Performance Evaluation of Highly Modified Asphalt-Based Binders in High Friction Surface Treatment: Comparative Study with Epoxy-Based System

Abstract

1. Introduction

2. Materials and Methodology

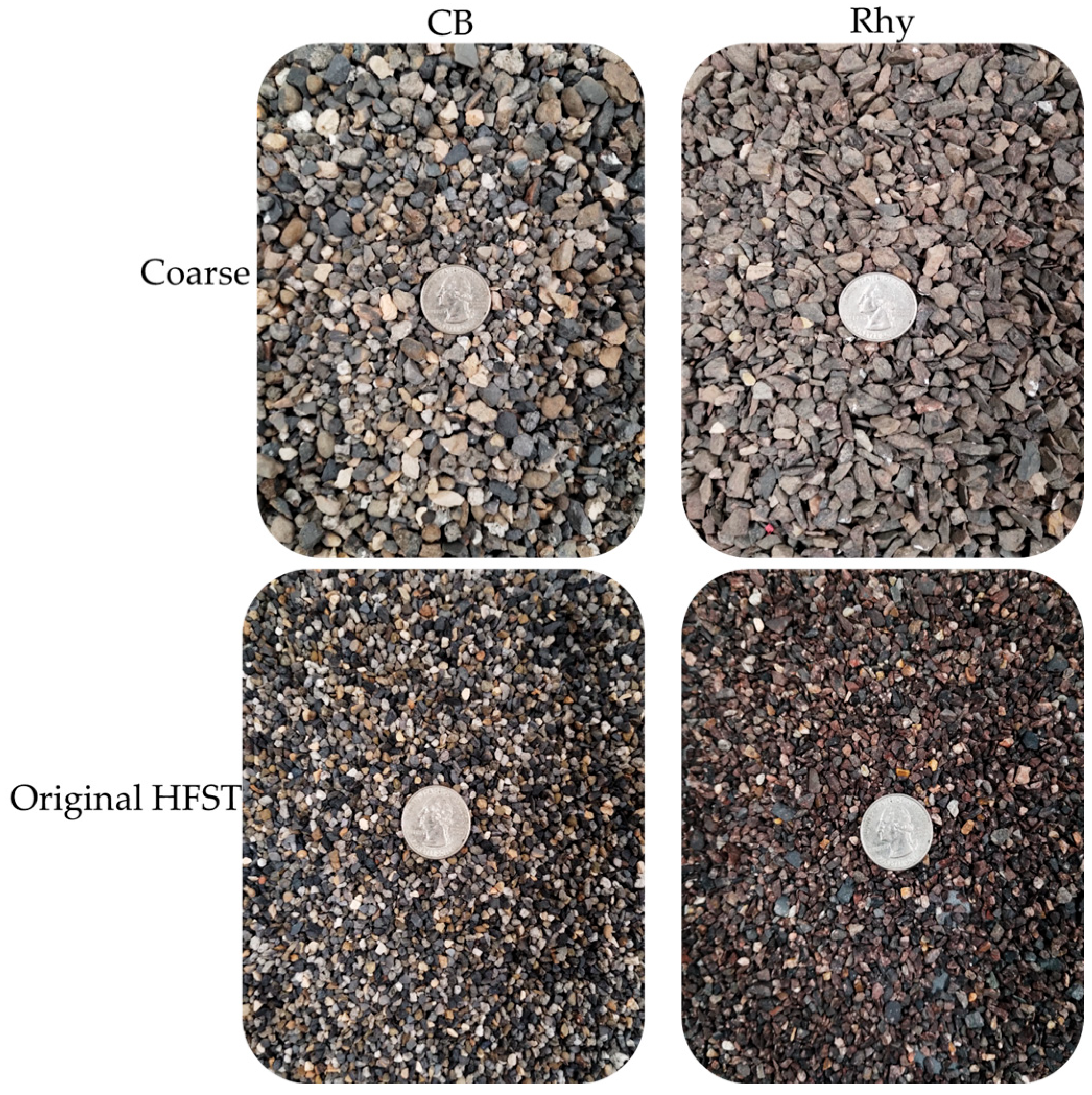

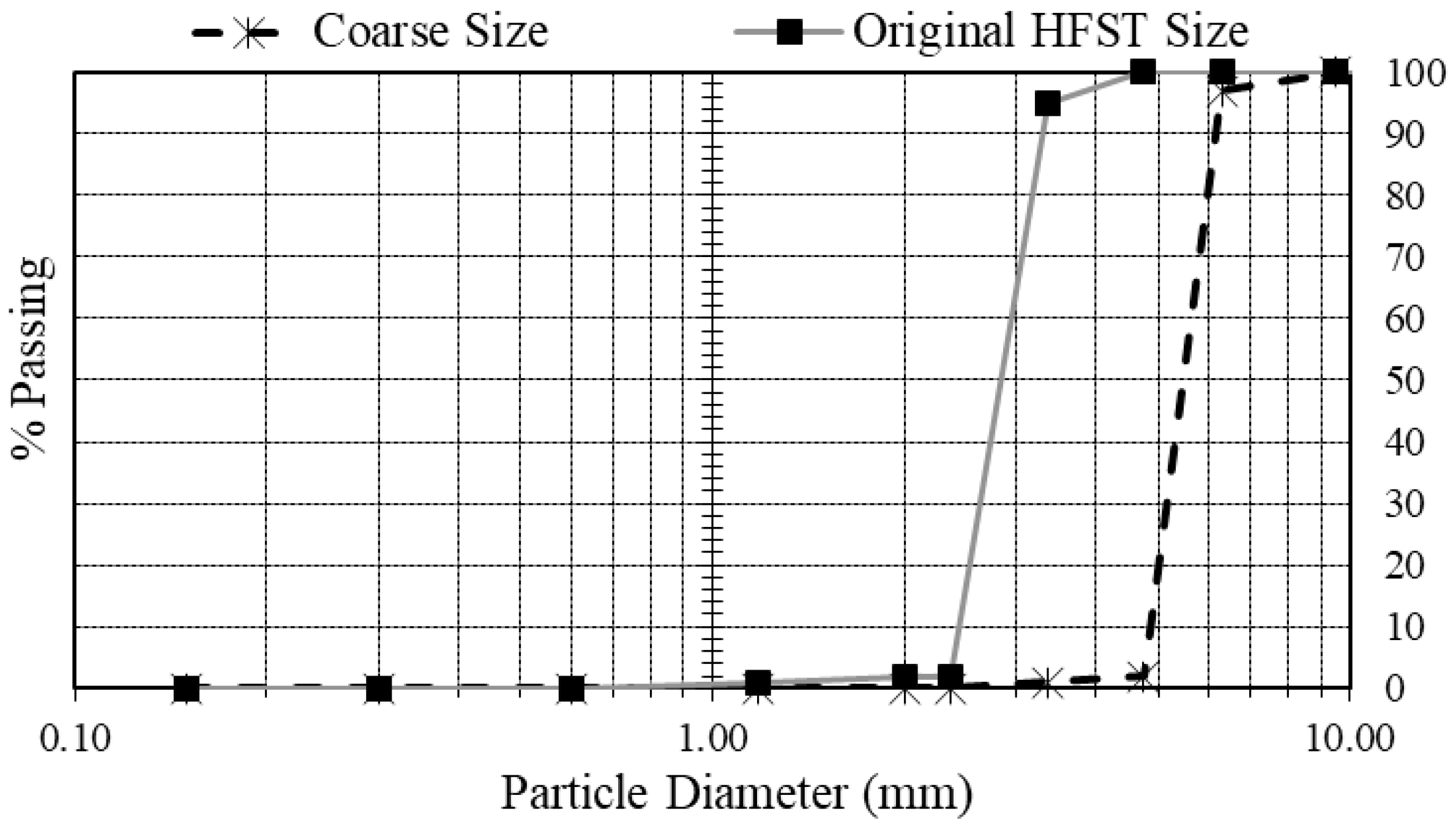

2.1. Aggregate

2.2. Binders

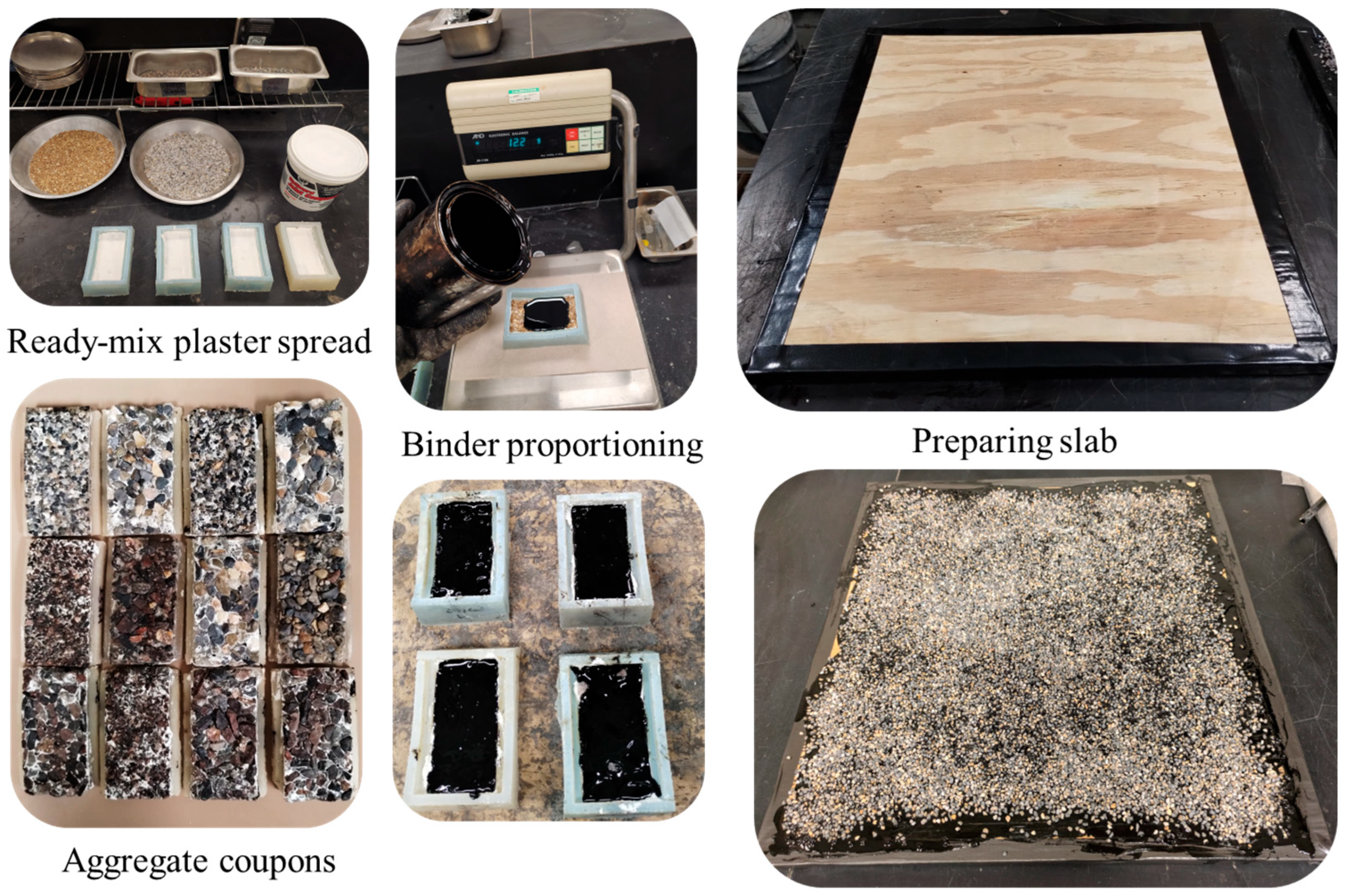

2.3. Fabricating HFST Specimens (Coupons and Slabs)

2.3.1. Preparation Process for Aggregate Coupons

2.3.2. Fabricating HFST Slabs

