Numerical Study of Geotextile-Reinforced Flexible Pavement Overlying Low-Strength Subgrade

Abstract

:1. Introduction

2. Materials and Methods

2.1. Pavement Materials

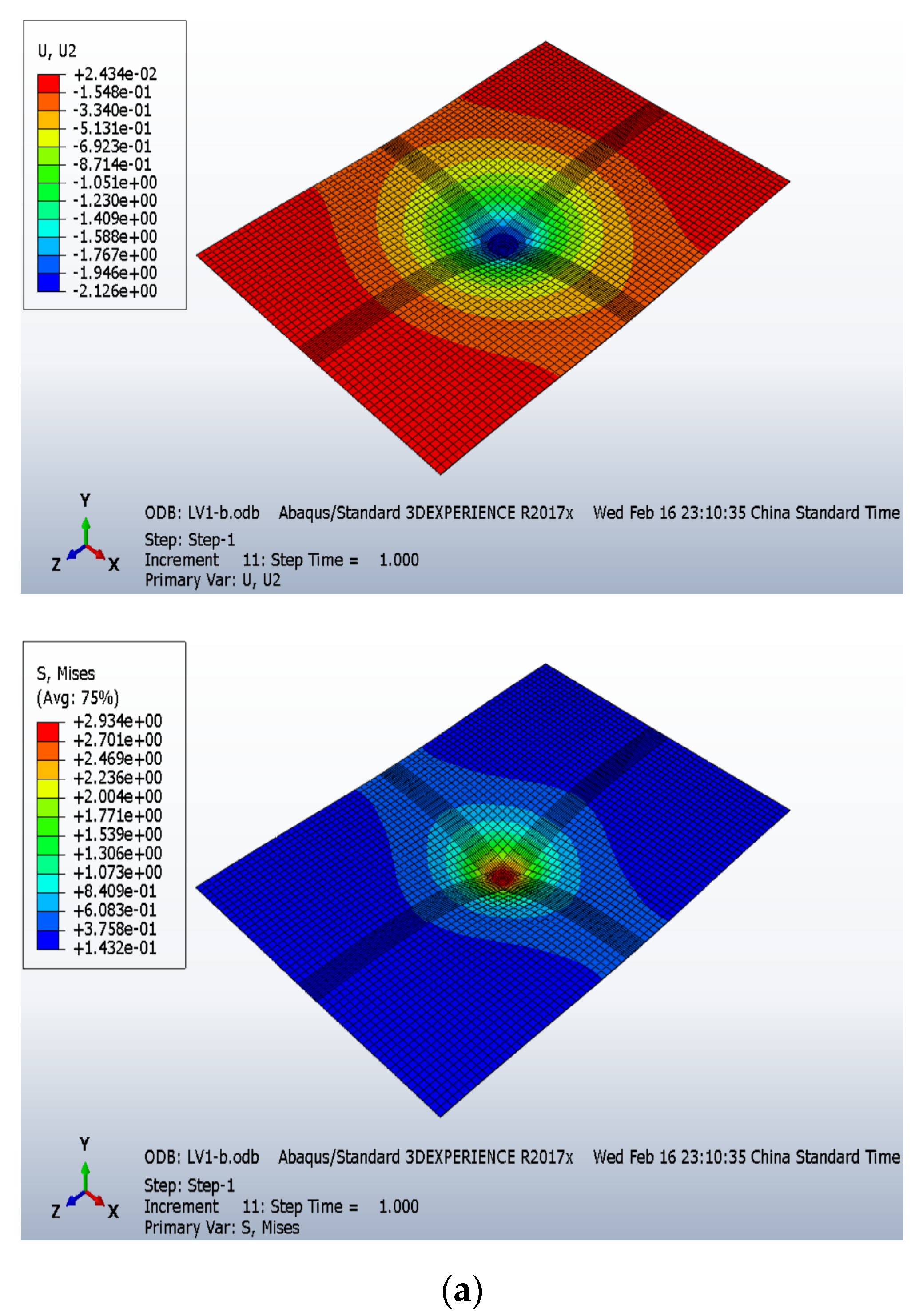

2.2. Finite Element Modeling

2.3. Validation

3. Results and Discussion

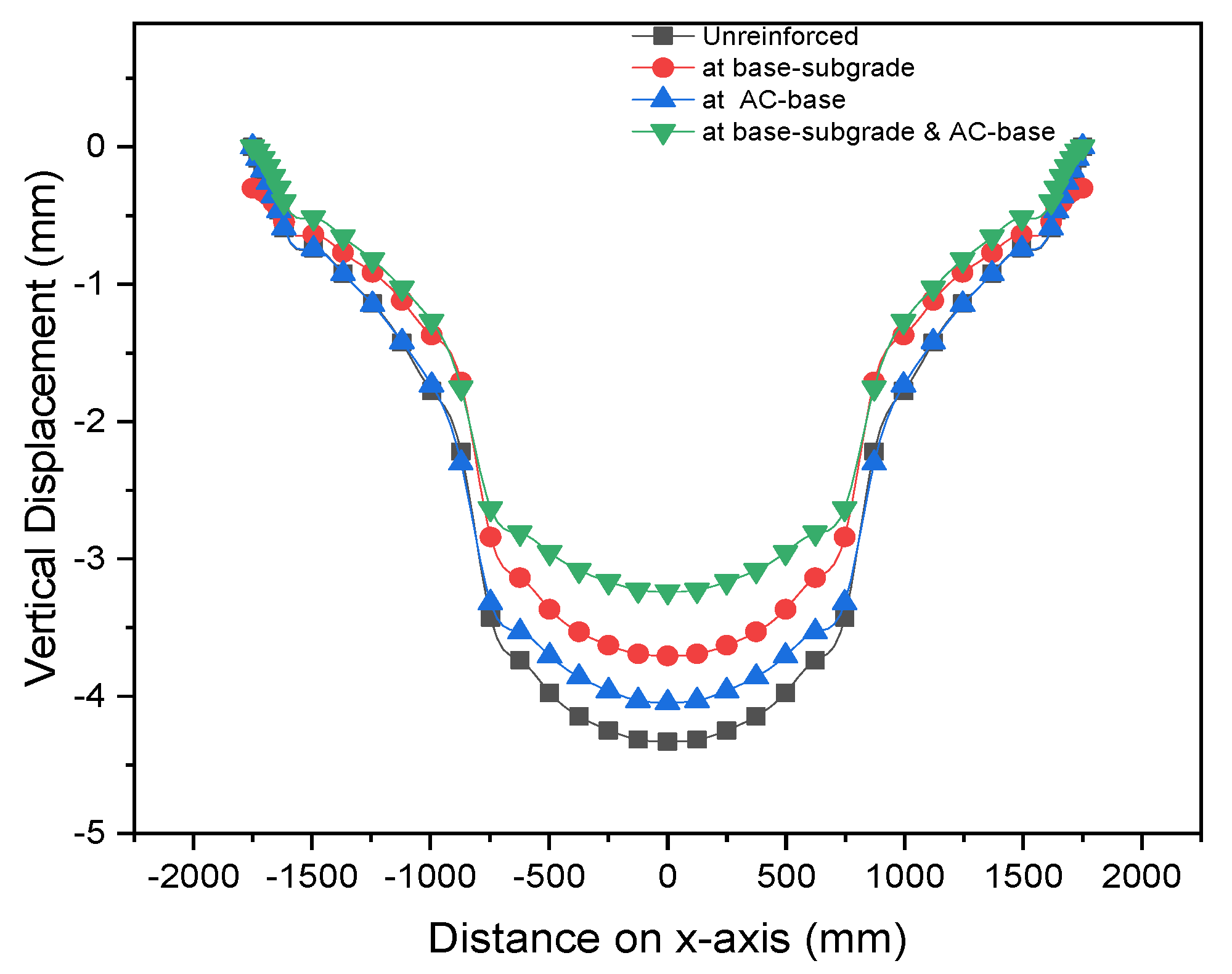

