Comparative Stress Analysis of Polyetherketoneketone (PEKK) Telescopic Crowns Supported by Different Primary Crown Materials

Abstract

:1. Introduction

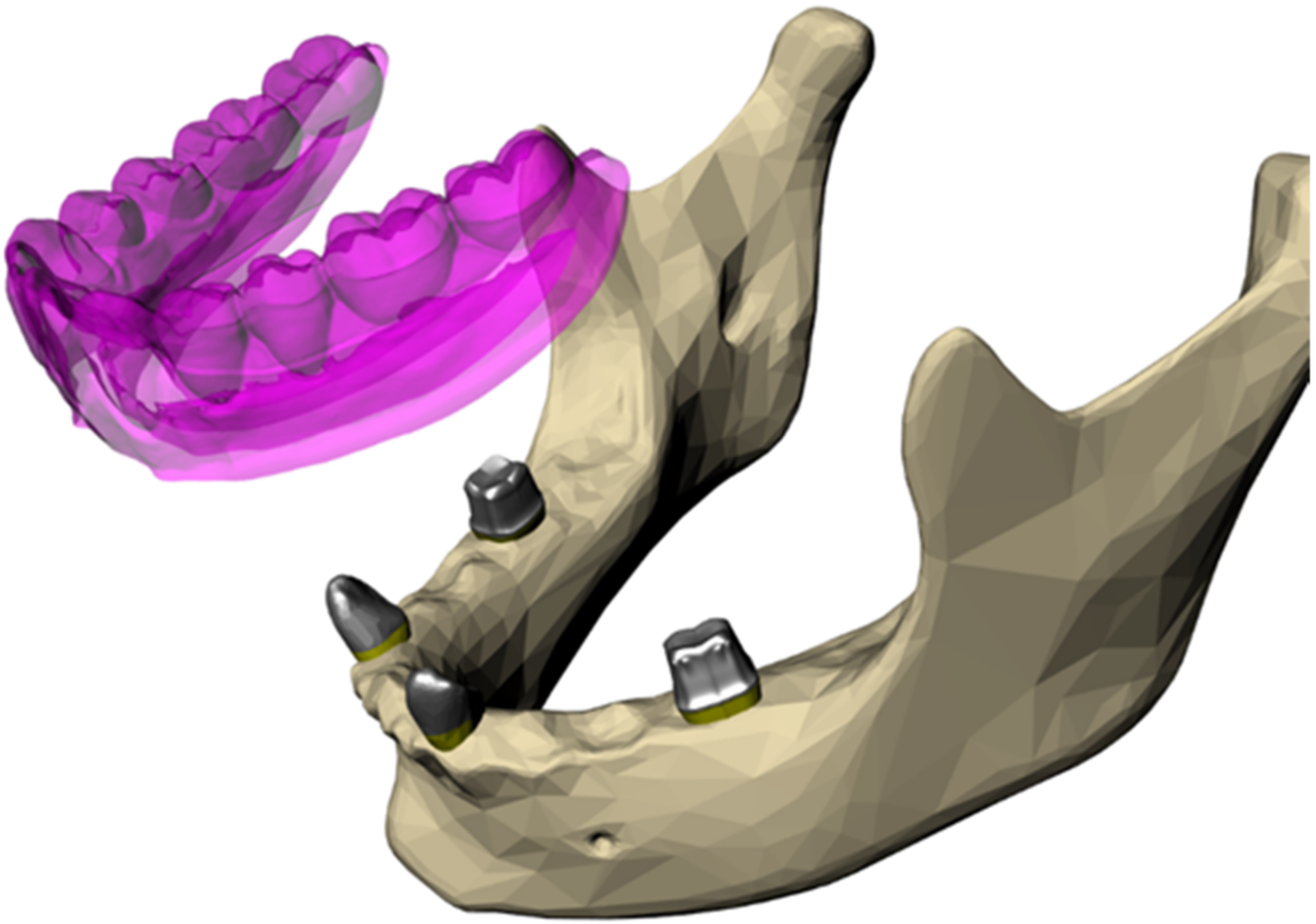

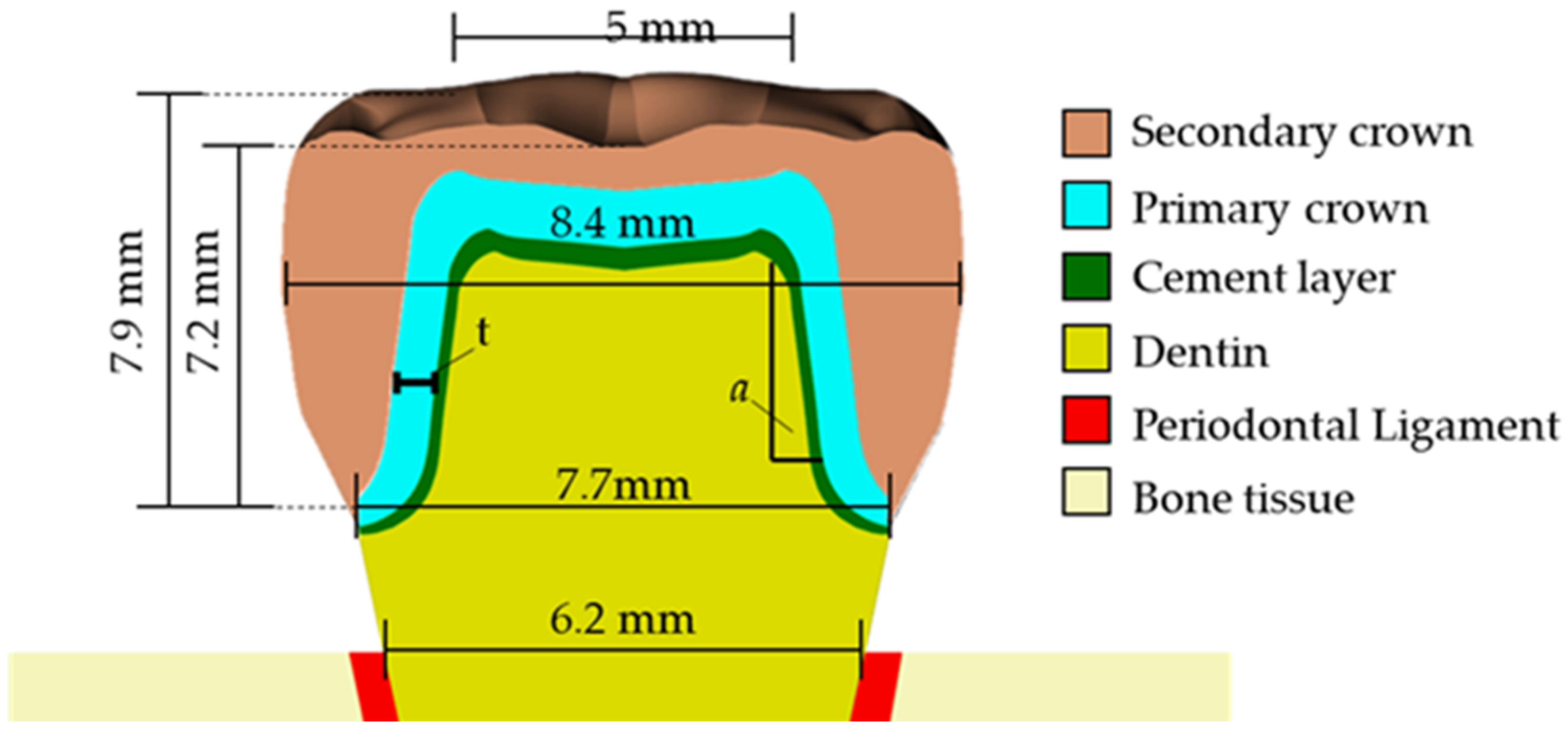

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schimmel, M.; Walther, M.; Al-Haj Husain, N.; Igarashi, K.; Wittneben, J.; Abou-Ayash, S. Retention Forces between Primary and Secondary CAD/CAM Manufactured Telescopic Crowns: An in Vitro Comparison of Common Material Combinations. Clin. Oral Investig. 2021, 25, 6297–6307. [Google Scholar] [CrossRef] [PubMed]

- Kamel, A.; Badr, A.; Fekry, G.; Tsoi, J. Parameters Affecting the Retention Force of CAD/CAM Telescopic Crowns: A Focused Review of in Vitro Studies. J. Clin. Med. 2021, 10, 4429. [Google Scholar] [CrossRef] [PubMed]

