Tension Performance of Precast Bridge Deck Longitudinal Joints with Different Configurations

Abstract

:1. Introduction

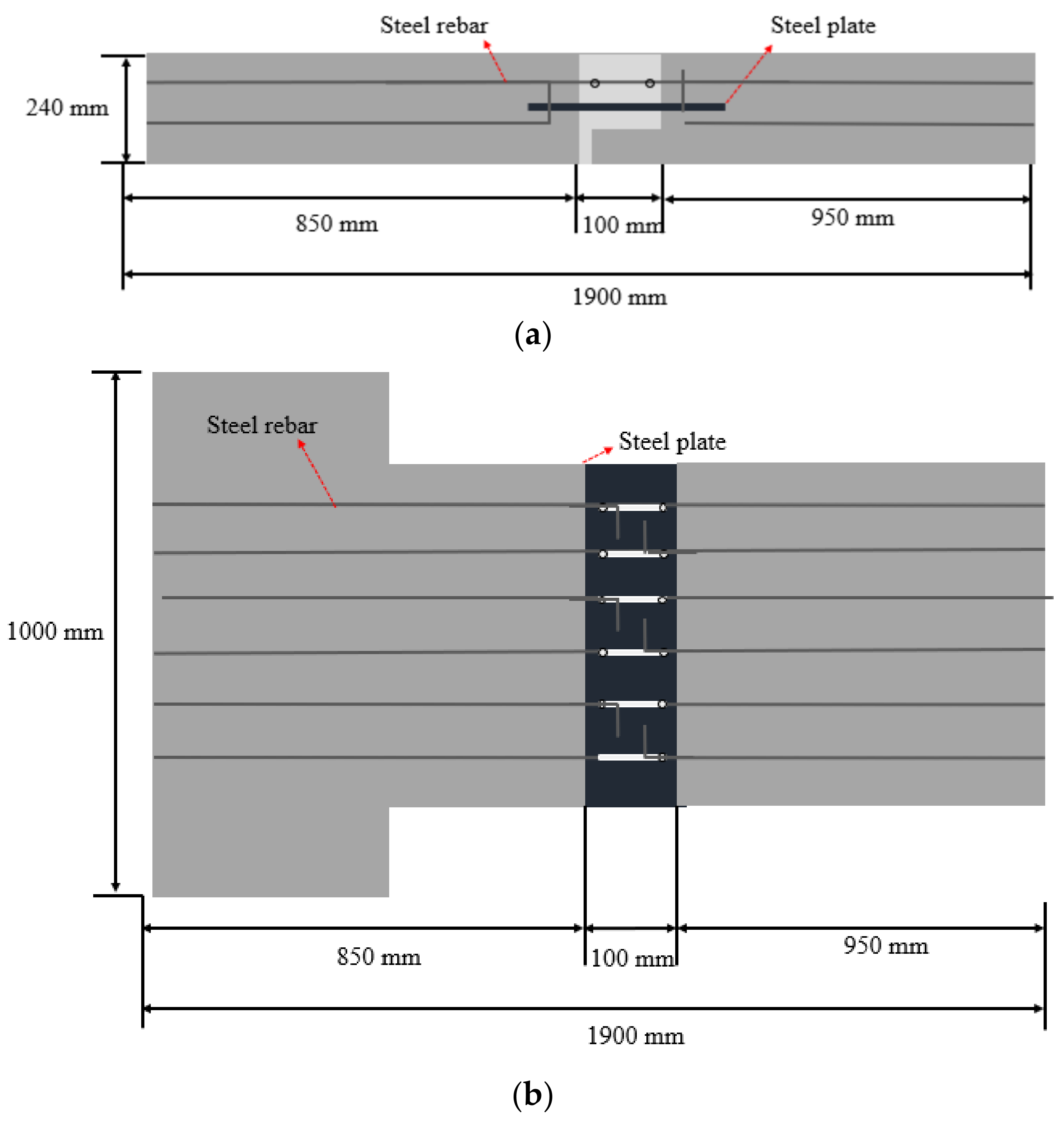

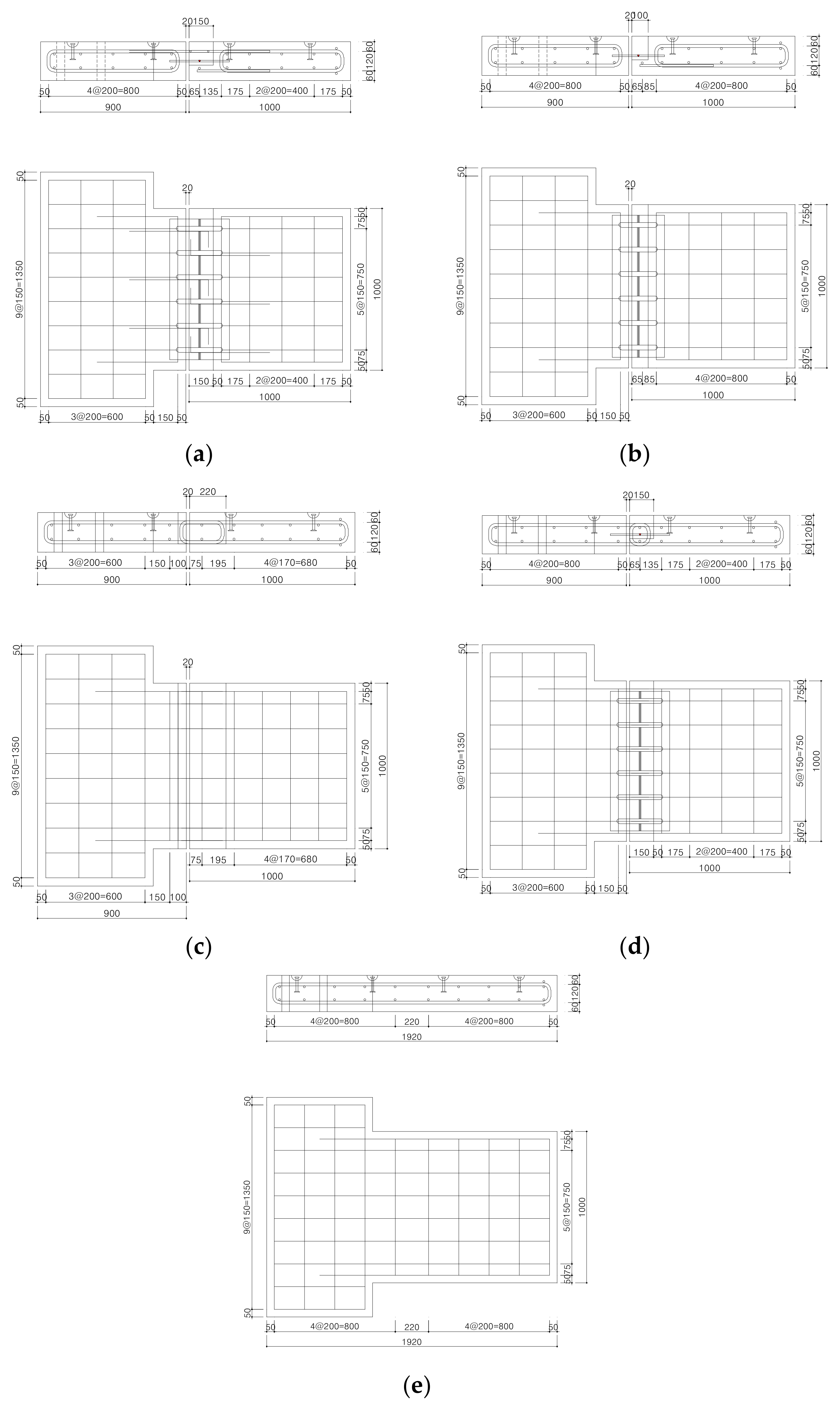

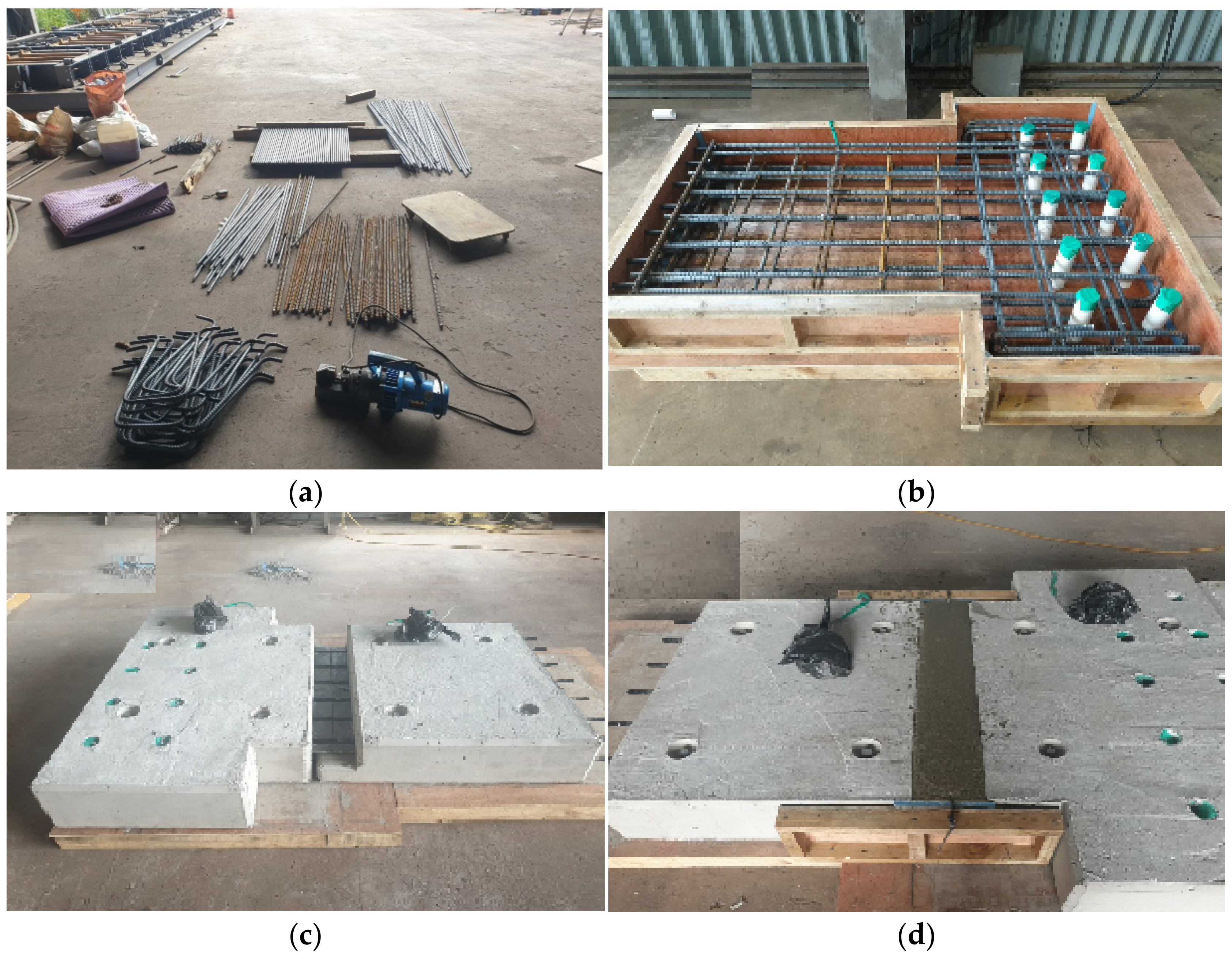

2. Materials and Methods