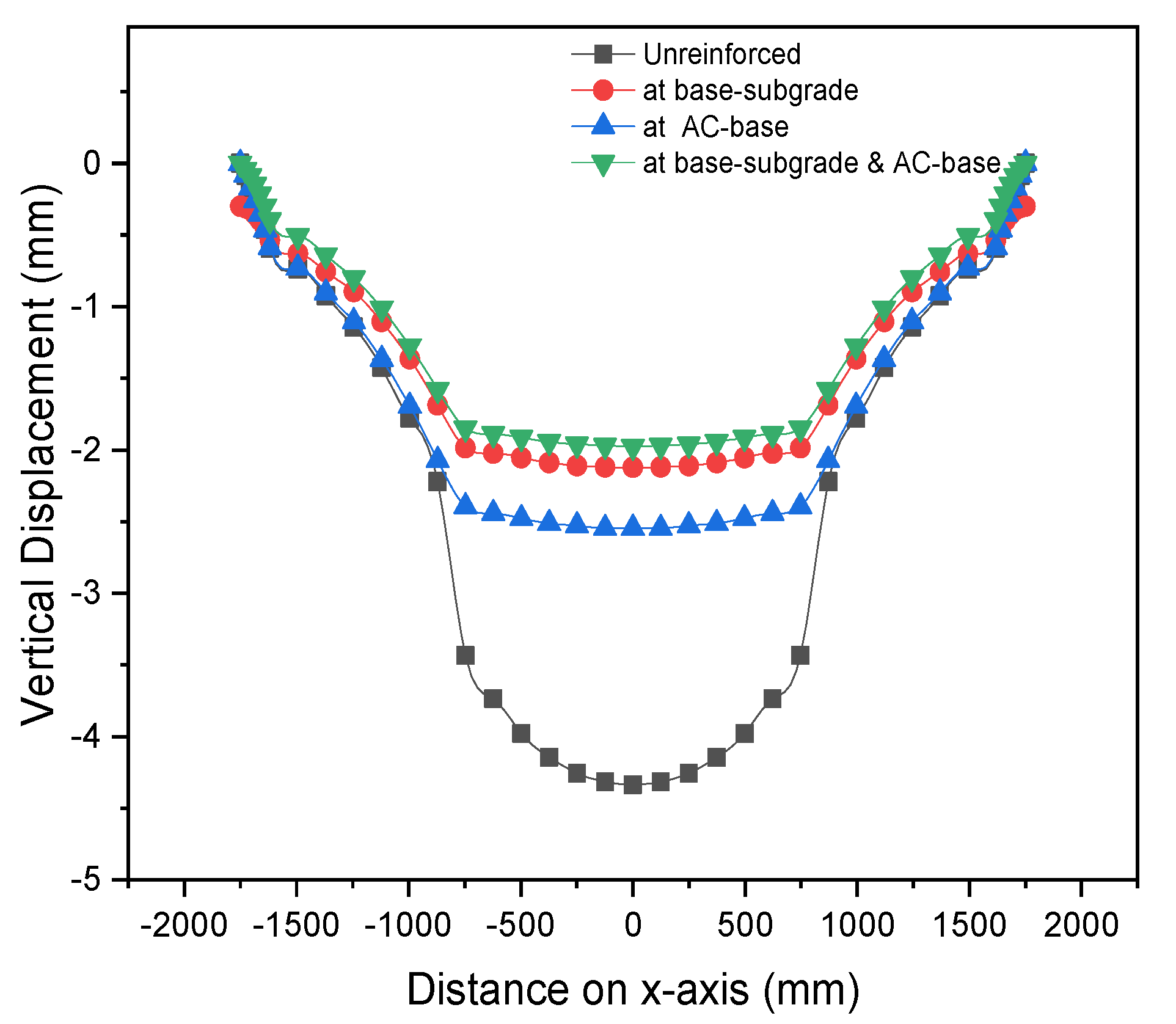

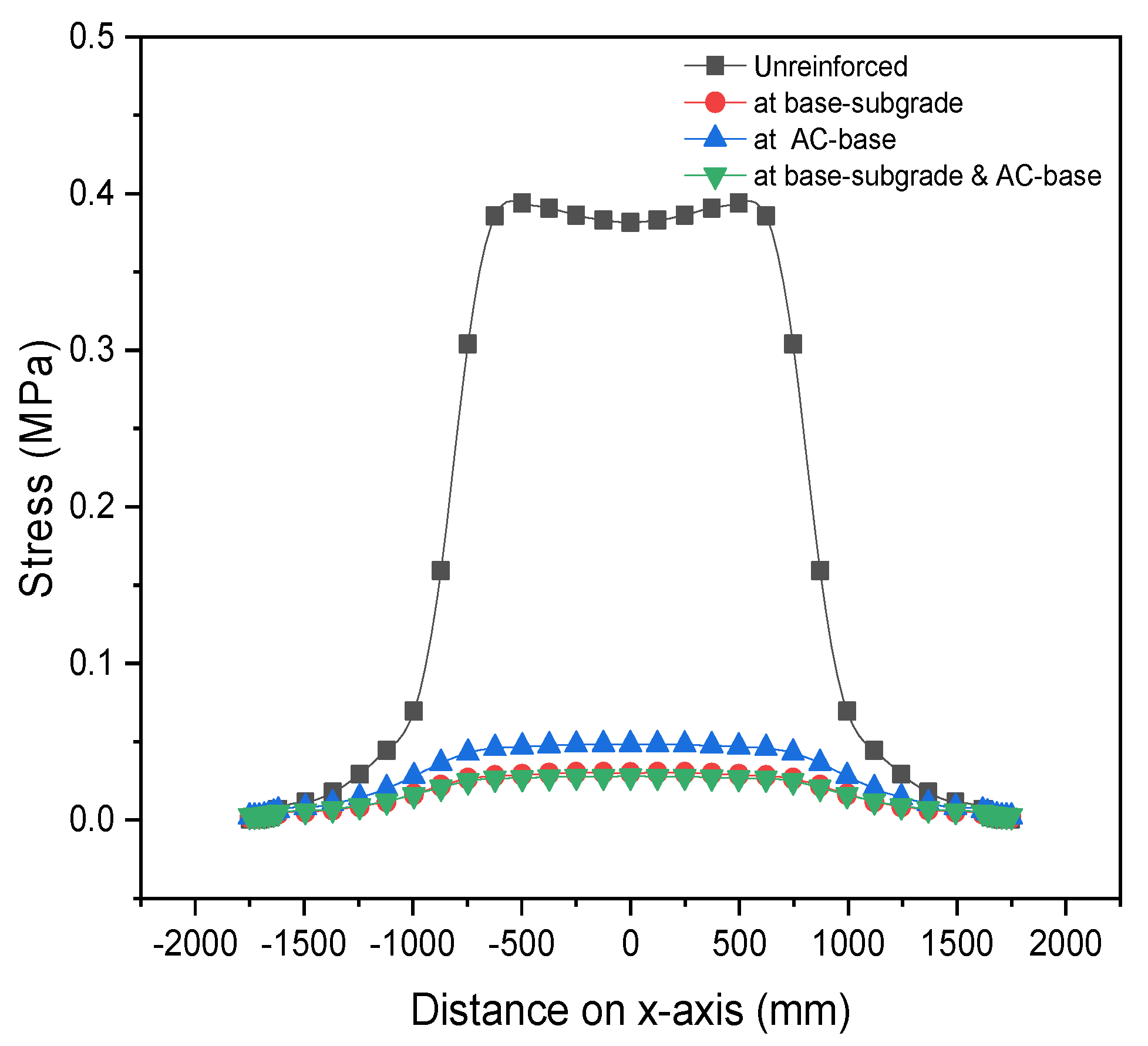

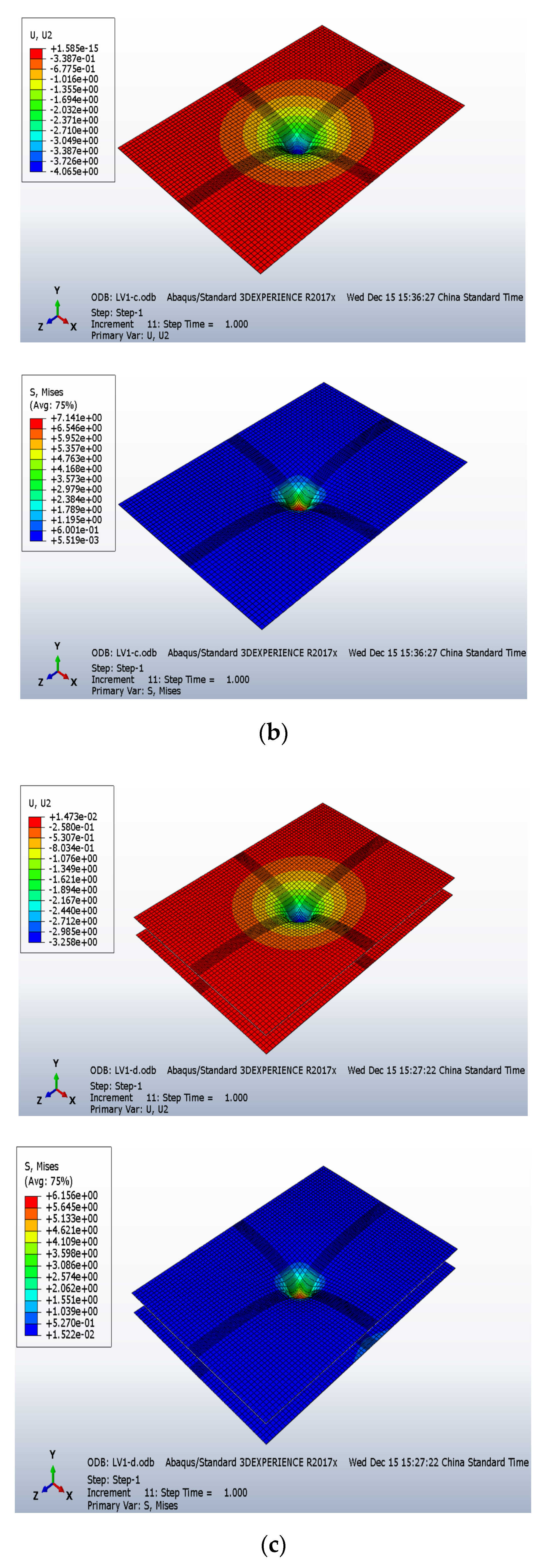

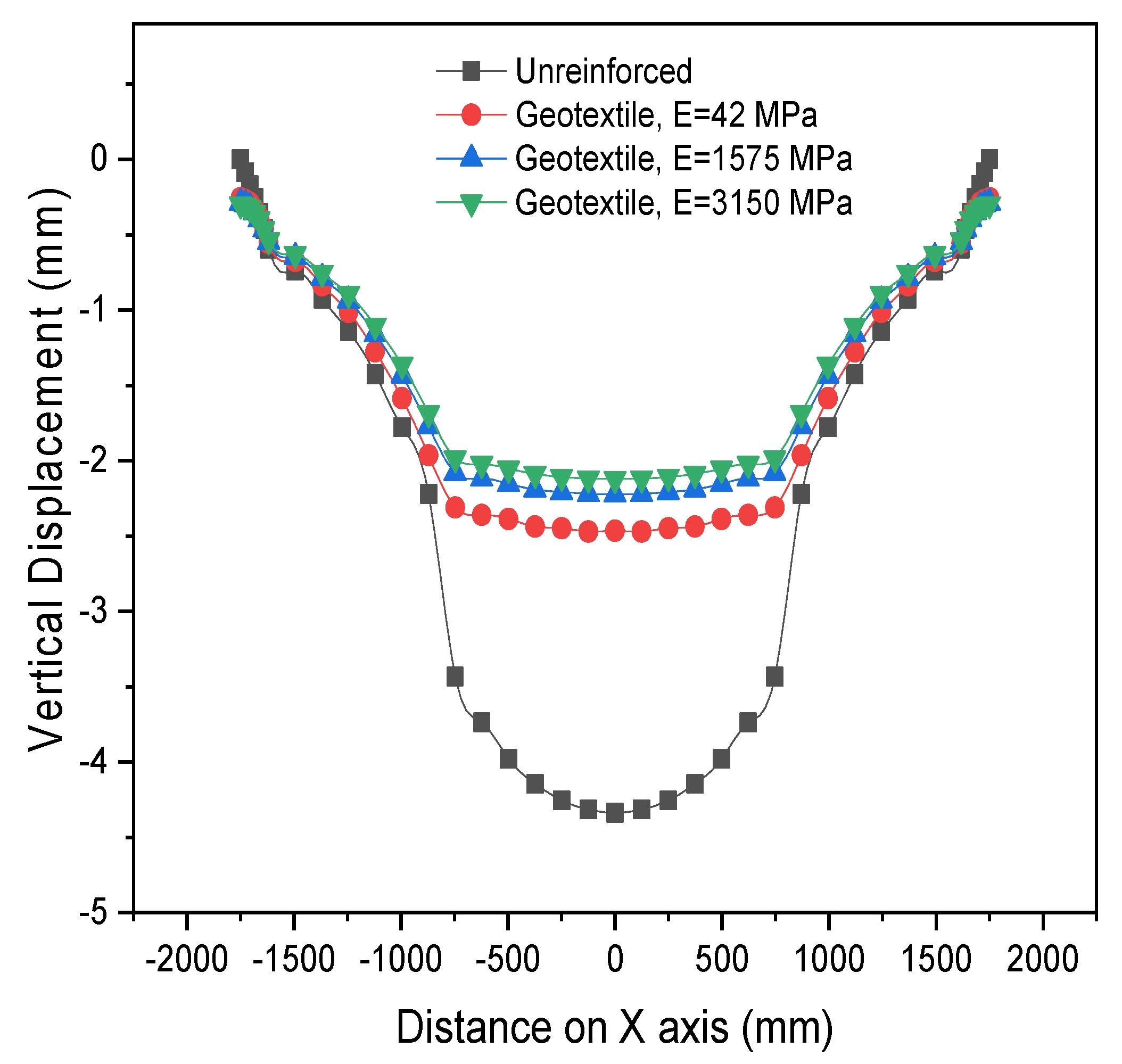

