Enhancement of the Magnetic Properties in Si4+-Li+-Substituted M-Type Hexaferrites for Permanent Magnets

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

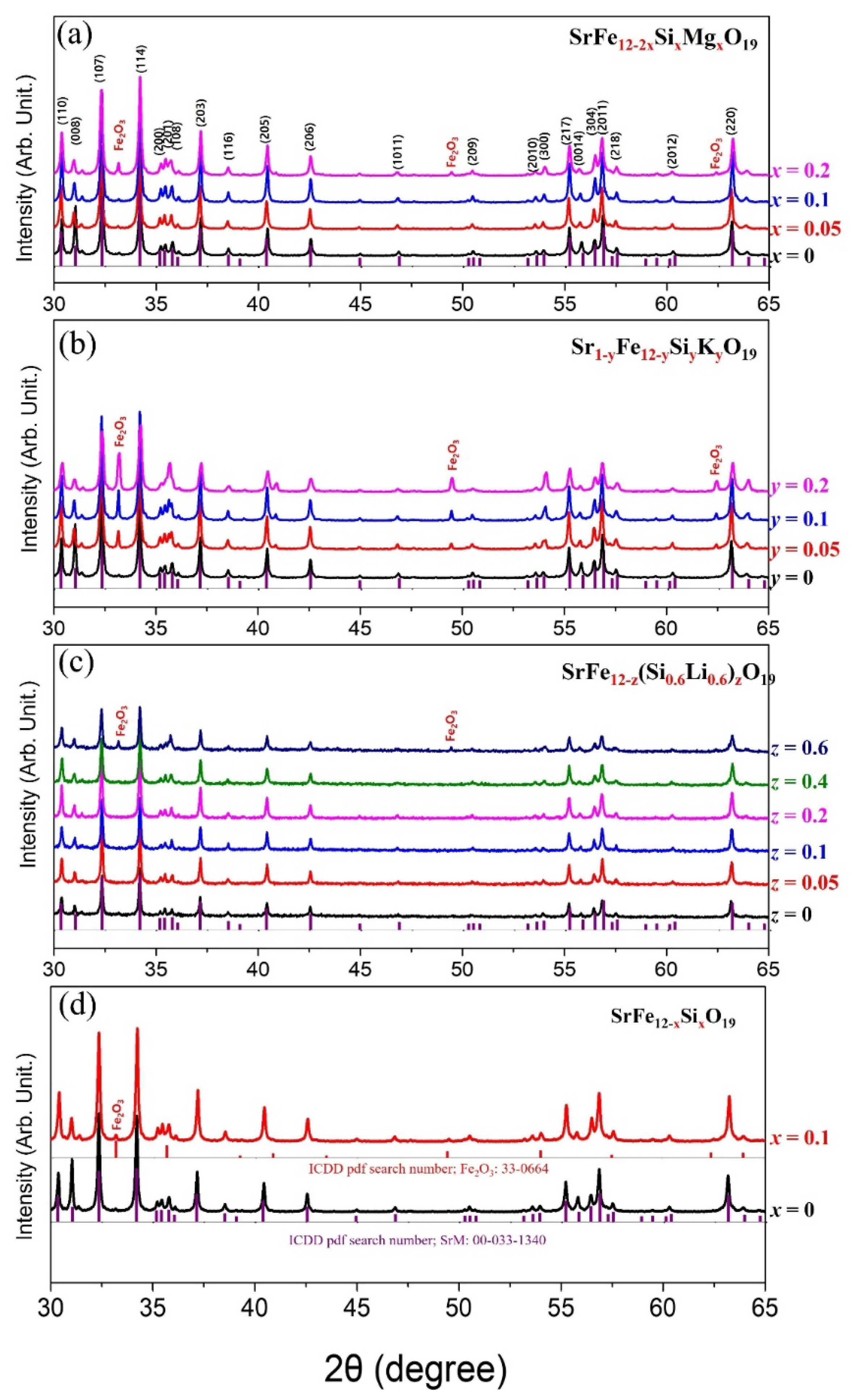

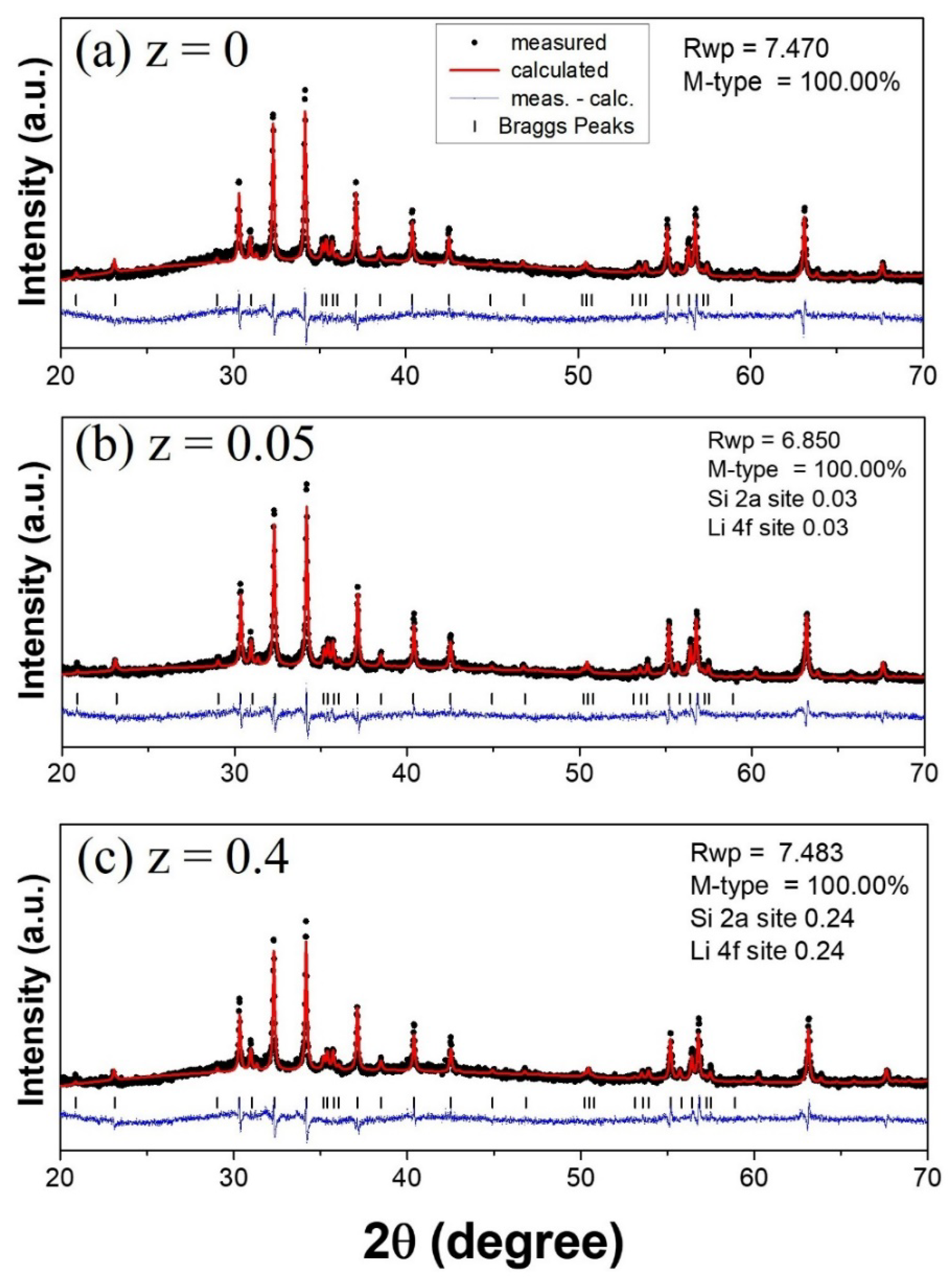

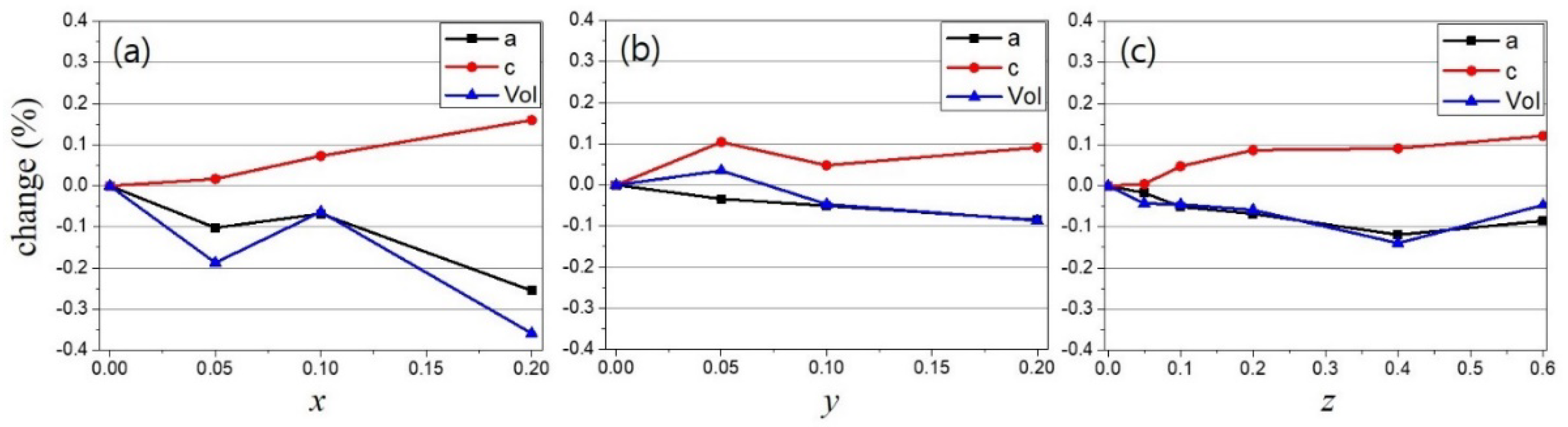

3.1. Crystalline Structure Analysis

3.2. Microstucture Analysis

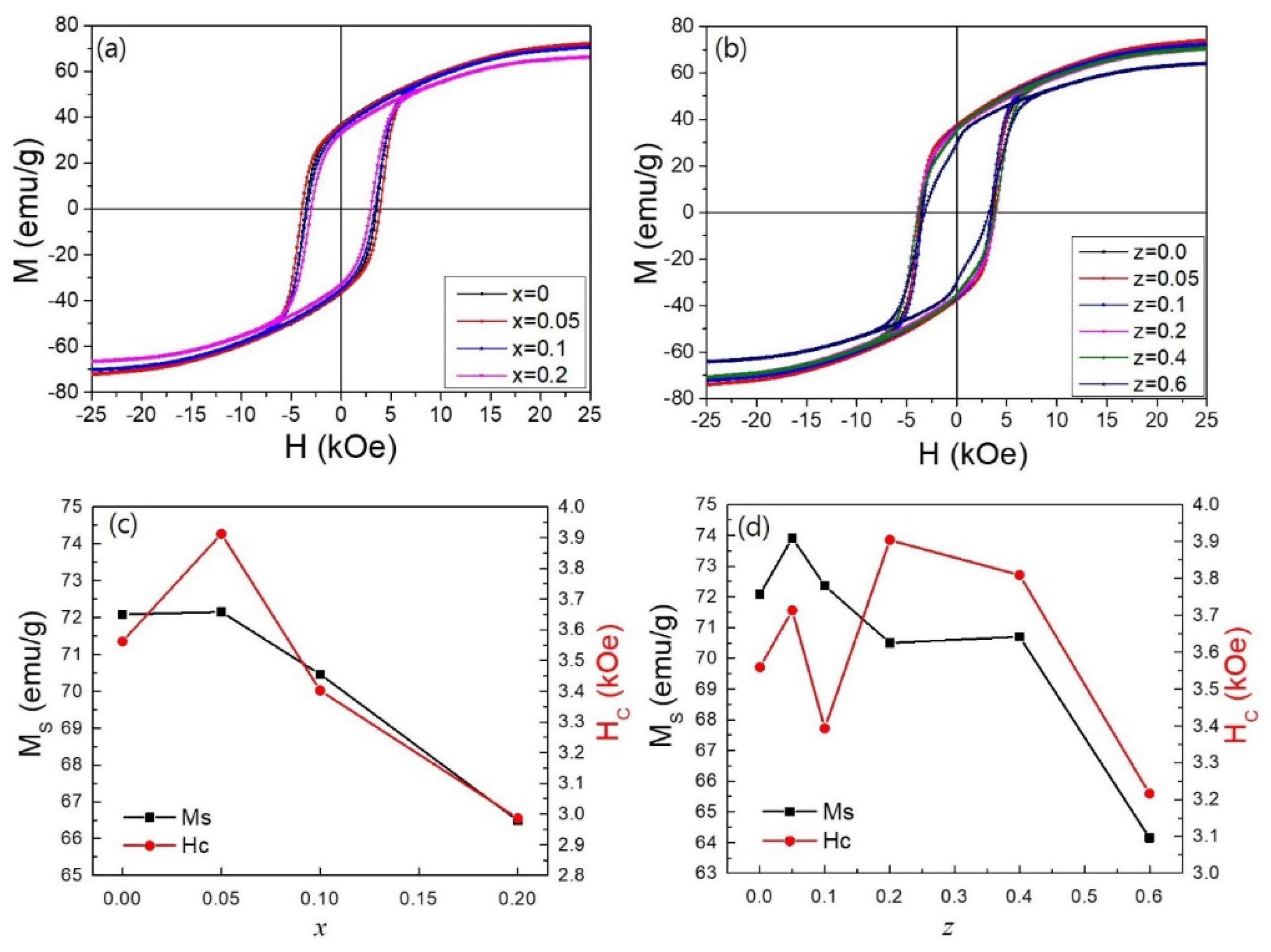

3.3. Magnetic Properties and Magnet Performances

