Polyamide 11 Composites Reinforced with Diatomite Biofiller—Mechanical, Rheological and Crystallization Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Diatomite

2.2. Preparation of Modified Diatomaceous Earth

2.3. Extrusion of the Biocomposite

2.4. Injection Moulding–The Production of Standardised Measuring Paddles

2.5. Characterisation Methods

- One-time wiping of the surface with a clean, dry cotton cloth,

- One-time wiping of the surface with a clean cotton cloth soaked with tap water,

- One-time wiping of the surface with a clean cotton cloth soaked with methanol,

- One-time wiping of the surface with a clean cotton cloth soaked with acetone.

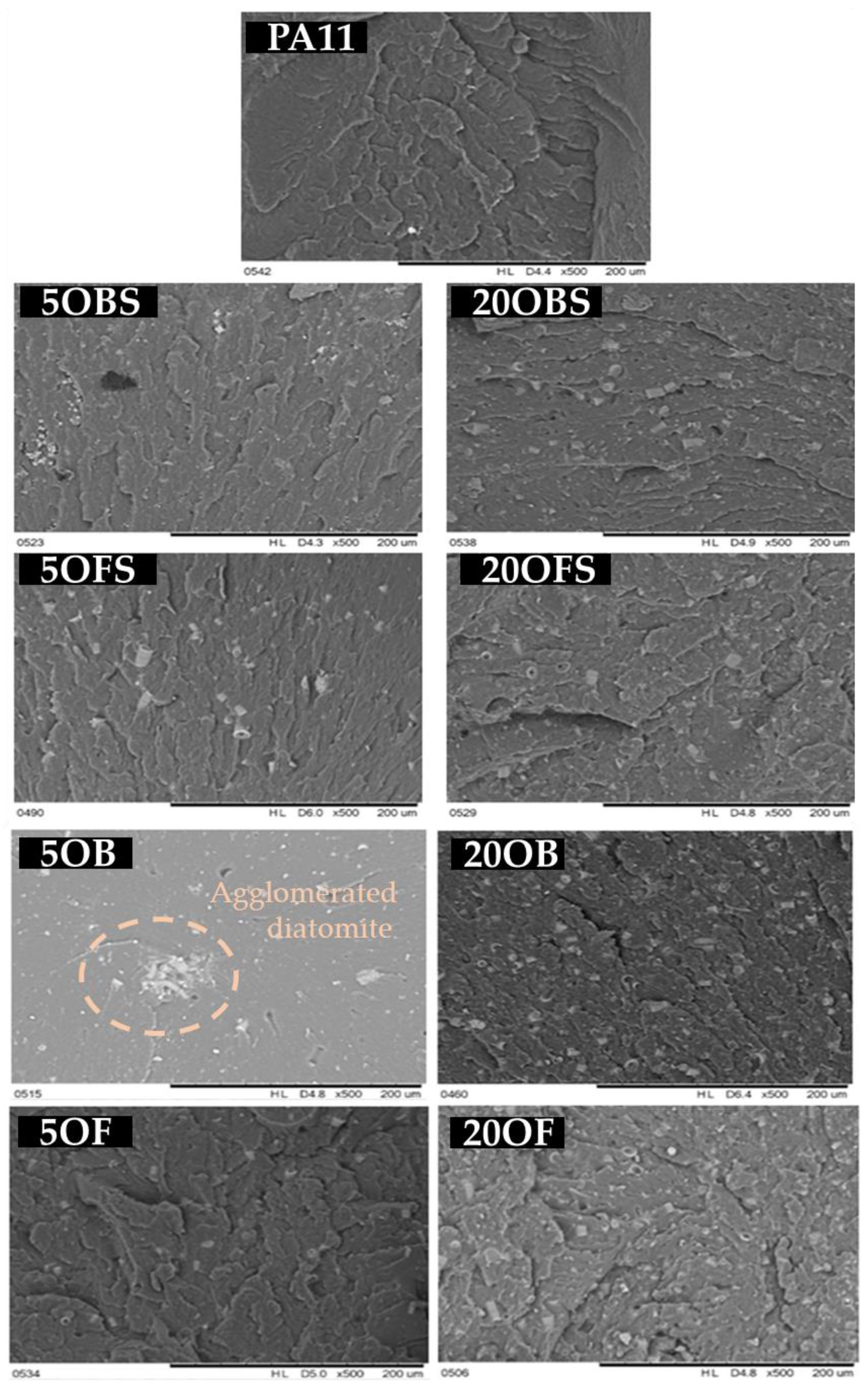

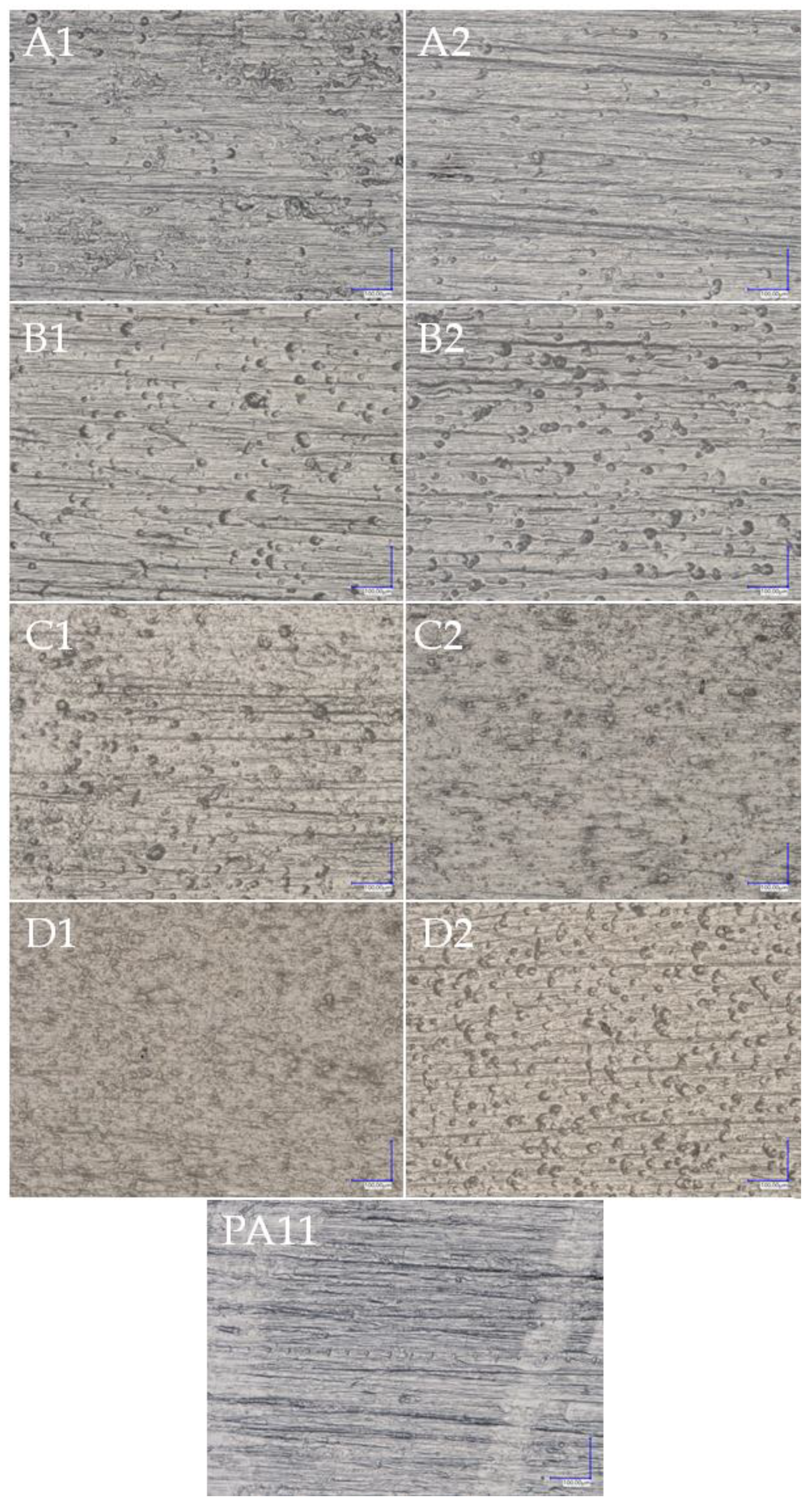

3. Results and Discussion

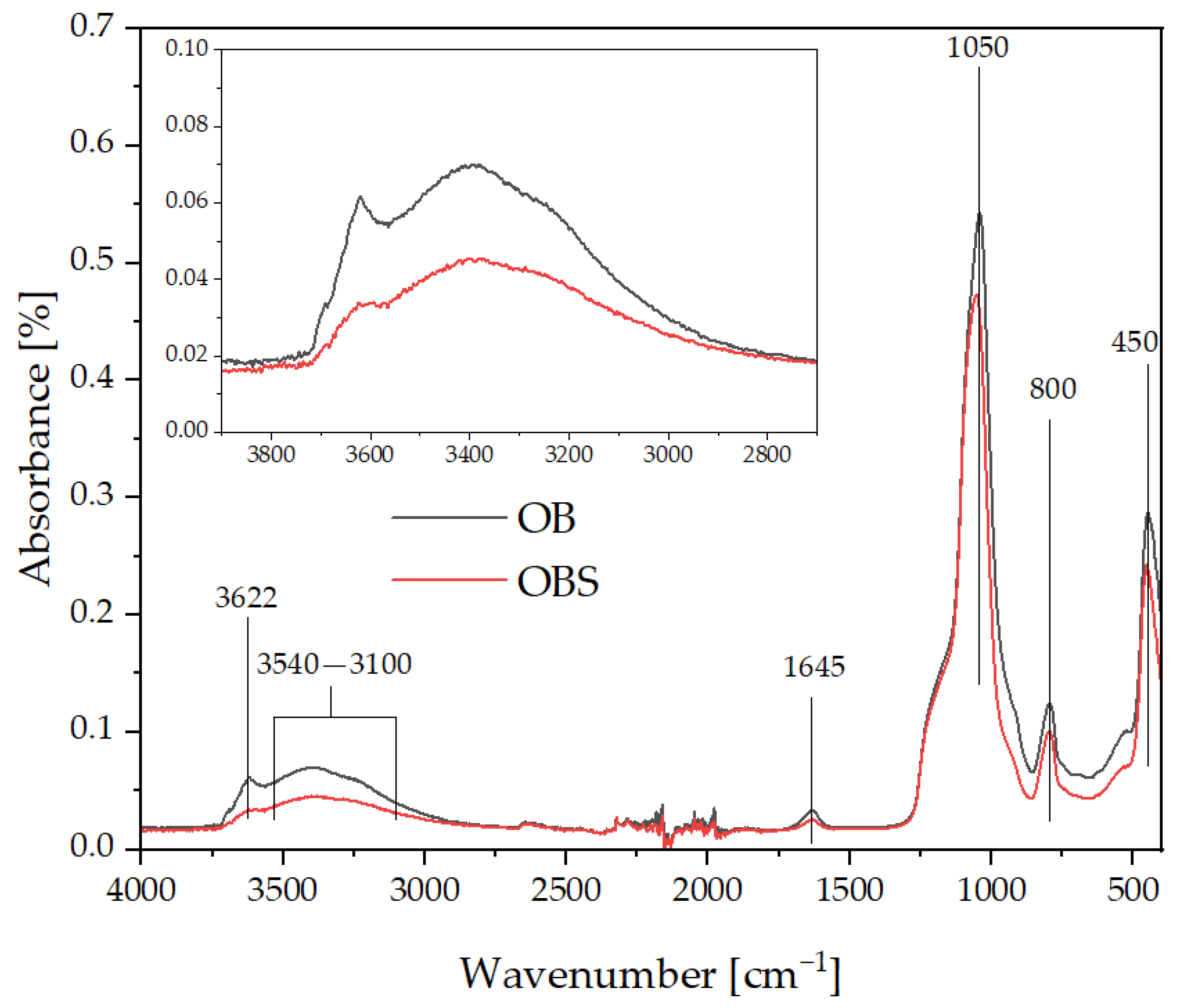

3.1. Infrared Spectroscopy (FT-IR)

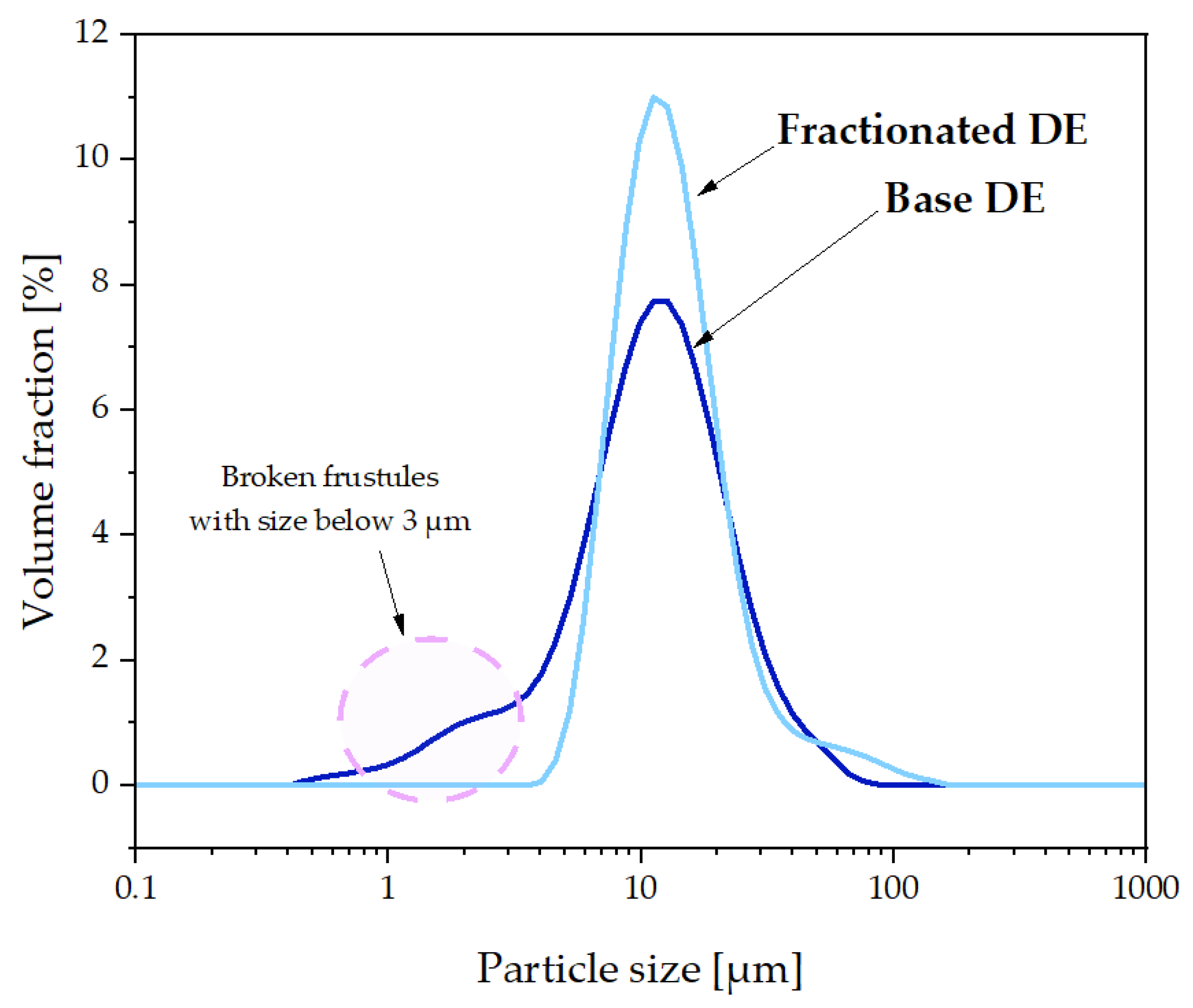

3.2. Particle Size Distribution

3.3. Crystallinity Analysis (XRD)

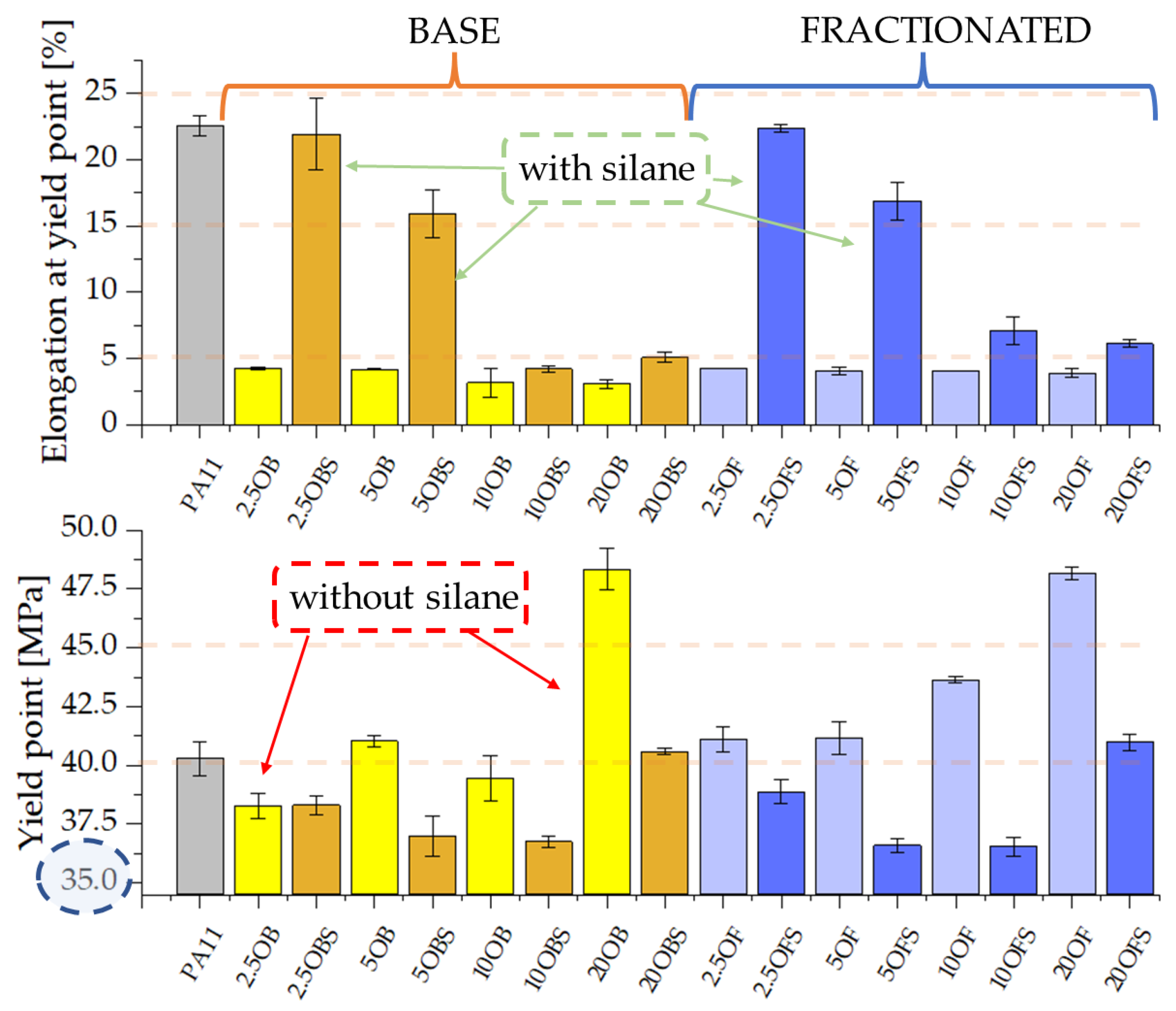

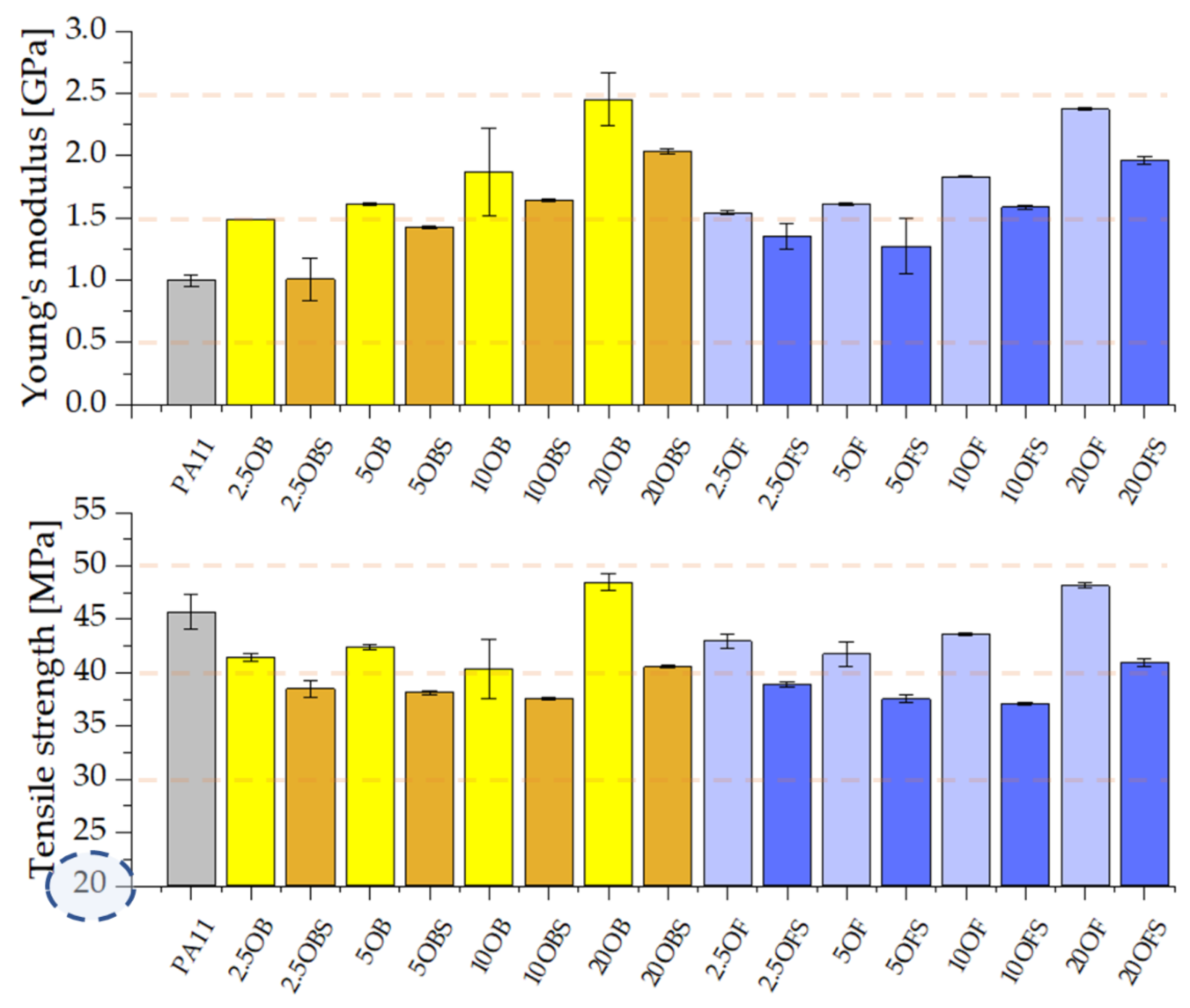

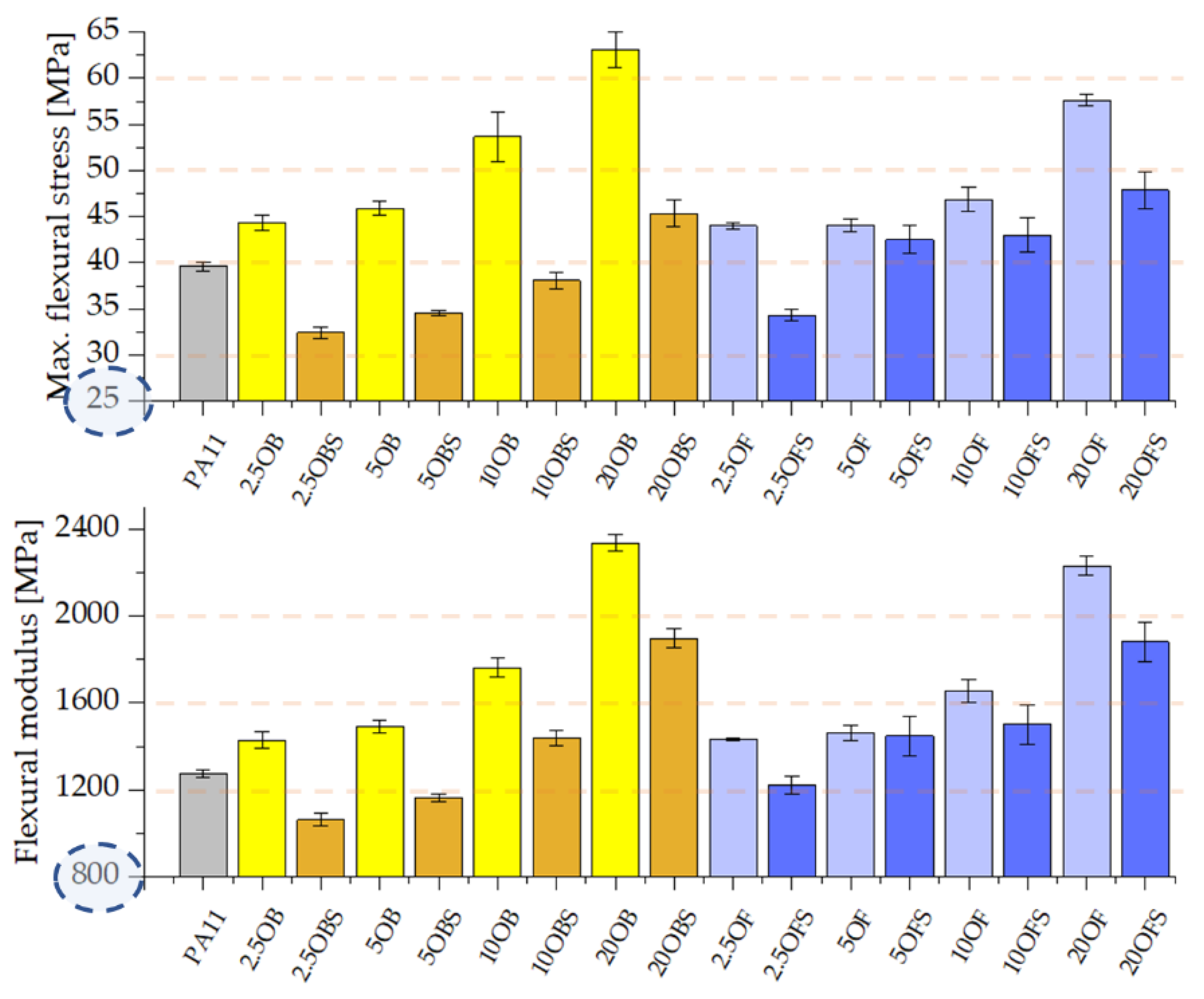

3.4. Test of the Composites’ Mechanical Characteristics

3.5. Rheology—Melt Flow Rate (MFR) and Viscosity

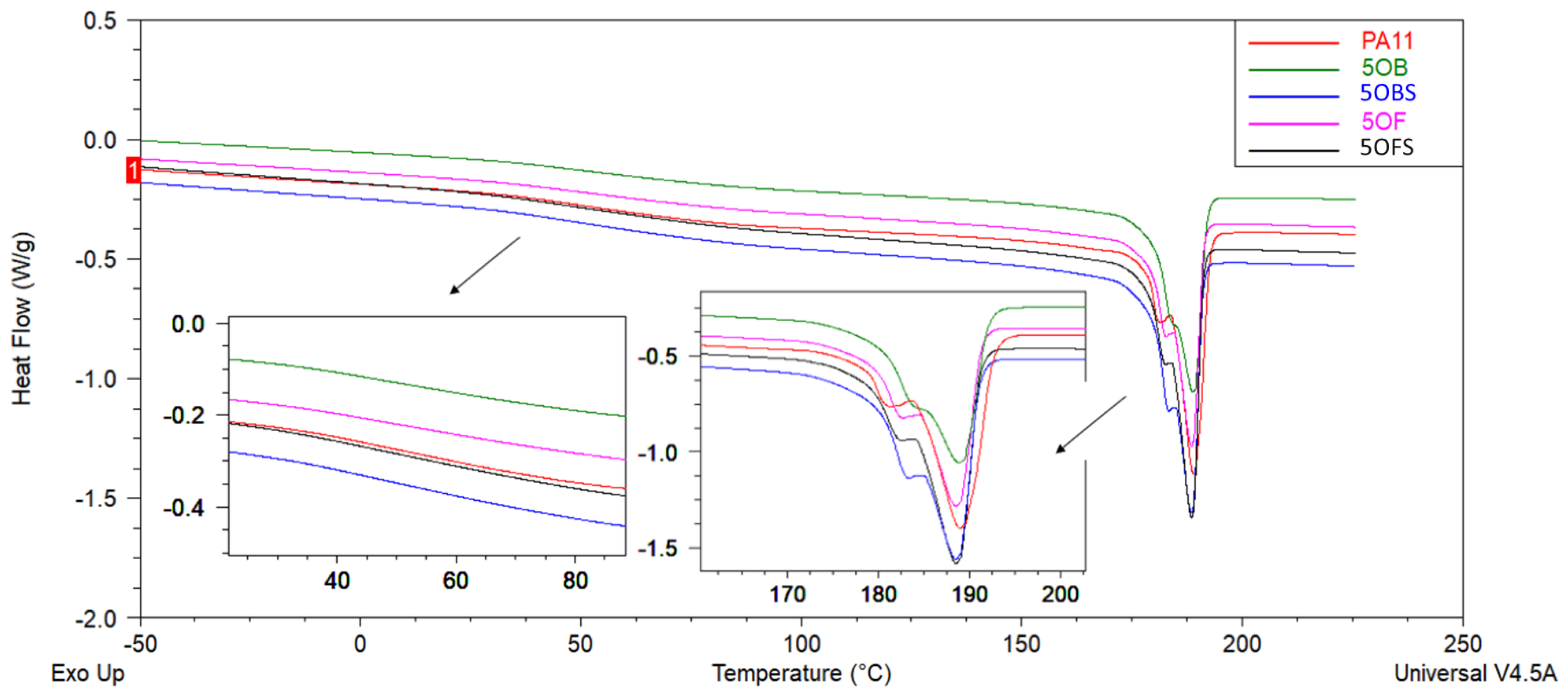