3.1. Pavement Response

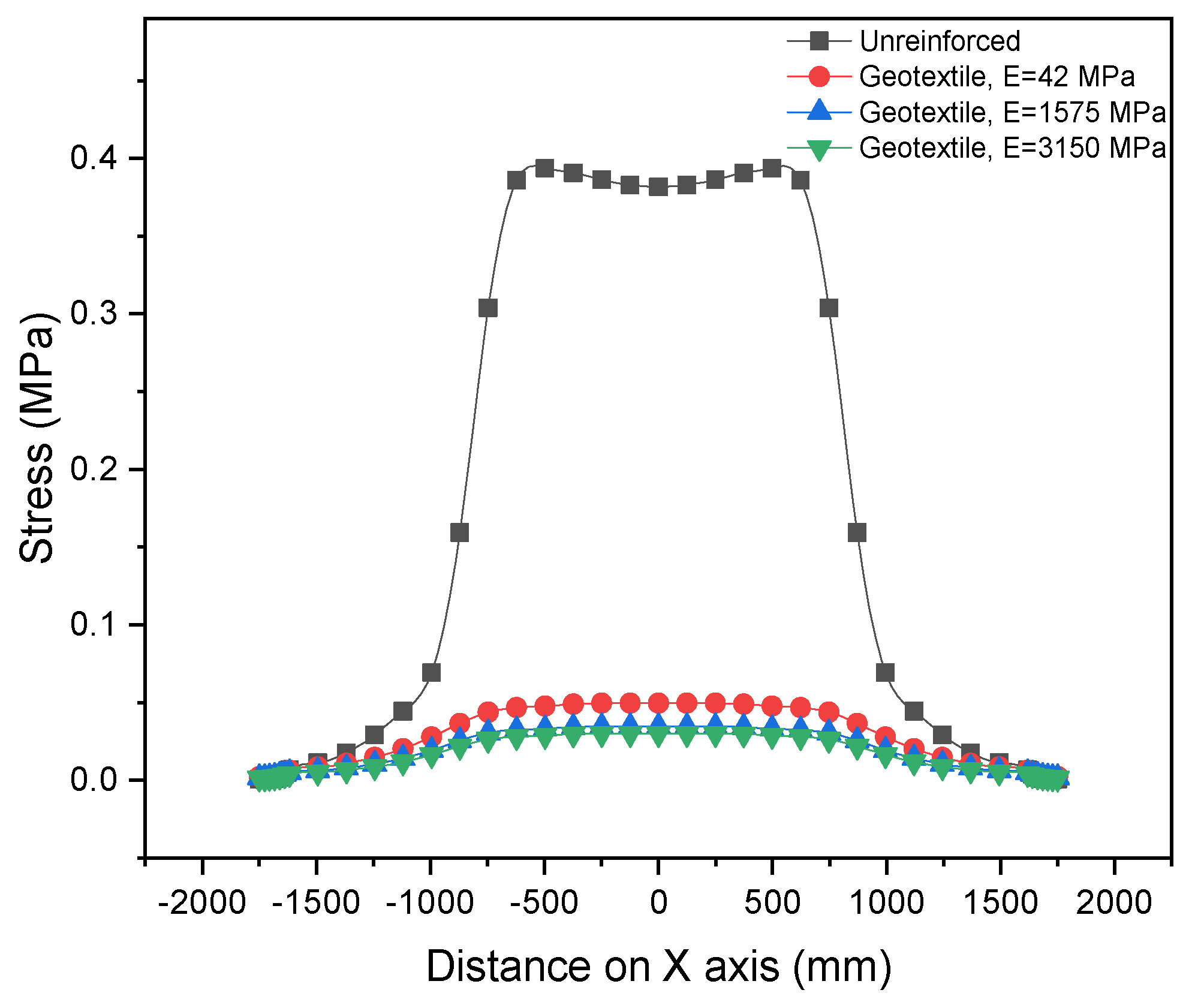

3.2. Effect of the Geotextile’s Elastic Modulus on Pavement Response

