Abstract

This paper presents a novel concept for significantly enhancing the strength and durability of ancient closed-box tombs. These tombs hold significant philosophical values, and their architecture serves as a valuable data source, providing insights into the cultural stage of the society in which it was constructed. Throughout medieval and modern times, clay bricks remained a prevalent material for tomb construction due to their affordability and design flexibility. However, these structures currently face neglect and weakening, requiring imperative intervention of protection to prevent them from potential deterioration or extinction. The key objective of this research is to explore the potential use of graphene oxide (GO), a novel nanomaterial, as a treatment method to enhance the durability of mud brick tombs in Aswan, Egypt. Samples of mud bricks were examined and characterized using various techniques, including SEM-EDX, TEM, PLM, XRF, XRD, and mechanical properties analysis. The results indicated that GO nanomaterials significantly improve the mechanical properties of mud brick tombs, allowing them to resist more compressive loading and ultimately resulting in more durable and long-lasting structures. By using these innovative materials, effective restoration and preservation of these ancient structures for future generations could be viable. This research has the potential to revolutionize the preservation of closed-box tombs, ensuring these historical landmarks stand longer the test of time.

1. Introduction

Clay, extracted from the Earth, stands as one of the most prevalent building materials globally. However, it is concurrently recognized as one of the most vulnerable due to inherent weaknesses and soil material heterogeneity, posing challenges in overall decay categorization and manipulations [1]. Clay brickwork is one of the oldest and strongest construction techniques used by humankind. Masonry consists of physically built stable masses of small fundamentals, with or without mortar. It was an essential building material in the Egyptian and Roman periods. Clay brick tombs continued to be used during medieval and modern times. Although there were several changes in clay brick use, shape and methods of manufacture along thousands of years of continuous growth, the ease of use that led its success stayed [2]. The clay bricks utilized in tomb construction exhibit diverse shapes, sizes, and colors, catering to various structural construction needs [3]. Notably, mud bricks undergo changes in color and size, including swelling and the emergence of fine and large cracks, particularly in humid environments, attributed to the impact of humidity [4].

In Aswan, Egypt, closed-box tombs have served as prominent funerary structures for millennia. Dotting the Aswan landscape, ancient closed-box tombs stand as silent testaments to past residents. Constructed from readily available Nile clay, these sealed chambers served not only as final resting places, but also as enduring markers of a civilization’s ingenuity. Historically, Aswan was renowned for its numerous Muslim jurists and hadith scholars and for hosting several Islamic cemeteries. The city functioned as an economic center, as it experienced a significant revival during the 9th century when the historic gold and emerald mines in the Eastern Desert at Wadi Allaqi, southeast of Aswan, were reopened. This economic resurgence attracted a growing population and established Aswan as a crucial stop for trade caravans [5]. Ancient closed-box tombs in Aswan transcended their role as mere resting places. Their construction served as a testament to the civilization’s engineering prowess. The positioning of these tombs, precisely behind the Nubian Museum, was deemed suitable due to its elevated location, protecting against flood-related risks and groundwater seepage. The architect utilized the natural surroundings, taking advantage of the nearby availability of silt and sand. Despite the inherent protection and arid atmospheric conditions, these tombs exhibit a poor state of preservation in their appearance.

The tombs examined in this study revealed the interment of the deceased following Islamic burial practices. The closed, rectangular projected tombs adhere to Islamic law. Following the burial of the deceased, the builder constructs a half-barrel-shaped structure to cover the rectangular section where the individual is interred [6]. This design results in tombs having the visual characteristic of a box covered with a half-barrel, notable for the specific bricks utilized in the superstructure. It is crucial to emphasize that this type of tomb lacks a dome, a feature commonly found in numerous Islamic cemeteries. The Earth’s surface predominantly comprises alluvial and fine sandy deposits, facilitating the exhumation, damage, and destruction of tombs. There is an inclination towards repurposing ancient cemeteries in general. In proximity to this area are the Fatimid Islamic cemeteries, which, while potentially sharing architectural similarities, exhibit distinct differences in the design of their upper domes [7].

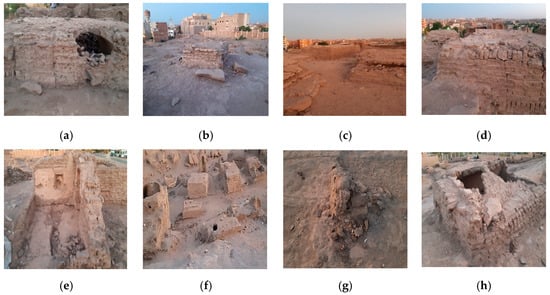

The tomb holds significant philosophical values, and its architecture serves as a valuable data source, providing insights into the cultural stage of the society in which it was constructed [8]. The tomb’s architecture witnessed rapid progress and development. It was originally only a pit with a small hill above it, and after that, it evolved into a huge and ornate structure over time. The technique employed for constructing existing tombs involved stacking stone piles and arranging them in a square formation. At the bottom of the tomb, the stone was arranged in a rectangular shape to show the architectural development of building the tomb in a more complex way so that it could bear the load of the building above [9]. Analyzing the evolution of cemetery architecture revealed a diversity in the design of structures erected over tombs. The cemeteries investigated in our research demand attention, showcasing a traditional Islamic form harmonious with the surrounding environment. Tombs are elevated above ground level, with a rectangular brick coffin constructed inside. In Aswan’s Islamic archaeological tombs, two predominant types are observed: the square tomb with a dome and the rectangular tomb, comprising a central square with a dome flanked by two rectangles, each featuring a flat or vaulted structure. Notably, some tombs in this study lack a dome [Figure 1a–d].

Figure 1.

