Anchor Shear Strength Damage under Varying Sand Content, Freeze-Thaw Cycles, and Axial Pressure Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

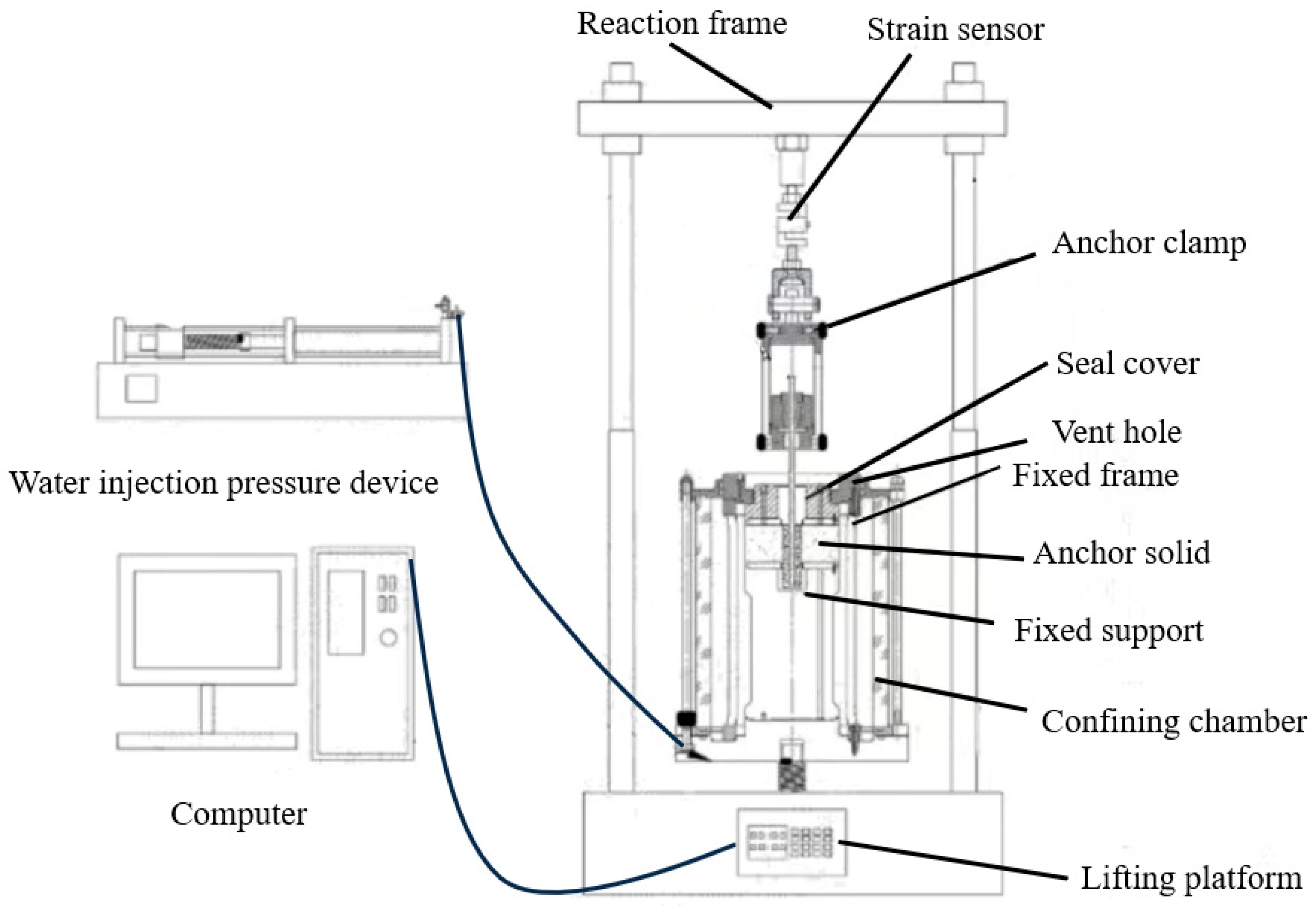

2.2. Testing Instruments

2.3. Test Method

- (1)

