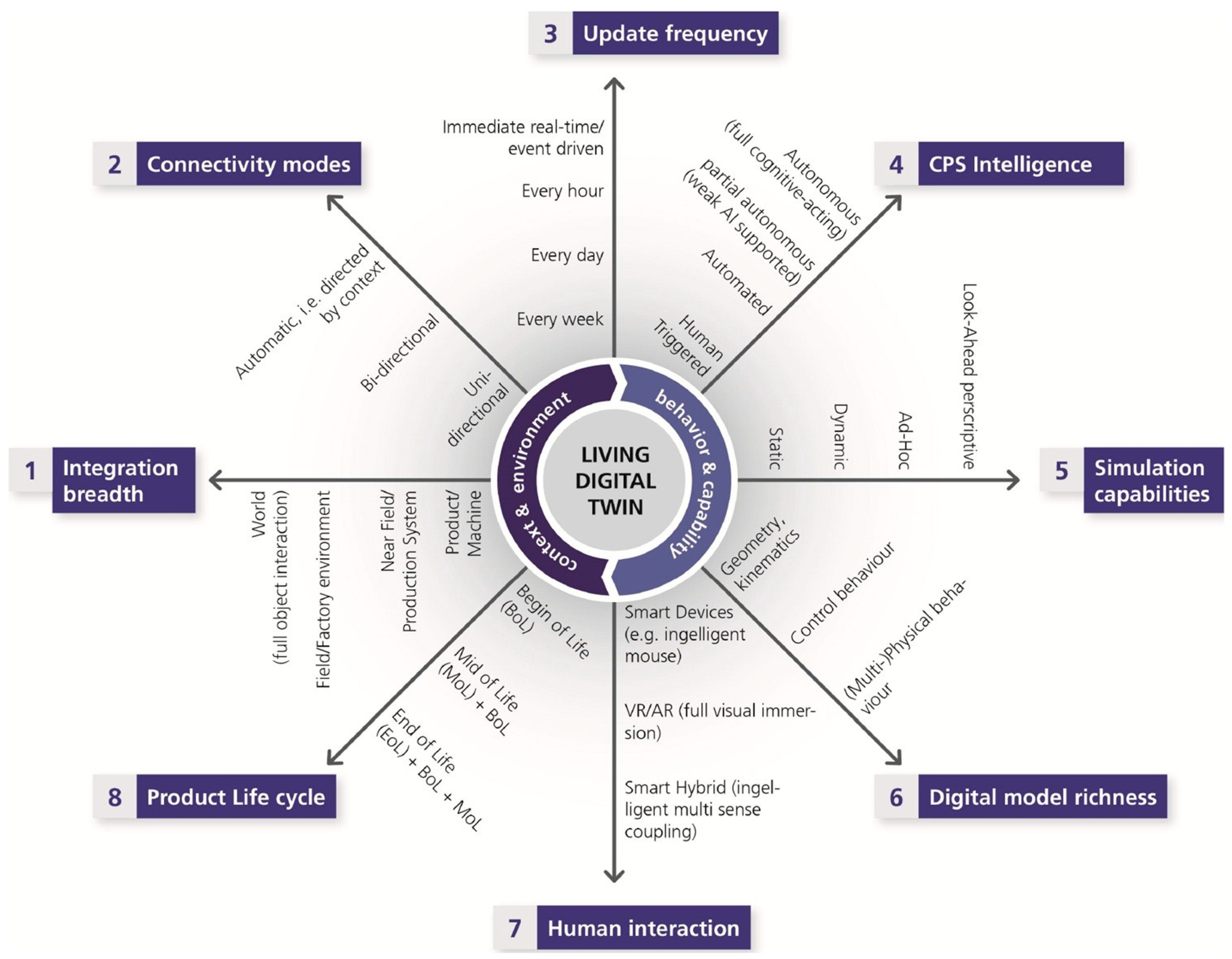

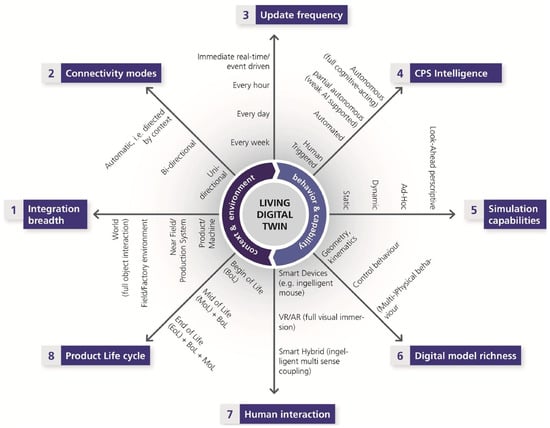

Industrie 4.0 is among many global endeavors that recognize the significance of industrial manufacturing for economic and societal development. Addressing this transformation entails grappling with socio-economic and political questions, including the future of labor, as well as tackling crucial technical and technological challenges that must be overcome to realize the full potential of this evolving landscape, as reported by Rosen et al. [49]. Digital Twins have emerged as innovative solutions for continuous digital monitoring, as reported by Stark et al. [50] in Figure 7. Based on this analysis, the paper identifies and presents design elements crucial for developing effective Digital Twins.

Figure 7.

The Digital Twin 8-D model. Reused with permission from Stark et al. [50].

In the Industry 4.0 era, Digital Twins serve as promising enablers for real-time replication and analysis of production systems. Cimino et al. [51] examine the current state of manufacturing and existing digital twin environments through a literature review, identifying gaps between implemented digital twins and their descriptions in the literature. Key areas of focus include the degree of digital twin integration with physical system control, particularly with Manufacturing Execution Systems (MES) in the Automation Pyramid, and the services offered compared to those in reference.

Overall, the increasing adoption and integration of Digital Twins in the manufacturing sector marks a significant stride in the evolution of smart manufacturing. While gaps still exist in digital twin implementation and the seamless fusion with Manufacturing Execution Systems, the studies reviewed offer promising solutions that navigate these challenges. Future research will undoubtedly continue to refine these approaches, further bridging the divide between theoretical concepts and practical implementations, thereby leading to a more holistic and efficient manufacturing environment.

4.1.4. Data Management in Industrial Operations

The effective implementation and maintenance of Digital Twins in industrial operations presents a significant challenge due to their high complexity and data demands. Digital twins are virtual representations of physical systems, consistently synchronized with real-time data, providing critical insights for informed decision-making. This section explores multiple facets of this issue, including the creation of high-fidelity digital twin models for specific tools, the construction of a digital twin within a research environment, the role of digital twins in various industrial domains, and the development of efficient data construction methods to support digital twin systems.

Wei et al. [52] address the challenges in implementing and maintaining a high-fidelity Digital Twin model for Computer Numerical Control Machine Tools (CNCMT). The authors propose a model consistency retention method, including a framework for both digital and physical spaces and principles for data management and performance attenuation updates. The study examines the implementation method for consistency retention, focusing on wear and damage updates separately. A case study involving a rolling guide-rail test bench digital twin model demonstrates the proposed method’s implementation flow and validates its operability and effectiveness, emphasizing the approach’s potential to improve CNCMT digital twin modeling and maintenance.

Semeraro et al. [13] aim to provide an overview of digital twins’ components, features, and challenges and their use in different application domains. The paper covers key questions related to the digital twin, such as where and when to use it, why it is essential, and how to design and implement it. The authors conducted a systematic literature review of various scientific research, tools, and technicalities in different application domains to address the challenges of implementing digital twins.

Melesse et al. [23] provide a systematic literature review on the role of Digital Twins in industrial operations, particularly in production, predictive maintenance, and after-sales services, and identify challenges in applying Digital Twin models to extend their role in these domains. The review highlights the need for a systematic approach to applying Digital Twin models and provides insights for practitioners, researchers, and experts in the field.