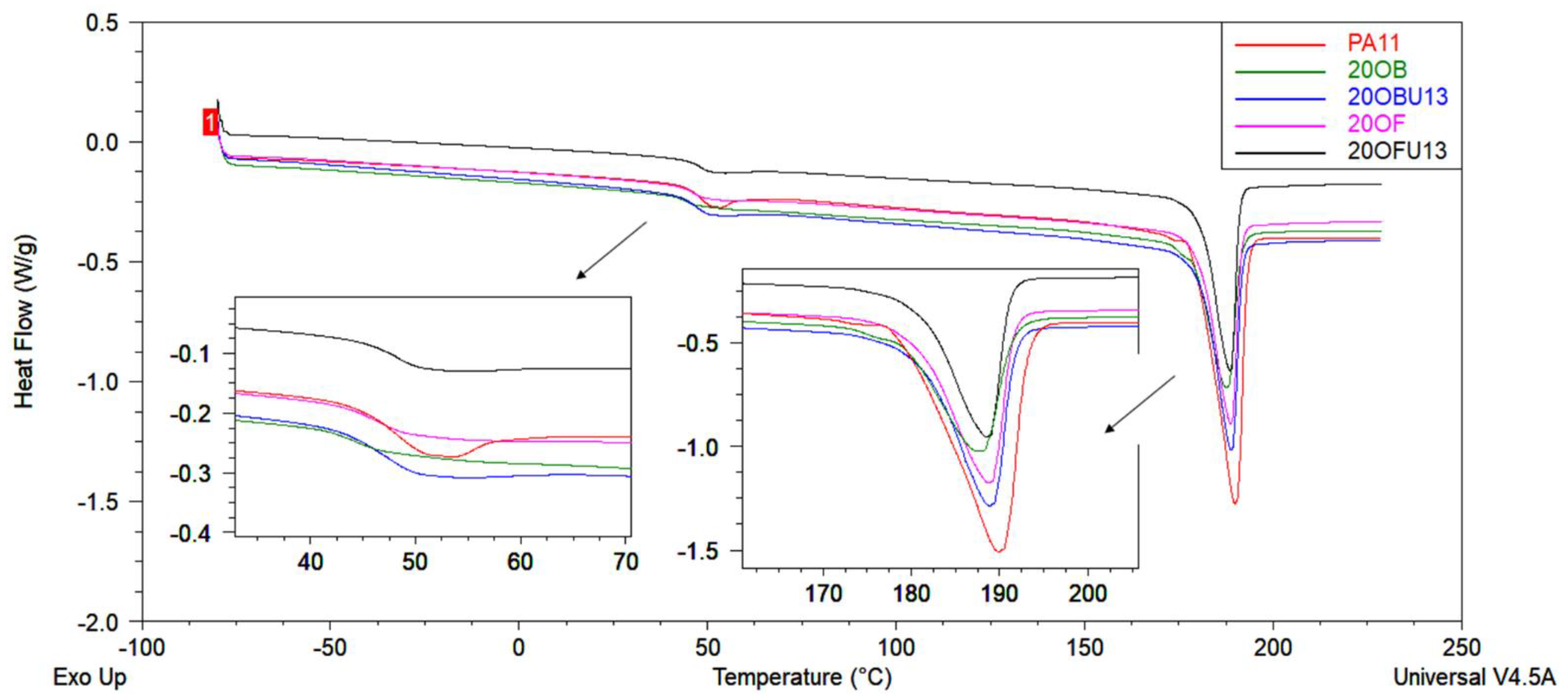

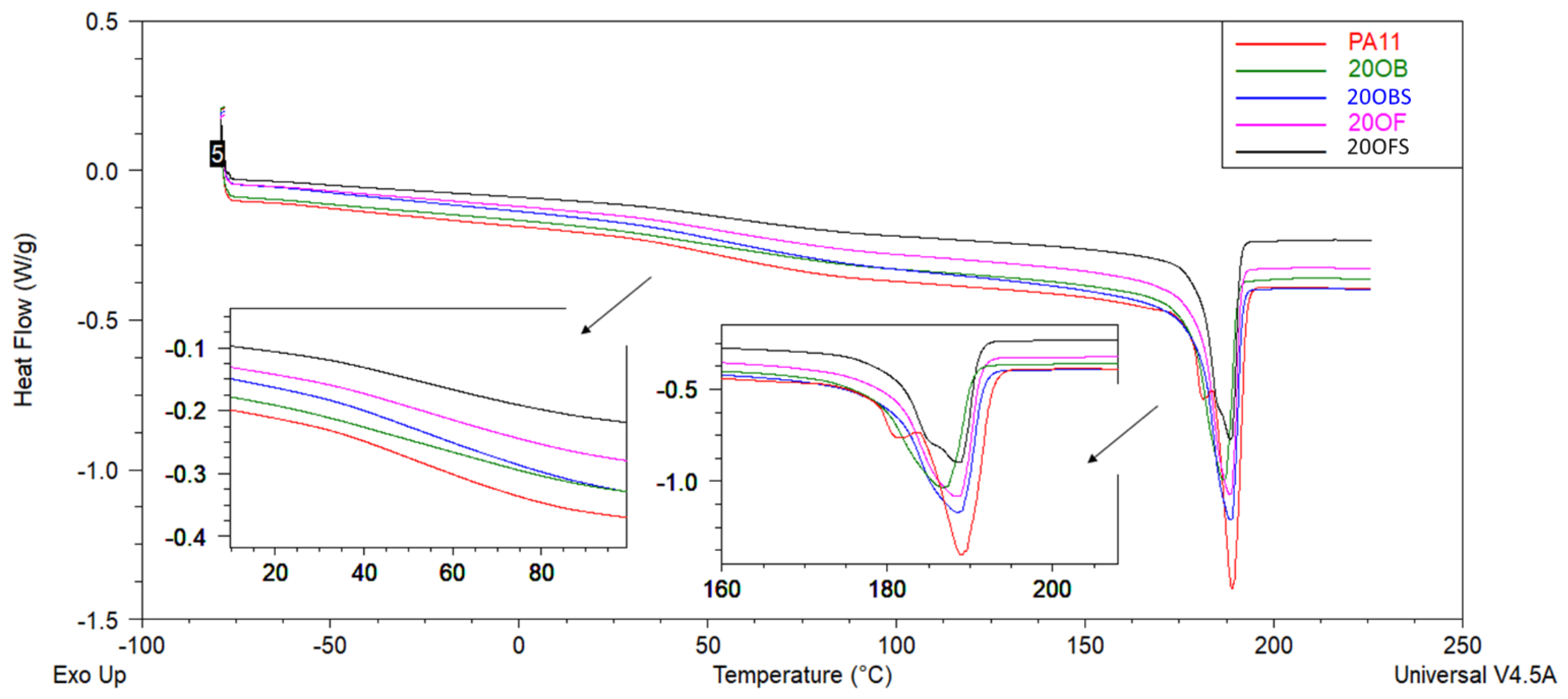

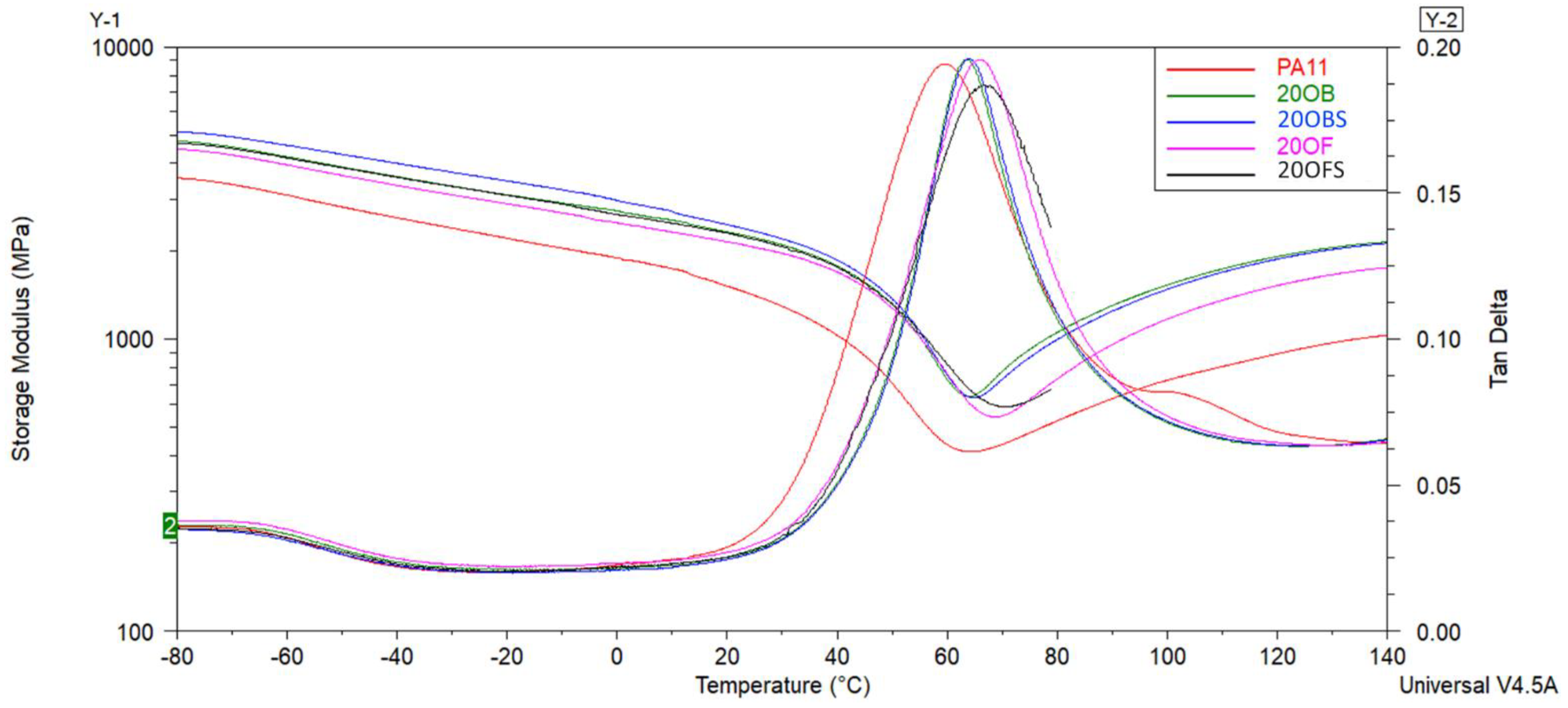

3.6. Thermal Analysis (DSC, DMTA)

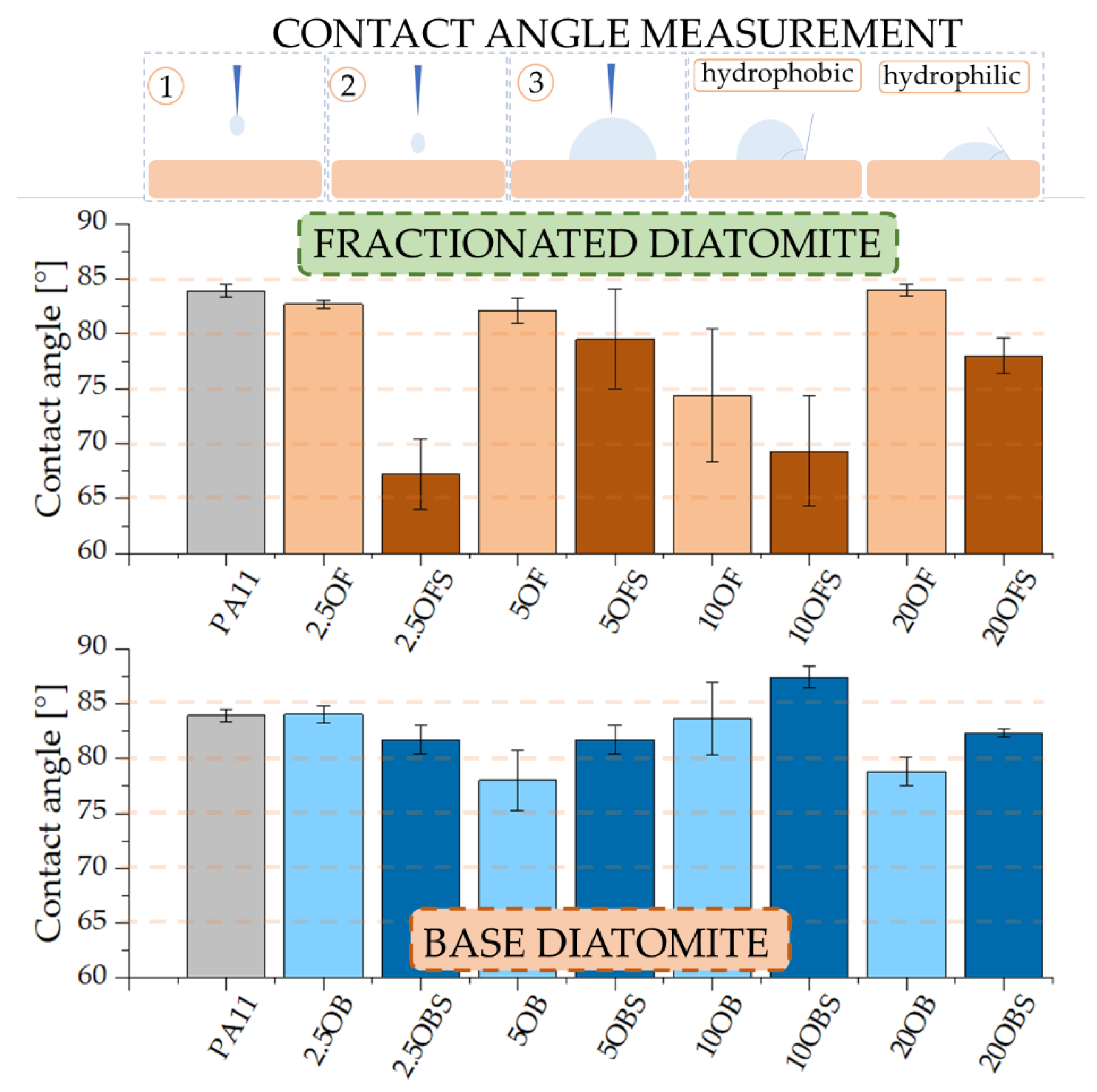

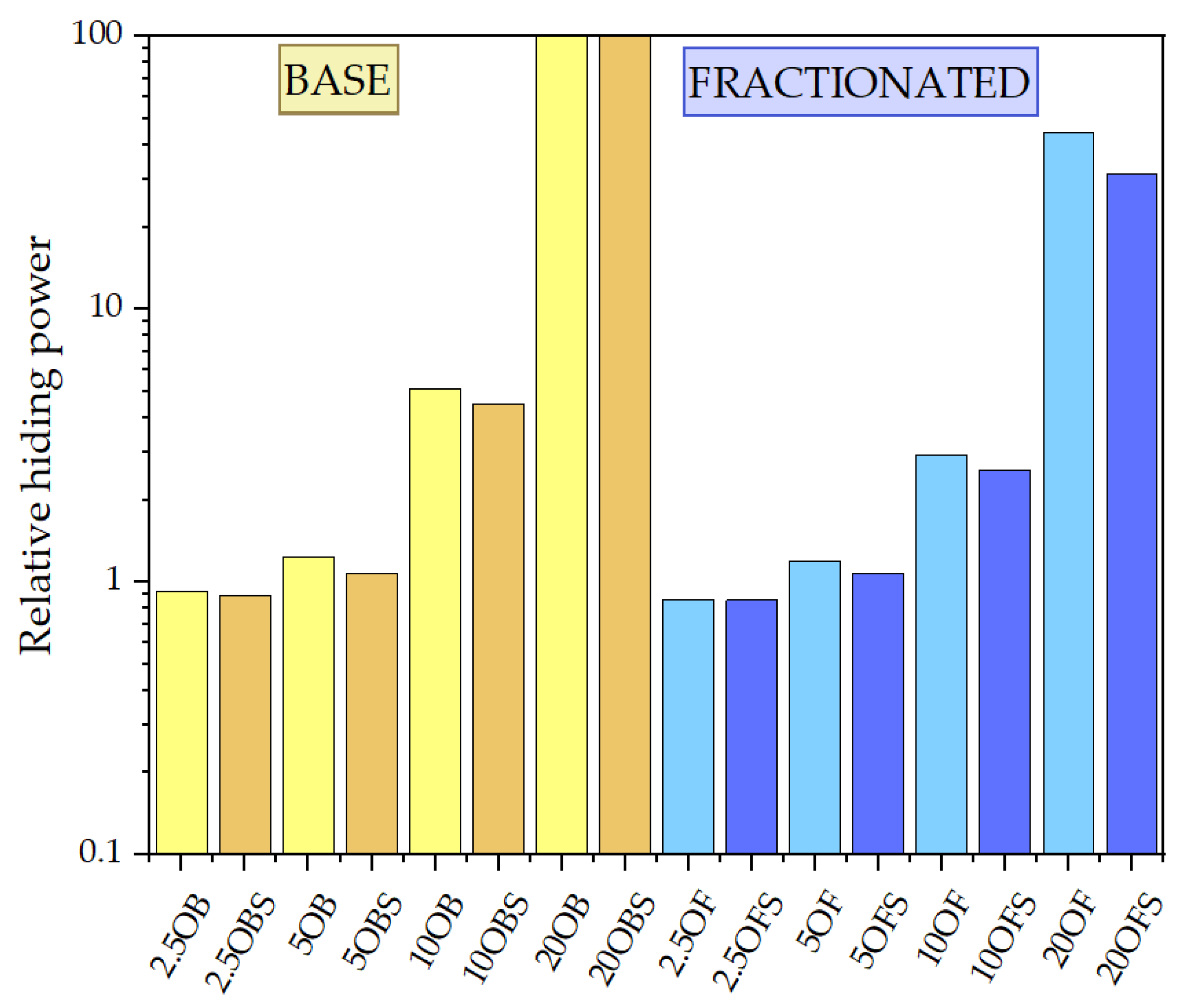

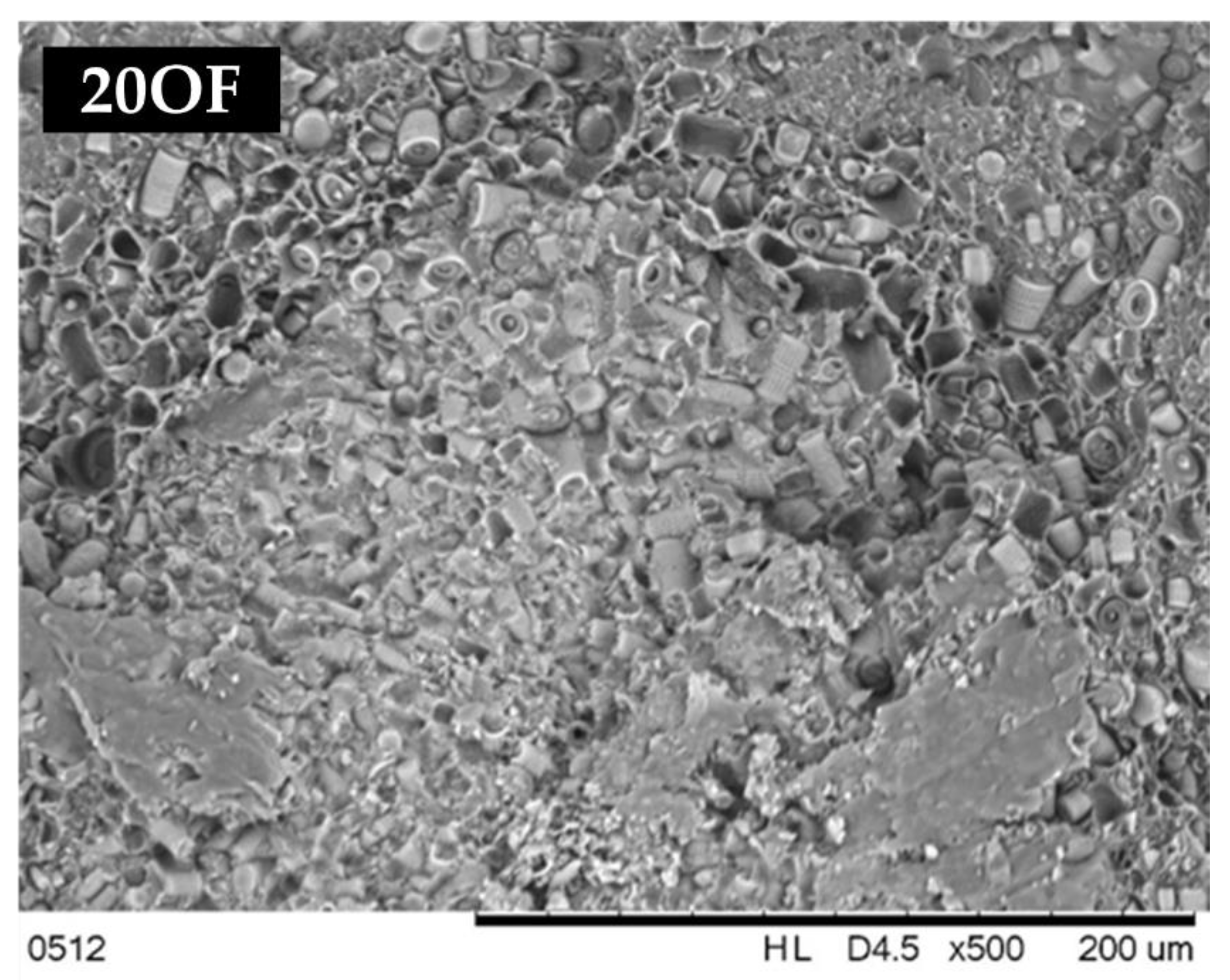

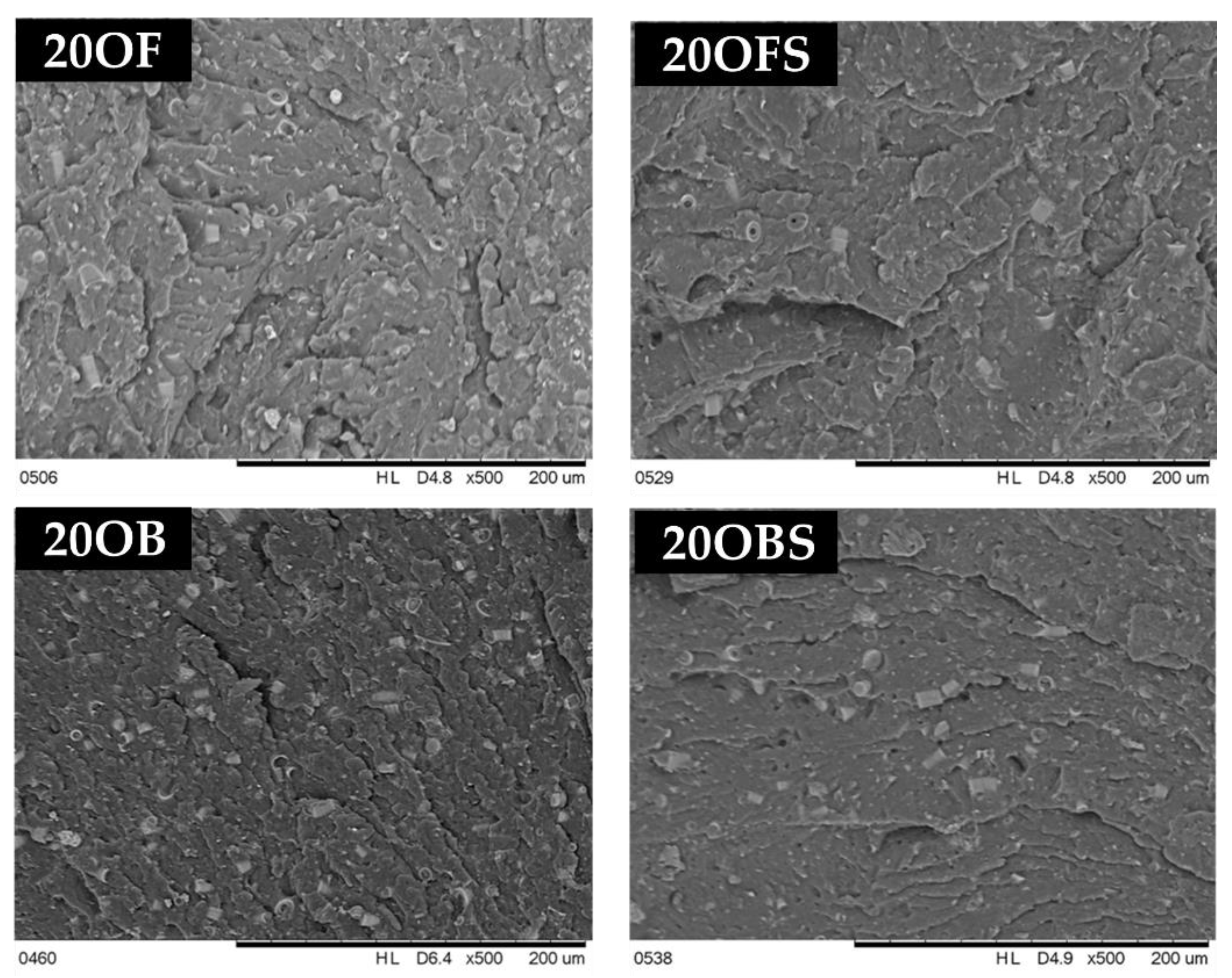

3.7. Surface Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Friedrich, K.; Almajid, A.A. Manufacturing Aspects of Advanced Polymer Composites for Automotive Applications. Appl. Compos. Mater. 2013, 20, 107–128. [Google Scholar] [CrossRef]

