1. Introduction

With the development of AI technology, mobile robots are appearing more and more frequently in public. According to the motion mode, mobile robots can be divided into wheeled robots [

1,

2], tracked robots [

3], and legged robots [

4,

5]. In the face of complex environments as well as rugged terrains, legged robots have incomparable flexibility and applicability compared with the other two kinds of robots.

The design idea of legged robots originated from bionics. Inspired by mammals, insects, amphibians, etc., legged robots try to imitate the structure as well as movement mode of different legs [

6]. Up to this point, there have been many different kinds of bionic legged robots that were designed and studied. With the support of the U.S. Department of Defense and by imitating a dog, Boston Dynamics developed the quadruped robot BigDog, which possessed strong obstacle crossing ability and could overcome rugged terrain [

7]. Inspired by insects, Case Western Reserve University designed a bionic insect robot that could jump, walk, turn, and avoid obstacles in a certain space [

8]. In China, also from the perspective of bionics and combining motion control analysis, different kinds of legged robots were designed by Shandong University [

9,

10], Harbin University of Science and Technology [

11], and Shanghai Jiaotong University [

12].

Common legged robots include biped robots, quadruped robots, hexapod robots, and octopod robots. For biped robots , the movement balance is difficult to control [

13,

14]. Even very simple walking similar to those in humans will become a big challenge for biped robots . For quadruped robots, they are able to walk steadily, but have strong dependencies on each leg [

15]. When one of the four legs breaks for some reason, the quadruped robot cannot continue working anymore. In contrast, hexapod robots can still adjust in the case that one leg breaks through an adaptive fault tolerant gait [

16]. Up to this point, there is very little work about octopod robots in terms of complex control [

17]. All in all, hexapod robots have natural advantages in movement stability and are studied a lot.

In terms of the hexapod robot’s stable movement in different terrains, most research realized this by switching gait. Bai et al. presented a novel CPG (center pattern generator)-based gait generation for a curved-leg hexapod robot and enabled the robot to achieve smooth and continuous mutual gait transitions [

18]. Ouyang presented an adaptive locomotion control approach for a hexapod robot by using a 3D two-layer artificial center pattern generator (CPG) network [

19]. These methods all obtained promising results in some aspects, but they could not confront any complex scene because of the limited gait patterns. Our current work, from another point of view, finds a new method to help the hexapod robot improve its movement stability for all kinds of terrains, which is achieved by adaptively planning the foot’s trajectory in order to stabilize the robot’s attitude. With this method, the gait can remain the same.

To implement the above theory on a physical robot, the robot should have the ability to sense its landing information firstly. In [

20], Zha et al. developed a new kind of free gait controller and applied it to a large-scale hexapod robot with heavy load, where sensory feedback signals of the foot position were employed in both the free gait planner and the gait regulator. In [

21], Faigl and Čížek presented a minimalistic approach for a hexapod robot’s adaptive locomotion control, which enabled traversing rough terrains with a small and affordable hexapod walking robot, and servomotor position feedback was also used to reliably detect the ground contact point. Up to this point, the problem of how to obtain landing information has not been sufficiently considered as well as studied in most legged robots. In [

21], this information was obtained by comparing the joint error and the error threshold. In some other works, based on the robot’s dynamic model, joint torque feedback was selected to judge whether the feet had touched the ground [

22]. However, the sensors used for such joint torque feedback are always with large volume and high in terms of price, which limits their utility in small robots. To solve these lingering issues, we create a new design of the legged robot’s foot by adding a short-stroke inching button in order to obtain accurate feedback of the foot’s landing information. By conducting experiments on our designed robot in real environments, this foot sensing structure is proved to be easy to use, with low cost and strong sensitivity.

The rest of the paper is structured as follows. Section II introduces the hexapod robot we designed in detail, including its mechanical structure and electrical structure, especially the new design of the robot’s foot sensing structure. To elucidate our method, the robot’s mathematic model is firstly given in section III. All details of the foot trajectory planning method including simulation verification are in Section IV. Section V provides the method’s application in a triangle gait. Section VI shows the experiment results. Conclusions are finally put forward in Section VII.