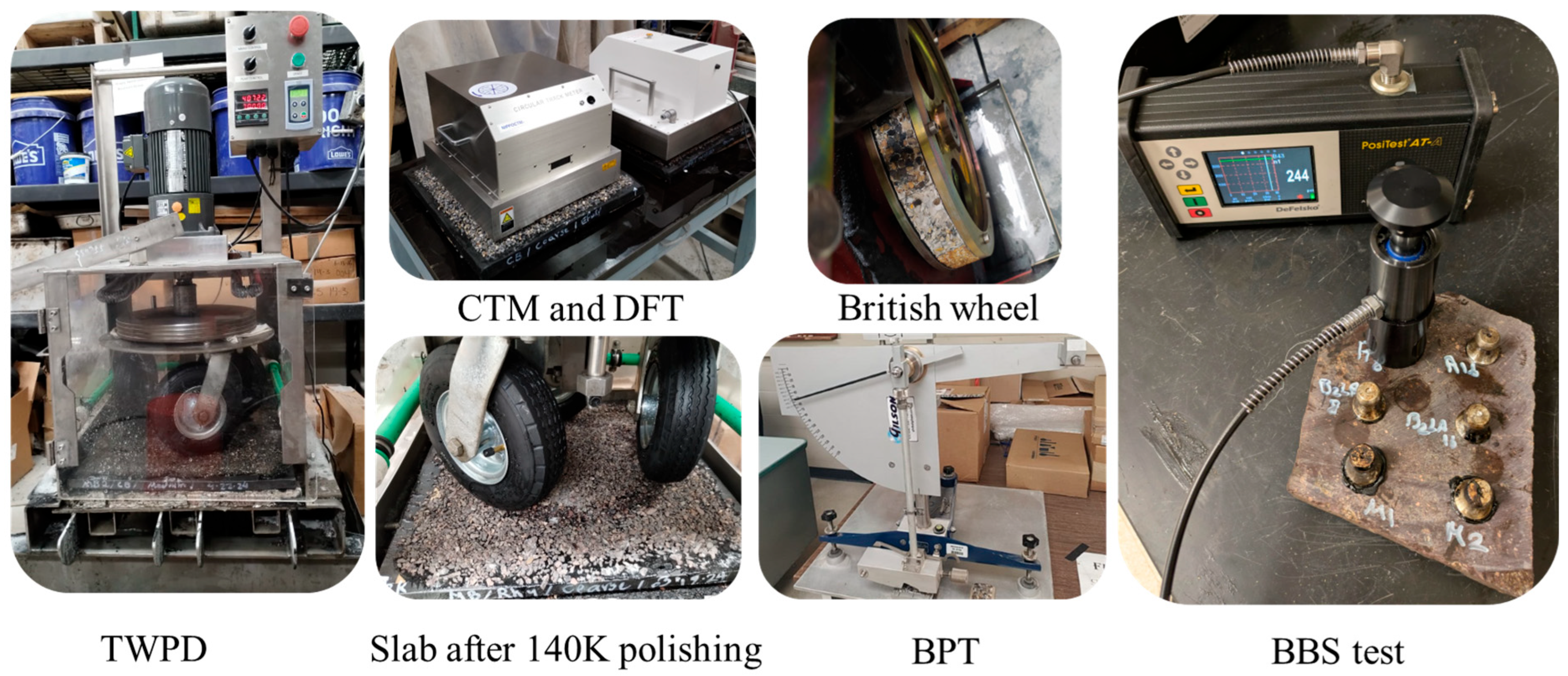

2.4. Assessment of Friction Properties Through Performance Tests

2.4.1. Evaluation with the BPT Device (British Pendulum Tester)

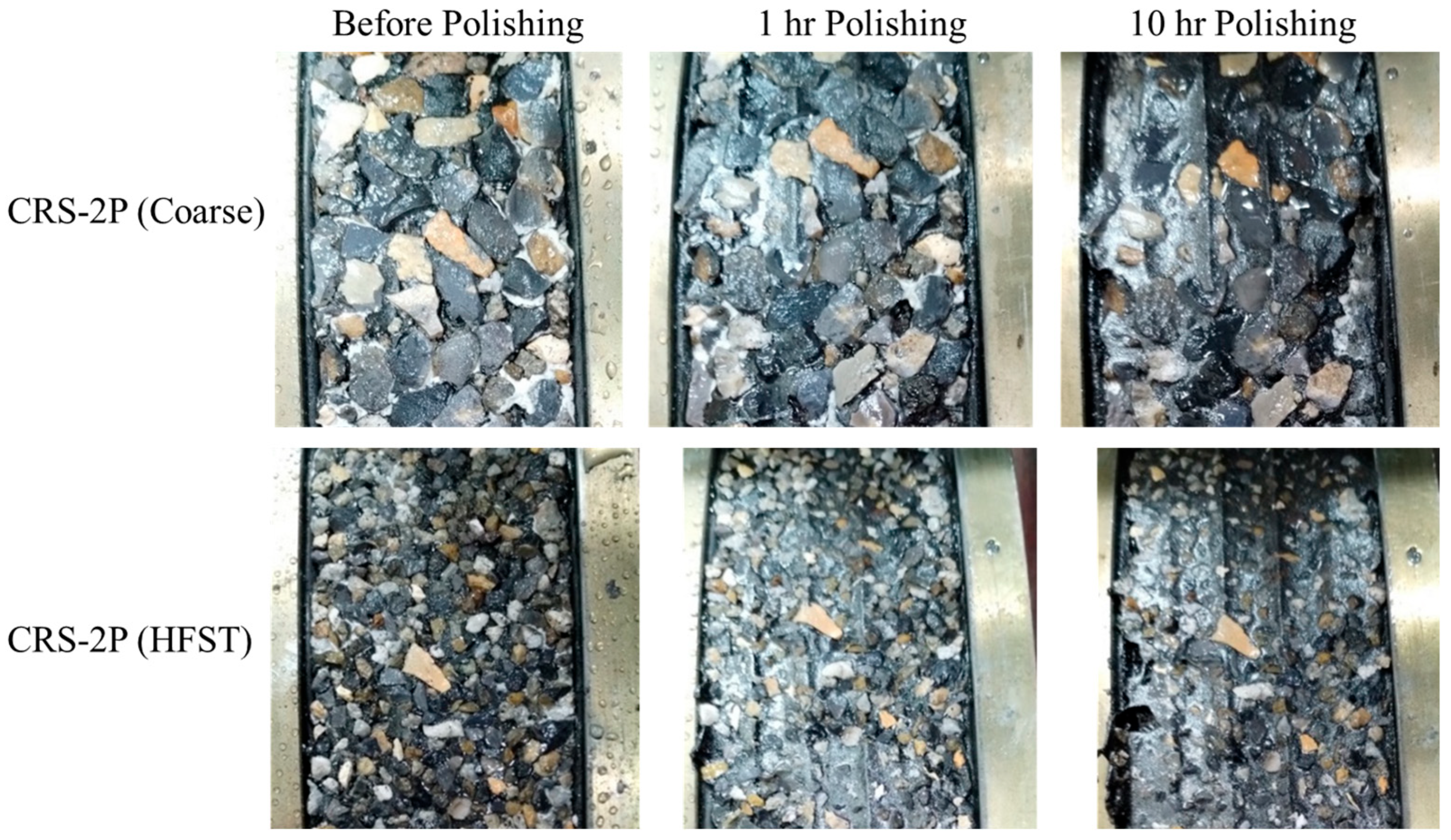

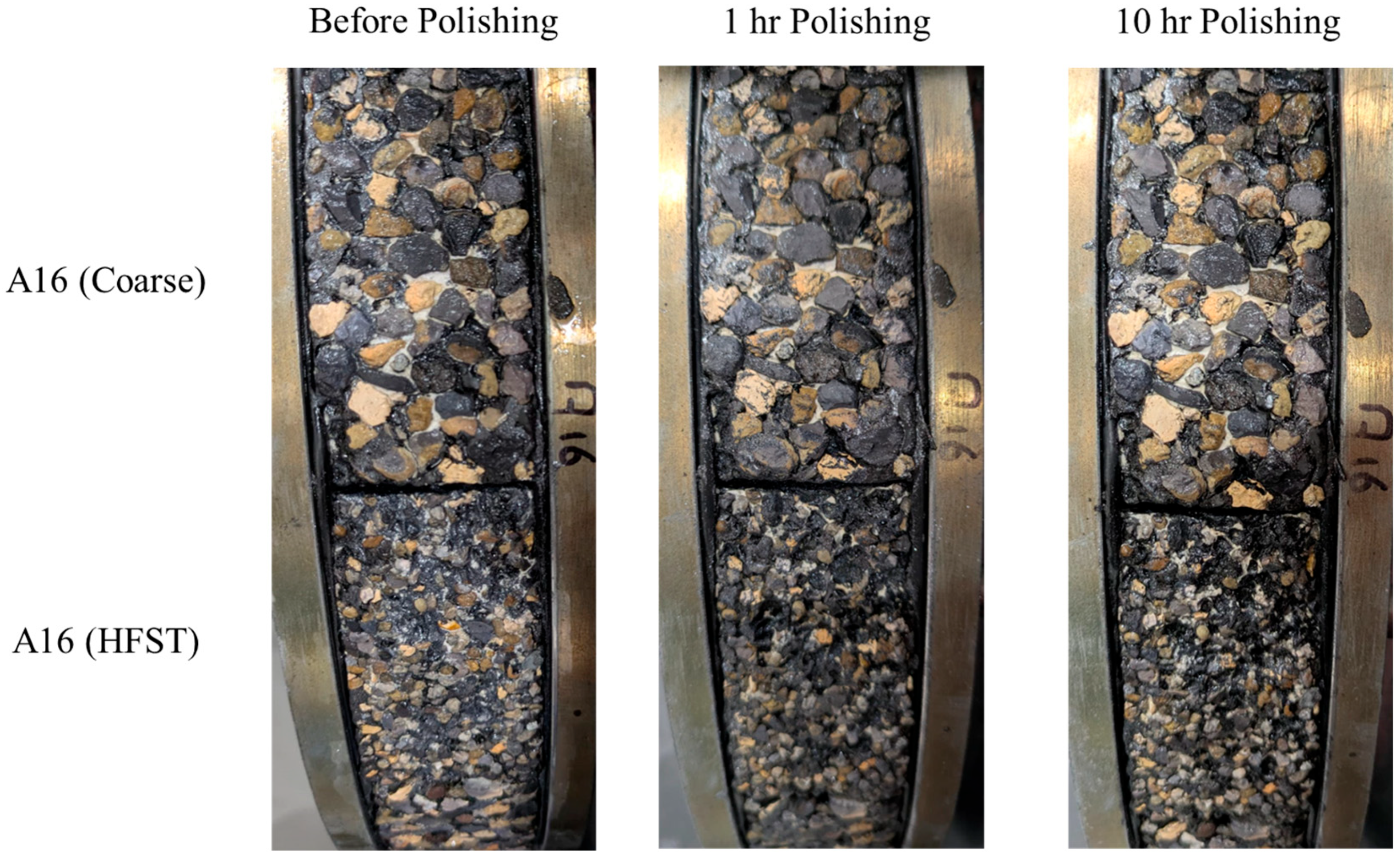

2.4.2. British Wheel-Based Accelerated Aggregate Polishing

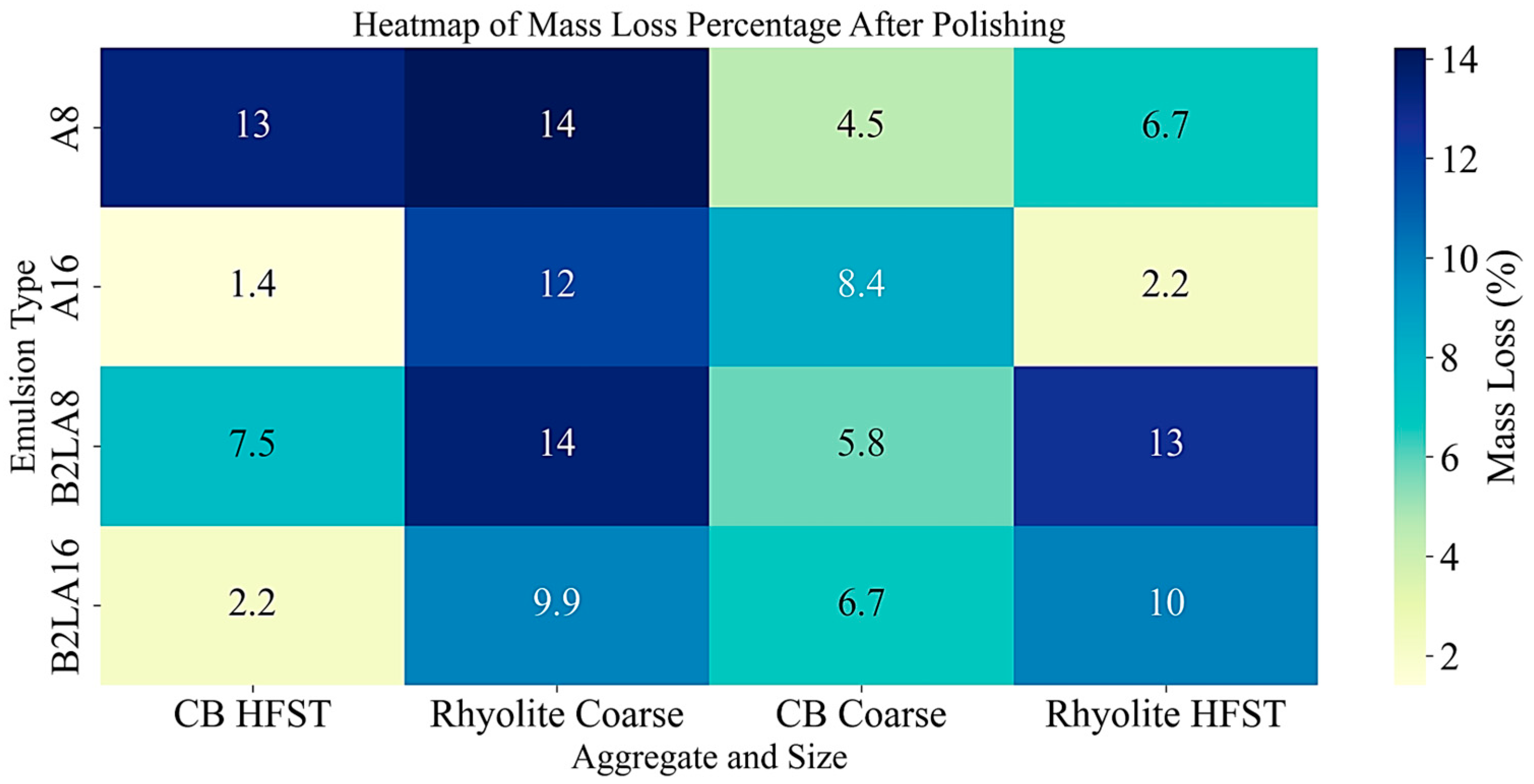

2.4.3. Mass Loss Rate

2.4.4. DFT and the Three-Wheel Polishing Device (TWPD) Evaluation

2.4.5. Circular Track Meter (CTM)

