Process Improvement and Application of Pavement Management System Based on Pavement Conditions in Jeju Island

Abstract

:1. Introduction

2. Literature Review

2.1. Studies on Pavement Condition Indexes and Factors That Influence Performance

2.2. Studies on Development of Pavement Management Strategies for Local Roads

2.3. Methods of Road Segmentation

3. Methodology

3.1. Dataset Construction

3.2. Condition Index Development

3.3. Pavement Segmentation for Management

4. Development of Jeju Pavement Condition Index

4.1. Analysis Results for Jeju Island Pavement Condition Status

4.2. Data Calibration

4.3. Index Development According to Distress Type

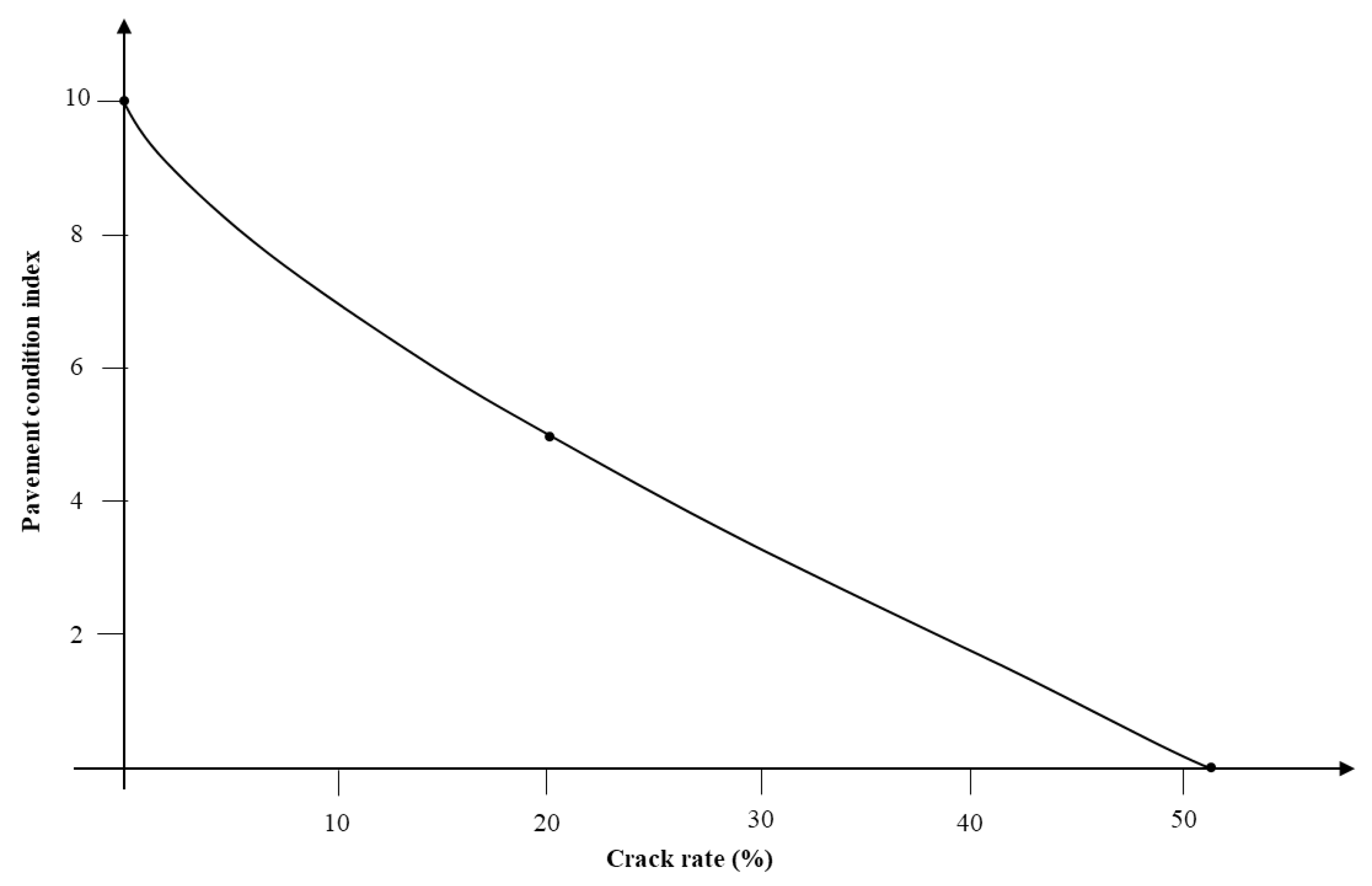

4.3.1. Crack Rate Index

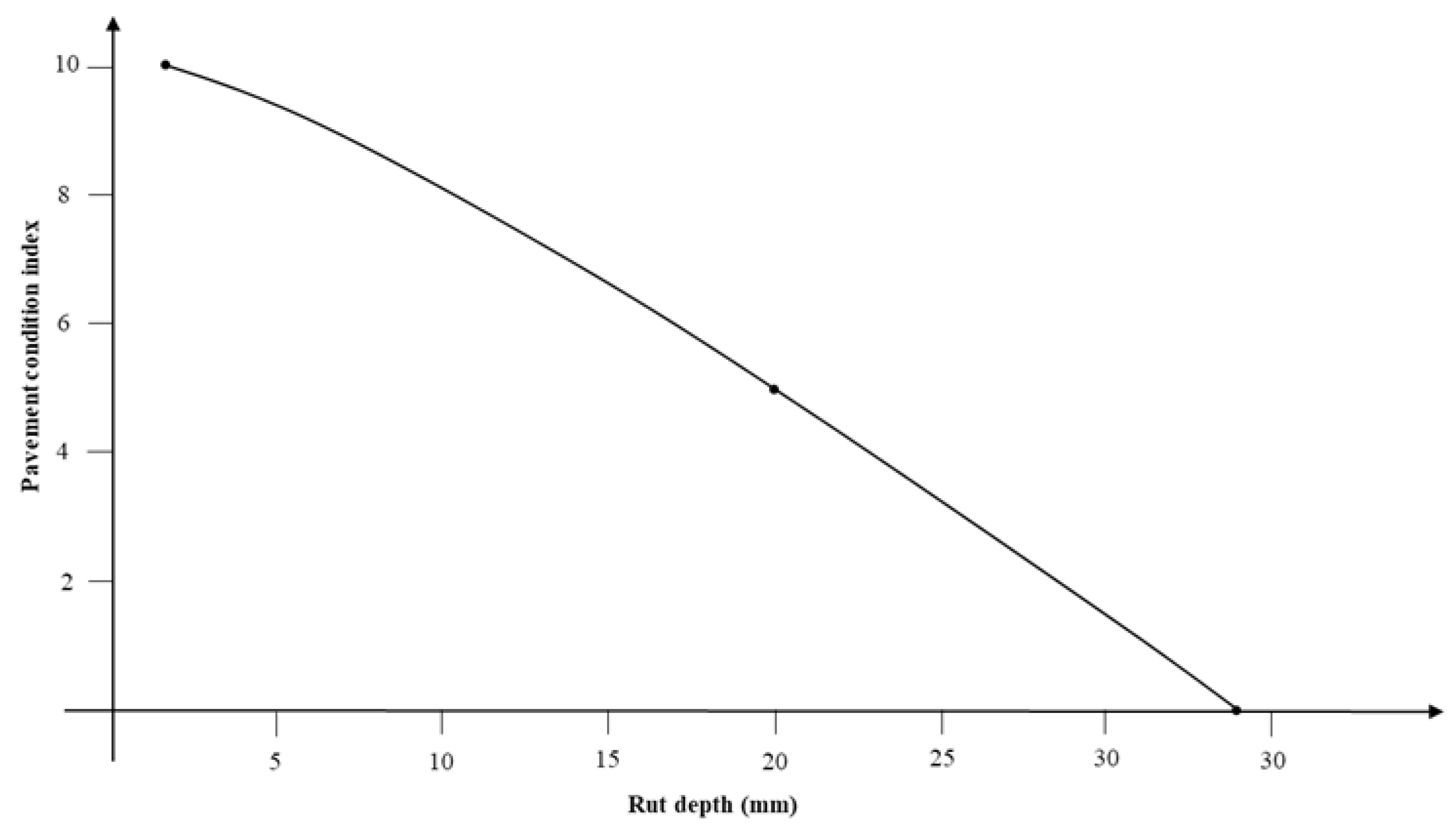

4.3.2. Rut Depth Index

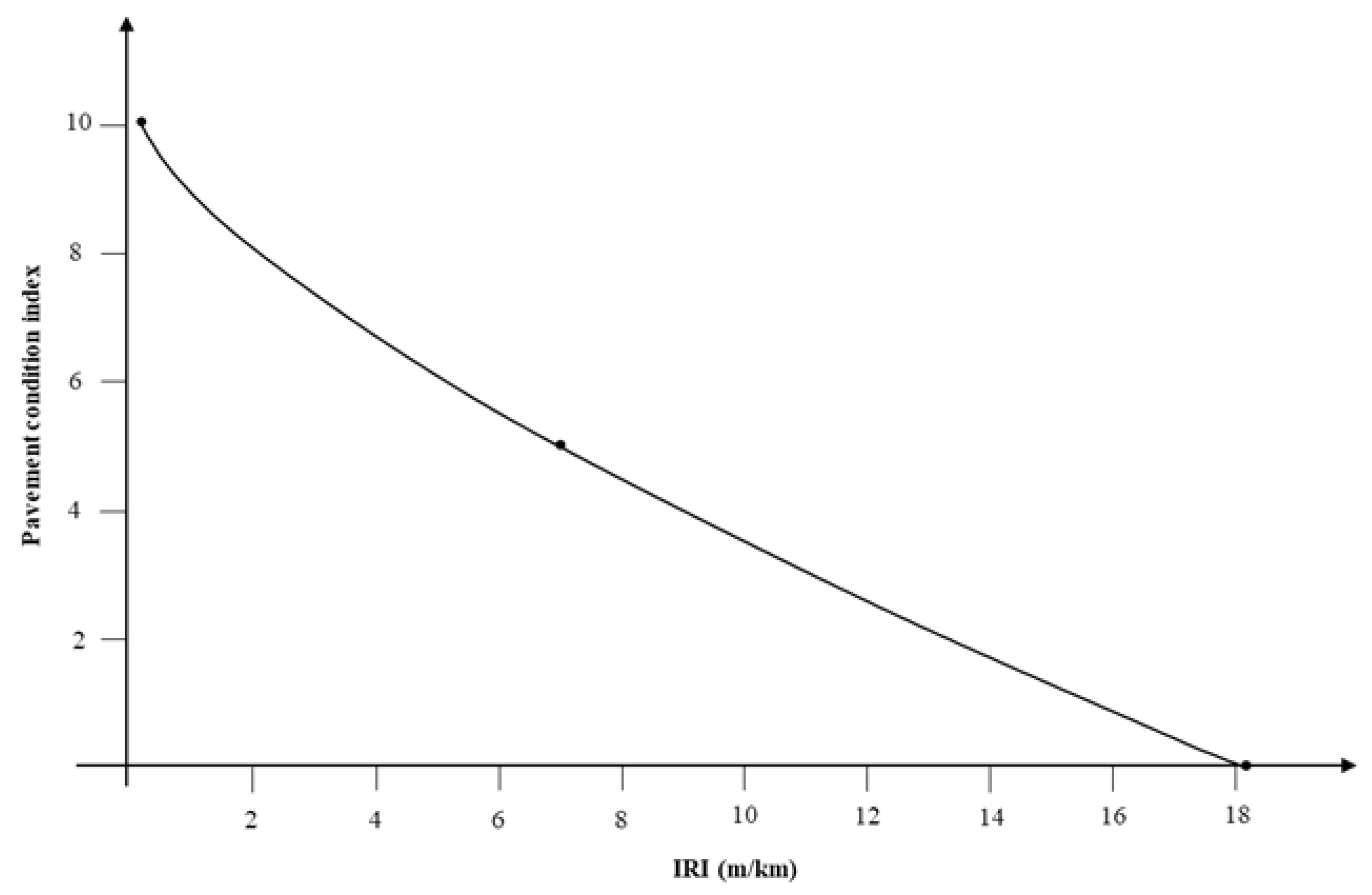

4.3.3. Roughness Index

4.3.4. Combined Index

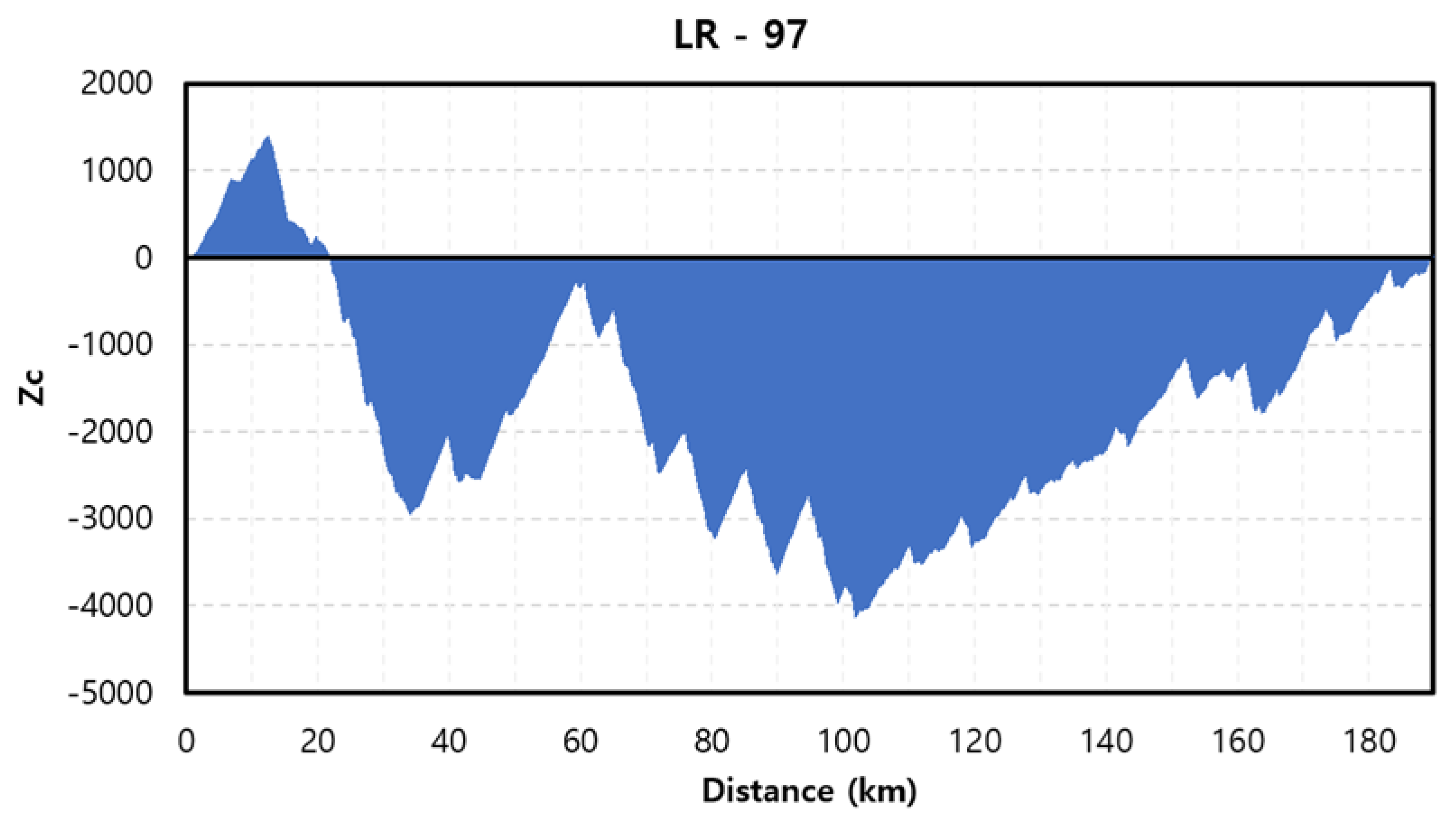