2. The Hexapod Robot

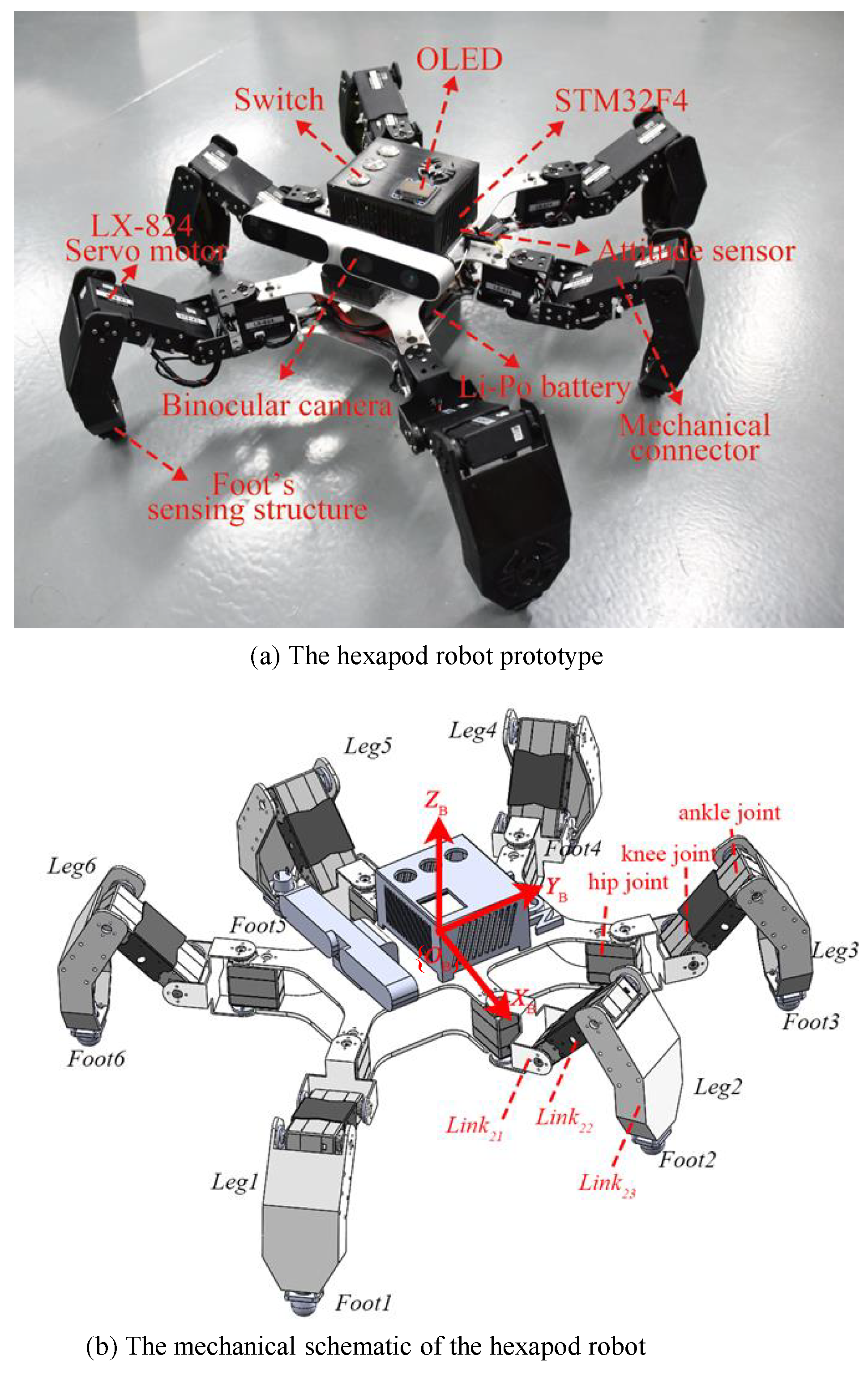

The robot we designed is as shown in

Figure 1, where (a) is the hexapod robot prototype, and (b) is its mechanical schematic. For the sake of description, the six legs are numbered as

to

in a counter-clockwise fashion.

2.1. The Hexapod Robot’s Mechanical Structure

From the perspective of mechanical structure, the hexapod robot is mainly composed of a body, legs, and feet. Normally, to better guarantee the stability and controllability, the hexapod robot is centrally symmetric.

2.1.1. The Body

For our hexapod robot, its body is composed of two identical plates with the length and width ratio of 2:1. These two plates are placed up and down and are fixedly connected by the hip joints of six legs. Located between the two plates is the battery. The STM32F4 microcontroller, binocular camera and attitude sensor are placed on the top of the upper plate.