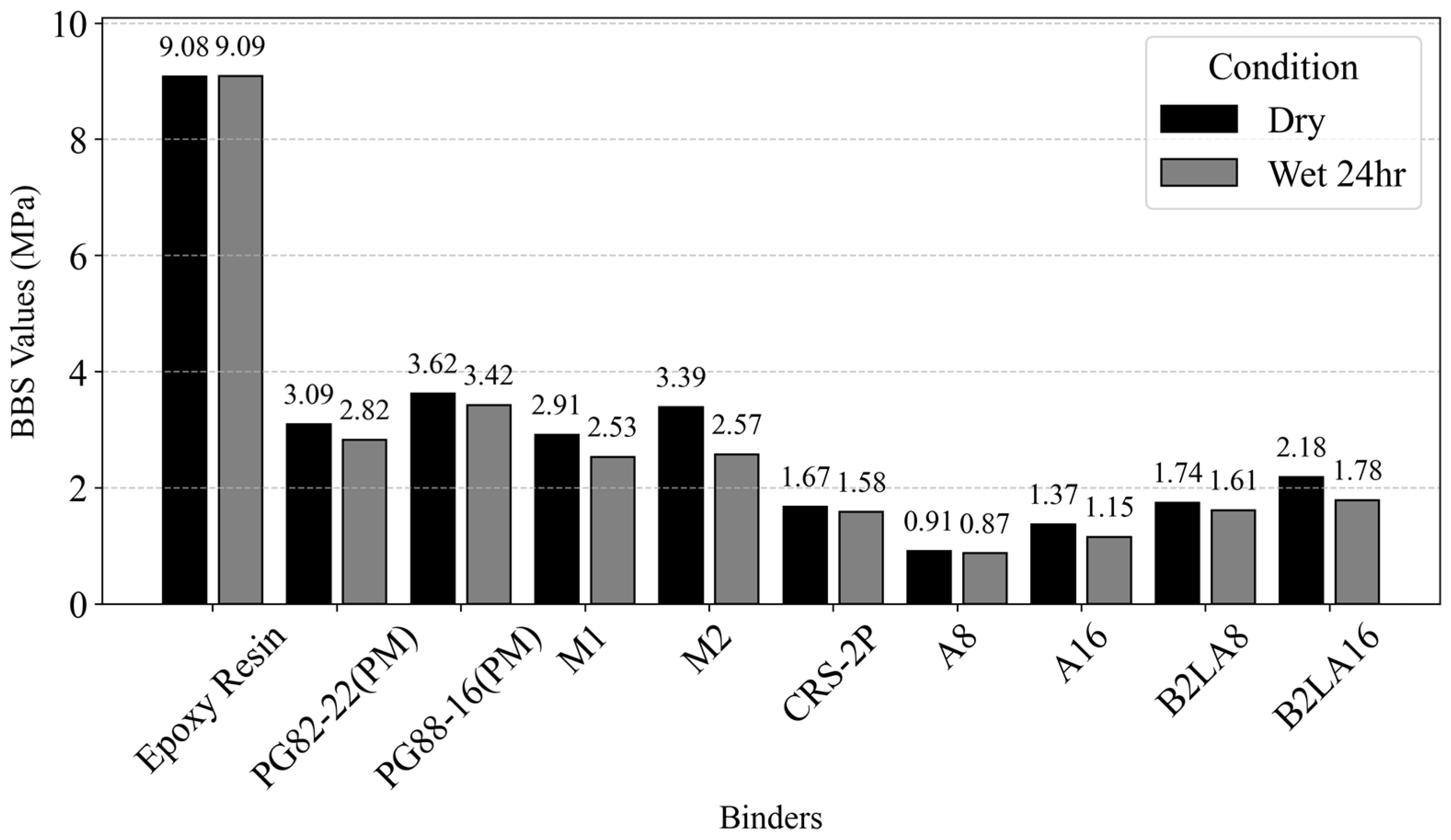

2.4.6. Binder Bond Strength Test (BBS)

- Substrate and Binder Preparation: Rhyolite substrates were extensively cleaned with an ultrasonic cleaner and dried at 170 °C for at least one hour with the pull-off stubs. To guarantee adequate workability, the binders were heated to their application temperatures—190 °C for mastics and 80 °C for emulsions—for at least an hour.

- Specimen Assembly: A silicone mold of about 40 mm by 40 mm (1.6 in by 1.6 in.) with an 8 mm (0.32-in.) diameter hole and a depth of 2.0 mm (0.08 in.) for mastics and polymer-modified binders was created on the base substrates. Silicone rings with a hole in the center of 21 mm in diameter were used for emulsion. A little drop of binder was poured into the hole of the silicone rings, and pull-off stubs were pushed into the binder, ensuring a consistent asphalt thickness of 0.2 mm.

- Curing and testing: Each specimen was allowed to cool to room temperature for one hour. Some specimens were then cured at ambient temperatures (25 °C, 30% humidity) for 24 h before being evaluated for Binder Bond Strength under dry conditions (BBSdry). Other specimens were immersed in a 40 °C water bath for 24 h, followed by a 1 h curing phase at room temperature, to replicate wet conditions. The BBS test was then performed on these immersion specimens to determine the Binder Bond Strength in wet conditions (BBSwet).