(a) Archaeological box tombs, (b) tomb opening closed with irregular mud brick and sand bricks, (c) erecting the rectangular brick coffin, (d) tombs in poor state of preservation and appearance, (e) remaining part of architectural elements, (f) numerous cemeteries in poor condition and collapsed, (g) completely lost tomb, (h) box tomb with evidence of closure in the vault, displaying significant collapse and loss of large parts.

These tombs are predominantly constructed with mud brick adobe blocks, susceptible to various deterioration factors, as identified by [10]. The most significant factor is continuous neglect over the years, exacerbated by the absence of a clear preservation strategy [11]. The continuous environmental changes and the inherent weakness of building materials in these cemeteries lead to significant issues such as large cracks, partial loss of bricks, and partial or complete collapse, as noted by [12]. Therefore, urgent interventions are imperative, as illustrated in Figure 1e–h.

Recent research has explored the potential of graphene for enhancing mortar performance [13,14]. Studies have shown that incorporating graphene into mortar formulations significantly improves its durability and mechanical properties [15,16]. Notably, some studies suggest that adding small amounts of graphene oxide (GO) powder, typically between 0.04% and 0.08% of the weight of the mortar mix, leads to a remarkable increase in mechanical strength [17,18].

This paper examines the potential of enhancing the durability of closed-box tombs in Aswan. A key objective of this research is to explore the use of graphene oxide (GO), a novel nanomaterial, as a treatment method for mud bricks. By incorporating GO into the mud brick composition, we aim to address the inherent weaknesses of mud brick materials, such as susceptibility to moisture and erosion, and explore a potential treatment method to improve the durability of mud brick tombs.

2. Design Methodology

This research employed a multi-faceted approach to assess the effectiveness of graphene oxide nanoparticles in enhancing the durability of mud bricks used in ancient closed-box tombs. The methodology involved a comprehensive characterization of damaged mud bricks followed by the incorporation of graphene oxide and subsequent mechanical testing.

Firstly, samples were extracted from the degraded tomb walls for cross-sectional analysis. These samples were examined under a polarizing microscope to understand the microstructure of the mud bricks. Subsequently, a scanning electron microscope (SEM) provided high-resolution images of the sample surfaces, revealing potential cracks or deterioration. Further investigation using a transmission electron microscope (TEM) was envisaged to gain deeper insights into the material’s composition at the nanoscale. Additionally, X-ray fluorescence (XRF) analysis identified the elemental makeup of the mud bricks, aiding in the design of an effective treatment strategy.

Following the in-depth characterization, graphene oxide nanoparticles were prepared using a suitable method. The prepared nanoparticles were then incorporated into the mud brick matrix, potentially through impregnation or other techniques. Finally, mechanical testing was conducted to evaluate the impact of graphene oxide on the mechanical properties of the treated mud bricks, such as compressive strength and flexural strength.

2.1. Samples Preparation for Cross-Sectional Analysis

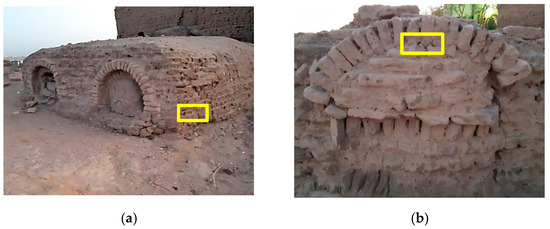

Two samples were collected from the damaged wall to investigate and characterize the mud bricks. A mixture of epoxy and hardener at a 100:2 mL ratio was used to embed the samples in epoxy Number 27751 for cross-sectional analysis. After the epoxy dried, regular observations were conducted by BM to ensure a smooth and high-quality surface on the samples. Subsequently, the samples were ground and polished using various sandpaper sizes, including wet-type sandpaper. The analysis uses a polarizing microscope. The observations were conducted with the BM model on the Olympus BX53. Scanning electron microscope was used for detailed observation of the samples utilizing the JEOL-5500LV model with an acceleration voltage of 20 kV [Figure 2a,b].

Figure 2.

(a) General view of the Islamic tomb, closed within the vault, and (b) samples of the Islamic tomb.

2.1.1. Polarizing Microscope Investigation

The cross-sections of mud brick samples were examined using the Olympus BX53 polarizing microscope equipped with UIS2 infinity-corrected optics. This microscope offers outstanding performance with polarized light for detailed sample analysis. The observations were conducted with the BM model on the Olympus BX53.

2.1.2. Scanning Electron Microscope Investigation

Scanning electron microscopy (SEM), utilizing the JEOL-5500LV model with an acceleration voltage of 20 kV, was employed to investigate the surface morphology of mud brick samples.

2.1.3. Transmission Electron Microscope Investigation

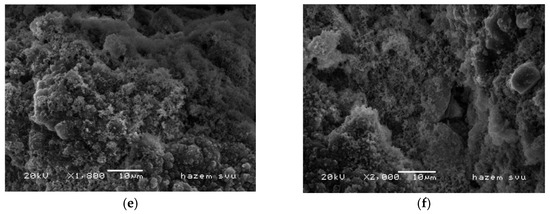

Transmission electron microscopy (TEM) was conducted using the JEOL JEM-2100 high-resolution transmission electron microscope, operating at an accelerating voltage of 200 kV. The samples under study exhibited an average size length of 1–3 µm, thickness ranging from 1 to 5 nm, and a sheet-like structure characteristic of graphene oxide nanomaterial.

2.1.4. X-ray Fluorescence Analysis

X-ray fluorescence (XRF) was employed to identify the elemental composition of mud bricks. X-ray fluorescence was performed using X-SUPEREME –HITACHI. The samples were prepared at the Central Laboratory of South Valley University, Egypt.