2.1.2. The Leg

As in

Figure 1b, for each leg, there are three joints from the direction of body to foot tip, which are the hip joint, the knee joint, and the ankle joint. Different joints are connected by links named as

(between the hip joint and the knee joint),

(between the knee joint and the ankle joint), and

(between the ankle joint and the foot tip) for the

leg. For the hexapod robot, the total of 18 degrees of freedom is utilized.

2.1.3. The Foot

To help the robot to sense its foot landing information, this paper creates a new design of the legged robot’s foot sensing structure as in

Figure 2. A short-stroke inching button is used here. Once one foot touches the ground, the reaction force from the ground will press the short-stroke inching button, and then landing information will be transferred to the controller. When the foot is lifted off the ground, the button is reset and prepares for the next landing. A hemispherical foot tip is designed to ensure that the short-stroke inching button can be pressed regardless of the direction of the foot’s fall.

2.2. The Hexapod Robot’s Electrical Structure

The hexapod robot’s electrical structure is shown in

Figure 3.

The sensory unit includes five parts as follows.

(1) Binocular camera for object capture and tracking.

(2) Attitude sensor MPU-9250 for measuring the robot’s posture. MPU-9250 is a System in Package (SiP) and contains a 3-axis gyroscope, a 3-axis accelerometer, and AK8963, a 3-axis digital compass. As accelerometers and magnetometers have high frequency noise while the gyroscope has low frequency noise, by utilizing their complementary characteristics in frequency and fusing the low-pass filtered accelerometer and magnetometer data with high-pass filtered gyroscope data, the attitude feedback information with high precision can be obtained.

(3) WIFI module for remote data transmission.

(4) Remote control receiver for instructions receiving.

(5) Foot sensing structure for landing information.

The control unit is STM32, and it outputs the commands to the motion unit, more specifically, the 18 servo motors through serial ports. For each leg, its three servo motors cooperate with each other in a certain time sequence and finally achieve the foot to reach the specified point in space.

The hexapod robot’s technical specifications are provided in

Table 1.

3. Hexapod Robot Kinematics Modeling

The robot’s kinematic model can help us quantitatively analyze the robot’s velocity, acceleration, attitude, and so on from a mathematical point of view. To establish the kinematic model of the hexapod robot, for each leg

i, three coordinates are defined at the hip joint (

), the knee joint ({

}), and the ankle joint ({

}), respectively, as depicted in

Figure 4. The reference coordinate is

. For each coordinate

, the

axis coincides with the axis of the

jth joint. The

axis is the common perpendicular between the axes of the

jth joint and the

th joint. The

axis is then determined according to the right-hand rule. In this paper, the kinematic model is based on the DH (Denavit–Hartenberg) method [

23], and the parameters are provided in

Table 2. Since the six legs are the same, we do not distinguish the leg number

i anymore, and only the joint number

j is considered in the description that follows.

The relative translations and rotations between the

th and the

jth joint coordinates are computed by the transformation matrix (1).

3.1. The Forward Kinematics

Based on (1), the transformation matrix from the coordinate

to

is the following.

The coordinate of the foot tip with respect to the coordinate

is the following.

Then, the coordinate of the foot tip with respect to the coordinate

is described in Equation (

4).

3.2. The Inverse Kinematics

A geometric method is used in this work for the inverse kinematics analysis. It is intuitive and clear, and the solution can be simultaneously unique by restricted conditions. The leg’s diagram for the solution to its inverse kinematics is shown in

Figure 5. The angle of CDF is

, resulting from the robot leg’s fixed mechanical structure design, as shown in

Figure 1 and

Figure 4. Based on this diagram and by combing geometric knowledge, we have the following.

Thus, the inverse kinematics can be easily obtained as follows.

4. The Three-Element Trajectory Determination Method

For a hexapod robot, planning its foot trajectory is very important, and it will affect the robot’s flexibility and stability. While moving, the robot’s leg may be in the support phase in order to drive the robot towards a certain direction or off the ground and in the transfer phase. The gait is then realized by switching between the support phase and transfer phase in different sequences. For each leg, its trajectory planning is worth studying in order to enrich the movement of legged robots.