- Priester, M.; Müller, W.-D.; Beuer, F.; Schmidt, F.; Schwitalla, A.D. Performance of PEKK Based Telescopic Crowns, a Comparative Study. Dent. Mater. 2021, 37, 1667–1675. [Google Scholar] [CrossRef] [PubMed]

- Fingerhut, C.; Schindler, H.J.; Schweizerhof, K.; Kordass, B.; Lenz, J. Finite Element Analysis of the Principles and Loosening Force of the Conical Telescopic Crown: A Computer-Based Study. Int. J. Comput. Dent. 2014, 17, 199–218. [Google Scholar]

- Hakkoum, M.A.; Wazir, G. Telescopic Denture. Open Dent. J. 2018, 12, 246–254. [Google Scholar] [CrossRef]

- Wagner, C.; Stock, V.; Merk, S.; Schmidlin, P.R.; Roos, M.; Eichberger, M.; Stawarczyk, B. Retention Load of Telescopic Crowns with Different Taper Angles between Cobalt-Chromium and Polyetheretherketone Made with Three Different Manufac-turing Processes Examined by Pull-off Test. J. Prosthodont. 2018, 27, 162–168. [Google Scholar] [CrossRef] [Green Version]

- Fischer, C.A.I.; Ghergic, D.L.; Vranceanu, D.M.; Ilas, S.A.; Comaneanu, R.M.; Baciu, F.; Cotrut, C.M. Assessment of Force Retention between Milled Metallic and Ceramic Telescopic Crowns with Different Taper Angles Used for Oral Rehabilitation. Materials 2020, 13, 4814. [Google Scholar] [CrossRef]

- Minervini, G.; Romano, A.; Petruzzi, M.; Maio, C.; Serpico, R.; Lucchese, A.; Candotto, V.; Di Stasio, D. Telescopic Overdenture on Natural Teeth: Prosthetic Rehabilitation on (OFD) Syndromic Patient and a Review on Available Literature. J. Biol. Regul. Homeost. Agents 2018, 32, 131–134. [Google Scholar]

- Minervini, G.; Romano, A.; Petruzzi, M.; Maio, C.; Serpico, R.; Di Stasio, D.; Lucchese, A. Oral-Facial-Digital Syndrome (OFD): 31-Year Follow-up Management and Monitoring. J. Biol. Regul. Homeost. Agents 2018, 32, 127–130. [Google Scholar]

- Antonelli, A.; Bennardo, F.; Brancaccio, Y.; Barone, S.; Femiano, F.; Nucci, L.; Minervini, G.; Fortunato, L.; Attanasio, F.; Giudice, A. Can Bone Compaction Improve Primary Implant Stability? An in Vitro Comparative Study with Osseodensi-fication Technique. Appl. Sci. 2020, 10, 8623. [Google Scholar] [CrossRef]

- Carlsson, G.E. Implant and Root Supported Overdentures—A Literature Review and Some Data on Bone Loss in Edentulous Jaws. J. Adv. Prosthodont. 2014, 6, 245–252. [Google Scholar] [CrossRef] [Green Version]

- De Carvalho, V.G.; Júnior, C.M.; Dos Santos, L.M.; de Paes Júnior, T.J. Overdenture on Dental Remaining in Oncological Patients: Case Report. Braz. Dent. Sci. 2020, 23, 7. [Google Scholar] [CrossRef]

- Moccia, S.; Nucci, L.; Spagnuolo, C.; d’Apuzzo, F.; Piancino, M.G.; Minervini, G. Polyphenols as Potential Agents in the Management of Temporomandibular Disorders. Appl. Sci. 2020, 10, 5305. [Google Scholar] [CrossRef]

- Minervini, G.; Nucci, L.; Lanza, A.; Femiano, F.; Contaldo, M.; Grassia, V. Temporomandibular Disc Displacement with Reduction Treated with Anterior Repositioning Splint: A 2-Year Clinical and Magnetic Resonance Imaging (MRI) Follow-Up. J. Biol. Regul. Homeost. Agents 2020, 34, 151–160. [Google Scholar]