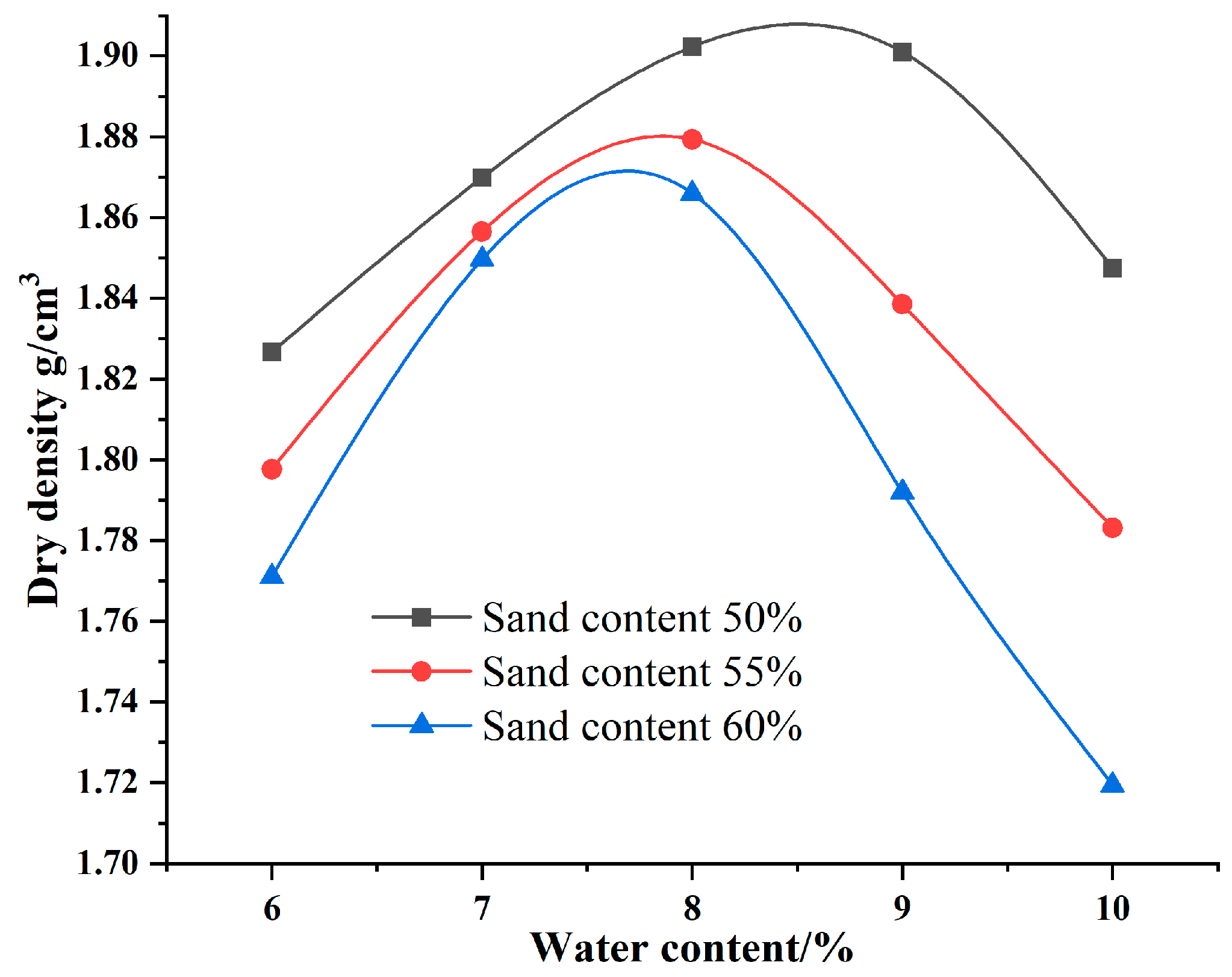

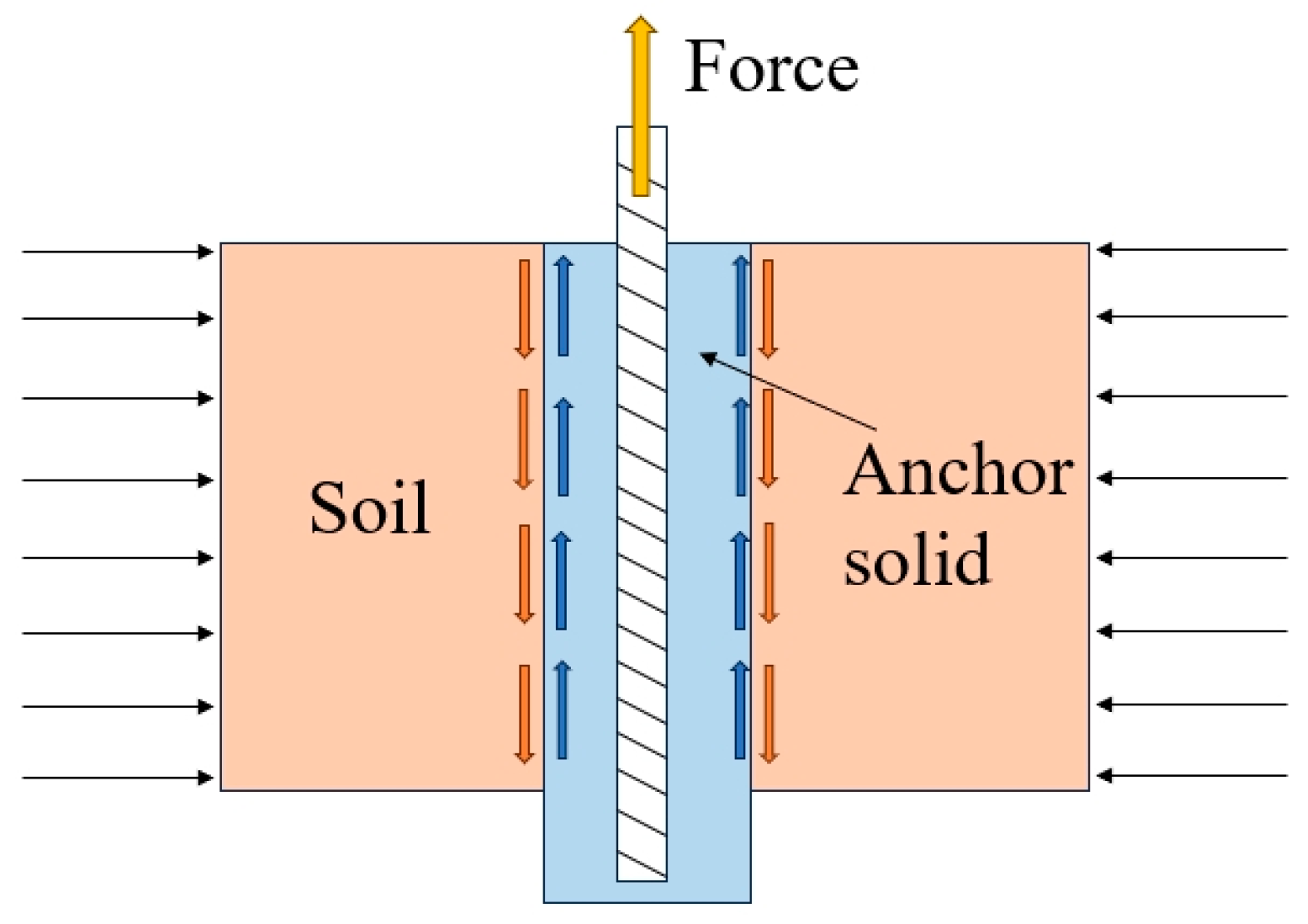

- Specimen production. The retrieved powdery clay is dried, crushed, and sieved again. A 0.075 mm sieve is used for sieving, and the sieved fine-grained soil is set aside for later use. The fine-grained soil is mixed uniformly with standard sand according to the different sand contents adopted for this work. Initial compaction experiments on soils with three different sand contents showed that the optimal moisture content varied, but all were concentrated at approximately 8%. The moisture content of the test specimens in this study is controlled at 8%. The soil mixture is prepared with an 8% moisture content to ensure even moisture distribution and minimal large clay particles. First, the compaction mould is assembled by fixing a hollow steel pipe to the base plate and connecting the cylinder wall to the bottom using bolts. Vaseline is applied to the surface of the hollow steel pipe to reduce friction with the compacted soil and facilitate smooth extraction, minimising interference with the soil. Once the compaction container is assembled, the soil is filled in five layers of a set amount of soil and compacted; compaction is stopped when the soil reaches the desired height. The compacted soil is scraped to make the layers more tightly bound. When the separation height is reached, filter paper and aluminium sheets are placed to separate the soil for later grouting and cutting, ensuring that the shear area of the anchor rod remains constant during the pull-out phase. Additional soil is poured in, and the compaction and scraping process is repeated until the soil sample is complete. The forces on the specimen are shown in Figure 3.

- (2)

- Bolt shear test system production. The demoulding process is carried out using an electric hydraulic demoulding device. After demoulding, the sample is sealed with plastic wrap and tightly wrapped with two hollow cylindrical acrylic plates around the anchor body. Rubber bands are then applied to the outer acrylic plate to provide circumferential restraint and prevent disturbance to the anchor body. The cement mortar mix ratio of standard sand−ordinary Portland cement−water is 1:1:0.45. The anchor positioning device is used to vertically place an M8 steel bar in the middle of the hole, and grouting material is made according to the mix ratio for soil anchor grouting. After thorough mixing, the grouting material is poured into the hollow soil body and compacted to prevent the formation of air bubbles in the mortar, which could affect the grouting strength. After the initial setting of the cement mortar, the specimens are cured at room temperature for 14 days. To minimise the boundary effect on the anchorage, the ratio of the soil body to the anchor body diameter and the steel bar diameter is greater than 5. The soil body has a diameter of 15 cm, the anchor body has a diameter of 3 cm, and the steel bar has a diameter of 8 mm. During the pull-out process, the soil body is subjected to circumferential confinement, which reduces the boundary effect on the anchor rod and ensures the accuracy of the test.

- (3)

- Freeze-thaw cycling. First, a cured specimen is cut, and the soil is separated along the filter paper to ensure that the bottom of the soil is smooth. The surface of the specimen is wrapped with plastic wrap and fixed in a fixed container, which was placed in a freeze-thaw cycle box. The temperature is designed to be −20° to 20°. Previous freeze-thaw cycle tests have shown that soil reaches a new stable state after 10 freeze-thaw cycles [35]. Therefore, the number of freeze-thaw cycles is set to 0, 1, 3, 8, and 11 for a total of 5 different freeze-thaw cycles. The freeze-thaw test adopts a large freeze-thaw cycle box with a temperature control range of −40° to 120° and an accuracy of ±0.1°, which can meet the test requirements. Temperature control adopts the 11 + 1 mode, which involves freezing for 11 h and stepped temperature adjustment for 1 h. The freezing and thawing stages are both 12 h to ensure that the sample can be fully frozen and thawed. Every cycle takes 24 h to complete, and after reaching the designed number of cycles is performed, the sample is removed from the box and rested for 3 h before shear testing.

- (4)

- Confining pressure setting. At the end of the freezing and thawing treatment, the solid anchor is placed into the anchor support with a hollow groove in the centre and the fixing device and confining pressure chamber are installed. The confining pressure chamber is filled when ready. The pump is used to quickly inject water, and the upper part of the confining pressure chamber has holes to remove air during the water injection stage. The bolts are tightened to close the holes when the water is about to overflow the chamber so that the entire confining pressure chamber is kept in a sealed environment. Afterwards, a pressurising device is used to pressurise the injected water. After the confining pressure reaches the set value, the confining pressure is kept stable for a period. The control and acquisition software is opened in the data acquisition terminal, and the corresponding parameters are input to pull the bolt at a steady rate of displacement. The shear displacement and shear stress in the drawing process are transmitted to the computer terminal through the acquisition system in real time for subsequent data storage and processing.