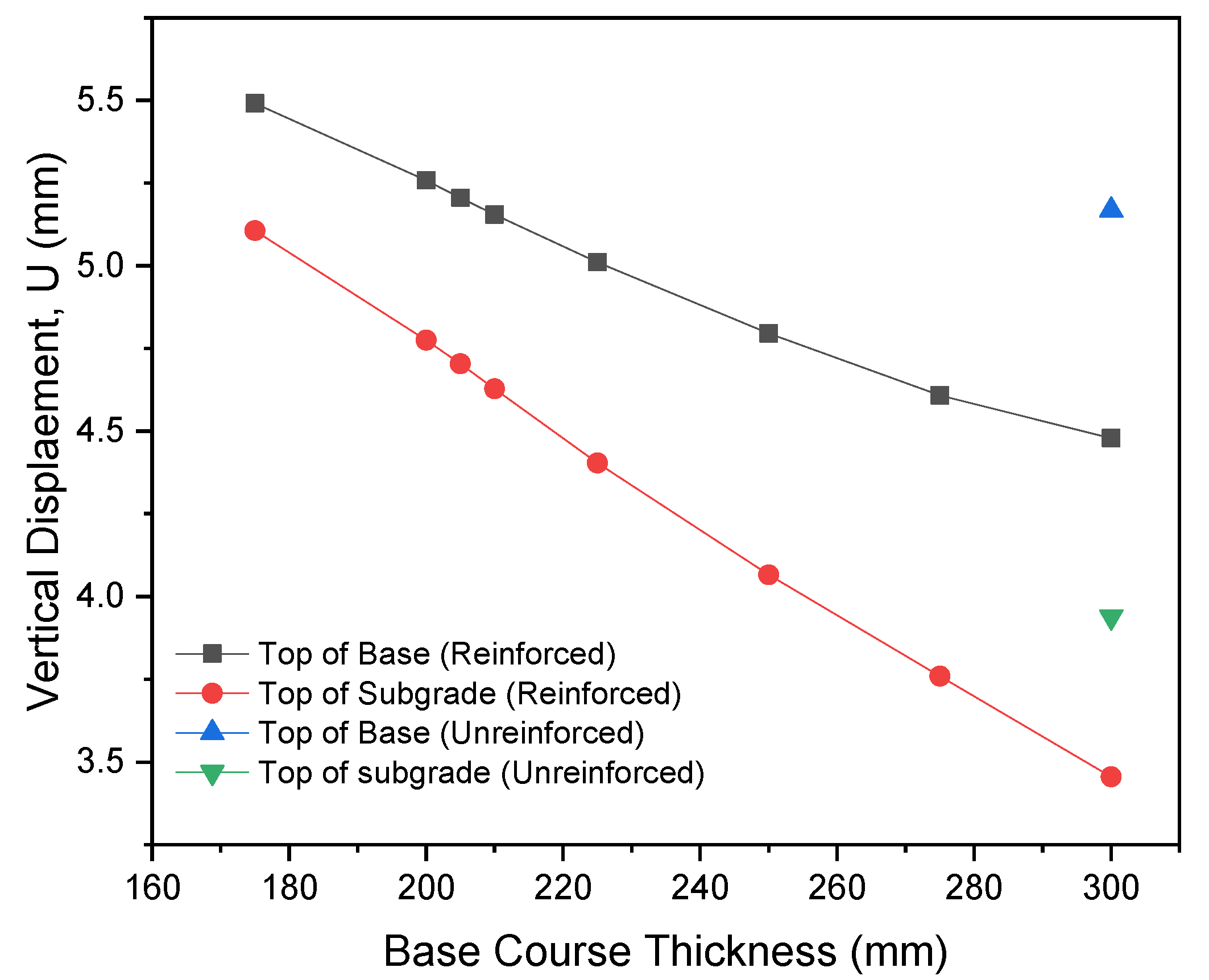

3.3. Effect of Reinforcement on Base Course Thickness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leonardi, G.; Bosco, D.L.; Palamara, R.; Suraci, F. Finite element analysis of geogrid-stabilized unpaved roads. Sustainability 2020, 12, 1929. [Google Scholar] [CrossRef] [Green Version]