- D’Apuzzo, F.; Minervini, G.; Grassia, V.; Rotolo, R.P.; Perillo, L.; Nucci, L. Mandibular Coronoid Process Hypertrophy: Diagnosis and 20-Year Follow-up with CBCT, MRI and EMG Evaluations. Appl. Sci. 2021, 11, 4504. [Google Scholar] [CrossRef]

- Minervini, G.; Lucchese, A.; Perillo, L.; Serpico, R.; Minervini, G. Unilateral Superior Condylar Neck Fracture with Dislocation in a Child Treated with an Acrylic Splint in the Upper Arch for Functional Repositioning of the Mandible. Cranio 2017, 35, 337–341. [Google Scholar] [CrossRef]

- Tribst, J.; de Araújo, R.; Ramanzine, N.; Santos, N.; Dal Piva, A.O.; Borges, A.; da Silva, J. Mechanical Behavior of Implant Assisted Removable Partial Denture for Kennedy Class II. J. Clin. Exp. Dent. 2020, e38–e45. [Google Scholar] [CrossRef]

- Zierden, K.; Kurzrock, L.; Wöstmann, B.; Rehmann, P. Nonprecious Alloy vs Precious Alloy Telescopic Crown-Retained Removable Partial Dentures: Survival and Maintenance Needs. Int. J. Prosthodont. 2018, 31, 459–464. [Google Scholar] [CrossRef]

- Brandt, S.; Winter, A.; Weigl, P.; Brandt, J.; Romanos, G.; Lauer, H.-C. Conical Zirconia Telescoping into Electroformed Gold: A Retrospective Study of Prostheses Supported by Teeth and/or Implants. Clin. Implant Dent. Relat. Res. 2019, 21, 317–323. [Google Scholar] [CrossRef]

- Arnold, C.; Schweyen, R.; Boeckler, A.; Hey, J. Retention Force of Removable Partial Dentures with CAD-CAM-Fabricated Telescopic Crowns. Materials 2020, 13, 3228. [Google Scholar] [CrossRef]

- Alqurashi, H.; Khurshid, Z.; Syed, A.U.Y.; Rashid Habib, S.; Rokaya, D.; Zafar, M.S. Polyetherketoneketone (PEKK): An Emerging Biomaterial for Oral Implants and Dental Prostheses. J. Adv. Res. 2021, 28, 87–95. [Google Scholar] [CrossRef]

- Tribst, J.P.M.; Dal Piva, A.M.; Dal Piva, A.M.d.O.; Borges, A.L.S.; Araújo, R.M.; da Silva, J.M.F.; Bottino, M.A.; Kleverlaan, C.J.; de Jager, N. Effect of Different Materials and Undercut on the Removal Force and Stress Distribution in Circumferential Clasps during Direct Retainer Action in Removable Partial Dentures. Dent. Mater. 2020, 36, 179–186. [Google Scholar] [CrossRef]

- Katzenbach, A.; Dörsam, I.; Stark, H.; Bourauel, C.; Keilig, L. Fatigue Behaviour of Dental Crowns Made from a Novel High-Performance Polymer PEKK. Clin. Oral Investig. 2021, 25, 4895–4905. [Google Scholar] [CrossRef]

- Villefort, R.F.; Tribst, J.P.M.; Dal Piva, A.M.d.O.; Borges, A.L.; Binda, N.C.; Ferreira, C.E.d.A.; Bottino, M.A.; von Zeidler, S.L.V. Stress Distribution on Different Bar Materials in Implant-Retained Palatal Obturator. PLoS ONE 2020, 15, e0241589. [Google Scholar] [CrossRef]

- Campaner, L.M.; Silveira, M.P.M.; de Andrade, G.S.; Borges, A.L.S.; Bottino, M.A.; Dal Piva, A.M.d.O.; Lo Giudice, R.; Ausiello, P.; Tribst, J.P.M. Influence of Polymeric Restorative Materials on the Stress Distribution in Posterior Fixed Partial Dentures: 3D Finite Element Analysis. Polymers 2021, 13, 758. [Google Scholar] [CrossRef]

- Kotthaus, M.; Hasan, I.; Keilig, L.; Grüner, M.; Bourauel, C.; Stark, H. Investigation of the Retention Forces of Secondary Telescopic Crowns Made from Pekkton® Ivory in Combination with Primary Crowns Made from Four Different Dental Alloys: An in Vitro Study. Biomed. Tech. 2019, 64, 555–562. [Google Scholar] [CrossRef]

