A Review of Flow Control for Gust Load Alleviation

Abstract

Featured Application

Abstract

1. Introduction

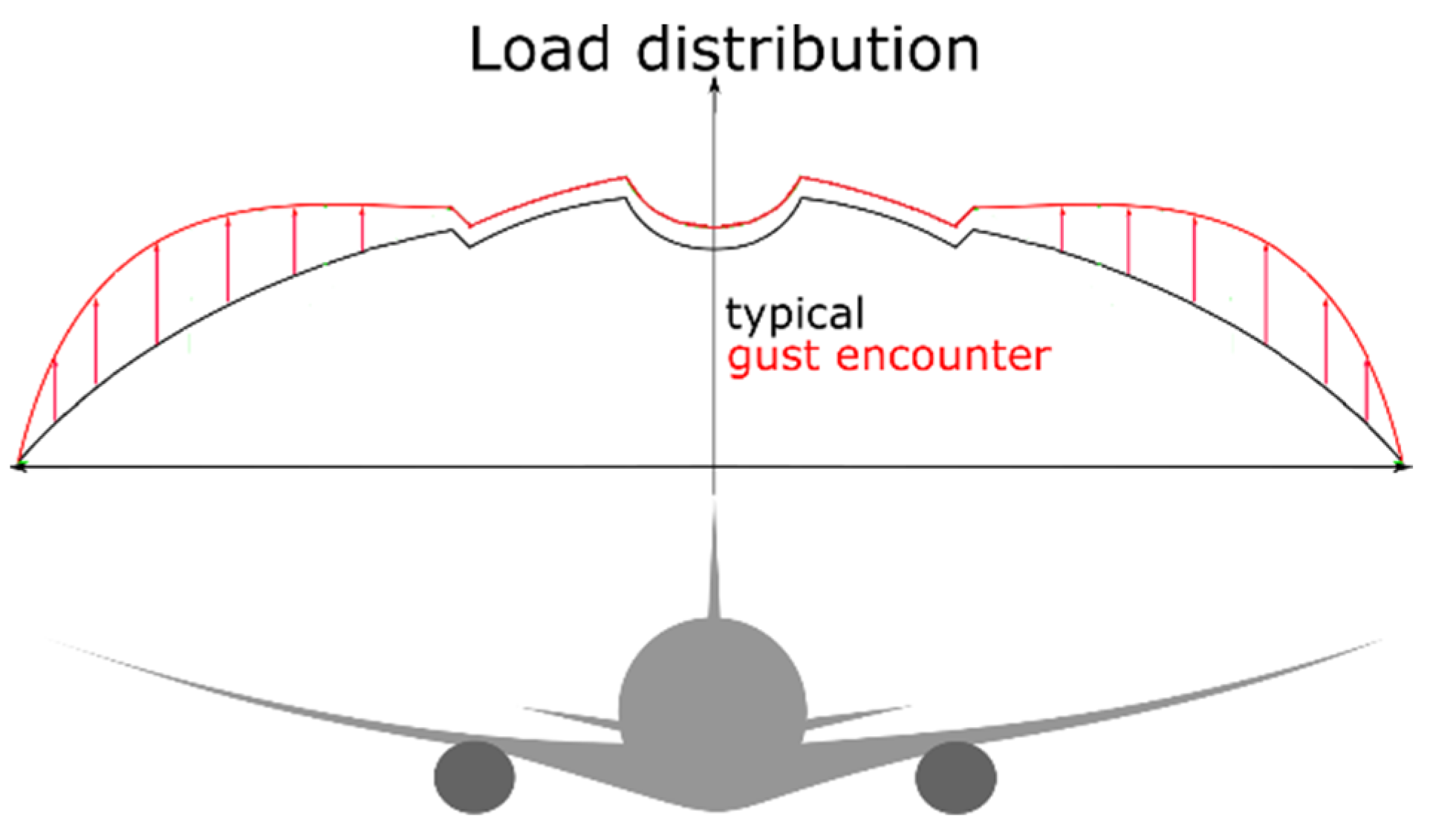

2. Basics of Gust Load Alleviation

2.1. Gust Load Definition

2.1.1. Discrete Gusts

2.1.2. Continuous Gusts

2.2. Gust Load Control Strategies

3. Flow Control Devices for Gust Load Alleviation

3.1. Traditional Control Surfaces

3.1.1. Trailing-Edge Flaps

3.1.2. Spoilers

3.2. Non-Traditional Control Surfaces

3.3. Passive Control Devices

3.4. Fluidic Actuators

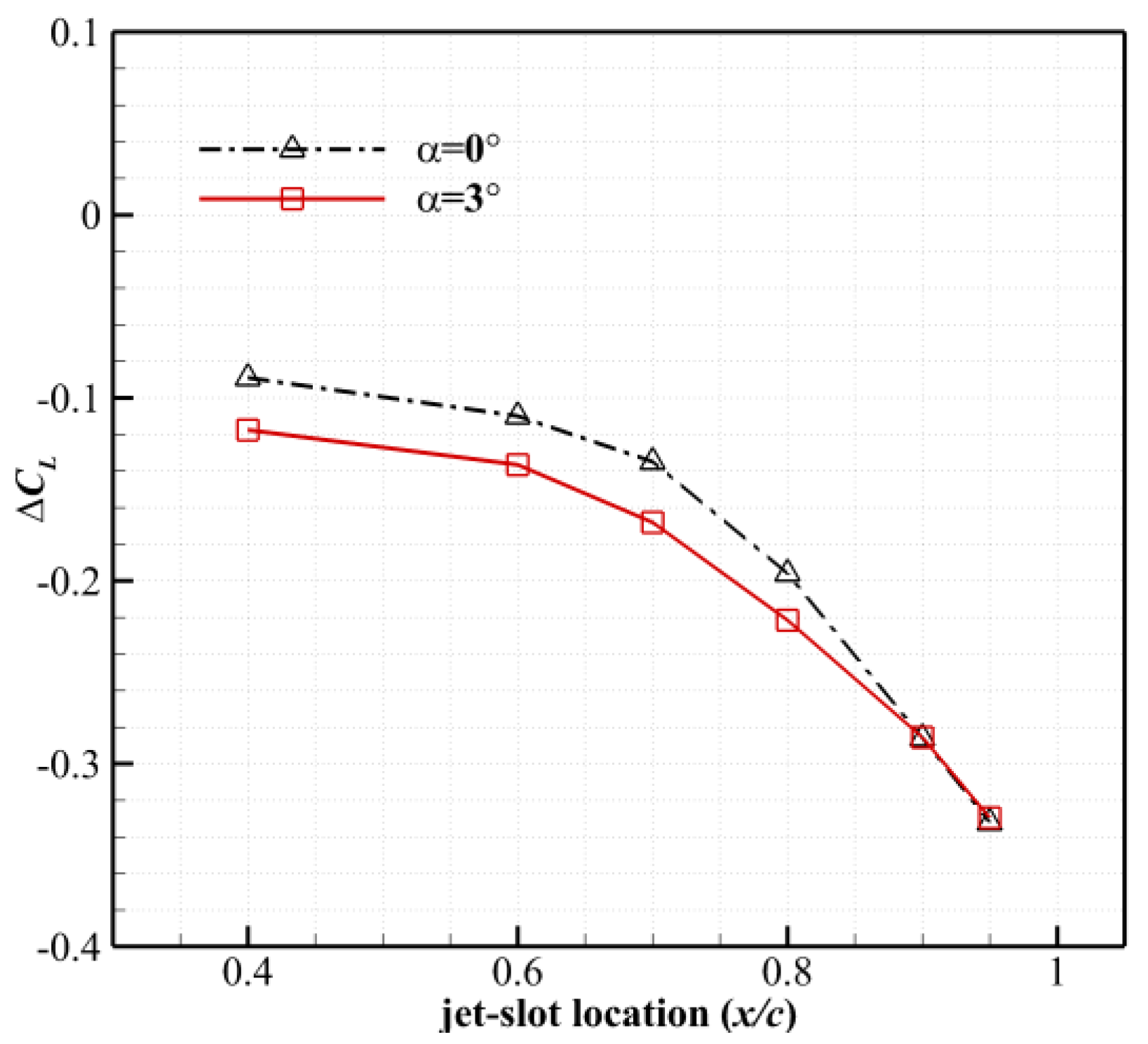

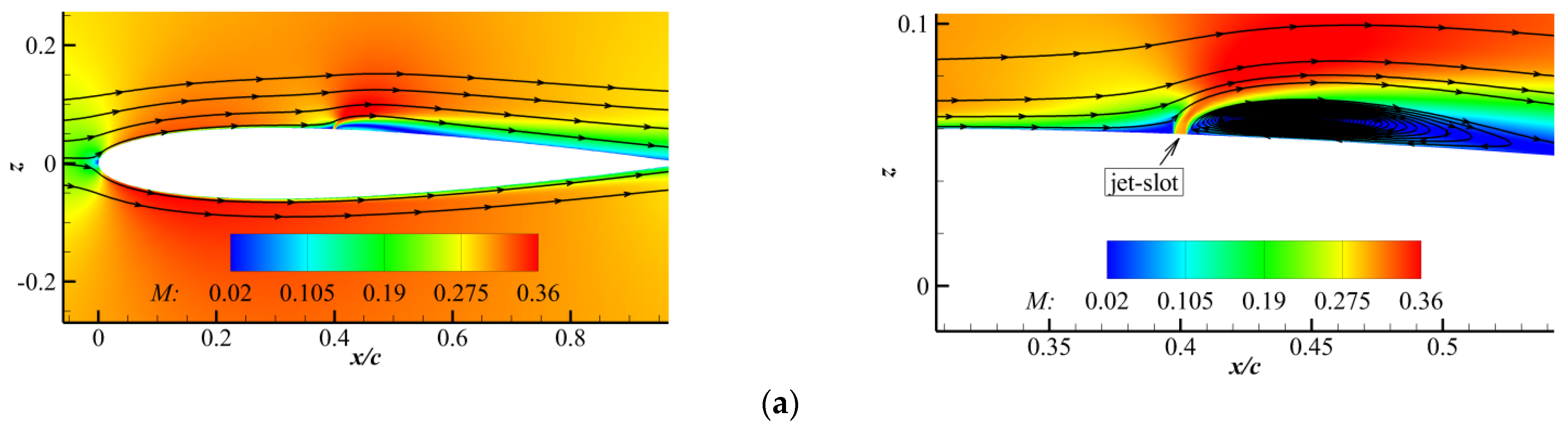

3.4.1. Surface Jet Blowing

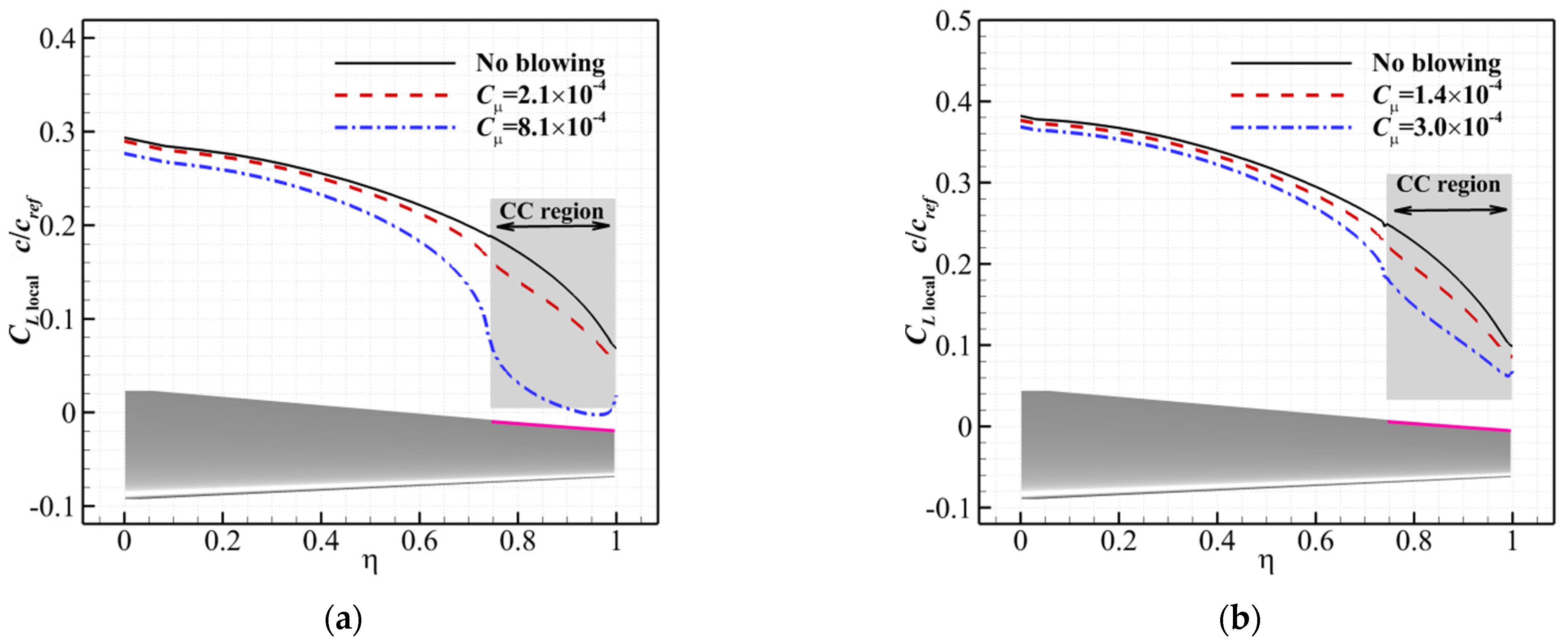

3.4.2. Circulation Control by Jet Blowing through the Trailing-Edge Coanda Device

