Abstract

The complexity of the explosions makes it difficult to evaluate a munition storage site’s safety. The peak overpressure associated with a blast wave that propagates from a blast is the governing factor that determines the damage to the buildings around the area. Current codes for predicting the blast pressure from an explosion are mostly applicable for a relatively long-range explosion instead of a near-field explosion. This study evaluated the rationale for the current criteria to assess limitations in the different methods and propose an alternative approach based on experimental and numerical results. This study used a small number of explosives and a small-sized ammunition storage magazine specimen to conduct explosion experiments inside an ammunition storage magazine. The ratio of the blast pressure outside the storage magazine to that at the portal of the storage magazine was compared with the empirical equations and experiments from the references, which were more conservative than the experimental values. The optimal exponential equation was proposed after a regression analysis; this equation is applicable to 1 to 653 times the portal diameter outside the ammunition storage magazine. In terms of the effect of a retaining wall on the blast inside the storage magazine, the longitudinal’s extreme value was reduced by 37–42%, while that of the transverse blast was increased by 8–20%. In terms of the numerical simulations, the extreme value of the external blast within one to five times the portal diameter range outside the ammunition storage magazine could be predicted effectively.

1. Introduction

In response to the requirements for building an army and preparing for war, the storage magazines used for ammunition mostly store ammunition at the maximum storage capacity, which is highly risky. Unsound storage facilities or mismanagement could induce an accidental explosion in the storage magazine, causing grave safety events, such as casualties and building failures. There are four types of effects of ammunition storage magazine explosions: blasts, fragments, thermal hazards, and ground shock. Of these, blasts have a more significant influence on structural and personal safety and must be carefully evaluated. However, an explosion field test is difficult and dangerous. Building a near-field explosion prediction model is an important research subject since it helps assess the blast pressure inside ammunition storage magazines and consider its range effect on blast propagation.

The earliest field test of ammunition storage magazine explosions began during the Second World War at the U.S. Naval Proving Ground. Since 1960, the U.S. Naval Ordnance Test Station has performed explosion experiments related to earth-covered ammunition storage magazines [1]. From 1971 to 1979, the Department of Defense Explosives Safety Board (DDESB) implemented tests on the range of safety measurements for ammunition storage magazines, which were known as ESKIMO (Explosive Safety Knowledge Improvement Operation) [2,3,4,5,6]. In 1982, Kingery et al. [7] used a 1/30 reduced scale ammunition storage magazine to implement an explosion experiment. They simulated the detonation wave transfer on the front, lateral, and back sides of an ammunition storage magazine. The results showed that the overpressure and impulse attenuation on the ammunition storage magazine’s lateral and back sides were apparent. In 1989, Kingery [8] compiled data from the literature about explosion experiments inside ammunition storage magazines from 1965 to 1985. They provided a ratio of the blast outside the magazine to the blast at the portal of the magazine, as well as a ratio of the distance from outside the portal of the magazine to the portal diameter. In 2005, Welch et al. [9] studied explosions outside an ammunition storage magazine, at the portal of the magazine, and inside the magazine, and provided an empirical equation for the blast inside the magazine. In 2006, Brill et al. [10] used a small-sized ammunition storage magazine to implement explosion experiments and study the effects of back-to-front, side-to-side, and front-to-back explosion loads near the magazine. The experimental results showed that the back-to-front load had a larger overpressure than the other two directions.

In terms of numerical simulations, in 1992, Hager et al. [11] used Autodyn 2D software to simulate a high-performance ammunition storage magazine bearing an implosion reaction. In 2008, Chen et al. [12] built a model for an explosion inside an ammunition storage magazine and found that the relatively low indoor explosion blast and impulse simulation values at normal temperatures could be improved by increasing the internal energy of the air. In 2009, Yu et al. [13,14] used the arbitrary Lagrangian–Eulerian (ALE) model to increase the fireball radius range temperature and discuss the explosion characterisitcs and safe distance of a retaining wall for an explosion inside an ammunition storage magazine; they found that the overpressure tended to be higher than that at a normal temperature. In 2010, Cheng et al. [15] compared the structure of a retaining wall under the effect of detonation waves with the results of Tancreto et al. [16] and Ishikawa et al. [17] and discussed the blast attenuation. The findings showed that the retaining wall had a noticeable effect on the blast attenuation within a limited range.

Explosion experiments are hampered by their high cost, difficult procurement of explosives, experimental site limitations, and large blast measurement variations. Hence, this study used a small number of explosives and a reduced-sized specimen for an ammunition storage magazine explosion experiment.

Additionally, LS-DYNA finite element software (source) was used for the explosion simulation study. This study further discussed the overpressure distribution in the near-field range of an ammunition storage magazine explosion. The explosion experiment and numerical simulations were validated and compared, and related empirical equations were proposed to evaluate the near-field explosion blasts of ammunition storage magazines.

2. Empirical Formulations

There have been many experimental and analytical investigations conducted to study blast effects and structural responses since the 1960s. There are many complexities to the blast wave’s behavior and its characteristics, the dominant factors include the charge type and weight, the stand-off, and the type of structure.

2.1. Chamber Pressure

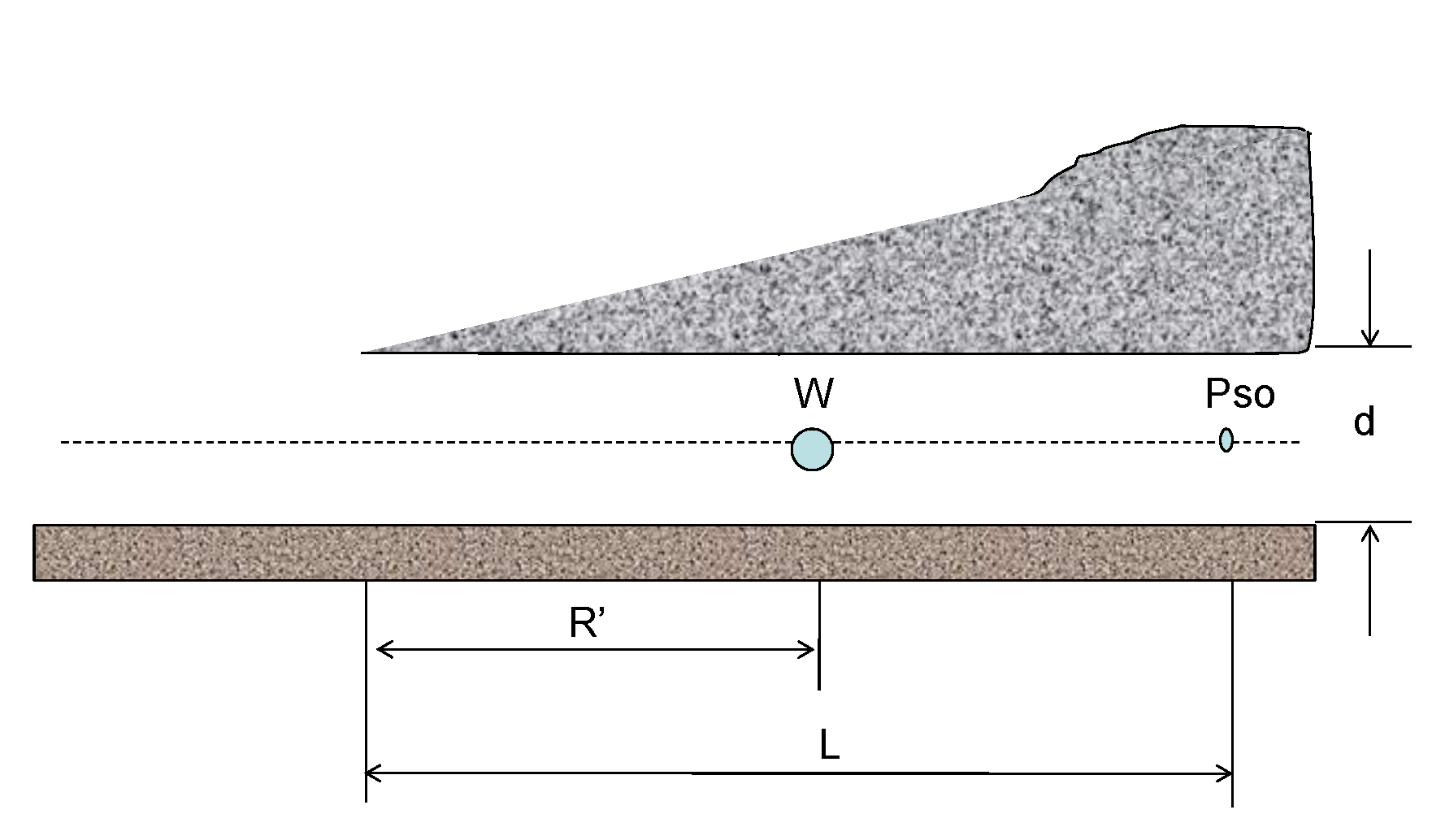

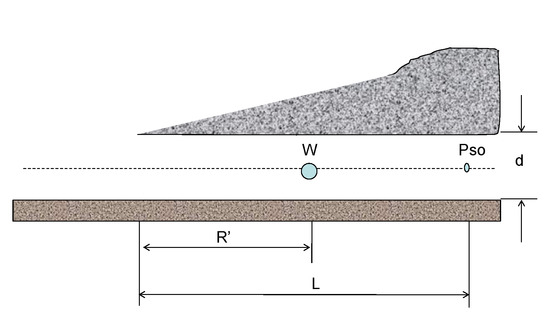

The empirical equation proposed by Welch et al. [9] in 2005, expressed as Equation (1), can be used to estimate the blast generated during the implosion of an ammunition storage magazine, as shown in Figure 1:

where

Figure 1.

Schematic diagram of the empirical equation.

- andfor; andfor

- : blast at the measuring point (kPa)

- : distance from the measuring point inside ammunition storage magazine to the portal (m)

- : portal diameter (m)

- : RDX charge weight (kg), where RDX is an organic compound with the formula (O2N2CH2)3.

- : distance from the explosion center point to the portal (m); is negative, meaning outside of the tunnel).

2.2. Exit Pressure

Various factors affect the blast propagation outside of a munition storage site, such as the storage chamber dimensions and volume, passageway dimensions and volume, mass and explosive type, exit pressure, tunnel diameter, and the angle off of the zero-degree axis. [18,19].

- DDESB [18]

The normalized peak overpressure data measured in the free-field beyond the tunnel portal versus the normalized distance were presented in [18]. The dimensionless pressure values can be obtained by dividing the calculated effective exit pressure by the recorded peak free-field pressure.

The exit pressure at the portal of the ammunition storage magazine can be derived from the loading density of the ammunition storage magazine, expressed as Equation (2):

where

- : blast pressure at the portal of the ammunition storage magazine (kPa)

- : C4 explosive weight (kg)

- : volume of the storage chamber (m3).

- b.

- Skjeltorp [19]

The explosive mass and storage chamber volume are essential parameters for evaluating the blast pressure. An empirical equation presented in [19] can be used to estimate the exit pressure from a tunnel:

where : TNT explosive weight (kg).

2.3. The Ratio of the Outside Pressure to the Exit Pressure

- (1)

- DDESB [18]

The inhabited building distance (IBD) can be estimated using the dimensionless relationship of the blast outside the storage magazine to the blast at the portal of the storage magazine ratio, expressed as Equation (4):

where

- : blast pressure outside the ammunition storage magazine (kPa)

- : distance from the measuring point to the portal (m)

- : portal diameter (m).

- (2)

- Helseth et al. [20]

A second method was proposed in [20]. It is noted that the experimental data were generated from shock tube tests. Practically, the desired parameters are the distance r at which a selected pressure would occur and an attenuation coefficient, which varies with the propagation angle:

where : attenuation coefficient. For θ = 0° to 30° (θ: angle in degrees, off-zero axis),; for θ = 30° to 60°, .

- (3)

- Skjeltorp et al. [19]

A method for predicting the pressure propagating outside of the tunnel exit for different angles was developed and presented in [19]. The basic equation is given as follows:

In terms of the specifications, the ammunition storage magazine explosion was limited to a far-field blast value ratio of r/d > 5, where r is the distance from the measuring point outside of the ammunition storage magazine to the portal and d is the portal diameter. The specified value of r/d < 5 for a near-field explosion is deficient. As ammunition storage magazine experiments are limited to specific experiment sites, it is challenging to perform full-scale investigations; as such, they are mostly replaced by reduced-scale experiments in various countries.