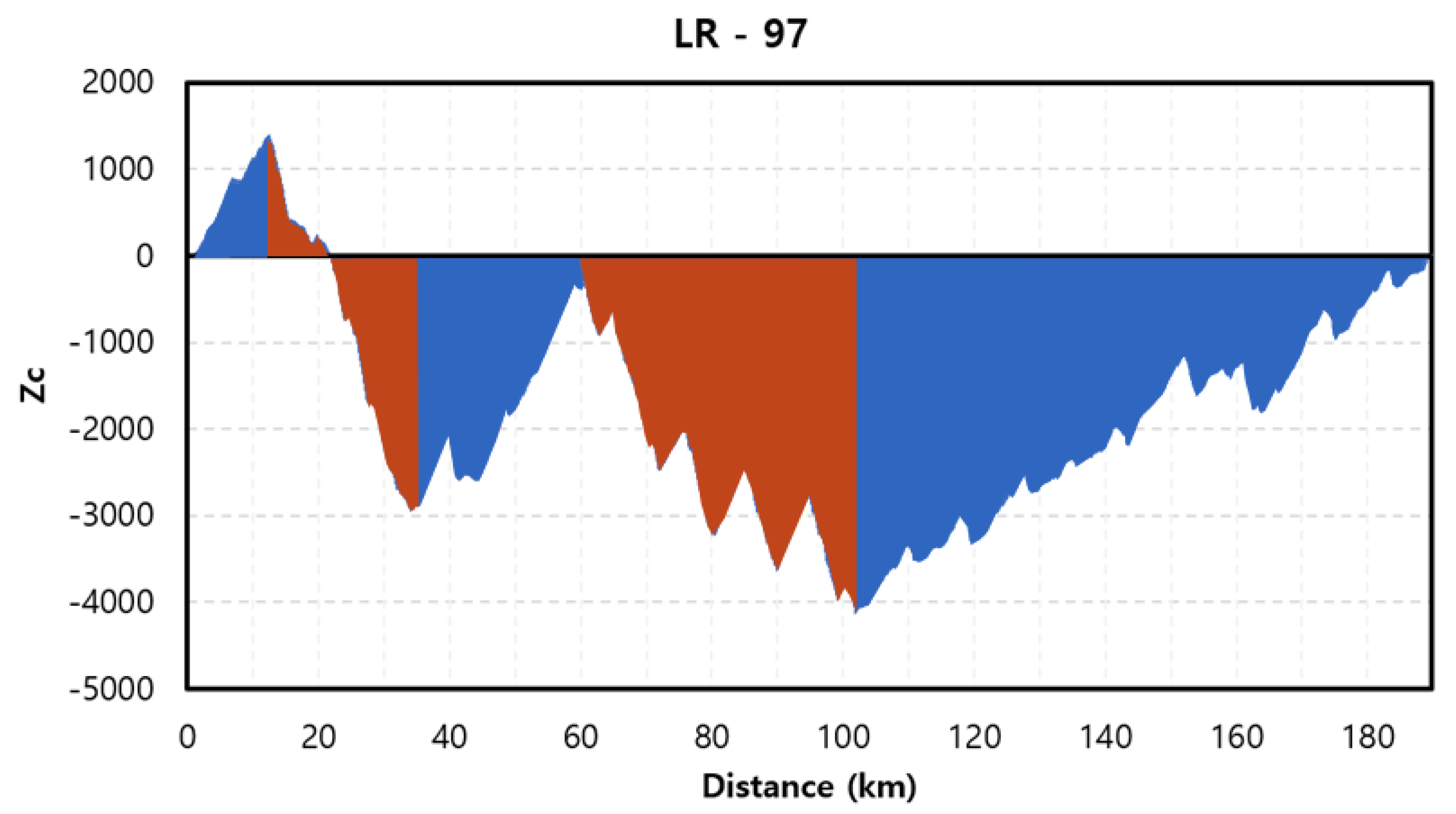

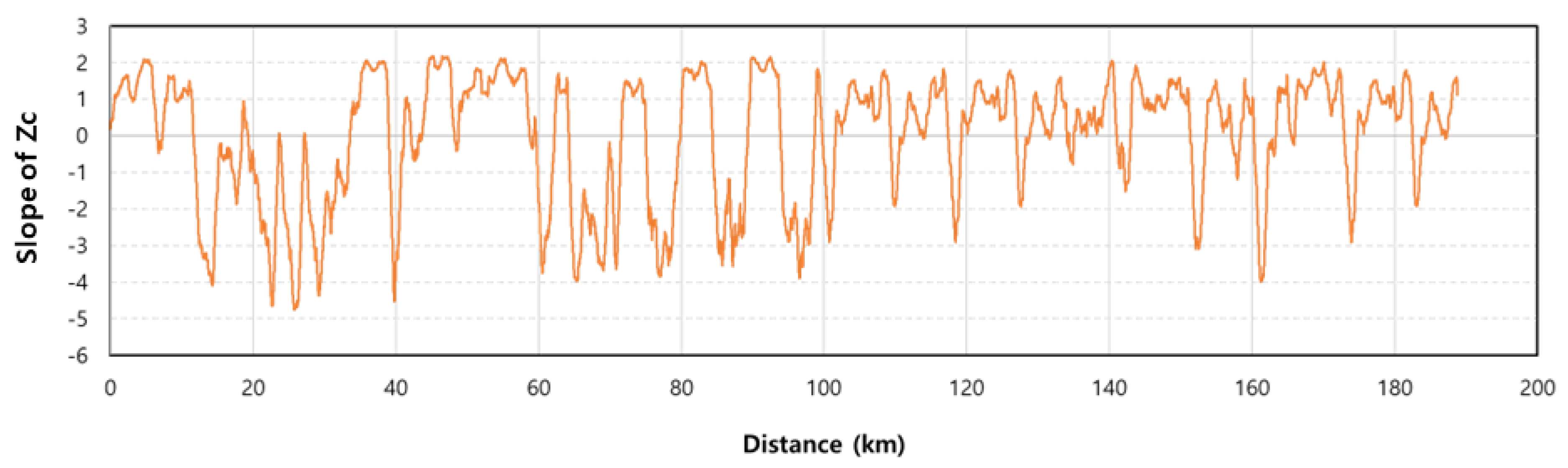

5. Pavement Segmentation Using JPCI-Based Cumulative Difference Approach; Case of LR-97

5.1. First Segmentation

5.2. Second Segmentation

5.3. Priority Selection Based on Repair Budget–LR-97 Case Study Standard

6. Conclusions

- JPCI was developed based on results that reflect the distribution (maximum, minimum, and management standard) of pavement conditions in the entire target road in terms of the following three factors: crack rate, rut depth, and roughness. Because of its basic model form, the process proposed in this study is likely to have an increased applicability;

- The representative distress type in Jeju Island pavements was determined to be the crack rate. In practice, the management standard for this fault type was set at 20%; however, before the introduction of PMS management, it was difficult to distinguish, based on visual inspections, whether