Deformation Behavior of Saturated Marine Silt under Principal Stress Rotation as Induced by Wave Loading

Abstract

:1. Introduction

2. Test Procedures

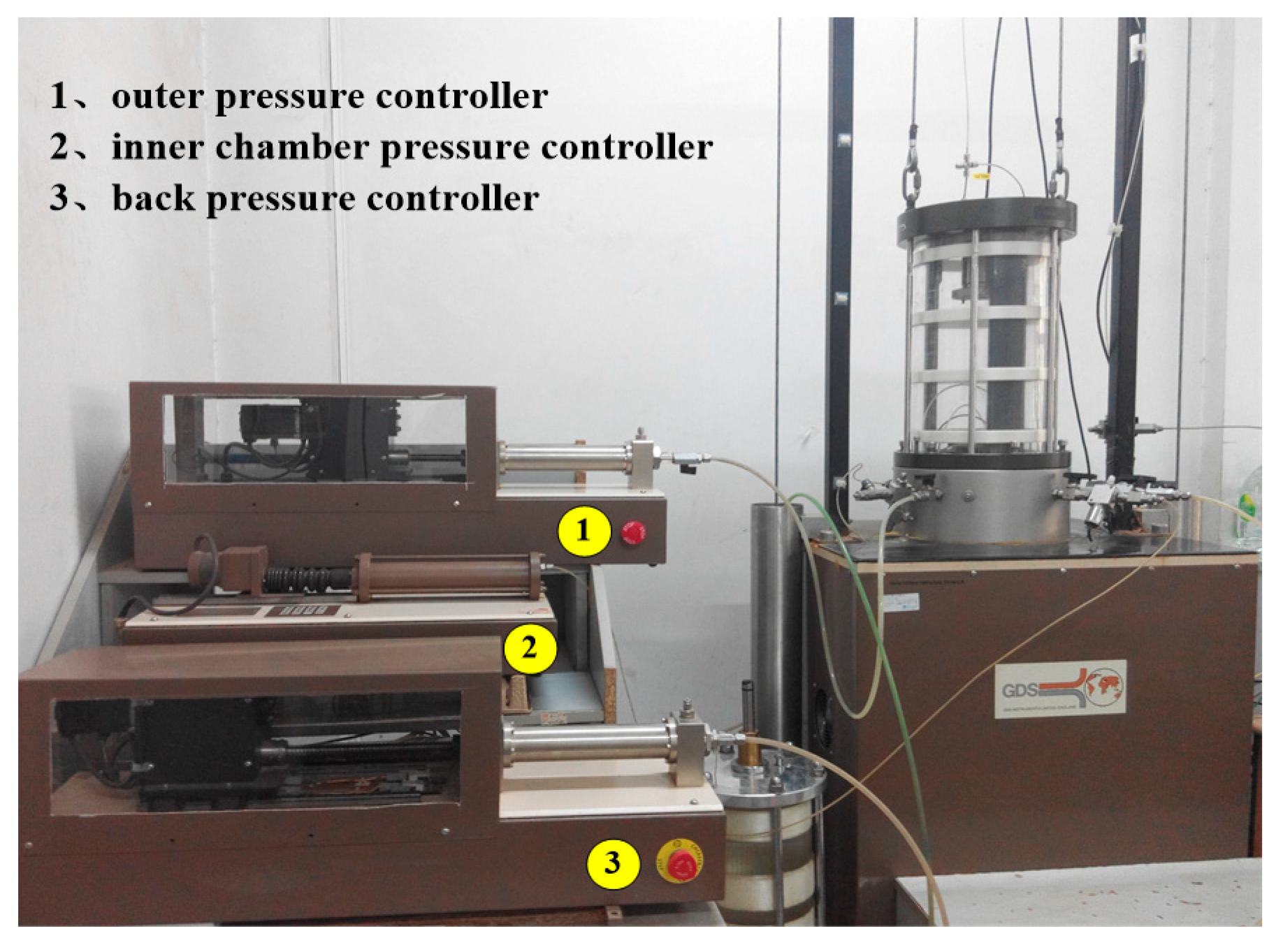

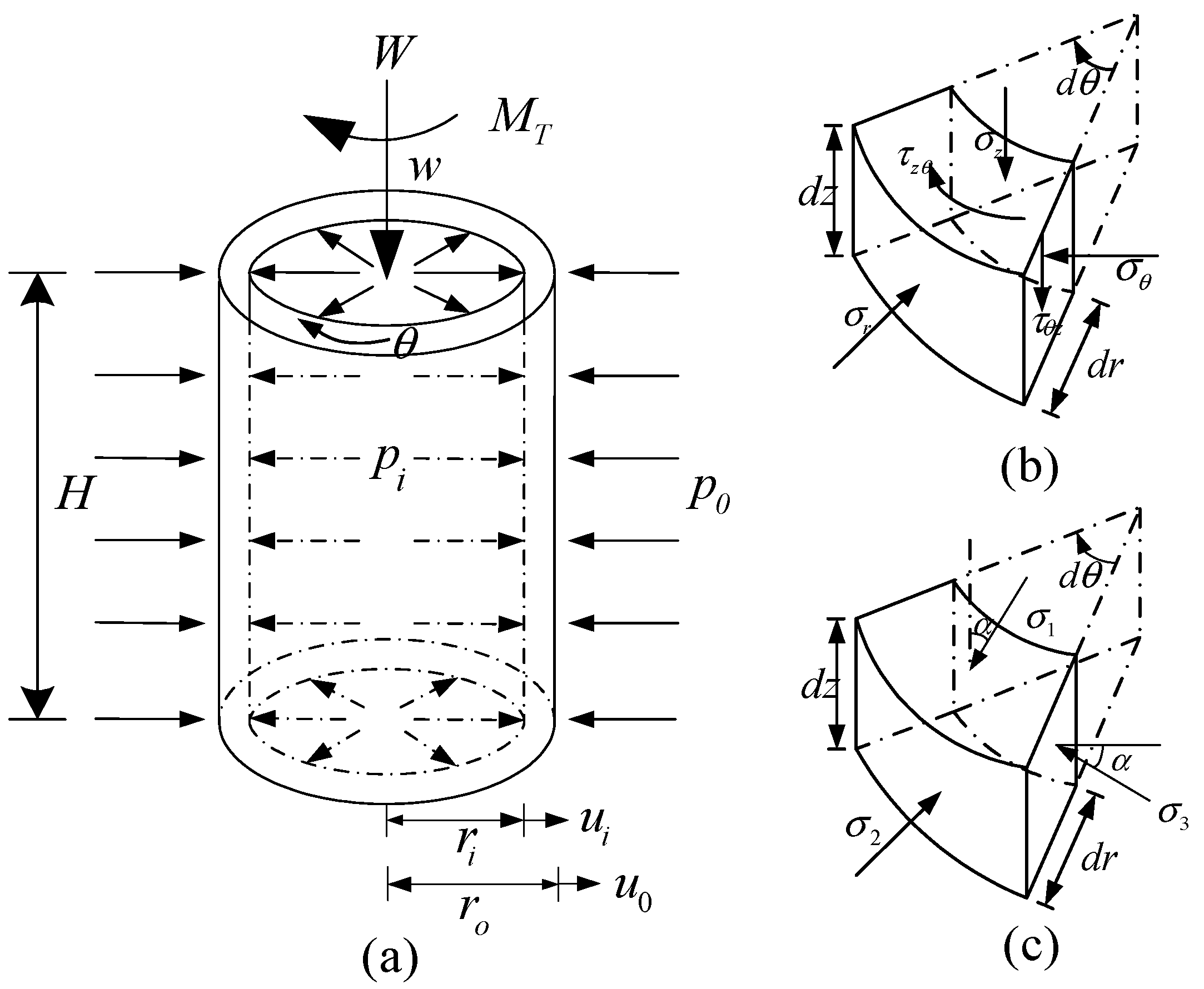

2.1. Experiment Equipment

2.2. Tested Material, Specimen Preparation and Saturation Method

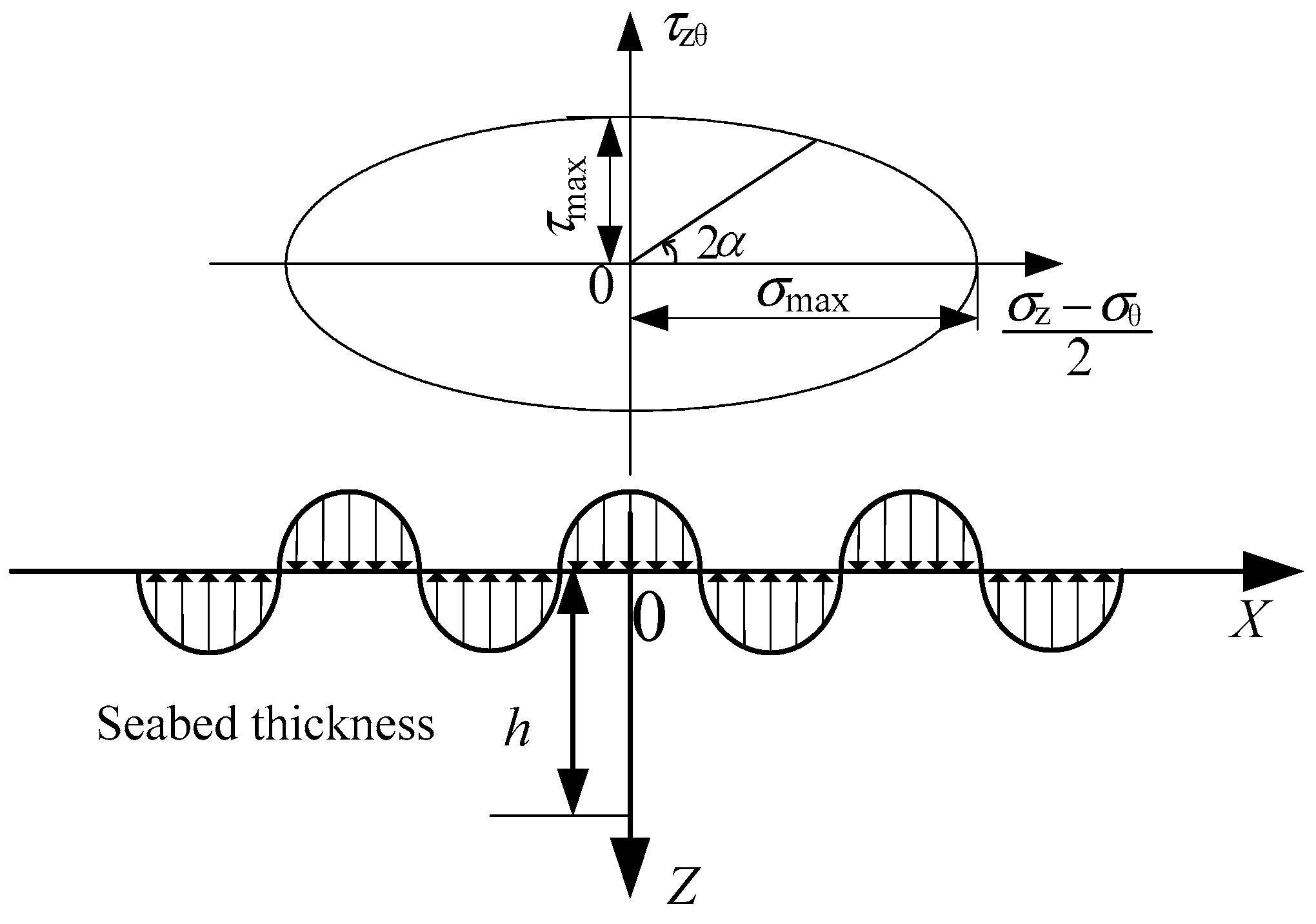

2.3. Test Program

3. Test Results and Analysis

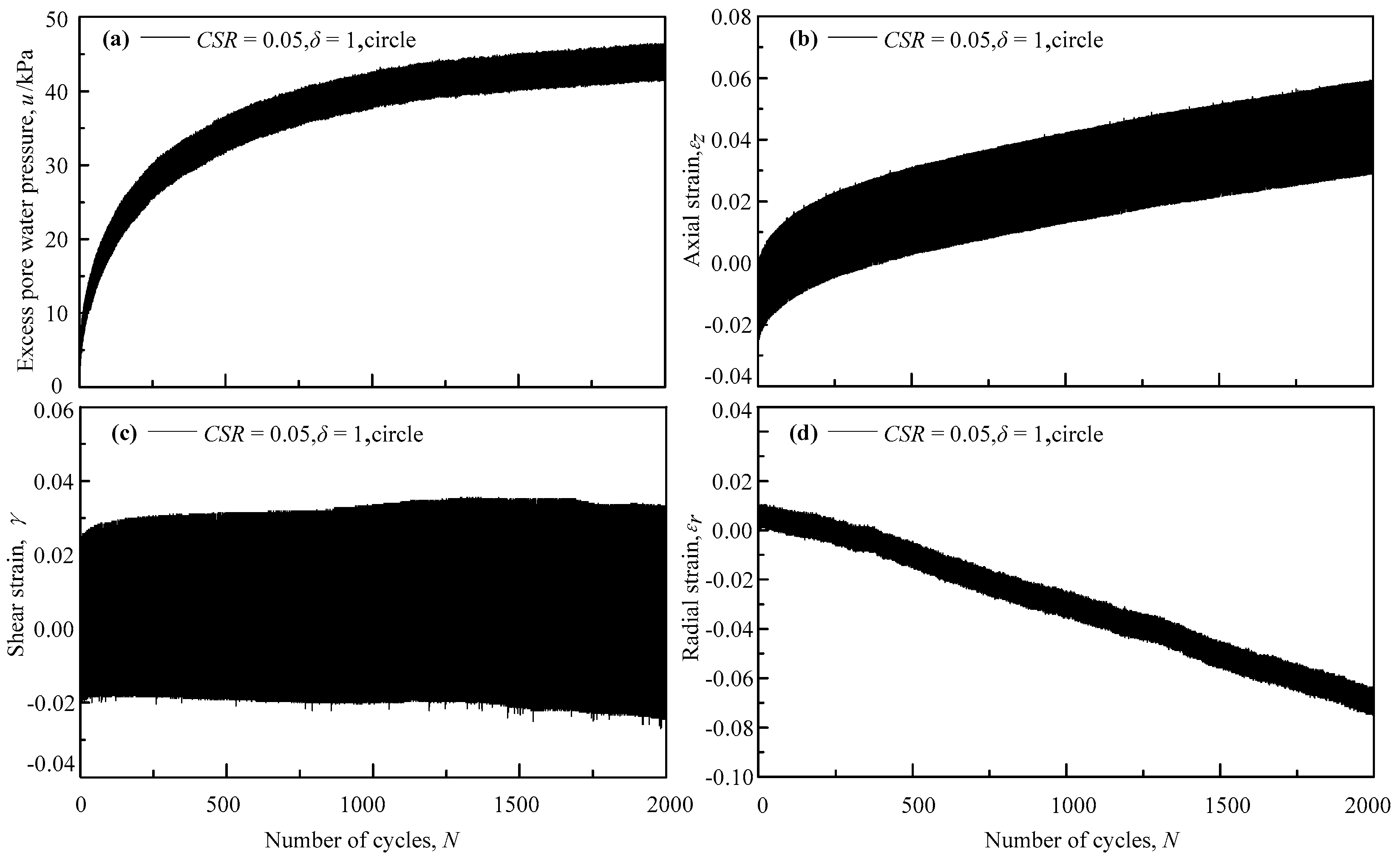

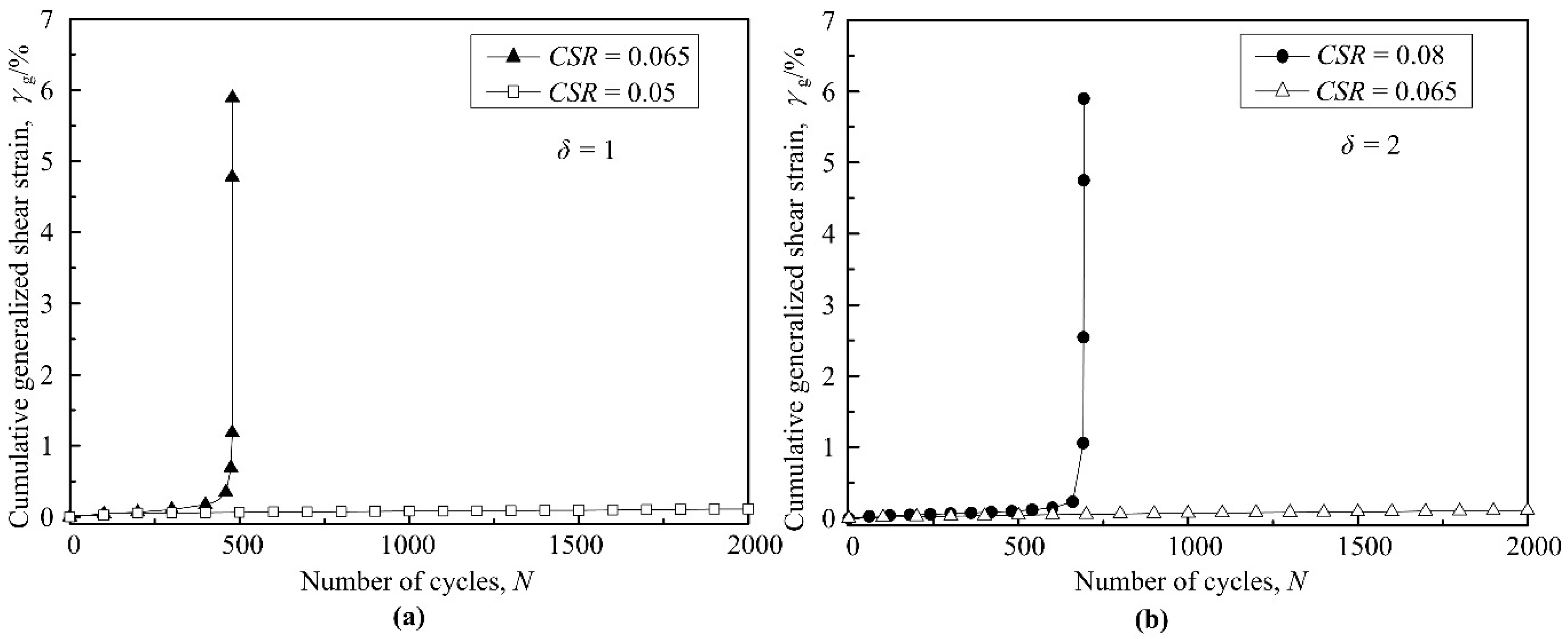

3.1. Typical Test Results of Saturated Silt Sample under Cyclic Axial–Torsional Combined Loading

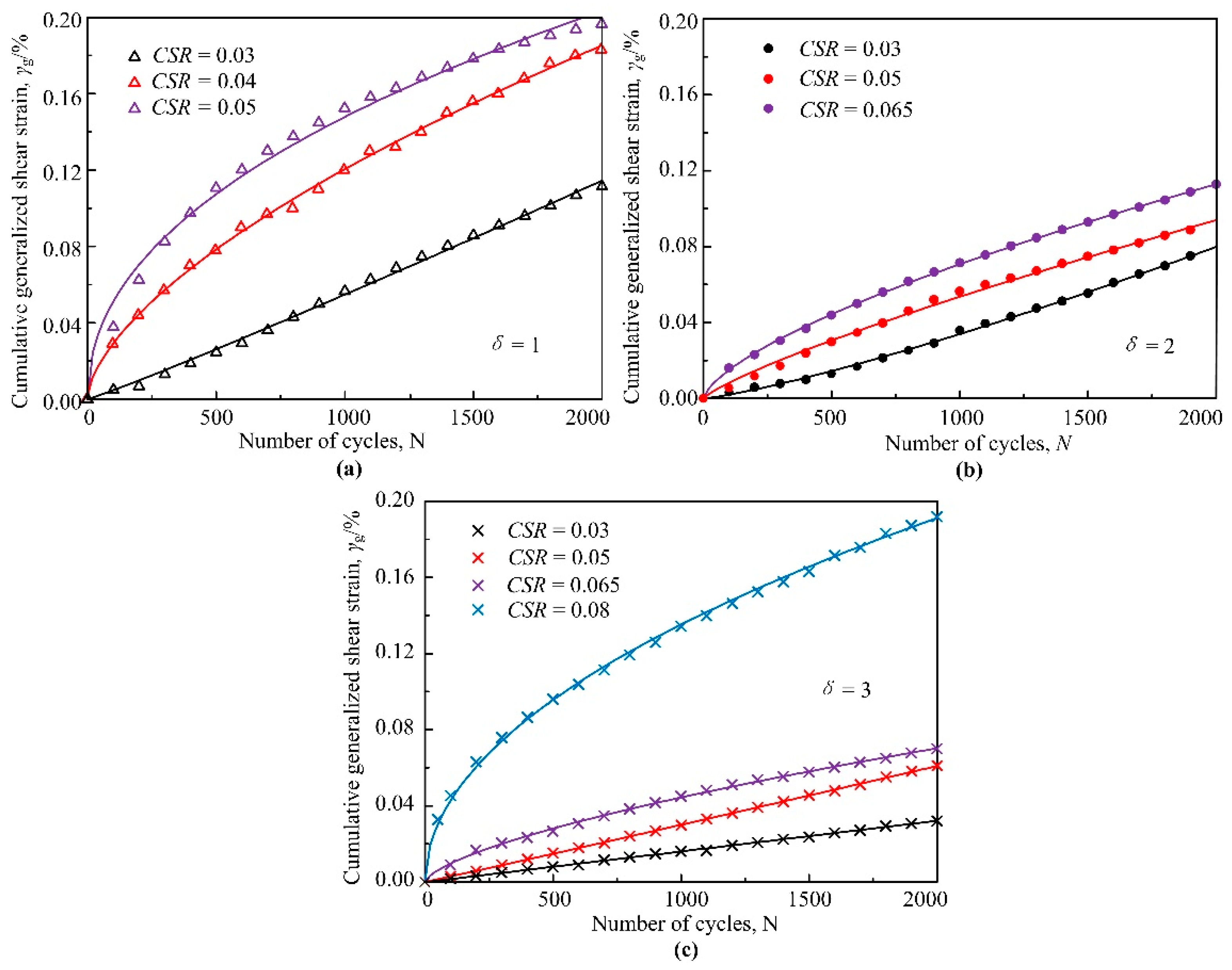