3. Analytical Model

3.1. Explosion Experiment Inside the Ammunition Storage Magazine

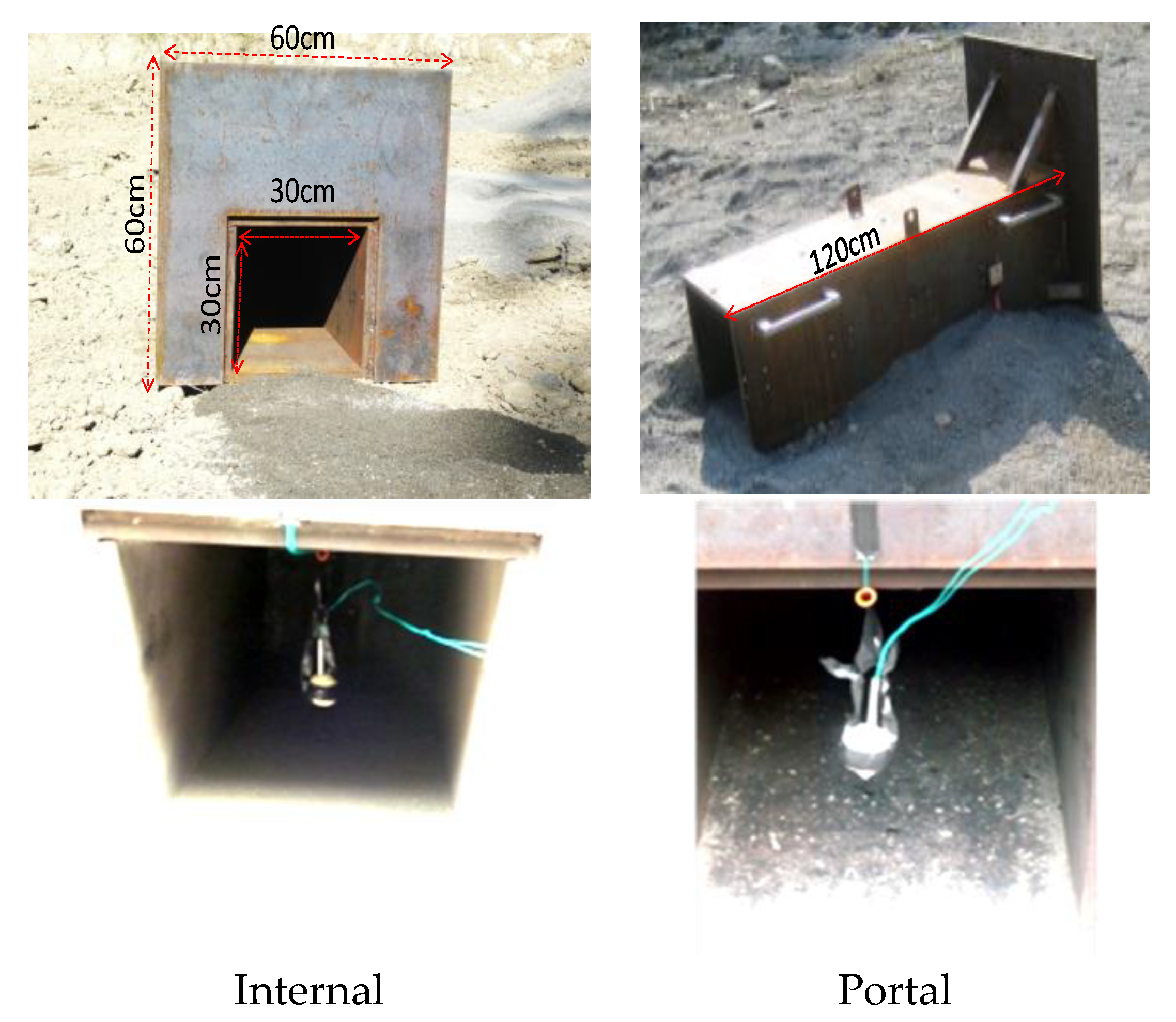

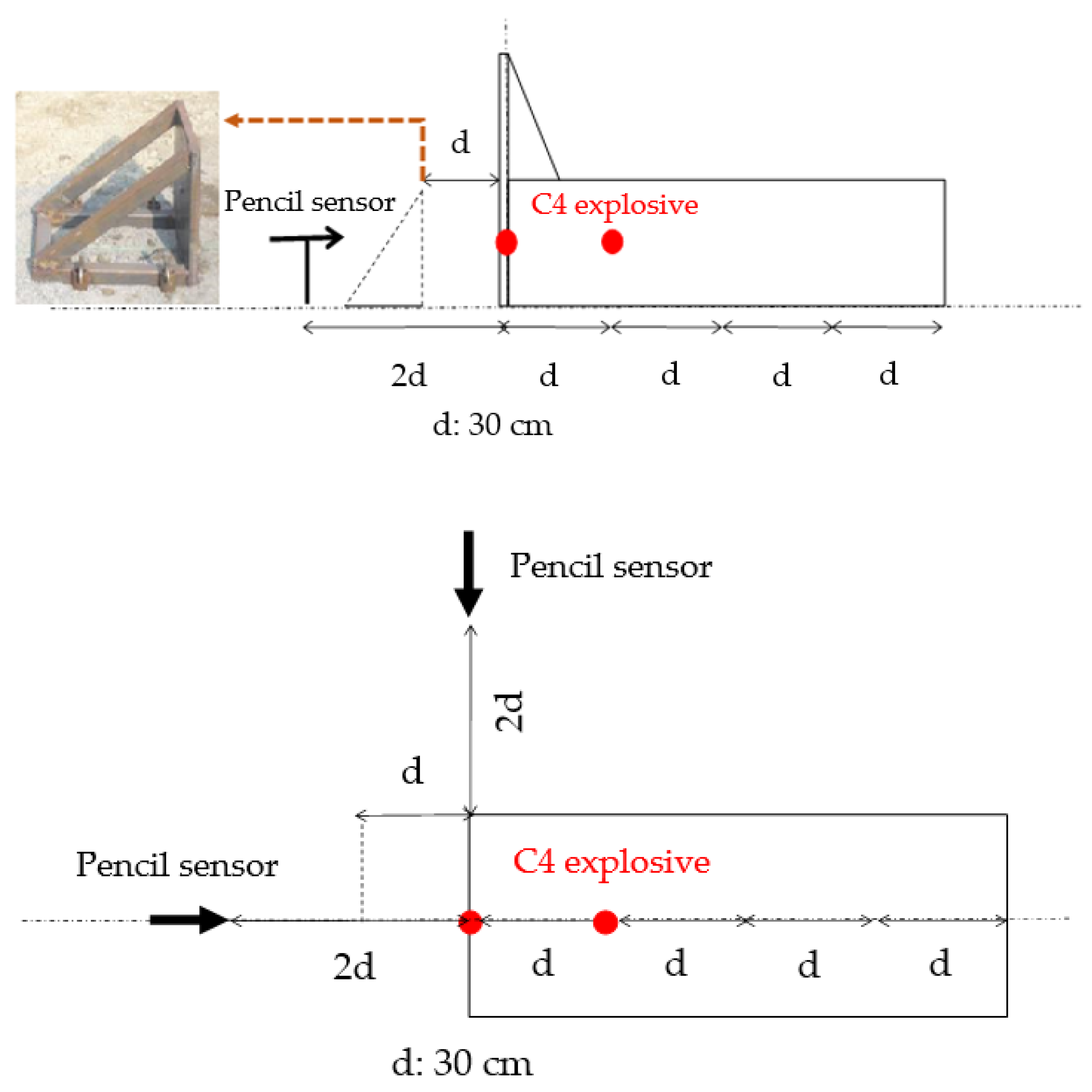

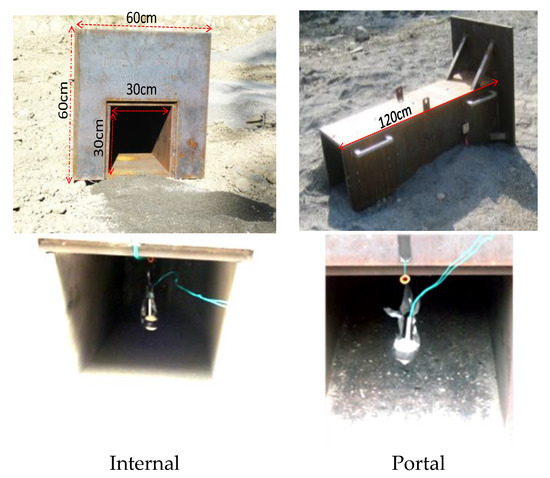

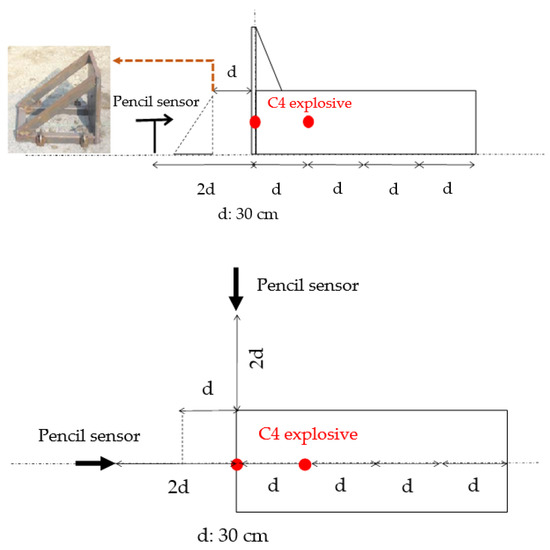

The explosion experiment was implemented by using a small-sized ammunition storage magazine and a small quantity of C4 explosives. The setup of the experiment model is shown in Figure 2. The ammunition storage magazine specimen was made of carbon steel. Its segments were attached using screws during assembly and then welded at the seams to avoid blast leakage. The specimen’s internal dimensions were 30 × 30 cm, 120 cm long, and 2 cm thick. A 120 cm long, 120 cm wide, and 2 cm thick steel plate was mounted on the top, right, and left sides of the portal at one end of the specimen. The plate was placed to enhance the portal structure and prevent the blast from being diffracted to the specimen’s backside and influencing the blast measurement. The two ends of the specimen were not closed. Next, 30 g of spherical C4 explosives were placed at the magazine’s portal and 30 cm away from the portal of the magazine inside the specimen to implement the explosion. The explosion center was located 15 cm above the ground. High-frequency pressure gauges were installed on the right inner wall of the ammunition storage magazine 15 cm above the ground and at 2, 30, 60, and 90 cm away from the magazine’s portal to measure the blast data.

Figure 2.

The setup of the experimental model.