cracks have occurred while users are driving vehicles on the road, or the difference between, for example, 20% and 30%. As such, it was assessed that the proportion of sections that exceeded the management standard was higher than in the case of rutting or roughness. Although rut depth and roughness are also managed based on certain standards, specifically 20 mm and 7 m/km, respectively, these two distress types are easily felt, and furthermore, these factors have a big effect on the driving performance and driving comfort of road users. Therefore, it was inferred that these fault types are managed more strictly than the crack rate and thus include few values that greatly deviate from the management standard;

- Through a smoothing process that is based on CDA results, it was possible to perform segmentation that reflects the characteristics of the Zc values. The smoothing process was performed using a moving average, and the variable range was set to be the minimum length for a repair section. In this study, segmentation was performed until the completion of the second decision-making, which was based on the minimum repair length. However, it was inferred that more practical results can be derived if judgment by a manager or engineer is used to perform merging and diverging of the sections that were determined to be in need of repair;

- In the case of LR-97, when the amount of repair was calculated using CDA, the budget increased to approximately 154% of the budget for when the repair sections were selected using only JPCI. These results occurred because CDA performs segmentation based on the extent to which values deviate from the average for the target section rather than the physical size of the JPCI value. Thus, from a macroscopic point of view, there is a proportion of good sections that are included among the sections that need repair. Nonetheless, it was judged that this can be used as evidentiary data for decision-making regarding preventative overlays.