- Castella, J.C.; Phaipasith, S. Rural roads are paving the way for land-use intensification in the uplands of Laos. Land 2021, 10, 330. [Google Scholar] [CrossRef]

- Chandak, P.G.; Patil, R.P.; Tapase, A.; Attar, A.C.; Sayyed, S.S. Performance Evaluation of Low Volume Rural Roads-A State-of-the-Art Review; Springer International Publishing: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Otto, A.; Rolt, J.; Mukura, K. The impact of drainage on the performance of low volume sealed roads. Sustainability 2020, 12, 6101. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Dessouky, S.H.; Kwon, J.; Tutumluer, E. Geogrid-reinforced low-volume flexible pavements: Pavement response and geogrid optimal location. J. Transp. Eng. 2012, 138, 1083–1090. [Google Scholar] [CrossRef]

- Alimohammadi, H.; Schaefer, V.R.; Zheng, J.; Li, H. Performance evaluation of geosynthetic reinforced flexible pavement: A review of full-scale field studies. Int. J. Pavement Res. Technol. 2021, 14, 30–42. [Google Scholar] [CrossRef]

- Al-Barqawi, M.; Aqel, R.; Wayne, M.; Titi, H.; Elhajjar, R. Polymer geogrids: A review of material, design and structure relationships. Materials 2021, 14, 4745. [Google Scholar] [CrossRef]

- Rimoldi, P.; Shamrock, J.; Kawalec, J.; Touze, N. Sustainable use of geosynthetics in dykes. Sustainability 2021, 13, 4445. [Google Scholar] [CrossRef]

- Imjai, T.; Pilakoutas, K.; Guadagnini, M. Performance of geosynthetic-reinforced flexible pavements in full-scale field trials. Geotext. Geomembr. 2019, 47, 217–229. [Google Scholar] [CrossRef]

- Wu, H.; Yao, C.; Li, C.; Miao, M.; Zhong, Y.; Lu, Y.; Liu, T. Review of application and innovation of geotextiles in geotechnical engineering. Materials 2020, 13, 1774. [Google Scholar] [CrossRef] [Green Version]

- Zornberg, J.G. Advances in the Use of Geosynthetics in Pavement Projects. Geosintec Iber. 2011, 1, 13. [Google Scholar]

- Nejad, F.M.; Noory, A.; Toolabi, S.; Fallah, S. Effect of using geosynthetics on reflective crack prevention. Int. J. Pavement Eng. 2015, 16, 477–487. [Google Scholar] [CrossRef]

- Miszkowska, A.; Lenart, S.; Koda, E. Changes of permeability of nonwoven geotextiles due to clogging and cyclic water flow in laboratory conditions. Water 2017, 9, 660. [Google Scholar] [CrossRef]

- Suraci, F.; Buonsanti, M.; Leonardi, G.; Palamara, R. A FEM simulation of the mechanical interaction between asphalt mixture and geogrid at micro-scale. Key Eng. Mater. 2018, 774, 595–600. [Google Scholar] [CrossRef]

- Mounes, S.M.; Karim, M.R.; Khodaii, A.; Almasi, M.H. Improving rutting resistance of pavement structures using geosynthetics: An overview. Sci. World J. 2014, 2014, 764218. [Google Scholar] [CrossRef] [Green Version]

- Ali, A.M. Evaluation of Flexible Pavement Reinforced with Geosynthetics using Static and Dynamic Loading Tests. Int. J. Eng. Res. 2018, 7, 222–226. [Google Scholar] [CrossRef]

- Shukla, S.K. Fundamentals of Geosynthetics; Institution of Civil Engineers Publishing: Perth, Australia, 2012. [Google Scholar]

- Aguiar-Moya, J.P.; Vargas-Nordcbeck, A.; Leiva-Villacorta, F.; Loría-Salazar, L.G. The Roles of Accelerated Pavement Testing in Pavement Sustainability: Engineering, Environment, and Economics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–905. [Google Scholar] [CrossRef]

- Siriwardane, H.; Gondle, R.; Kutuk, B. Analysis of flexible pavements reinforced with geogrids. Geotech. Geol. Eng. 2010, 28, 287–297. [Google Scholar] [CrossRef]

- Neves, J.; Lima, H.; Gonçalves, M. A Numerical Study on the Implications of Subgrade Reinforcement with Geosynthetics in Pavement Design. Procedia Eng. 2016, 143, 888–895. [Google Scholar] [CrossRef] [Green Version]

- Conrado-Palafox, A.L.; Equihua-Anguiano, L.N.; Hernández-Hernández, V.A. Numerical evaluation for roads considering the addition of geogrids in karst geohazards zones. Infrastructures 2021, 6, 120. [Google Scholar] [CrossRef]