3. Results and Analysis

3.1. Shear Characteristics Tests of Anchor Rods under Static Loading

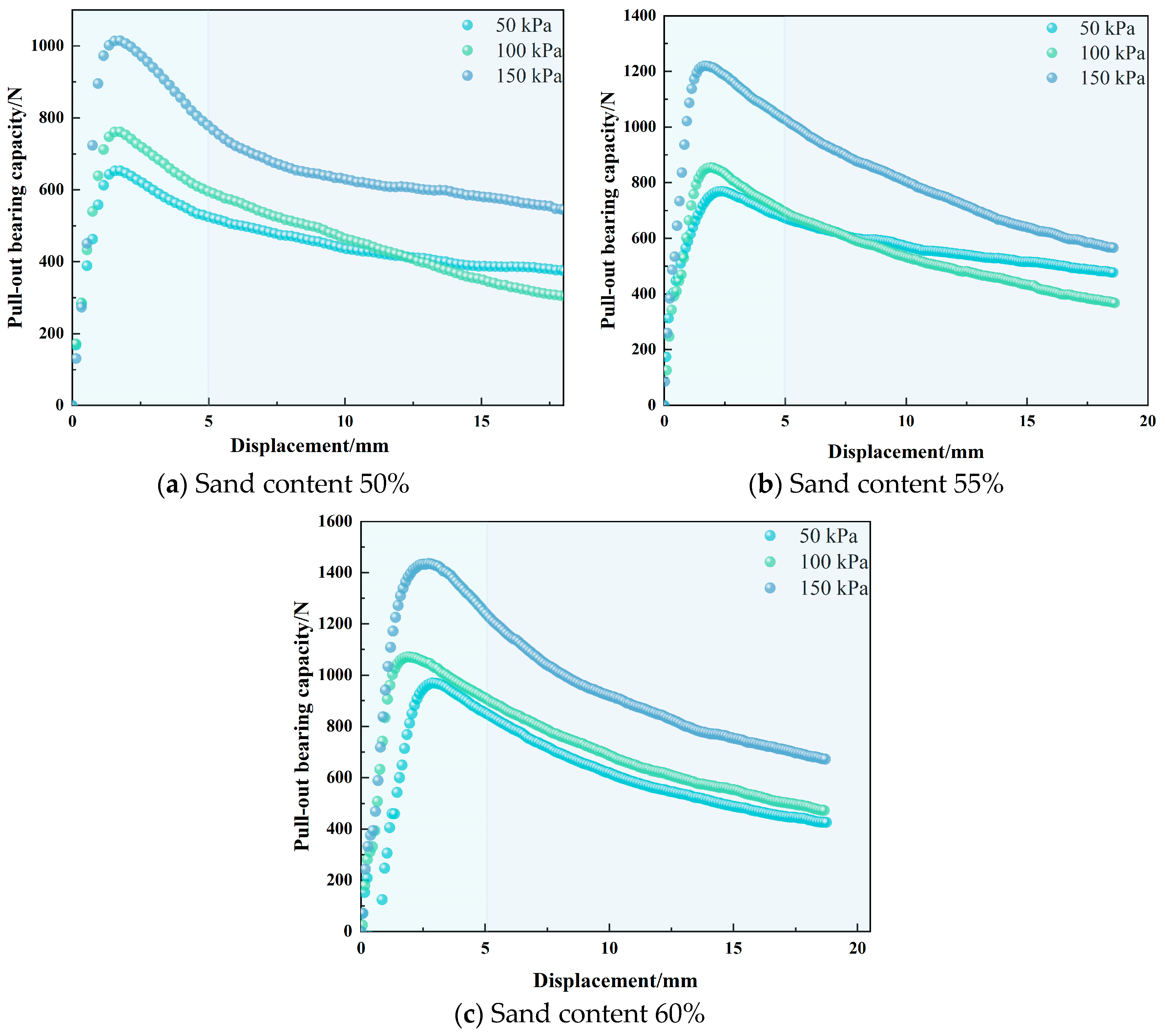

3.1.1. Ultimate Pull-Out Force of an Anchor Rod under Static Loading

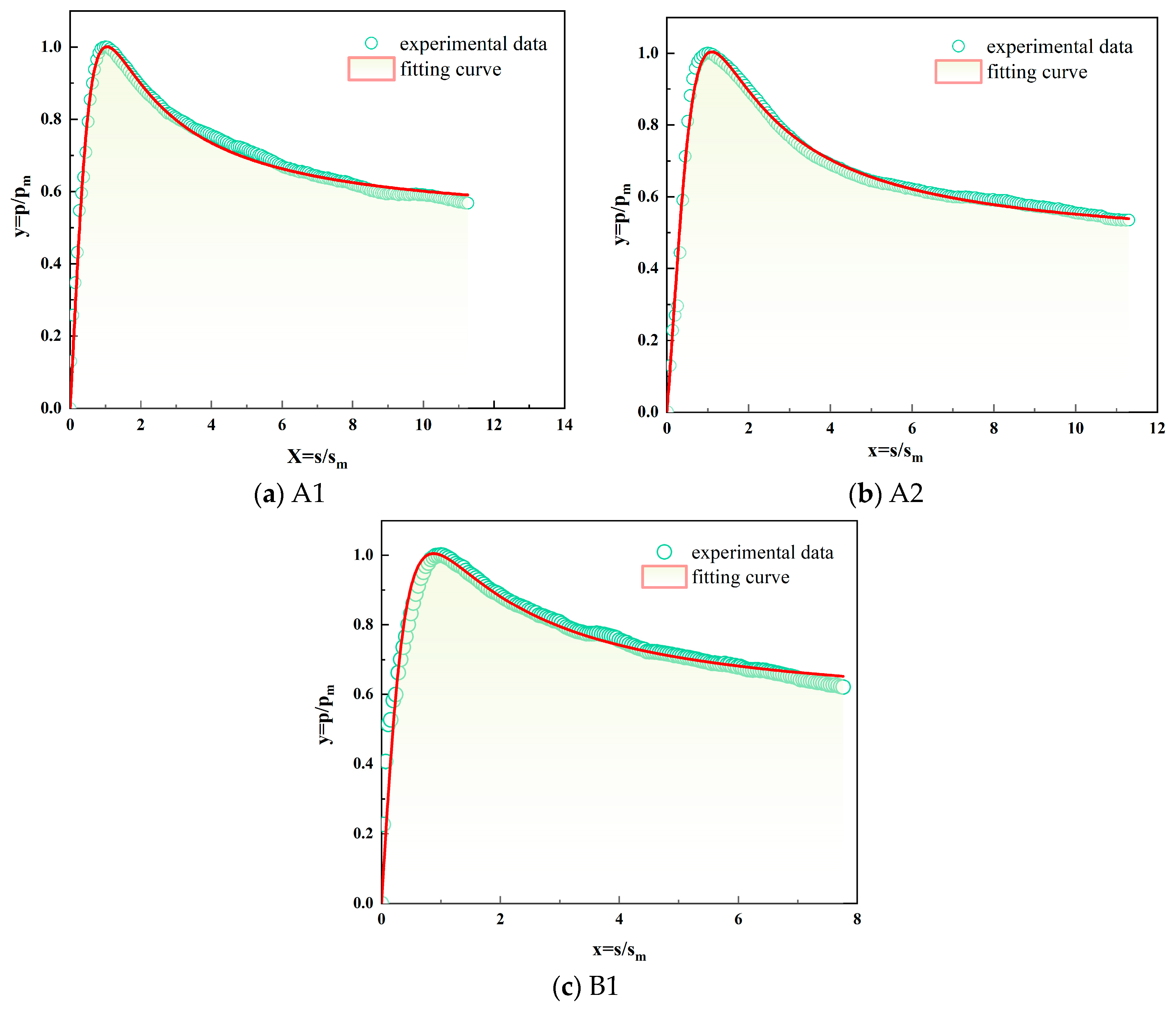