2.1.5. X-ray Diffraction Analysis

X-ray diffraction (XRD) was utilized to identify graphene oxide nanoparticles. X-ray diffraction pattern was performed using XPERT-PRO Powder Diffractometer system, with 2 theta (20°–80°), with Minimum step size 2 Theta: 0.001, and at wavelength (Kα) = 1.54614°. The samples were prepared at the Central Laboratory of South Valley University, Egypt.

2.2. Preparation of Graphene Oxide

The most exciting and productive periods in scientific research often coincide with the discovery of novel materials, offering opportunities to explore and address scientific challenges. The discovery of free-standing graphene ushered in one such period. Graphene, a two-dimensional (2D) crystalline carbon allotrope, has garnered significant research interest due to its exceptional intrinsic features and electronic properties. Despite its relatively short history, graphene has already unveiled a multitude of new physical and chemical properties to investigate, presenting a plethora of potential applications in various technological fields, including nanocomposites, nano-electronics, sensors, batteries, supercapacitors, and hydrogen storage.

Preparation Method

The synthesis of graphene involved the chemical reduction of graphene oxide through two distinct processes: sodium borohydride reduction and hydrothermal reduction. The initial graphene oxide was prepared using an enhanced version of Hummer’s method. In this approach, a mixture of concentrated H2SO4/H3PO4 (360:40 mL) was added to a blend of graphite flakes (3.0 g, 1 wt equiv.) and KMnO4 (18.0 g, 6 wt equiv.), generating a slight exotherm at 35–40 °C. The reaction was then heated to 50 °C and stirred for 12 h [19]. Following cooling to room temperature, the mixture was poured onto ice (~400 mL) with 30% H2O2 (3 mL). For workup, the mixture underwent sieving through a metal U.S. Standard testing sieve (W.S. Tyler, Mentor, OH, USA, 300 μm) and subsequent filtration through polyester fiber (Carpenter Co., Riverside, CA, USA). The filtrate was centrifuged (4000 rpm for 4 h), and the supernatant was decanted [20]. The residual solid underwent successive washes with 200 mL of water, 200 mL of 30% HCl, and 200 mL of ethanol. After each wash, the mixture was sifted through the U.S. Standard testing sieve and filtered through polyester fiber, with the filtrate centrifuged (4000 rpm for 4 h), the supernatant decanted, and the solid dried [21].

2.3. Preparation of the Innovative Nanomaterial Graphene Oxide for Consolidation

The GONs (average size 40–50 nm) were dispersed in water of 0.5% and 1%. The nanomaterial was then treated using the sonication technique by dispersing 0.5 gm wt% of GONs powder in 1000 mL of distilled water and 1% using the sonication technique by dispersing 1 gm wt % of GONs powder in 1000 mL of distilled water for 20 min using an ultrasonic mixture and magnetic stirrer.

2.4. Mechanical Testing

The uniaxial compression test was employed to measure the treated mud bricks’ compressive strength (UCS). This test aids in determining the maximum stress and compression load that leads to specimen failure (σ = P/A), where σ is stress, P is the force applied, and A is the cross-sectional area. The sample was positioned accurately in the center of the loading plate during the test. Samples must be measured exactly to be 3 cm × 3 cm before performing the test inside the device. The test is performed by applying pressure on the sample to reach the maximum force that the sample can resist before it collapses. The compression test was conducted using a universal testing machine at the Central Laboratory, South Valley University, Qena, Egypt.

3. Results

3.1. Closed-Box Tombs Archaeological Deterioration Factors

The archaeological heritage of closed-box tombs is deteriorating primarily due to environmental factors, such as erosion and harsh weathering, posing continuous threats to site stability. Initial assessments are crucial to determine the structural integrity of deteriorating buildings, followed by developing plans and measures to preserve essential parts and areas, preventing collapse and further decay [22]. Identifying risk factors that may accelerate the site’s deterioration is integral to environmental impact analysis, alongside immediate studies to achieve preservation goals.

The extreme temperature standards, particularly the high summer temperatures reaching up to 50 degrees, significantly impact the mud bricks in closed-box tombs in Aswan. These conditions result in increased thermal loads, manifesting in various types of cracks, including substantial ones. The wind damages closed-box tombs, causing weathering, and weakening mud bricks due to windstorms. Unanticipated rainfall in 2022 in Aswan has further damaged numerous adobe walls.

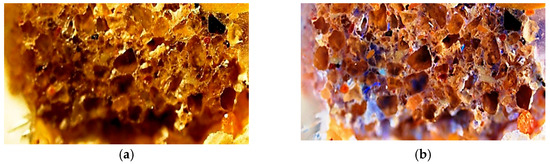

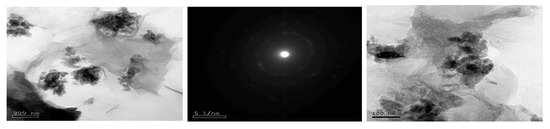

3.2. Polarizing Microscope Investigation

The polarizing microscope is a valuable method for investigating the minerals in mud bricks. Through polarized light microscopy (PLM), the analysis of mud brick samples revealed the presence of sand, aggregates, straw as a binding agent, and clay minerals. This composition contributes to an increased porosity of mud bricks under both UV and normal light conditions, as depicted in [Figure 3a,b].

Figure 3.

(a) Photomicrograph of cross-section image showing the structures of mud brick under normal light using PLM (BMM). (b) The same image under UV light.