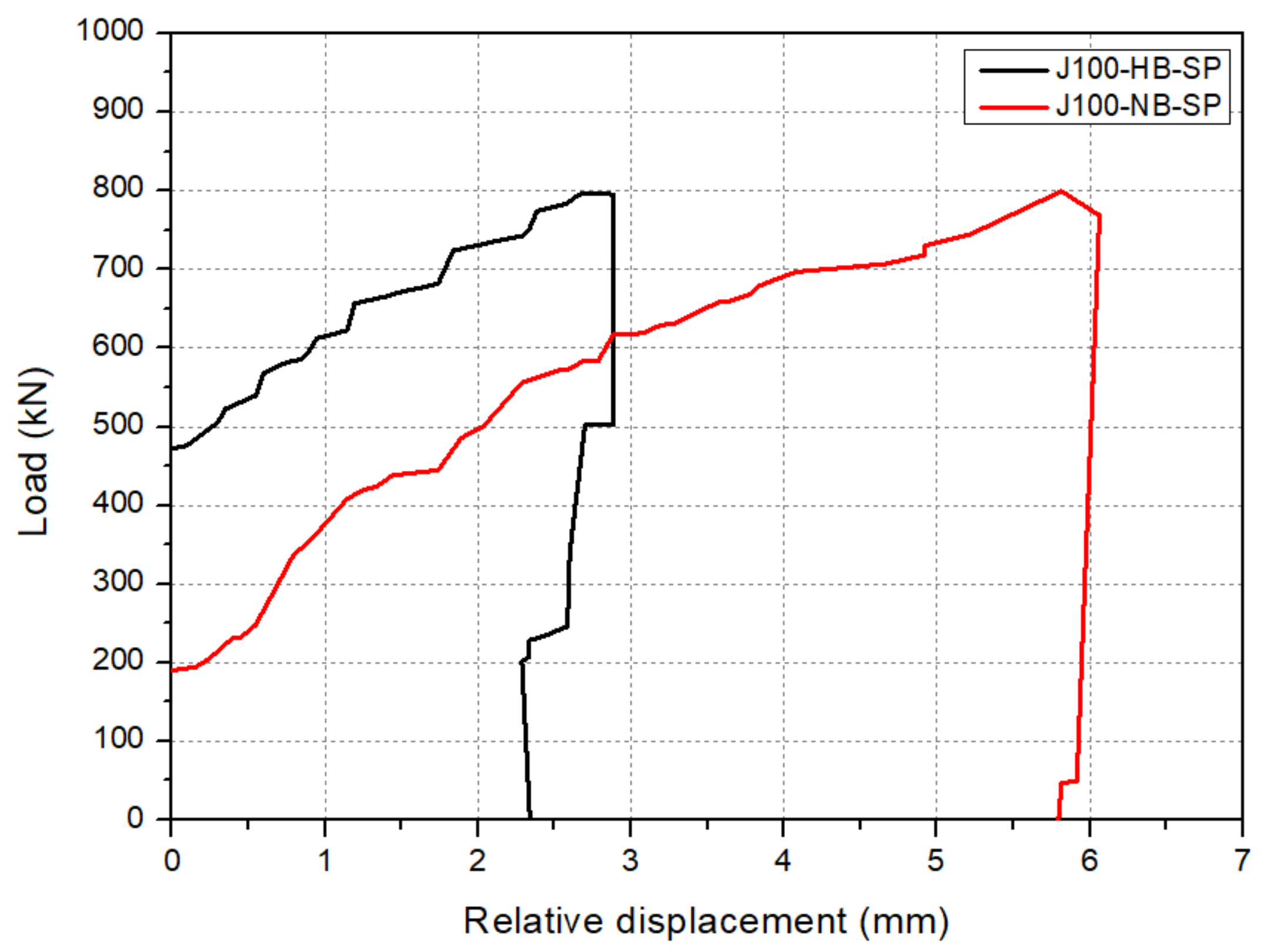

3. Results and Discussion

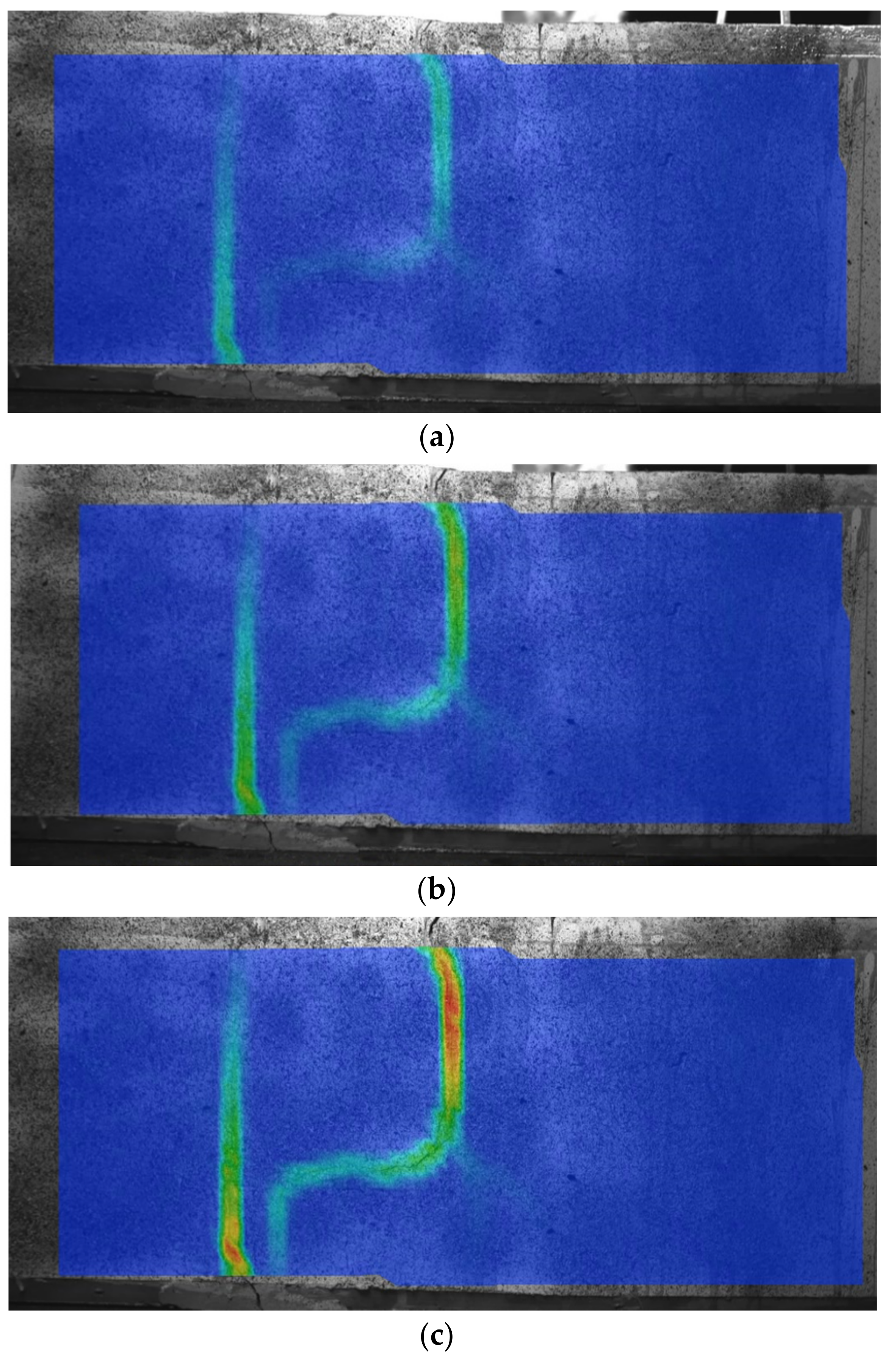

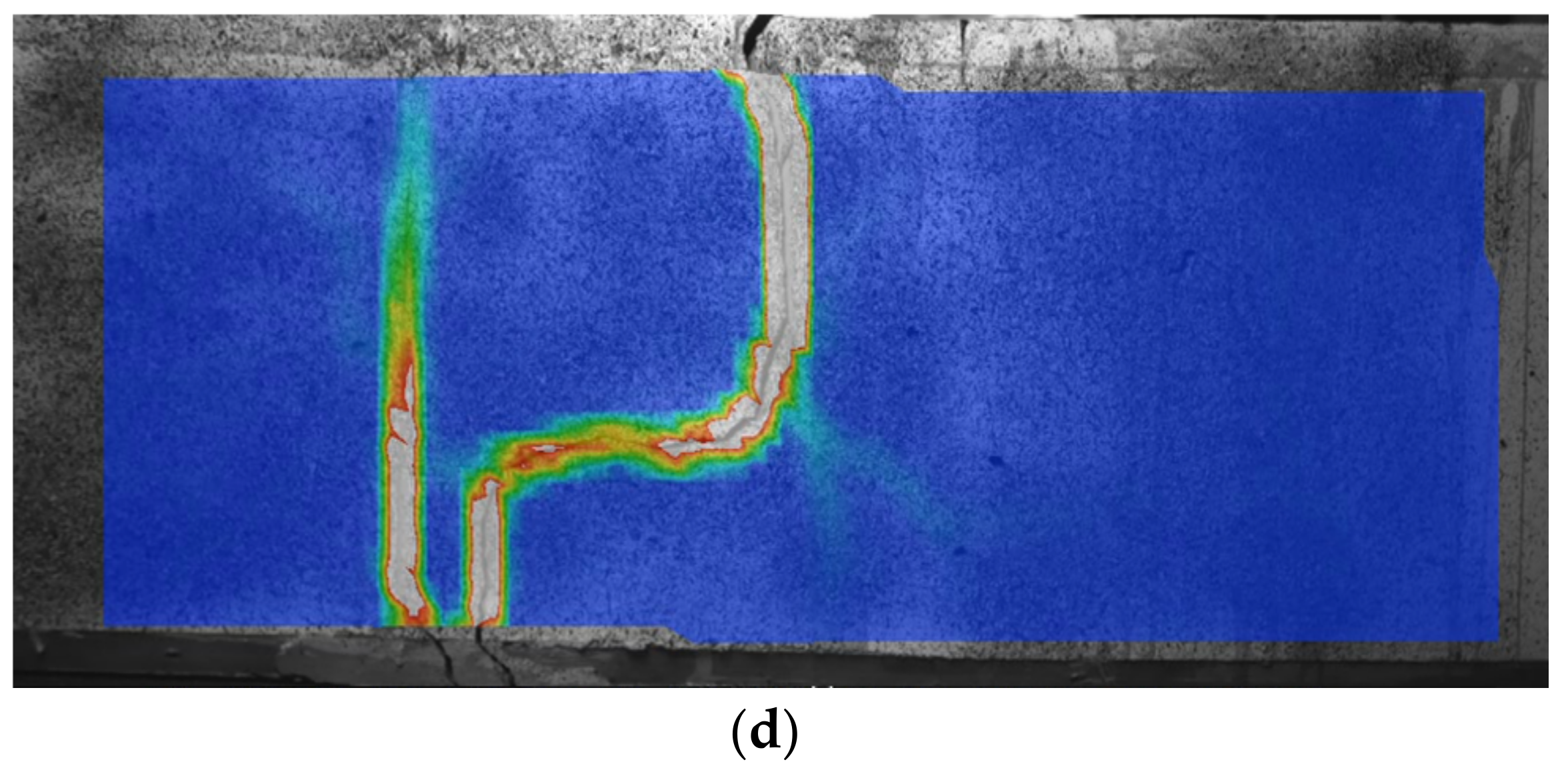

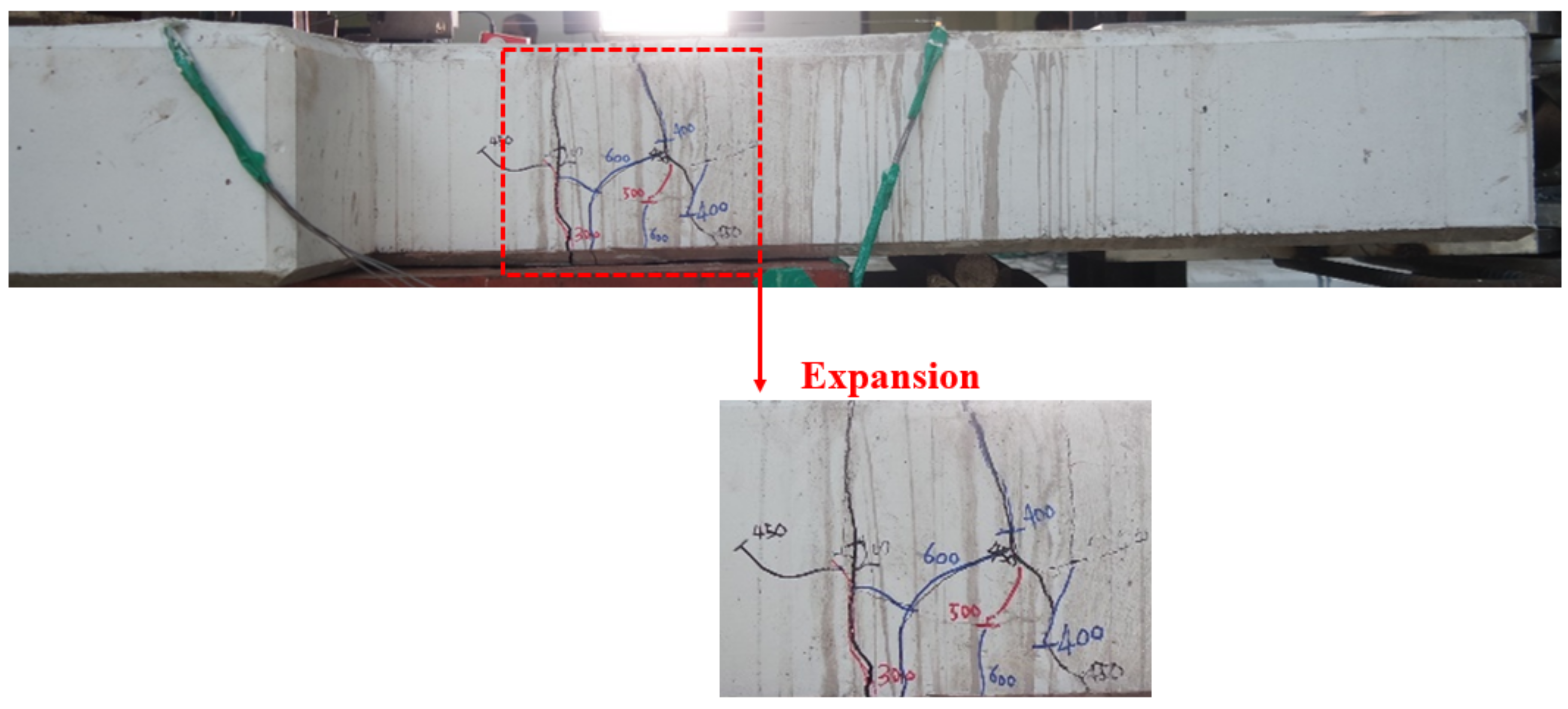

Cracking Behavior

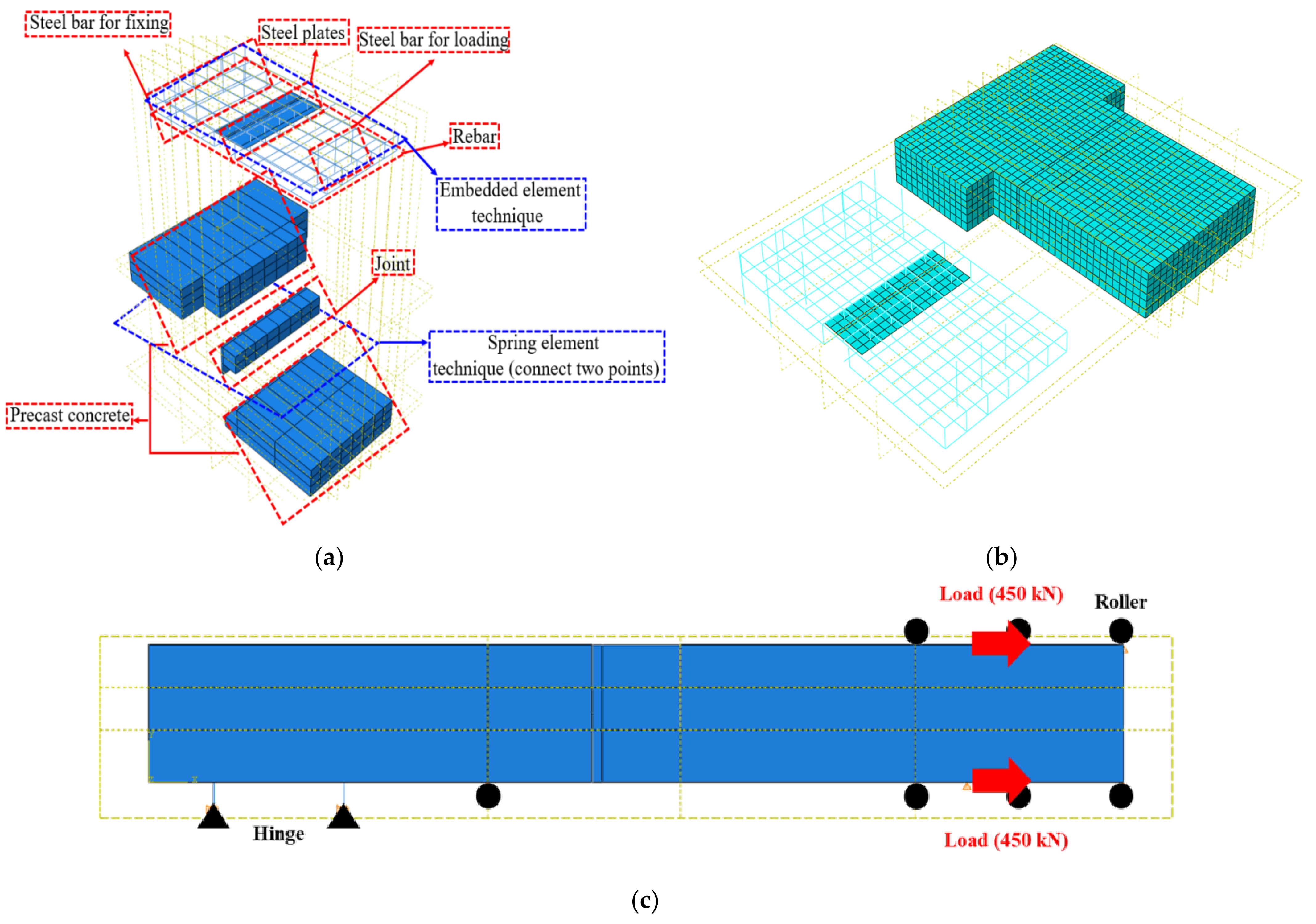