Kong et al. [53] propose a data construction method to support the efficient and accurate operation of Digital Twin Systems (DTS) manufacturing workshop, which relies heavily on manufacturing data. The proposed method is designed based on the functional requirements, taking into account the characteristics of manufacturing data, such as its coupling and large-amount nature. The framework of data construction consists of a data representation module, a data organization module, and a data management module. The effectiveness of the proposed method is demonstrated by applying it to the cutting tool wear prediction case study. This study provides a valuable reference for developing efficient data support for the applications of digital twin systems.

Overall, the studies discussed highlight the potential of Digital Twin technology in transforming industrial operations, with a focus on production, predictive maintenance, and after-sales services. Crucially, they underscore the importance of maintaining model consistency, efficient data construction, and realistic digital twin construction for effective application. With these advances, digital twin technology stands poised to enhance decision-making processes, improve tool maintenance, and streamline industrial operations, reinforcing the need for continued research and practical application development in this area.

4.2. Energy and Agriculture

Digital Twin technology, an innovation that pairs the virtual and physical world, is increasingly transforming the energy and agriculture sectors. The technology’s capacity to model complex systems, detect anomalies, predict risks, and optimize operational processes presents significant potential to address industry challenges and improve efficiencies. From function-structure-behavior-control-intelligence-performance frameworks for smart manufacturing systems to predictive maintenance of CNC machine tools, digital twins are reshaping existing paradigms. In the energy sector, digital twins aid in predicting risk probabilities in oil pipeline systems and optimizing fuel cell operations. Simultaneously, in the agriculture sector, they offer valuable insights into farming operations and foster an understanding of the value digital twins could bring to this industry.

Leng et al. [54] explore the integration of digital twin technologies in smart manufacturing system (SMS) design, addressing the challenges of concurrent design and unified modeling for complex, multi-field systems. Priyanka et al. [55] propose a Digital Twin-based framework that leverages machine learning and prognostics algorithms to analyze and predict risk probability rates in oil pipeline systems. The framework focuses on detecting failure precursors through pressure data analysis and remaining useful life (RUL) evaluation. It employs Dirichlet Process Clustering and Canopy clustering to identify abnormal pressure changes, while manifold learning methods extract features from multiple oil substation data. Kernel-based SVM algorithms evaluate the best feature probability rates, enabling on-time control actions across the entire oil pipeline system through efficient wireless data communication. The proposed Virtual Intelligent Integrated Automated Control System predicts risk rates in the oil industry by integrating transmission lines through enhanced wireless information networks in remote locations.

Wang et al. [56] present a surrogate modeling method that combines a state-of-the-art three-dimensional proton exchange membrane fuel cell (PEMFC) physical model with a data-driven model to develop multi-physics-resolved digital twins. The surrogate model demonstrates prediction accuracy comparable to the comprehensive 3D physical model while significantly reducing computational cost and time. Test-set relative root mean square errors (rRMSEs) of multi-physics fields range from 3.88% to 24.80%, effectively capturing the multi-physics field distribution characteristics. Two model-based designs, the PEMFC healthy operation envelope and state map, are demonstrated using the developed digital twin framework. This research showcases the potential of integrating data-driven approaches with comprehensive physical models to create digital twins for complex systems like PEMFCs.

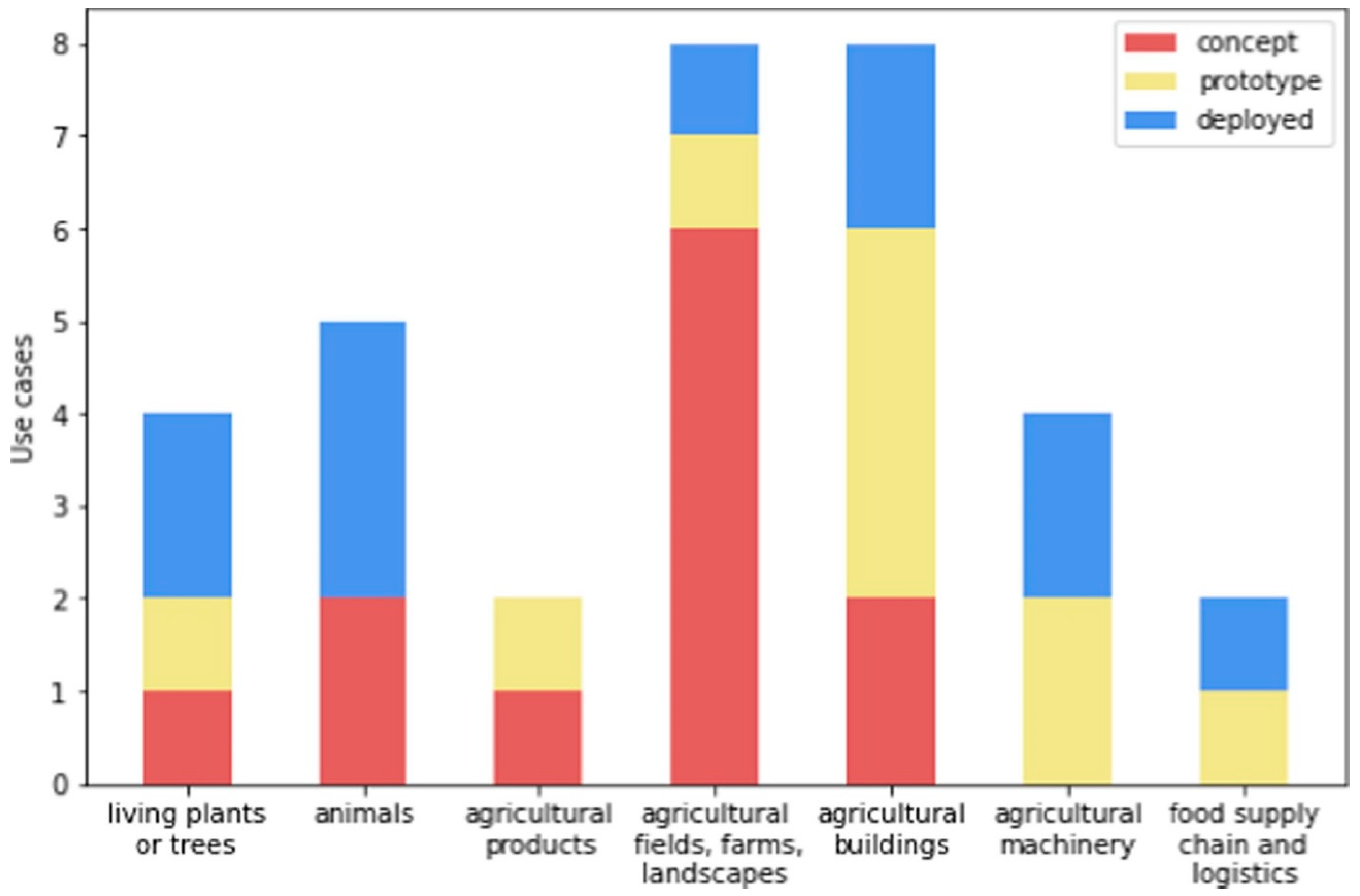

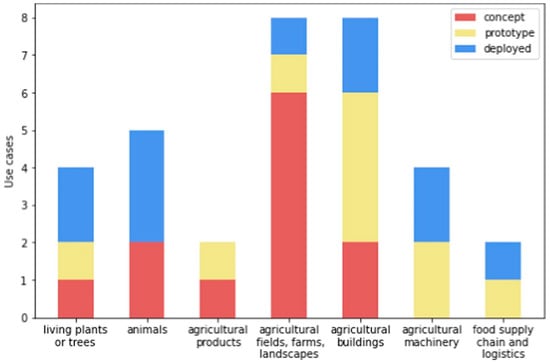

Pylianidis et al. [7] investigate digital twins’ adoption and potential benefits in the agriculture sector, using a mixed-method approach to analyze literature from 2017 to 2020. The paper concludes by recognizing the unique features of agricultural digital twins, showcasing the transformative potential of this technology within the industry. Figure 8 displays the various physical twin types and the maturity of each use case as represented by their TRL levels.