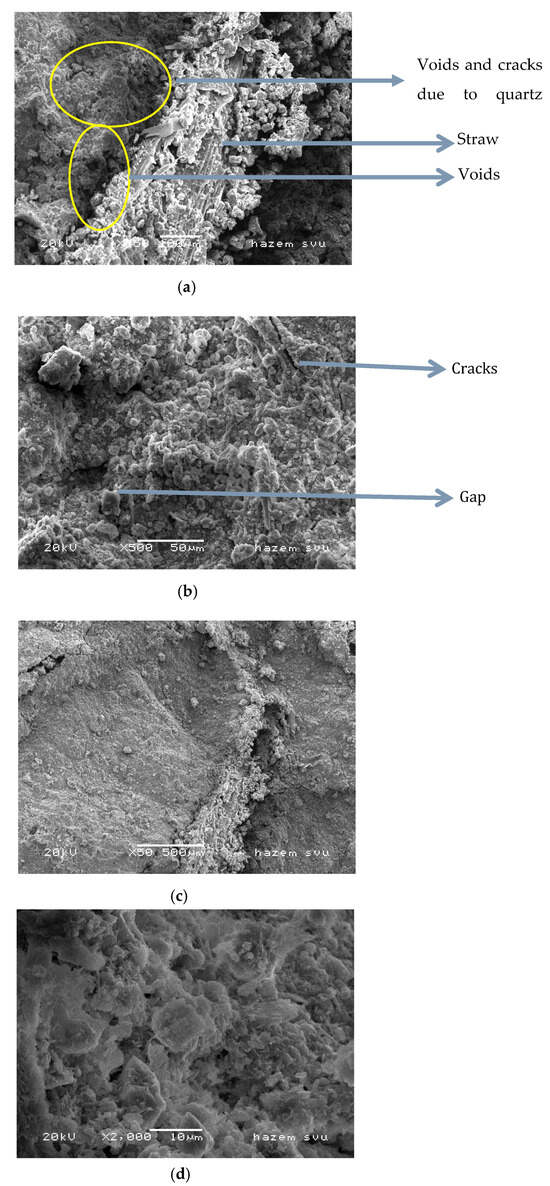

3.3. Scanning Electron Microscope Investigation (Before Treatment)

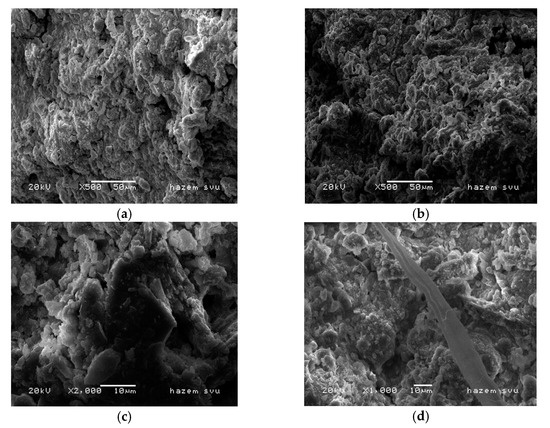

SEM images obtained before treatment indicated that mud brick samples exhibit numerous voids and cracks attributed to harsh weathering conditions. Additionally, there is evidence of grain rotation in quartz, organic material (straw), and clay minerals within the samples, as illustrated in [Figure 4a,b].

Figure 4.

(a–d) SEM photomicrographs illustrating gaps and cracks attributed to harsh weather conditions.

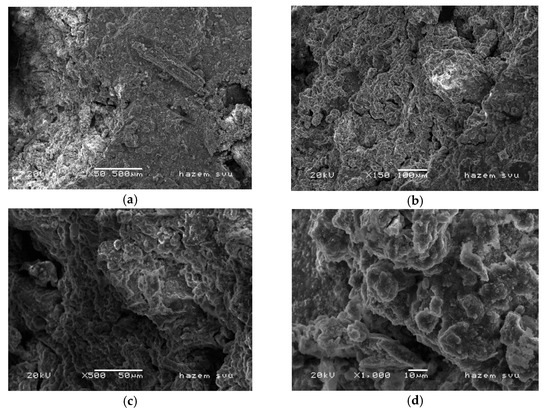

3.4. Scanning Electron Microscope Investigation (After Treatment)

The results obtained from the scanning electron microscope (SEM) after the consolidation of graphene oxide nanoparticles (0.5%) revealed the distribution of GO nanoparticles on the surface, effectively dispersed in the cracks of the mud brick samples (Figure 4a–d and Figure 5a–d). The results obtained from the scanning electron microscope (SEM) after the consolidation of graphene oxide nanoparticles (1%) revealed the distribution of GO nanoparticles on the surface, effectively dispersed in the cracks of the mud brick samples [Figure 6a–f].

Figure 5.

(a–d) SEM photomicrographs demonstrating the distribution of GO nanoparticles (0.5%) on the surface and their effective dispersion within cracks.

Figure 6.

(a–f) SEM photomicrographs demonstrating the distribution of GO nanoparticles (1%) on the surface and more dispersion within cracks.

3.5. Transmission Electron Microscope Investigation

TEM images of graphene oxide nanoparticles indicated a size of 200 nanometers. Morphological investigation revealed thick, flat flake layers with non-uniform particle sizes and a rough surface in graphene oxide, as depicted in Figure 7.

Figure 7.

TEM images of GO along with the SAED pattern, TEM images of graphene oxide nanoparticles indicated a size of 100- 200 nanometers. Morphological investigation revealed thick, flat flake layers with non-uniform particle sizes and a rough surface in graphene oxide.