3.2. Effect of CSR on the Development of Cumulative Generalized Shear Strain

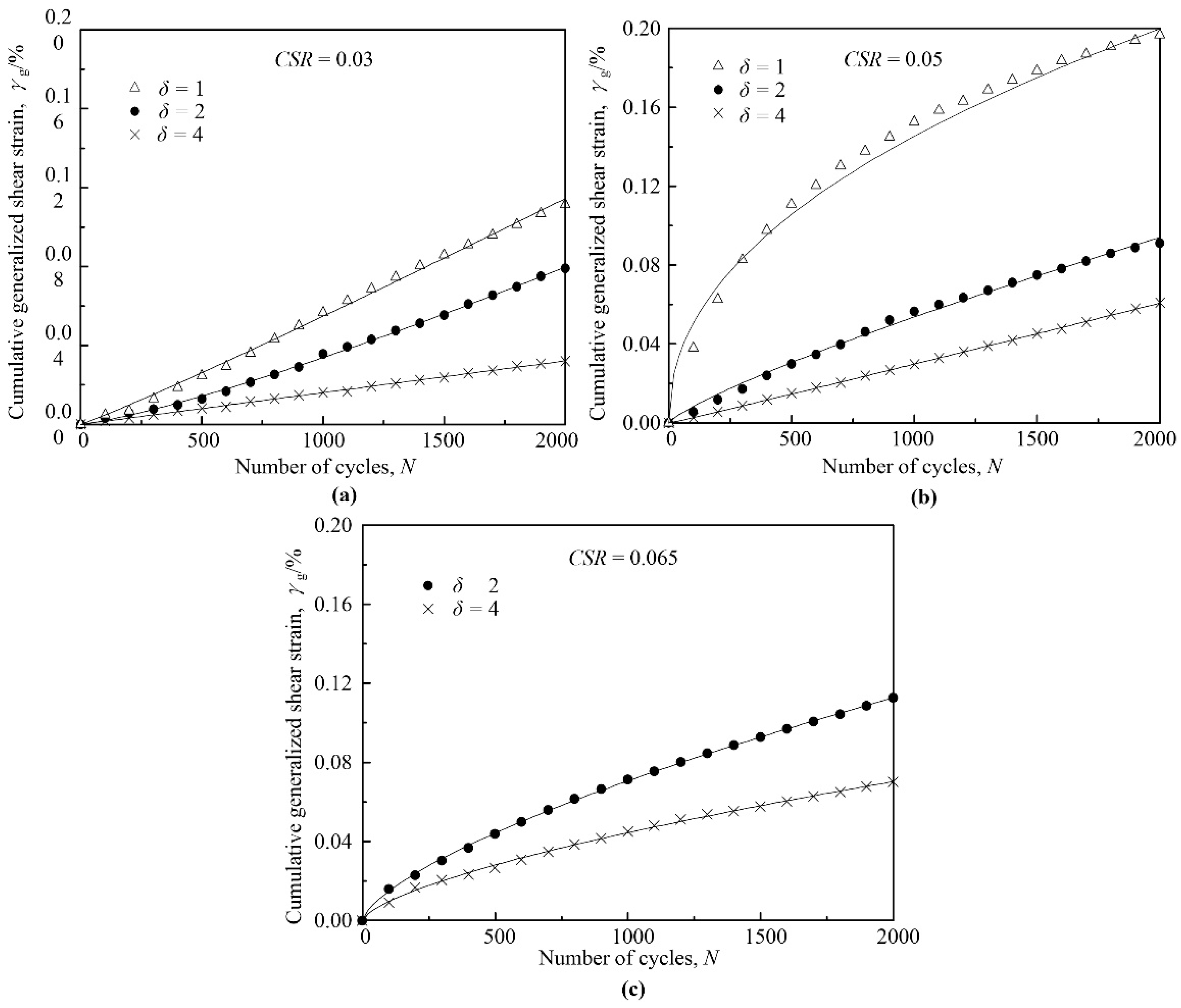

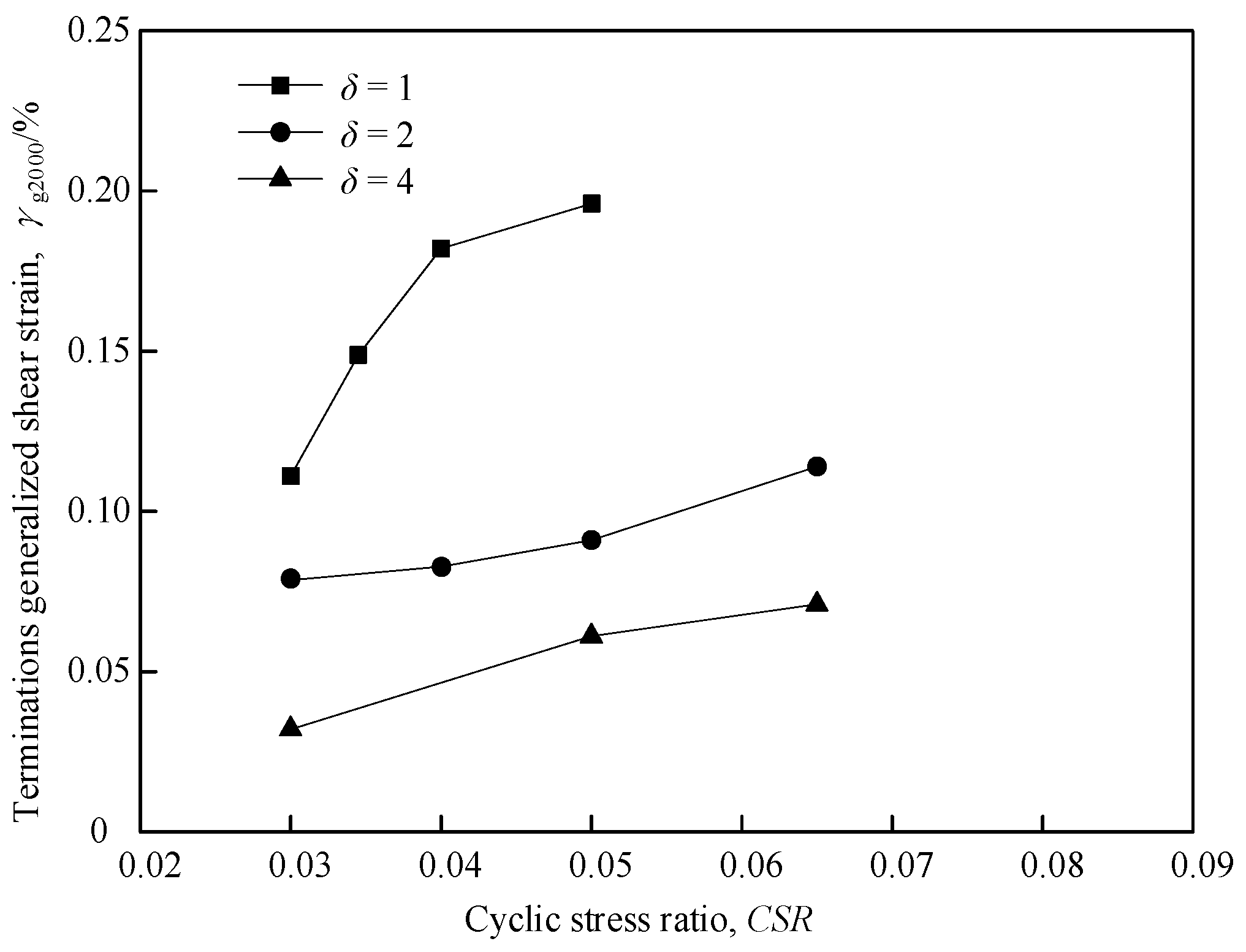

3.3. Effect of δ on the Development of Cumulative Generalized Shear Strain

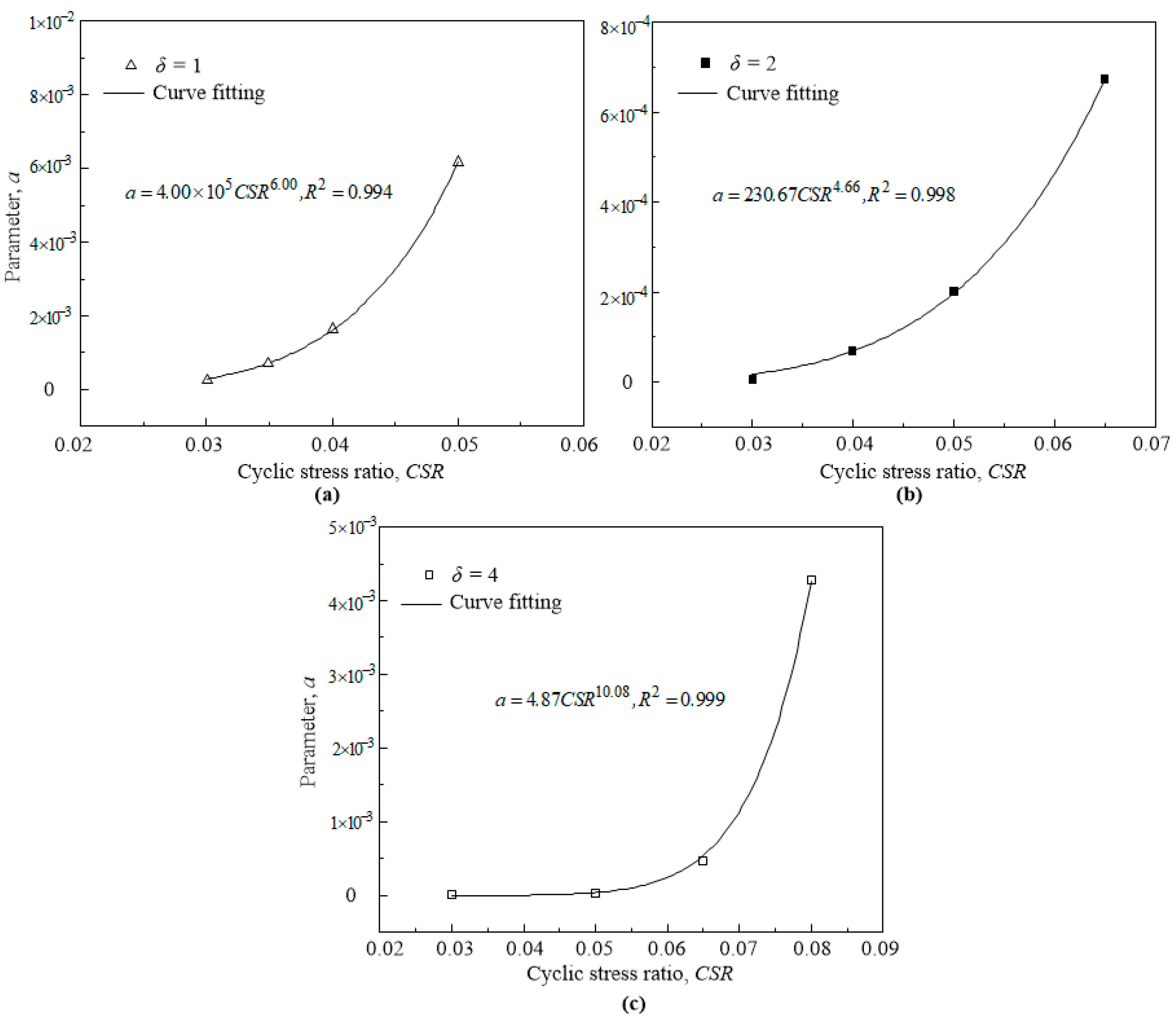

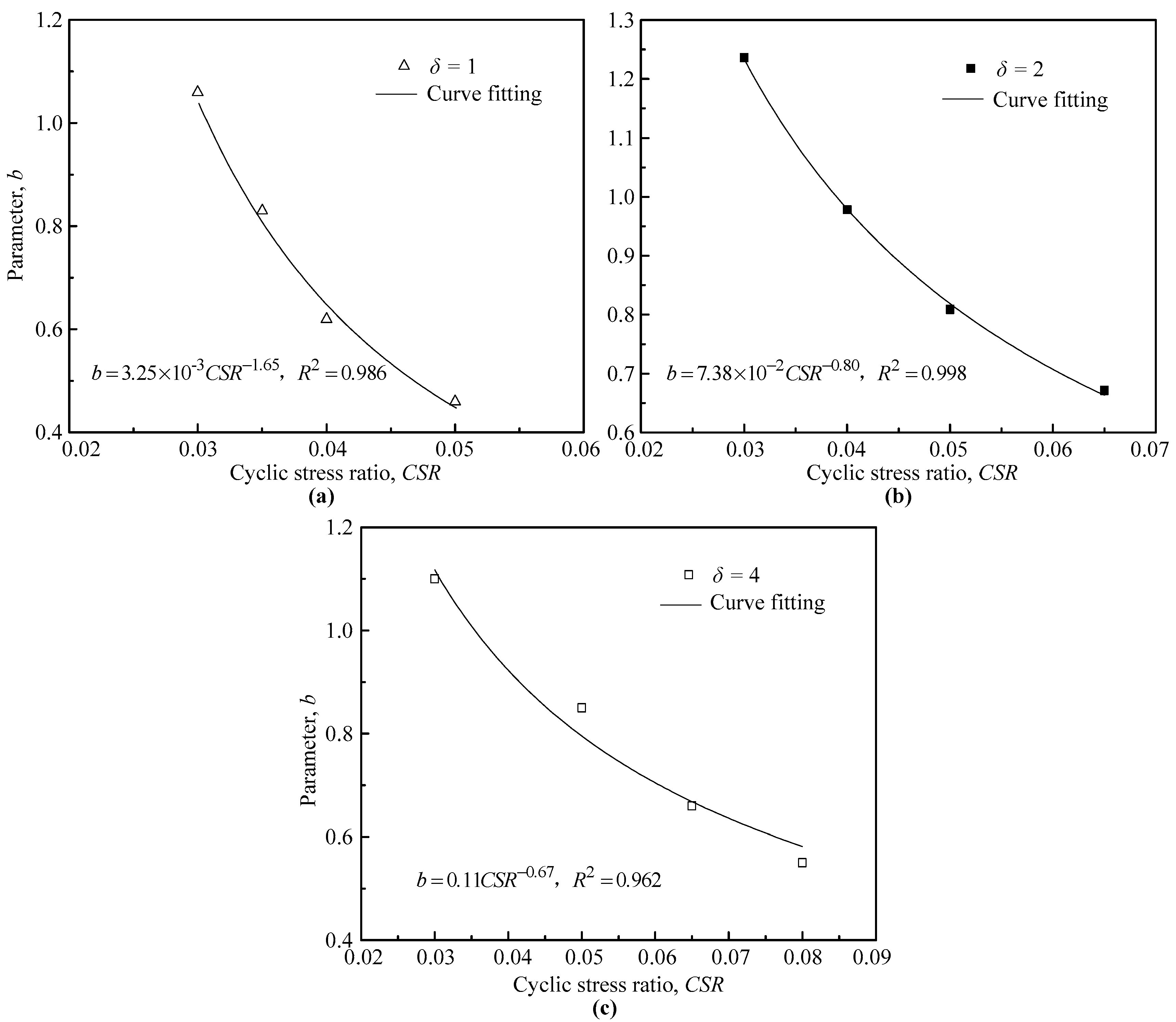

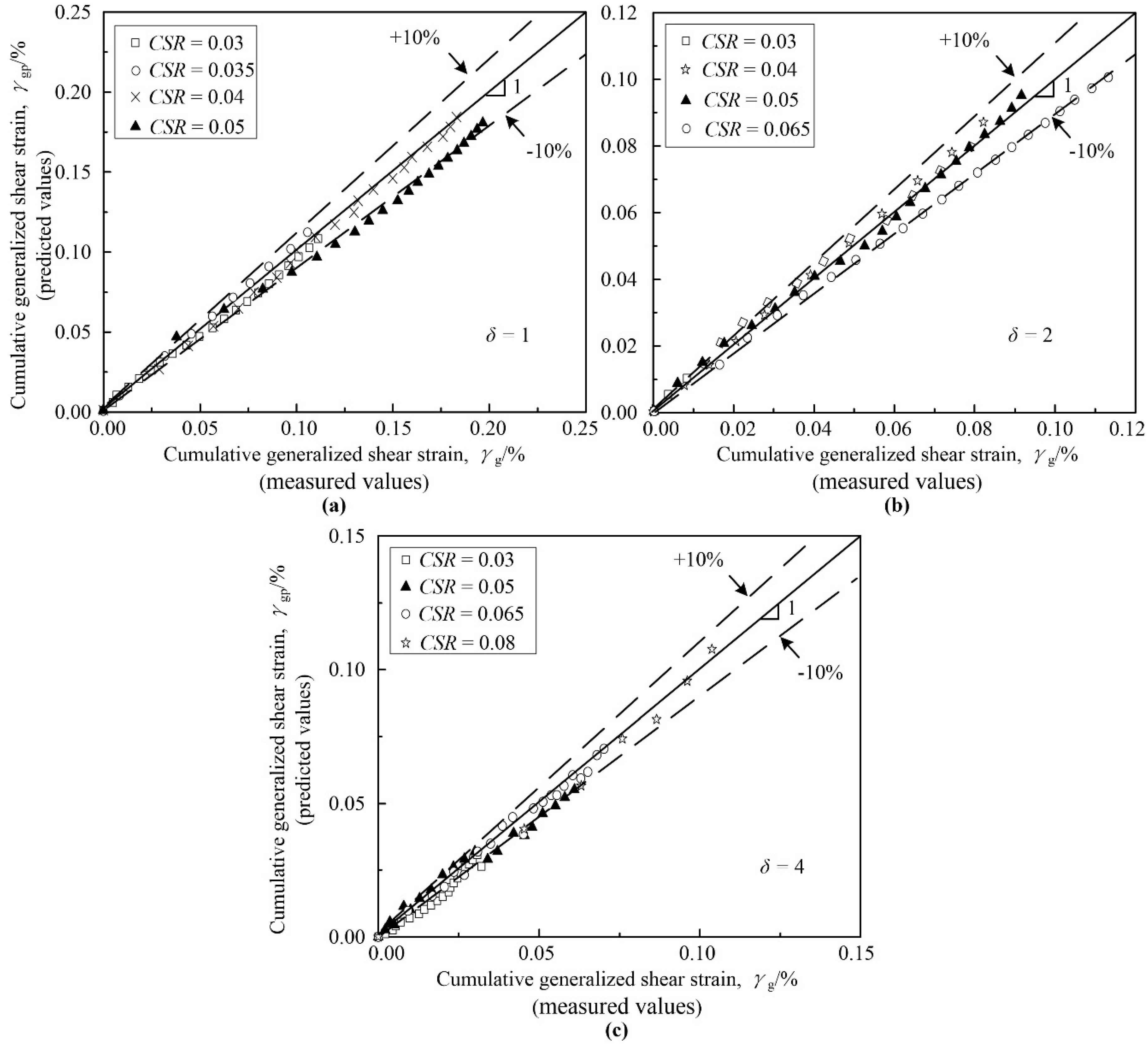

3.4. The Predict Model of Cumulative Generalized Shear Strain

4. Conclusions

- (1)

- When CSR is small, the generalized shear strain of marine silt is small under wave loading. However, with the increase in CSR, the value of generalized shear strain is larger under the same confining pressure.