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Ministry of Land, Infrastructure and Transport. MOLIT Statistics System, Road Status Survey; Ministry of Land, Infrastructure and Transport: Sejong, Republic of Korea, 2019.

- Ministry of Land, Infrastructre and Transport. 2021 PMS Final Report; Ministry of Land, Infrastructure and Transport: Sejong, Republic of Korea, 2021. (In Korean)

- Korea Institute of Civil Engineering and Building Technology. 2020 Operation and Improvement of the Jeju Pavement Management System(PMS); Korea Institute of Civil Engineering and Building Technology: Goyang-si, Republic of Korea, 2020. (In Korean) [Google Scholar]

- Jin, M.S.; Song, Y.W. Development of Pavement Condition Index for Asphalt Pavement. Int. J. Highw. Eng. 2004, 6, 55–63. [Google Scholar]

- Suh, Y.C.; Kwon, S.H.; Jung, D.H.; Jeong, J.H.; Kang, M.S. Development of HPCI Prediction Model for Concrete Pavement Using Expressway PMS Database. Int. J. Highw. Eng. 2017, 19, 83–95. [Google Scholar] [CrossRef]

- Sirhan, M.; Bekhor, S.; Sidess, A. Implementation of Deep Neural Networks for Pavement Condition Index Prediction, American Society of Civil Engineers. J. Transp. Eng. Part B 2022, 148, 04021070. [Google Scholar] [CrossRef]

- Issa, A.; Samaneh, H.; Ghanim, M. Predicting pavement condition index using artificial neural networks approach. Ain Shams Eng. J. 2021, 13, 101490. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, J.H.; Kim, Y.T.; Lee, K.H.; Ohm, B.S.; Woo, B.C.; Jeong, J.H. Analysis of Factors Affecting Performance of Jeju Island Local Pavement. Int. J. Highw. Eng. 2022, 24, 39–51. [Google Scholar] [CrossRef]

- MoLIT. Road Condition, e-National Indicators. Available online: https://www.http://www.index.go.kr/ (accessed on 17 November 2022).