3.6. X-ray Fluorescence Analysis

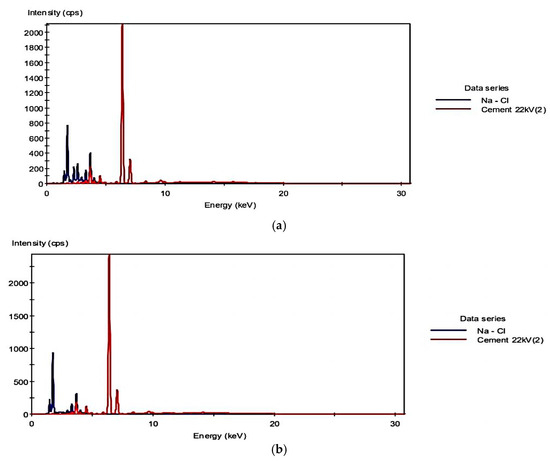

X-ray fluorescence (XRF) has been utilized to identify the elemental composition of mud brick minerals. The samples of mud bricks exhibited the presence of various elements, including calcite (Ca) as calcium carbonate (CaCO3), silica (SiO2) as quartz, sodium (Na), sodium chloride (NaCl), chloride (Cl), magnesium (Mg), aluminum (Al), and clay minerals, with prominent peaks for silicon (Si) and aluminum (Al). Additionally, iron (Fe) elements are identified as iron compounds, and sulfate (S) is present in the form of calcium sulfate (CaSO4·2H2O) [Figure 8a,b] and Table 1.

Figure 8.

(a,b): XRF spectrum of a clay brick sample from a closed-box tomb. The elemental composition of clay brick minerals is shown. The presence of calcite (Ca), silica (SiO2), sodium (Na), chloride (Cl), magnesium (Mg), aluminum (Al), and clay minerals is shown, with prominent peaks for silicon (Si) and aluminum (Al).

Table 1.

Elemental composition analysis of mud brick samples from the closed-box tomb.

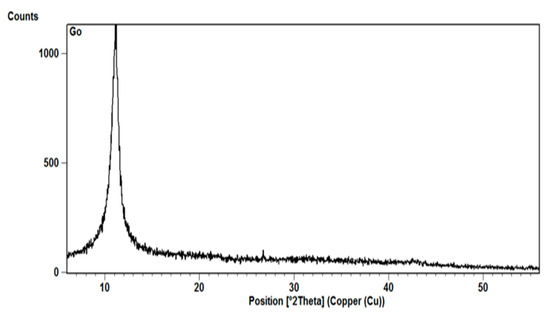

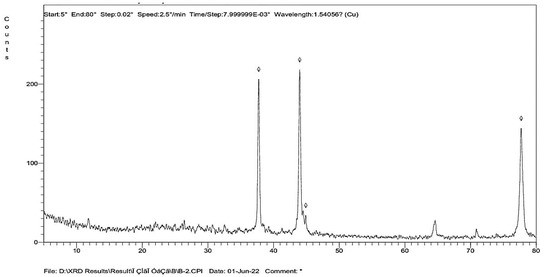

3.7. XRD Analysis of GO Nanoparticles

Graphene oxide nanoparticles were analyzed using X-ray diffraction (XRD). The XRD pattern was obtained using the XPERT-PRO Powder Diffractometer system, covering a 2-theta range from 10° to 50°. The XRD pattern of the graphene oxide nanoparticles is illustrated in Figure 8. Mud brick was analyzed using X-ray diffraction (XRD). The XRD pattern of the mud brick is illustrated in Figure 9 and Figure 10.

Figure 9.

XRD pattern of graphene oxide.

Figure 10.

XRD pattern of mud brick.

3.8. Treatment of Samples

As a result of the above studies, the studied mud bricks were evaluated using the following criteria:

- (a)

- Pre-consolidation: The first step was to apply temporary strips of tissue paper with GON 0.5% and 1%, in order to prevent weak parts of the mud brick from collapsing.

- (b)

- Mechanical cleaning: After the mud bricks had been pre-consolidated, surface deposits were carefully removed using an air pump to remove dust from mud bricks.

- (c)

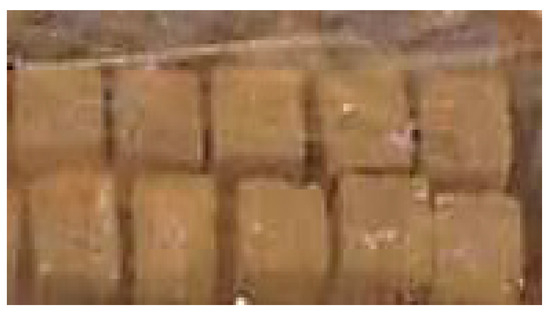

- Treatment of mud bricks: The goal of this treatment was to consolidate the mud bricks and treat them to stop them from collapsing in the long term. To treat the mud bricks multiple brushings per day for 3 consecutive days were performed in order to apply GONs onto the mud brick surfaces. The surfaces of the mud bricks were also treated with polyethylene sheets to prevent the treatment from evaporating. A multiple brushing process was conducted 2–4 times daily over three consecutive days to apply graphene oxide nanoparticles to the mud brick surfaces. Additionally, the mud brick surfaces were protected from evaporation by polyethylene sheets during this treatment [Figure 11].

Figure 11. Treatment of the mud bricks surfaces with polyethylene sheets.

Figure 11. Treatment of the mud bricks surfaces with polyethylene sheets.