- Borges, A.L.S.; Tribst, J.P.M.; de Lima, A.L.; Dal Piva, A.M.d.O.; Özcan, M. Effect of Occlusal Anatomy of CAD/CAM Feldspathic Posterior Crowns in the Stress Concentration and Fracture Load. Clin. Exp. Dent. Res. 2021, 7, 1190–1196. [Google Scholar] [CrossRef]

- Hojjatie, B.; Anusavice, K.J. Three-Dimensional Finite Element Analysis of Glass-Ceramic Dental Crowns. J. Biomech. 1990, 23, 1157–1166. [Google Scholar] [CrossRef]

- Ausiello, P.; Ciaramella, S.; Fabianelli, A.; Gloria, A.; Martorelli, M.; Lanzotti, A.; Watts, D.C. Mechanical Behavior of Bulk Direct Composite versus Block Composite and Lithium Disilicate Indirect Class II Restorations by CAD-FEM Modeling. Dent. Mater. 2017, 33, 690–701. [Google Scholar] [CrossRef] [Green Version]

- Xin, H.; Shepherd, D.E.T.; Dearn, K.D. Strength of Poly-Ether-Ether-Ketone: Effects of Sterilisation and Thermal Ageing. Polym. Test. 2013, 32, 1001–1005. [Google Scholar] [CrossRef]

- Carreño-Morelli, E.; Bidaux, J.-E.; Rodríguez-Arbaizar, M.; Girard, H.; Hamdan, H. Production of Titanium Grade 4 Com-ponents by Powder Injection Moulding of Titanium Hydride. Powder Metall. 2014, 57, 89–92. [Google Scholar] [CrossRef]

- Lankford, J. Plastic Deformation of Partially Stabilized Zirconia. J. Am. Ceram. Soc. 1983, 66, c212–c213. [Google Scholar] [CrossRef]

- Dikova, T. Properties of Co-Cr Dental Alloys Fabricated Using Additive Technologies; IntechOpen: London, UK, 2018. [Google Scholar]

- Dal Piva, A.M.D.O.; Tribst, J.P.M.; Borges, A.L.S.; Souza, R.O.d.A.e.; Bottino, M.A. CAD-FEA modeling and analysis of dif-ferent full crown monolithic restorations. Dent. Mater. 2018, 34, 1342–1350. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abbasi, M.R.A.; Vinnakota, D.N.; Sankar, V.; Kamatham, R. Comparison of Stress Induced in Mandible around an Implant-Supported Overdenture with Locator Attachment and Telescopic Crowns—A Finite Element Analysis. Med. Pharm. Rep. 2020, 93, 181–189. [Google Scholar] [CrossRef]

- Lee, C.-G.; Paek, J.-H.; Kim, T.-H.; Kim, M.-J.; Kim, H.-S.; Kwon, K.-R.; Woo, Y.-H. Erratum: A FEM Study on Stress Distribution of Tooth-Supported and Implant-Supported Overdentures Retained by Telescopic Crowns. J. Korean Acad. Prosthodont. 2012, 50, 218. [Google Scholar] [CrossRef]

- Emera, R.K.; Altonbary, G.; Elbashir, S. Comparison between All Zirconia, All PEKK, and Zirconia-PEKK Telescopic At-tachments for Two Implants Retained Mandibular Complete Overdentures: In Vitro Stress Analysis Study. J. Dent. Implant. 2019, 9, 24. [Google Scholar] [CrossRef]

- Wöstmann, B.; Balkenhol, M.; Weber, A.; Ferger, P.; Rehmann, P. Long-Term Analysis of Telescopic Crown Retained Removable Partial Dentures: Survival and Need for Maintenance. J. Dent. 2007, 35, 939–945. [Google Scholar] [CrossRef]

- Tribst, J.P.M.; dos Santos, A.F.C.; da Cruz Santos, G.; da Silva Leite, L.S.; Lozada, J.C.; Silva-Concílio, L.R.; Baroudi, K.; Amaral, M. Effect of Cement Layer Thickness on the Immediate and Long-Term Bond Strength and Residual Stress between Lithium Disilicate Glass-Ceramic and Human Dentin. Materials 2021, 14, 5153. [Google Scholar] [CrossRef]