Figure 8.

Categorization of agricultural physical twins, with colors representing the maturity level of the digital twin. Reused with permission from Pylianidis et al. [7].

Uhlemann et al. [57] highlight the challenges faced by SMEs in fully automating data acquisition and processing, as well as the lack of knowledge about the benefits of digitalization. Overall, a digital twin is a transformative force in the energy and agriculture sectors, driving advancements in system modeling, risk prediction, and operation optimization. Its ability to create high-accuracy virtual representations of complex physical systems has far-reaching implications, from enabling proactive maintenance strategies to enhancing decision-making processes. This potent combination of physical and virtual realities fosters innovative solutions to traditional industry challenges. Despite considerable strides, a comprehensive understanding of digital twins’ potential continues to unfold, suggesting promising opportunities for future research and development. These technological advancements hold great promise to shape a future where digital twin technology is integrated seamlessly into the fabric of these industries.

4.3. Maintenance and Construction

Digital Twin technology, characterized by creating virtual models of physical systems, has been making remarkable strides in the industrial sectors, notably in maintenance and construction. Its unique capability to simulate, monitor, and predict the performance of systems has immense potential to revolutionize these fields. The application of digital twins encompasses a broad range of areas, from predictive maintenance of industrial machinery to smart construction project management. Integrating the power of other cutting-edge technologies, digital twins are creating high-fidelity virtual models that enable advanced project management and improved lifecycle monitoring of complex equipment. This paradigm shift offers potential solutions to industry challenges such as low productivity and slow technological advancements while facilitating an enhanced understanding of system operations.

Digital Twins have seen widespread implementation for maintenance. It has garnered significant research interest due to its potential impact on company operations, such as shutting down entire production lines or ensuring worker safety. Errandonea et al. [21] review digital twin applications for maintenance, detailing the concepts and strategies for both “Digital Twin” and “maintenance”, followed by a literature review exploring their intersection. Besides examining current digital twin applications in maintenance, the paper also identifies future research directions and open issues in the field.

Pan and Zhang [58] propose a closed-loop digital twin framework integrating Building Information Modeling (BIM), the Internet of Things (IoT), and data mining techniques for smart construction project management. Tao et al. [59] present a new method for improving the accuracy and efficiency of prognostics and health management (PHM) using digital twin technology. The digital twin is an emerging technology that allows for physical-virtual convergence, making it an effective tool for monitoring complex equipment lifecycles in harsh environments. The paper outlines the construction of a general digital twin for complex equipment and proposes a new method for PHM that makes use of the interaction mechanism and fused data of digital twin.

The construction industry faces challenges such as low productivity, limited research and development, and slow technology advancements. Digital twin technology has transformed industries like manufacturing and automotive, offering potential solutions for construction industry challenges. Opoku et al. [17] analyze the current state of digital twin applications in construction using a systematic review and science mapping method. It examines the concept’s evolution, key technologies, and six areas of application throughout a project’s lifecycle: building information modeling, structural system integrity, facilities management, monitoring, logistics processes, and energy simulation. The research highlights the digital twin’s potential to address numerous construction industry challenges, emphasizing the need for greater awareness and application of digital twin in this sector.