- (2)

- The influence of the cyclic loading amplitude ratio δ on the generalized shear strain of marine silt is significant. With the increase in δ, the value of generalized shear strain is smaller. When the δ = 1, the generalized shear strain is the most significant.

- (3)

- The modified Monismith model exerts a significant advantage in the evaluation of the generalized shear strain behavior of the non-liquefaction marine silt in geotechnical engineering practice. The variables a and b both present a moderately strong power correlation with CSR. In addition, the proposed prediction method, based on the modified Monismith model, is in good agreement with our measurements, with an error that is generally less than 10%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Groot, M.B.; Bolton, M.D.; Foray, P.; Meijers, P. Physics of liquefaction phenomena around marine structures. J. Waterw. Port Coast. Ocean Eng. 2006, 132, 227–243. [Google Scholar] [CrossRef]

- Suleman, K.F.; Shahid, A. Determination of the desiccation behavior of clay slurries. Int. J. Min. Sci. Technol. 2017, 27, 981–988. [Google Scholar]

- Kjekstad, O.; Lunne, T. Soil parameters used for design of gravity platforms in the North Sea. Appl. Ocean Res. 1981, 3, 50–58. [Google Scholar] [CrossRef]

- Kasper, T.; Steenfelt, J.S.; Pedersen, L.M.; Jackson, P.G. Stability of an immersed tunnel in offshore conditions under deep water wave impact. Coast. Eng. 2008, 55, 753–760. [Google Scholar] [CrossRef]

- Puzrin, A.M.; Alonso, E.E.; Pinyol, N.M. Caisson Failure Induced by Liquefaction: Barcelona Harbour, Spain Geomechanics of Failures; Springer: Dordrecht, The Netherlands, 2010; pp. 85–148. [Google Scholar]

- Del Campo, J.M.; Negro, V. Failures of harbour walls at Malaga and Barcelona. Bull. Eng. Geol. Environ. 2011, 70, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Cui, L.; Sheng, Q.; Ruan, B.; Xu, D.D.; Dong, Y.K. A quantitative