3.5. Summary of the Characteristics of These Flow Control Devices

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| s | non-dimensional time |

| CL | lift coefficient |

| Mjet | the Mach number of the jet |

| momentum coefficient | |

| peak value of the momentum coefficient with the one-minus-cosine profile | |

| M∞ | Mach number of the freestream flow |

| angle of attack | |

| freestream velocity | |

| pressure coefficient | |

| chord length | |

| mean aerodynamic chord length | |

| Cartesian coordinates in streamwise, spanwise and vertical directions |

References

- Psaraftis, H. Green Transportation Logistics: The Quest for Win-Win Solutions; International Series in Operations Research & Management Science; Springer: Berlin/Heidelberg, Germany, 2015; Volume 226. [Google Scholar]

- Salam, I.R.; Bil, C. Multi-disciplinary analysis and optimisation methodology for conceptual design of a box-wing aircraft. Aeronaut. J. 2016, 120, 1315–1333. [Google Scholar] [CrossRef]

- Chakraborty, I.; Nam, T.; Gross, J.R.; Mavris, D.N.; Schetz, J.A.; Kapania, R.K. Comparative Assessment of Strut-Braced and Truss-Braced Wing Configurations Using Multidisciplinary Design Optimization. J. Aircr. 2015, 52, 2009–2020. [Google Scholar] [CrossRef]

- Colliss, S.P.; Babinsky, H.; Nöbler, K.; Lutz, T. Vortical structures on three-dimensional shock control bumps. J. Aircr. 2016, 53, 2338–2350. [Google Scholar] [CrossRef]

- Bruce, P.J.K.; Babinsky, H. Experimental Study into the Flow Physics of Three-Dimensional Shock Control Bumps. J. Aircr. 2012, 49, 1222–1233. [Google Scholar] [CrossRef]