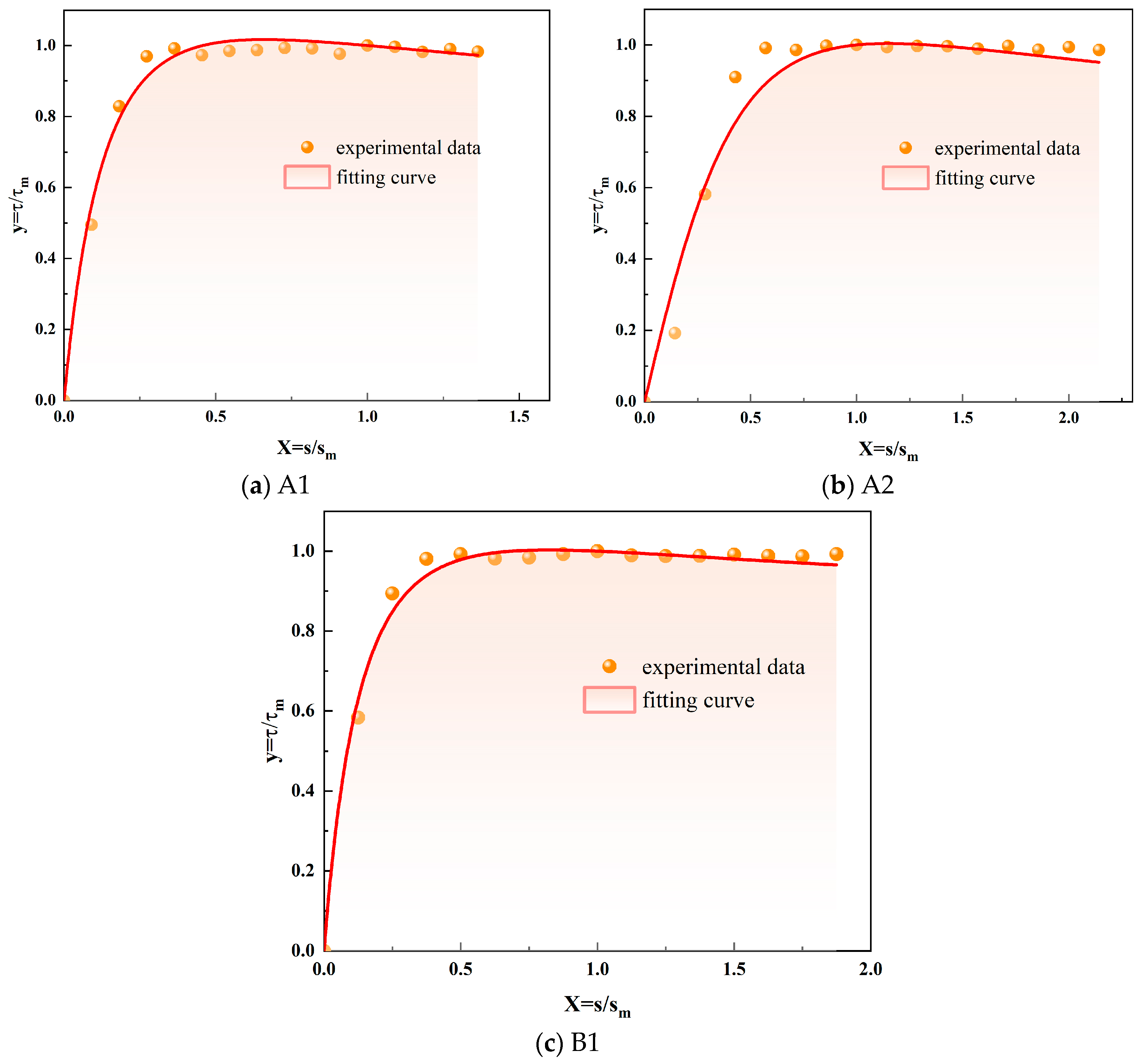

3.1.2. Constitutive Relationship of the Anchor-Soil Interface throughout the Test Process

3.2. Feature Analysis of the Shear Stress-Displacement Curve of the Anchor-Soil Contact Surface