- Moon, H.C.; Suh, Y.C. Development of Pavement Condition Index for the Municipal Pavements. Int. J. Highw. Eng. 2008, 10, 221–230. [Google Scholar]

- Imam, A.I.; Suleiman, A. Development of a Flexible Pavement Condition Rating Model Using Multi-attribute Utility Theory. Int. J. Pavement Res. Technol. 2022, 1–22. [Google Scholar] [CrossRef]

- Shah, Y.U.; Jain, S.S.; Tiwari, D.; Jain, M.K. Development of Overall Pavement Condition Index for Urban Road Network. Soc. Behav. Sci. 2013, 104, 332–341. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.Y.; Prozzi, J.A. Segmentation of Highway Networks for Maintenance Operations, Technical Report, CHPP Report-UTA#8-2021. 2021. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwi50Nf-w-n7AhXEDKYKHYtqDCEQFnoECA8QAQ&url=https%3A%2F%2Fwww.chpp.egr.msu.edu%2Fwp-content%2Fuploads%2F2021%2F10%2F31.-CHPP-Report-UTA8-2021.pdf&usg=AOvVaw2He21ZOC1l9TTHh-0DoXBV (accessed on 17 November 2022).

- Prashant, R.P.; Zala, L.B.; Amit, A.A. Flexible Pavement Overlay Design Using Cumulative Difference Approach of Homogeneous Section. Int. J. Tech. Innov. Morden Eng. Sci. (IJTIMES) 2018, 4, 474–483. [Google Scholar]

- Thomas, F. Generating Homogeneous Road Sections Based on Surface Measurements: Available Methods. In Proceedings of the 2nd European Pavement and Asset Management Conference, Berlin Germany, 21–23 March 2004; Statens väg-och transportforskningsinstitut: Linköping, Sweden, 2004. [Google Scholar]

- El Gendy, A.; Shalaby, A. Using quality control charts to segment road surface condition data. In Proceedings of the Seventh International Conference on Managing Pavement Assets, ICMPA 2008, Calgary, AB, Canada, 23–28 June 2008. [Google Scholar]

- Misra, R.; Das, A. Identification of Homogeneous Sections from Road Data. Int. J. Pavement Eng. 2003, 4, 229–233. [Google Scholar] [CrossRef]

- AASHTO. AASHTO Guide for design of pavement structure Appendix J: Analysis Unit Delineation By Cumulative Differences; American Association of State Highway and Transportation Official: Washington, DC, USA, 1993.

- Cafiso, S.; Graziano, A.D. Definition of Homogenous Sections in Pavement Measurements. Soc. Behav. Sci. 2012, 53, 1069–1079. [Google Scholar] [CrossRef] [Green Version]

- Arhin, S.A.; Williams, L.N.; Ribbiso, A.; Anderson, M.F. Predicting Pavement Condition Index Using International Roughness Index in a Dense Urban Area. J. Civ. Eng. Res. 2015, 5, 10–17. [Google Scholar] [CrossRef]

- Lee, J.H.; Jung, D.H.; Lee, M.S.; Jeon, S.I. A Feasibility Study for the Prediction of Concrete Pavement Condition Index (CPCI) Based on Machine Learning. Appl. Sci. 2022, 12, 8731. [Google Scholar] [CrossRef]

- Korea Institute of Civil Engineering and Building Technology. 2021 Operation and Improvement of the Jeju Pavement Management System(PMS); Korea Institute of Civil Engineering and Building Technology: Goyang-si, Republic of Korea, 2021. (In Korean) [Google Scholar]

| Distress Type | Minimum Value | Maximum Value |

|---|---|---|

| Crack rate (%) | 0.00 | 51.943 |

| Rut Depth (mm) | 1.76 | 33.92 |

| IRI (m/km) | 0.2 | 18.17 |

| JPCI Rate | Class | Pavement Condition | Action |

|---|---|---|---|

| 8–10 | Very Good | Almost-good-as-new pavement | Do nothing |

| 6–8 | Good | Partial damage | General/Preventive maintenance |

| 4–6 | Fair | Intermittent breakage observed (“JPCI = 5” corresponds to crack rate over 20% or rut depth over 20 mm or IRI over 7 m/km) | Preventive maintenance/ M&R strategy required |