- König, B.; Pätzold, M.; Lutz, T.; Krämer, E.; Rosemann, H.; Richter, K.; Uhlemann, H. Numerical and Experimental Validation of Three-Dimensional Shock Control Bumps. J. Aircr. 2009, 46, 675–682. [Google Scholar] [CrossRef]

- Ogawa, H.; Babinsky, H.; Pätzold, M.; Lutz, T. Shock-Wave/Boundary-Layer Interaction Control Using Three-Dimensional Bumps for Transonic Wings. AIAA J. 2008, 46, 1442–1452. [Google Scholar] [CrossRef]

- Messing, R.; Kloker, M.J. Investigation of suction for laminar flow control of three-dimensional boundary layers. J. Fluid Mech. 2010, 658, 117–147. [Google Scholar] [CrossRef]

- Chernoray, V.G.; Dovgal, A.V.; Kozlov, V.V.; Lfdahl, L. Experiments on secondary instability of streamwise vortices in a swept-wing boundary layer. J. Fluid Mech. 2005, 534, 295–325. [Google Scholar] [CrossRef]

- Krishnan, K.S.G.; Bertram, O.; Seibel, O. Review of hybrid laminar flow control systems. Prog. Aerosp. Sci. 2017, 93, 24–52. [Google Scholar] [CrossRef]

- Brion, V.; Dandois, J.; Jacquin, L. Laminar buffet and flow control. In Proceedings of the 7th European Conference for Aeronautics and Space Sciences, Milano, Italy, 3–6 July 2017. [Google Scholar]

- Ashill, P.R.; Fulker, J.L.; Hackett, K.C. A review of recent developments in flow control. Aeronaut. J. 2005, 109, 205–232. [Google Scholar] [CrossRef]

- Joslin, R.D. Overview of Laminar Flow Control; NASA/TP-1998-208705; NASA Langley Research Center: Hampton, Virginia, USA, 1998.

- Hybrid Laminar Flow Control Study Final Technical Report; NASA-CR-165930; NASA Langley Research Center: Hampton, VA, USA, 1982.

- Murai, Y. Frictional drag reduction by bubble injection. Exp. Fluids 2014, 55, 1773. [Google Scholar] [CrossRef]

- Fuaad, P.A.; Baig, M.F.; Khan, B.A. Turbulent drag reduction using active control of buoyancy forces. Int. J. Heat Fluid Flow 2016, 61, 585–598. [Google Scholar] [CrossRef]

- Ahmad, H.; Baig, M.F.; Fuaad, P.A. Numerical investigation of turbulent-drag reduction induced by active control of streamwise travelling waves of wall-normal velocity. Eur. J. Mech. B Fluids 2015, 49, 250–263. [Google Scholar] [CrossRef]

- Wang, Y.-S.; Huang, W.-X.; Xu, C.-X. Active control for drag reduction in turbulent channel flow: The opposition control schemes revisited. Fluid Dyn. Res. 2016, 48, 055501. [Google Scholar] [CrossRef]

- Liebeck, R.H. Design of the Blended Wing Body Subsonic Transport. J. Aircr. 2004, 41, 10–25. [Google Scholar] [CrossRef]

- Graham, W.R.; Hall, C.A.; Vera Morales, M. The potential of future aircraft technology for noise and pollutant emissions reduction. Transp. Policy 2014, 34, 36–51. [Google Scholar] [CrossRef]

- Lebofsky, S.; Ting, E.; Nguyen, N.; Trinh, K. Optimization for Load Alleviation of Truss-Braced Wing Aircraft with Variable Camber Continuous Trailing Edge Flap. In Proceedings of the 33rd AIAA Applied Aerodynamics Conference, Dallas, TX, USA, 22–26 June 2015. [Google Scholar]

- Jemitola, P.O.; Fielding, J.P. Box wing aircraft conceptual design. In Proceedings of the 28th International Congress of the Aeronautical Sciences, Brisbane, Australia, 23–28 September 2012. [Google Scholar]

- Guo, S.; Los, J.; Liu, Y. Gust Alleviation of a Large Aircraft with a Passive Twist Wingtip. Aerospace 2015, 2, 135–154. [Google Scholar] [CrossRef]

- European Aviation Safety Agency. Certification Specifications for Large Aeroplanes CS-25; European Aviation Safety Agency: Cologne, Germany, 2008.

- Johnston, J.F. Accelerated Development and Flight Evaluation of Active Controls Concepts for Subsonic Transport Aircraft. Volume 1: Load Alleviation/Extended Span Development and Flight Tests; NASA-CR-159097; NASA Langley Research Center: Hampton, VA, USA, 1979.