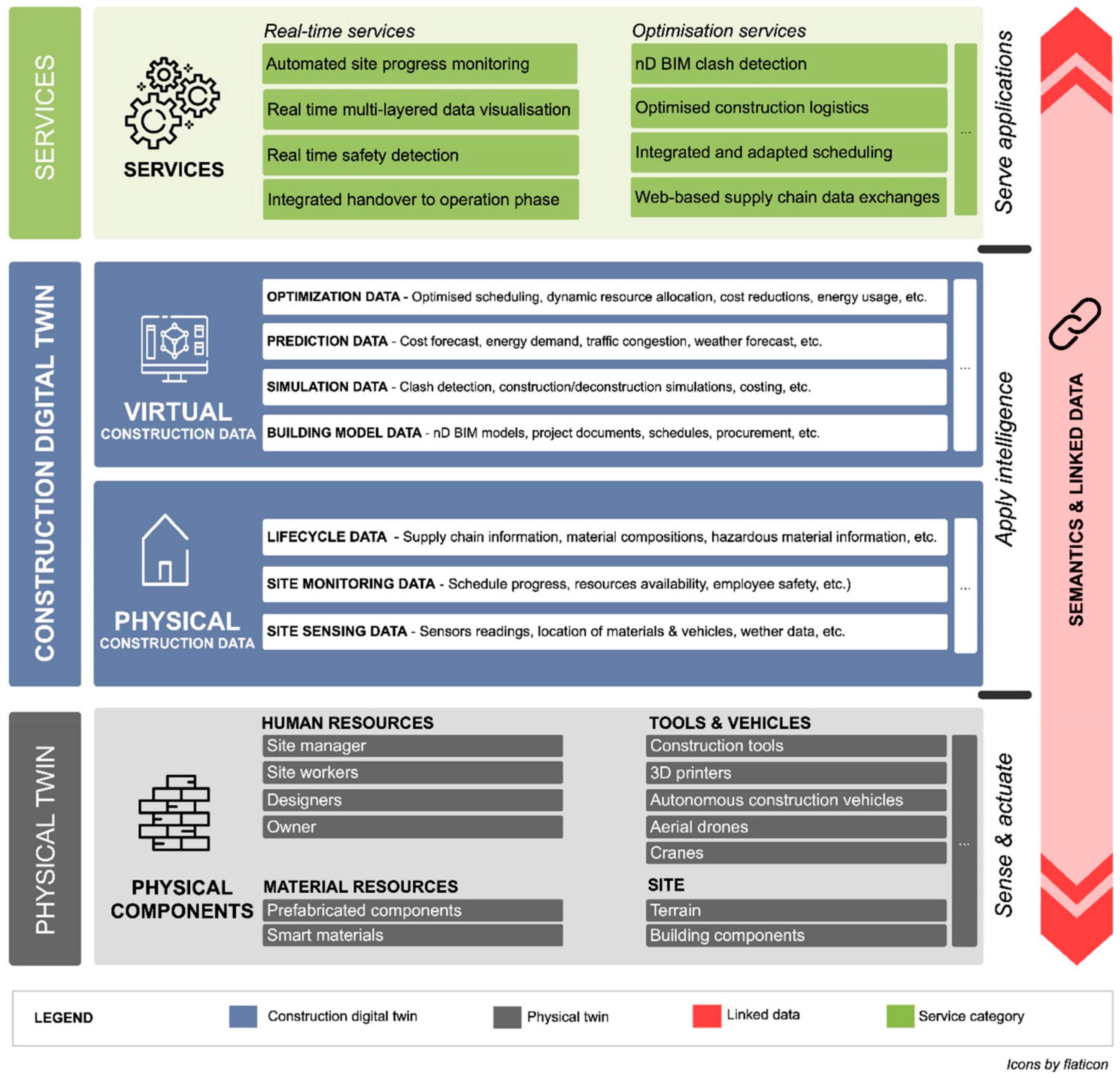

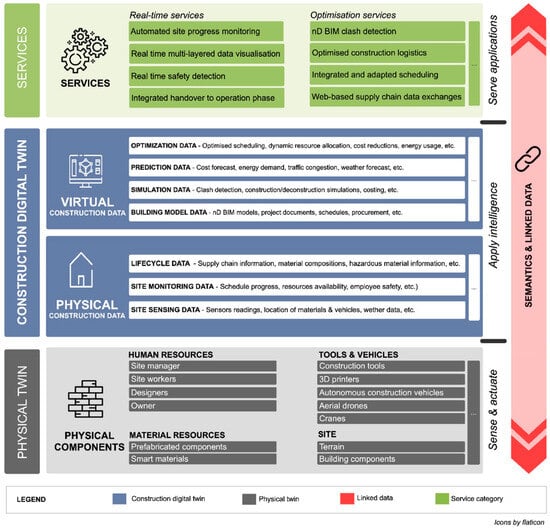

The engineering, architecture, and construction sector is increasingly influenced by digital technologies that facilitate monitoring, managing, simulating, and optimizing engineering systems throughout the lifecycle of built assets. While Building Information Modeling (BIM) offers building components with standardized semantic representation, the Digital Twin technology provides a more holistic and process-oriented characterization, addressing the limitations of BIM, such as semantic completeness in control systems and urban artifacts. Boje et al. [60] review BIM applications during the construction stage, identifying limitations and requirements, and introduce a Construction Digital Twin. The definition, underpinning research themes, and future research areas are discussed to explore the potential of this comprehensive approach in the digital age. Numerous recurring ideas in the literature related to digital twins are categorized within the Virtual-Data-Physical framework, as depicted in Figure 9.

Figure 9.

Utilization of construction Digital Twin data for enabling smart construction services. Reused with permission from Boje et al. [60].

Ozturk [61] conducted a bibliometric search and scientometric analysis of 197 papers from the Scopus database, revealing that current research spans model-based information management, building information management, and interactions between buildings and smart cities. Key focus areas include virtual-physical building integration, building lifecycle management, and information-integrated production, while information-based predictive management and virtual-based information utilization require further attention. The study recommends that future research concentrate on integrating digital twins with their physical counterparts for enhanced building lifecycle performance. Limitations include a relatively small sample size because of the novelty of the subject, with future research advised to incorporate practice-oriented innovations and industry-driven improvements for more comprehensive results.

Overall, Digital Twin technology holds substantial promise in reshaping the maintenance and construction sectors. Through its ability to provide high-precision virtual models of physical systems, digital twins enhance predictive maintenance capabilities, facilitate smart construction management, and help overcome longstanding industry challenges. The technology’s future seems to lie in fully integrating digital twins with their physical counterparts to comprehensively understand building lifecycle performance. Despite the promising progress, several areas warrant further research, with potential for considerable practical applications. Given digital twins’ numerous benefits, they are poised to become an integral part of the maintenance and construction sectors, driving operational efficiency and technological advancement.

4.4. Transportation and Smart Cities

The advent of digital twin technology is revolutionizing various sectors, and the transportation industry and smart cities are no exception. Digital twins leverage advancements in IoT, cloud computing, artificial intelligence, and big data to create dynamic, real-time replicas of physical systems, facilitating their monitoring, control, and optimization. This technology holds significant promise in enhancing battery management systems, contributing to the development of smart electric vehicles, revolutionizing urban planning, and addressing acute traffic management issues in cities. It also provides a unified framework for disaster management, boosting situation assessment, decision-making, and stakeholder coordination. From simulating complex traffic scenarios to creating interactive 3D city models, digital twins are setting new benchmarks in transportation and urban governance.

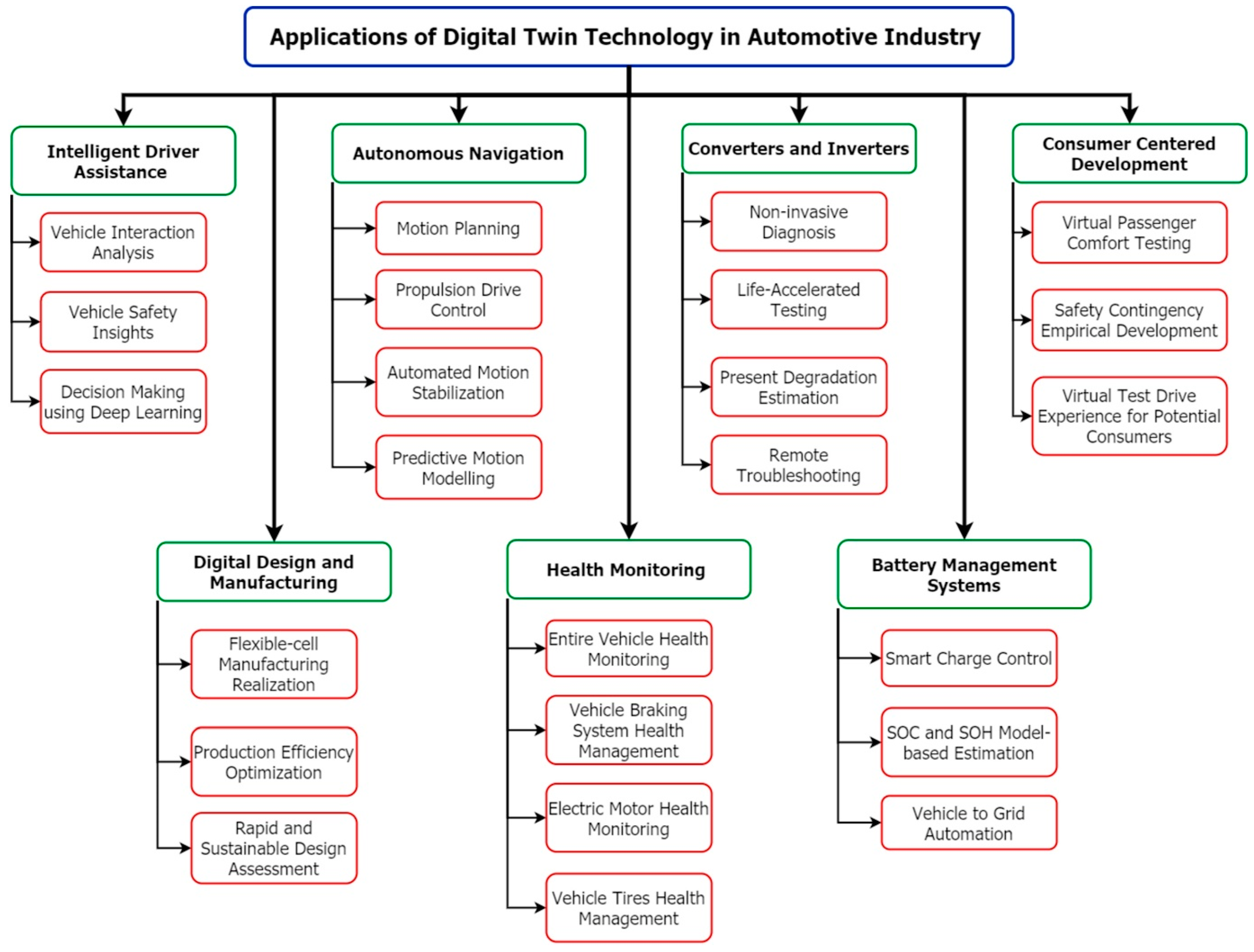

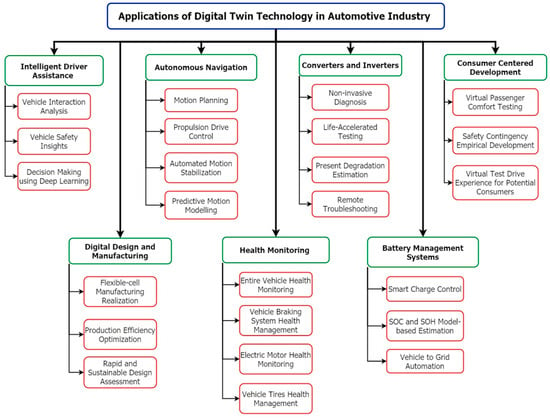

Li et al. [62] introduce a cloud battery management system that leverages cloud computing to enhance battery systems’ computational power and data storage capabilities. IoT technology enables seamless transmission of battery data to the cloud, creating a digital twin for the battery system. This digital twin facilitates battery diagnostics and monitoring of charge and aging levels. The cloud battery management system’s functionality and stability are validated through prototypes for both stationary and mobile applications under field operation and experimental testing. Figure 10 illustrates a summary of digital twin applications within the automotive industry.