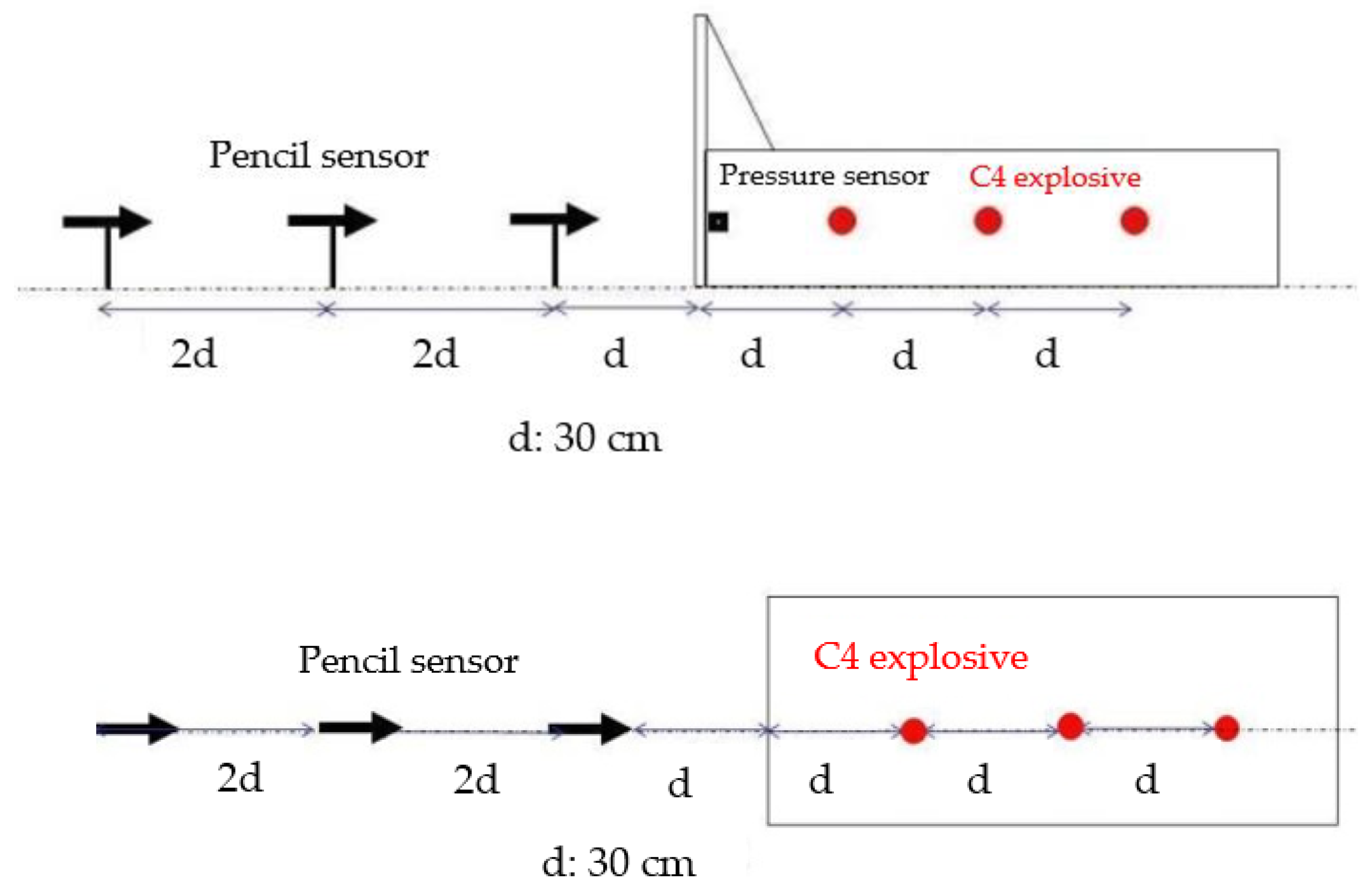

Moreover, to study the explosion inside the ammunition storage magazine and the blast’s outward transfer, 30 g of spherical C4 explosive was placed in the ammunition storage magazine. Two types of pressure sensors were used in the experiments. Both types of sensors were calibrated before conducting the test. The blast pressure pencil probes were installed outside the portal to measure the external blast wave, and the high-frequency pressure gauges were mounted on the right inner wall of the tunnel to record the internal blast pressure. The installed sensors’ positions were designed to measure the propagating wave at the near portal and 1×, 2×, and 3× the portal diameter inside the ammunition storage, which were 2, 30, 60, and 90 cm away from the portal, respectively. All the sensors were placed in the half of the portal height, which was 15 cm above the ground. The pencil-type blast sensors were mounted at 30, 90, and 150 cm outside the ammunition storage magazine specimen, set 15 cm above the ground, and arranged longitudinally to study the outward transfer of the detonation waves and the blast attenuation characteristics after the explosion inside the magazine. The experimental configuration is shown in Figure 3.

Figure 3.

Internal explosion and external blast meter mounting locations ((upper): side view, (lower): top view).

3.2. Experiment on the Retaining Wall Effect

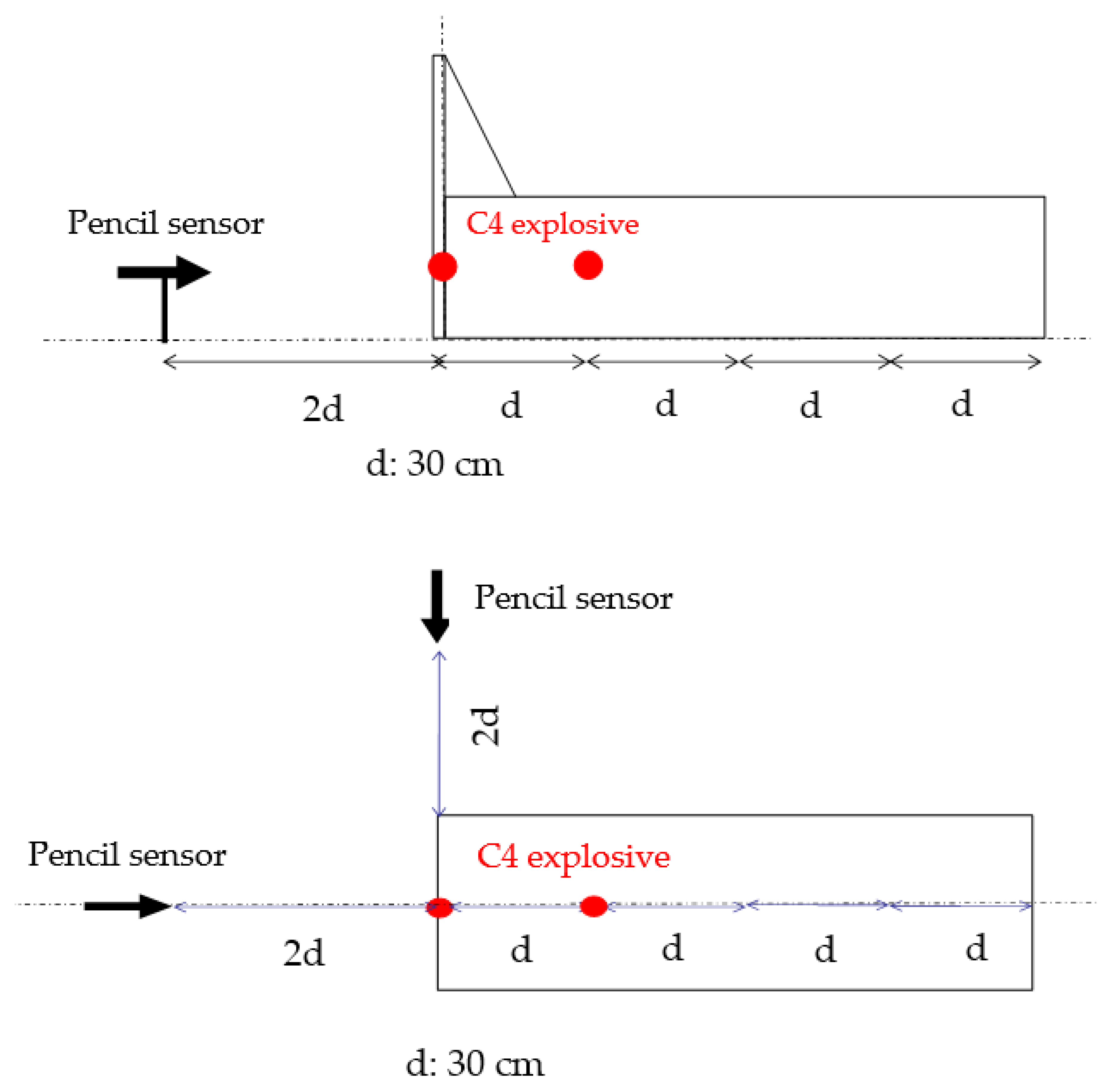

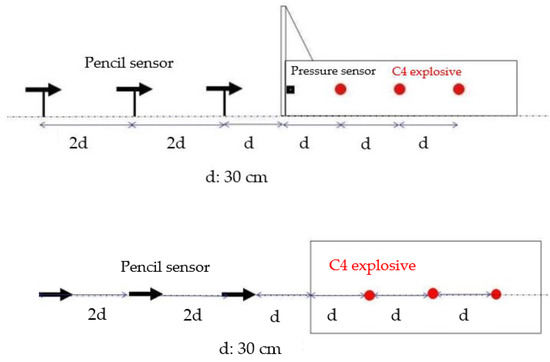

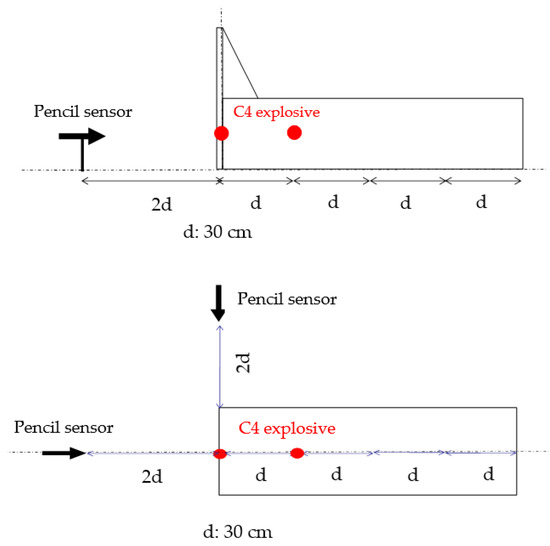

To evaluate the influence of a retaining wall on the near-field blast of an explosion inside the ammunition storage magazine, experiments for explosions inside the ammunition storage magazine without a retaining wall and for explosions with a retaining wall were created.

- (1)

- Without a retaining wall

This study placed 30 g of spherical C4 explosive at the ammunition storage magazine portal and 30 cm away from the portal inside the ammunition storage magazine to implement the experiment. The explosive center was located 15 cm above the ground. Two pencil sensors were located 15 cm above the ground and arranged longitudinally and transversely 60 cm away from the magazine’s portal to measure the overpressure generated without a retaining wall outside the ammunition storage magazine. The experimental configuration is shown in Figure 4.

Figure 4.

Explosion experiment without a retaining wall ((upper): side view, (lower): top view).

- (2)

- With a retaining wall

The same mass of C4 explosive and ignition position as the previous experiment were used to perform the explosion experiment using a retaining wall. A steel retaining wall was located 30 cm away from the portal. The retaining wall size was 30 × 30 cm and had a thickness of 2 cm. The pencil sensors were arranged in the same manner as that for the experiment without a retaining wall, as shown in Figure 5.

Figure 5.

Explosion experiment with retaining wall ((upper): side view, (lower): top view).

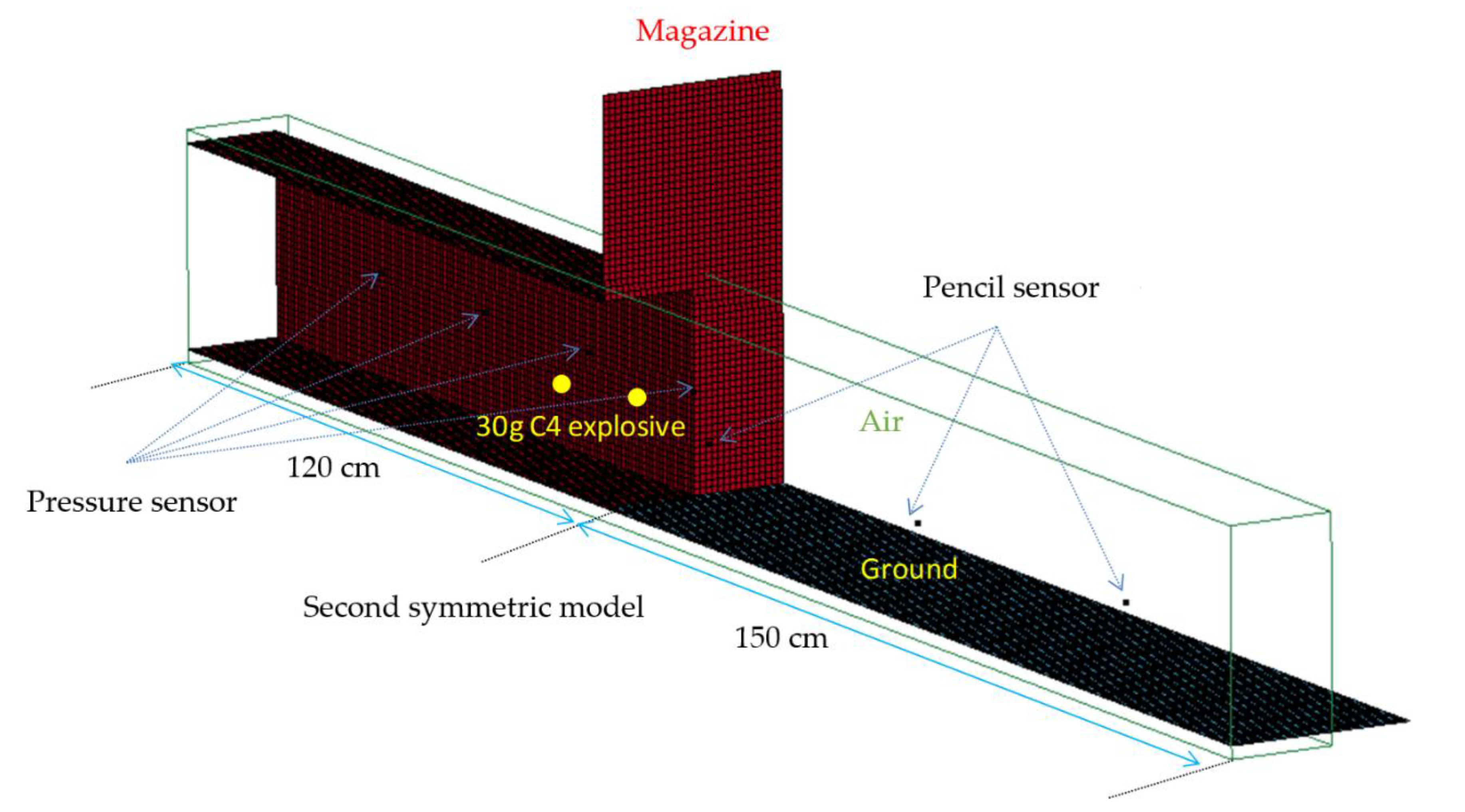

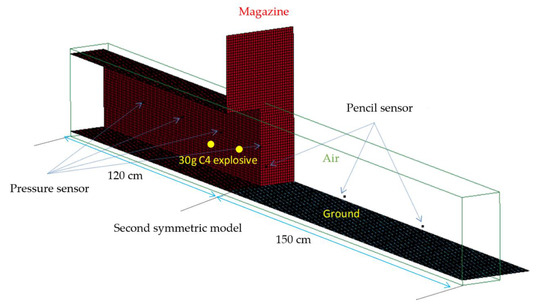

3.3. Numerical Simulations

LS-DYNA finite element analysis software was used for the numerical simulations of the blast transfer after an explosion. The Fluid-Structure Interaction (FSI) model is shown in Figure 6. The numerical model comprised the air, explosives, the ammunition storage magazine, and the ground. As the analysis model had symmetric properties, half of the symmetrical model was used for the analysis and a symmetrical constraint condition was provided on the symmetrical plane. The air and explosive models were built using an ALE mesh, and the ALE multi-material method was used, based on a mesh size of 0.5 cm. The *INITIAL_VOLUME_FRACTION_GEOMETRY command was used to build the explosive model, and the explosive shape and size were set up in the range of the air mesh. The explosive detonation point was set up using the *INITIAL_DETONATION command. The detonation points in the analysis model were set at the center of the portal (Figure 2) and 30 cm away from the portal inside the ammunition storage magazine, and the explosive centers were 15 cm above the ground. Finally, the *DATABASE_TRACER command was used to obtain the air mesh overpressure in the pressure gauge position compared with the experimental results. The ammunition storage magazine and ground models were built using a Lagrangian mesh and a four-node shell element, and the Belytschko–Tsay plate theory was used, which was based on a mesh size of 1.0 cm. As the air model was not infinitely large, the boundaries outside the symmetrical plane needed to have stress wave non-reflecting boundary conditions to match the physical phenomenon. The fluid and solid meshes were built using superposition, and the *CONSTRAINED_LAGRANGE_IN_SOLID command was used to calculate the coupling stress. The constitutive models and material parameters adapted from [21] were used in this study, as shown in Table 1.