- Disney, T.E. C-5A Active Load Alleviation System. J. Spacecr. Rocket. 1977, 14, 81–86. [Google Scholar] [CrossRef]

- Al-Battal, N. Flow Control for Loads Control. Ph.D. Thesis, University of Bath, Bath, UK, 2019. [Google Scholar]

- Payne, B.W. Designing a Load Alleviation System for a Modern Civil Aircraft. In Proceedings of the 15th Congress of the International Council of the Aeronautical Sciences, London, UK, 7–12 September 1986. ICAS-86-5.2.3. [Google Scholar]

- Xu, J.; Kroo, I. Aircraft Design with Maneuver and Gust Load Alleviation. In Proceedings of the 29th AIAA Applied Aerodynamics Conference, Honolulu, Hawaii, 27 June 2011. AIAA Paper 2011-3180. [Google Scholar]

- Yonghong, L. Gust Load Alleviation by Fluidic Actuators on a Blended-Wing-Body Configuration. Ph.D. Thesis, Sheffield University, Sheffield, UK, 2020. [Google Scholar]

- Paterson, E.; Baker, W.; Kunz, R.; Peltier, L. RANS and Detached-Eddy Simulation of the NCCR Airfoil. In Proceedings of the 2004 Users Group Conference (DOD_UGC’04), Williamsburg, VA, USA, 7–11 June 2004; pp. 112–122. [Google Scholar]

- Anonymous. BAE Systems success in flapless flight. Aircr. Eng. Aerosp. Technol. 2006, 78. [Google Scholar] [CrossRef]

- Wright, J.R. Introduction to Aircraft Aeroelasticity and Dynamic Loads, 2nd ed.; Cooper, J.E., Ed.; Wiley: Chichester, UK, 2015. [Google Scholar]

- Rabadan, G.J.; Schmitt, N.P.; Pistner, T.; Rehm, W. Airborne Lidar for Automatic Feedforward Control of Turbulent In-Flight Phenomena. J. Aircr. 2010, 47, 392–403. [Google Scholar] [CrossRef]

- Alam, M.; Hromcik, M.; Hanis, T. Active gust load alleviation system for flexible aircraft: Mixed feedforward/feedback approach. Aerosp. Sci. Technol. 2015, 41, 122–133. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, W.; Liu, X.; He, Q.; Qin, Y. Gust response stabilization for rigid aircraft with multi-control-effectors based on a novel integrated control scheme. Aerosp. Sci. Technol. 2018, 79, 625–635. [Google Scholar] [CrossRef]

- Fazelzadeh, S.A.; Jafari, S.M. Active control law design for flutter suppression and gust alleviation of a panel with piezoelectric actuators. Smart Mater. Struct. 2008, 17, 035013. [Google Scholar] [CrossRef]

- Patil, M.J.; Hodges, D.H. Output Feedback Control of the Nonlinear Aeroelastic Response of a Slender Wing. J. Guid. Control Dyn. 2002, 25, 302–308. [Google Scholar] [CrossRef]

- Liu, X.; Sun, Q.; Cooper, J.E. LQG based model predictive control for gust load alleviation. Aerosp. Sci. Technol. 2017, 71, 499–509. [Google Scholar] [CrossRef]

- Liu, X.; Sun, Q. Improved LQG Method for Active Gust Load Alleviation. J. Aerosp. Eng. 2017, 30, 04017006. [Google Scholar] [CrossRef]

- Frost, S.; Taylor, B.; Bodson, M. Investigation of Optimal Control Allocation for Gust Load Alleviation in Flight Control. In Proceedings of the AIAA Atmospheric Flight Mechanics Conference, Minneapolis, MN, USA, 13–16 August 2012. AIAA 2012-4858. [Google Scholar]

- Al-Battal, N.; Cleaver, D.; Gursul, I. Lift reduction by counter flowing wall jets. Aerosp. Sci. Technol. 2018, 78, 682–695. [Google Scholar] [CrossRef]

- Al-Battal, N.; Cleaver, D.; Gursul, I. Aerodynamic Load Control through Blowing. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016. AIAA 2016-1820. [Google Scholar]

- Abbott, I.H.; Doenhoff, A.E. Theory of Wing Sections: Including a Summary of Airfoil Data; Dover Publications, Inc.: New York, NY, USA, 1959. [Google Scholar]

- Anderson, J.D. Introduction to Flight, 8th ed.; McGraw-Hill Education: New York, NY, USA, 2016. [Google Scholar]

- Frederick, M.; Kerrigan, E.C.; Graham, J.M.R. Gust alleviation using rapidly deployed trailing-edge flaps. J. Wind Eng. Ind. Aerodyn. 2010, 98, 712–723. [Google Scholar] [CrossRef]

- Costes, M.; Gravelle, A.; Philippe, J.; Vogel, S.; Triebstein, H. Investigation of Unsteady Subsonic Spoiler and Flap Aerodynamics. J. Aircr. 1987, 24, 629–637. [Google Scholar] [CrossRef]

- Bak, C.; Gaunaa, M.; Andersen, P.B.; Buhl, T.; Hansen, P.; Clemmensen, K. Wind tunnel test on airfoil Risø-B1-18 with an Active Trailing Edge Flap. Wind Energy 2010, 13, 207–219. [Google Scholar] [CrossRef]

- Sven Geisbauer, T.L. Towards the Investigation of Unsteady Spoiler Aerodynamics. In Proceedings of the 35th AIAA Applied Aerodynamics Conference, Denver, CO, USA, 5–9 June 2017. A.A. Forum. [Google Scholar]

- Mack, M.D.; Seetharam, H.D.; Kuhn, W.G.; Bright, J.T. Aerodynamics of Spoiler Control Devices. In Proceedings of the AIAA Aircraft Systems and Technology Meeting, New York, NY, USA, 20–22 August 1979. A.P. 1979-1873. [Google Scholar]

- Wentz, J.W.; Ostowari, C.; Seetharam, H.C. Effects of Design Variables on Spoiler Control Effectiveness, Hinge Moments and Wake Turbulence. In Proceedings of the 19th AIAA Aerospace Sciences Meeting, Louis, MO, USA, 12–15 January 1981. AIAA Paper 1981-0072. [Google Scholar]

- Maskell, E.C. Pressure Distributions Illustrating Flow Reattachment behind a Forward Mounted Flap; ARC-CP-211; Her Majesty’s Stationery Office: London, UK, 1955.

