Development of Add-On Planar Translational Driving System for Aerial Manipulation with Multirotor Platform

Abstract

:1. Introduction

2. Concept of ATD

- (1)

- The ATD allows the multi-rotor aircraft to move horizontally while keeping its attitude horizontal. This leads to easier and fine position control, and the positioning accuracy can be improved.

- (2)

- When applying a force to an object sideways in aerial work, the attitude of the aircraft is horizontal, so the force can be applied continuously and stably. Moreover, the addition of ATD increases the force that can be generated compared to the case of a normal multirotor aircraft alone.

- (3)

- The vertical thrust is generated by the multirotor aircraft, and the horizontal thrust is generated by ATD. Since these can be controlled independently, the structure makes it easy to generate horizontal force at any given height of the multi-rotor aircraft.

- (4)

- While moving horizontally using ATD, the driving force of the multi-rotor aircraft can be devoted to keeping the altitude and attitude of the aircraft constant. Therefore, it may become robust due to disturbances such as wind.

- (5)

- The proposed ATD is add-on type and can be retrofitted to a multirotor, which means it can work with any of typical multirotors, from hobby to industrial ones.

3. Design and Implementation of the ATD

3.1. Mechanical Structure

3.2. Components of the System

- Position control mode allows the multirotor to translate automatically by keeping body frame horizontal. In the UAV controller, control inputs of roll and pitch angle are set to 0, yaw angle rate is controlled automatically, throttle is controlled manually, and break-like motion is disabled. In the ATD controller, the ducted fans are controlled automatically.

- Manual ATD control mode allows the operator to control the multirotor manually and translate it with fixed attitude of the airframe. In the UAV controller, the control inputs are set the same as in position control mode. The ATD controller is designed based on CH1∼2 input values on the RC for operating the multirotor translating in horizontal, and a brake-like motion is designed for stopping the multirotor immediately after the operation.

- Manual UAV control mode allows the operator to control the multirotor manually which is same as typical operation. The UAV’s roll and pitch angle, yaw rate, and throttle are set based on RC input of CH1∼4 and brake-like motion is enabled. The ducted fans in the ATD controller are disabled.