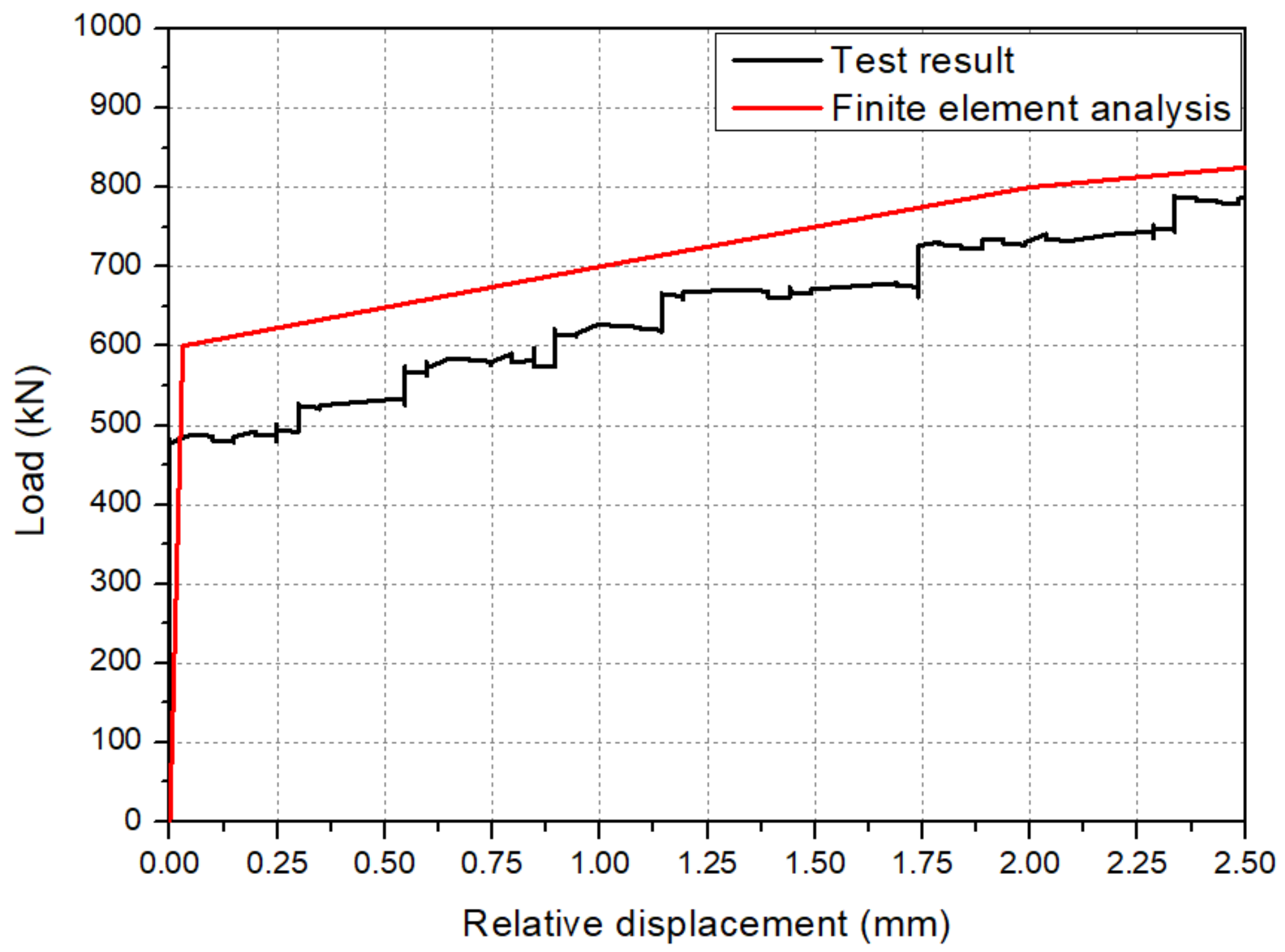

4. Finite Element Analysis

5. Conclusions

- When the width of the precast bridge deck joint using hooked rebars and a steel plate was 100 mm (J100-HB-SP), the initial cracking load was 20% higher, and the final load was 18% higher than when the width of the same joint configuration was 150 mm (J150-HB-SP). Therefore, the joint width should be set to 100 mm to ensure that the precast bridge deck joint has high initial cracking and final loads.

- The use of hooked rebars and a steel plate in a 100 mm wide precast bridge deck joint (J100-HB-SP) resulted in a 61% higher initial cracking load than when no rebars were provided in an otherwise equivalent joint (J100-NB-SP). Thus, steel rebars are required to prevent precast bridge deck joints from cracking at low loads.

