All-Cellulose Nanofiber-Based Sustainable Triboelectric Nanogenerators for Enhanced Energy Harvesting

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

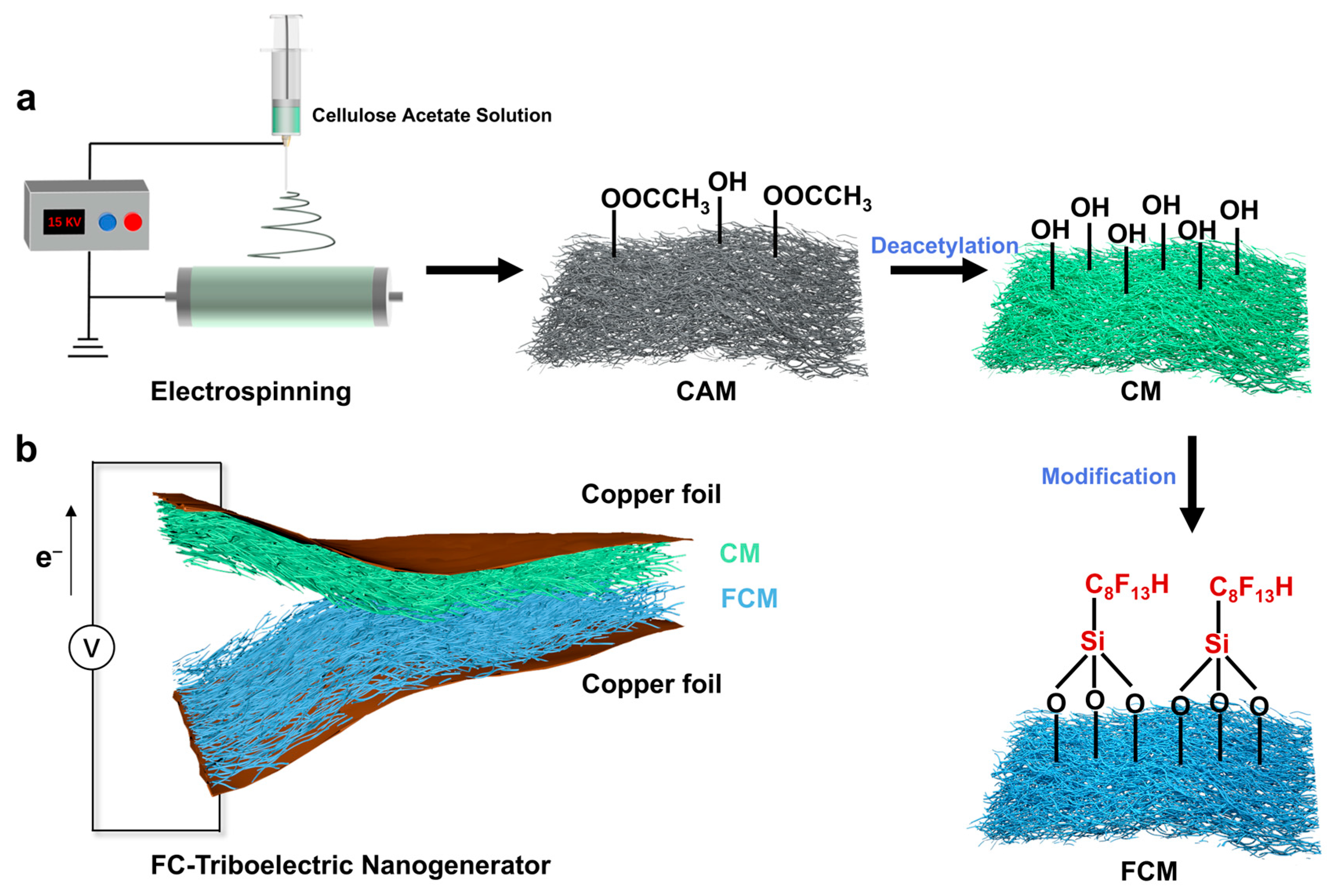

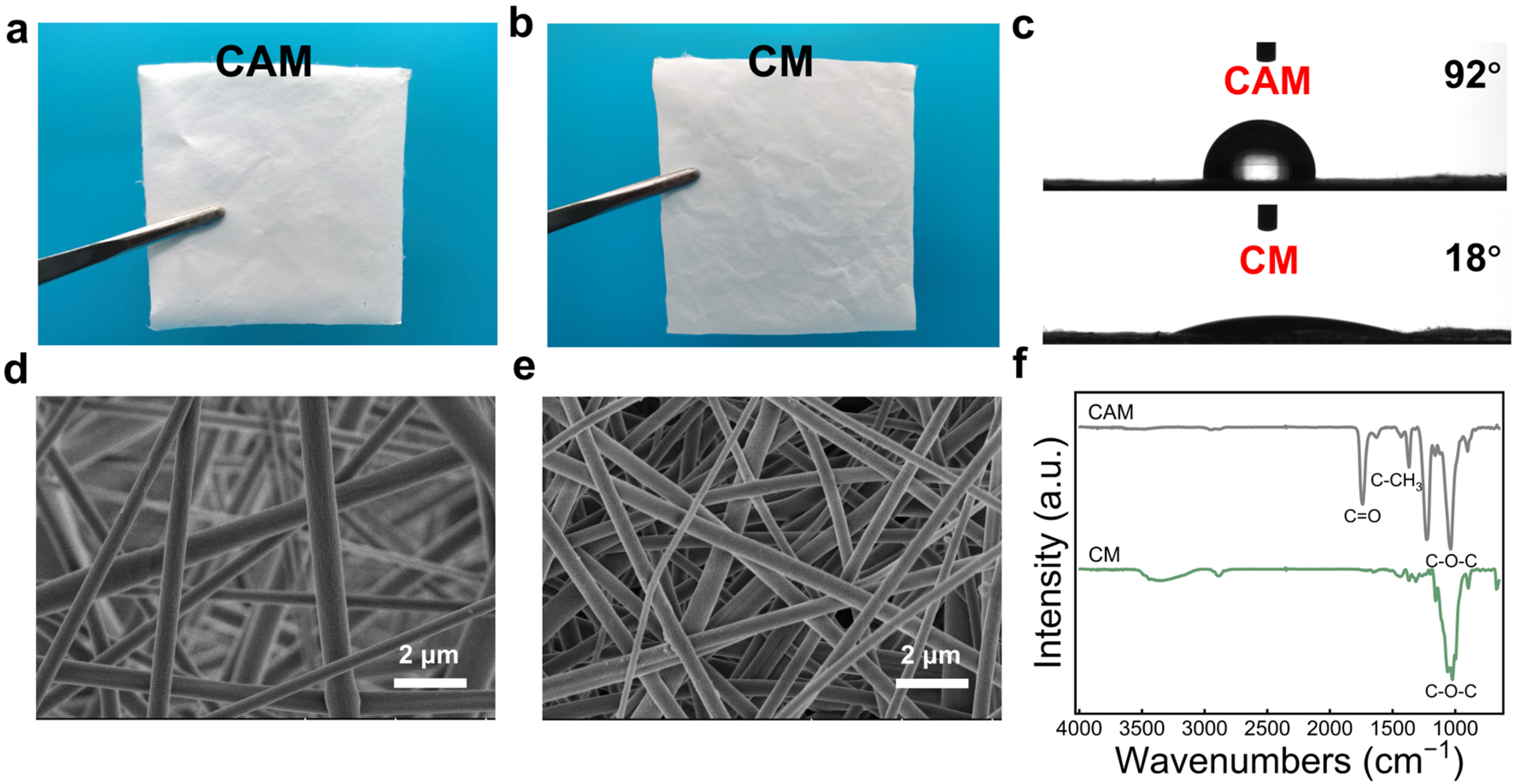

2.2. Preparation of the Cellulose Acetate Membrane (CAM)

2.3. Preparation of the Cellulose Membrane (CM)

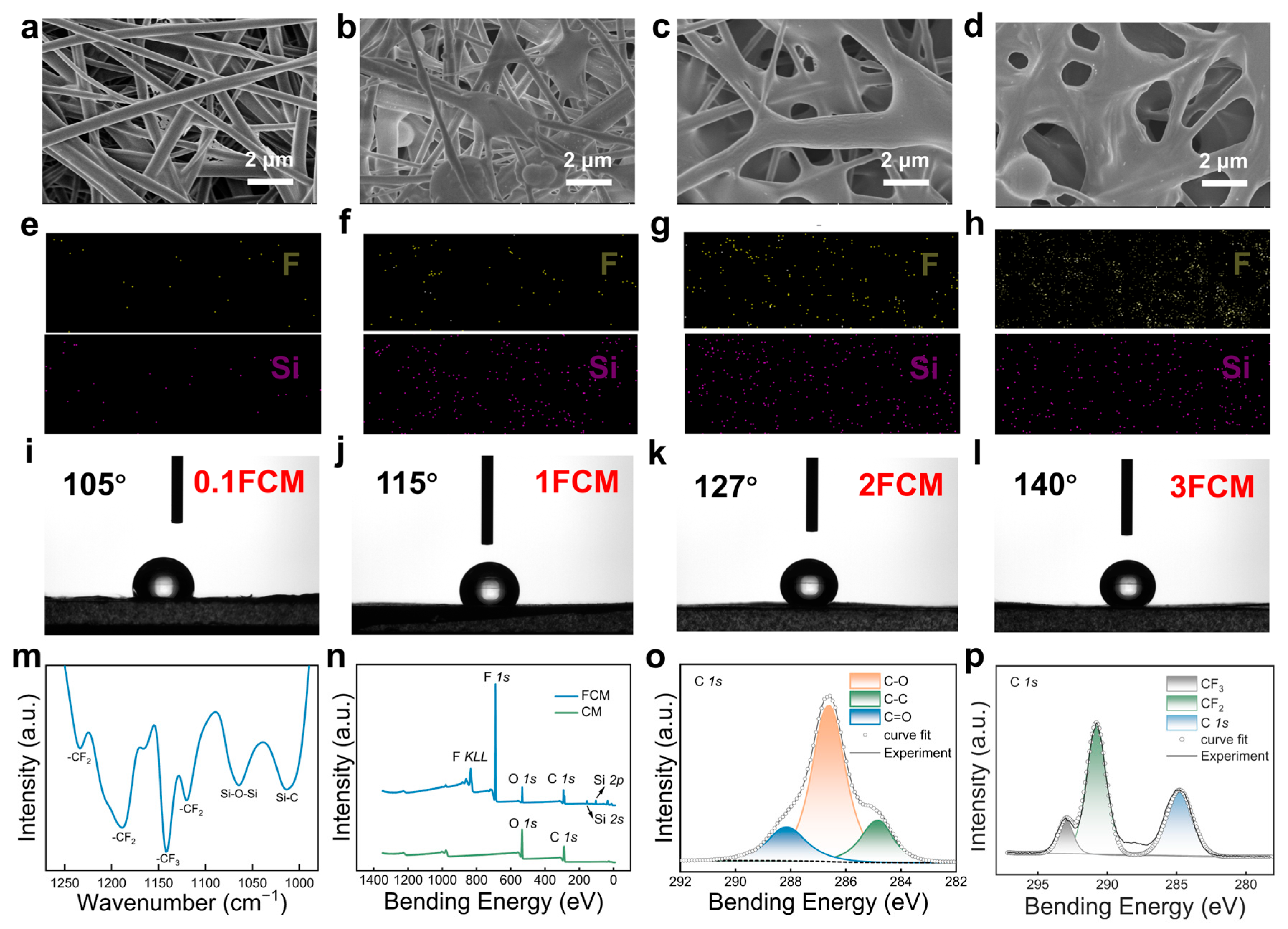

2.4. Preparation of the Fluorinated Cellulose Membrane (FCM)

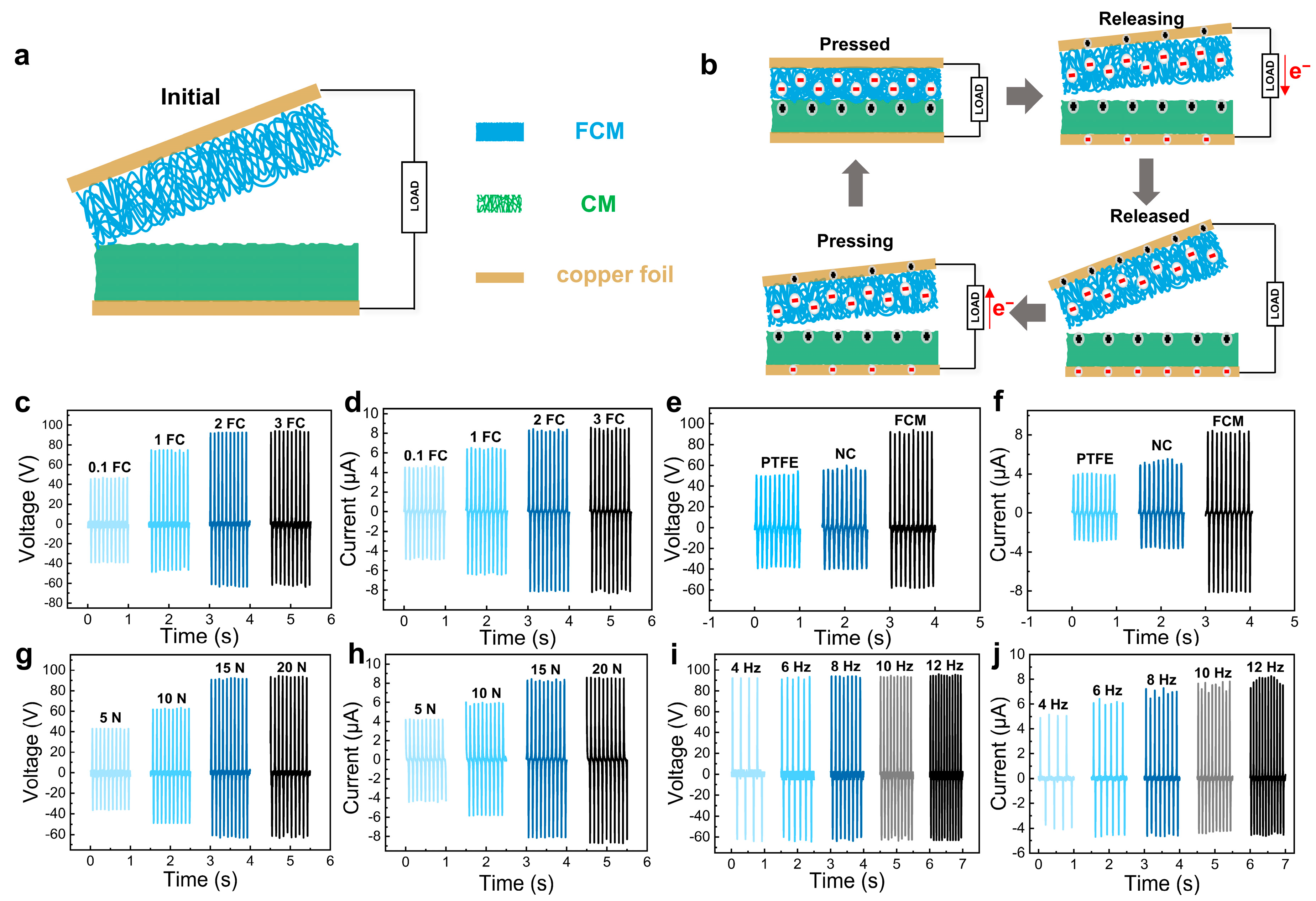

2.5. Fabrication of FCM/CM-Based Triboelectric Nanogenerator (FC-TENG)

2.6. Characterizations

2.7. Triboelectric Generation Performance Experiments

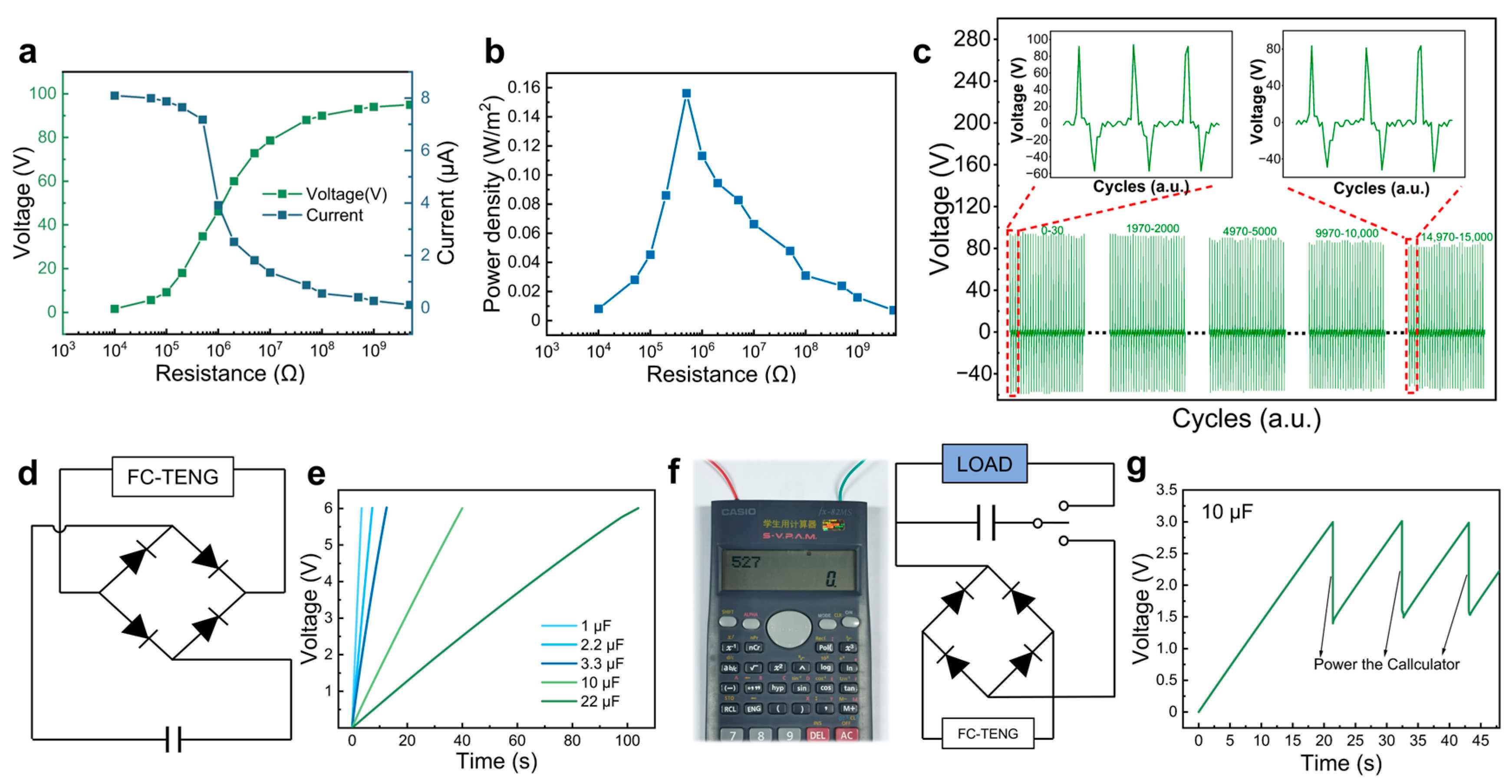

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Li, F.; Li, Y.; Novoselov, K.S.; Liang, F.; Meng, J.; Ho, S.