In this paper, we design a three-element trajectory determination method to help the robot plan its foot’s movement. The three elements used are the start point in support phase , the end point in support phase , and the joint angle changes in transfer phase . and are used to control the height, distance, and the direction of the movement, while is used to make decisions on the lifting motion of the leg. Applying this method to legged robots, this paper transfers the six variables of and to another three variables that are related to the movement of legged robots, which are height, direction, and distance. Such a transfer is based on some restrictions such as symmetry, equal altitude, vertical landing, etc. is set according to the feedback information from the foot. The trajectory planning methods in the support phase and transfer phase are different, and they are elaborated separately.

4.1. Trajectory Planning in Support Phase

By using MATLAB,

Figure 6 simulates the trajectory planning process in the support phase, where

,

, and

represent the hip joint, the knee joint, and the ankle joint, respectively, while

represents the foot tip.

is fixed in

. In

Figure 6a,

and

are the start point and the end point of the foot, while

and

are the start point and the end point of the hip joint in

Figure 6b.

Traditionally, during the hexapod robot’s movement, the angles of the knee joint

and the ankle joint

are always fixed and not considered. Then, based on the forward kinematics model, the foot will rotate around the hip joint

, and its trajectory is

, as shown in

Figure 6a. When the foot is on the ground, the body needs to move forward with the foot

as the fulcrum, and the joint

will then move along the trajectory

, as shown in

Figure 6b. As the relative position of the hip joint to the robot’s body center remains unchanged, the center of the robot will also move according to

, which means the robot will shake. Therefore, to ensure accuracy in direction as well as stability while moving, the hexapod robot’s foot trajectory in the support phase should better be a straight line

, as shown in

Figure 6a. Then,

will move along

, as shown in

Figure 6b. Here, the robot’s moving direction keeps constant to ensure that the robot moves in a straight line.

According to the inverse kinematics model, the foot’s trajectory in straight line is planned in Cartesian space. To ensure the robot’s speed, the trajectory’s continuity, and the servo motor’s angular velocity, a spline of linear function with parabolic blends is used in (12).

can be

,

, and

, which are the foot’s coordinates in

X axis,

Y axis, and

Z axis, respectively.

to

are the parameters, and they are different for different axes.

is the movement time of the parabola phase, and it is the same for

,

, and

in order to guarantee the stabilization of movement acceleration.

is the time of the total support phase. Some restricted conditions are set at the same time in (13).

Take

as an example, as

and

; according to (13), we have the following.

By combining all of the restricted conditions, we have the following.

For a given robot, when and are set, the equations above can be solved. The same can be performed for and , and the trajectory of the foot in support phase can be obtained and is defined as . According to the inverse kinematics model in (11), the angle function of the three joints can be obtained and is defined as .

4.2. Trajectory Planning in Transfer Phase

Transfer phase is the phase when the foot is in the air and moves from the end point of one movement period to the start point of the next movement period. Compared with support phase, the transfer phase has fewer restrictions. The only requirement is that the foot should complete its trajectory in time .

The trajectory planning in transfer phase is performed in joint-space. Considering computational simplicity as well as the trajectory’s reliability, this paper designs trajectory planning to occur in this phase as the superposition of two functions: one is what we call the joint angle reverse-chronological function and the other is the joint angle changes interpolation function.

4.2.1. Joint Angle Reverse-Chronological Function

We named it as reverse-chronological function because the trajectory planned based on this function is symmetrical with the trajectory in the support phase along the time

. As it is planned in joint-space, we provide the joint angle reverse-chronological function as Equation (

16).

4.2.2. Joint Angle Changes Interpolation Function

The joint angle changes interpolation function is defined as

, where

is the angle changes interpolation function for the

joint. Considering the continuity of the velocity as well as the acceleration, for each joint,

is a quartic polynomial, as described in Equation (

17):

where

to

are the parameters of

and will be different according to different joints.

To ensure the continuity of the joint angle, the joint angle changes at the start and end time should be zero. To ensure the stability of the joint rotation, the velocity of the joint angle changes at the start, and the end time should also be zero.

To realize the symmetry of the angle changes, we hope that

arrives at the set joint angle change

at the middle time of this phase; thus, we have the following.

Then, the relationship matrices (20) and (21) can be obtained as follows.

is set according to the real terrain situation. Based on Formula (21), the parameters to can be solved, and is obtained.

By superimposing

and

, the trajectory function of the transfer phase

in joint-space is described as follows (22).