Figure 10.

Digital twin application in automotive. Reused with permission from Bhatti et al. [1].

Rudskoy et al. [63] address the acute traffic management issues faced by cities and highlight the need for modernization using digital twins and artificial intelligence. By integrating Intelligent Transport Systems (ITS), it is possible to address key challenges within the transport network and foster its effective development. The article examines real-life ITS implementation cases and proposes a reference model for the services offered by these systems.

Smart cities are considered a solution to global warming, population growth, and resource depletion. Digital twins, IoT, 5G, blockchain, collaborative computing, simulation, and AI technologies hold great promise for transforming urban governance. Deng et al. [64] introduce a digital twin city (DTC). Additionally, the paper discusses relevant theories, research directions, and frameworks concerning digital twin cities.

Digital twins, initially developed for enhancing manufacturing processes, have evolved with advancements in building information models (BIM) and IoT-generated big data, enabling the creation of digital twin smart cities. These accurate 3D city models can be shared online, allowing the public to explore proposed urban planning and policy changes, fostering transparency and ease of dissemination. Citizens can interact with the model, providing feedback on planned alterations and reporting local issues. Digital twins also facilitate experimentation in areas requiring 3D data, such as flood evacuation planning. White et al. [65] present a public and open digital twin of Dublin’s Docklands area, demonstrating its utility in urban planning, skyline, and green space management and enabling user interaction and feedback on proposed changes.

Overall, the adoption of digital twin technology is undeniably transforming transportation and the design of smart cities. By creating an interactive and virtual replica of battery systems, electric vehicles, city infrastructure, and disaster scenarios, digital twins offer improved diagnostic and monitoring capabilities, streamlined decision-making, and enhanced stakeholder engagement. However, while the technology promises significant advancements, it also poses substantial challenges requiring further research and development. The increasing sophistication of digital twins is expected to significantly address intricate challenges in transportation, urban planning, and disaster management, thereby contributing to the advancement of sustainability and efficiency in the future.

5. Challenges and Solutions of Digital Twin Technology

5.1. Connection between Physical and Virtual Models

Digital twins are crucial for smart factories and manufacturing under the Industry 4.0 paradigm. Jiang et al. [66] focus on rapid digital twin modeling methods and connection implementation mechanisms between physical and virtual systems at the workshop level. Discrete event system (DES) modeling theory is applied to a three-dimensional digital twin model. Seven basic elements are identified to formally represent a manufacturing system, with logistics path networks and service cells introduced for uniform description. A new interconnection and data interaction mechanism is designed for through-life applications, with discrete cells mapped onto production-process-oriented digital manufacturing modules. The proposed method and connection mechanism are demonstrated through a real-world workshop digital twin, showcasing practicality and usefulness.

5.2. Human Digital Twin

Digital Twin technology, predominantly applied in advanced manufacturing, Product Lifecycle Management (PLM), and smart healthcare, is explored by Shengli [67] for its potential use in the full lifecycle management of humans. The concept of an Augmented Digital Twin serves as the foundation for the Human Digital Twin (HDT), the paper’s core idea. Drawing from Digital Twin applications in various fields and advancements in Data Mining, Data Fusion Analysis, Artificial Intelligence, Deep Learning, and Human-Computer Science, it is concluded that Human Digital Twin is a feasible approach for full lifecycle health management. Shengli [67] presents the Human Digital Twin’s concept, conceptual model, and characteristics, comparing it to traditional Digital Twins to demonstrate its potential. Human Digital Twin System Architecture and Implementation Approach are proposed to discuss Human Digital Twin construction. However, the authors emphasize the challenges in achieving the Human Digital Twin due to its complexity, various aspects involved, and security and social ethics concerns.

5.3. Networking Requirements for Digital Twin

Digital twin technology serves as an innovation accelerator, offering a live replica of physical systems and delivering numerous benefits, including accelerated business processes, enhanced productivity, and cost-effective innovation. As an ideal solution for various challenges in domains such as Industry 4.0, education, healthcare, and smart cities, digital twin technology must ensure a synchronized real-time copy of the physical system. The network connecting the physical and digital twins must meet specific requirements, such as low-latency real-time communication, data security, and quality. Mashaly [68] presents an overview of digital twin technology and its application domains, a comprehensive discussion of its networking requirements, and proposed technologies that enable these demands.

5.4. Barriers and Enablers in the Process Industry

The concept of “digital twins” has seen a surge in practical applications across various industries since its introduction in 2002. However, due to the novelty of the concept, organizations face significant challenges when implementing digital twins, particularly in the process industry, where accurately representing and modeling the underlying physics of production processes is highly complex. Perno et al. [69] consolidate the fragmented literature on enabling factors and challenges in digital twin implementation for the process industry by organizing existing studies and focusing on barriers and enablers. By doing so, it contributes to the current body of knowledge on digital twins and proposes conceptual models that depict enablers, barriers, and their mutual relationships in digital twin implementation.

5.5. Data Integration and Management

Manufacturing operations produce data that can enhance process capability, adaptability, and awareness. Cyber-physical systems collect data from manufacturing equipment, often using protocols such as MTConnect, to drive change and improve production output. Additionally, Manufacturing Execution Systems (MES) can monitor process output, consumable usage, and operator productivity. However, MTConnect data and MES data typically reside in separate, proprietary, and costly systems. Urbina Coronado et al. [70] introduce a new, low-cost MES, utilizing Android devices and cloud computing tools, that integrates MTConnect data with operator-collected production data, making it particularly suitable for small manufacturing enterprises. A case study tracking a titanium parts production run demonstrates the correlation between MES and MTConnect data from a machine tool. This research contributes to the development of a Shop Floor Digital Twin, a comprehensive digital model of the shop floor for production control and optimization.