Figure 6.

Numerical simulation model.

Table 1.

Material parameters of the external tunnel explosion analysis (data from [21]).

4. Results

4.1. Blast inside the Ammunition Storage Magazine

- (1)

- Experimental results

A C4 explosive was used to implement an explosion inside the ammunition storage magazine. The explosive was detonated at the portal and at 1× the portal diameter inside the ammunition storage magazine. The experimentally measured overpressure was used for the regression analysis to obtain the empirical equations of the internal blast, as shown in Equations (7) and (8):

where

- internal blast value of the ammunition storage magazine (kPa)

- ratio of the distance from the measuring point to the portal inside the ammunition storage magazine (l) to the portal diameter ().

- (2)

- Comparison of the empirical equations

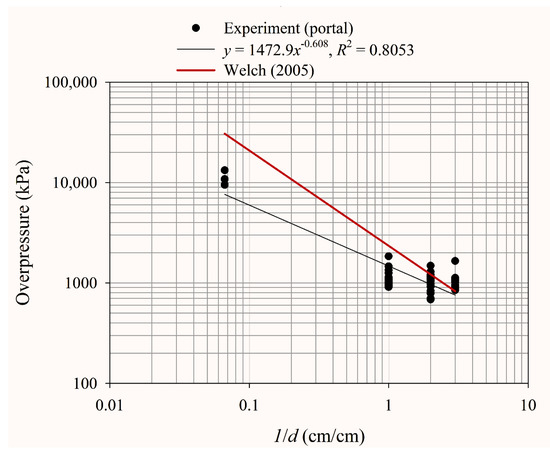

- Explosion at the portal

The empirical equation of Welch et al. [9] was compared with the experimental results, as shown in Figure 7. It was observed that the measured value was smaller than the Welch empirical equation when the ratio of the distance from the measuring point to the portal inside the ammunition storage magazine (l) to the portal diameter (d) ranged from 0.067 to 1, and that the relative errors were 184.67% and 115.86%. However, the Welch empirical equation was close to the experimental value when l/d = 2–3, where the relative errors were 17.23% and −16.79%.

Figure 7.

Comparison of the empirical equations of the internal blast extreme values (explosion at portal).

- b

- Explosion at 1× the portal diameter inside the ammunition storage magazine

The empirical equation of Welch et al. [9] and the experimental results of this study are shown in Figure 8. When the ratio of the distance from the measuring point to the portal inside the ammunition storage magazine (l) to the portal diameter (d) was 1.0, the empirical equation was smaller than the experimental value, where the relative error was −70.42%. However, the empirical equation was close to the experimental value when l/d = 2~3, where the relative errors were 1.74% and 10.3%.

Figure 8.

Comparison between the empirical equation of the internal blast extreme values and the experimental values (explosion at 1× the portal diameter).

According to the empirical equation of Welch et al. [9] and the experimental results of this study, the Welch empirical equation was more applicable to the explosive source in the explosion range inside the ammunition storage magazine.

- (3)

- Numerical simulation results

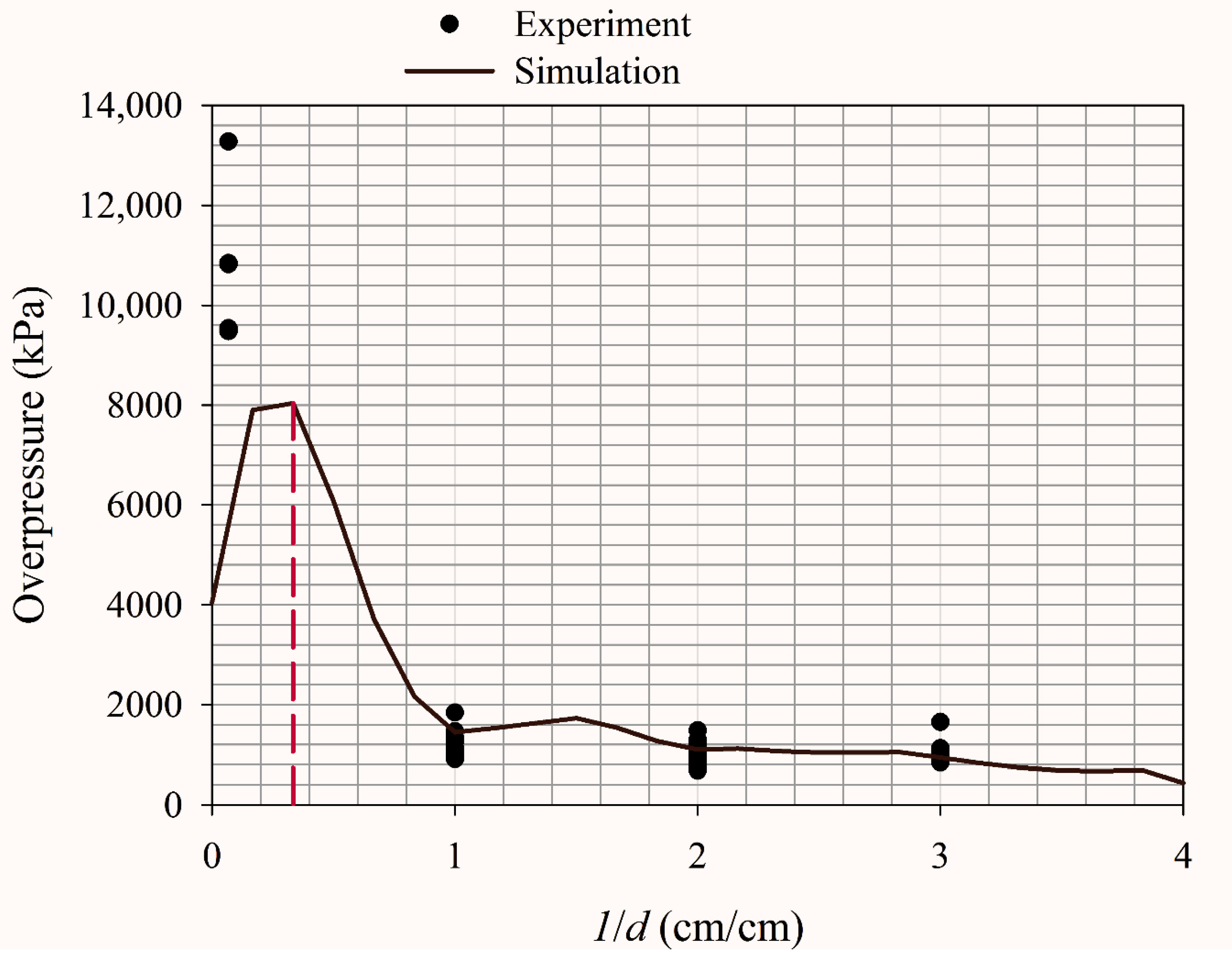

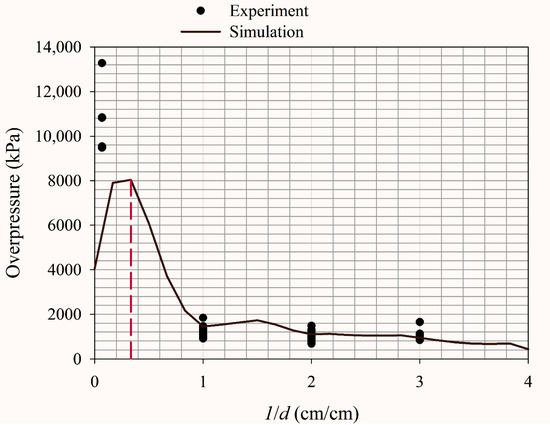

- Explosion at the portal

The numerical simulation result is shown in Figure 9. Within a 0.5× diameter away from the portal inside the ammunition storage magazine, the overpressure increased due to the overlap of the incident pressure and the ammunition storage magazine’s reflected pressure. However, starting at a distance of 0.5× the diameter outside the portal, the overpressure decreased as the distance from the portal increased. The numerical simulation result showed that in the portal section and at a 1× portal diameter range of the ammunition storage magazine, the relative errors between the numerical simulation and the experimental overpressure were −62.48% and 33.43%, indicating that the relative error of the near-field blast in the ammunition storage magazine was still considerable. Thus, a finer mesh division is required to implement further investigations. However, at a distance of 2× to 3× the portal diameter inside the ammunition storage magazine, the relative errors decreased to 6.2% and −5.61%, respectively, which meant that the numerical simulation result was close to the experimental value.

Figure 9.

Numerically simulated internal blast and experimentally measured values (explosion at the portal).