By combining

(t) in support phase and

(t) in transfer phase together, the total trajectory of one joint during a movement period in joint-space is defined as the dotted line in

Figure 7. The red dotted line is

(t). The blue dotted line is

(t), and it is the superposition of the green line

and the pink line

.

4.3. Verification of the Three-Element Trajectory Determination Method

The trajectory of one foot based on the three-element trajectory determination method during one movement period in Cartesian space is simulated in

Figure 8, in which counter clockwise is selected as the positive direction and

,

.

From

Figure 8a, it can be observed that, during the time

, the foot’s coordinates in

X and

Z axes remain unchanged, and the robot only moves along the

Y axis, which confirms that the robot is moving in a straight line.

Figure 8b is the foot’s trajectory in space, the straight line is the trajectory in support phase, and the arc line is the trajectory in transfer phase.

Here, we also provide the angle curve of the three joints as in

Figure 9. We can observe that, while moving, all of the three angle curves are continuous and smooth, which further demonstrates the stability and practicability of our trajectory planning method for legged robots.

5. The Three-Element Trajectory Determination Method in Triangle Gait

The advantage of our designed trajectory method is reflected in the realization that the robot’s horizontal posture is maintained during movements. For the three elements,

is set according to the feedback information from the foot. What else needs to be performed is to select the start point

and the end point

. Supposing the target height of the robot’s body is

Z , target moving direction is

, and the moving step is

D, then it can be divided into three steps for our method. The details are described by combining

Figure 10.

5.1. Stable Point Determination

First of all, to improve our method’s stability and flexibility in triangle gait, in this paper, we treat the stable posture for a legged robot as the posture where

in

Figure 1b is perpendicular to the ground and the hip joint’s angle

in

Figure 5 is simultaneously zero. The foot’s point is now called a stable point. As in

Figure 10, the points on the line

are all stable points. As

is perpendicular to the ground, by geometric knowledge, we obtain the following.

For the foot’s inverse kinematics in (11), with the above conditions, there will be only one degree of freedom. To help the hexapod robot adapt to rugged terrains, we set Z as input so that we can obtain the expected stable point P.

5.2. Start Point and End Point Selection

After the stable point

P is determined, what also needs to be performed is to select the start point

and the end point

of the support phase. For a hexapod robot, it is symmetric, and the triangle gait is simultaneously repetitive. Thus, the stable point during movement will be the middle point of the trajectory in the support phase. Supposing that the target moving direction is

, the trajectory in the support phase is along the line

, as shown in

Figure 10. Ideally,

, and the coordinates of

and

can be computed. In reality, the feet can only reach a limited range (as in

Figure 10, the foot of

can only arrive at the points between the two dotted arc lines); thus, the selection of

and

should depend on specific conditions.

Extend

and intersect it with the outer arc at point

H. Extend

and intersect it with the inner arc at point

G. If

, this means both of the points

and

can be reached, and they can be the selected points. Then, the priority is given to movement stability, and all feet move equidistant around their respective stable points. If

, this means the point

cannot be reached, and the selected points are

and

G. If

, this means the point

cannot be reached, then the selected points are

H and

. If

, then the trajectory will be the line

. Thus, we have the following.

Transform the start point and the end point that were obtained above under the world coordinate to the coordinate . Then, the trajectory of each foot can be planned by using the method in Section IV.

7. Conclusions

Legged robots have high movement flexibility, which makes them more suitable for various complex terrains. However, the complex control algorithm and trajectory planning also accompany the robot. Reasonable trajectory planning methods will greatly reduce the difficulty of control algorithm designs. Thus, this paper designs a new trajectory planning method for legged robots named the three-element trajectory determination method. Meanwhile, to realize this method’s application on a physical robot, this paper creates a new design of the legged robot’s foot sensing structure in order to help obtain landing information. To show how the method works, the details of its application in a triangle gait are given. Indicated by the observation of our experiments, this paper makes an improvement of the traditional triangle gait, where an adjustment phase is added at the end of transfer phase to help the robot adjust its foot position when it deviates from the original planned trajectory because of changing terrain. A control flowchart with the introduced adjustment phase is also given. Experiments are carried out in a slope environment and an obstacle environment. The results prove that our method is effective and stable in practice .

Hexapod robots have extensive prospect and are worth studying. In this paper, the improvement of the movement of hexapod robots mainly focuses on the trajectory planning method. In the future, we plan to take attitude information into account in order to develop novel control algorithm designs.