- Croom, D.R.; Shufflebarger, C.C.; Huffman, J.K. An Investigation of Forward-Located Fixed Spoilers and Deflectors as Gust Alleviators on an Unswept-Wing Model; NACA-TN-3705; NACA: Boston, MA, USA, 1956. [Google Scholar]

- Siddalingappa, S.R.; Hancock, G.J. An Introduction to the Aerodynamics of Spoilers; Paper QMC EP-1034; Department of Aeronautical Engineering, Queen Mary College: London, UK, 1980. [Google Scholar]

- Mabey, D.G. Experimental Methods to Determine Control Effectiveness in Wind Tunnels. In AGARD Special Course on Aerodynamic Characteristics of Controls; AGARD-R-711 Paper 5; AGARD: Neuilly sur Seine, France, July 1995. [Google Scholar]

- Hancock, G.J. Dynamic Effects of Controls. In AGARD Special Course on Aerodynamic Characteristics of Controls; AGARD-R-711 Paper 4; AGARD: Neuilly sur Seine, France, July 1995. [Google Scholar]

- Consigny, H.; Gravelle, A.; Molinaro, R. Aerodynamic Characteristics of a Moving Two-Dimensional Spoiler in Subsonic and Transonic Flow. J. Aircr. 1984, 21, 683–687. [Google Scholar] [CrossRef]

- Kalligas, K. The Dynamic Characteristics of Two-Dimensional Spoilers at Low Speeds. Ph.D. Thesis, Department of Aeronautical Engineering, University of Bristol, Bristol, UK, 1986. [Google Scholar]

- Nelson, C.F.; Koga, D.J.; Eaton, J.K. Unsteady, Separated Flow Behind an Oscillating, Two-Dimensional Spoiler. AIAA J. 1990, 28, 845–852. [Google Scholar] [CrossRef]

- Mineck, R.E. Reynolds Number Effects on the Performance of Ailerons and Spoilers. In Proceedings of the 39th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2001. AIAA Paper 2001-0908. [Google Scholar]

- Geisbauer, S. Numerical Simulation and Validation of Aerodynamics of Static and Dynamic Spoilers. J. Aircr. 2021, 58, 1187–1203. [Google Scholar] [CrossRef]

- Roth, D.; Enenkl, B.; Dieterich, O. Active rotor control by flaps for vibration reduction—Full scale demonstrator and first flight test results. In Proceedings of the 32nd European Rotorcraft Forum, Maastricht, The Netherlands, 12–14 September 2006. [Google Scholar]

- Kota, S.; Hetrick, J.A.; Osborn, R.; Paul, D.; Pendleton, E.; Flick, P.; Tilmann, C. Design and application of compliant mechanisms for morphing aircraft structures. In Proceedings of the SPIE, San Diego, CA, USA, 4–5 August 2003; pp. 24–33. [Google Scholar]

- Buhl, T.; Gaunaa, M.; Bak, C. Potential Load Reduction Using Airfoils with Variable Trailing Edge Geometry. J. Sol. Energy Eng. 2005, 127, 503–516. [Google Scholar] [CrossRef]

- Chow, R.; Dam, C.P.V. Unsteady Computational Investigations of Deploying Load Control Microtabs. J. Aircr. 2006, 43, 1458–1469. [Google Scholar] [CrossRef]

- Blaylock, M.; Chow, R.; van Dam, C.P. Comparison of Microjets with Microtabs for Active Aerodynamic Load Control. In Proceedings of the 5th Flow Control Conference, Chicago, IL, USA, 28 June–1 July 2010. AIAA 2010-4409. [Google Scholar]

- Johnson, S.J.; Baker, J.P.; Van Dam, C.P.; Berg, D. An overview of active load control techniques for wind turbines with an emphasis on microtabs. Wind Energy 2010, 13, 239–253. [Google Scholar] [CrossRef]

- Van Dam, C.P.; Berg, D.E.; Johnson, S.J. Active Load Control Techniques for Wind Turbines; SAND2008-4809; Sandia National Laboratories (SNL): Albuquerque, NM, USA; Livermore, CA, USA, 2008. [Google Scholar]

- Guo, S.; Jing, Z.W.; Li, H.; Lei, W.T.; He, Y.Y. Gust response and body freedom flutter of a flying-wing aircraft with a passive gust alleviation device. Aerosp. Sci. Technol. 2017, 70, 277–285. [Google Scholar] [CrossRef]

- Castrichini, A.; Siddaramaiah, V.H.; Calderon, D.E.; Cooper, J.E.; Wilson, T.; Lemmens, Y. Preliminary investigation of use of flexible folding wing tips for static and dynamic load alleviation. Aeronaut. J. 2017, 121, 73–94. [Google Scholar] [CrossRef]

- Castrichini, A.; Cooper, J.E.; Wilson, T.; Carrella, A.; Lemmens, Y. Nonlinear Negative Stiffness Wingtip Spring Device for Gust Loads Alleviation. J. Aircr. 2017, 54, 627–641. [Google Scholar] [CrossRef]