3.3. Control

4. Force Measurement of ATD

5. Comparison of the Performance between ATD with Multirotor Control

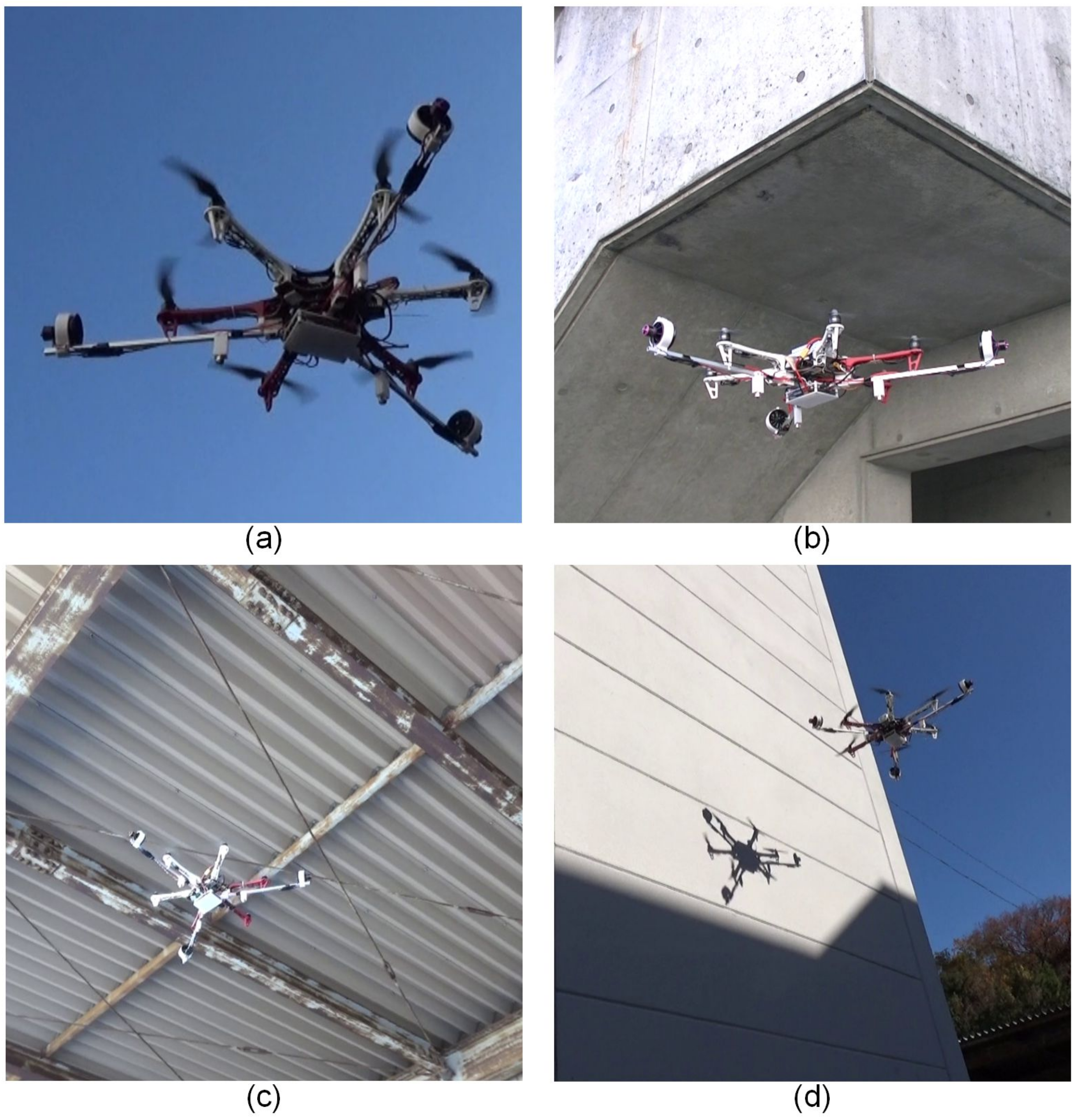

6. Experiments

6.1. Position Control

6.2. Experiment of Translational Movement in Different Directions

6.3. Experiment of Push and Pull Operation

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Lippitt, C.D.; Zhang, S. The impact of small unmanned airborne platforms on passive optical remote sensing: A conceptual perspective. Int. J. Remote Sens. 2018, 39, 4852–4868. [Google Scholar] [CrossRef]

- Ruggiero, F.; Lippiello, V.; Ollero, A. Aerial Manipulation: A Literature Review. IEEE Robot. Autom. Lett. 2018, 3, 1957–1964. [Google Scholar] [CrossRef] [Green Version]

- Ding, X.; Guo, P.; Xu, K.; Yu, Y. A review of aerial manipulation of small-scale rotorcraft unmanned robotic systems. Chin. J. Aeronaut. 2019, 32, 200–214. [Google Scholar] [CrossRef]

- Mendoza-Mendoza, J.; Gonzalez-Villela, V.J.; Aguilar-Ibanez, C.; Suarez-Castanon, M.; Fonseca-Ruiz, L. Snake Aerial Manipulators: A Review. IEEE Access 2020, 8, 28222–28241. [Google Scholar] [CrossRef]

- Suarez, A.; Real, F.; Vega, V.M.; Heredia, G.; Rodriguez-Castaño, A.; Ollero, A. Compliant Bimanual Aerial Manipulation: Standard and Long Reach Configurations. IEEE Access 2020, 8, 88844–88865. [Google Scholar] [CrossRef]

- Fumagalli, M.; Naldi, R.; Macchelli, A.; Carloni, R.; Stramigioli, S.; Marconi, L. Modeling and Control of a Flying Robot for Contact Inspection. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vilamoura, Portugal, 7–12 October 2012; pp. 3532–3537. [Google Scholar]

- Thomas, J.; Loianno, G.; Daniilidis, K.; Kumar, V. Visual Servoing of Quadrotors for Perching by Hanging From Cylindrical Objects. IEEE Robot. Autom. Lett. 2016, 1, 57–64. [Google Scholar] [CrossRef] [Green Version]

- Paul, H.; Ono, K.; Ladig, R.; Shimonomura, K. A Multirotor Platform Employing a Three-Axis Vertical Articulated Robotic Arm for Aerial Manipulation Tasks. In Proceedings of the 2018 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM 2018), Auckland, New Zealand, 9–12 July 2018; pp. 478–485. [Google Scholar]