- Muhammad, A.; Rahman Md, R.; Baini, R.; Bakri, M.K.B. Applications of Sustainable Polymer Composites in Automobile and Aerospace Industry, Advances in Sustainable Polymer Composites; Woodhead Publishing Series in Composites Science and Engineering: Cambridge, UK, 2021; pp. 185–207. [Google Scholar]

- Motavalli, M.; Czaderski, C.; Schumacher, A.; Gsell, D. 4—Fibre Reinforced Polymer Composite Materials for Building and Construction, Textiles, Polymers and Composites for Buildings; Woodhead Publishing: Cambridge, UK, 2010; pp. 69–128. [Google Scholar]

- Połeć, I.; Hine, P.J.; Bonner, M.J.; Ward, I.M.; Barton, D.C. Die drawn wood polymer composites. I. Mechanical properties. Compos. Sci. Technol. 2010, 70, 45–52. [Google Scholar] [CrossRef]

- Borah, J.S.; Kim, D.S. Recent development in thermoplastic/wood composites and nanocomposites: A review. Korean J. Chem. Eng. 2016, 33, 3035–3049. [Google Scholar] [CrossRef]

- Durmaz, B.U.; Aytac, A. Investigation of the mechanical, thermal, morphological and rheological properties of bio-based polyamide11/poly(lactic acid) blend reinforced with short carbon fiber. Mater. Today Commun. 2022, 30, 103030. [Google Scholar] [CrossRef]

- Rahmani, H.; Najafi, S.H.M.; Ashori, A. Mechanical performance of epoxy/carbon fiber laminated composites. J. Reinf. Plast. Compos. 2014, 33, 733–740. [Google Scholar] [CrossRef]

- Kuram, E. Hybridization effect of talc/glass fiber as a filler in polycarbonate/acrylonitrile-butadiene-styrene composites. Compos. Part B Eng. 2019, 173, 106954. [Google Scholar] [CrossRef]

- Jubinville, D.; Abdelwahab, M.; Mohanty, A.K.; Misra, M. Comparison in composite performance after thermooxidative aging of injection molded polyamide 6 with glass fiber, talc, and a sustainable biocarbon filler. J. Appl. Polym. Sci. 2020, 137, 48618. [Google Scholar] [CrossRef]