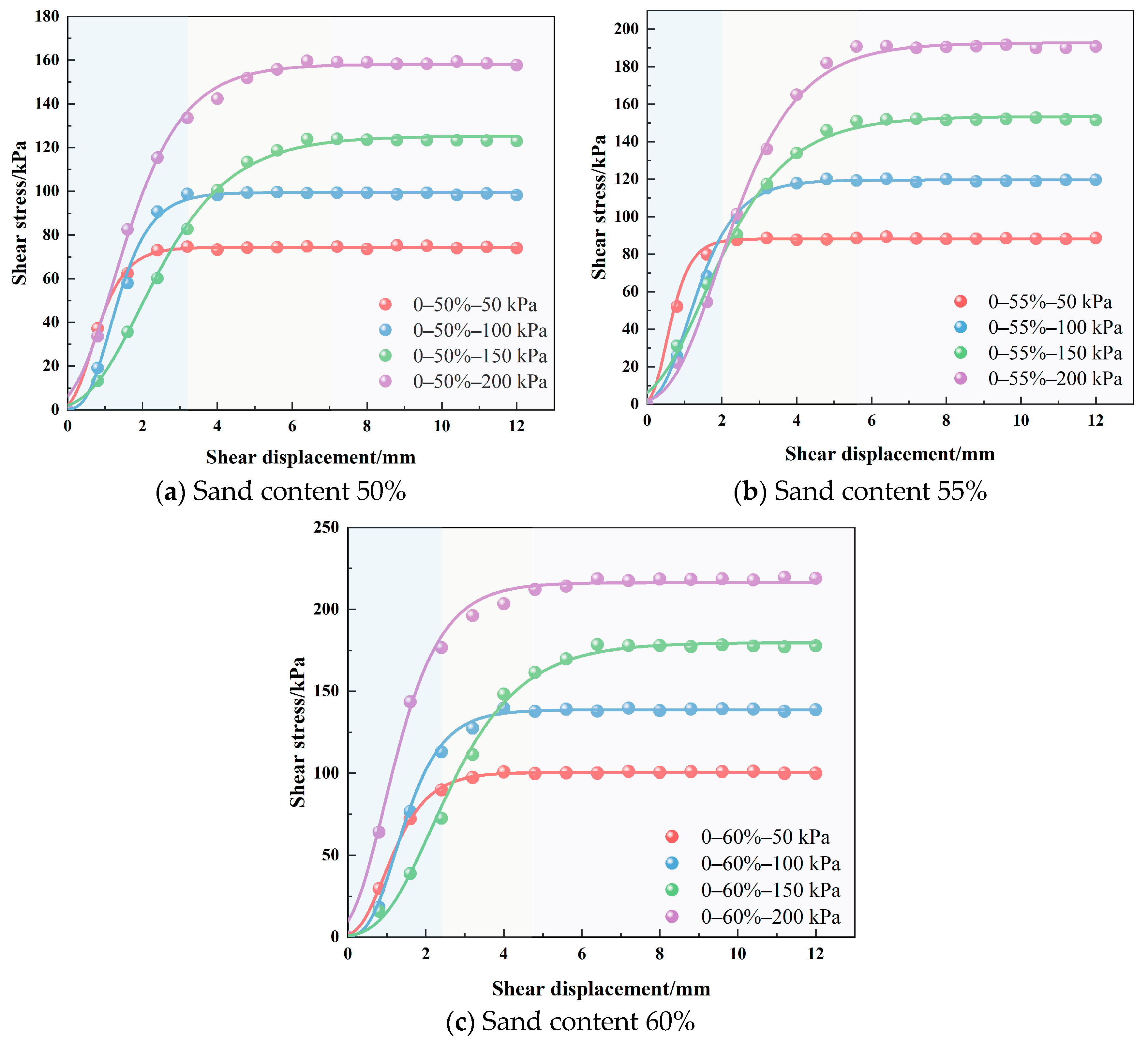

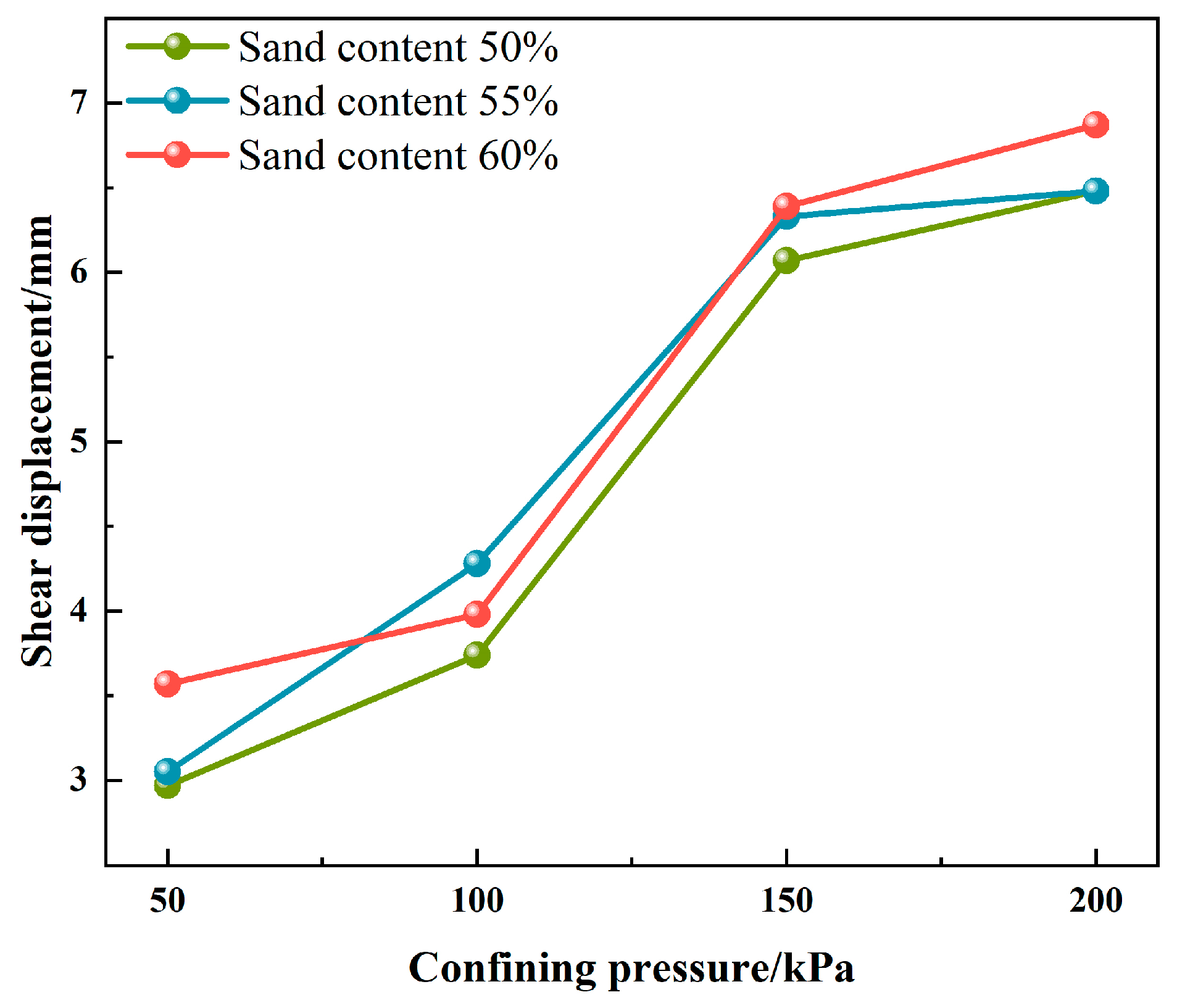

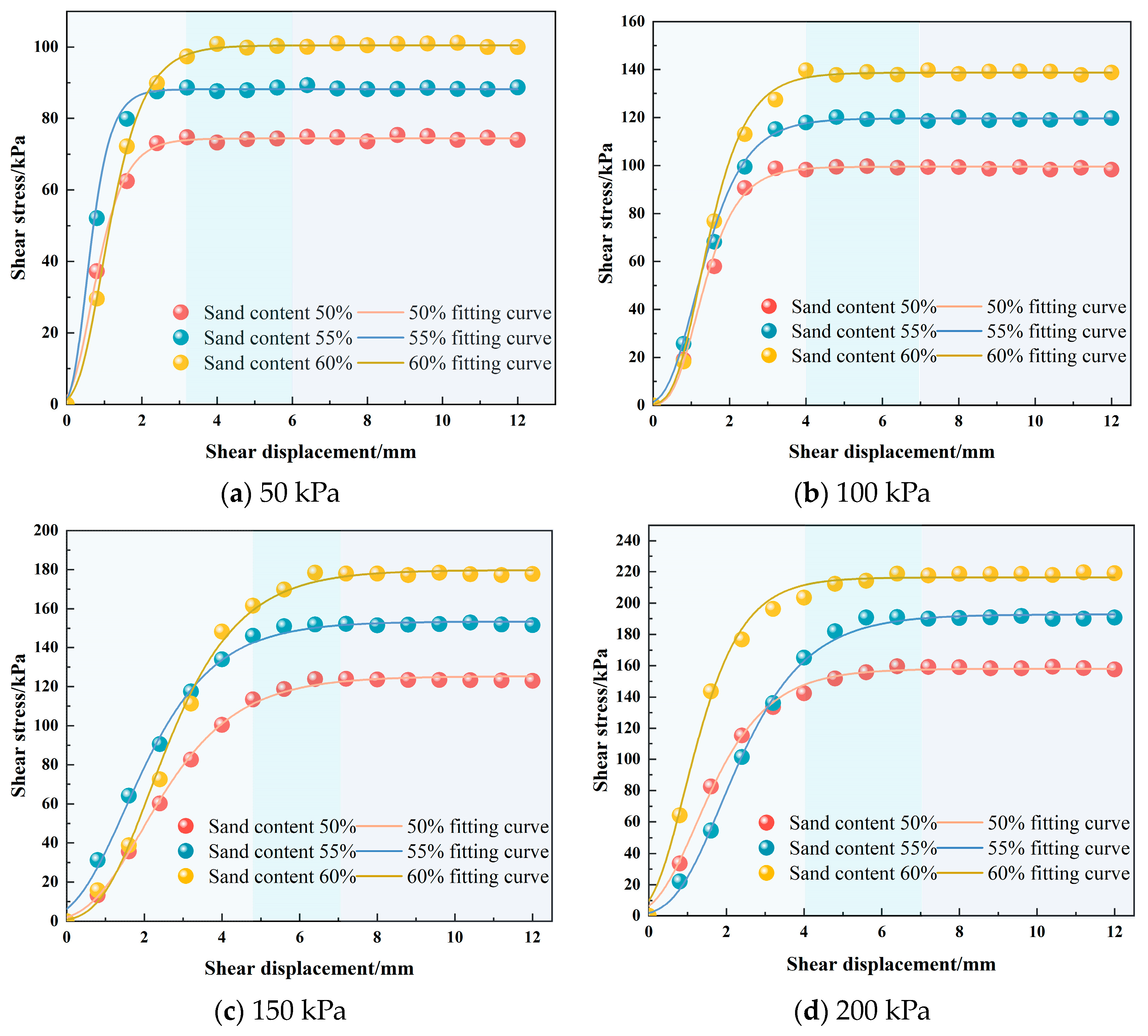

3.2.1. Analysis of the Influence of Confining Pressure on the Shear Stress-Displacement Curve of an Anchor-Soil Contact Surface