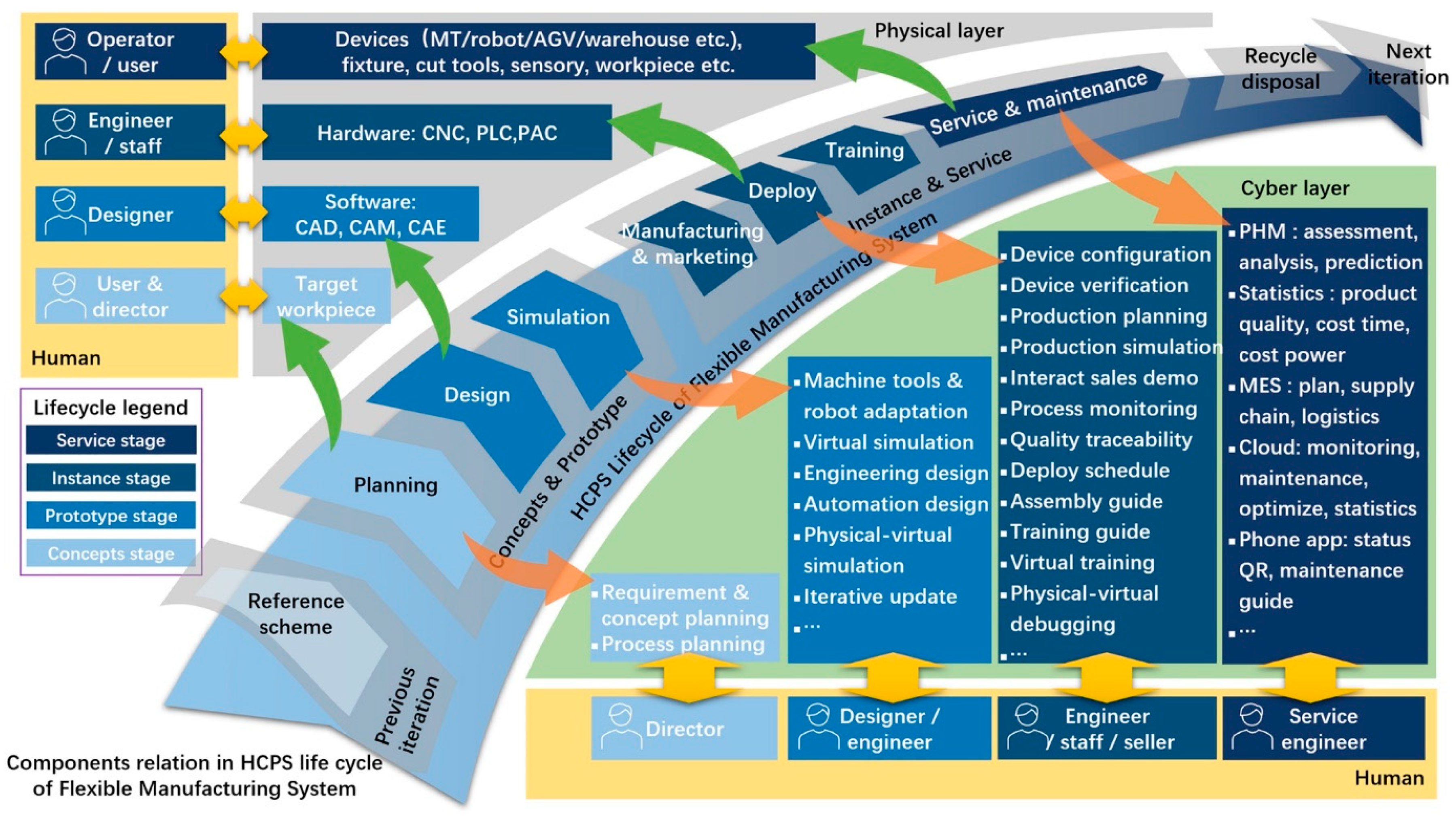

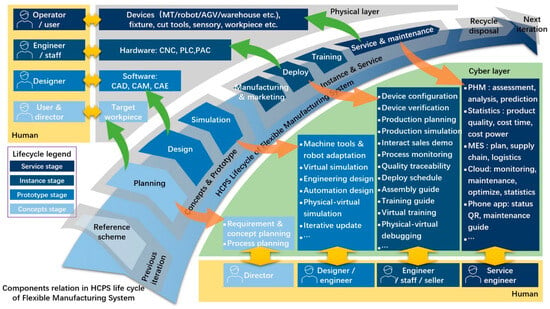

5.6. Visualized Architecture for Flexible Manufacturing Systems

Fan et al. [71] present a general architecture of digital-twin visualization for flexible manufacturing systems (FMS), addressing the human–machine interaction problem in the context of Human-Cyber-Physical Systems (HCPS) and focusing on full life cycle functional services and lightweight architecture. Connections among FMS life cycle prototypes is shown in Figure 11. The proposed architecture explores digital-twin Cyber-Physical modeling of multi-source heterogeneous information and 3D visualized human–machine interaction with digital-twin scenario information. The study thoroughly investigates the visualization method of high-value information across the life cycle stages and introduces the “Geometric information (G)-Historical samples (H)-Object attribute (O)-Snapshot collection (S)-Topology constraint (T)” (GHOST) digital-twin modeling concept, as well as methods for developing virtual digital-twin scenes architecture. Experimental results of the developed prototypes for the general platform of digital-twin RESTful services and cross-platform general visual mock-up software demonstrate the effectiveness of this method in various aspects of the FMS lifecycle.

Figure 11.

Connections among FMS life cycle prototypes. Reused with permission from Fan et al. [71].

6. The Limitations of the Term “Digital Twin”

6.1. Limited Understanding

One of the drawbacks of the term “digital twin” is its limited understanding. The term “digital twin” may present challenges in comprehension for individuals lacking technical expertise and may not fully encapsulate the technology’s comprehensive scope and potential for those who lack familiarity with it. Because of this, it may be challenging for non-technical people to completely understand the notion of digital twin technology and its potential advantages. Furthermore, it could cause misunderstandings and erroneous interpretations of the technology, which might delay the implementation of digital twin technology in some sectors or organizations. This restriction can be removed by making explanations of digital twin technology easier to access and comprehend and by emphasizing its potential advantages in a way that is clear to non-technical people.

6.2. Limited Scope

Another drawback of the phrase “digital twin” is its restricted scope. “Digital twin” refers to a virtual model that is merely a copy of the physical system. However, the virtual model can be more than just a copy; it can also have extra analytical and simulation features that can be utilized to boost the physical system’s performance. Because of this, it may be challenging for consumers to completely comprehend the capabilities of digital twin technology and to appreciate all of its potential advantages. It could also result in a limited vision of the technology, which might hinder the adoption of digital twin technology in some businesses or organizations. This constraint can be overcome by giving digital twin technology more thorough and inclusive descriptions, showing its analytical powers and capacity to go beyond basic reproduction, and emphasizing its potential benefits in a straightforward manner.

6.3. Limited Recognition in Certain Industries

Another drawback of the phrase “digital twin” is its limited acceptance in some businesses. The phrase “digital twin” may be connected to some sectors of the economy, such as manufacturing, but may not be as well-known or understood in others, like healthcare or construction. Because of this, it may be challenging for sectors of the economy that are less experienced with digital twin technology to completely understand and utilize it. It could also result in a limited perception of the technology’s potential, which might hinder the adoption of digital twin technology in some sectors or organizations. The term “digital twin” has limited usage in some industries, which is another disadvantage. While the term “digital twin” may be commonly utilized in certain industries, such as manufacturing, its usage and comprehension may not be as prevalent in other sectors, such as healthcare. Because of this, it could be difficult for economic sectors with less exposure to digital twin technology to fully comprehend and make use of it. Additionally, it can lead to a restricted understanding of the technology’s potential, which might make it more difficult for particular industries or organizations to implement digital twin technology.

6.4. Limited to Specific Types of Systems

Another restriction related to the phrase “digital twin” is that it is limited to specific kinds of systems. For some systems, like industrial systems, the phrase “digital twin” may be more often used or understood than for other systems, such as social systems. Because of this, it may be challenging for users to fully comprehend the possibilities of digital twin technology and to fully grasp its potential advantages for various kinds of systems. It could also result in a limited vision of the technology, which might hinder the adoption of digital twin technology in some businesses or organizations. This drawback can be overcome by giving more thorough and comprehensive descriptions of digital twin technology, showing its ability to integrate with many types of systems, and emphasizing its potential advantages in a simple manner. Additionally, it can help illustrate the potential advantages of the technology and promote wider adoption across other sorts of systems by offering case studies and examples that are particular to different types of systems.