- b

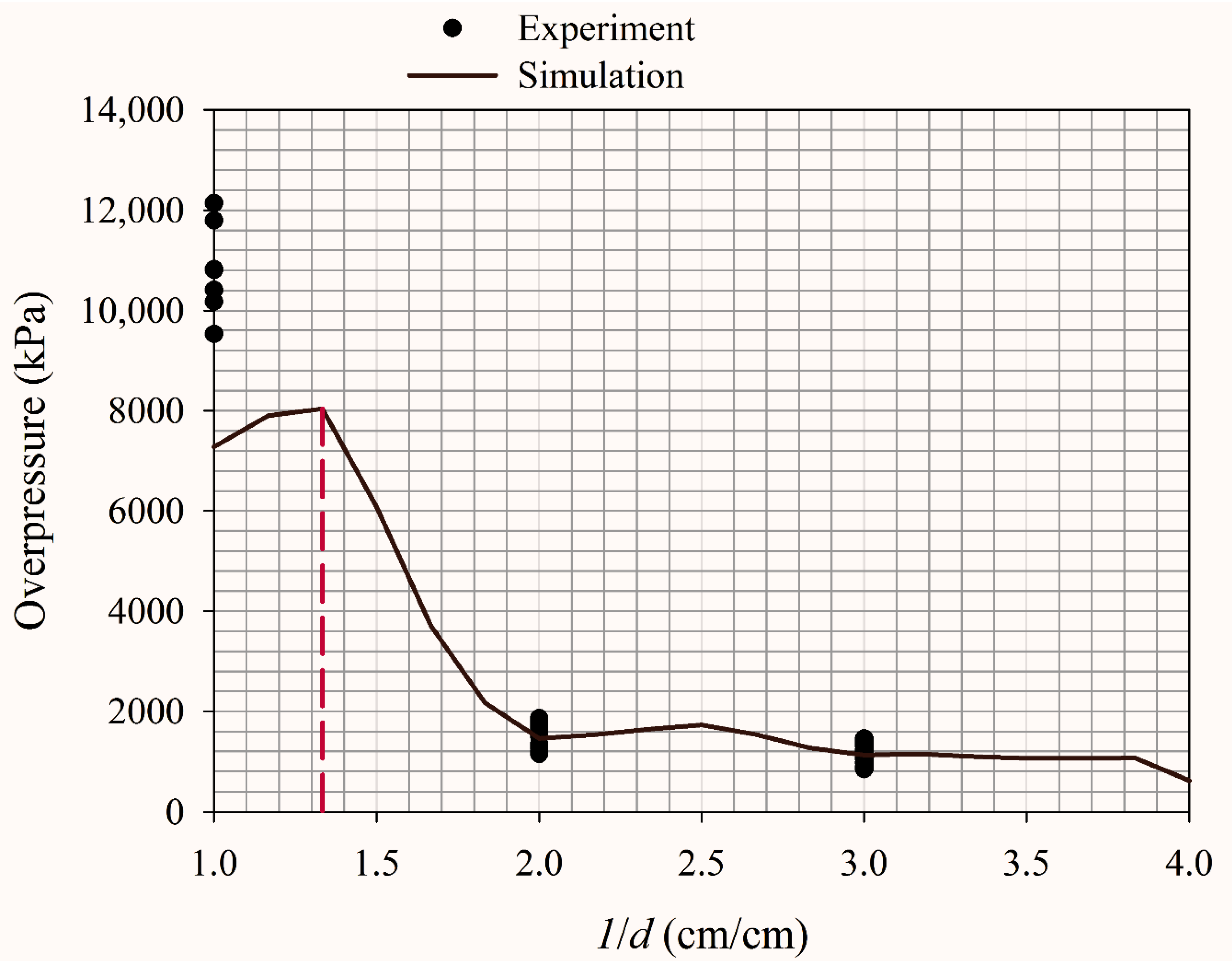

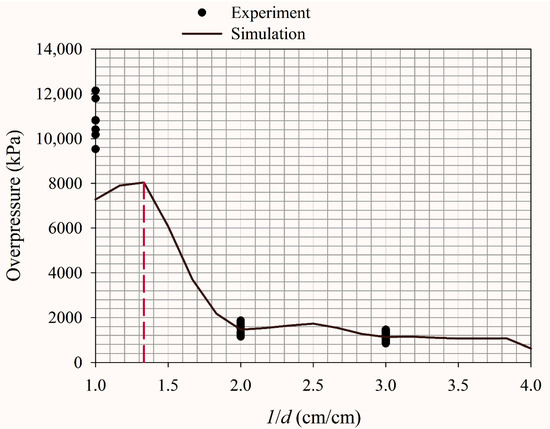

- Explosion at 1× the portal diameter inside the ammunition storage magazine

The numerical simulation result is shown in Figure 10. Within a distance of 1.5× the portal diameter from the explosive source, the overpressure increased due to the overlap of the incident pressure and the reflected pressure inside the ammunition storage magazine. Outside a distance of 1.5× the portal diameter from the explosive source, the overpressure decreased as the distance from the portal increased. The numerical simulation result showed that within a 1× portal diameter range of the ammunition storage magazine, the relative error between the overpressure of the numerical simulation and the experiment was −32.67%, indicating that the relative error of the near-field blast in the ammunition storage magazine was still large and that a more refined mesh division is required for further investigations. However, within a 2× to 3× portal diameter range inside the ammunition storage magazine, the relative errors decreased to −7.12% and −3.91%, meaning the numerical simulation result was close to the experimental values.

Figure 10.

Numerically simulated internal blast and experimental measured values (explosion at 1× the portal diameter).

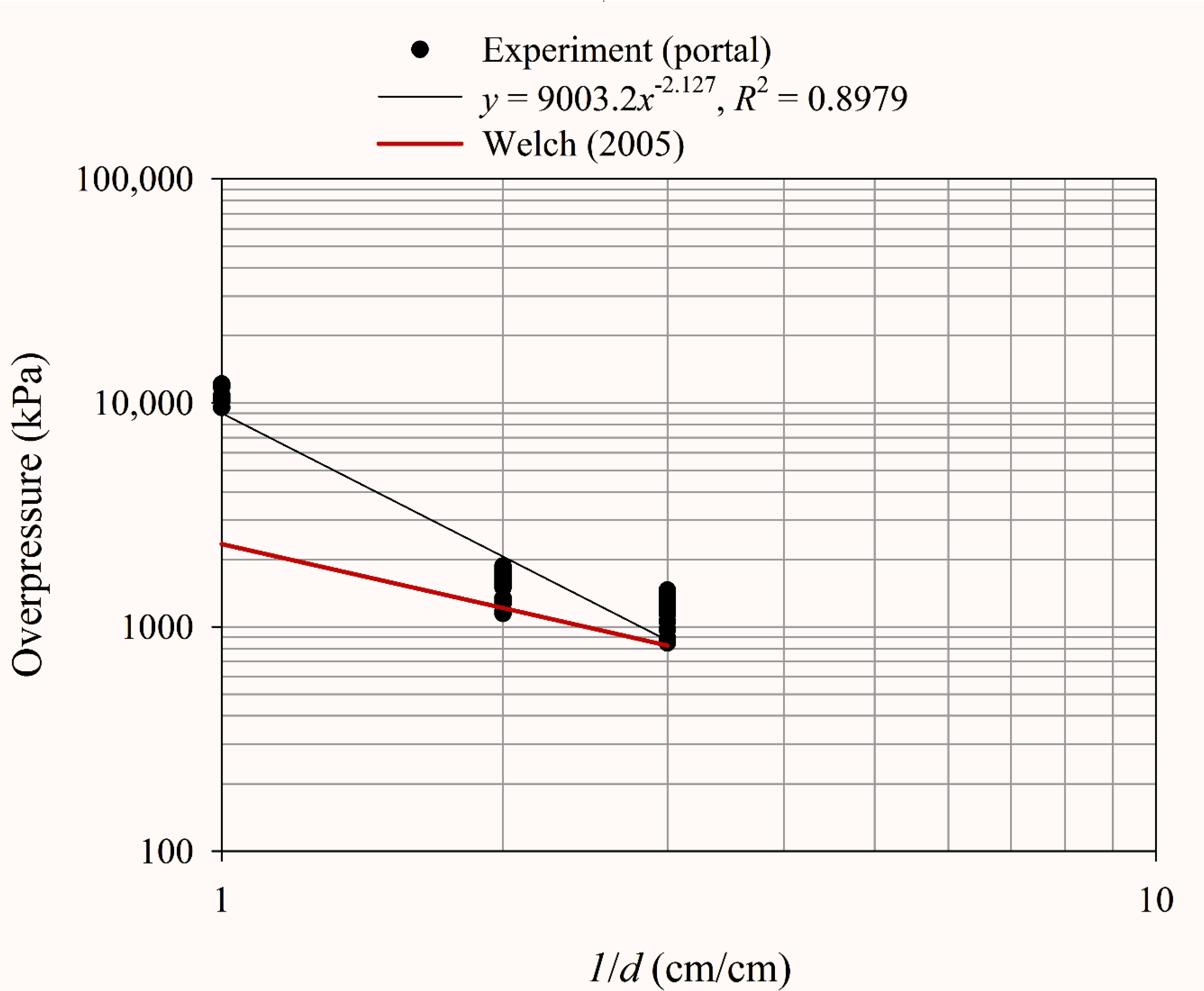

4.2. Blast at the Portal of the Ammunition Storage Magazine

- (1)

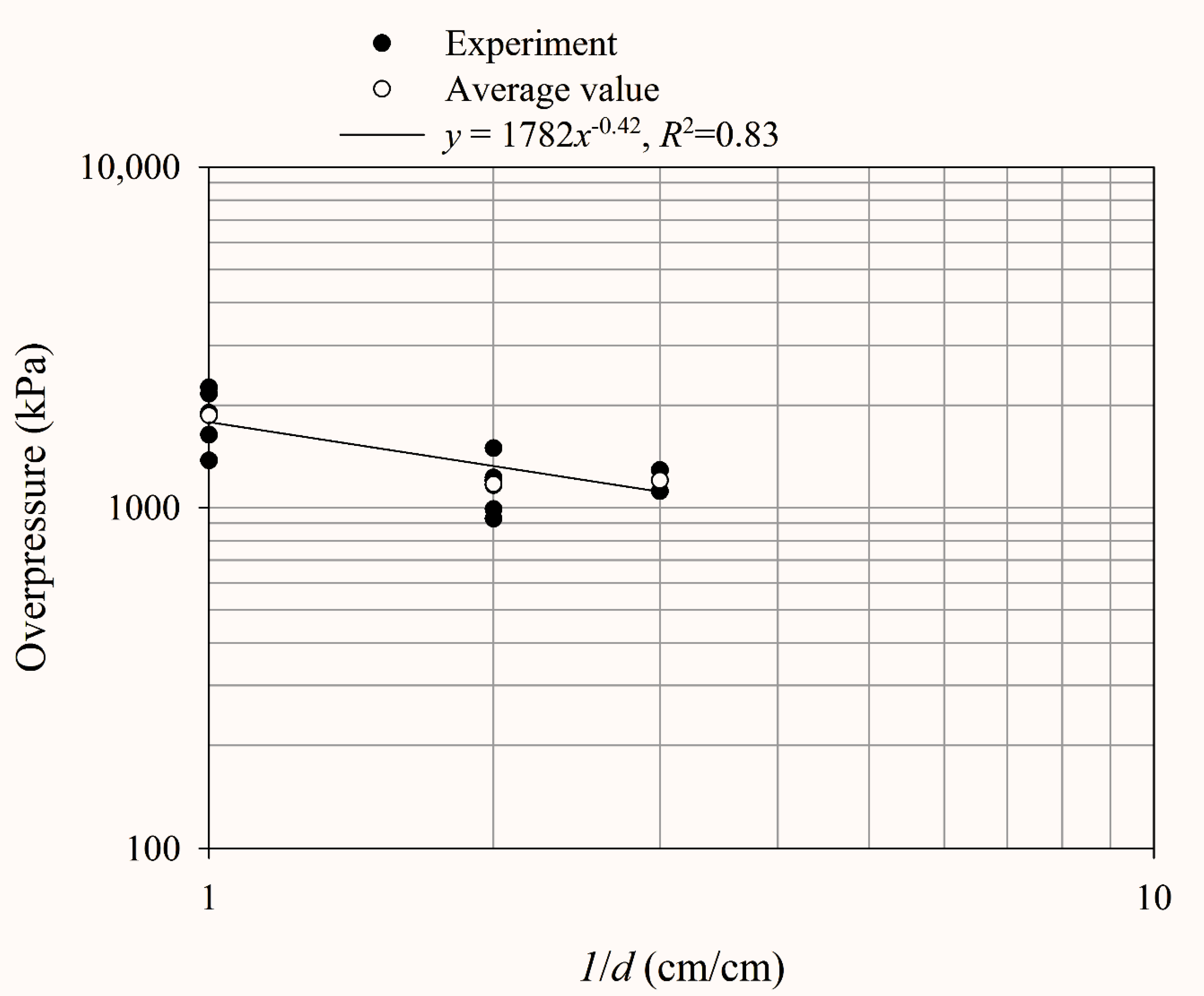

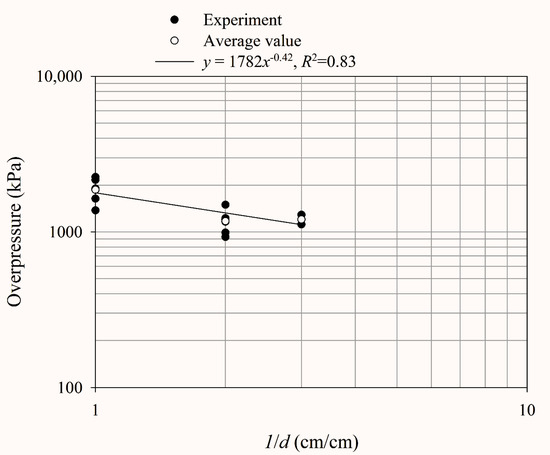

- Experimental results

Regression analysis was used for the blast at the portal inside the ammunition storage magazine, where the ratio (x) of the distance from the measuring point to the outlet inside the ammunition storage magazine (l) to the portal diameter (d) was used to obtain the power regression equation with R2 = 0.830, as expressed in Equation (9). It was applicable to 1× to 3× the portal diameter range from the explosive source to the portal inside the ammunition storage magazine, as shown in Figure 11.

where internal blast value of the ammunition storage magazine (kPa).

Figure 11.

Blast at the portal inside the ammunition storage magazine.