- Taherkhani, H.; Jalali, M. Investigating the performance of geosynthetic-reinforced asphaltic pavement under various axle loads using finite-element method. Road Mater. Pavement Des. 2017, 18, 1200–1217. [Google Scholar] [CrossRef]

- Ibrahim, E.M.; El-Badawy, S.M.; Ibrahim, M.H.; Gabr, A.; Azam, A. Effect of geogrid reinforcement on flexible pavements. Innov. Infrastruct. Solut. 2017, 2, 54. [Google Scholar] [CrossRef]

- Kim, M.; Lee, J.H. Effects of geogrid reinforcement in low volume flexible pavement. J. Civ. Eng. Manag. 2013, 19, S14–S22. [Google Scholar] [CrossRef] [Green Version]

- Calvarano, L.S.; Leonardi, G.; Palamara, R. Finite Element Modelling of Unpaved Road Reinforced with Geosynthetics. Procedia Eng. 2017, 189, 99–104. [Google Scholar] [CrossRef]

- Borden, R.H.; Mousavi, S.; Gabr, M. Optimum Location of the Geogrid Reinforcement in Unpaved Road. Can. Geotech. J. 2017, 54, 1047–1054. [Google Scholar]

- Leng, J.; Gabr, M.A. Numerical analysis of stress-deformation response in reinforced unpaved road sections. Geosynth. Int. 2005, 12, 111–119. [Google Scholar] [CrossRef]

- Pavement Design Guideline for Low Volume Sealed Roads; Republic of Kenya Ministry of Transport, Infrastructure, Housing and Urban Development: Nairobi, Kenya, 2017.

- Erickson, H.L.; Drescher, A. The Use of Geosynthetics to Reinforce Low Volume Roads; Final Report; Minnesota Department of Transportation: St. Paul, MN, USA, 2001; p. 125. [Google Scholar]

- ASTM D 4595-09; Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method. ASTM: West Conshohocken, PA, USA, 2009.

- Cook, R.D.; Malkus, D.S.; Plesha, M.E.; Witt, R. Concepts and Applications of Finite Element Analysis; John Wiley and Sons, Inc.: Indianapolis, IN, USA, 2003. [Google Scholar]

- Liu, P.; Xing, Q.; Dong, Y.; Wang, D.; Oeser, M.; Yuan, S. Application of Finite Layer Method in Pavement Structural Analysis. Appl. Sci. 2017, 7, 611. [Google Scholar] [CrossRef] [Green Version]

- Latha, G.M.; Somwanshi, A. Bearing capacity of square footings on geosynthetic reinforced sand. Geotext. Geomembr. 2009, 27, 281–294. [Google Scholar] [CrossRef]

- Baadiga, R.; Saride, S.; Balunaini, U.; Madhira, M.R. Influence of tensile strength of geogrid and subgrade modulus on layer coefficients of granular bases. Transp. Geotech. 2021, 29, 100557. [Google Scholar] [CrossRef]

- Leonardi, G.; Suraci, F. A 3D-FE model for the rutting prediction in geogrid reinforced flexible pavements. Sustainability 2022, 14, 3695. [Google Scholar] [CrossRef]

| Course/Layer | Model | Poisson Ratio, ν | Elastic Modulus, E (MPa) | Density, Υ (Kg/m3) | Thickness (mm) |

|---|---|---|---|---|---|

| AC | Linear Elastic Model | 0.35 | 2200 | 2240 | 40 |

| Base | Mohr–Coulomb Model | 0.35 | 50 | 1850 | 300 |

| Subgrade | Mohr–Coulomb Model | 0.35 | 10 | 1282 | 2000 |

| Materials | Mohr Coulomb Plasticity Model | ||

|---|---|---|---|

| Plasticity | Cohesion | ||

| Friction Angle (φ) | Dilation Angle (ψ) | Cohesion Yield Stress (MPa) | |

| Base | 40 | 10 | 0.15 |

| Subgrade | 10 | 0 | 0.0436 |

| Geotextile Description | Strength at 5% Strain (kN/m) | E (MPa) Assuming t = 0.00254 m | Poisson Ratio |

|---|---|---|---|

| Soft | 5.3 | 42 | 0.3 |

| Medium | 200 | 1575 | 0.3 |

| Stiff | 400 | 3150 | 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Z.; Ndiema, K.M.; Lekalpure, R.L.; Kiptum, C.K. Numerical Study of Geotextile-Reinforced Flexible Pavement Overlying Low-Strength Subgrade. Appl. Sci. 2022, 12, 10325. https://doi.org/10.3390/app122010325

Yin Z, Ndiema KM, Lekalpure RL, Kiptum CK. Numerical Study of Geotextile-Reinforced Flexible Pavement Overlying Low-Strength Subgrade. Applied Sciences. 2022; 12(20):10325. https://doi.org/10.3390/app122010325

Chicago/Turabian StyleYin, Zihong, Kevin Maraka Ndiema, Raymond Leiren Lekalpure, and Clement Kiprotich Kiptum. 2022. "Numerical Study of Geotextile-Reinforced Flexible Pavement Overlying Low-Strength Subgrade" Applied Sciences 12, no. 20: 10325. https://doi.org/10.3390/app122010325