3. Results and Discussions

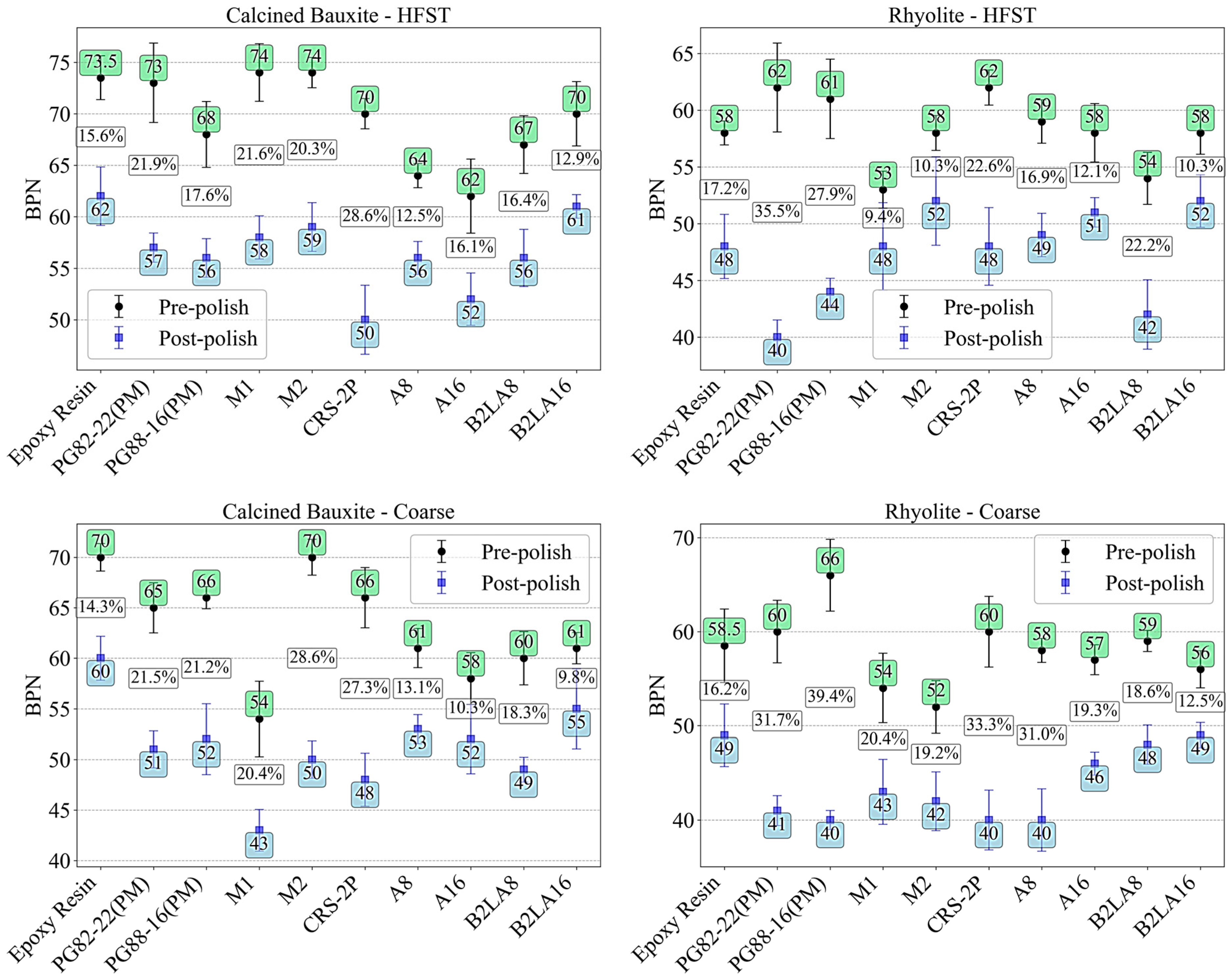

3.1. Influence of Different Aggregate and Binder Combinations on BPN

3.2. Influence of Aggregate Size, Gradation, and Binder Type on COF

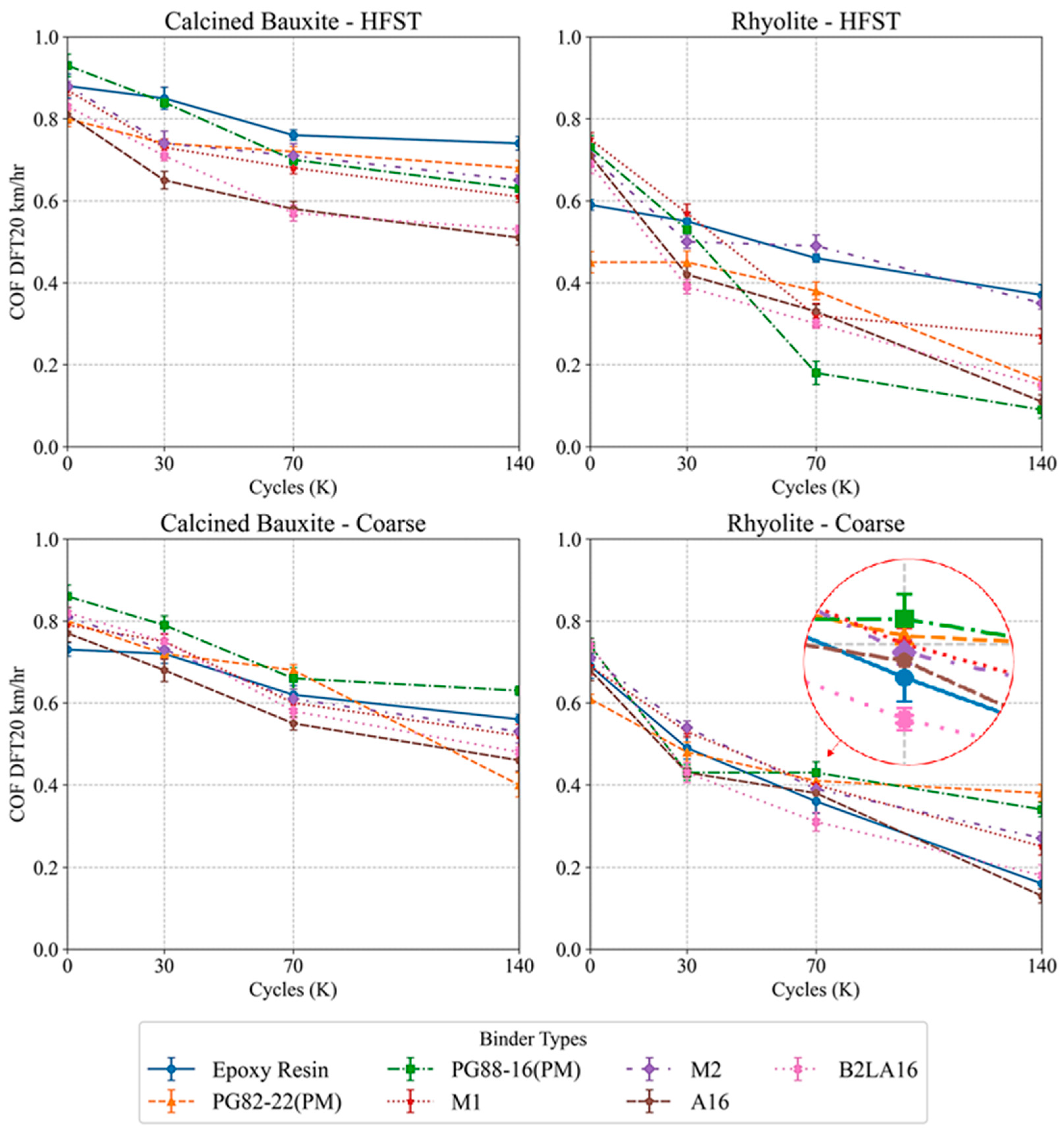

3.3. Influence of Aggregate Size, Gradation, and Binder Type on MPD (mm)

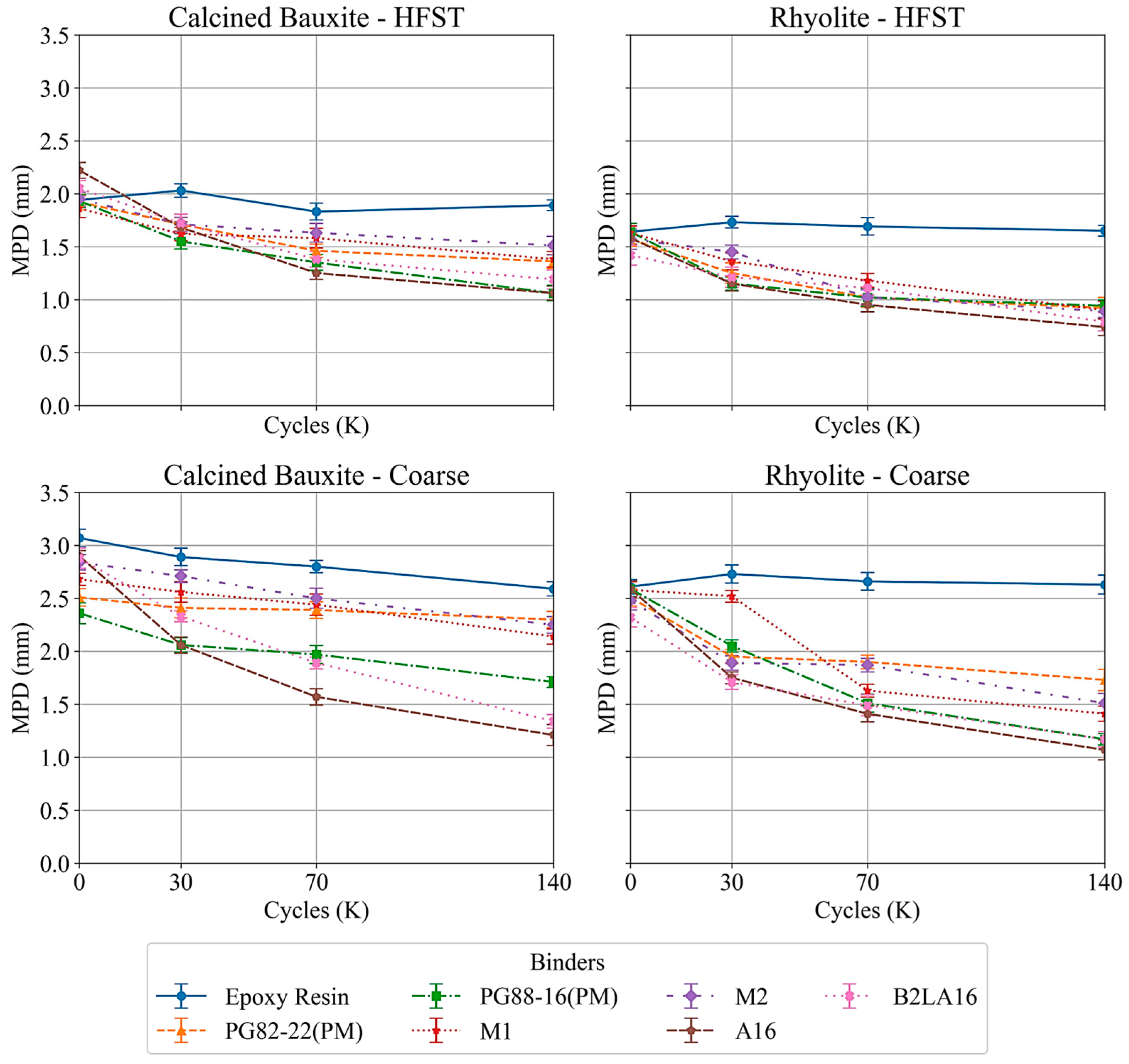

3.4. Binder Bond Strength (BBS) Test Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pérez-Acebo, H.; Isasa, M.; Gurrutxaga, I.; Alonso-Solórzano, Á. Analysis of the Skid Resistance Decrease in Bituminous Pavements in Dual-Carriageway Tunnels. Buildings 2024, 14, 3963. [Google Scholar] [CrossRef]

- de Leon Izeppi, E.; Flintsch, G.W.; McGhee, K. Field Performance of High Friction Surfaces; Virginia Transportation Research Council: Charlottesville, VA, USA, 2010; Report No. FHWA/VTRC 10-CR6. [Google Scholar]

- AASHTO MP 41-22; Standard Specification for High Friction Surface Treatment for Asphalt and Concrete Pavements Using Calcined Bauxite. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- Merritt, D.K.; Lyon, C.; Persaud, B. Evaluation of Pavement Safety Performance; United States; Federal Highway Administration: McLean, VA, USA, 2015. [Google Scholar]

- Pranav, C.; Tsai, Y.C. High Friction Surface Treatment Deterioration Analysis and Characteristics Study. Transp. Res. Rec. 2021, 2675, 370–384. [Google Scholar] [CrossRef]

- Roshan, A.; Abdelrahman, M. Developing an effective approach to assess pavement condition for high friction surface treatment (HFST) installation. Acta Polytech. 2024, 64, 571–581. [Google Scholar] [CrossRef]