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Went, J.J.; Rathenau, G.W.; Gorter, E.W.; Van Oosterhout, G.W. Ferroxdure. A Class of Permanent Magnetic Materials. Philips Tech. Rev. 1952, 13, 194–208. [Google Scholar]

- Ashiq, M.N.; Iqbal, M.J.; Najam-ul-Haq, M.; Gomez, P.H.; Qureshi, A.M. Synthesis, magnetic and dielectric properties of Er–Ni doped Sr-hexaferrite nanomaterials for applications in High density recording media and microwave devices. J. Magn. Magn. Mater. 2012, 324, 15–19. [Google Scholar] [CrossRef]

- Pullar, R.C. Hexagonal ferrites: A review of the synthesis, properties and applications of hexaferrite ceramics. Prog. Mater. Sci. 2012, 57, 1191–1334. [Google Scholar] [CrossRef]

- Taguchi, H. Recent improvements of ferrite magnets. J. Phys. IV Fr. 1997, 7, C1-299–C1-302. [Google Scholar] [CrossRef]

- Bai, J.; Liu, X.; Xie, T.; Wei, F.; Yang, Z. The effects of La–Zn substitution on the magnetic properties of Sr-magnetoplumbite ferrite nano-particles. Mater. Sci. Eng. 2000, 68, 182–185. [Google Scholar] [CrossRef]

- Kang, Y.-M.; Kwon, Y.-H.; Kim, M.-H.; Lee, D.-Y. Enhancement of magnetic properties in Mn-Zn substituted M-type Sr-hexaferrites. J. Magn. Magn. Mater. 2015, 382, 10–14. [Google Scholar] [CrossRef]