-H.; Zhao, T.; Zhou, H.; Ahmad, A.; Zhu, Y.; et al. Bioresource Upgrade for Sustainable Energy, Environment, and Biomedicine. Nano-Micro Lett. 2023, 15, 35. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Chen, L.; Khoo, K.S.; Gupta, V.K.; Sharma, M.; Show, P.L.; Yap, P.-S. Exploitation of Lignocellulosic-Based Biomass Biorefinery: A Critical Review of Renewable Bioresource, Sustainability and Economic Views. Biotechnol. Adv. 2023, 69, 108265. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Luo, R.; Bai, Y.; Shao, J.; Ji, J.; Wang, E.; Li, Z.; Meng, H.; Li, Z. Molecular Doped Biodegradable Triboelectric Nanogenerator with Optimal Output Performance. Adv. Funct. Mater. 2024, 2400277. [Google Scholar] [CrossRef]

- Zi, Y.; Niu, S.; Wang, J.; Wen, Z.; Tang, W.; Wang, Z.L. Standards and Figure-oFCMerits for Quantifying the Performance of Triboelectric Nanogenerators. Nat. Commun. 2015, 6, 8376. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.-R.; Tian, Z.-Q.; Lin Wang, Z. Flexible Triboelectric Generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Hao, Y.; Yang, J.; Niu, Z.; Wang, M.; Liu, H.; Qin, Y.; Zhang, C.; Li, X. High-Output Triboelectric Nanogenerator Based on L-Cystine/Nylon Composite Nanofiber for Human Bio-Mechanical Energy Harvesting. Nano Energy 2023, 118, 108964. [Google Scholar] [CrossRef]

- Zheng, Q.; Fang, L.; Guo, H.; Yang, K.; Cai, Z.; Meador, M.A.B.; Gong, S. Highly Porous Polymer Aerogel Film-Based Triboelectric Nanogenerators. Adv. Funct. Mater. 2018, 28, 1706365. [Google Scholar] [CrossRef]

- Niu, S.; Wang, Z.L. Theoretical Systems of Triboelectric Nanogenerators. Nano Energy 2015, 14, 161–192. [Google Scholar] [CrossRef]