- Wei, F.; Xing, M.; Li, S.; Shan, J.; Guan, B. Physical and Mechanical Properties of Epoxy–Bauxite Mortar of High-Friction Surface Treatment. J. Mater. Civ. Eng. 2020, 32, 04020146. [Google Scholar] [CrossRef]

- Bennert, T.; Blight, R.; Ganji, V.; Tulanowski, D.; Gresavage, S. Development of High Friction Surface Treatment Prescreening Protocols and an Alternative Friction Application. Transp. Res. Rec. 2021, 2675, 345–355. [Google Scholar] [CrossRef]

- Roshan, A.; Abdelrahman, M. Friction Enhancements to Asphalt Pavement Surfaces; No. cmr 24-015; Missouri Department of Transportation, Construction and Materials Division: Jefferson City, MO, USA, 2024. [Google Scholar]

- Roshan, A.; Abdelrahman, M. Impact of Aggregate Characteristics on Frictional Performance of Asphalt-Based High Friction Surface Treatments. CivilEng 2025, 6, 4. [Google Scholar] [CrossRef]

- Gómez, N.H.; Oeser, M.; Fleischel, O. Chemical modification of bitumen with novel isocyanate-based additive to enhance asphalt performance. Constr. Build. Mater. 2021, 301, 124128. [Google Scholar] [CrossRef]

- Roshan, A.; Abdelrahman, M. Evaluating Friction Characteristics of High Friction Surface Treatment Application Under Varied Polishing and Slippery Conditions. Transp. Res. Rec. 2024. [Google Scholar] [CrossRef]

- Missouri Geological Survey, Geological Survey Program. Rhyolite—PUB2927. Missouri Department of Natural Resources. 2020. Available online: https://dnr.mo.gov/document-search/rhyolite-pub2927/pub2927 (accessed on 10 January 2025).