- Kools, F.; Morel, A.; Grössinger, R.; Le Breton, J.M.; Tenaud, P. LaCo-substituted ferrite magnets, a new class of high-grade ceramic magnets; intrinsic and microstructural aspects. J. Magn. Magn. Mater. 2002, 242–245, 1270–1276. [Google Scholar] [CrossRef]

- Ogata, Y.; Takami, T.; Kubota, Y. Development of La-Co substituted ferrite magnets. J. Jpn. Soc. Powder Metall. 2003, 50, 636–641. [Google Scholar] [CrossRef] [Green Version]

- Kobayashi, Y.; Hosokawa, S.; Oda, E.; Toyota, S. Magnetic properties and composition of Ca-La-Co M-type ferrites. J. Jpn. Soc. Powder Metall. 2008, 55, 541–546. [Google Scholar] [CrossRef] [Green Version]

- Kang, Y.-M.; Moon, K.-S. Magnetic properties of Ce-Mn substituted M-type Sr-hexaferrites. Ceram. Inter. 2015, 41, 12828–12834. [Google Scholar] [CrossRef]

- Barrera, V.; Betancourt, I. M-type hexaferrites with enhanced coercivity. IEEE Trans. Magn. 2013, 49, 4630–4633. [Google Scholar] [CrossRef]

- Wang, H.Z.; Yao, B.; Xu, Y.; He, Q.; Wen, G.H.; Long, S.W.; Fan, J.; Li, G.D.; Shan, L.; Lie, B.; et al. Improvement of the coercivity of strontium hexaferrite induced by substitution of Al3+ ions for Fe3+ ions. J. Alloys Comp. 2012, 537, 43–49. [Google Scholar] [CrossRef]

- Ahn, K.; Ryu, B.; Korolev, D.; Kang, Y.J. Substantial enhancement in intrinsic coercivity on M-type strontium hexaferrite through the increase in magneto-crystalline anisotropy by co-doping of group-V and alkali elements. Appl. Phys. Lett. 2013, 103, 242417. [Google Scholar] [CrossRef]

- Kang, Y.-M. High saturation magnetization in La–Ce–Zn–doped M-type Sr-hexaferrites. Ceram. Int. 2015, 41, 4354–4359. [Google Scholar] [CrossRef]

- Moon, K.-S.; Kang, Y.-M. Structural and magnetic properties of Ca-Mn-Zn-substituted M-type Sr-hexaferrites. J. Eur. Ceram. Soc. 2016, 36, 3383–3389. [Google Scholar] [CrossRef]

- Shekhawat, D.; Singh, A.K.; Roy, P.K. Structural and electro-magnetic properties of high (BH)max La-Sm substituted Sr-hexaferrite for brushless DC electric motors application. J. Mol. Struct. 2019, 1179, 787–794. [Google Scholar] [CrossRef]

- Eikeland, A.Z.; Stingaciu, M.; Mamakhel, A.H.; Saura-Múzquiz, M.; Christensen, M. Enhancement of magnetic properties through morphology control of SrFe12O19 nanocrystallites. Sci. Rep. 2018, 8, 7325. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, J.; Lee, E.J.; Hwang, T.-Y.; Kim, J.; Choa, Y.-H. Anisotropic characteristics and improved magnetic performance of Ca–La–Co-substituted strontium hexaferrite nanomagnets. Sci. Rep. 2020, 10, 15929. [Google Scholar] [CrossRef] [PubMed]

- Nishio, H.; Minachi, Y.; Yamamoto, H. Effect of factors on coercivity in Sr-La-Co sintered ferrite magnets. IEEE Trans. Magn. 2009, 45, 5281–5288. [Google Scholar] [CrossRef]