3.9. Uniaxial Compressive Strength of the Mud Brick Specimens before and after Treatment

Uniaxial compressive strength is a valuable mechanical property for evaluating the performance of mud brick materials to withstand loads. It refers to the maximum stress a mud brick can resist when a compressive force is applied in a single direction, typically along its vertical axis. This test provides valuable insights into durability and the material performance. The compressive strength of mud brick specimens is measured using a compression testing machine and the sample size is 3 × 3 × 3 cm3. The specimens are carefully positioned between the platens of the machine, ensuring proper alignment. A constant and controlled load is then applied axially to the top platen, inducing a compressive stress on the brick in the vertical direction. This load is steadily increased until the specimen fractures, and the maximum force achieved is used to calculate the compressive strength. The compressive strength is calculated from the failure load divided by the cross-sectional area resisting the load and reported in units of pound-force per square inch (psi) or megapascals (MPa). A total of 15 mud brick specimens were tested to evaluate the effectiveness of graphene oxide nanoparticle (GON) treatment. The tests included five control specimens, five specimens treated with 0.5% GON, and five specimens treated with 1% GON. The control group provided a baseline value representing the inherent compressive strength of the untreated mud bricks.

The result showed that the samples with natural additives gave compressive strengths with an average of 2.06 MPa. Upon comparing the compressive strength before and after treatment with graphene oxide nanoparticles (GONs), as indicated in Table 2, the results suggest that the GONs, effectively dispersed within the pores, significantly improved the mechanical properties of the mud brick samples. The treatment added a protective layer to the surface of the mud bricks which resulted in increasing the compressive strength of material. This indicates that the GON treatment successfully reinforced the mud brick structure, allowing it to resist more compressive loading.

Table 2.

The compressive strengths of the mud bricks before and after the treatment with GON.

4. Discussion

Closed-box tombs currently face neglect and weakening, requiring crucial intervention to protect them from potential deterioration or extinction. The findings of this study revealed that extreme temperatures and wind significantly affected the structural integrity and preservation of mud bricks used in closed-box tombs. Understanding the effects of these environmental factors on mud bricks is crucial for the preservation of these historical tombs. The arid climate of Aswan region, characterized by extreme temperatures reaching up to 50 degrees Celsius and significant daily fluctuations, poses a unique challenge to the preservation of mud brick tombs. The intense solar heat can cause substantial thermal expansion within the bricks, leading to cracking and spalling. Conversely, rapid nighttime cooling induces condensation and moisture accumulation within the tomb. This moisture weakens the mud bricks and promotes the growth of hygroscopic salts, which can cause internal fracturing and material breakdown. Over extended periods, these cyclical stresses can cause significant structural degradation, jeopardizing the integrity of the tomb and endangering the precious artifacts it contains.

Furthermore, the influence of wind on closed-box tombs in arid environments presents a complex challenge. While the enclosed nature of these structures shields the internal surfaces from direct wind erosion, it also introduces a weathering mechanism. Persistent high winds laden with sand particles can act as an abrasive force on the tomb’s exterior, particularly around the entrance. Over extended timescales, this abrasion can widen existing cracks or gaps in the mud bricks, compromising the overall integrity of the seal. This weakening of the entrance, designed to prevent external elements from entering, ironically creates a pathway for the very elements—windblown sand and potentially moisture—to infiltrate the tomb interior and accelerate degradation of the contained artifacts. The long-term deterioration processes that affect the physical, mechanical, and structural properties of building materials over time have been examined in various aspects by numerous researchers [23,24].

The preservation of mud brick materials is significantly influenced by the cumulative effects of various deterioration processes. Analysis of the altered properties of mud bricks shows a gradual decline in key parameters as the material ages, which is directly linked to the length of exposure to these harmful factors. SEM images obtained before treatment indicated that mud brick samples exhibit numerous voids and cracks attributed to harsh weathering conditions. However, the SEM post-treatment images revealed successful interaction between graphene oxide nanoparticles and mud brick grains, effectively clogging surface pores. Polarizing microscopy is invaluable for investigating the minerals in mud bricks, including sand, aggregates, straw as a binding agent, and clay minerals. The XRF analysis accurately identified major and minor compositions of the mud bricks, highlighting iron oxide (Fe) as a minor element and silica (Si) as the main element. Furthermore, the XRD analysis identified the composition of graphene oxide nanoparticles. The samples collected from the closed-box tombs were analyzed by XRD. The results showed that the major components of mud brick are Quartz, Orthoclase, Calcite and Kaolinite with traces of Montmorillonite.

The uniaxial compressive strength tests of the mud brick specimens provided a crucial evaluation of the effectiveness of the graphene oxide nanoparticle (GON) treatment method in preserving mud bricks. Upon comparing the compressive strength before and after treatment with GONs, the results suggest that the GONs, effectively dispersed within the pores, significantly improved the mechanical properties of the mud brick. The treatment improved the compressive strength of the mud bricks by adding a protective layer to their surface. This indicates that the GON treatment successfully reinforced the mud brick structure, allowing it to resist more compressive loading. This higher compressive strength demonstrates the ability of the treated mud bricks to resist greater loads, ultimately resulting in more durable and long-lasting structures. Based on these study findings, applying these compositions to treat mud bricks in the closed-box tombs in Aswan, Egypt, is recommended. This finding aligns with earlier research that explored the potential use of graphene oxide (GO) to enhance building materials [25,26]. Some of these studies focused on strengthening cement mixtures for improved mechanical performance, while others investigated GO’s potential as a protective layer to extend the durability of concrete [27,28]. Overall, these studies have demonstrated the significant effect of GO in improving the strength and durability of building materials. The application of GONs to mud brick conservation is a new area with limited research [29,30]. More studies are needed to assess its effectiveness and long-term impact. Researchers can gain valuable insights into the potential of this new approach for strengthening and preserving mud brick structures. Future research will build upon these findings, utilizing nanocomposites to strengthen and retrofit intervention plans and strategies for treating mud brick artifacts.

5. Conclusions

This study examined the potential of graphene oxide nanoparticles (GONs) as a treatment for mud bricks with the aim of consolidating mud bricks used in closed-box tombs. It demonstrated the effectiveness of transmission electron microscopy (TEM) as a non-destructive method for investigating the shape sheets of graphene oxide nanoparticles and their consolidating effectiveness.

