Evolution of High Toughness Cementitious Composites Gas Permeability after Thermal-Mechanical Coupling Damage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Mix Proportions of Specimens

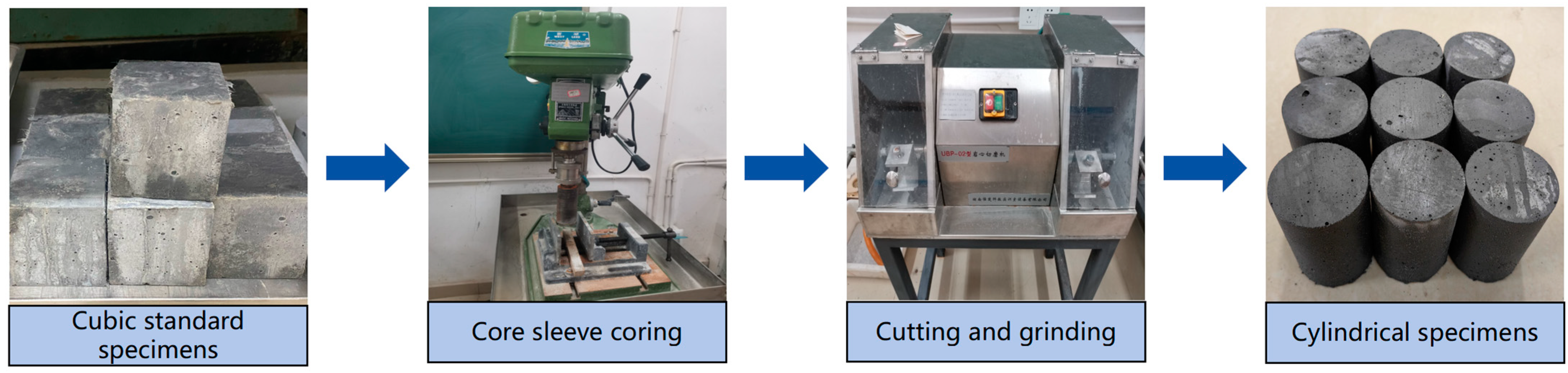

2.2. Test Methods

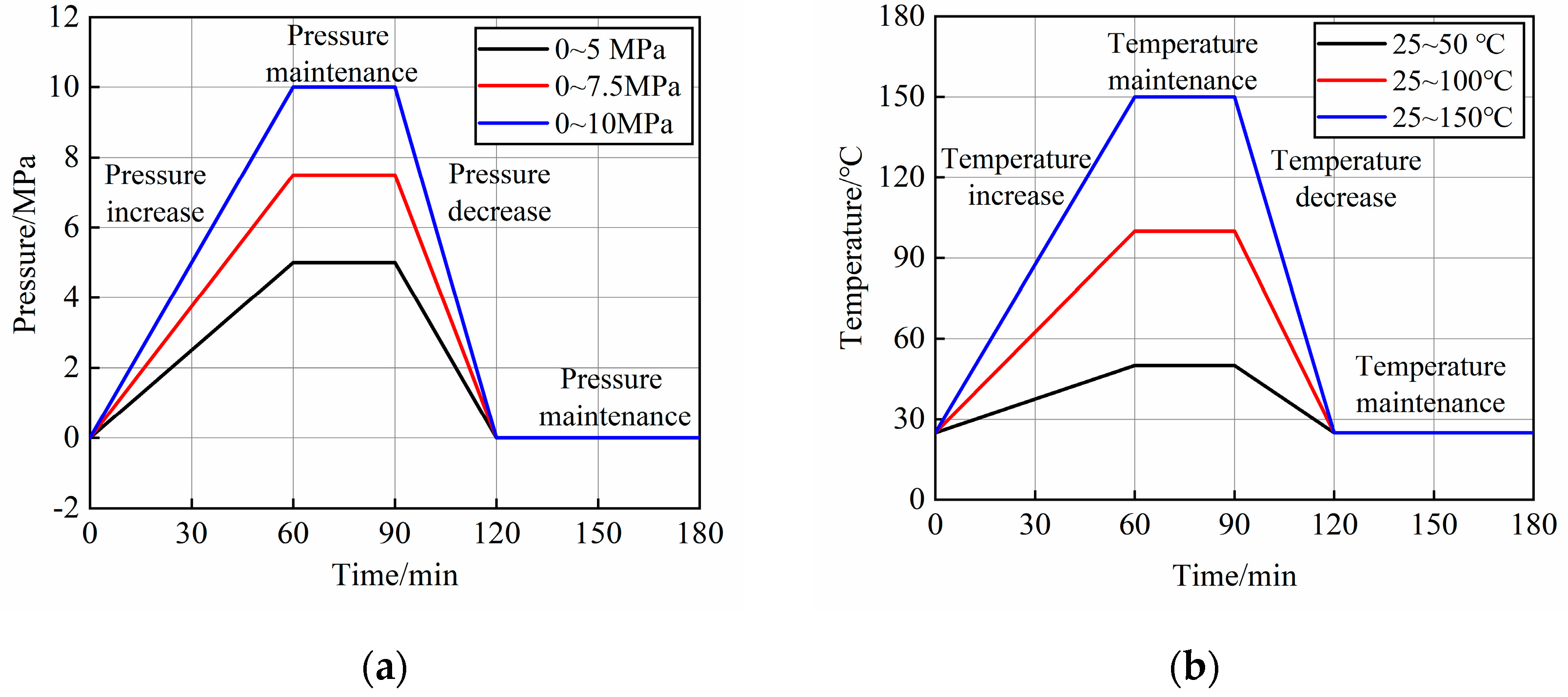

2.2.1. Temperature-Pressure Synchronous Cyclic Loading Test

2.2.2. Temperature–Pressure Synchronous Cyclic Loading Test

2.2.3. Mercury Intrusion Porosimetry Test