- Bhatta, T.; Maharjan, P.; Cho, H.; Park, C.; Yoon, S.H.; Sharma, S.; Salauddin, M.; Rahman, M.T.; Rana, S.S.; Park, J.Y. High-Performance Triboelectric Nanogenerator Based on MXene Functionalized Polyvinylidene Fluoride Composite Nanofibers. Nano Energy 2021, 81, 105670. [Google Scholar] [CrossRef]

- Chu, Y.; Han, R.; Meng, F.; Cao, Z.; Wang, S.; Dong, K.; Yang, S.; Liu, H.; Ye, X.; Tang, F. Theoretical Study on the Output of Contact-Separation Triboelectric Nanogenerators with Arbitrary Charging and Grounding Conditions. Nano Energy 2021, 89, 106383. [Google Scholar] [CrossRef]

- Yang, B.; Zeng, W.; Peng, Z.; Liu, S.; Chen, K.; Tao, X. A Fully Verified Theoretical Analysis of Contact-Mode Triboelectric Nanogenerators as a Wearable Power Source. Adv. Energy Mater. 2016, 6, 1600505. [Google Scholar] [CrossRef]

- Liao, H.; Na, J.; Zhou, W.; Hur, S.; Chien, P.M.; Wang, C.; Wang, L.; Yamauchi, Y.; Yuan, Z. Enhancing Energy Harvesting Performance and Sustainability of Cellulose-Based Triboelectric Nanogenerators: Strategies for Performance Enhancement. Nano Energy 2023, 116, 108769. [Google Scholar] [CrossRef]

- Meng, X.; Cai, C.; Luo, B.; Liu, T.; Shao, Y.; Wang, S.; Nie, S. Rational Design of Cellulosic Triboelectric Materials for Self-Powered Wearable Electronics. Nano-Micro Lett. 2023, 15, 124. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Daoud, W.A. Triboelectric and Piezoelectric Effects in a Combined Tribo-Piezoelectric Nanogenerator Based on an Interfacial ZnO Nanostructure. Adv. Funct. Mater. 2016, 26, 8194–8201. [Google Scholar] [CrossRef]