- Castrichini, A.; Siddaramaiah, V.; Calderon, D.; Cooper, J.; Wilson, T.; Lemmens, Y. Nonlinear Folding Wing Tips for Gust Loads Alleviation. J. Aircr. 2016, 53, 1391–1399. [Google Scholar] [CrossRef]

- Chan, D.T.; Jones, G.S.; Milholen, W.E.; Goodliff, S.L. Transonic Drag Reduction Through Trailing-Edge Blowing on the FAST-MAC Circulation Control Model. In Proceedings of the 35th AIAA Applied Aerodynamics Conference, Denver, CO, USA, 5–9 June 2017. AIAA AVIATION Forum, AIAA 2017-3246. [Google Scholar]

- Cui, W.; Zhu, H.; Xia, C.; Yang, Z. Comparison of Steady Blowing and Synthetic Jets for Aerodynamic Drag Reduction of a Simplified Vehicle. Procedia Eng. 2015, 126, 388–392. [Google Scholar] [CrossRef][Green Version]

- Zahn, J.; Rist, U. Active and Natural Suction at Forward-Facing Steps for Delaying Laminar–Turbulent Transition. AIAA J. 2017, 55, 1343–1354. [Google Scholar] [CrossRef]

- Guo, Z.; Kloker, M.J. Control of crossflow-vortex-induced transition by unsteady control vortices. J. Fluid Mech. 2019, 871, 427–449. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, S.; Meng, Q.; Wang, S. Flow separation control using unsteady pulsed suction through endwall bleeding holes in a highly loaded compressor cascade. Aerosp. Sci. Technol. 2018, 72, 455–464. [Google Scholar] [CrossRef]

- Greenblatt, D.; Wygnanski, I.J. The control of flow separation by periodic excitation. Prog. Aerosp. Sci. 2000, 36, 487–545. [Google Scholar] [CrossRef]

- Paul, A.R.; Joshi, S.; Jindal, A.; Maurya, S.P.; Jain, A. Experimental Studies of Active and Passive Flow Control Techniques Applied in a Twin Air-Intake. Sci. World J. 2013, 2013, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Paul, A.R.; Kuppa, K.; Yadav, M.S.; Dutta, U. Flow Improvement in Rectangular Air Intake by Submerged Vortex Generators. J. Appl. Fluid Mech. 2011, 4, 77–86. [Google Scholar]

- Ebrahimi, A.; Hajipour, M.; Ghamkhar, K. Experimental study of stall control over an airfoil with dual excitation of separated shear layers. Aerosp. Sci. Technol. 2018, 82–83, 402–411. [Google Scholar] [CrossRef]

- Amitay, M.; Glezer, A. Role of Actuation Frequency in Controlled Flow Reattachment over a Stalled Airfoil. AIAA J. 2002, 40, 209–216. [Google Scholar] [CrossRef]

- Korbacher, G.K.; Sridhar, K. A Review of the Jet Flap; UTIA Review, No. 14; University of Toronto Press: Toronto, ON, CA, 1960. [Google Scholar]

- Traub, L.W.; Miller, A.C.; Rediniotis, O. Comparisons of a Gurney and Jet-Flap for Hinge-Less Control. J. Aircr. 2004, 41, 420–423. [Google Scholar] [CrossRef]

- Blaylock, M.; Chow, R.; Cooperman, A.; Dam, C.P. Comparison of pneumatic jets and tabs for Active Aerodynamic Load Control. Wind Energy 2014, 17, 1365–1384. [Google Scholar] [CrossRef]

- Rao, P.; Strganac, T.; Rediniotis, O. Control of aeroelastic response via synthetic jet actuators. In Proceedings of the 41st Structures, Structural Dynamics, and Materials Conference and Exhibit, Atlanta, GA, USA, 3 April 2000; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2000. [Google Scholar] [CrossRef]

- De Breuker, R.; Abdalla, M.; Marzocca, P.; Gürdal, Z. Flutter suppression using synthetic jet actuators: The typical section. In Proceedings of the 17th International Conference on Adaptive Structures and Technologies, Taipei, Taiwan, 16–19 October 2006; pp. 402–409. [Google Scholar]

- De Vries, H.; Boeije, C.; Cleine, I.; van Emden, E.; Zwart, G.; Stobbe, H.; Hirschberg, A.; Hoeijmakers, H. Fluidic Load Control for Wind Turbine Blades. In Proceedings of the 47th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5 January 2009. AIAA 2009-684. [Google Scholar] [CrossRef]

- Heathcote, D.; Al-Battal, N.; Gursul, I.; Cleaver, D. Control of Wing Loads by Means of Blowing and Mini-Tabs. In Proceedings of the European Drag Reduction and Flow Control Meeting—EDRFCM 2015, Cambridge, UK, 23–26 March 2015. [Google Scholar]

- Lockwood, V.E.; Vogler, R.D. Exploratory Wind-Tunnel Investigation at High Subsonic and Transonic Speeds of Jet Flaps on Unswept Rectangular Wings; NACA-TN-4353; NACA: Boston, MA, USA, 1958.