3. Test Results and Analyses

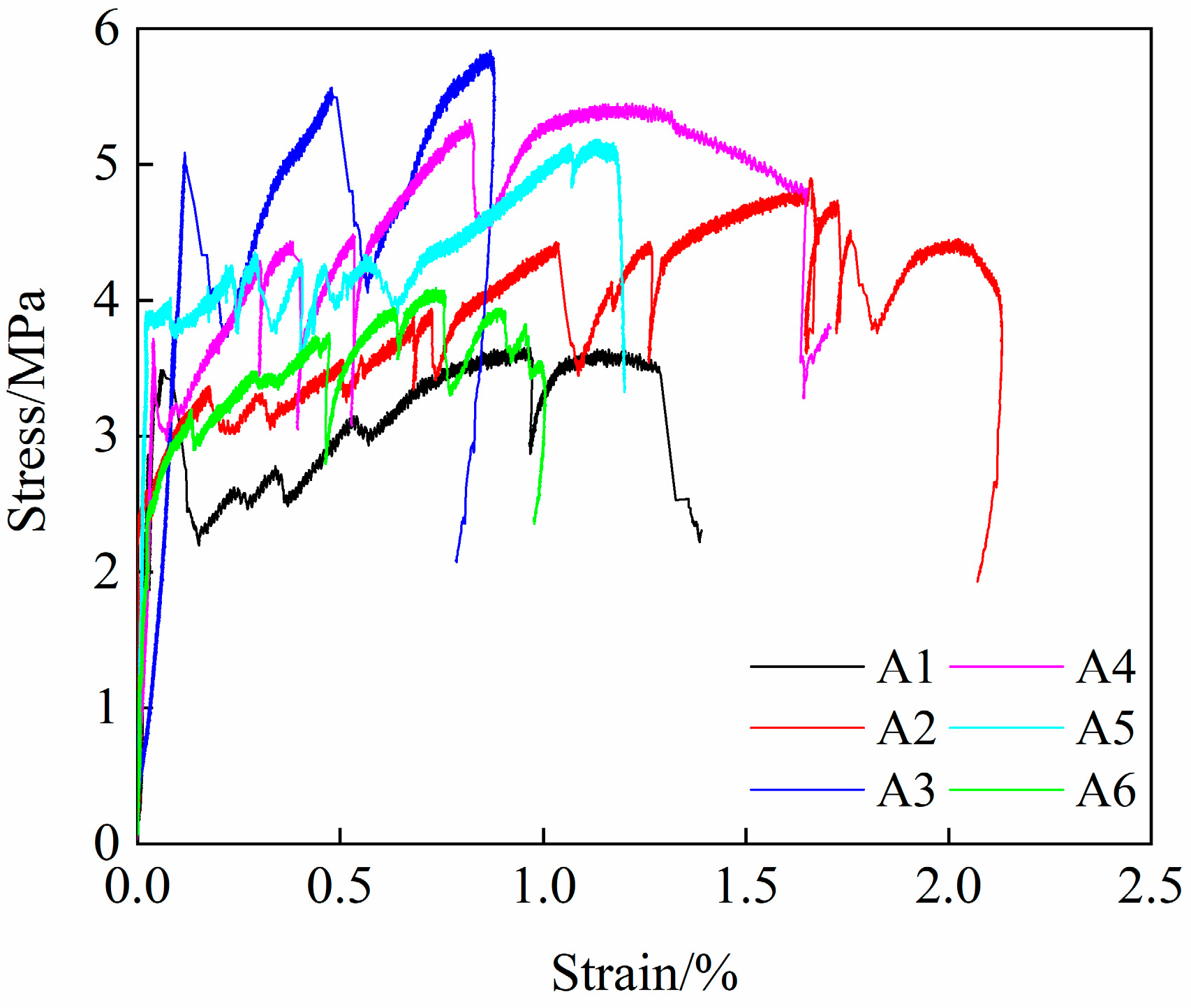

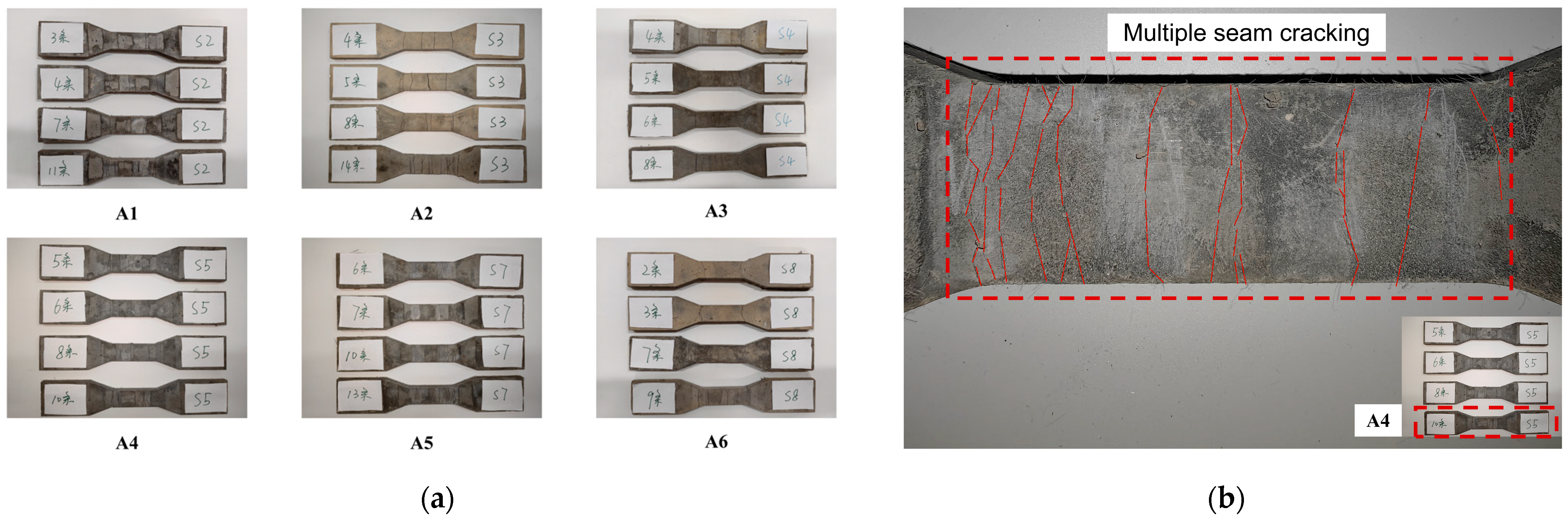

3.1. Basic Physical and Mechanical Properties of Test Materials

3.2. High-Pressure Gas Permeation Test Results and Analyses

3.3. Mercury Intrusion Porosimetry Test Results and Analyses

4. Conclusions

- (1)

- The compressive strength of HTCC 28d is 33.5 MPa, and it shows “tensile strain hardening” in tension, the ultimate tensile strength is 5.44 MPa, the ultimate tensile strain is 1.65%, and the average crack width is between 41and 49 μm, which indicates good toughness and crack controlling ability. HTCC are well adapted to the concrete lining of underground lined rock caverns in terms of toughness and resistance to cracking. At the same time, HTCC have a broad application prospect in underground engineering and all kinds of projects that have certain requirements for sealing performance.

- (2)