- Moon, K.-S.; Yu, P.-Y.; Kang, Y.-M. Microstructure and magnetic properties of La-Ca-Co substituted M-type Sr-hexaferrites with controlled Si diffusion. Appl. Sci. 2020, 10, 7570. [Google Scholar] [CrossRef]

| Composition | x, y, z | a (Å) | c (Å) | c/a | vol. (Å3) |

|---|---|---|---|---|---|

| SrFe12−2xSixMgxO19 | 0 | 5.885 | 23.055 | 3.917 | 691.50 |

| 0.05 | 5.879 | 23.059 | 3.922 | 690.21 | |

| 0.1 | 5.881 | 23.072 | 3.923 | 691.06 | |

| 0.2 | 5.870 | 23.092 | 3.934 | 689.02 | |

| Sr1−yFe12−ySiyKyO19 | 0.05 | 5.883 | 23.079 | 3.923 | 691.74 |

| 0.1 | 5.882 | 23.066 | 3.921 | 691.17 | |

| 0.2 | 5.880 | 23.076 | 3.925 | 690.90 | |

| SrFe12−z(Si0.6Li0.6)zO19 | 0.05 | 5.884 | 23.056 | 3.919 | 691.20 |

| 0.1 | 5.882 | 23.066 | 3.921 | 691.19 | |

| 0.2 | 5.881 | 23.075 | 3.924 | 691.09 | |

| 0.4 | 5.878 | 23.076 | 3.926 | 690.53 | |

| 0.6 | 5.880 | 23.083 | 3.926 | 691.18 |

| Composition | x, z | ρ (g/cm3) | MS (emu/g) | HC (Oe) |