3.2.2. Numerical Simulation

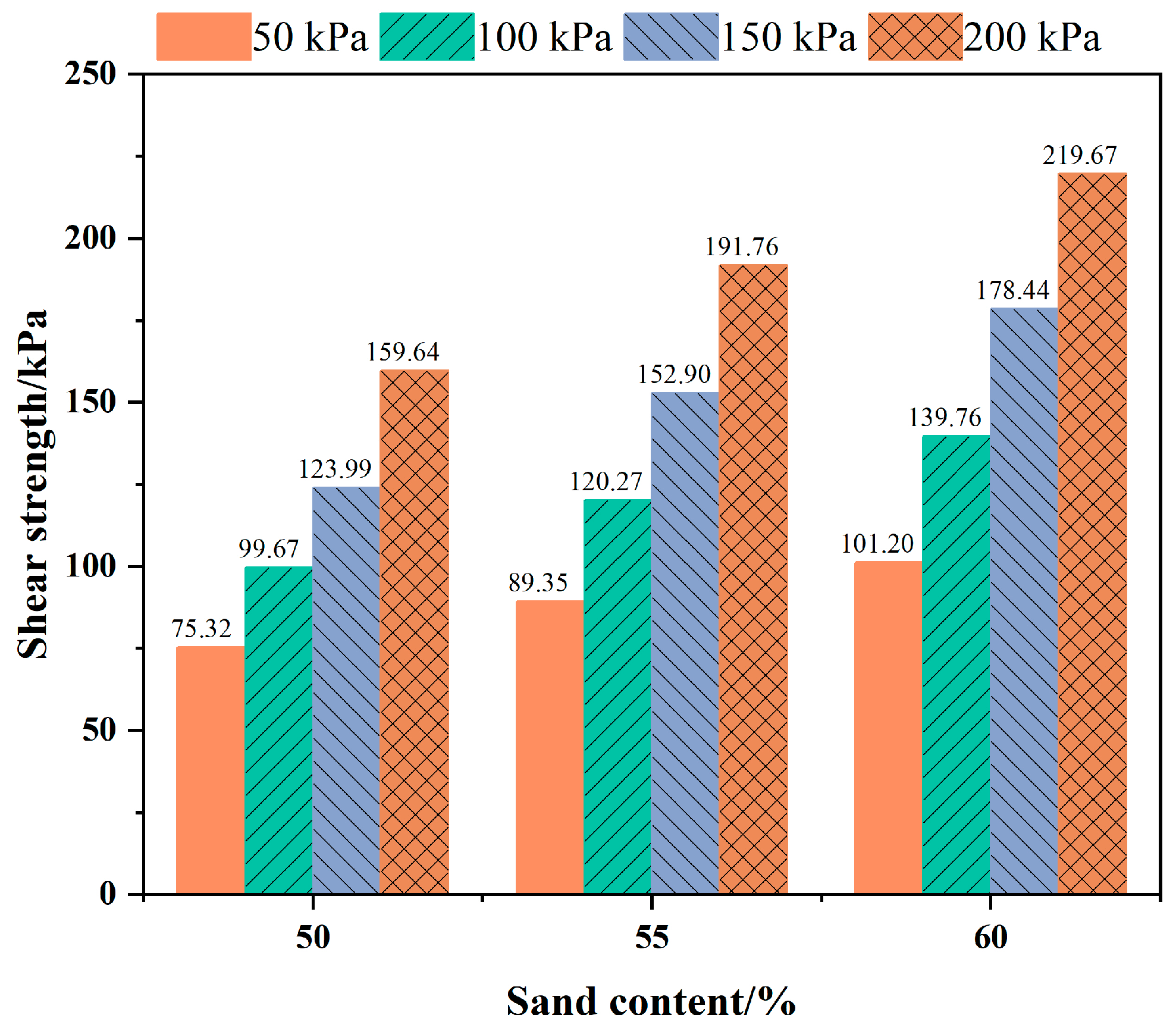

3.2.3. The Influence of Sand Content on the Shear Strength of an Anchor-Soil Contact Surface

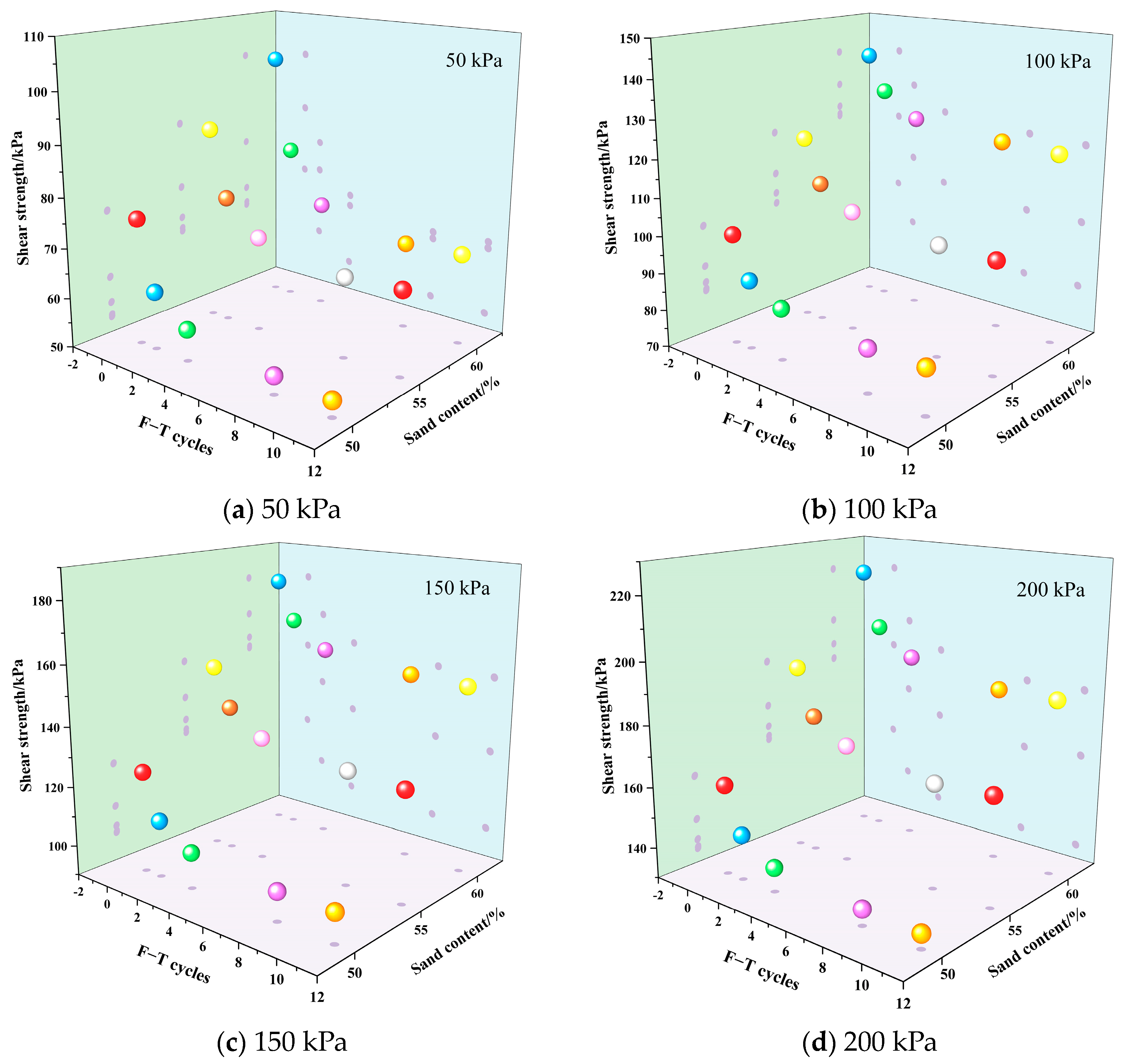

3.2.4. Influence of Freeze-Thaw Cycling on the Strength of a Contact Surface

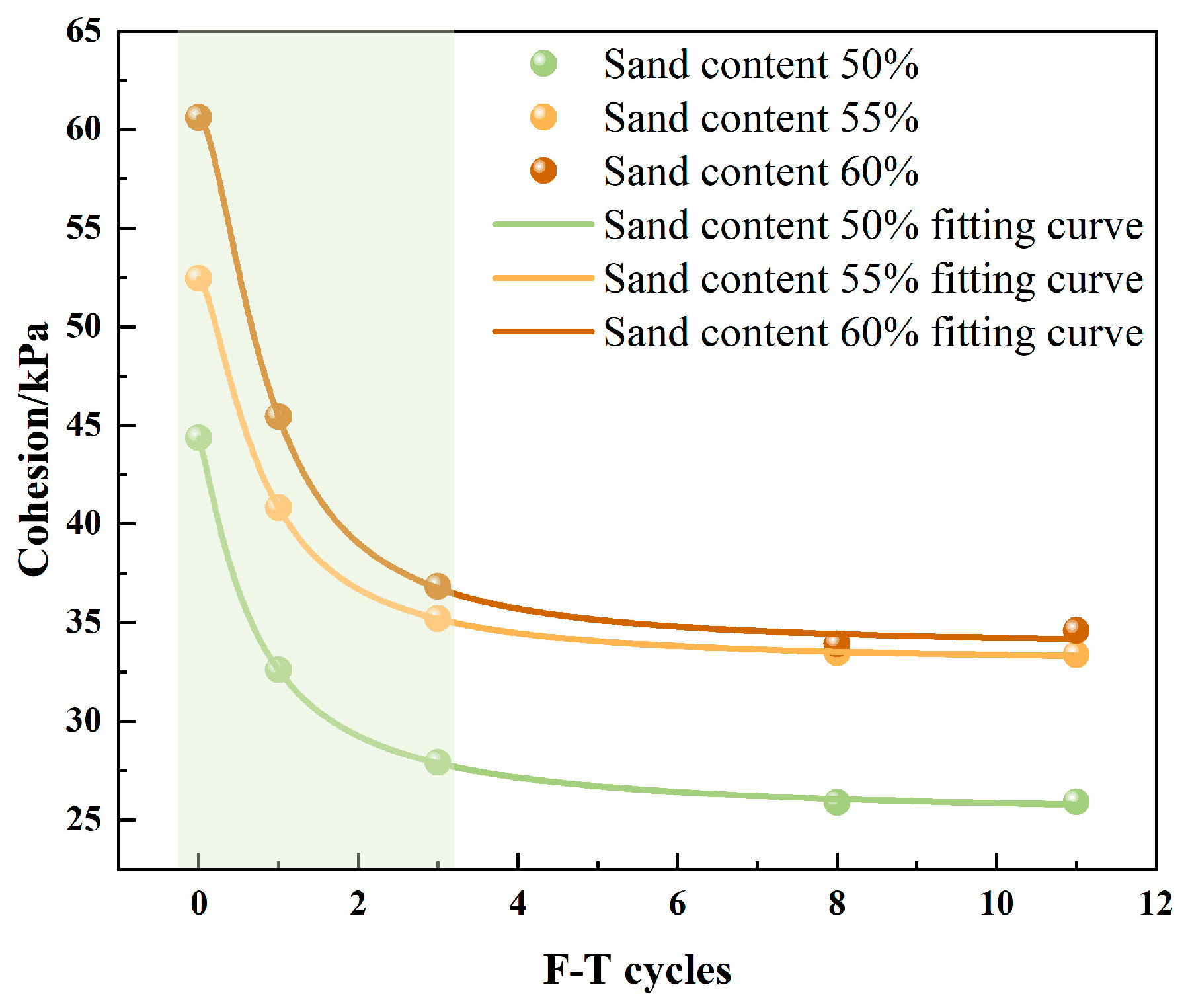

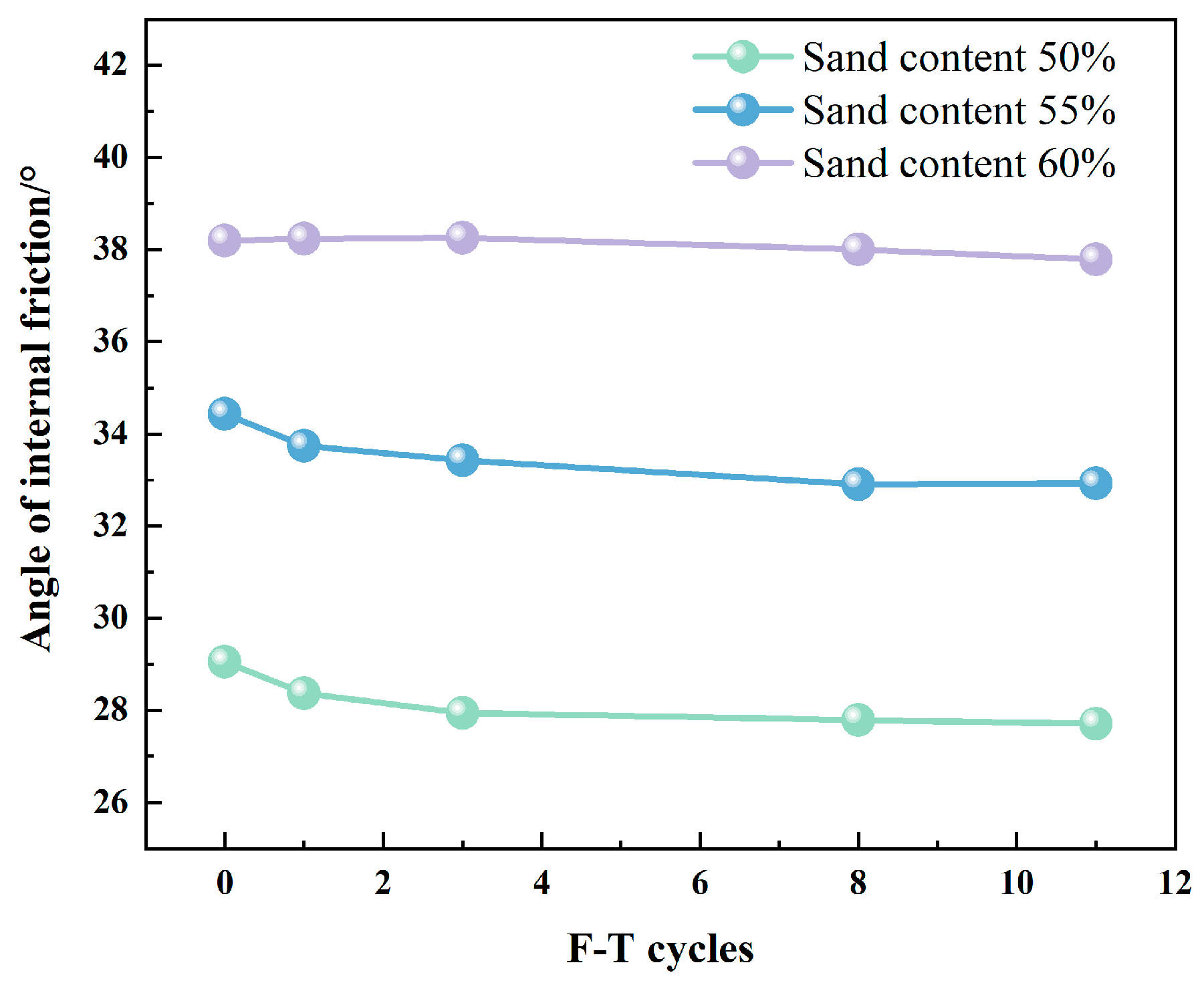

3.2.5. Influence of Freeze-Thaw Cycles on the Apparent Cohesion and Internal Friction Angle of the Contact Surface

4. Discussion

5. Conclusions

- (1)

- The pull-out model of anchor rods is different than the shear model, and both curves can be fitted using a comprehensive model and normalized, with the fitting results showing a high degree of agreement with the measured curves.

- (2)

- The increase in the confining pressure has a significant effect on the shear strength of the anchor-soil interface. With a 50% sand content, the shear strengths under 100 kPa, 150 kPa, and 200 kPa confining pressures are approximately 1.32, 1.64, and 2.12 times higher than that under 50 kPa pressure, respectively, and the corresponding peak displacement is also increased by more than two times. The pattern of peak displacements observed in soils with different sand content is consistent, with sand content having a small effect on peak displacements.

- (3)

- Under the same confining pressure, the shear strength of the anchor-soil interface is greatly affected by the sand content of the soil. Under the condition of 50 kPa, the anchor-soil interface shear strength with a 55% sand content and 60% sand content is 1.18 times and 1.34 times that of with a 50% sand content, respectively.

- (4)

- Freeze-thaw cycles significantly reduce the shear strength of an anchor-soil interface. Comparing the results of the decreases in shear strength for different sand content rates, the results with 50–60% sand contents are 19.3%, 16.7%, and 14.5%, respectively, under 50 kPa. The appropriate increase in sand content will improve the freeze-thaw resistance of the anchored soil body. The anchor soil with a sand content of 60% experiences an increase in confining pressure from 50kPa to 200kPa, resulting in a decrease in shear strength damage from 32.5% to 14.6%. After a freeze-thaw cycle, the cohesion of the soil specimens with different sand contents is reduced by more than 30%, and the decrease in the internal friction angle is very small.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Z.; Peng, W.; Cao, J.; Xie, D. Application of Wireless Sensor Network in Rock Bolt Pulling Force Distribution Pattern Monitoring. Iop Conf. Ser. Earth Environ. Sci. 2019, 267, 042005. [Google Scholar] [CrossRef]

- Ho, S.C.M.; Li, W.; Wang, B.; Song, G. A load measuring anchor plate for rock bolt using fiber optic sensor. Smart Mater. Struct. 2017, 26, 057003. [Google Scholar] [CrossRef]