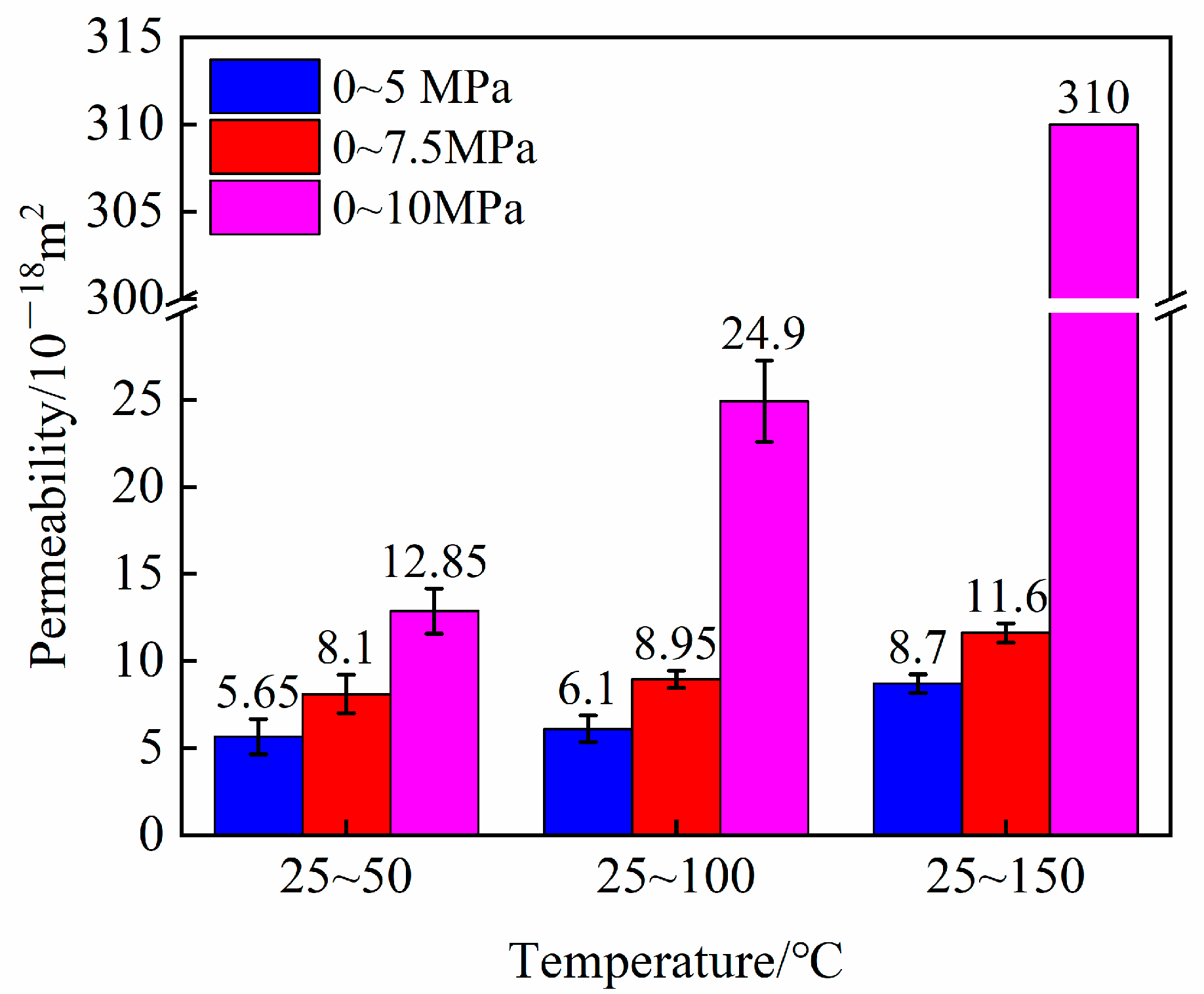

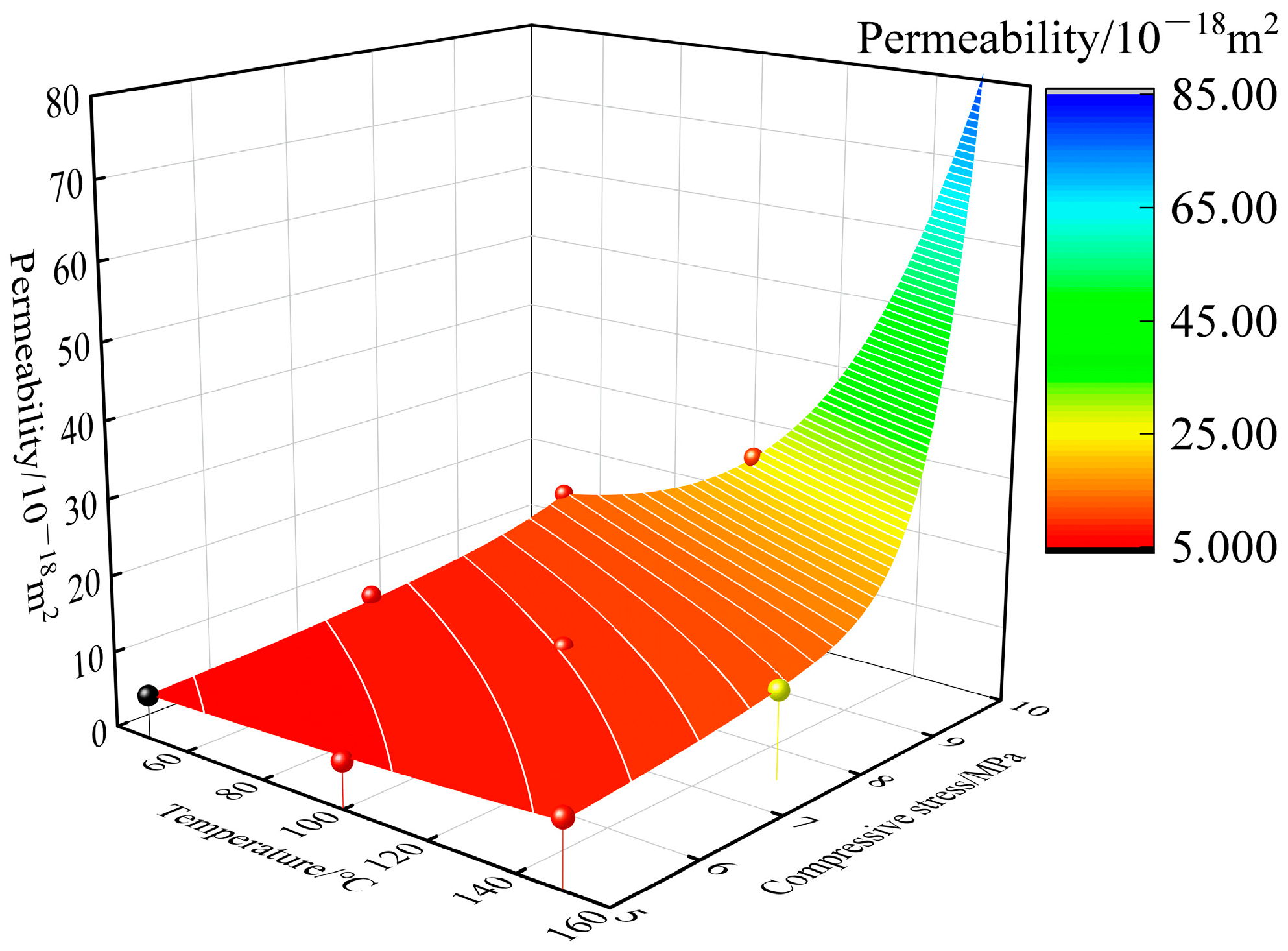

- Both temperature and compressive stress cause the deterioration of HTCC gas permeability, but compressive stress is the main cause of the increased permeability of HTCC materials. The average gas permeability of the HTCC control group was 4.09 × 10−18 m2. The increase in gas permeability varies at different stress ratios for compressive stress. The maximum increase in gas permeability of specimens with different compressive stress combinations (compressive stress ratios) of 0~5 MPa (0.15), 0~7.5 MPa (0.22), and 0~10 MPa (0.30) was 112.7%, 183.6%, and 508.8% when the temperature was increased from 25~50 °C to 25~150 °C as compared with the control group. Accordingly, when HTCC are used as the lining layer of CAES underground lined rock caverns, it is recommended that the operating temperature of the caverns should not be higher than 100 °C and the compressive stress ratio is less than 0.30.

- (3)

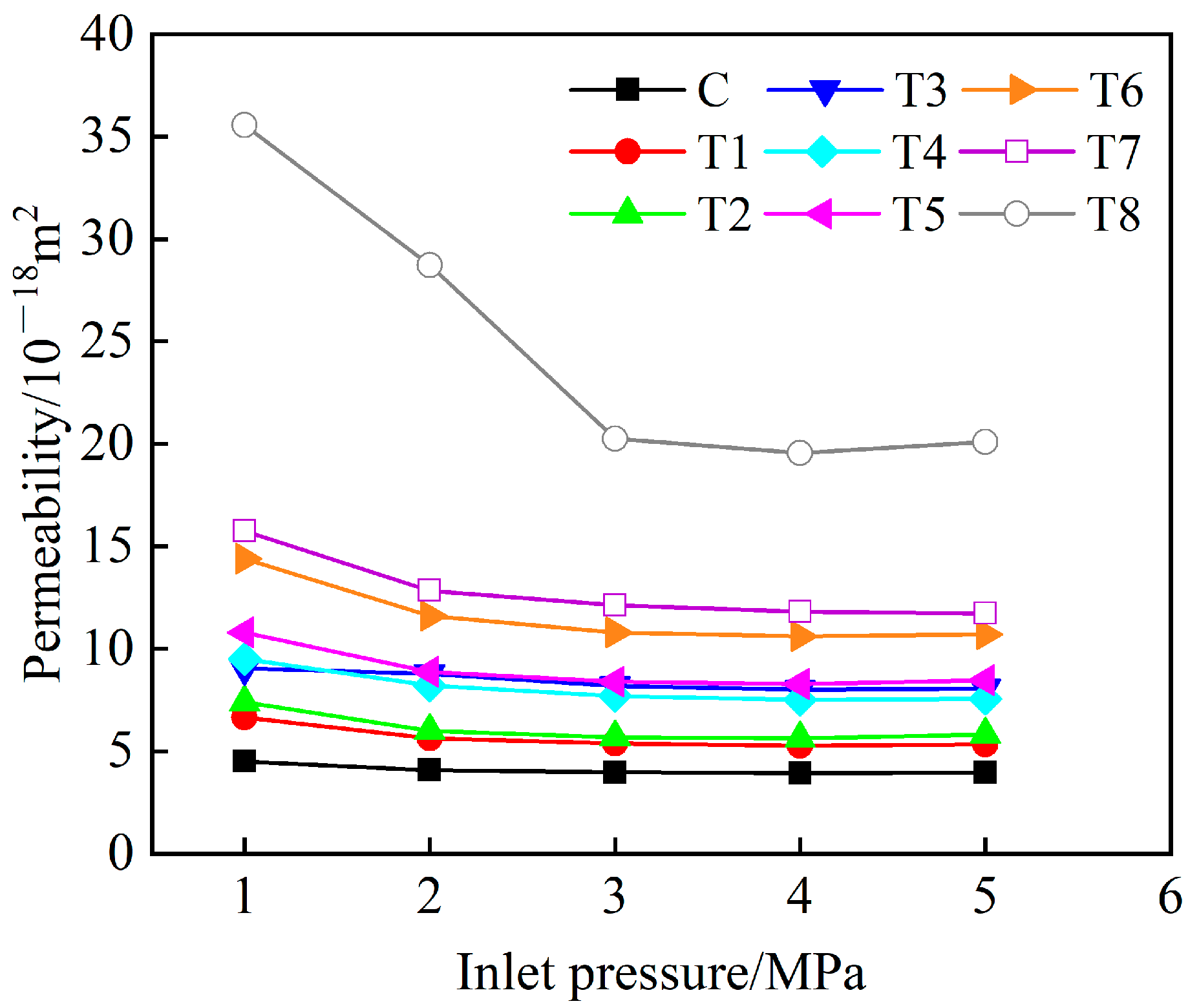

- The gas permeability decreases gradually with the increase in inlet pressure, but it basically stabilizes when the inlet pressure exceeds 3 MPa.