- Halim, K.A.A.; Farrell, J.B.; Kennedy, J.E. Preparation and characterisation of polyamide 11/montmorillonite (MMT) nanocomposites for use in angioplasty balloon applications. Mater. Chem. Phys. 2013, 143, 336–348. [Google Scholar] [CrossRef]

- Guo, F.; Aryana, S.; Han, Y.; Jiao, Y. A Review of the Synthesis and Applications of Polymer–Nanoclay Composites. Appl. Sci. 2018, 8, 1696. [Google Scholar] [CrossRef] [Green Version]

- Cazan, C.; Enesca, A.; Andronic, L. Synergic Effect of TiO2 Filler on the Mechanical Properties of Polymer Nanocomposites. Polymers 2021, 13, 2017. [Google Scholar] [CrossRef]

- Brząkalski, D.; Przekop, R.E.; Frydrych, M.; Pakuła, D.; Dobrosielska, M.; Sztorch, B.; Marciniec, B. Where ppm Quantities of Silsesquioxanes Make a Difference—Silanes and Cage Siloxanes as TiO2 Dispersants and Stabilizers for Pigmented Epoxy Resins. Materials 2022, 15, 494. [Google Scholar] [CrossRef] [PubMed]

- Oliver-Ortega, H.; Méndez, J.A.; Mutjé, P.; Tarrés, Q.; Espinach, F.X.; Ardanuy, M. Evaluation of Thermal and Thermomechanical Behaviour of Bio-Based Polyamide 11 Based Composites Reinforced with Lignocellulosic Fibres. Polymers 2017, 9, 522. [Google Scholar] [CrossRef] [Green Version]

- Bajwa, D.S.; Adhikari, S.; Shojaeiarani, J.; Bajwa, S.G.; Pandey, P.; Shanmugam, S.R. Characterization of bio-carbon and ligno-cellulosic fiber reinforced bio-composites with compatibilizer. Constr. Build. Mater. 2019, 204, 193–202. [Google Scholar] [CrossRef]

- Balaji, K.V.; Shirvanimoghaddam, K.; Rajan, G.S.; Ellis, A.V.; Naebe, M. Surface treatment of Basalt fiber for use in automotive composites. Mater. Today Chem. 2020, 17, 100334. [Google Scholar]

- Saleem, A.; Medina, L.; Skrifvars, M. Mechanical performance of hybrid bast and basalt fibers reinforced polymer composites. J. Polym. Res. 2020, 27, 61. [Google Scholar] [CrossRef]

- More, A.P. Flax fiber–based polymer composites: A review. Adv. Compos. Hybrid Mater. 2022, 5, 1–20. [Google Scholar] [CrossRef]

- Ediz, N.; Bentli, I.; Tatar, I. Improvement in filtration characteristics of diatomite by calcination. Int. J. Miner. Process. 2010, 94, 129–134. [Google Scholar] [CrossRef]

- Choińska, E.; Sobiecki, J.R.; Święszkowski, W.; Kurzydłowski, K.J. Silanization as a method for improving PLLA coating adhesion to the intramedullary nails—Preliminary studies. Eng. Biomater. 2010, 96–98, 88–92. [Google Scholar]

- Watanabe, R.; Sugahara, A.; Hagihara, H.; Sakamoto, K.; Nakajima, Y.; Naganawa, Y. Mechanical Properties of Multiscale Graphene Oxide/Basalt Fiber/Epoxy Composites. Fibers Polym. 2019, 20, 138–146. [Google Scholar]

- Watanabe, R.; Sugahara, A.; Hagihara, H.; Sakamoto, K.; Nakajima, Y.; Naganawa, Y. Polypropylene-Based Nanocomposite with Enhanced Aging Stability by Surface Grafting of Silica Nanofillers with a Silane Coupling Agent Containing an Antioxidant. ACS Omega 2020, 5, 12431–12439. [Google Scholar] [CrossRef]

- Ahangaran, F.; Navarchian, A.H. Recent advances in chemical surface modification of metal oxide nanoparticles with silane coupling agents: A review. Adv. Colloid Interface Sci. 2020, 286, 102298. [Google Scholar] [CrossRef] [PubMed]

- Dobrosielska, M.; Dobrucka, R.; Kozera, P.; Brząkalski, D.; Gabriel, E.; Głowacka, J.; Jałbrzykowski, M.; Kurzydłowski, K.J.; Przekop, R.E. Beeswax as a natural alternativeto synthetic waxes for fabricationof PLA/diatomaceous earthcomposites. Sci. Rep. 2023, 13, 1161. [Google Scholar] [CrossRef] [PubMed]

- Dobrosielska, M.; Dobrucka, R.; Pajewska-Szmyt, M.; Kozera, P.; Gabriel, E.; Głowacka, J.; Brząkalski, D.; Kurzydłowski, K.J.; Przekop, R.E. Effect of Wax Additives and Silanization of Diatom Surfaces on Thermomechanical Properties of Polylactide Composites. Polymers 2022, 14, 5511. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Lim, K.P.; Tjiu, W.C.; Pramoda, K.P.; Chen, Z.-K. Preparation and characterization of nylon 11/organoclay nanocomposites. Polymer 2003, 44, 3529–3535. [Google Scholar] [CrossRef]

- Mancic, L.; Pontón, P.I.; Letichevsky, S.; Costa, A.M.; Marinkovic, B.A.; Rizzo, F.C. Application of silane grafted titanate nanotubes in reinforcing of polyamide 11 composites. Compos. Part B Eng. 2016, 93, 153–162. [Google Scholar] [CrossRef]

- Benobeidallah, B.; Benhamida, A.; Dorigato, A.; Sola, A.; Messori, M.; Pegoretti, A. Structure and Properties of Polyamide 11 Nanocomposites Filled with Fibrous Palygorskite Clay. JRM 2019, 7, 1. [Google Scholar] [CrossRef] [Green Version]

- Cong, D.V.; Giang, N.V.; Trung, T.H.; Hoang, T.; Lam, T.D. Biocomposites from polyamide 11 reinforced by organic silane modified jute fibers: Fabrication and characterization. J. Appl. Polym. Sci. 2022, 139, 11. [Google Scholar] [CrossRef]

- Dobrosielska, M.; Dobrucka, R.; Kozera, P.; Kozera, R.; Kołodziejczak, M.; Gabriel, E.; Głowacka, J.; Jałbrzykowski, M.; Kurzydłowski, K.J.; Przekop, R.E. Biocomposites Based on Polyamide 11/Diatoms with Different Sized Frustules. Polymers 2022, 14, 3153. [Google Scholar] [CrossRef]

- Dobrosielska, M.; Dobrucka, R.; Brząkalski, D.; Frydrych, M.; Kozera, P.; Wieczorek, M.; Jałbrzykowski, M.; Kurzydłowski, K.J.; Przekop, R.E. Influence of Diatomaceous Earth Particle Size on Mechanical Properties of PLA/Diatomaceous Earth Composites. Materials 2022, 15, 3607. [Google Scholar] [CrossRef]

- PN-EN ISO 527-1:2020-01; Plastics—Determination of Mechanical Properties under Static Stretching—Part 1: General Principles. PKN: Płock, Poland, 2020.

- EN ISO 178:2010; Plastics—Determination of Flexural Properties. PKN: Płock, Poland, 2010.

- EN ISO 179-1:2010; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. PKN: Płock, Poland, 2010.

- PN-EN ISO 178:2019-06; Plastics—Determination of Bending Properties. PKN: Płock, Poland, 2019.

- EN ISO 1133-1:2022; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method. PKN: Płock, Poland, 2022.

- Patel, A.K.; Bajpai, R.; Keller, J.M. On the crystallinity of PVA/palm leaf biocomposite using DSC and XRD techniques. Microsyst. Technol. 2013, 20, 41–49. [Google Scholar] [CrossRef]

- EN ISO 2813:2014; Paints and Varnishes—Determination of Gloss Value at 20°, 60° and 85°. PKN: Płock, Poland, 2014.

- Zemnukhova, L.A.; Panasenko, A.E.; Artem’yanov, A.P.; Tsoy, E.A. Dependence of Porosity of Amorphous Silicon Dioxide Prepared from Rice Straw on Plant Variety. BioResources 2015, 10, 3713–3723. [Google Scholar] [CrossRef] [Green Version]

- Wardhani, G.; Nurlela, N.; Azizah, M. Silica Content and Structure from Corncob Ash with Various Acid Treatment(HCl, HBr, and Citric Acid. Molekul 2017, 12, 174–181. [Google Scholar] [CrossRef] [Green Version]

- Penga, Z.-W.; Hsieh, P.-T.; Lin, Y.-J.; Huang, C.-J.; Li, C.-C. Investigation on blistering behavior for n-type silicon solar cells. 5th International Conference on Silicon Photovoltaics, Silicon PV. Energy Procedia 2015, 77, 827–831. [Google Scholar] [CrossRef] [Green Version]

- Reka, A.A.; Pavlovski, B.; Fazlija, E.; Berisha, A.; Pacarizi, M.; Daghmehchi, M.; Sacalis, C.; Jovanovski, G.; Makreski, P.; Oral, A. Diatomaceous Earth: Characterization, thermal modification, and application. Open Chem. 2021, 19, 451–461. [Google Scholar] [CrossRef]

- Ricou, P.; Pinel, E.; Juhasz, N. Temperature Experiments for Improved Accuracy in The Calculation of Polyamide-11 Crystallinity by X-ray Diffraction, International Centre for Diffraction Data. Adv. X-ray Anal. 2005, 48, 170–175. [Google Scholar]

- Flores-Rojas, E.; Schnabel, D.; Justo-Cabrera, E.; Solorza-Feria, O.; Poggi-Varaldo, H.M.; Breton-Deval, L. Using Nano Zero-Valent Iron Supported on Diatomite to Remove Acid Blue Dye: Synthesis, Characterization, and Toxicology Test. Sustainability 2021, 13, 13899. [Google Scholar] [CrossRef]