6.5. Limited to 2D Representation

Another restriction linked with the phrase “digital twin” is its confinement to 2D representation. The name “digital twin” implies a two-dimensional representation of the physical system, although modern technology may create a three-dimensional model that can be changed in real-time. This can improve decision-making and system knowledge. This incomplete portrayal may hinder people’s ability to comprehend the capabilities and potential advantages of digital twin technology and may also delay the adoption of this technology in some sectors or organizations. This barrier can be overcome by describing digital twin technology in a more thorough and inclusive manner, showing its capacity to deliver 3D representation that can be moved and altered in real-time and emphasising its potential benefits in a simple manner. Additionally, it can serve to illustrate the potential advantages of the technology and promote wider adoption by offering instances of 3D representation that can be moved and altered in real time.

7. Why 3D Digital Twin?

7.1. The Advantages of the Term “3D Digital Twin”

The adoption of terminology plays a significant role in shaping/influencing our understanding, comprehension, and perception of technological advancements. The name “3D digital twin” has numerous benefits compared to the generic “digital twin” term. Within the domain of digital twin technology, the phrase “3D digital twin” arises as a refined and accurate substitute for the traditional term “digital twin”. This section aims to clarify the specific benefits of the term “3D digital twin” compared to its predecessor.

7.1.1. More Accurate Description

One benefit of using “3D digital twin” instead of “digital twin” is a more accurate description. A more precise and comprehensive definition of the technology is “3D digital twin”, which highlights its analytical capabilities, enables a more intuitive understanding of the system, and helps speed up decision-making. It talks about how the technology can offer a 3D representation that can be utilized for various analyses and to draw valuable conclusions from the data. The full extent and potential of the technology can be better communicated to individuals who are unfamiliar with it thanks to this more accurate description. It can also be easier to tell it apart from other, possibly less analytically capable, similar technologies.

7.1.2. Emphasizes the Analytical Capabilities

Another benefit of adopting the term “3D digital twin” instead of “digital twin” is that it highlights the analytical capabilities. The phrase “3D digital twin” highlights the technology’s capacity to offer sophisticated analytical features like modeling, optimization, and prediction. In addition to helping to separate it from other comparable technologies that might not have the same analytical skills, this can help to more effectively communicate the technology’s full extent and promise to others unfamiliar with it. In addition, emphasizing the analytical capabilities may appeal to businesses and organizations needing sophisticated analytical capabilities to improve their productivity, security, and efficiency. Consequently, this technology’s adoption is likely to surge in various industries and across diverse systems, thereby augmenting its acceptance and comprehension.

7.1.3. More Inclusive

Another benefit of employing “3D digital twin” instead of “digital twin” is that it is more inclusive. A more encompassing word that can be used to describe a larger range of systems and sectors is “3D digital twin”. It focuses on how the technology may offer sophisticated analytical skills, 3D representation, and real-time monitoring, which can be helpful in a variety of disciplines and businesses, including manufacturing, energy, transportation, construction, healthcare, and social systems. Because of its inclusivity, it is more readily accepted and understood across a variety of businesses and systems. Furthermore, it offers a three-dimensional representation that is capable of being modified instantaneously, facilitating a more instinctive comprehension of the system and potentially expediting the process of making decisions. Those who are unfamiliar with the technology may be better able to understand its entire breadth and potential thanks to this, and it may also make it easier to identify it from other, maybe inferior, technologies that may not have the same analytical capabilities or 3D representation.

7.1.4. Better Understanding for Non-Technical Individuals

Another benefit of employing “3D digital twin” rather than “digital twin” is that it is easier for non-technical people to understand. Because it highlights analytical skills, 3D representation, and real-time monitoring, which can be easier for people to understand. To people who are unfamiliar with the technology, the term “3D digital twin” may perhaps better appropriately represent the full range and possibilities of the technology. Consequently, the aforementioned technology has the potential to be more widely embraced and comprehended across various industries and systems, leading to a higher adoption rate. In addition, it can help people understand digital twin technology and its potential advantages for many fields by making explanations of the technology easier to access and comprehend and by emphasizing those advantages in a form that is understandable to non-technical people.

7.2. Limitation of 3D Digital Twin

While the term “3D digital twin” may more accurately embody the technology traditionally known as “digital twin”, there are several disadvantages to adopting this terminology. Firstly, the phrase “3D digital twin” is less recognized in the industry than “digital twin”. This lack of familiarity could pose challenges in communicating the technology’s purpose and educating stakeholders about its capabilities.