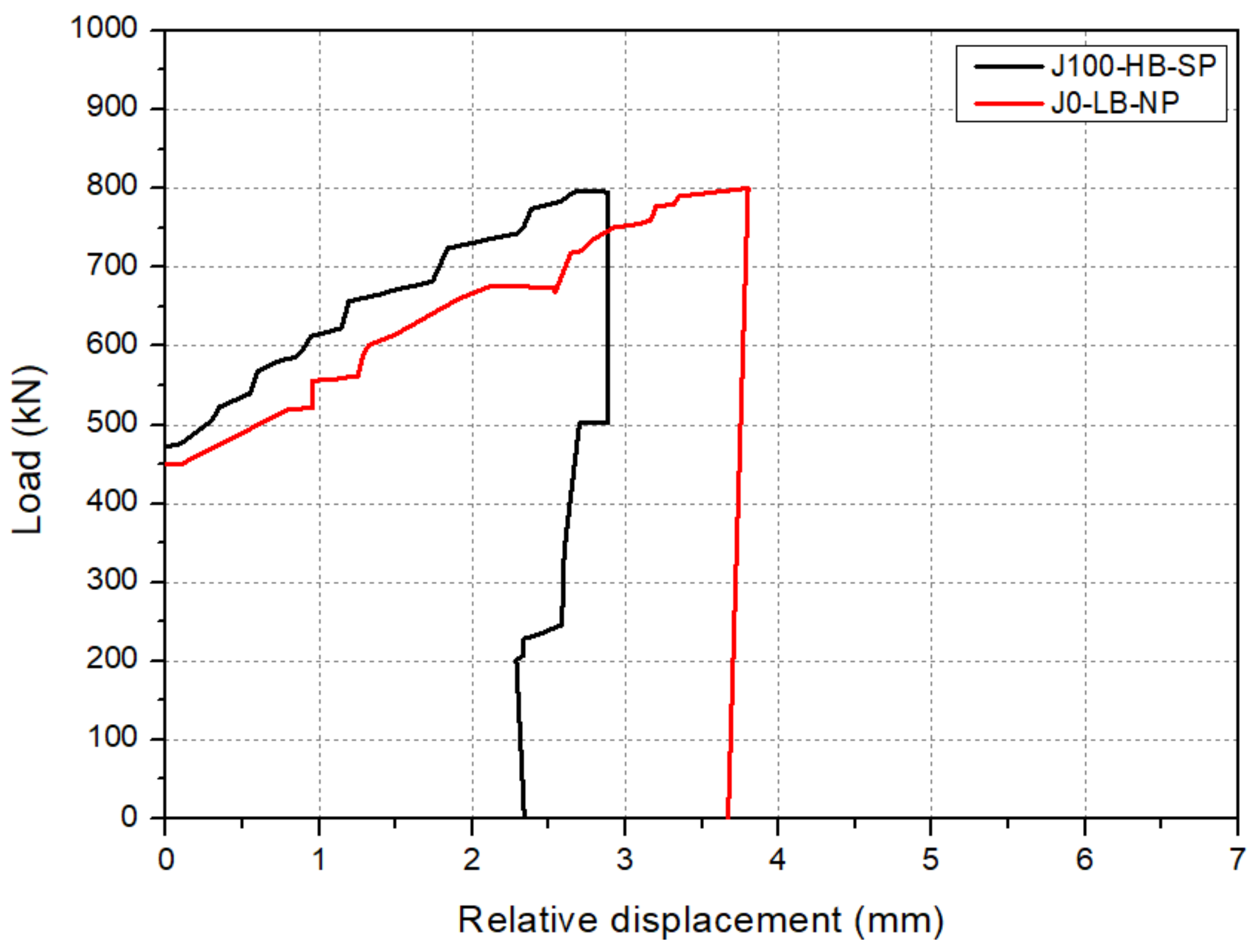

- Although their behaviors were otherwise similar, the final relative displacement of the precast bridge deck joint was larger when using looped rebars and no steel plate (J0-LB-NP) than when using hooked rebars and a steel plate (J100-HB-SP).

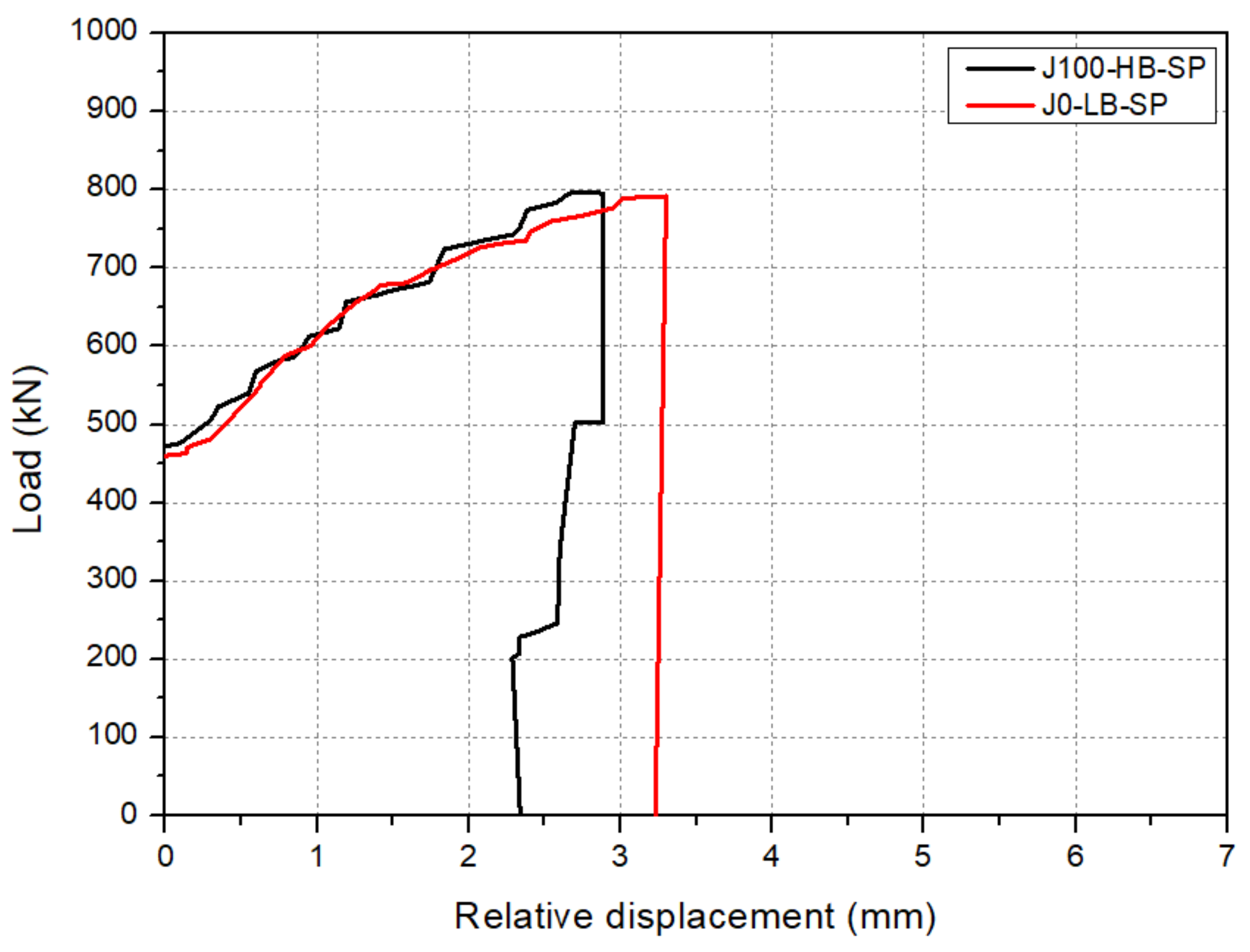

- Similar precast bridge deck joint behaviors were observed when using looped rebars and a steel plate (J0-LB-SP) or hooked rebars and a steel plate (J100-HB-SP), but the final relative displacement of the latter was 38% smaller, owing to the limited connectivity provided by looped rebars. Therefore, hooked rebars should be used to ensure joint connectivity.