- Roshan, A.; Abdelrahman, M. Improving aggregate abrasion resistance prediction via Micro-Deval test using ensemble machine learning techniques. Eng. J. 2024, 28, 15–24. [Google Scholar] [CrossRef]

- Tang, N.; Xue, C.; Hao, G.; Huang, W.; Zhu, H.; Li, R. Sustainable Production of Eco-Friendly Rubberized Asphalt Binders Through Chemically Crosslinking with Polymer Modifier. J. Clean. Prod. 2023, 422, 138633. [Google Scholar] [CrossRef]

- AASHTO M320-23; Standard Specification for Performance-Graded Asphalt Binder. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2023.

- AASHTO T 313; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2009.

- AASHTO T 315-22; Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- Roshan, A.; Abdelrahman, M. Predicting flexural-creep stiffness in bending beam rheometer (BBR) experiments using advanced super learner machine learning techniques. Res. Eng. Struct. Mater. 2024, 10, 1195–1208. [Google Scholar] [CrossRef]

- Roshan, A.; Abdelrahman, M. Influence of Aggregate Properties on Skid Resistance of Pavement Surface Treatments. Coatings 2024, 14, 1037. [Google Scholar] [CrossRef]

- NJDOT. DIVISION 420. Available online: https://njdotlocalaidrc.com/perch/resources/Uploads/njdot-high-friction-surface-treatment-guidelinesfinalfeb2019.docx (accessed on 20 November 2023).

- Zhao, H.; Wei, F.; Wang, C.; Li, S.; Shan, J. Determination of friction performance of high friction surface treatment based on alternative macrotexture metric. Materials 2021, 14, 6895. [Google Scholar] [CrossRef] [PubMed]

- Roshan, A.; Abdelrahman, M. Performance and Economic Evaluation of Asphalt-Based High Friction Surface Treatment (HFST) Applications. Appl. Sci. 2025, 15, 873. [Google Scholar] [CrossRef]

- AASHTO T278-90; Standard Method of Test for Surface Frictional Properties Using the British Pendulum Tester. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2021.

- AASHTO T279; Standard Method of Test for Accelerated Polishing of Aggregates Using the British Wheel. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

- ASTM E1911-19; Standard Test Method for Measuring Paved Surface Frictional Properties Using the Dynamic Friction Tester. ASTM International: West Conshohocken, PA, USA, 2019.

- AASHTO PP 104-21; Sample Preparation and Polishing of Asphalt Mixture for Dynamic Friction Testing. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- ASTM E2157-15; Standard Test Method for Measuring Pavement Macrotexture Properties Using the Circular Track Meter. ASTM International: West Conshohocken, PA, USA, 2019.

- AASHTO T361-22; Determining Asphalt Binder Bond Strength by Means of the Binder Bond Strength (BBS) Test. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- Heitzman, M.; Turner, P.; Greer, M. High Friction Surface Treatment Alternative Aggregates Study; No. NCAT Report 15-04; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2015. [Google Scholar]

- Xue, X.; Zheng, X.; Guan, B.; Liu, J.; Ding, D.; Xiong, R.; Zhao, H.; Wei, F. Long-term skid resistance of high-friction surface treatment of pavement using high-alumina refractory waste. Constr. Build. Mater. 2022, 351, 128961. [Google Scholar] [CrossRef]

- Heitzman, M.; Vrtis, M. Development of Alternative High Friction Surfaces for Oklahoma; Oklahoma Department of Transportation: Oklahoma City, OK, USA, 2016. [Google Scholar]

- Guan, B.; Wu, J.; Xie, C.; Fang, J.; Zheng, H.; Chen, H. Influence of macrotexture and microtexture on the skid resistance of aggregates. Adv. Mater. Sci. Eng. 2018, 2018, 1437069. [Google Scholar] [CrossRef]

- Li, S.; Cong, P.; Yu, D.; Xiong, R.; Jiang, Y. Laboratory and field evaluation of single layer and double layer high friction surface treatments. Transp. Res. Rec. 2019, 2673, 552–561. [Google Scholar] [CrossRef]

| Properties | CB (HFST) | CB (Coarse) | Rhy (HFST) | Rhy (Coarse) |

|---|---|---|---|---|

| Bulk specific gravity | 3.25 | 3.22 | 2.57 | 2.55 |

| Water absorption (%) | 1.5 | 2.2 | 1.7 | 1.1 |

| LAA value (%) | Grade D | C | D | C |

| 16.01 | 11 | 15.11 | 19 | |

| MDA value (%) | 15 min/30 min | 95 min | 15 min/30 min | 95 min |

| 2.45/4.2 | 5.03 | 2.6/4.74 | 3.7 | |

| Aggregate gradation | ||||

| 3/8″ (9.5 mm) | na | 100% | na | 100% |

| 1/4″ (6.30 mm) | na | 97% | na | 97% |

| No 4 (4.75 mm) | 100% | 2% | 100% | 2% |

| No 6 (3.35 mm) | 95–100% | 1% | 95–100% | 1% |

| No 16 (1.18 mm) | 0–5% | na | 0–5% | na |

| No 30 (0.59 mm) | 0–0.2% | na | 0–0.2% | na |

| Binder | |

|---|---|

| PG64-22 + 8% SBS + 0.1% Sulfur | PG82-22 (PM) |

| PG76-22 + 6% SBS + 0.1% Sulfur | PG88-16 (PM) |

| Mastic1 | M1 |

| Mastic2 | M2 |

| Emulsion + 8% Latex | A8 |

| Emulsion + 16% Latex | A16 |

| Emulsion + 8% Latex + Isocyanate-based additive | B2LA8 |

| Emulsion + 16% Latex + Isocyanate-based additive | B2LA16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roshan, A.; Abdelrahman, M.; Ragab, M. Performance Evaluation of Highly Modified Asphalt-Based Binders in High Friction Surface Treatment: Comparative Study with Epoxy-Based System. Buildings 2025, 15, 1425. https://doi.org/10.3390/buildings15091425

Roshan A, Abdelrahman M, Ragab M. Performance Evaluation of Highly Modified Asphalt-Based Binders in High Friction Surface Treatment: Comparative Study with Epoxy-Based System. Buildings. 2025; 15(9):1425. https://doi.org/10.3390/buildings15091425

Chicago/Turabian StyleRoshan, Alireza, Magdy Abdelrahman, and Mohyeldin Ragab. 2025. "Performance Evaluation of Highly Modified Asphalt-Based Binders in High Friction Surface Treatment: Comparative Study with Epoxy-Based System" Buildings 15, no. 9: 1425. https://doi.org/10.3390/buildings15091425

APA StyleRoshan, A., Abdelrahman, M., & Ragab, M. (2025). Performance Evaluation of Highly Modified Asphalt-Based Binders in High Friction Surface Treatment: Comparative Study with Epoxy-Based System. Buildings, 15(9), 1425. https://doi.org/10.3390/buildings15091425