CZTSe-Based Solar Cell Performance Improvement Using the CSLO Technique

Abstract

:1. Introduction

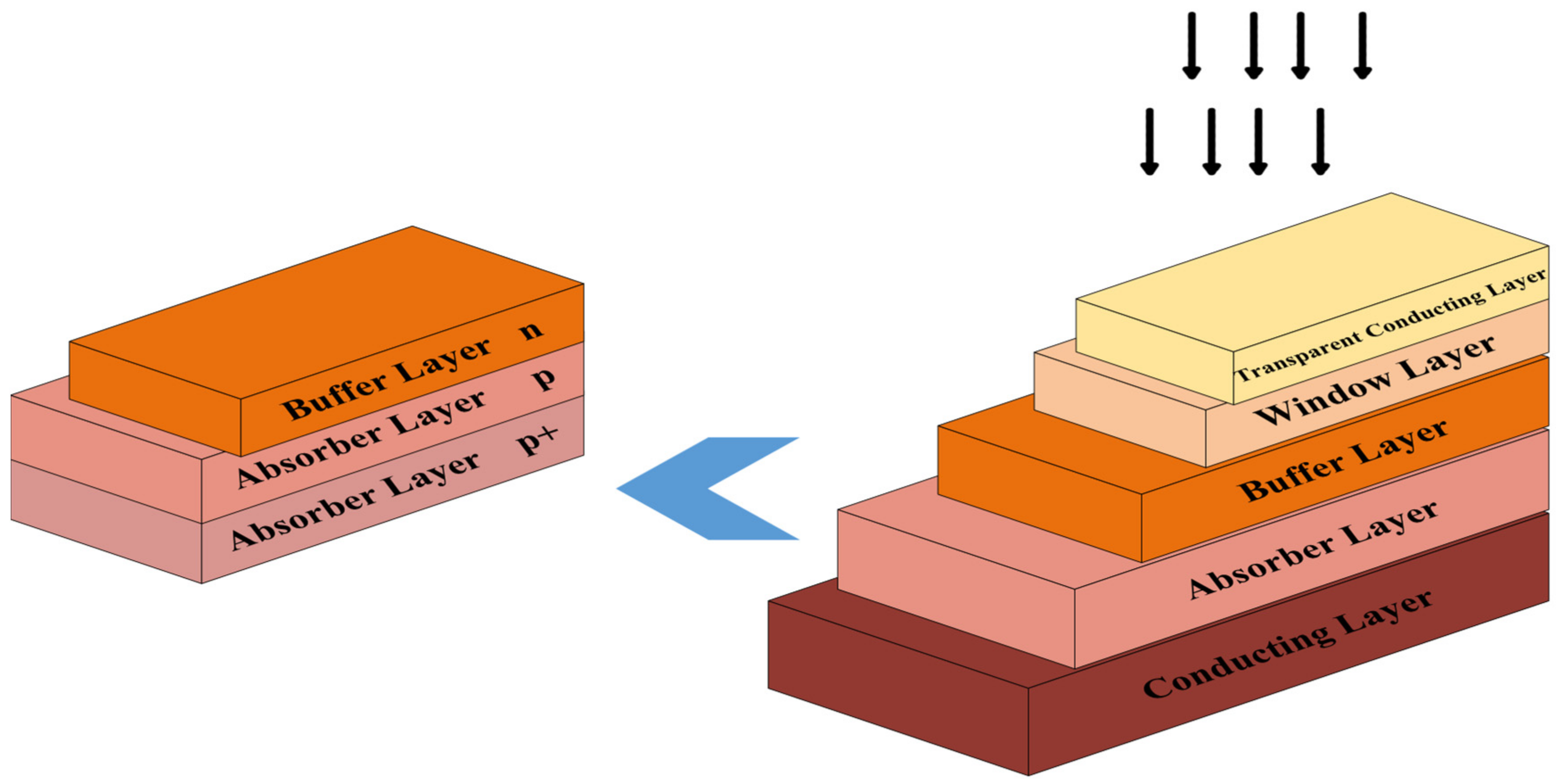

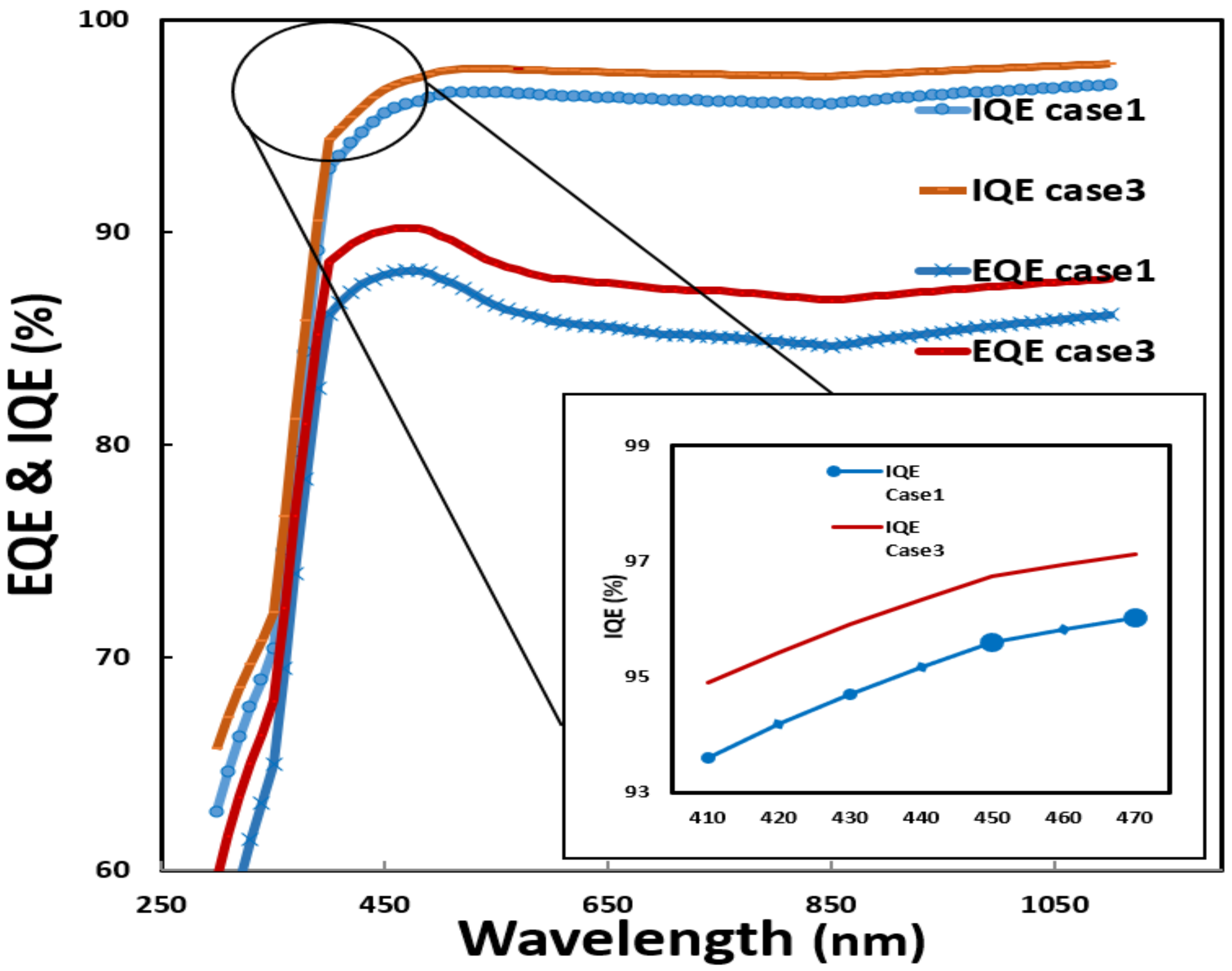