- Feng, Y.; Zheng, Y.; Ma, S.; Wang, D.; Zhou, F.; Liu, W. High Output Polypropylene Nanowire Array Triboelectric Nanogenerator through Surface Structural Control and Chemical Modification. Nano Energy 2016, 19, 48–57. [Google Scholar] [CrossRef]

- Park, H.; Oh, S.-J.; Kim, M.; Lee, C.; Joo, H.; Bae, J.W.; Lee, J.-H. Plasticizer Structural Effect for Sustainable and High-Performance PVC Gel-Based Triboelectric Nanogenerators. Nano Energy 2023, 114, 108615. [Google Scholar] [CrossRef]

- Zhang, Y.; Zou, J.; Wang, S.; Hu, X.; Liu, Z.; Feng, P.; Jing, X.; Liu, Y. Tailoring Nanostructured MXene to Adjust Its Dispersibility in Conductive Hydrogel for Self-Powered Sensors. Compos. Part B Eng. 2024, 272, 111191. [Google Scholar] [CrossRef]

- He, P.; Chen, W.; Li, J.; Zhang, H.; Li, Y.; Wang, E. Keggin and Dawson Polyoxometalates as Electrodes for Flexible and Transparent Piezoelectric Nanogenerators to Efficiently Utilize Mechanical Energy in the Environment. Sci. Bull. 2020, 65, 35–44. [Google Scholar] [CrossRef]

- Jian, G.; Meng, Q.; Jiao, Y.; Meng, F.; Cao, Y.; Wu, M. Enhanced Performances of Triboelectric Nanogenerators by Filling Hierarchical Flower-like TiO2 Particles into Polymethyl Methacrylate Film. Nanoscale 2020, 12, 14160–14170. [Google Scholar] [CrossRef]

- Chandrarathna, S.C.; Graham, S.A.; Ali, M.; Ranaweera, A.L.A.K.; Karunarathne, M.L.; Yu, J.S.; Lee, J. Analysis and Experiment of Self-Powered, Pulse-Based Energy Harvester Using 400 V FEP-Based Segmented Triboelectric Nanogenerators and 98.2% Tracking Efficient Power Management IC for Multi-Functional IoT Applications. Adv. Funct. Mater. 2023, 33, 2213900. [Google Scholar] [CrossRef]

- Zheng, Z.; Yu, D.; Wang, B.; Guo, Y. Ultrahigh Sensitive, Eco-Friendly, Transparent Triboelectric Nanogenerator for Monitoring Human Motion and Vehicle Movement. Chem. Eng. J. 2022, 446, 137393. [Google Scholar] [CrossRef]

- Han, G.H.; Lee, S.H.; Gao, J.; Shin, H.S.; Lee, J.W.; Choi, K.J.; Yang, Y.; Song, H.-C.; Kim, Y.; Baik, J.M. Sustainable Charged Composites with Amphiphobic Surfaces for Harsh Environment–Tolerant Non-Contact Mode Triboelectric Nanogenerators. Nano Energy 2023, 112, 108428. [Google Scholar] [CrossRef]

- Bhatta, T.; Sharma, S.; Shrestha, K.; Shin, Y.; Seonu, S.; Lee, S.; Kim, D.; Sharifuzzaman, M.; Rana, S.S.; Park, J.Y. Siloxene/PVDF Composite Nanofibrous Membrane for High-Performance Triboelectric Nanogenerator and Self-Powered Static and Dynamic Pressure Sensing Applications. Adv. Funct. Mater. 2022, 32, 2202145. [Google Scholar] [CrossRef]

- Yu, B.; Yu, H.; Wang, H.; Zhang, Q.; Zhu, M. High-Power Triboelectric Nanogenerator Prepared from Electrospun Mats with Spongy Parenchyma-like Structure. Nano Energy 2017, 34, 69–75. [Google Scholar] [CrossRef]

- Yu, B.; Yu, H.; Huang, T.; Wang, H.; Zhu, M. A Biomimetic Nanofiber-Based Triboelectric Nanogenerator with an Ultrahigh Transfer Charge Density. Nano Energy 2018, 48, 464–470. [Google Scholar] [CrossRef]

- Mao, Y.; Zhang, N.; Tang, Y.; Wang, M.; Chao, M.; Liang, E. A Paper Triboelectric Nanogenerator for Self-Powered Electronic Systems. Nanoscale 2017, 9, 14499–14505. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Soin, N.; Prashanthi, K.; Chen, J.; Dong, S.; Zhou, E.; Zhu, Z.; Narasimulu, A.A.; Montemagno, C.D.; Yu, L.; et al. Emulsion Electrospinning of Polytetrafluoroethylene (PTFE) Nanofibrous Membranes for High-Performance Triboelectric Nanogenerators. ACS Appl. Mater. Interfaces 2018, 10, 5880–5891. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Oh, S.; Kim, D.; Kim, M.; Lee, C.; Joo, H.; Woo, I.; Bae, J.W.; Lee, J. Plasticized PVC-Gel Single Layer-Based Stretchable Triboelectric Nanogenerator for Harvesting Mechanical Energy and Tactile Sensing. Adv. Sci. 2022, 9, 2201070. [Google Scholar] [CrossRef] [PubMed]