- (4)

- The results of analyzing the pore structure in the Mercury intrusion porosimetry test show that the porosity of HTCC decreases and the gas permeability increases as the maximum cycling temperature increases. This indicates that the expansion of the HTCC matrix occurs while the effective porosity within the material increases. The temperature effect produces microcracks.

- (5)

- The results of analyzing the pore structure in the mercury intrusion porosimetry test show that the porosity of HTCC rises and the gas permeability increases with the increase in the maximum cyclic stress. This indicates that the compressive stress will have a damaging effect on the HTCC matrix, with the coarsening of the pore size and increased connectivity of the internal pores of the material.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Budt, M.; Wolf, D.; Span, R.; Yan, J.Y. A review on compressed air energy storage: Basic principles, past milestones and recent developments. Appl. Energy 2016, 170, 250–268. [Google Scholar] [CrossRef]

- Zhou, S.W.; Xia, C.C.; Du, S.G.; Zhang, P.Y.; Zhou, Y. An analytical solution for mechanical responses induced by temperature and air pressure in a lined rock cavern for underground compressed air energy storage. Rock Mech. Rock Eng. 2015, 48, 749–770. [Google Scholar] [CrossRef]

- Kim, H.M.; Rutqvist, J.; Ryu, D.W.; Choi, B.H.; Sunwoo, C.; Song, W.K. Exploring the concept of compressed air energy storage(CAES) in lined rock caverns at shallow depth: A modeling study of air tightness and energy balance. Appl. Energy 2011, 92, 653–667. [Google Scholar] [CrossRef]

- Zhou, Y.; Xia, C.C.; Zhao, H.B.; Wang, X.J.; Mei, S.H.; Zhou, S.W. A method for estimating air leakage through inner seals and mechanical responses of the surrounding rock of lined rock caverns for compressed air energy storage. Chin. J. Rock Mech. Eng. 2017, 36, 297–309. [Google Scholar] [CrossRef]

- Allen, R.D.; Doherty, T.J.; Fossum, A.F. Geotechnical Issues and Guidelines for Storage of Compressed Air in Excavated Hard Rock Caverns; Pacific Northwest Laboratory: Richland, WA, USA, 1982. [Google Scholar] [CrossRef]

- Jiang, Z.M.; Li, P.; Zhao, H.B.; Feng, S.R.; Tang, D. Experimental study on performance of shallow rock cavern for compressed air energy storage. Rock Soil Mech. 2020, 41, 235–241. [Google Scholar] [CrossRef]

- Jiang, Z.M.; Gan, L.; Zhang, D.X.; Xiao, Z.Z.; Liao, J.H. Study on distribution characteristics and evolution law of liner cracks in underground cavern for compressed air energy storage. Chin. J. Geotech. Eng. 2024, 46, 110–119. [Google Scholar] [CrossRef]

- Kim, H.M.; Rutqvist, J.; Kim, H.; Park, D.; Ryu, D.W.; Park, E.S. Failure Monitoring and Leakage Detection for Underground Storage of Compressed Air Energy in Lined Rock Caverns. Rock Mech. Rock Eng. 2016, 49, 573–584. [Google Scholar] [CrossRef]

- Li, V.C. On Engineered Cementitious Composites (ECC) A Review of the Material and Its Applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Xu, S.L.; Cai, X.H. Experimental studies on permeability and carbonation properties of ultra high toughness cemen-titious composites. Acta Mater. Compos. Sin. 2010, 27, 177–183. [Google Scholar] [CrossRef]

- Xu, S.L.; Zhou, F.; Li, Q.H.; Chen, B.K.; Jiang, X.; Yin, X.; Wu, P. Comparative study on performance of UHTCC and RPC thick panels under hard projectile impact loading. Cem. Concr. Compos. 2021, 122, 104134. [Google Scholar] [CrossRef]

- Khaledi, K.; Mahmoudi, E.; Datcheva, M.; Schanz, T. Analysis of compressed air storage caverns in rock salt considering thermo-mechanical cyclic loading. Environ. Earth Sci. 2016, 75, 1149. [Google Scholar] [CrossRef]

- Ye, B.; Cheng, Z.R.; Ni, X.Q. Effects of multiple heating-cooling cycles on the permeability and microstructure of a mortar. Constr. Build. Mater. 2018, 176, 156–164. [Google Scholar] [CrossRef]

- Lin, Z.; Xu, W.Y.; Wang, W.; Zhang, J.C.; Wang, H.L.; Wang, R.B. Experimental Study on Hydraulic and Macro-Mechanical Property of a Mortar under Heating and Cooling Treatment. J. Adv. Concr. Technol. 2016, 14, 261–270. [Google Scholar] [CrossRef]

- Zhao, D.F.; Jia, P.H.; Liu, H.X.; Gao, H.J.; Liu, Y.C. An experimental study on microstructure of high strength concrete after high temperature and uniaxial compressive fatigue. J. Vib. Shock 2018, 37, 83–88. [Google Scholar] [CrossRef]

- Zhou, X.G.; Wu, J.L. Preliminary Research on Fatigue Behavior of Concrete after Exposed to High Temperature. Ind. Constr. 1996, 26, 33–35. [Google Scholar]

- JC/T2461-2018; Standard Test Method for Mechanical Properties of Ductile Reinforced Cementitious Composites. Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2018.