- Shimahara, S.; Suphachart, L.; Ladig, R.; Shimonomura, K. Aerial torsional manipulation employing multirotor flying robot. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 1596–1600. [Google Scholar]

- Ikeda, T.; Yasui, S.; Minamiyama, S.; Ohara, K.; Ashizawa, S.; Ichikawa, A.; Okino, A.; Oomichi, T.; Fukuda, T. Stable impact and contact force control by UAV for inspection of floor slab of bridge. Adv. Robot. 2018, 32, 1061–1076. [Google Scholar] [CrossRef]

- Tognon, M.; Franchi, A. Omnidirectional Aerial Vehicles With Unidirectional Thrusters: Theory, Optimal Design, and Control. IEEE Robot. Autom. Lett. 2018, 3, 2277–2282. [Google Scholar] [CrossRef] [Green Version]

- Park, S.; Lee, J.; Ahn, J.; Kim, M.; Her, J.; Yang, G.; Lee, D. ODAR: Aerial Manipulation Platform Enabling Omnidirectional Wrench Generation. IEEE/ASME Trans. Mechatron. 2018, 23, 1907–1918. [Google Scholar] [CrossRef]

- Oosedo, A.; Abiko, S.; Narasaki, S.; Kuno, A.; Konno, A.; Uchiyama, M. Large attitude change flight of a quad tilt rotor unmanned aerial vehicle. Adv. Robot. 2016, 30, 326–337. [Google Scholar] [CrossRef]

- Allenspach, M.; Bodie, K.; Brunner, M.; Rinsoz, L.; Taylor, Z.; Kamel, M.; Siegwart, R.; Nieto, J. Design and optimal control of a tiltrotor micro-aerial vehicle for efficient omnidirectional flight. Int. J. Robot. Res. (IJRR) 2020, 39, 1305–1325. [Google Scholar] [CrossRef]

- Zhao, M.; Anzai, T.; Shi, F.; Chen, X.; Okada, K.; Inaba, M. Design, Modeling, and Control of an Aerial Robot DRAGON: A Dual-Rotor-Embedded Multilink Robot With the Ability of Multi-Degree-of-Freedom Aerial Transformation. IEEE Robot. Autom. Lett. 2018, 3, 1176–1183. [Google Scholar] [CrossRef]

- Zhao, M.; Shi, F.; Anzai, T.; Okada, K.; Inaba, M. Online Motion Planning for Deforming Maneuvering and Manipulation by Multilinked Aerial Robot Based on Differential Kinematics. IEEE Robot. Autom. Lett. 2020, 5, 1602–1609. [Google Scholar] [CrossRef]

- Park, S.; Lee, Y.; Heo, J.; Lee, D. Pose and Posture Estimation of Aerial Skeleton Systems for Outdoor Flying. In Proceedings of the International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 704–710. [Google Scholar]

| Gross weight | 0.69 kg without battery |

| Size | 0.7 m (W) × 0.6 m (D) × 0.12 m (H) |

| Number of ducted fan | 3 |

| Ducted fan size/motor | 50 mm/4300 KV |

| Max thrust | 950 g for each ducted fan |

| L | 0.4 m |

| L is adjustable depending on multirotor size. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miyazaki, R.; Paul, H.; Shimonomura, K. Development of Add-On Planar Translational Driving System for Aerial Manipulation with Multirotor Platform. Appl. Sci. 2021, 11, 1462. https://doi.org/10.3390/app11041462

Miyazaki R, Paul H, Shimonomura K. Development of Add-On Planar Translational Driving System for Aerial Manipulation with Multirotor Platform. Applied Sciences. 2021; 11(4):1462. https://doi.org/10.3390/app11041462

Chicago/Turabian StyleMiyazaki, Ryo, Hannibal Paul, and Kazuhiro Shimonomura. 2021. "Development of Add-On Planar Translational Driving System for Aerial Manipulation with Multirotor Platform" Applied Sciences 11, no. 4: 1462. https://doi.org/10.3390/app11041462

APA StyleMiyazaki, R., Paul, H., & Shimonomura, K. (2021). Development of Add-On Planar Translational Driving System for Aerial Manipulation with Multirotor Platform. Applied Sciences, 11(4), 1462. https://doi.org/10.3390/app11041462