- Zhao, K.; Sun, W.; Zhang, X.; Meng, J.; Zhong, M.; Qiang, L.; Liu, M.-J.; Gu, B.-N.; Chung, C.-C.; Liu, M.; et al. High-Performance and Long-Cycle Life of Triboelectric Nanogenerator Using PVC/MoS2 Composite Membranes for Wind Energy Scavenging Application. Nano Energy 2022, 91, 106649. [Google Scholar] [CrossRef]

- Kim, H.; Kim, J.; Jun, K.; Kim, J.; Seung, W.; Kwon, O.H.; Park, J.; Kim, S.; Oh, I. Silk Nanofiber-Networked Bio-Triboelectric Generator: Silk Bio-TEG. Adv. Energy Mater. 2016, 6, 1502329. [Google Scholar] [CrossRef]

- Tao, X.; Li, S.; Shi, Y.; Wang, X.; Tian, J.; Liu, Z.; Yang, P.; Chen, X.; Wang, Z.L. Triboelectric Polymer with High Thermal Charge Stability for Harvesting Energy from 200 °C Flowing Air. Adv. Funct. Mater. 2021, 31, 2106082. [Google Scholar] [CrossRef]

- Wang, S.; Cheng, A.; Liu, F.; Zhang, J.; Xia, T.; Zeng, X.; Fan, W.; Zhang, Y. Catalytic Conversion Network for Lignocellulosic Biomass Valorization: A Panoramic View. Ind. Chem. Mater. 2023, 1, 188–206. [Google Scholar] [CrossRef]

- Zhang, C.; Mo, J.; Fu, Q.; Liu, Y.; Wang, S.; Nie, S. Wood-Cellulose-Fiber-Based Functional Materials for Triboelectric Nanogenerators. Nano Energy 2021, 81, 105637. [Google Scholar] [CrossRef]

- Du, T.; Chen, Z.; Dong, F.; Cai, H.; Zou, Y.; Zhang, Y.; Sun, P.; Xu, M. Advances in Green Triboelectric Nanogenerators. Adv. Funct. Mater. 2024, 34, 2313794. [Google Scholar] [CrossRef]

- Lv, Q.; Ma, X.; Zhang, C.; Han, J.; He, S.; Liu, K.; Jiang, S. Nanocellulose-Based Nanogenerators for Sensor Applications: A Review. Int. J. Biol. Macromol. 2024, 259, 129268. [Google Scholar] [CrossRef]

- Li, T.; Li, S.X.; Kong, W.; Chen, C.; Hitz, E.; Jia, C.; Dai, J.; Zhang, X.; Briber, R.; Siwy, Z.; et al. A Nanofluidic Ion Regulation Membrane with Aligned Cellulose Nanofibers. Sci. Adv. 2019, 5, eaau4238. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Zhu, Y.; Cheng, W.; Chen, W.; Wu, Y.; Yu, H. Cellulose-Based Flexible Functional Materials for Emerging Intelligent Electronics. Adv. Mater. 2021, 33, 2000619. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Jiang, C.; Ying, Y.; Ping, J. Biotriboelectric Nanogenerators: Materials, Structures, and Applications. Adv. Energy Mater. 2020, 10, 2002001. [Google Scholar] [CrossRef]

- Wu, S.; Li, G.; Liu, W.; Yu, D.; Li, G.; Liu, X.; Song, Z.; Wang, H.; Liu, H. Fabrication of Polyethyleneimine-Paper Composites with Improved Tribopositivity for Triboelectric Nanogenerators. Nano Energy 2022, 93, 106859. [Google Scholar] [CrossRef]

- Varghese, H.; Hakkeem, H.M.A.; Chauhan, K.; Thouti, E.; Pillai, S.; Chandran, A. A High-Performance Flexible Triboelectric Nanogenerator Based on Cellulose Acetate Nanofibers and Micropatterned PDMS Films as Mechanical Energy Harvester and Self-Powered Vibrational Sensor. Nano Energy 2022, 98, 107339. [Google Scholar] [CrossRef]

- Nie, S.; Fu, Q.; Lin, X.; Zhang, C.; Lu, Y.; Wang, S. Enhanced Performance of a Cellulose Nanofibrils-Based Triboelectric Nanogenerator by Tuning the Surface Polarizability and Hydrophobicity. Chem. Eng. J. 2021, 404, 126512. [Google Scholar] [CrossRef]