- Benazzi, S.; Grosse, I.R.; Gruppioni, G.; Weber, G.W.; Kullmer, O. Comparison of Occlusal Loading Conditions in a Lower Second Premolar Using Three-Dimensional Finite Element Analysis. Clin. Oral Investig. 2014, 18, 369–375. [Google Scholar] [CrossRef]

- Borges, A.L.S.; De Lima, A.L.; Campaner, L.M.; Bottino, M.A.; Dal Piva, A.M.d.O.; Tribst, J.P.M. Influence of Occlusal Anatomy on Acrylic Resin CAD/CAM Crowns Fracture Load and Stress Distribution. Dent. 3000 2021, 9, 36–45. [Google Scholar] [CrossRef]

- Qian, Y.; Zhou, X.; Yang, J. Correlation between Cuspal Inclination and Tooth Cracked Syndrome: A Three-Dimensional Reconstruction Measurement and Finite Element Analysis. Dental Traumatol. 2013, 29, 226–233. [Google Scholar] [CrossRef]

- Celik, H.K.; Koc, S.; Kustarci, A.; Rennie, A.E.W. A Literature Review on the Linear Elastic Material Properties Assigned in Finite Element Analyses in Dental Research. Mater. Today Commun. 2022, 30, 103087. [Google Scholar] [CrossRef]

| Material | Elastic Modulus (MPa) | Poisson Ratio |

|---|---|---|

| Dentin | 18,600 | 0.23 |

| Bone tissue | 13,700 | 0.30 |

| Resin cement | 8000 | 0.30 |

| Zirconia (3Y-TZP) | 200,000 | 0.30 |

| Titanium (Ti-6Al-4V) | 110,000 | 0.30 |

| CoCr | 220,000 | 0.30 |

| PEKK | 5100 | 0.40 |

| Model (PC + SC) | Stress (MPa) | Microstrain | Strain Energy (mJ) | |||

|---|---|---|---|---|---|---|

| SC | PC | Cement Layer | PDL | Bone | ||

| PEKK + PEKK | 158.3 | 46.4 | 2.15 | 126 | 365 | 0.111 |

| Titanium + PEKK | 152.2 | 67.5 | 3.28 | 126 | 364 | 0.115 |

| Zirconia + PEKK | 151.1 | 68.8 | 3.29 | 125 | 365 | 0.115 |

| CoCr + PEKK | 150.9 | 68.9 | 3.29 | 125 | 366 | 0.115 |

| Material | Yield Strength | References |

|---|---|---|

| PEKK | 165 MPa | [30] |

| Titanium | 519 MPa | [31] |

| Zirconia | 1190 MPa | [32] |

| CoCr | 540 MPa | [33] |

| Model (PC + SC) | Failure Risk | |

|---|---|---|

| SC | PC | |

| PEKK + PEKK | 0.96 | 0.28 |

| Titanium + PEKK | 0.92 | 0.13 |

| Zirconia + PEKK | 0.92 | 0.06 |

| CoCr + PEKK | 0.91 | 0.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tribst, J.P.M.; Dal Piva, A.M.d.O.; Syed, A.U.Y.; Alrabiah, M.; Al-Aali, K.A.; Vohra, F.; Abduljabbar, T. Comparative Stress Analysis of Polyetherketoneketone (PEKK) Telescopic Crowns Supported by Different Primary Crown Materials. Appl. Sci. 2022, 12, 3446. https://doi.org/10.3390/app12073446

Tribst JPM, Dal Piva AMdO, Syed AUY, Alrabiah M, Al-Aali KA, Vohra F, Abduljabbar T. Comparative Stress Analysis of Polyetherketoneketone (PEKK) Telescopic Crowns Supported by Different Primary Crown Materials. Applied Sciences. 2022; 12(7):3446. https://doi.org/10.3390/app12073446

Chicago/Turabian StyleTribst, João Paulo Mendes, Amanda Maria de Oliveira Dal Piva, Azeem Ul Yaqin Syed, Mohammed Alrabiah, Khulud A. Al-Aali, Fahim Vohra, and Tariq Abduljabbar. 2022. "Comparative Stress Analysis of Polyetherketoneketone (PEKK) Telescopic Crowns Supported by Different Primary Crown Materials" Applied Sciences 12, no. 7: 3446. https://doi.org/10.3390/app12073446