- Barnard, C.; Kallu, R.R.; Warren, S.; Thareja, R. Inflatable rock bolt bond strength versus rock mass rating (RMR): A comparative analysis of pull-out testing data from underground mines in Nevada. Int. J. Min. Sci. Technol. 2016, 26, 19–22. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Horpibulsuk, S.; Udomchai, A.; Arulrajah, A.; Tangsutthinon, T. Pullout resistance mechanism of bearing reinforcement embedded in coarse-grained soils: Laboratory and field investigations. Transp. Geotech. 2020, 22, 100297. [Google Scholar] [CrossRef]

- Chen, A.; Wang, Q.; Chen, Z.; Chen, J.; Chen, Z.; Yang, J. Investigating pile anchor support system for deep foundation pit in a congested area of Changchun. Bull. Eng. Geol. Environ. 2020, 80, 1125–1136. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Z. Analysis of Deep Foundation Pit Pile-Anchor Supporting System Based on FLAC3D. Geofluids 2022, 2022, 1699292. [Google Scholar] [CrossRef]

- Su, T.; Zhou, Y.; Wang, Z.; Ye, S. Large Scale Model Test Study of Foundation Pit Supported by Pile Anchors. Appl. Sci. 2022, 12, 9792. [Google Scholar] [CrossRef]

- Cui, G.; Ma, S.; Liu, Z.; Liu, S.; Xi, C.; Cheng, Z. Effect of freeze-thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin. Rev. Adv. Mater. Sci. 2022, 61, 756–768. [Google Scholar] [CrossRef]

- Su, W.; Fragaszy, R.J. Uplift Testing of Model Anchors. J. Geotech. Eng. 1988, 114, 961–983. [Google Scholar] [CrossRef]

- Martín, L.B.; Tijani, M.; Hadj-hassen, F. A new analytical solution to the mechanical behaviour of fully grouted rockbolts subjected to pull-out tests. Constr. Build. Mater. 2011, 25, 749–755. [Google Scholar] [CrossRef]

- Ghadimi, M.; Shahriar, K.; Jalalifar, H. A new analytical solution for the displacement of fully grouted rock bolt in rock joints and experimental and numerical verifications. Tunn. Undergr. Space Technol. 2015, 50, 143–151. [Google Scholar] [CrossRef]

- Xi, X.H.; Gu, S.C. Shearing Stress Model of Damage Bolt in Tunnel. Appl. Mech. Mater. 2011, 90–93, 1761–1767. [Google Scholar] [CrossRef]

- Zhu, Z.; Shu, X.; Li, Z.; Tian, H.; Tian, Y. Stress analysis of full-length grouted bolt under shear deformation of anchor interface. J. Mt. Sci. 2022, 19, 3286–3301. [Google Scholar] [CrossRef]

- Chen, C.; Liang, G.; Tang, Y.; Xu, Y. A new method for indoor testing of interface characteristics between anchor solid and soil for anchor rods. J. Geotech. Eng. 2015, 37, 1115–1122. (In Chinese) [Google Scholar]

- Chang, D.; Liu, J. Review of the influence of freeze-thaw cycles on the physical and mechanical properties of soil. Sci. Cold Arid. Reg. 2013, 5, 457–460. [Google Scholar]

- Qi, J.; Vermeer, P.A.; Cheng, G. A review of the influence of freeze-thaw cycles on soil geotechnical properties. Permafr. Periglac. Process. 2006, 17, 245–252. [Google Scholar] [CrossRef]

- Konrad, J. Physical processes during freeze-thaw cycles in clayey silts. Cold Reg. Sci. Technol. 1989, 16, 291–303. [Google Scholar] [CrossRef]