- Lutyński, M.; Sakiewicz, P.; Lutyńska, S. Characterization of Diatomaceous Earth and Halloysite Resources of Poland. Minerals 2019, 9, 670. [Google Scholar] [CrossRef] [Green Version]

- Ilia, I.K.; Stamatakis, M.G.; Perraki, T.S. Mineralogy and technical properties of clayey diatomites from north and central Greece. Cent. Eur. J. Geosci. 2009, 1, 393–403. [Google Scholar] [CrossRef]

- Thomas, P.; Ashokbabu, A.; Vaish, R. Structural, thermal and dielectric properties and thermal degradation kinetics of nylon 11/CaCu3Ti4O12 (CCTO) nanocomposites. J. Therm. Anal. Calorim. 2019, 141, 1123–1135. [Google Scholar] [CrossRef]

- Moriyama, T.; Sumiya, N.; Saito, T. Impact strength improvement of polyamide 11 without flexural modulus reduction by dispersing poly(butylene succinate) particles. Polym. J. 2016, 48, 221–224. [Google Scholar] [CrossRef]

- Latko, P.; Kolbuk, D.; Kozera, R.; Boczkowska, A. Microstructural Characterization and Mechanical Properties of PA11 Nanocomposite Fibers. J. Mater. Eng. Perform. 2016, 25, 68–75. [Google Scholar] [CrossRef] [Green Version]

- Bahrami, M.; Abenojar, J.; Martínez, M.A. Comparative Characterization of Hot-Pressed Polyamide 11 and 12: Mechanical, Thermal and Durability Properties. Polymers 2021, 13, 3553. [Google Scholar] [CrossRef]

- Stoclet, G.; Sclavons, M.; Devaux, J. Relations between structure and property of polyamide 11 nanocomposites based on raw clays elaborated by water-assisted extrusion. J. Appl. Polym. Sci. 2013, 127, 4809–4824. [Google Scholar] [CrossRef]

- Castagnet, S.; Thilly, L. High-pressure dependence of structural evolution in polyamide 11 during annealing. J. Polym. Sci. Part B Polym. Phys. 2009, 47, 2015–2025. [Google Scholar] [CrossRef]

- Mancic, L.; Osman, R.F.M.; Costa, A.M.L.M.; d’Almeida, J.R.M.; Marinkovic, B.A.; Rizzo, F.C. Thermal and mechanical properties of polyamide 11 based composites reinforced with surface modified titanate nanotubes. Mater. Des. 2015, 83, 459–467. [Google Scholar] [CrossRef]

- Da Cruz, B.D.S.M.; Tienne, L.G.P.; Gondim, F.F.; da Silva Candido, L.; Chaves, E.G.; Marques, M.D.F.V.; da Luz, F.S.; Monteiro, S.N. Graphene nanoplatelets reinforced Polyamide-11 nanocomposites thermal stability and aging for application in flexible pipelines. J. Mater. Res. Technol. 2022, 18, 1842–1854. [Google Scholar] [CrossRef]

- Nash, N.H.; Ray, D.; Young, T.M.; Stanley, W.F. The influence of hydrothermal conditioning on the Mode-I, thermal and flexural properties of Carbon/Benzoxazine composites with a thermoplastic toughening interlayer. Compos. Part A Appl. Sci. Manuf. 2015, 76, 135–144. [Google Scholar] [CrossRef]

| Temperature at Heating Zones (°C) | Nozzle | TS6 | TS5 | TS4 | TS3 | TS2 | TS1 |

| 235 | 250 | 250 | 255 | 255 | 250 | 250 | |

| Torque, M (Nm) | Nozzle Pressure, P50 (bar) | Revolutions per Minute, N (1/min) | |||||

| 20–78 | 0.6 | 14 | |||||

| Temperature [°C] | Nozzle | Zone 3 | Zone 2 | Zone 1 | Traverse |

| 215 | 220 | 215 | 210 | 40 | |

| Mold Closing Force (kN) | Clamping Time (s) | Cooling Down Time (s) | Screw Diameter (mm) | ||

| 800 | 4 | 30 | 25 | ||

| Biocomposite Type | Filler Concentration | Abbreviation |

|---|---|---|

| PA11 + original diatoms + 1% wt. APTES[a] | 2.5% | 2.5OBS |

| 5% | 5OBS | |

| 10% | 10OBS | |

| 20% | 20OBS | |

| PA11 + fractionated diatoms + 1% wt. APTES[a] | 2.5% | 2.5OFS |

| 5% | 5OFS | |

| 10% | 10OFS | |

| 20% | 20OFS | |

| PA11 | - | PA11 |

| 1st Heating | Cooling | 2nd Heating | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sample | Tg (°C) | Tm (°C) | Hm (J/g) | Χ (%) | Tc (°C) | Tm1 (°C) | Tm2 (°C) | Hm (J/g) | Χ (%) | |

| PA11 | 48.7 | 190.0 | 56.9 | 27.6 | 163.9 | 181.4 | 189.0 | 51.6 | 25.0 | |

| 5OBS | 47.9 | 189.4 | 52.0 | 26.6 | 167.8 | 183.4 | 188.5 | 50.5 | 25.8 | |

| 5OFS | 49.8 | 188.7 | 48.8 | 24.9 | 167.8 | 182.7 | 188.5 | 51.7 | 26.4 | |

| 20OBS20OBU13 | 46.9 | 188.9 | 44.3 | 26.9 | 169.5 | - | 188.5 | 45.7 | 27.7 | |

| 20OFS | 48.2 | 188.5 | 34.6 | 21.0 | 169.2 | - | 188.6 | 32.1 | 19.5 | |

| 1st Heating | Cooling | 2nd Heating | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sample | Tg (°C) | Tm (°C) | Hm (J/g) | Χ (%) | Tc (°C) | Tm1 (°C) | Tm2 (°C) | Hm (J/g) | Χ (%) | |

| PA11 | 48.7 | 190.0 | 56.9 | 27.6 | 163.9 | 181.4 | 189.0 | 51.6 | 25.0 | |

| 5OB | 46.8 | 189.5 | 44.6 | 22.8 | 167.6 | 182.6 | 189.0 | 45.0 | 23.0 | |

| 5OF | 44.0 | 189.5 | 48.7 | 24.9 | 167.1 | 182.8 | 188.6 | 50.3 | 25.7 | |

| 20OB | 44.6 | 187.6 | 36.4 | 22.1 | 167.8 | - | 186.6 | 44.1 | 26.8 | |

| 20OF | 46.6 | 188.7 | 39.2 | 23.8 | 169.7 | - | 188.4 | 44.7 | 27.1 | |

| Sample | Tg (°C) | E′ (MPa) | tan δ |

|---|---|---|---|

| PA11 | 59.6 | 1409 | 0.194 |

| 5OB | 66.4 | 1649 | 0.214 |

| 5OBS | 63.2 | 1291 | 0.219 |

| 5OF | 64.2 | 1534 | 0.227 |

| 5OFS | 64.2 | 1560 | 0.214 |

| 20OB | 63.4 | 2222 | 0.196 |

| 20OBS | 64.0 | 2340 | 0.196 |

| 20OF | 65.8 | 2062 | 0.196 |

| 20OFS | 66.9 | 2190 | 0.187 |

| Gloss 60° [GU] | SD [GU] | Gloss 60° [GU] | SD [GU] | Gloss 60° [GU] | SD [GU] | Gloss 60° [GU] | SD [GU] | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.5OB | 24.53 | 0.50 | 2.5OBS | 22.20 | 0.36 | 2.5OF | 23.00 | 0.08 | 2.5OFS | 22.97 | 1.13 |

| 5OB | 21.90 | 0.54 | 5OBS | 22.30 | 1.12 | 5OF | 35.70 | 1.13 | 5OFS | 20.70 | 0.36 |

| 10OB | 17.50 | 2.12 | 10OBS | 21.30 | 1.45 | 10OF | 26.10 | 0.75 | 10OFS | 27.03 | 0.62 |

| 20OB | 15.07 | 0.74 | 20OBS | 12.47 | 0.17 | 20OF | 16.57 | 0.12 | 20OFS | 15.47 | 0.42 |

| PA11 | 31.50 | 1.93 | |||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobrosielska, M.; Dobrucka, R.; Brząkalski, D.; Kozera, P.; Martyła, A.; Gabriel, E.; Kurzydłowski, K.J.; Przekop, R.E. Polyamide 11 Composites Reinforced with Diatomite Biofiller—Mechanical, Rheological and Crystallization Properties. Polymers 2023, 15, 1563. https://doi.org/10.3390/polym15061563

Dobrosielska M, Dobrucka R, Brząkalski D, Kozera P, Martyła A, Gabriel E, Kurzydłowski KJ, Przekop RE. Polyamide 11 Composites Reinforced with Diatomite Biofiller—Mechanical, Rheological and Crystallization Properties. Polymers. 2023; 15(6):1563. https://doi.org/10.3390/polym15061563

Chicago/Turabian StyleDobrosielska, Marta, Renata Dobrucka, Dariusz Brząkalski, Paulina Kozera, Agnieszka Martyła, Ewa Gabriel, Krzysztof J. Kurzydłowski, and Robert E. Przekop. 2023. "Polyamide 11 Composites Reinforced with Diatomite Biofiller—Mechanical, Rheological and Crystallization Properties" Polymers 15, no. 6: 1563. https://doi.org/10.3390/polym15061563

APA StyleDobrosielska, M., Dobrucka, R., Brząkalski, D., Kozera, P., Martyła, A., Gabriel, E., Kurzydłowski, K. J., & Przekop, R. E. (2023). Polyamide 11 Composites Reinforced with Diatomite Biofiller—Mechanical, Rheological and Crystallization Properties. Polymers, 15(6), 1563. https://doi.org/10.3390/polym15061563