analysis of the effect of end plate of fully-grouted bolts on the global stability of tunnel. Tunn. Undergr. Space Technol. 2021, 114, 104010. [Google Scholar] [CrossRef]

- Fredsøe, J. Pipeline–seabed interaction. J. Waterw. Port Coast. Ocean Eng. 2016, 142, 03116002. [Google Scholar] [CrossRef] [Green Version]

- Sassa, S.; Sekiguchi, H. Analysis of wave-induced liquefaction of sand beds. Géotechnique 2001, 51, 115–126. [Google Scholar] [CrossRef]

- Arthur, J.R.F.; Menzies, B.K. Inherent anisotropy in a sand. Geotechniqu 1972, 22, 115–128. [Google Scholar] [CrossRef]

- Ishihara, K.; Towhata, I. Sand response to cyclic rotation of principal stress directions as induced by wave loads. Soils Found. 1983, 23, 11–26. [Google Scholar] [CrossRef] [Green Version]

- Nakata, Y.; Hyodo, M.; Murata, H.; Yasufuku, N. Flow deformation of sands subjected to principal stress rotation. Soils Found. 1998, 38, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Gutierrez, M.; Ishihara, K. Non-coaxiality and energy dissipation in granular materials. Soils Found. 2000, 40, 49–59. [Google Scholar] [CrossRef] [Green Version]

- Zdravković, L.; Jardine, R.J. The effect on anisotropy of rotating the principal stress axes during consolidation. Geotechnique 2001, 51, 69–83. [Google Scholar] [CrossRef]