- Chamberlain, E.J.; Gow, A.J. Effect of freezing and thawing on the permeability and structure of soils. Eng. Geol. 1979, 13, 73–92. [Google Scholar] [CrossRef]

- Leuther, F.; Schlüter, S. Impact of freeze-thaw cycles on soil structure and soil hydraulic properties. Soil 2021, 7, 179–191. [Google Scholar] [CrossRef]

- Nartowska, E.; Kozłowski, T. The Effect of Freeze-Thaw Cycling and the Initial Mass of Water on the Unfrozen Water Content of Calcium Bentonites Modified by Copper Ions. Minerals 2022, 12, 66. [Google Scholar] [CrossRef]

- Zhao, Y.; Hu, X. How Do Freeze-Thaw Cycles Affect the Soil Pore Structure in Alpine Meadows Considering Soil Aggregate and Soil Column Scales? J. Soil Sci. Plant Nutr. 2022, 22, 4207–4216. [Google Scholar] [CrossRef]

- Eskişar, T.; Altun, S.; Kalıpcılar, İ. Assessment of strength development and freeze-thaw performance of cement treated clays at different water contents. Cold Reg. Sci. Technol. 2015, 111, 50–59. [Google Scholar] [CrossRef]

- Zhao, L.; Peng, J.; Ma, P.; Leng, Y.; Ma, Z. Microstructure response to shear strength deterioration in loess after freeze-thaw cycles. Eng. Geol. 2023, 323, 107229. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Lan, W.; Wang, S. Shear strength and damage mechanism of saline intact loess after freeze-thaw cycling. Cold Reg. Sci. Technol. 2019, 164, 102779. [Google Scholar] [CrossRef]

- Xu, J.; Ren, J.; Wang, Z.; Wang, S.; Yuan, J. Strength behaviors and meso-structural characters of loess after freeze-thaw. Cold Reg. Sci. Technol. 2018, 148, 104–120. [Google Scholar] [CrossRef]

- Qi, J.; Ma, W.; Song, C. Influence of freeze-thaw on engineering properties of a silty soil. Cold Reg. Sci. Technol. 2008, 53, 397–404. [Google Scholar] [CrossRef]

- Qu, Y.; Ni, W.; Niu, F.; Mu, Y.; Luo, J.; He, H. Shear Properties and Mechanism of Freeze-Thaw Interface in Unsaturated Coarse-Grained Soil from Qinghai-Tibet Plateau. Adv. Civ. Eng. 2021, 2021, 6688724. [Google Scholar] [CrossRef]

- Liu, J.; Chang, D.; Yu, Q. Influence of freeze-thaw cycles on mechanical properties of a silty sand. Eng. Geol. 2016, 210, 23–32. [Google Scholar] [CrossRef]

- Khoury, N.N.; Zaman, M.M. Effect of Wet-Dry Cycles on Resilient Modulus of Class C Coal Fly Ash-Stabilized Aggregate Base. Transp. Res. Rec. J. Transp. Res. Board 2002, 1787, 13–21. [Google Scholar] [CrossRef]

- Yao, Z.; Du, X.; Zhang, Z. Effects of ultra-freezing/thawing cycles on the mechanical properties and microstructure of Shanghai clay. In Proceedings of the Third International Conference on Optoelectronic Science and Materials (icosm 2021), Spie, Hefei, China, 10–12 September 2021. [Google Scholar]

- Mu, J.; Pei, X.; Huang, R.; Rengers, N.; Zou, X. Degradation characteristics of shear strength of joints in three rock types due to cyclic freezing and thawing. Cold Reg. Sci. Technol. 2017, 138, 91–97. [Google Scholar] [CrossRef]

- He, P.; Mu, Y.; Yang, Z.; Ma, W.; Dong, J.; Huang, Y. Freeze-thaw cycling impact on the shear behavior of frozen soil-concrete interface. Cold Reg. Sci. Technol. 2020, 173, 103024. [Google Scholar] [CrossRef]

- Pan, R.; Yang, P.; Shi, X.; Zhang, T. Effects of freeze-thaw cycles on the shear stress induced on the cemented sand–structure interface. Constr. Build. Mater. 2023, 371, 130671. [Google Scholar] [CrossRef]

- Dong, J.; Tao, C.; Zhong, S.; Wu, Z.; Yan, X. Shear behaviour of anchor solid-soil interface under confining pressure and freeze-thaw cycles. Arab. J. Geosci. 2022, 15, 879. [Google Scholar] [CrossRef]

- Pan, J.; Wang, B.; Wang, Q.; Ling, X.; Liu, J.; Fang, R.; Wang, Z. Deformation characteristics of the shear band of silty clay–concrete interface under the influence of freeze-thaw. Cold Reg. Sci. Technol. 2023, 206, 103750. [Google Scholar] [CrossRef]

- Yang, L.; Liu, Q. Statistical damage constitutive model for soil-structure contact surface. J. Undergr. Space Eng. 2006, 79–82+86. (In Chinese) [Google Scholar]

| Sand Content/% | Cohesion/kPa | Friction/° |

|---|---|---|

| 50 | 53.03 | 25.93 |

| 55 | 55.04 | 27.25 |

| 60 | 50.03 | 26.15 |

| Number | Sand Content/% | Pressure/kPa | Freeze-Thaw Cycles |

|---|---|---|---|

| MG1 | 50 | 50 | 0/1/3/8/11 |

| MG2 | 100 | ||

| MG3 | 150 | ||

| MG4 | 200 | ||

| MG5 | 55 | 50 | 0/1/3/8/11 |

| MG6 | 100 | ||

| MG7 | 150 | ||

| MG8 | 200 | ||

| MG9 | 60 | 50 | 0/1/3/8/11 |

| MG10 | 100 | ||

| MG11 | 150 | ||

| MG12 | 200 |

| Number | A1 | A2 | A3 | B1 | B2 | B3 | C1 | C2 | C3 |

|---|---|---|---|---|---|---|---|---|---|

| a | 1.84 | 1.30 | 1.48 | 2.84 | 1.39 | 1.40 | 0.89 | 1.13 | 1.62 |

| b | 1.92 | 1.49 | 1.66 | 2.54 | 1.53 | 1.61 | 1.21 | 1.44 | 1.55 |

| Correlation coefficient | 0.98 | 0.93 | 0.98 | 0.95 | 0.96 | 0.94 | 0.94 | 0.96 | 0.99 |

| Number | A1 | A2 | A3 | B1 | B2 | B3 | C1 | C2 | C3 |

|---|---|---|---|---|---|---|---|---|---|

| a | 9.17 | 2.52 | 1.32 | 8.82 | 2.82 | 2.94 | 6.49 | 1.19 | 0.94 |

| b | 7.98 | 2.77 | 1.58 | 8.36 | 2.91 | 2.29 | 5.17 | 1.75 | 1.32 |

| Correlaion coefficient | 0.99 | 0.96 | 0.99 | 0.99 | 0.98 | 0.99 | 0.98 | 0.97 | 0.98 |

| Material Parameter | Young’s Modulus (GPa) | Poisson’s Ratio | Friction Angle (deg) | Cohesion (kPa) |

|---|---|---|---|---|

| Soil | 0.02 | 0.35 | 25.93 | 53.03 |

| Anchor | 29 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, J.; Wang, Y.-C.; Wu, Z.-H.; Gong, F.-W.; Zhao, Y.-D.; Zhang, H.-F. Anchor Shear Strength Damage under Varying Sand Content, Freeze-Thaw Cycles, and Axial Pressure Conditions. Buildings 2024, 14, 1772. https://doi.org/10.3390/buildings14061772

Dong J, Wang Y-C, Wu Z-H, Gong F-W, Zhao Y-D, Zhang H-F. Anchor Shear Strength Damage under Varying Sand Content, Freeze-Thaw Cycles, and Axial Pressure Conditions. Buildings. 2024; 14(6):1772. https://doi.org/10.3390/buildings14061772

Chicago/Turabian StyleDong, Jie, Yin-Chen Wang, Zhi-Hui Wu, Feng-Wu Gong, Ya-Dong Zhao, and Hong-Feng Zhang. 2024. "Anchor Shear Strength Damage under Varying Sand Content, Freeze-Thaw Cycles, and Axial Pressure Conditions" Buildings 14, no. 6: 1772. https://doi.org/10.3390/buildings14061772

APA StyleDong, J., Wang, Y.-C., Wu, Z.-H., Gong, F.-W., Zhao, Y.-D., & Zhang, H.-F. (2024). Anchor Shear Strength Damage under Varying Sand Content, Freeze-Thaw Cycles, and Axial Pressure Conditions. Buildings, 14(6), 1772. https://doi.org/10.3390/buildings14061772