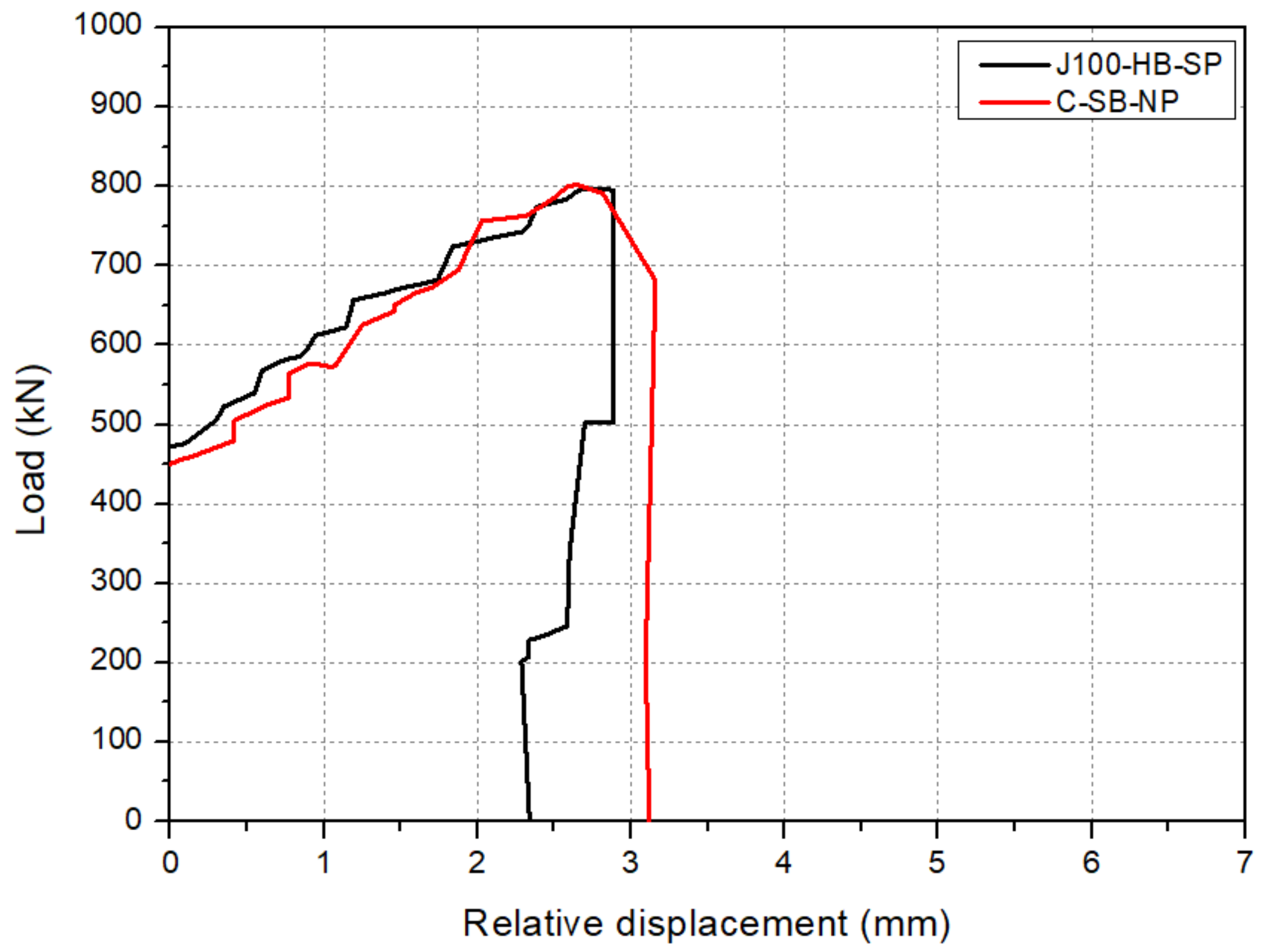

- The overall structural performance of the optimal precast bridge deck joint (J100-HB-SP) was similar to that of an equivalent monolithic CIP bridge deck (C-SB-NP), indicating that J100-HB-SP is a suitable configuration for a precast bridge deck longitudinal joint.

- The final crack geometry of J100-HB-SP was similar to the final crack geometry observed using a high-speed PCIe camera. In addition, since diagonal cracks did not occur until the final load of 800 kN, the structural behavior of J100-HB-SP can be confirmed as safe.

- The load–relative displacement curve and overall crack pattern obtained using the FEM were similar to those observed during the test, and the final relative displacements were within 2%. Therefore, the proposed FEM was able to accurately predict the structural behavior of the precast bridge deck longitudinal joint.

- The gap between the appropriate longitudinal connections on the bridge deck was 100 mm, and the joint between the installed hook reinforcement and steel plate showed the most optimal longitudinal behavior.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yee, A.A. Social and environmental benefits of precast concrete technology. PCI J. 2001, 46, 14–19. [Google Scholar] [CrossRef] [Green Version]

- Di, J.; Han, B.; Qin, F. Investigation of U-bar joints between precast bridge decks loaded in combined bending and shear. Structures 2020, 27, 37–45. [Google Scholar] [CrossRef]

- Leblouba, M.; Barakat, S.; Ahmed, M.S.; Al-Toubat, S. Shear strength at the interface of precast bridge concrete decks and girders subjected to cyclic loading with varying speeds. Eng. Struct. 2019, 196, 109296. [Google Scholar] [CrossRef]

- Hu, M.; Jia, Z.; Han, Q.; Ni, Y.; Jiao, C.; Long, P. Shear behavior of innovative high performance joints for precast concrete deck panels. Eng. Struct. 2022, 261, 114307. [Google Scholar] [CrossRef]

- El-Khier, M.A.; Morcous, G. Precast concrete deck-to-girder connection using Ultra-High Performance Concrete (UHPC) shear pockets. Eng. Struct. 2021, 248, 113082. [Google Scholar] [CrossRef]

- Li, Q.; Song, Z. Ensemble-learning-based prediction of steel bridge deck defect condition. Appl. Sci. 2022, 12, 5442. [Google Scholar] [CrossRef]

- Ma, H.Y.; Shi, X.F.; Zhang, Y. Long-term behavior of precast concrete deck using longitudinal prestressed tendons in composite I-girder bridges. Appl. Sci. 2018, 8, 2598. [Google Scholar] [CrossRef]

- Cusson, D.; Repette, W.L. Early-age cracking in reconstructed concrete bridge barrier walls. ACI Mater. J. 2000, 97, 438–446. [Google Scholar]

- Desmettre, C.; Charron, J.P. Water permeability of reinforced concrete with and without fiber subjected to static and constant tensile loading. Cem. Concr. Res. 2012, 42, 945–952. [Google Scholar] [CrossRef]

- Choi, H.K.; Golewski, G. Parametric analysis on seismic performance of hybrid precast concrete beam-column joint. Adv. Civ. Eng. 2020, 2020, 8856327. [Google Scholar] [CrossRef]

- Wang, Y.H.; Yu, J.; Liu, J.P.; Zhou, B.X.; Chen, Y.F. Experimental study on assembled monolithic steel-prestressed concrete composite beam in negative moment. J. Constr. Steel. Res. 2020, 167, 105667. [Google Scholar] [CrossRef]

- Liu, H.; Kong, P.; Ye, T. Influence of precast member corbels on seismic performance of precast beam-slab-column joints. Adv. Civ. Eng. 2021, 2021, 7107569. [Google Scholar] [CrossRef]

- Shen, C.; Song, Y.; Yan, L.; Li, Y.; Ma, X.; He, S.; Han, X. Experimental and numerical investigation on the bearing behavior of curved continuous twin I-girder composite bridge with precast concrete slab. Adv. Civ. Eng. 2021, 2021, 8872092. [Google Scholar] [CrossRef]

- Mitchell, G.; Tolnai, M.; Gokani, V.; Picon, R.; Yang, S.; Klingner, R.E.; Williamson, E.B. Design of Retrofit Vehicular Barriers Using Mechanical Anchors; TRB Report No. FHWA/TX-07/0-4823-CT-1; The University of Texas at Austin: Austin, TX, USA, 2006. [Google Scholar]

- Charron, J.; Niamba, E.; Massicotte, B. Static and dynamic behavior of high- and ultrahigh-performance fiber-reinforced concrete precast bridge parapets. ASCE J. Br. Eng. 2011, 16, 413–421. [Google Scholar] [CrossRef]

- Rueda-García, L.; Senach, J.L.B.; Sosa, P.F.M.; Prada, M.Á.F. Analysis of the shear strength mechanism of slender precast concrete beams with cast-in-place slab and web reinforcement. Eng. Struct. 2021, 246, 113043. [Google Scholar] [CrossRef]

- Abokifa, M.; Moustafa, M.A. Experimental behavior of precast bridge deck systems with non-proprietary UHPC transverse field joints. Materials 2021, 14, 6964. [Google Scholar] [CrossRef]

- Abdel-Qader, I.; Abu-Amara, F.; Abudayyeh, O. Fractals and independent component analysis for defect detection in bridge decks. Adv. Civ. Eng. 2011, 2011, 506464. [Google Scholar] [CrossRef] [Green Version]

- Al-Fakher, U.; Manalo, A.; Ferdous, W.; Aravinthan, T.; Zhuge, Y.; Bai, Y.; Edoo, A. Bending behaviour of precast concrete slab with externally flanged hollow FRP tubes. Eng. Struct. 2021, 241, 112433. [Google Scholar] [CrossRef]