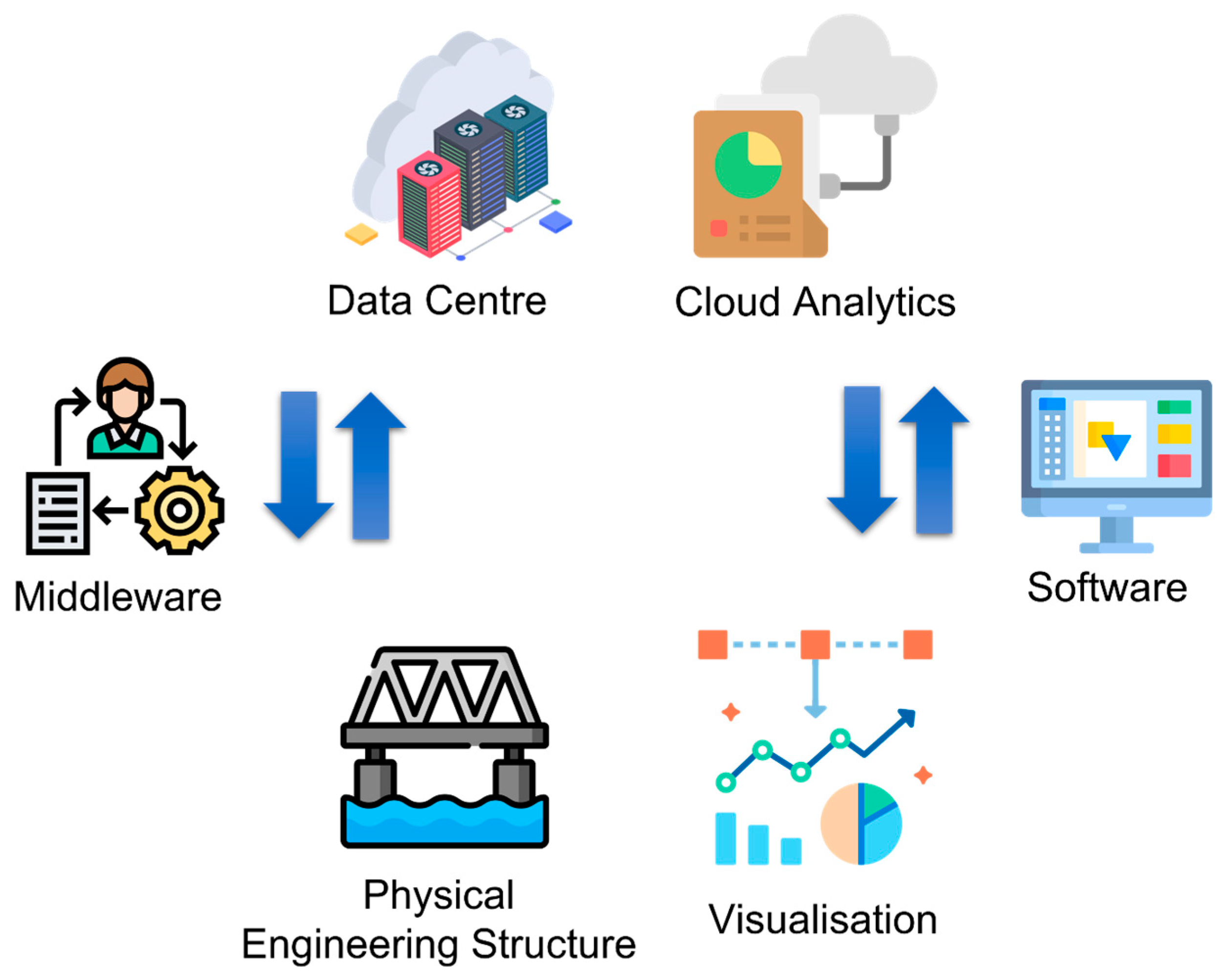

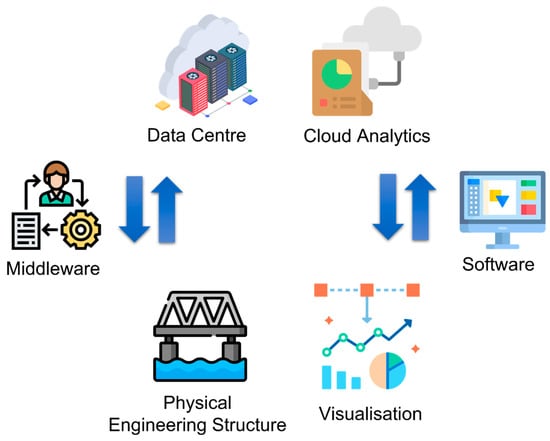

Despite some limitations mentioned above, the advantages of using the term 3D digital twin outweigh its limitations. Figure 12 shows the schematic illustration of a 3D digital twin that serves as a virtual representation of a physical object or system that can be used for simulation, analysis, and control purposes by combining three elements: data, engineering structure, and visualization interface.

Figure 12.

Schematic illustration of 3D digital twin.

8. Conclusions and Future Research

This review paper systematically explains digital twin concepts, applications, challenges, and solutions by organizing the selected publications into a comprehensive and coherent outline. The paper showcases the vast potential of digital twins to revolutionize Industry 4.0 and beyond, emphasizing its interdisciplinary nature and versatility across various domains and industries.

Using the “3D digital twin” terminology can provide a more accurate and appropriate description of the technology commonly known as “digital twin”. The proposed phrase highlights the exciting potential of the technology to generate a dynamic and immersive three-dimensional model of a physical system, allowing for real-time manipulation and analysis. This terminology highlights how the technology is designed to be very visual and easy to use, making it easier to understand the system’s status and make quick decisions. Moreover, the term “3D digital twin” highlights the technology’s powerful analytical potential. Seeing how the technology’s real-time data processing and analytical functions can help optimize and improve performance is great. By focusing on these features, the term highlights the potential of the technology as a powerful tool for gaining real-time insights.

“3D digital twin” has a wide range of applicability, encompassing various industries and systems, including healthcare, construction, and social systems. A positive aspect of the technology is its wide range of applications, which highlights its adaptability and versatility. Moreover, the use of “3D digital twin” has the potential to enhance understanding, especially for those who are not technically inclined. This clear and accessible terminology will assist people to understand the technology better and appreciate its capabilities and potential benefits. Although it may take some time to implement, the sector has the potential to widely accept a terminology change. Despite its name, the technology is a powerful tool that can enhance safety, reliability, affordability, and efficiency in various industries.

Further research into 3D digital twins could prioritize several crucial domains to augment their functionalities and tackle current challenges. Firstly, by investigating advanced visualization techniques, such as augmented reality (AR) and virtual reality (VR), we can potentially create user interfaces that are more immersive and intuitive. Furthermore, the development of advanced algorithms and analytics techniques for processing real-time data has the potential to enhance the optimization, predictive maintenance, anomaly detection, and decision support capabilities. Furthermore, implementing standardized data formats and integration frameworks could help resolve interoperability concerns and enable smooth integration with current systems. Finally, doing research on performance evaluation, security and privacy measures, scalability, and the socio-technical implications of digital twin adoption has the potential to improve their dependability, scalability, and societal effect.

Author Contributions

Conceptualization, A.L.H. and I.V.; methodology, A.L.H., A.T., M.I. and D.W.D.; software, M.I.; validation, A.T.; formal analysis, A.L.H., S.G.H., D.W.D. and I.V.; investigation, S.G.H., M.I. and I.V.; resources, D.W.D.; data curation, M.I. and M.E.M.S.; writing—original draft preparation, A.L.H., S.G.H., M.E.M.S. and D.W.D.; writing—review and editing, A.L.H. and I.V.; visualization, M.I.; supervision, A.T. and I.V.; project administration, A.L.H. and M.E.M.S.; funding acquisition, A.T., S.G.H. and I.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bhatti, G.; Mohan, H.; Singh, R.R. Towards the future of smart electric vehicles: Digital twin technology. Renew. Sustain. Energy Rev. 2021, 141, 110801. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication; White Paper; Michael Grieves, LLC: Melbourne, FL, USA, 2014; Volume 1, pp. 1–7. [Google Scholar]

- Yang, W.; Tan, Y.; Yoshida, K.; Takakuwa, S. Digital twin-driven simulation for a cyber-physical system in Industry 4.0. In DAAAM International Scientific Book; 2017; pp. 227–234. Available online: https://www.daaam.info/Downloads/Pdfs/science_books_pdfs/2017/Sc_Book_2017-018.pdf (accessed on 5 March 2024).

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Gabor, T.; Belzner, L.; Kiermeier, M.; Beck, M.T.; Neitz, A. A simulation-based architecture for smart cyber-physical systems. In Proceedings of the 2016 IEEE International Conference on Autonomic Computing (ICAC), Wuerzburg, Germany, 17–22 July 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 374–379. [Google Scholar]

- Goodwin, T.; Xu, J.; Celik, N.; Chen, C.-H. Real-time digital twin-based optimization with predictive simulation learning. J. Simul. 2024, 18, 47–64. [Google Scholar] [CrossRef]

- Pylianidis, C.; Osinga, S.; Athanasiadis, I.N. Introducing digital twins to agriculture. Comput. Electron. Agric. 2021, 184, 105942. [Google Scholar] [CrossRef]

- Stojanovic, N.; Milenovic, D. Data-driven digital twin approach for process optimization: An industry use case. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 4202–4211. [Google Scholar]

- Okhuijsen, B.; Wade, K. Real-time production optimization-applying a digital twin model to optimize the entire upstream value chain. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019; SPE: Richardson, TX, USA, 2019; p. D011S012R002. [Google Scholar]

- Min, Q.; Lu, Y.; Liu, Z.; Su, C.; Wang, B. Machine learning based digital twin framework for production optimization in petrochemical industry. Int. J. Inf. Manag. 2019, 49, 502–519. [Google Scholar] [CrossRef]

- Villalonga, A.; Negri, E.; Biscardo, G.; Castano, F.; Haber, R.E.; Fumagalli, L.; Macchi, M. A decision-making framework for dynamic scheduling of cyber-physical production systems based on digital twins. Annu. Rev. Control 2021, 51, 357–373. [Google Scholar] [CrossRef]

- Villalonga, A.; Negri, E.; Fumagalli, L.; Macchi, M.; Castaño, F.; Haber, R. Local Decision Making based on Distributed Digital Twin Framework. IFAC-PapersOnLine 2020, 53, 10568–10573. [Google Scholar] [CrossRef]

- Semeraro, C.; Lezoche, M.; Panetto, H.; Dassisti, M. Digital twin paradigm: A systematic literature review. Comput. Ind. 2021, 130, 103469. [Google Scholar] [CrossRef]

- Sjarov, M.; Lechler, T.; Fuchs, J.; Brossog, M.; Selmaier, A.; Faltus, F.; Donhauser, T.; Franke, J. The Digital Twin Concept in Industry—A Review and Systematization. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; Volume 1, pp. 1789–1796. [Google Scholar]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]