- Lux, K.H. Design of salt caverns for the storage of natural gas, crude oil and compressed air: Geomechanical aspects of construction, operation and abandonment. Geol. Soc. Lond. Spec. Publ. 2009, 313, 93–128. [Google Scholar] [CrossRef]

- Kim, H.M.; Rutqvist, J.; Jeong, J.H.; Choi, B.H.; Ryu, D.W.; Song, W.K. Characterizing Excavation Damaged Zone and Stability of Pressurized Lined Rock Caverns for Underground Compressed Air Energy Storage. Rock Mech. Rock Eng. 2013, 46, 1113–1124. [Google Scholar] [CrossRef]

- Schmidt, F.; Menéndez, J.; Konietzky, H.; Pascual-Muñoz, P.; Castro, J.; Loredo, J.; Sánchez, A.B. Converting closed mines into giant batteries: Effects of cyclic loading on the geomechanical performance of underground compressed air energy storage systems. J. Energy Storage 2020, 32, 101882. [Google Scholar] [CrossRef]

- Jiang, Z.M.; Liu, L.L.; Li, S.L.; Liu, L.T.; Zhao, H.B.; Mei, S.H.; Li, P. Numerical study on mechanical characteristics of the Ping jiang pilot cavern for compressed air energy storage. J. Chang. Univ. Sci. Technol. (Nat. Sci.) 2017, 14, 62–68. [Google Scholar] [CrossRef]

- Houaria, M.B.A.; Abdelkader, M.; Marta, C.; Abdelhafid, K. Comparison between the permeability water and gas permeability of the concretes under the effect of temperature. Energy Procedia 2017, 139, 725–730. [Google Scholar] [CrossRef]

- Sogbossi, H.; Verdier, J.; Multon, S. Permeability and damage of partially saturated concrete exposed to elevated temperature. Cem. Concr. Compos. 2020, 109, 103563. [Google Scholar] [CrossRef]

- Fu, C.Q.; Ye, H.L.; Jin, X.Y.; Yan, D.M.; Jin, N.G.; Peng, Z.X. Chloride penetration into concrete damaged by uniaxial tensile fatigue loading. Constr. Build. Mater. 2016, 125, 714–723. [Google Scholar] [CrossRef]

- Desmettre, C.; Charron, J.P. Water permeability of reinforced concrete with and without fiber subjected to static and constant tensile loading. Cem. Concr. Res. 2012, 42, 945–952. [Google Scholar] [CrossRef]

- Yuan, J.Y.; Chen, X.D.; Shen, N.; Fan, X.Q.; Lu, J. Experimental study on the pore structure variation of self-compacting rubberised concrete under fatigue load. Road Mater. Pavement Des. 2021, 22, 716–733. [Google Scholar] [CrossRef]

- Chen, D.; Yu, X.T.; Liao, Y.T.; Wang, Q.F.; Wang, X. Progress of Study on Sulfate Attack on Concrete Material. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2016, 35, 24–30. [Google Scholar]

- Cui, Z.L.; Zhang, X.H.; Tang, B. Effect of Different Curing Environments on Strength and Carbonation of Fly Ash Concrete. Bull. Chin. Ceram. Soc. 2019, 38, 65–69. [Google Scholar] [CrossRef]

- Wang, H.L.; Xu, W.Y.; Zuo, J.; Shao, J.F.; Jia, Z.J. Evolution law of the permeability and porosity for low-permeability rock based on gas permeability test. J. Hydraul. Eng. 2015, 46, 208–216. [Google Scholar] [CrossRef]

- Pei, Y.; Agostini, F.; Skoczylas, F. The effects of high temperature heating on the gas permeability and porosity of a cementitious material. Cem. Concr. Res. 2017, 95, 141–151. [Google Scholar] [CrossRef]

- Kjellsen, K.O.; Detwiler, R.J.; Gjørv, O.E. Backscattered electron imaging of cement pastes hydrated at different temperatures. Cem. Concr. Res. 1990, 20, 308–311. [Google Scholar] [CrossRef]

- Bošnjak, J.; Ožbolt, J.; Hahn, R. Permeability measurement on high strength concrete without and with polypropylene fibers at elevated temperatures using a new test setup. Cem. Concr. Res. 2013, 53, 104–111. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, L.; Wang, Z.D.; Cao, Y.; Tang, B.G.; Du, P.; Huang, P.F. Research and progress on durability of concrete under combined mechanical load and environment actions. J. Sustain. Cem.-Based Mater. 2018, 37, 855–865. [Google Scholar] [CrossRef]