- Mander, T.J.; Henley, M.D.; Scott, R.M.; Head, M.H.; Mander, J.B.; Trejo, D. Experimental performance of full-depth precast, prestressed concrete overhang, bridge deck panels. J. Bridge Eng. 2010, 15, 503–510. [Google Scholar] [CrossRef]

- Mohd Radzi, N.A.; Hamid, R.; Mutalib, A.A.; Amrul Kaish, A.B.M. A review of precast concrete beam-to-column connections subjected to severe fire conditions. Adv. Civ. Eng. 2020, 2020, 8831120. [Google Scholar] [CrossRef]

- Mander, T.J.; Mander, J.B.; Hite Head, M. Modified yield line theory for full-depth precast concrete bridge deck overhang panels. J. Bridge Eng. 2011, 16, 12–20. [Google Scholar] [CrossRef]

- Wells, Z.G.; Barr, P.J.; James, P.H. Performance of posttensioned curved-strand connections in transverse joints of precast deck panels. J. Bridge Eng. 2013, 18, 1062–1073. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Lu, Z.; Li, J. Experimental study and numerical simulation of a laminated reinforced concrete shear wall with a vertical seam. Appl. Sci. 2017, 7, 629. [Google Scholar] [CrossRef] [Green Version]

- Lu, Z.; Wang, Z.; Li, J.; Huang, B. Studies on seismic performance of precast concrete columns with grouted splice sleeve. Appl. Sci. 2017, 7, 571. [Google Scholar] [CrossRef] [Green Version]

- Mander, T.J.; Henley, M.D.; Scott, R.M.; Head, M.H.; Mander, J.B.; Trejo, D. Experimental investigation of full-depth precast overhang panels for concrete bridge decks. In Structures Congress 2009: Don’t Mess with Structural Engineers: Expanding Our Role; American Society of Civil Engineers: Reston, VA, USA, 2009; pp. 1–9. [Google Scholar]

- Zhu, P.; Ma, Z.Z.; Cao, Q.; French, C.C. Fatigue evaluation of transverse U-bar joint details for accelerated bridge construction. J. Bridge Eng. 2012, 17, 191–200. [Google Scholar] [CrossRef]

- Zafar, M.N.; Saleem, M.A.; Xia, J.; Saleem, M.M. Experimental characterization of prefabricated bridge deck panels prepared with prestressed and sustainable ultra-high performance concrete. Appl. Sci. 2020, 10, 5132. [Google Scholar] [CrossRef]

- Badie, S.S.; Tadros, M.K.; Girgis, A.F. Full-Depth Precast Concrete Bridge Deck Panel Systems; NCHRP Report 584; Transportation Research Board: Washington, DC, USA, 2008. [Google Scholar]

- Ye, H.; Wang, X.; Fang, N.; Su, Z. Low-temperature performance and evaluation index of gussasphalt for steel bridge decks. Adv. Mater. Sci. Eng. Sci. 2019, 2019, 2951412. [Google Scholar] [CrossRef] [Green Version]

- Amini, P.; Moghimbeigi, A.; Zayeri, F.; Tapak, L.; Maroufizadeh, S.; Verbeke, G. Longitudinal joint modelling of ordinal and overdispersed count outcomes: A bridge distribution for the ordinal random intercept. Comput. Math. Methods Med. 2021, 2021, 5521881. [Google Scholar] [CrossRef]

- Tan, Y.; Zheng, S.; Xiao, H.; Xing, J. Influencing factors of snow melting and deicing on carbon fiber embedded in bridge decks. Adv. Civ. Eng. 2022, 2022, 8773149. [Google Scholar] [CrossRef]

- Menkulasi, F.; Roberts-Wollmann, C.L. Behavior of horizontal shear connections for full-depth precast concrete bridge decks on prestressed I-girders. PCI J. 2005, 50, 60–73. [Google Scholar] [CrossRef]

- Nasrin, S.; Ibrahim, A. Flexural response of Ultra-High-Performance Concrete (UHPC) hybrid bridge deck connections made with local materials. Constr. Build. Mater. 2021, 270, 121451. [Google Scholar] [CrossRef]

- Sriboonma, K. Effects of fillet weld to large-size stud shear connector in full-depth precast bridge deck panel. Mater. Today Proc. 2022, 52, 2548–2554. [Google Scholar] [CrossRef]

- Hube, M.A.; Mosalam, K.M. Experimental and computational evaluation of in-span hinges in reinforced concrete box-girder bridges. J. Struct. Eng. 2011, 137, 1245–1253. [Google Scholar] [CrossRef]

- ABAQUS. Abaqus 2021. In Dassault Systems; Simulia Corp: Providence, RI, USA, 2021. [Google Scholar]

- ACI Committe 318. Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary (ACI 318R-19); American Concrete Institute: Detroi, MI, USA, 2019. [Google Scholar]

- ASTM A615/A615M; Standard Specification for Deformed and Plain Carbon-Steel Bar for Concrete Reinforcement. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM A572/A572M; Standard Specification for High-Strength Low-alloy Columbium–Vanadium Structural Steel. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM E8/E8M; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2011.

- ASHTO. AASHTO LRFD Bridge Design Specification, 4th ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2007. [Google Scholar]

- Ministry of Land Transport and Traffic. Explanation of Design Standards for Highway Bridge; Ministry of Land Transport and Traffic: Seoul, Republic of Korea, 2010.

| Test Unit Name | Joint Width | Rebar Type | Steel Plate |

|---|---|---|---|

| J100-HB-SP | 100 mm (J100) | Hooked rebar (HB) | Steel plate (SP) |

| J150-HB-SP | 150 mm (J150) | Hooked rebar (HB) | Steel plate (SP) |

| J100-NB-SP | 100 mm (J100) | No rebar (NB) | Steel plate (SP) |

| J0-LB-NP | NA (J0) * | Looped rebar (LB) | No plate (NP) |

| J0-LB-SP | NA (J0) * | Looped rebar (LB) | Steel plate (SP) |

| C-SB-NP | Cast-in-place (C) | Straight rebar (SB) | No plate (NP) |

| Test Unit Name | Initial Cracking Load (kN) | Final Load (kN) | Final Relative Displacement (mm) |

|---|---|---|---|

| J100-HB-SP | 490 | 800 | 2.34 |

| J150-HB-SP | 390 | 660 | 5.15 |

| J100-NB-SP | 190 | 800 | 5.75 |

| J0-LB-NP | 450 | 800 | 3.67 |

| J0-LB-SP | 460 | 800 | 3.23 |

| C-SB-NP | 450 | 800 | 3.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.; Cho, S.; Na, H.; Han, J.; Lee, H. Tension Performance of Precast Bridge Deck Longitudinal Joints with Different Configurations. Appl. Sci. 2022, 12, 12892. https://doi.org/10.3390/app122412892

Kang S, Cho S, Na H, Han J, Lee H. Tension Performance of Precast Bridge Deck Longitudinal Joints with Different Configurations. Applied Sciences. 2022; 12(24):12892. https://doi.org/10.3390/app122412892

Chicago/Turabian StyleKang, Sunho, Sanghyeon Cho, Hyungcheol Na, Junhee Han, and Heeyoung Lee. 2022. "Tension Performance of Precast Bridge Deck Longitudinal Joints with Different Configurations" Applied Sciences 12, no. 24: 12892. https://doi.org/10.3390/app122412892

APA StyleKang, S., Cho, S., Na, H., Han, J., & Lee, H. (2022). Tension Performance of Precast Bridge Deck Longitudinal Joints with Different Configurations. Applied Sciences, 12(24), 12892. https://doi.org/10.3390/app122412892