|---|---|---|---|---|

| SrFe12−2xSixMgxO19 | 0 | 2.75 | 72.08 | 3562 |

| 0.05 | 2.87 | 72.15 | 3912 | |

| 0.1 | 2.91 | 70.46 | 3402 | |

| 0.2 | 4.07 | 66.49 | 2986 | |

| SrFe12−z(LizSiz)0.6O19 | 0 | 2.75 | 72.08 | 3559 |

| 0.05 | 3.09 | 73.92 | 3713 | |

| 0.1 | 3.24 | 72.36 | 3393 | |

| 0.2 | 3.23 | 70.5 | 3904 | |

| 0.4 | 3.90 | 70.7 | 3809 | |

| 0.6 | 3.84 | 64.15 | 3216 |

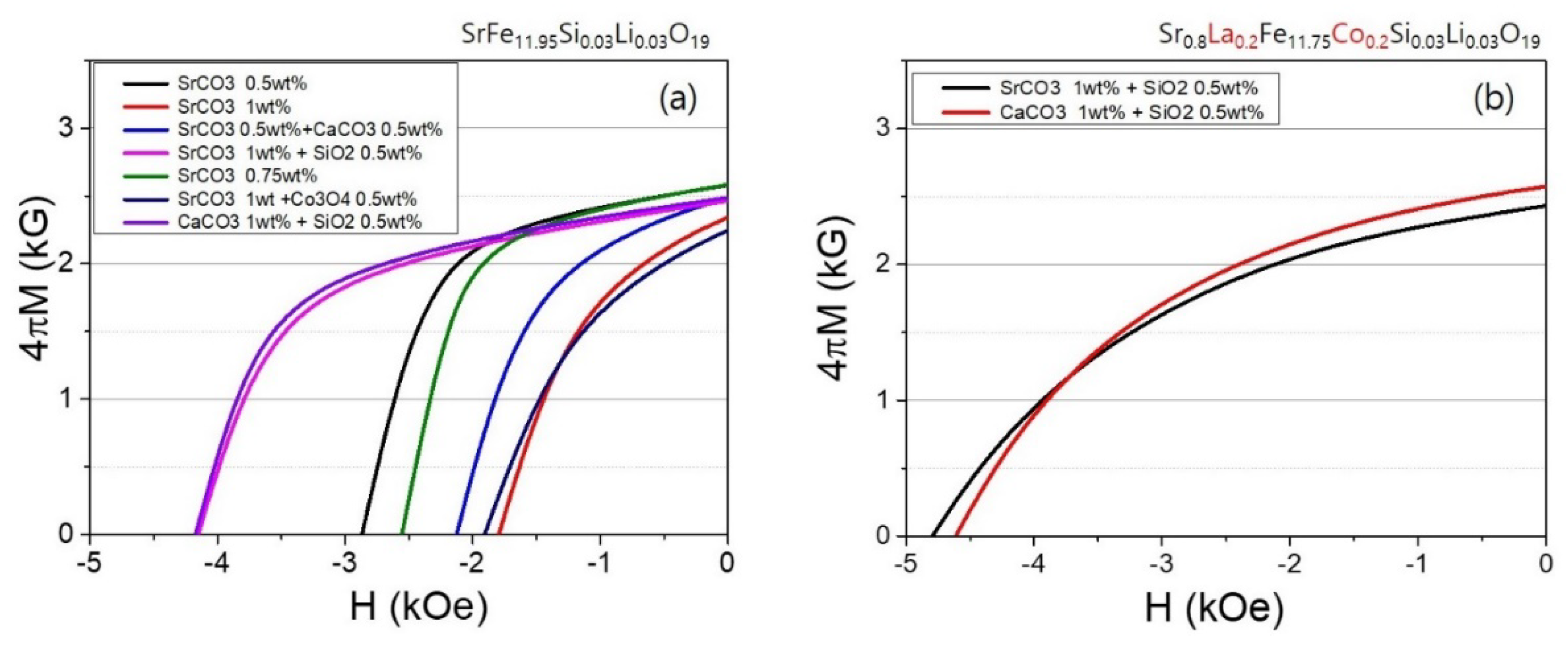

| Composition | Additives | ρ (g/cm3) | Br (G) | HC (Oe) |

|---|---|---|---|---|

| SrFe11.95Li0.03Si0.03O19 | SrCO3 0.5wt% | 4.92 | 2629 | 2878 |

| SrCO3 0.75 wt% | 4.93 | 2631 | 2554 | |

| SrCO3 1 wt% | 5.04 | 2459 | 1810 | |

| SrCO3 0.5 wt% + CaCO3 0.5 wt% | 5.04 | 2596 | 2129 | |

| SrCO3 1 wt% + SiO2 0.5 wt% | 4.70 | 2509 | 4149 | |

| SrCO3 1 wt% + Co3O4 0.5 wt% | 5.04 | 2375 | 1914 | |

| CaCO3 1 wt% + SiO2 0.5 wt% | 4.80 | 2528 | 4165 | |

| Sr0.8La0.2Fe11.75Co0.2Li0.03Si0.03O19 | SiO2 0.5 wt% + SrCO3 1.0 wt% | 4.68 | 2420 | 4786 |