- Qu, F.L.; Li, W.G.; Dong, W.K.; Tam, V.W.Y.; Yu, T. Durability deterioration of concrete under marine environment from material to structure: A critical review. J. Build. Eng. 2021, 35, 102074. [Google Scholar] [CrossRef]

| Groups | Vf/% | Components (kg·m−3) | |||||

|---|---|---|---|---|---|---|---|

| Cement | Fly Ash | Sand | Water | PCE 1 | HPMC 2 | ||

| A1 | 1.5 | 593 | 711 | 474 | 339 | 5.22 | 0.59 |

| A2 | 2.0 | 593 | 711 | 474 | 339 | 5.22 | 0.59 |

| A3 | 2.0 | 593 | 711 | 474 | 287 | 5.22 | 0.59 |

| A4 | 2.0 | 593 | 711 | 474 | 312 | 5.22 | 0.59 |

| A5 | 2.0 | 717 | 587 | 474 | 339 | 5.22 | 0.59 |

| A6 | 2.0 | 652 | 652 | 474 | 339 | 5.22 | 0.59 |

| Pressure/Temperature Increase Time (min) | Pressure/Temperature Maintenance Time (min) | Pressure/Temperature Decrease Time (min) | Pressure/Temperature Maintenance Time (min) |

|---|---|---|---|

| 60 | 30 | 30 | 60 |

| Specimen Codes | Pressurization Range | Temperature Control Range | Cycles |

|---|---|---|---|

| C(Control group) | \ | \ | \ |

| T1 | 0~5 MPa | 25~50 °C | 10 |

| T2 | 25~100 °C | ||

| T3 | 25~150 °C | ||

| T4 | 0~7.5 MPa | 25~50 °C | |

| T5 | 25~100 °C | ||

| T6 | 25~150 °C | ||

| T7 | 0~10 MPa | 25~50 °C | |

| T8 | 25~100 °C | ||

| T9 | 25~150 °C |

| Groups | Compressive Strength 1 (MPa) | Tensile Initial Cracking Strength 1 (MPa) | Tensile Initial Strain 1 (%) | Peak Tensile Stress 1 (MPa) | Tensile Ultimate Strain 1 (%) | Modulus of Elasticity 1 (GPa) |

|---|---|---|---|---|---|---|

| A1 | 34.9 ± 2.9 | 3.48 | 0.057 | 3.65 | 1.32 | 8.5 |

| A2 | 29.4 ± 3.0 | 3.37 | 0.177 | 4.90 | 2.13 | 8.4 |

| A3 | 43.8 ± 1.3 | 5.05 | 0.118 | 5.81 | 0.88 | 10.7 |

| A4 | 33.5 ± 2.8 | 3.73 | 0.036 | 5.44 | 1.65 | 8.9 |

| A5 | 44.4 ± 1.6 | 3.92 | 0.030 | 5.18 | 1.20 | 10.4 |

| A6 | 35.1 ± 4.3 | 3.17 | 0.128 | 4.07 | 1.01 | 10.8 |

| Specimen Codes | Permeability (×10−18 m2) | Average Permeability (×10−18 m2) | ||||

|---|---|---|---|---|---|---|

| 1 MPa 1 | 2 MPa 1 | 3 MPa 1 | 4 MPa 1 | 5 MPa 1 | ||

| C | 4.51 | 4.08 | 3.97 | 3.93 | 3.96 | 4.09 ± 0.22 |

| T1 | 6.64 | 5.62 | 5.38 | 5.27 | 5.33 | 5.65 ± 1.01 |

| T2 | 7.39 | 6.00 | 5.68 | 5.62 | 5.82 | 6.10 ± 0.76 |

| T3 | 9.04 | 8.78 | 8.20 | 8.01 | 8.06 | 8.70 ± 0.54 |

| T4 | 9.50 | 8.21 | 7.70 | 7.51 | 7.56 | 8.10 ± 1.11 |

| T5 | 10.80 | 8.87 | 8.39 | 8.28 | 8.47 | 8.95 ± 0.49 |

| T6 | 14.40 | 11.60 | 10.80 | 10.60 | 10.70 | 11.60 ± 0.55 |

| T7 | 15.75 | 12.84 | 12.13 | 11.80 | 11.73 | 12.85 ± 1.30 |

| T8 | 35.56 | 28.73 | 20.26 | 19.56 | 20.10 | 24.90 ± 2.33 |

| T9 | >310 | >310 | ||||

| Specimen Codes | Porosity (%) | Average Pore Diameter (nm) | Median Pore Diameter (nm) | The Most Probable Aperture (nm) | Specific Pore Volume (mL/g) |

|---|---|---|---|---|---|

| T1 | 23.628 | 43.41 | 1291 | 15.07 | 0.128 |

| T2 | 15.107 | 38.01 | 235.1 | 12.62 | 0.08 |

| T3 | 10.959 | 36.12 | 274 | 6.9 | 0.056 |

| T6 | 19.483 | 51.68 | 1070 | 11 | 0.108 |

| T9 | 22.782 | 33.04 | 56.27 | 6.92 | 0.124 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Z.; Zhang, D. Evolution of High Toughness Cementitious Composites Gas Permeability after Thermal-Mechanical Coupling Damage. Buildings 2024, 14, 1923. https://doi.org/10.3390/buildings14071923

Zeng Z, Zhang D. Evolution of High Toughness Cementitious Composites Gas Permeability after Thermal-Mechanical Coupling Damage. Buildings. 2024; 14(7):1923. https://doi.org/10.3390/buildings14071923

Chicago/Turabian StyleZeng, Zhe, and Dengxiang Zhang. 2024. "Evolution of High Toughness Cementitious Composites Gas Permeability after Thermal-Mechanical Coupling Damage" Buildings 14, no. 7: 1923. https://doi.org/10.3390/buildings14071923