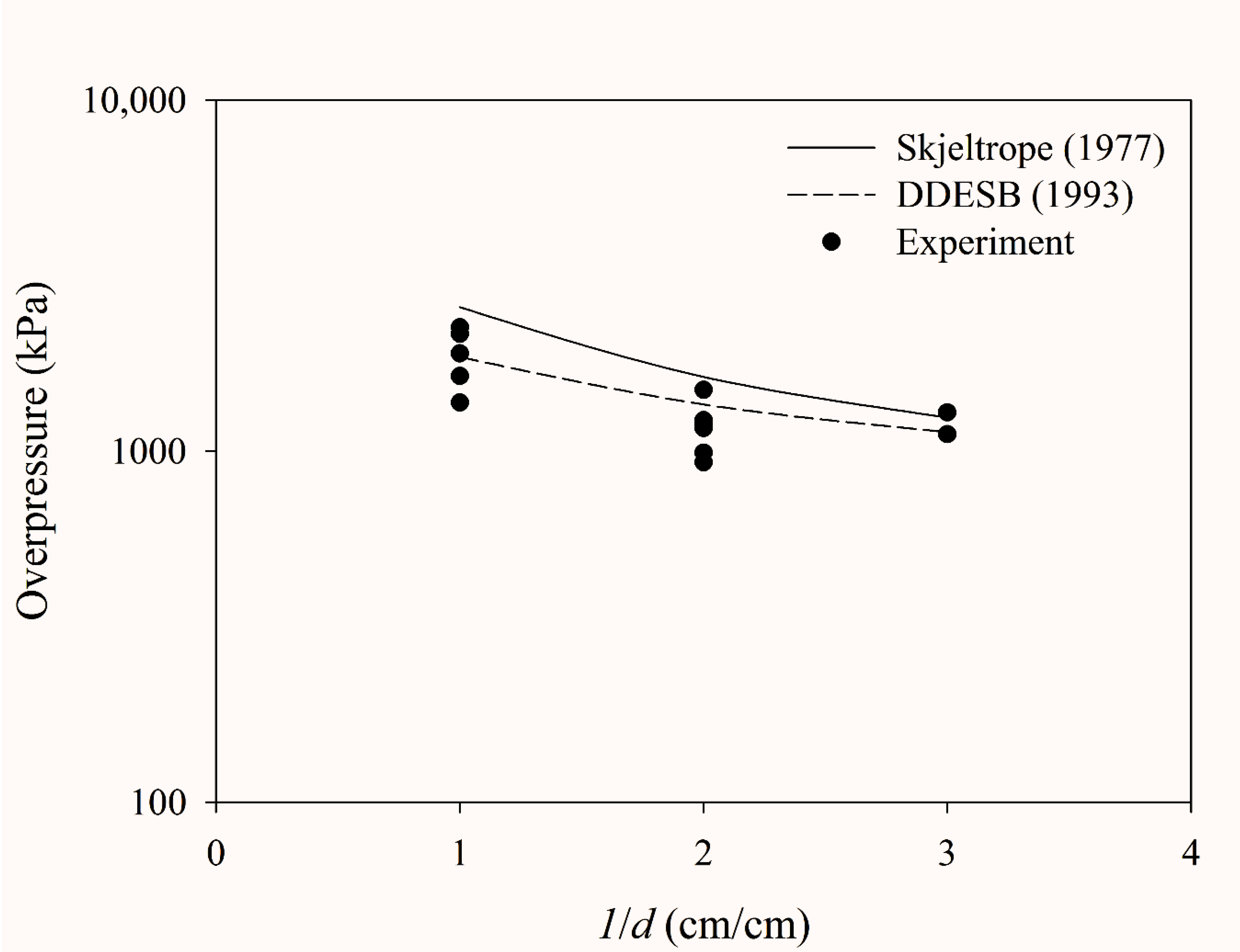

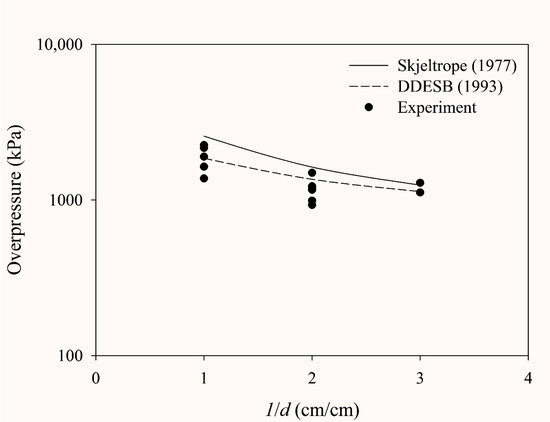

- (2)

- Comparison of empirical equations

The empirical equations of Skjeltorp [19] and DDESB [18] for the portal blast extreme values were compared with the experimental results from this study, as shown in Figure 12. It was observed that when l/d = 1, 2, or 3, the calculation results of the Skjeltorp empirical equation were relatively high. In contrast, the DDESB empirical equation was close to the experimental work of this study. The relative errors were −0.44%, 16%, and −5.81%, respectively, meaning that the DDESB empirical equation was more suitable for analyzing the outlet overpressure when the explosive detonated at l/d = 1, 2, or 3.

Figure 12.

Comparison of the extreme blast values at the portal of the ammunition storage magazine.

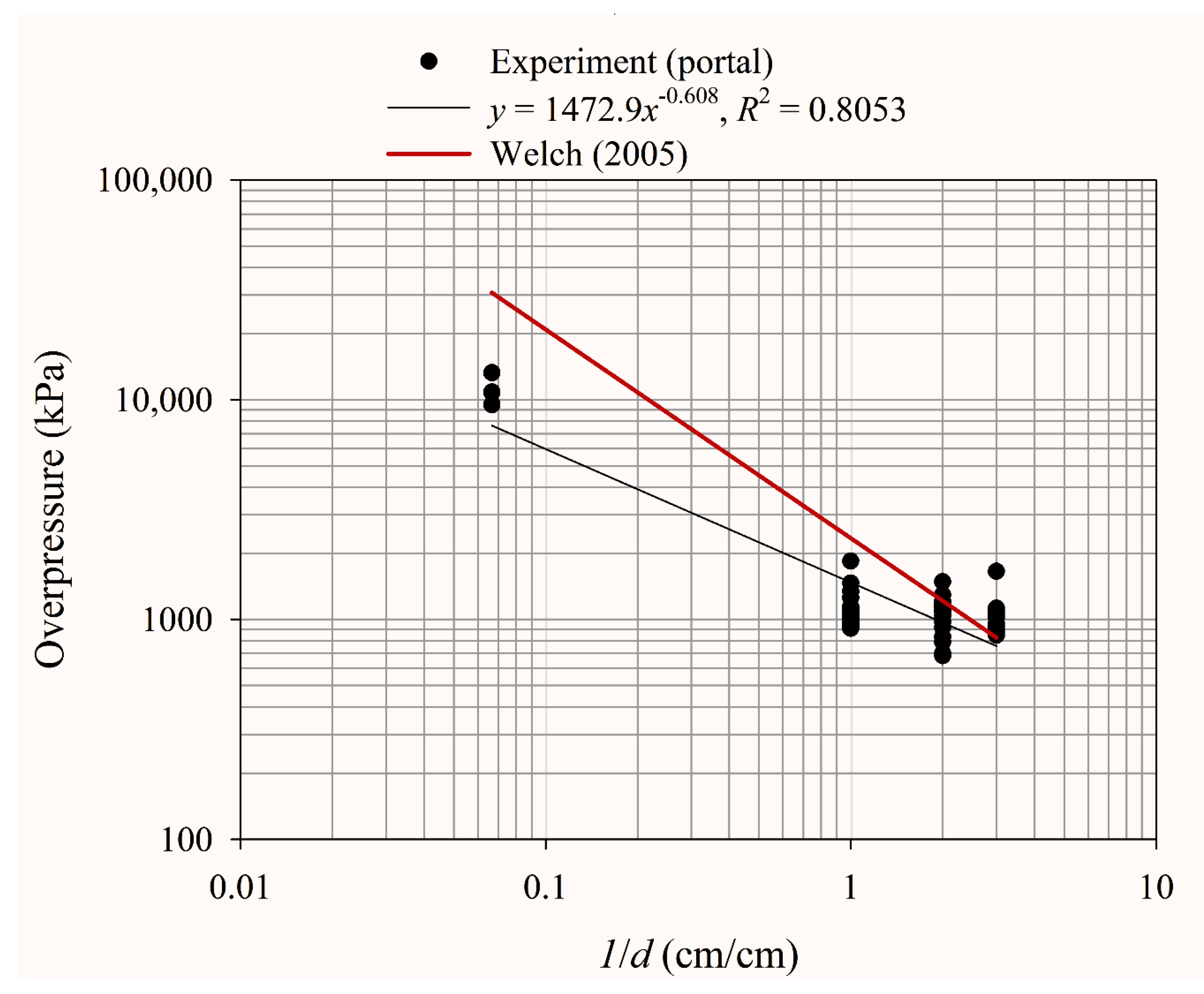

4.3. Ratio of the Blast outside the Ammunition Storage Magazine to the Blast at the Portal of Ammunition Storage Magazine

- (1)

- Experimental results

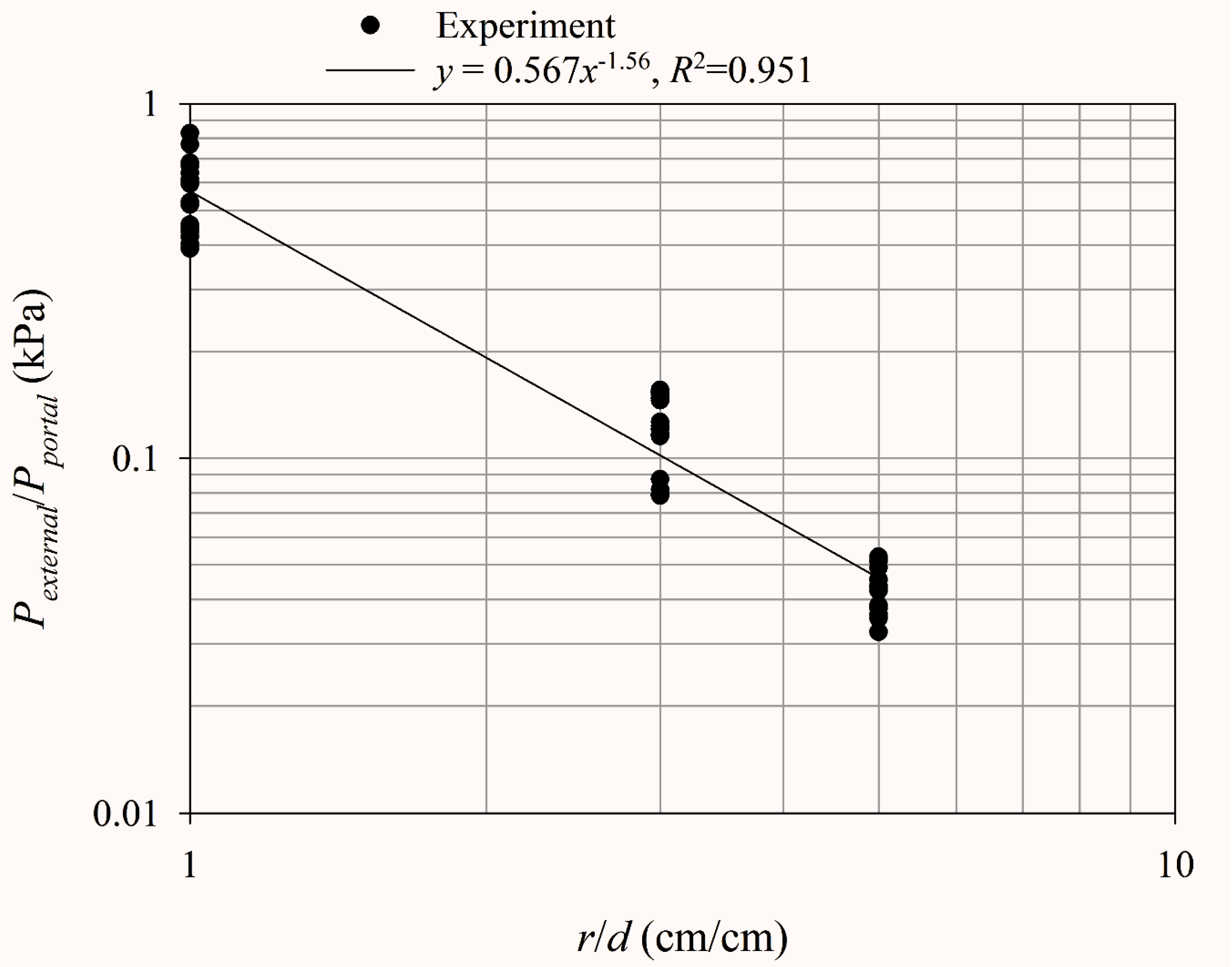

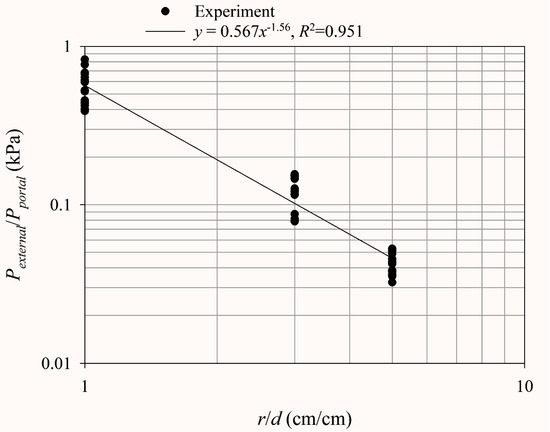

A regression analysis was performed by setting a variable as the ratio of r to d to normalize the blast pressure outside the ammunition storage magazine and the portal blast value. The prediction model was obtained and is expressed as Equation (10). The equation was applicable to r/d = 1~5, as shown in Figure 13. Furthermore, the blast’s extreme values at the portal of the ammunition storage magazine in Equations (9) and (10) were multiplied to obtain the extreme values of the blast outside the ammunition storage magazine.

where ratio of the blast outside the ammunition storage magazine to the blast at the portal of the ammunition storage magazine.