Closed-box tombs have served as prominent funerary structures for millennia in Aswan, Egypt. These closed-box tombs are highly vulnerable to collapse as a result of ongoing weathering and various deterioration mechanisms. The ultimate objective of this research is to extend the durability of mud brick materials, thereby ensuring effective restoration and preservation of these historical and cultural structures for future generations. Deterioration mechanisms of architectural elements are complex since they are influenced by a variety of factors including physical, chemical, human, and biological agents. These ongoing factors can lead to the complete loss of these elements. Diagnostics and observation are therefore essential practices for understanding and mitigating the impact of hazards on the stability of materials and archaeological sites.

The results indicated that extreme temperatures and wind significantly affect the structural integrity of mud bricks in closed-box tombs. Furthermore, the moisture weakens the mud bricks and promotes the growth of hygroscopic salts, which can cause internal fracturing and material breakdown. Over extended periods, these cyclical stresses can cause significant structural degradation, jeopardizing the integrity of the tomb and endangering the precious artifacts it contains. Scanning electron microscopy (SEM) images obtained before treatment indicated that mud brick samples exhibit numerous voids and cracks attributed to harsh weathering conditions. The X-ray fluorescence (XRF) analysis accurately identified major and minor compositions of the mud bricks, highlighting iron oxide (Fe) as a minor element and silica (Si) as the main element.

The graphene oxide nanoparticles proved to be suitable for consolidating mud bricks, leading to the enhanced mechanical properties of the mud bricks. Upon comparing the compressive strength before and after treatment with GONs, the results suggest that the GONs, effectively dispersed within the pores, significantly improved the mechanical properties of the mud brick. The treatment improved the compressive strength and durability of the mud bricks by adding a protective layer to their surface. This indicates that the GON treatment successfully reinforced the mud brick structure, allowing it to resist more compressive loading. By using these innovative materials and techniques, effective restoration and preservation of these ancient structures for future generations could be viable. This consolidation technique has the potential to revolutionize the preservation of closed-box tombs, ensuring these historical landmarks stand the test of time.

Author Contributions

G.A.A. and M.T.; methodology, M.B. and M.M.E.K. software, A.S. and G.A.A. validation, M.B. and M.M.E.K. formal analysis, G.A.A. and M.T.; investigation A.S. and G.A.A. resources G.A.A. and M.T. data curation, M.B. and M.M.E.K. writing—original draft preparation, M.M.E.K. writing—review and editing; A.S., G.A.A. and M.T. visualization, M.M.E.K. supervision A.S. and G.A.A. All authors have read and agreed to the published version of the manuscript.

Funding

The research reported herein was funded by the Deanship of Scientific Research at the University of Ha’il, Saudi Arabia, under the contract: RG-23238.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors would like to express their deepest gratitude to the Deanship of Scientific Research at the University of Ha’il for providing the necessary support to conduct this research.

Conflicts of Interest

The authors have no conflicts of interest.

References

- Rainer, L. Deterioration and pathology of earthen architecture. Terra Lit. Rev. 2008, 45–61. [Google Scholar]

- Francisco, M.F.; Lourenço, P.B.; Fernando, C. Ancient Clay Bricks: Manufacture and Properties. In Materials, Technologies and Practice in Historic Heritage Structures, 1st ed.; Springer: Dordrecht, The Netherlands, 2010; Chapter 3, pp. 29–48. [Google Scholar] [CrossRef]

- Alsubaie, M.S.; Almutery, S.B.; Almoufleh, A.A.; Khalil, M.M.E.; Sallam, A. Architectural Heritage Conservation in the City of Qurh: Assessing and Stabilizing Islamic Era Mud Brick Structures. Mediterr. Archaeol. Archaeom. 2024, 24, 50–73. [Google Scholar] [CrossRef]

- Khalil, M.M.E.; Khodary, S.M.; Youssef, Y.M.; Alsubaie, M.S.; Sallam, A. Geo-Environmental Hazard Assessment of Archaeological Sites and Archaeological Domes—Fatimid Tombs—Aswan, Egypt. Buildings 2022, 12, 2175. [Google Scholar] [CrossRef]

- Björnesjö, S.; et Speiser, P. The South Necropolis of the Fatimid Cemetery of Aswan. Ann. Islam. 2014, 48, 117–134. [Google Scholar] [CrossRef]

- Afifi, M.N. Funerary Domes Remaining in Upper Egypt in the Islamic Era A Comparative Architectural Archaeological Study. Ph.D. Thesis, Faculty of Archeology, Cairo University, Giza, Egypt, 2002. Available online: http://fa-arch.cu.edu.eg/en/AllPHDsIslamic.html (accessed on 23 December 2023).

- Huber, R.; Edwards, D.N. Gebel adda Cemetery One, 1963. Post-medieval reuse of X-Group tumuli. Sudan Nubia 2010, 14, 83–90. [Google Scholar]

- Makmur, M.; Mulyadi, Y.; Hasanuddin, H.; Hadrawi, M.; Kalsum, N.; Sahroni, A.; Wattimena, L. Tomb Architecture. In Proceedings of the 9th Asbam International Conference (Archeology, History, & Culture in The Nature of Malay) (ASBAM 2021), Makassar, Indonesia, 27–8 October 2021; Atlantis Press: Amsterdam, The Netherlands, 2022; pp. 102–109. [Google Scholar] [CrossRef]

- Moguin, M. Ancient Solutions for Future Sustainability: Building with Adobe, Rammed Earth and Mud. In Proceedings of the Sustainable Construction: Proceedings of the First International Conference of CIB TG, Tampa, FL, USA, 6–9 November 1994; pp. 543–552. Available online: https://www.irbnet.de/daten/iconda/CIB_DC24848.pdf (accessed on 23 December 2023).