- Petalas, A.L.; Dafalias, Y.F.; Papadimitriou, A.G. SANISAND-FN: An evolving fabric-based sand model accounting for stress principal axes rotation. Int. J. Numer. Anal. Methods Geomech. 2019, 43, 97–123. [Google Scholar] [CrossRef]

- Triantafyllos, P.K.; Georgiannou, V.N.; Dafalias, Y.F.; Georgopoulos, I.-O. Novel findings on the dilatancy and noncoaxiality of sand under generalised loading. Acta Geotech. 2021, 16, 1699–1734. [Google Scholar] [CrossRef]

- Georgiannou, V.N.; Konstadinou, M.; Triantafyllos, P. Sand behavior under stress states involving principal stress rotation. J. Geotech. Geoenviron. Eng. 2018, 144, 04018028. [Google Scholar] [CrossRef]

- Sze, H.Y.; Yang, J. Failure modes of sand in undrained cyclic loading: Impact of sample preparation. J. Geotech. Geoenviron. Eng. 2014, 140, 152–169. [Google Scholar] [CrossRef] [Green Version]

- Jeng, D.S.; Hsu, J.S.C. Wave-induced soil response in a nearly saturated sea-bed of finite thickness. Geotechnique 1996, 46, 427–440. [Google Scholar] [CrossRef]

- Huang, B.; Chen, X.; Zhao, Y. A new index for evaluating liquefaction resistance of soil under combined cyclic shear stresses. Eng. Geol. 2015, 199, 125–139. [Google Scholar] [CrossRef]

- Liang, F.; Zhang, H.; Chen, S. Effect of vertical load on the lateral response of offshore piles considering scour-hole geometry and stress history in marine clay. Ocean Eng. 2018, 158, 64–77. [Google Scholar] [CrossRef]

- Chen, G.X.; Zhou, Z.L.; Pan, H.; Sun, T.; Li, X.J. The influence of undrained cyclic loading patterns and consolidation states on the deformation features of saturated fine sand over a wide strain range. Eng. Geol. 2016, 204, 77–93. [Google Scholar]

- Zhuang, H.Y.; Wang, R.; Chen, G.X.; Miao, Y.; Zhao, K. Shear modulus reduction of saturated sand under large liquefaction-induced deformation in cyclic torsional shear tests. Eng. Geol. 2018, 240, 110–122. [Google Scholar] [CrossRef]

- Hight, D.W.; Gens, A.; Symes, M.J. The development of a new hollow cylinder apparatus for investigating the effects of principal stress rotation in soils. Geotechnique 1983, 33, 355–383. [Google Scholar] [CrossRef]

- Chen, G.; Wu, Q.; Zhou, Z.; Ma, W.; Chen, W.; Khoshnevisan, S.; Yang, J. Undrained anisotropy and cyclic resistance of saturated silt subjected to various patterns of principal stress rotation. Géotechnique 2020, 70, 317–331. [Google Scholar] [CrossRef]

- Skempton, A.W. The pore-pressure coefficients A and B. Geotechnique 1954, 4, 143–147. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, P.; Jeng, D.; Yang, Q. Cyclic strength of sand under a nonstandard elliptical rotation stress path induced by wave loading. J. Hydrodyn. 2017, 29, 89–95. [Google Scholar] [CrossRef]

- O’Reilly Mike, P.; Stephen, F.B. (Eds.) Cyclic Loading of Soils: From Theory to Design; Blackie: Glasgow, UK, 1991. [Google Scholar]

- Xia, K.; Wang, J. Shear principal, and equivalent strains in equal-channel angular deformation. Metall. Mater. Trans. A 2002, 33, 467. [Google Scholar] [CrossRef]

- Monismith, C.L.; Ogawa, N.; Freeme, C.R. Permanent deformation characteristics of subgrade soils due to repeated loading. Transp. Res. Rec. 1975, 537, 1–17. [Google Scholar]

- Seed, H.B.; Lee, K.L. Liquefaction of saturated sands during cyclic loading. J. Soil Mech. Found. Div. 1966, 92, 105–134. [Google Scholar] [CrossRef]

- EIMohtar, C.S. Evaluation of the 5% double amplitude strain criterion. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering, Alexandria, Egypt, 5–9 October 2009; IOS Press: Amsterdam, The Netherlands, 2009; pp. 80–83. [Google Scholar]

| Physical Parameters | Symbol | Value |

|---|---|---|

| Specific gravity | Gs | 2.70 |

| Plastic Index | PI | 3 |

| Maximum void ratio | emax | 1.22 |

| Minimum void ratio | emin | 0.65 |

| Case No. | σmax (kPa) | τmax (kPa) | Δ | CSR | Stress Path | Case No. | σmax (kPa) | τmax (kPa) | δ | CSR | Stress Path |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 3 | 3 | 1 | 0.03 | Circle | S9 | 5 | 2.5 | 2 | 0.05 | Oval |

| S2 | 3.5 | 3.5 | 1 | 0.035 | Circle | S10 | 6.5 | 3.25 | 2 | 0.065 | Oval |

| S3 | 4 | 4 | 1 | 0.04 | Circle | S11 | 8 | 4 | 2 | 0.08 | Oval |

| S4 | 5 | 5 | 1 | 0.05 | Circle | S12 | 3 | 0.75 | 4 | 0.03 | Oval |

| S5 | 6.5 | 6.5 | 1 | 0.065 | Circle | S13 | 5 | 1.25 | 4 | 0.05 | Oval |

| S6 | 8 | 8 | 1 | 0.08 | Circle | S14 | 6.5 | 1.625 | 4 | 0.065 | Oval |

| S7 | 3 | 1.5 | 2 | 0.03 | Oval | S15 | 8 | 2 | 4 | 0.08 | Oval |

| S8 | 4 | 2 | 2 | 0.04 | Oval |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, L.; Sheng, Q.; Niu, Z.; Chang, L. Deformation Behavior of Saturated Marine Silt under Principal Stress Rotation as Induced by Wave Loading. Appl. Sci. 2021, 11, 9458. https://doi.org/10.3390/app11209458

Cui L, Sheng Q, Niu Z, Chang L. Deformation Behavior of Saturated Marine Silt under Principal Stress Rotation as Induced by Wave Loading. Applied Sciences. 2021; 11(20):9458. https://doi.org/10.3390/app11209458

Chicago/Turabian StyleCui, Lan, Qian Sheng, Zhenzhen Niu, and Liuming Chang. 2021. "Deformation Behavior of Saturated Marine Silt under Principal Stress Rotation as Induced by Wave Loading" Applied Sciences 11, no. 20: 9458. https://doi.org/10.3390/app11209458