Figure 13.

Ratio of the blast outside the ammunition storage magazine to the blast at the portal of the ammunition storage magazine.

- (2)

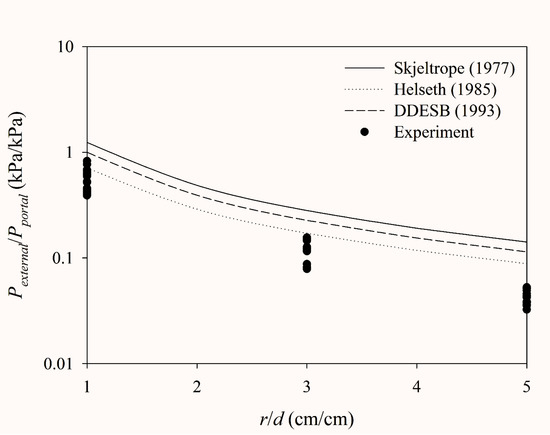

- Comparison of the empirical equations

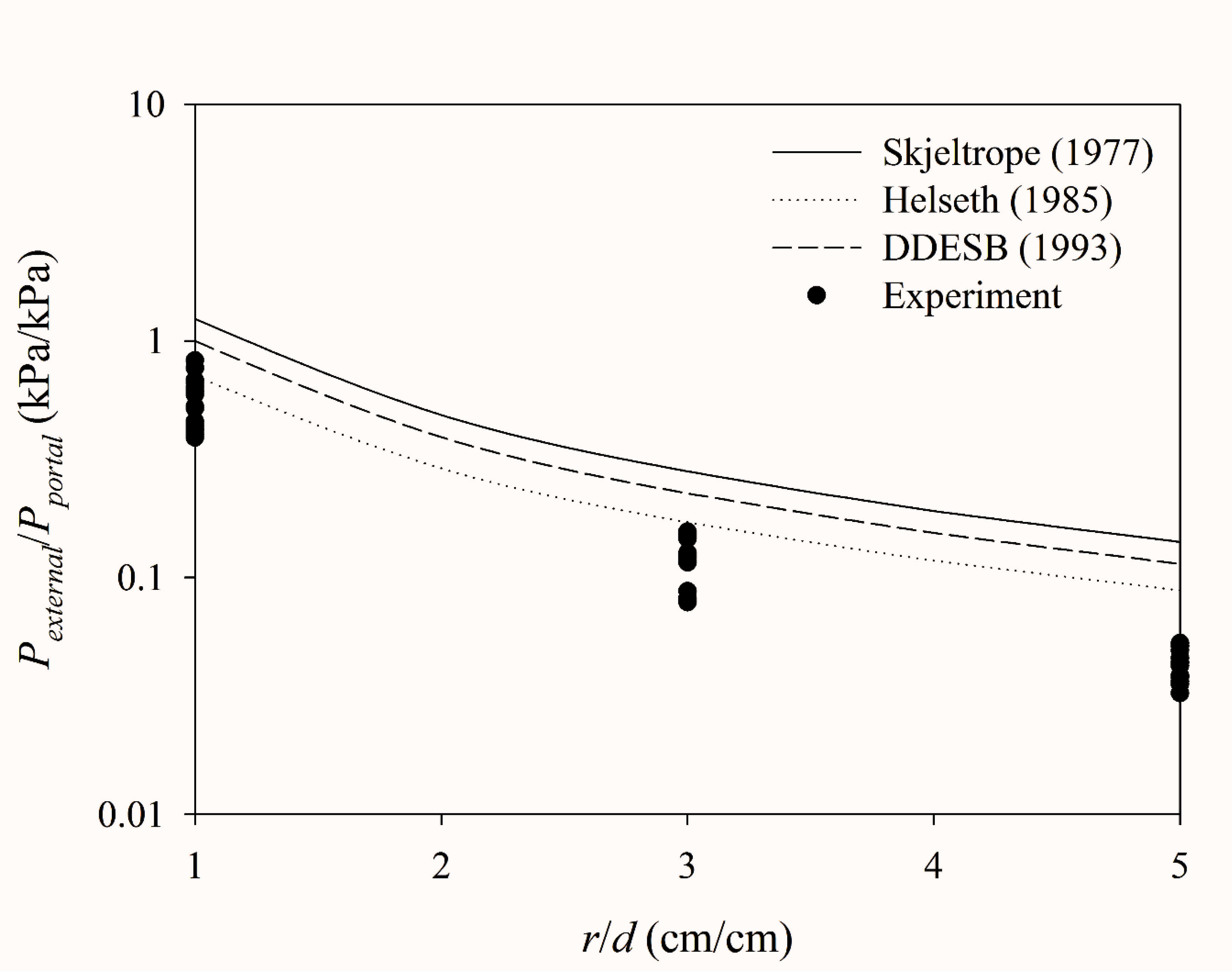

The empirical equations of Skjeltope [19] and DDESB [18] for the extreme value of the blast at the portal of the ammunition storage magazine were compared with the experimental results. Additionally, the empirical equations of Skjeltorp [19], Helseth [20], and DDESB [18] were used to compare the ratios of the blast outside the ammunition storage magazine to the blast at the portal of the ammunition storage magazine, as shown in Figure 14. It was observed that within a 1~3× portal diameter distance from the ammunition storage magazine portal, the empirical equations were relatively high, the Skjeltorp empirical equation had the maximum error, and the Helseth empirical equation had the smallest error.

Figure 14.

Ratios of the blast outside the ammunition storage magazine to the blast at the portal of the ammunition storage magazine from the empirical equations and the experiment.

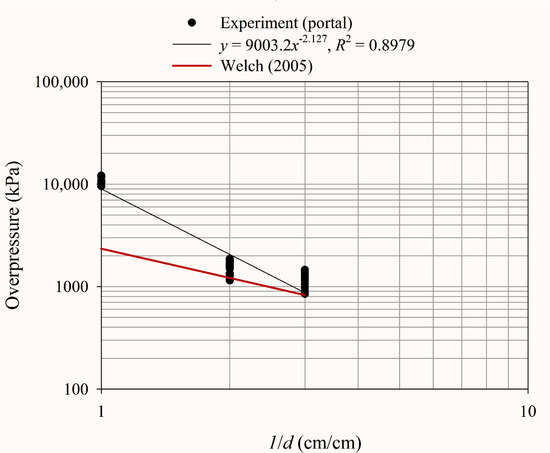

- (3)

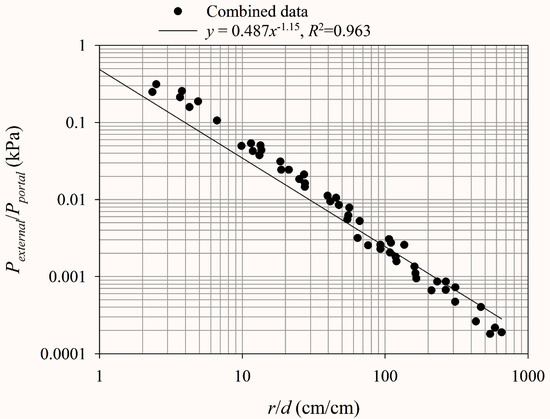

- Empirical comparison with references

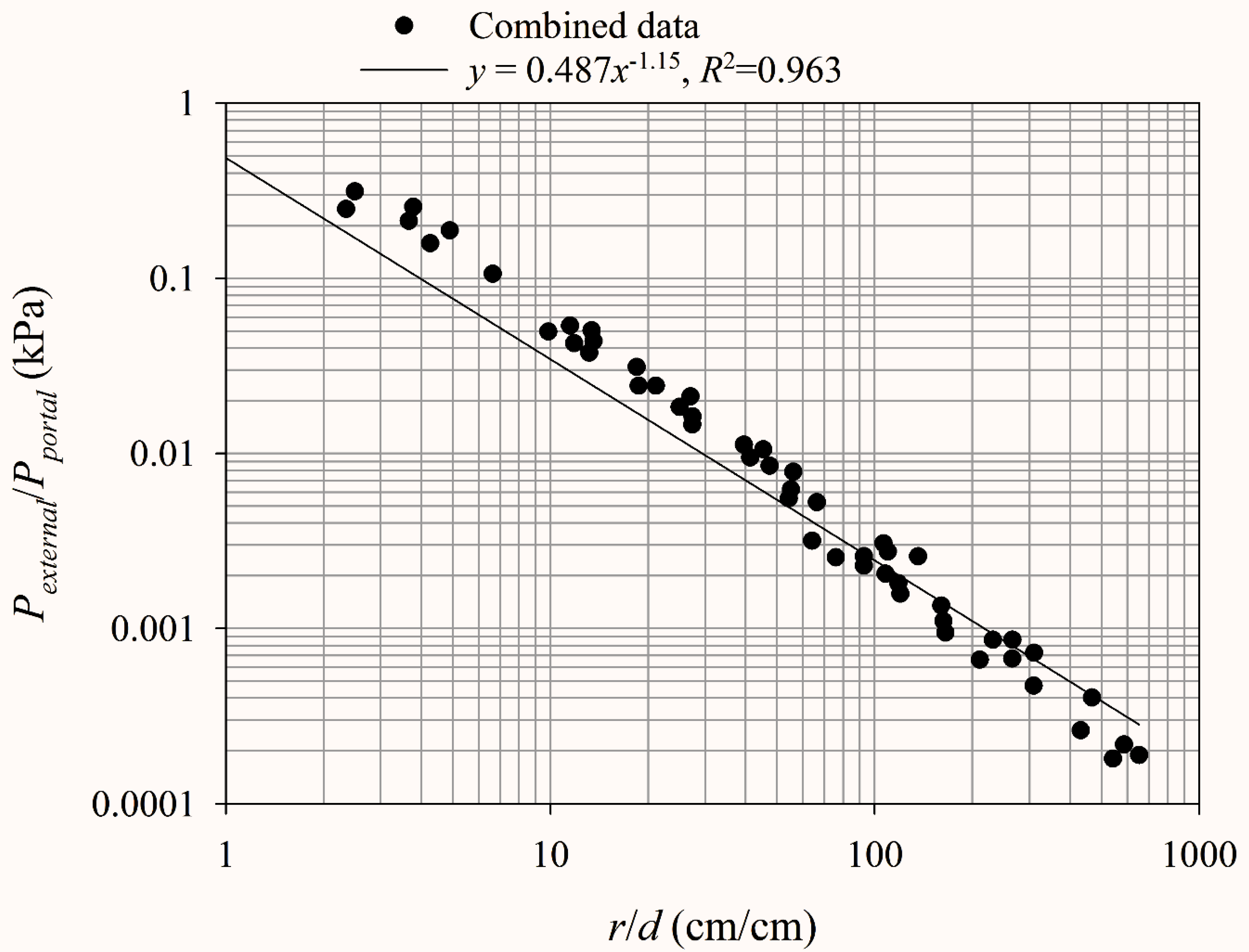

This study’s experimental values were combined with the observed values of Kingery [8], and regression analysis was used to propose the empirical equation for the near-field explosion blast correction, as shown in Figure 15 and Equation (11). The equation was applicable to r/d = 1~653.

where ratio of the blast outside the ammunition storage magazine to the blast at the portal of the ammunition storage magazine.

Figure 15.

Regression equation for the external blast to portal blast ratio.