- Mikolowsky, W.; McMahon, H. An Experimental Investigation of a Jet Issuing from a Wing in Crossflow. J. Aircr. 1973, 10, 546–553. [Google Scholar] [CrossRef]

- Li, Y.; Qin, N. Gust load alleviation by normal microjet. Aerosp. Sci. Technol. 2021, 117, 106919. [Google Scholar] [CrossRef]

- Al-Battal, N.H.; Cleaver, D.J.; Gursul, I. Unsteady actuation of counter-flowing wall jets for gust load attenuation. Aerosp. Sci. Technol. 2019, 89, 175–191. [Google Scholar] [CrossRef]

- Mueller-Vahl, H.; Nayeri, C.; Paschereit, C.O.; Greenblatt, D. Control of Unsteady Aerodynamic Loads Using Adaptive Blowing. In Proceedings of the 32nd AIAA Applied Aerodynamics Conference, Atlanta, GA, USA, 16–20 June 2014. [Google Scholar]

- De Breuker, R.; Abdalla, M.; Marzocca, P. Aeroelastic Control and Load Alleviation using Optimally Distributed Synthetic Jet Actuators. In Proceedings of the 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Honolulu, Hawaii, 23 April 2007; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2007. [Google Scholar] [CrossRef]

- Alexander, M.G.; Anders, S.G.; Johnson, S.K.; Florance, J.P.; Keller, D.F. Trailing Edge Blowing on a Two-Dimensional Six-Percent Thick Elliptical Circulation Control Airfoil up to Transonic Conditions; NASA/TM-2005-213545; Sponsoring Organization; NASA Langley Research Center: Hampton, VA, USA, 2005.

- Ahuja, K.; Sankar, L.; Englar, R.J.; Munro, S.; Liu, Y. Application of Circulation Control Technology to Airframe Noise Reduction; GIT. Annual Performance Report; Georgia Institute of Technology: Atlanta, GA, USA, 2000; Volume 5928, pp. 1–2146. [Google Scholar]

- Nichols, J.H.; Englar, R.J. Advanced circulation control wing system for navy stol aircraft. J. Aircr. 1981, 18, 1044–1050. [Google Scholar] [CrossRef]

- Cook, M.V.; Buonanno, A.; Erbslöh, S.D. A circulation control actuator for flapless flight control. Aeronaut. J. 2008, 112, 483–489. [Google Scholar] [CrossRef]

- Englar, R.; Smith, M.; Kelley, S. Application of circulation control to advanced subsonic transport aircraft. I—Airfoil development. II—Transport application. J. Aircr. 1994, 31, 1160–1177. [Google Scholar] [CrossRef]

- Crowther, W.; Wilde, P.; Gill, K.; Michie, S.M. Towards Integrated design of fluidic flight controls for a flapless aircraft. Aeronaut. J. 2009, 113, 699–713. [Google Scholar] [CrossRef]

- John, P. The flapless air vehicle integrated industrial research (FLAVIIR) programme in aeronautical engineering. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2010, 224, 355–363. [Google Scholar] [CrossRef]

- Wilde, P.; Buonanno, A.; Crowther, W.; Savvaris, A. Aircraft control using fluidic maneuver effectors. In Proceedings of the 26th AIAA Applied Aerodynamics Conference, Honolulu, Hawaii, 18–21 August 2008. AIAA 2008-6406. [Google Scholar]

- Hoholis, G.; Steijl, R.; Badcock, K. Circulation Control as a Roll Effector for Unmanned Combat Aerial Vehicles. J. Aircr. 2016, 53, 1875–1889. [Google Scholar] [CrossRef]

- Wilde, P.I.A.; Crowther, W.J.; Harley, C.D. Application of circulation control for three-axis control of a tailless flight vehicle. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2010, 224, 373–386. [Google Scholar] [CrossRef]

- Li, Y.; Qin, N. Airfoil gust load alleviation by circulation control. Aerosp. Sci. Technol. 2020, 98, 105622. [Google Scholar] [CrossRef]

- Li, Y.; Qin, N. Gust load alleviation on an aircraft wing by trailing edge Circulation Control. J. Fluids Struct. 2021, 107, 103407. [Google Scholar] [CrossRef]

| Flow Control Category | Typical Devices | Advantages | Limitations |

|---|---|---|---|

| Active flow control | Traditional control surfaces: Trailing-edge flaps and Spoilers | Robustness for a large range of incoming flow speeds | large size and heavy low-frequency responses |

| Fluidic actuators: Surface jets and CC | high-frequency responses small size and less weight | decreases in gust load alleviation effects with increasing incoming flow speeds | |

| Passive flow control | wingtip twist and flexible wing-fold devices | no extra energy required simple structural mechanism | Poor robustness away from design point |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Qin, N. A Review of Flow Control for Gust Load Alleviation. Appl. Sci. 2022, 12, 10537. https://doi.org/10.3390/app122010537

Li Y, Qin N. A Review of Flow Control for Gust Load Alleviation. Applied Sciences. 2022; 12(20):10537. https://doi.org/10.3390/app122010537

Chicago/Turabian StyleLi, Yonghong, and Ning Qin. 2022. "A Review of Flow Control for Gust Load Alleviation" Applied Sciences 12, no. 20: 10537. https://doi.org/10.3390/app122010537

APA StyleLi, Y., & Qin, N. (2022). A Review of Flow Control for Gust Load Alleviation. Applied Sciences, 12(20), 10537. https://doi.org/10.3390/app122010537