| 2–4 | Poor | Structural distress or deterioration occurred | Large-scale rehabilitation (overlay, inlay, etc.) required |

| 0–2 | Very Poor | Large scale distresses are widely distributed over the section | Reconstruction |

| Route | Length (km) | Avg. | Rank (by JPCI) |

|---|---|---|---|

| Total | 2053.41 | 7.033 | - |

| LR-1132 | 122.91 | 6.912 | 6 |

| LR-1131 | 421.35 | 7.173 | 3 |

| LR-97 | 189.76 | 6.335 | 9 |

| LR-1136 | 847.77 | 7.169 | 4 |

| LR-1115 | 77.47 | 6.127 | 10 |

| LR-1117 | 42.10 | 7.148 | 5 |

| LR-1118 | 74.13 | 6.599 | 7 |

| LR-1135 | 114.10 | 7.776 | 1 |

| LR-1139 | 76.00 | 6.462 | 8 |

| LR-Aejoro | 87.82 | 7.376 | 2 |

| 1st Decision | 2nd Decision | |||

|---|---|---|---|---|

| M&R Not Needed | M&R Needed | M&R Not Needed | M&R Needed | |

| Length (km·lane) | 117.17 | 86.71 | 118.64 | 71.12 |

| JPCI avg. | 7.53 | 4.38 | 7.45 | 4.38 |

| Criteria | Length | M&R Required Length | Budget for M&R (won) | M&R Ratio |

|---|---|---|---|---|

| JPCI | 189.76 km | 46.32 km | 4.076 billion | 24.41% |

| CDA | 71.12 km | 6.259 billion | 37.48% |

| No. | Start Point | End Point | Length (km·Lane) | JPCI Avg. | Priority |

|---|---|---|---|---|---|

| 1 | 11.65 | 33.6 | 21.95 | 4.37 | 6 |

| 2 | 39.03 | 41.13 | 2.1 | 3.93 | 3 |

| 3 | 42.13 | 43.66 | 1.53 | 6.00 | 17 |

| 4 | 58.76 | 62.26 | 3.5 | 4.49 | 7 |

| 5 | 64.28 | 71.62 | 7.34 | 3.80 | 1 |

| 6 | 75.07 | 79.91 | 4.84 | 3.80 | 1 |

| 7 | 84.4 | 89.36 | 4.96 | 4.00 | 4 |

| 8 | 93.93 | 98.73 | 4.8 | 3.90 | 2 |

| 9 | 99.8 | 101.64 | 1.84 | 4.50 | 10 |

| 10 | 109.35 | 111.22 | 1.87 | 5.30 | 15 |

| 11 | 117.45 | 119.29 | 1.84 | 4.50 | 10 |

| 12 | 127 | 128.87 | 1.87 | 5.30 | 15 |

| 13 | 141.07 | 143 | 1.93 | 5.20 | 12 |

| 14 | 151.37 | 153.59 | 2.22 | 4.30 | 5 |

| 15 | 157.14 | 158.43 | 1.29 | 5.60 | 16 |

| 16 | 160.29 | 163.37 | 3.08 | 4.60 | 11 |

| 17 | 172.94 | 174.78 | 1.84 | 4.50 | 10 |

| 18 | 182.49 | 184.36 | 2.32 | 5.30 | 15 |

| Total | 71.12 | 4.38 | - | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ohm, B.-S.; Jung, D.-H.; Lee, S.-H.; Choi, J.-Y.; Kim, Y.-M. Process Improvement and Application of Pavement Management System Based on Pavement Conditions in Jeju Island. Appl. Sci. 2022, 12, 12548. https://doi.org/10.3390/app122412548

Ohm B-S, Jung D-H, Lee S-H, Choi J-Y, Kim Y-M. Process Improvement and Application of Pavement Management System Based on Pavement Conditions in Jeju Island. Applied Sciences. 2022; 12(24):12548. https://doi.org/10.3390/app122412548

Chicago/Turabian StyleOhm, Byung-Sik, Dong-Hyuk Jung, Su-Hyung Lee, Ji-Young Choi, and Yeong-Min Kim. 2022. "Process Improvement and Application of Pavement Management System Based on Pavement Conditions in Jeju Island" Applied Sciences 12, no. 24: 12548. https://doi.org/10.3390/app122412548