- (4)

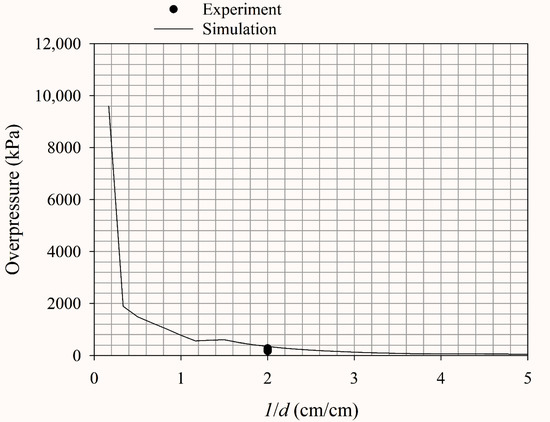

- Numerical simulation

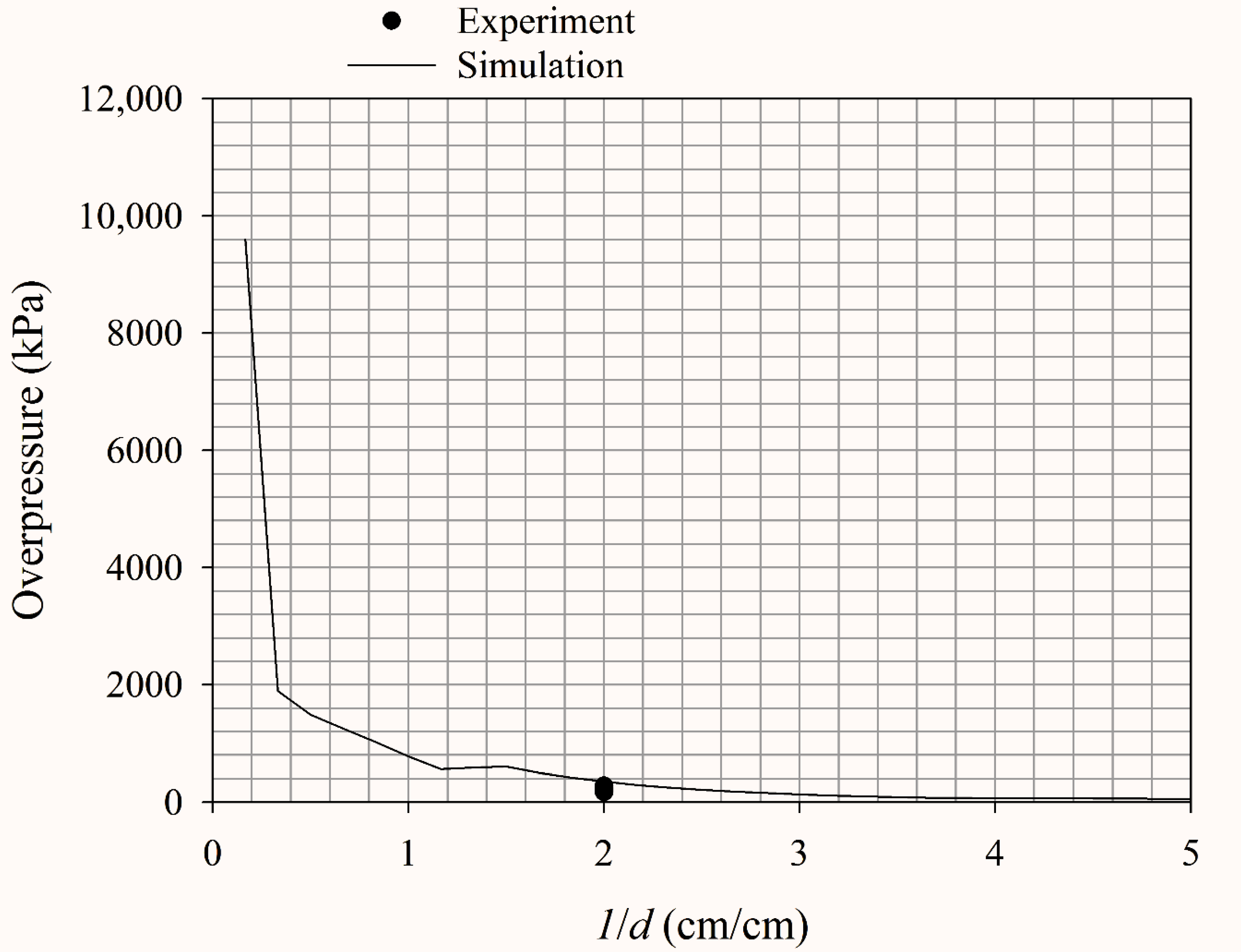

- Portal explosion

The numerical simulation result of the blast outside the ammunition storage magazine when the explosive detonated at the magazine’s portal is shown in Figure 16. The numerical simulation result was 353 kPa at 2× l/d from the portal; the empirical average value was 213.29 kPa. The numerical simulation error was 65.5%, indicating that the near-field blast’s relative error in the ammunition storage magazine was still considerable. A finer mesh is needed for further investigations.

Figure 16.

Comparison between the numerical simulation result and the experimental value of the blast outside the ammunition storage magazine (portal explosion).

- b

- Explosion at 1× the portal diameter inside the ammunition storage magazine

When the explosive detonated at 1× the portal diameter inside the ammunition storage magazine, the numerical simulation result of the blast outside the ammunition storage magazine was as shown in Table 2. The portal section represents the blast meter located 2 cm away from the portal inside the ammunition storage magazine specimen, while 1d, 3d, and 5d represent the blast pressure pencil probes arranged longitudinally at 30, 90, and 150 cm outside the ammunition storage magazine. According to Table 2, in the portal section, as the portal’s blast value was the result of relatively complex interactions, the numerical simulation value was relatively high. The error was −46.64%, indicating that mesh refinement is required for investigations. However, when the ratios of the distance from the measuring point outside the ammunition storage magazine to the portal (r) to the portal diameter (d) were 1, 3, and 5, the numerical simulation results were 1.98%, 1.18%, and −9.19%, respectively, meaning this simulation could make predictions effectively.

Table 2.

Numerical simulation results for blast outside the ammunition storage magazine.

4.4. Effect of the Retaining Wall on the Near-Field Blast

- (1)

- Explosive detonating at the portal

For the explosive detonated at the portal, the experimental result of the effect of a retaining wall on the blast of the explosion inside the ammunition storage magazine is shown in Table 3. In terms of the longitudinal blast pressure pencil probes, the error of the blast average values with/without a retaining wall was −41.85%, meaning that the longitudinal blast extreme value of the ammunition storage magazine decreased when a retaining wall was provided. Regarding the transverse blast pressure pencil probes, the error of the blast average values with/without a retaining wall was 20.18%, meaning that the blast was transferred transversely when a retaining wall was provided, and the transverse blast extreme value of the ammunition storage magazine increased.

Table 3.

Experimental results of the effect of a retaining wall on the explosion blast inside the ammunition storage magazine.

- (2)

- Comparison with the explosion at 1× the portal diameter inside the ammunition storage magazine

For the explosive detonated at 1× the portal diameter inside the ammunition storage magazine, the experimental result of the retaining wall’s effect on the blast attenuation of the explosion inside the ammunition storage magazine is as shown in Table 4. In terms of the longitudinal blast pressure pencil probes, the error of the blast average values with/without a retaining wall was −36.60%, indicating that the longitudinal blast extreme value of the ammunition storage magazine decreased when a retaining wall was provided. Regarding the transverse blast pressure pencil probes, the error of the blast average values with/without a retaining wall was 7.77%, indicating that the blast was transferred transversely when a retaining wall was provided and that the transverse blast extreme value of the ammunition storage magazine increased. This result was coincident with the result of the explosion at the portal.

Table 4.

Experimental result of using a retaining wall for blast attenuation (explosionat 1× the portal diameter inside the ammunition storage magazine).

5. Conclusions

This study used a small number of explosives and a small-sized ammunition storage magazine specimen to conduct experiments on explosions inside an ammunition storage magazine to measure the peak overpressure. The experimental results and numerical simulations were validated and compared to build a blast prediction model for near-field explosions in ammunition storage magazines to provide an alternative evaluation for protective design evaluations. The optimal power equation was proposed through regression analysis and was applicable to 1× to 653× the portal diameter outside the ammunition storage magazine. Additionally, under the effect of a retaining wall on the blast of an explosion inside the ammunition storage magazine, the ammunition storage magazine’s longitudinal overpressure was reduced by 37–42%, and the transverse blast was increased by 8–20%. Regarding the numerical simulations, the external overpressure within 1× to 5× the portal diameter range outside the ammunition storage magazine could be predicted effectively. However, the numerical simulation error was still noticeable for the range of less than 1× the portal diameter; as such, further mesh refinement is required to minimize the discrepancy. The proposed approach could serve as an efficient evaluation tool for protective facilities.

Author Contributions

Conceptualization, C.-W.H.; data curation, C.-W.H. and Y.-K.T.; formal analysis, C.-W.H. and P.-W.W.; investigation, C.-W.H., Y.-K.T., T.-A.C., and P.-W.W.; methodology, C.-W.H., Y.-K.T., and T.-A.C.; supervision, C.-W.H. and P.-W.W.; writing—original draft, C.-W.H.; writing—review and editing, Y.-K.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Swisdak, M.M. A Reexamination of the Airblast and Debris Produced by Expiosions Inside Earth–Covered Igloos; NAVSWC Report; TR 91–102; Paperback; USA, 1991; pp. 557–573. [Google Scholar]

- Weals, F.H. ESKIMO I Magazine Separation Test; NWC Report, TP 5430; USA, 1973; pp. 1–92. [Google Scholar]

- Weals, F.H. ESKIMO II Magazine Separation Test; NWC Report, TP 5557; USA, 1974; pp. 1–93. [Google Scholar]

- Weals, F.H. ESKIMO III Magazine Separation Test; NWC Report, TP 5771; USA, 1976; pp. 1–70. [Google Scholar]

- Weals, F.H.; Wilson, C.H. ESKIMO IV Magazine Separation Test; NWC Report; TP 5873; USA, 1977; pp. 1–54. [Google Scholar]

- Weals, F.H.; Finder, B. ESKIMO V Magazine Separation Test; NWC Report; TP 6076; USA, 1979; pp. 1–78. [Google Scholar]

- Kingery, C.N.; Coulter, G.A. Effect of Low Loading Density on Blast Propagation from Earth Covered Magazines; BRL Report; ARBRL–TR–02453; Maryland, USA, 1982; pp. 1–111. [Google Scholar]

- Kingery, C.N. Survey of Airblast Data Releated to Underground Munition Storage Sites; BRL Report; BRL–TR–3012; USA, 1989; pp. 1–34. [Google Scholar]

- Welch, B.; McMahon, W.; Davis, K. Transportation Tunnels and Ter–Rorist Attacks; ERDC: Vicksburg, MS, USA; pp. 1–77.

- Brill, A.; Me–Bar, Y.; Genussov, R.; Sadwin, L. Experimental Small–Scale Study of Blast Loads on Ammunition Magazines. In Proceedings of the 19th International Symposium on Military Aspects of Blast and Shock Conference, Calgary, AB, Canada, 2–6 October 2006; pp. 1–8. [Google Scholar]

- Hager, K.; Tancreto, J. AUTODYN 2D Predictions for Small Scale HP Magazine Cell Wall Tests. In Proceedings of the 25th Explosives Safety Seminar, Anaheim, CA, USA, 18–20 August 1992; pp. 373–420. [Google Scholar]

- Chen, H.C.; Hung, C.W.; Yu, W.F.; Cheng, D.S. Validation of Fluid Structure Interaction Models of Magazines Subjected to Internal Explosion. In Proceedings of the 8th International Conference on Shock & Impact Loads on Structures, Adelaide, Australia, 2–4 December 2009; pp. 1–9. [Google Scholar]

- Yu, W.F.; Hung, C.W.; Cheng, D.S. Effect of Subdividing Stacks on Blast Overpressure fromExplosion inside Ammunition Storage Magazine. J. Explos. Propellants 2009, 24, 25–40. [Google Scholar]

- Yu, W.F.; Hung, C.W.; Cheng, D.S. Effect of Blast wall on Safety Distance and Blast Overpressure for Ammunition Storage Magazine Subjected to Internal Explosion. J. Chung Cheng Inst. Technol. 2010, 39, 131–145. [Google Scholar]

- Cheng, H.L.; Wang, K.Y. A Study of the Effect of a Blast Wall on Pressure Attenuation. J. Chung Cheng Inst. Technol. 2011, 40, 85–96. [Google Scholar]

- Tancreto, J.E.; Conway, R.; Malvar, L.J. Response of Tilt–Up Reinforced Concrete and Unreinforced Masonry to Blast Loads. In Proceedings of the 12th International Symposium on Internation of the Effects of Munitions with Structures, Orlando, FL, USA, 18–21 September 2007; pp. 1–32. [Google Scholar]

- Ishikawa, N.; Beppu, M. Lessons From Past Explosive Tests on Protective Structures in Japan. Int. J. Impact Eng. 2007, 34, 1535–1545. [Google Scholar] [CrossRef]

- Swisdak, M.M.; Ward, J.M. The DDESB Blast Effects Computer. Available online: https://edms.energy.gov/EM/HASC%20Shared%20Documents/BlastEffectsComputer4.0Description.pdf (accessed on 11 April 2012).

- Skjeltorp, A.T. Underground Ammunition Storage: Blast Propagation in the Tunnel System. Available online: https://apps.dtic.mil/dtic/tr/fulltext/u2/a027066.pdf (accessed on 28 May 2015).

- Helseth, E.S. Blast Effects From Accidental Explosions; Report NR 174/85; Norwegian Defence Construction Service: Oslo, Noway, 1985. [Google Scholar]

- Hung, C.W.; Lai, H.H.; Shen, B.C.; Wu, P.W.; Chen, T.A. Development and Validation of Overpressure Response Model in Steel Tunnels Subjected to External Explosion. Appl. Sci. 2020, 10, 6166. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).