- Tian, J.; Chen, X.; Wang, Z.L. Environmental Energy Harvesting Based on Triboelectric Nanogenerators. Nanotechnology 2020, 31, 242001. [Google Scholar] [CrossRef] [PubMed]

- Yao, C.; Yin, X.; Yu, Y.; Cai, Z.; Wang, X. Chemically Functionalized Natural Cellulose Materials for Effective Triboelectric Nanogenerator Development. Adv. Funct. Mater. 2017, 27, 1700794. [Google Scholar] [CrossRef]

- Lee, K.Y.; Chun, J.; Lee, J.; Kim, K.N.; Kang, N.; Kim, J.; Kim, M.H.; Shin, K.; Gupta, M.K.; Baik, J.M. Hydrophobic Sponge Structure-Based Triboelectric Nanogenerator. Adv. Mater. 2014, 26, 5037–5042. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Zhao, W.; Shi, X.; Sun, T.; Ju, J.; Tang, Y. Multifunctional Monitoring System Based on BaTiO3@CMC Aerogel-Based Triboelectric Nanogenerator. J. Electron. Mater. 2023, 52, 7124–7131. [Google Scholar] [CrossRef]

- Cui, P.; Parida, K.; Lin, M.; Xiong, J.; Cai, G.; Lee, P.S. Transparent, Flexible Cellulose Nanofibril–Phosphorene Hybrid Paper as Triboelectric Nanogenerator. Adv. Mater. Inter. 2017, 4, 1700651. [Google Scholar] [CrossRef]

- Sun, Z.; Yang, L.; Liu, S.; Zhao, J.; Hu, Z.; Song, W. A Green Triboelectric Nano-Generator Composite of Degradable Cellulose, Piezoelectric Polymers of PVDF/PA6, and Nanoparticles of BaTiO3. Sensors 2020, 20, 506. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zhang, W.; Du, G.; Fu, Q.; Mo, J.; Nie, S. Superhydrophobic Cellulosic Triboelectric Materials for Distributed Energy Harvesting. Chem. Eng. J. 2023, 452, 139259. [Google Scholar] [CrossRef]

- Shi, X.; Chen, S.; Zhang, H.; Jiang, J.; Ma, Z.; Gong, S. Portable Self-Charging Power System via Integration of a Flexible Paper-Based Triboelectric Nanogenerator and Supercapacitor. ACS Sustain. Chem. Eng. 2019, 7, 18657–18666. [Google Scholar] [CrossRef]

- Jakmuangpak, S.; Prada, T.; Mongkolthanaruk, W.; Harnchana, V.; Pinitsoontorn, S. Engineering Bacterial Cellulose Films by Nanocomposite Approach and Surface Modification for Biocompatible Triboelectric Nanogenerator. ACS Appl. Electron. Mater. 2020, 2, 2498–2506. [Google Scholar] [CrossRef]

- Roy, S.; Ko, H.-U.; Maji, P.K.; Van Hai, L.; Kim, J. Large Amplification of Triboelectric Property by Allicin to Develop High Performance Cellulosic Triboelectric Nanogenerator. Chem. Eng. J. 2020, 385, 123723. [Google Scholar] [CrossRef]

- Zhang, C.; Lin, X.; Zhang, N.; Lu, Y.; Wu, Z.; Liu, G.; Nie, S. Chemically Functionalized Cellulose Nanofibrils-Based Gear-like Triboelectric Nanogenerator for Energy Harvesting and Sensing. Nano Energy 2019, 66, 104126. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, M.; Chen, Y.; Sha, J.; Xu, Y.; Chen, S.; Xu, F. All-Cellulose Nanofiber-Based Sustainable Triboelectric Nanogenerators for Enhanced Energy Harvesting. Polymers 2024, 16, 1784. https://doi.org/10.3390/polym16131784

Cao M, Chen Y, Sha J, Xu Y, Chen S, Xu F. All-Cellulose Nanofiber-Based Sustainable Triboelectric Nanogenerators for Enhanced Energy Harvesting. Polymers. 2024; 16(13):1784. https://doi.org/10.3390/polym16131784

Chicago/Turabian StyleCao, Mengyao, Yanglei Chen, Jie Sha, Yanglei Xu, Sheng Chen, and Feng Xu. 2024. "All-Cellulose Nanofiber-Based Sustainable Triboelectric Nanogenerators for Enhanced Energy Harvesting" Polymers 16, no. 13: 1784. https://doi.org/10.3390/polym16131784

APA StyleCao, M., Chen, Y., Sha, J., Xu, Y., Chen, S., & Xu, F. (2024). All-Cellulose Nanofiber-Based Sustainable Triboelectric Nanogenerators for Enhanced Energy Harvesting. Polymers, 16(13), 1784. https://doi.org/10.3390/polym16131784