| SiO2 0.5 wt% + CaCO3 1.0 wt% | 4.92 | 2582 | 4608 |

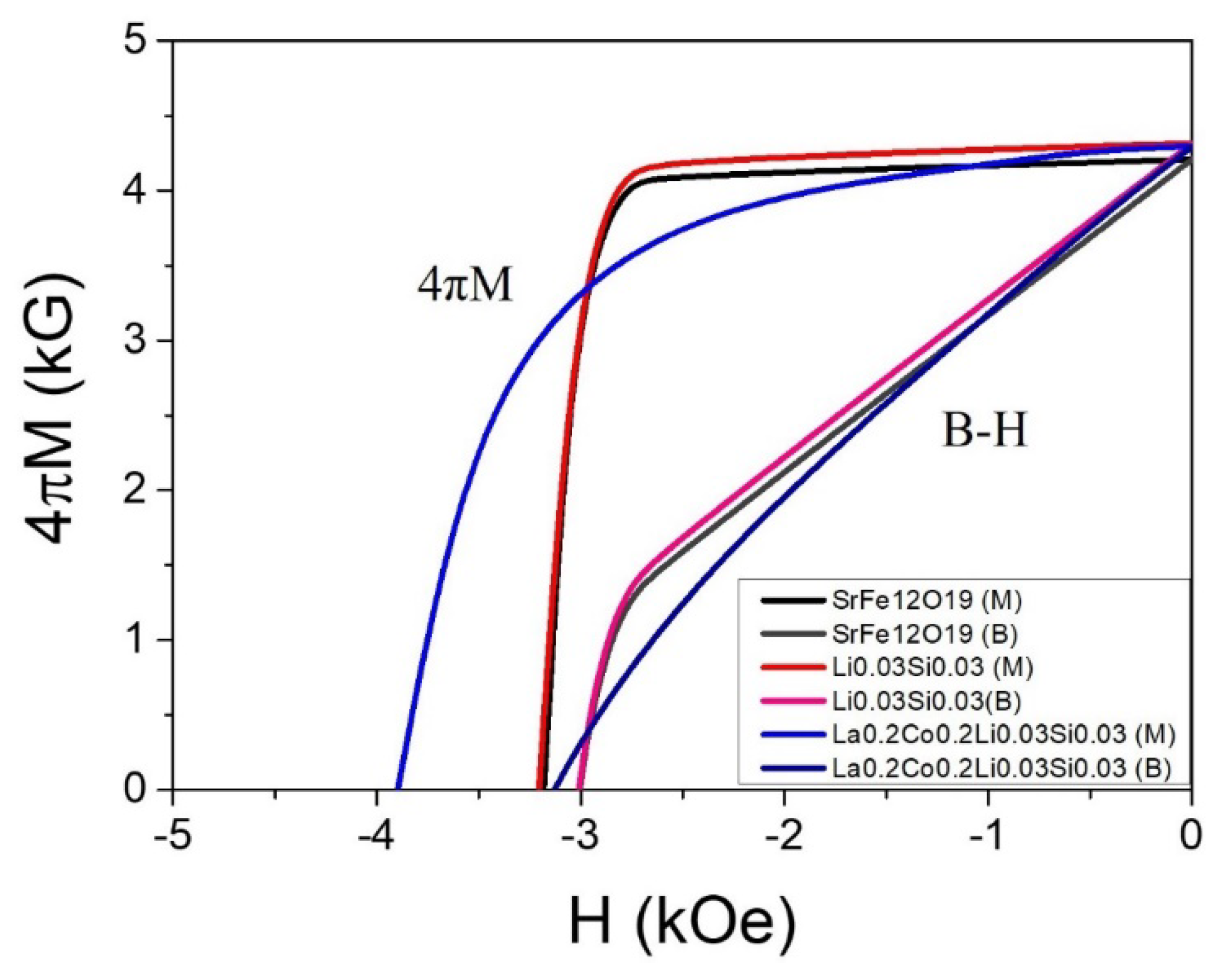

| Magnet Composition | ρ (g/cm3) | iHC (Oe) | bHC (Oe) | Br (G) | BHmax (M·G·Oe) |

|---|---|---|---|---|---|

| SrFe12O19 | 4.95 | 3182 | 3002 | 4207 | 4.24 |

| SrFe11.95Li0.03Si0.03O19 | 4.94 | 3206 | 3009 | 4314 | 4.46 |

| Sr0.8La0.2Fe11.75Co0.2Li0.03Si0.03O19 | 5.02 | 3897 | 3138 | 4293 | 3.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, J.-Y.; Lee, K.-H.; Kang, Y.-M.; Yoo, S.-I. Enhancement of the Magnetic Properties in Si4+-Li+-Substituted M-Type Hexaferrites for Permanent Magnets. Appl. Sci. 2022, 12, 12295. https://doi.org/10.3390/app122312295

You J-Y, Lee K-H, Kang Y-M, Yoo S-I. Enhancement of the Magnetic Properties in Si4+-Li+-Substituted M-Type Hexaferrites for Permanent Magnets. Applied Sciences. 2022; 12(23):12295. https://doi.org/10.3390/app122312295

Chicago/Turabian StyleYou, Jin-Young, Kang-Hyuk Lee, Young-Min Kang, and Sang-Im Yoo. 2022. "Enhancement of the Magnetic Properties in Si4+-Li+-Substituted M-Type Hexaferrites for Permanent Magnets" Applied Sciences 12, no. 23: 12295. https://doi.org/10.3390/app122312295