- El-Gohary, M. The contrivance of new mud bricks for restoring and preserving the Edfa ancient granary-Sohag, Egypt. Int. J. Conserv. Sci. 2012, 3, 67–78. [Google Scholar]

- Bityukova, L.; Limberg, M. Complex study of composition of building stones of the historical objects in Tallinn (Estonia) and assessment of stone deterioration on the base of geochemical data. Geophys. Res. Abstr. 2005, 7, 1–4. [Google Scholar]

- Yasser, A. Modern Technology Applications in the Restoration of an Ancient Mud Brick Houses in Dakhla Oasis, Egypt. Int. J. Archaeol. 2016, 4, 87–94. [Google Scholar] [CrossRef]

- Faria, P.; Duarte, P.; Barbosa, D.; Ferreira, I. New composite of natural hydraulic lime mortar with graphene oxide. Constr. Build. Mater. 2017, 156, 1150–1157. [Google Scholar] [CrossRef]

- Diekamp, A.; Stalder, R.; Konzett, J.; Mirwald, P.W. Lime mortar with natural hydraulic components: Characterisation of reaction rims with FTIR imaging in ATR-mode. Hist. Mortars 2012, 7, 105–113. [Google Scholar]

- Zhang, C.; Zhu, X.; Wang, Z.; Sun, P.; Ren, Y.; Zhu, J. Facile synthesis and strongly microstructure dependent electrochemical properties of graphene/manganese dioxide composites for supercapacitors. Nano. Res. Lett. 2014, 9, 490. [Google Scholar] [CrossRef]

- Katman, H.B.Y.; Khai, W.J.; Kırgız, M.S.; Nehdi, M.L.; Benjeddou, O.; Thomas, B.S.; Papatzani, S.; Rambhad, K.; Kumbhalkar, M.A.; Karimipour, A. Transforming conventional construction binders and grouts into high-performance nano-carbon-binders and grouts for today’s construction. Buildings 2022, 12, 1041. [Google Scholar] [CrossRef]

- Shang, Y.; Zhang, D.; Yang, C.; Liu, Y.; Liu, Y. Effect of graphene oxide on the rheological properties of cement pastes. Constr. Build. Mater. 2015, 96, 20–28. [Google Scholar] [CrossRef]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.H.; Li, G.; Zhu, J.W.; Wang, M.C. Mechanical properties and microstructure of a graphene oxide–cement composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.; Jiang, D.; Zhang, Y.; Dubonos, S.; Grigorieva, I.; Firsov, A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Mueller, M.B.; Gilje, S.; Kaner, R.B.; Wallace, G. Processable Aqueous Dispersions of Graphene Nanosheets. Nat. Nanotechnol. 2008, 3, 101–105. [Google Scholar] [CrossRef]

- Marcano, D.C.; Jacob, M.; Alexander, S.; Sun, Z.; Alexander, S.; Lawrence, B.; Wei, L.; James, M. Improved synthesis of graphene oxide. ACS Nano 2010, 4, 4806–4814. [Google Scholar] [CrossRef]

- Hatır, M.E. Determining the weathering classification of stone cultural heritage via the analytic hierarchy process and fuzzy inference system. J. Cult. Herit. 2020, 44, 120–134. [Google Scholar] [CrossRef]

- Zaremba, M.; Trzciński, J.; Szczepański, T.; Bobrowska, A.; Welc, F. Influence of Deterioration on the Preservation of Mud Brock Architectural Based on the Monument from the Tell El-Retaba Archaeological Site. Int. J. Conserv. Sci. 2021, 12, 67–86. [Google Scholar] [CrossRef]

- Fort, R.; Alvarez de Buergo, M.; Gomez-Heras, M.; Vazquez-Calvo, C. Heritage, Weathering and Conservation, 1st ed.; Taylor and Francis: Abingdon, UK, 2006. [Google Scholar]

- Korayem, A.H.; Ghoddousi, P.; Javid, A.A.S.; Oraie, M.A.; Ashegh, H. Graphene oxide for surface treatment of concrete: A novel method to protect concrete. Constr. Build. Mater. 2020, 243, 118229. [Google Scholar] [CrossRef]

- Bheel, N.; Mohammed, B.S.; Liew, M.S.; Zawawi, N.A.W.A. Effect of Graphene Oxide as a Nanomaterial on the Durability Behaviors of Engineered Cementitious Composites by Applying RSM Modelling and Optimization. Buildings 2023, 13, 2026. [Google Scholar] [CrossRef]

- Zeng, W.; Wu, S.; Pang, L.; Sun, Y.; Chen, Z. The Utilization of Graphene Oxide in Traditional Construction Materials: Asphalt. Materials 2017, 10, 48. [Google Scholar] [CrossRef] [PubMed]

- Fonseka, I.; Mohotti, D.; Wijesooriya, K.; Lee, C.-K.; Mendis, P. Influence of Graphene oxide on abrasion resistance and strength of concrete. Constr. Build. Mater. 2023, 404, 133280. [Google Scholar] [CrossRef]

- Lin, J.; Shamsaei, E.; de Souza, F.B.; Sagoe-Crentsil, K.; Duan, W.H. Dispersion of graphene oxide–silica nanohybrids in alkaline environment for improving ordinary Portland cement composites. Cem. Concr. Compos. 2020, 106, 103488. [Google Scholar] [CrossRef]

- Alex, A.G.; Kedir, A.; Tewele, T.G. Review on effects of graphene oxide on mechanical and microstructure of cement-based materials. Constr. Build. Mater. 2022, 360, 129609. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).