2. Modeling and Simulation for Material Selection

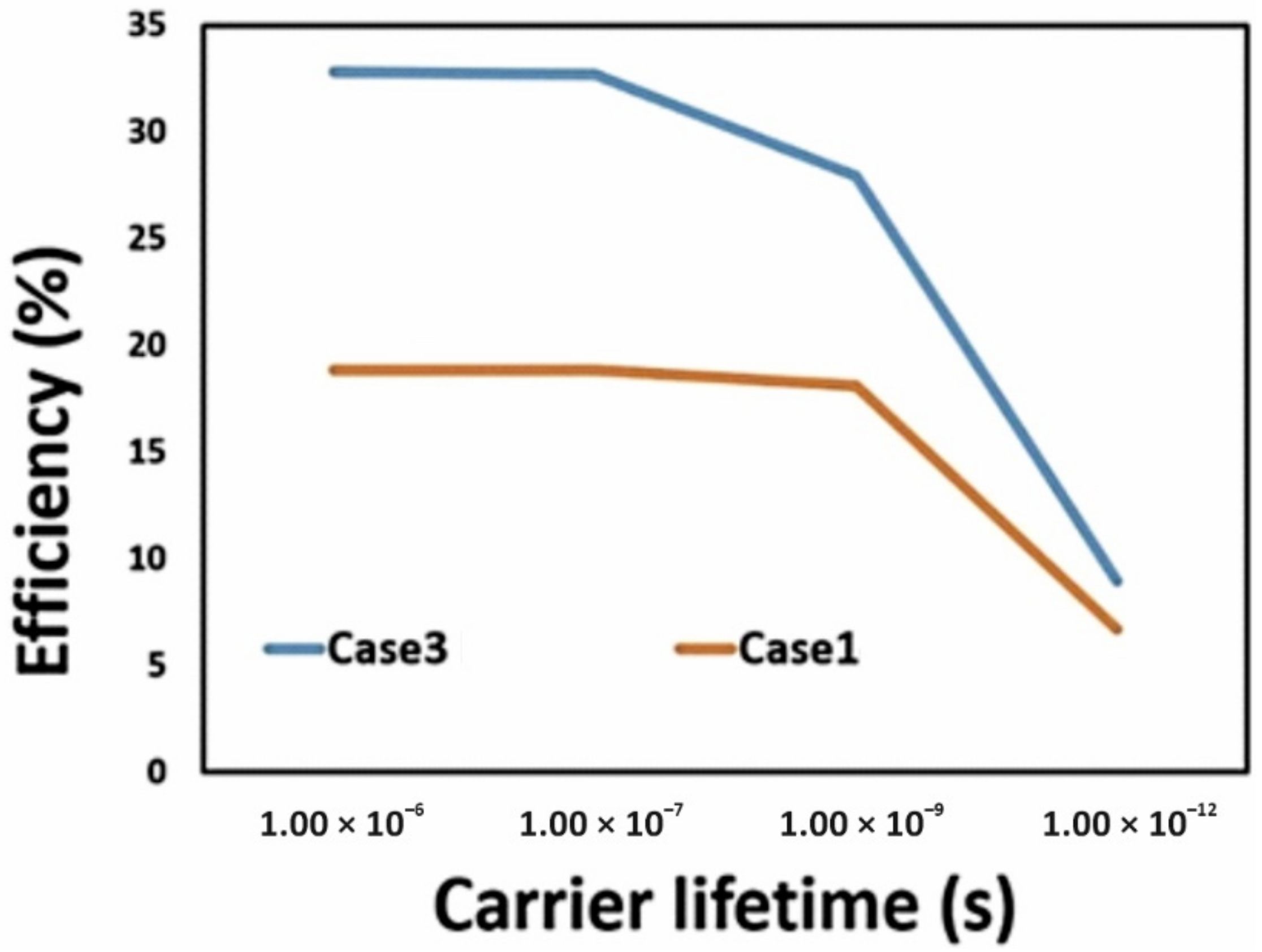

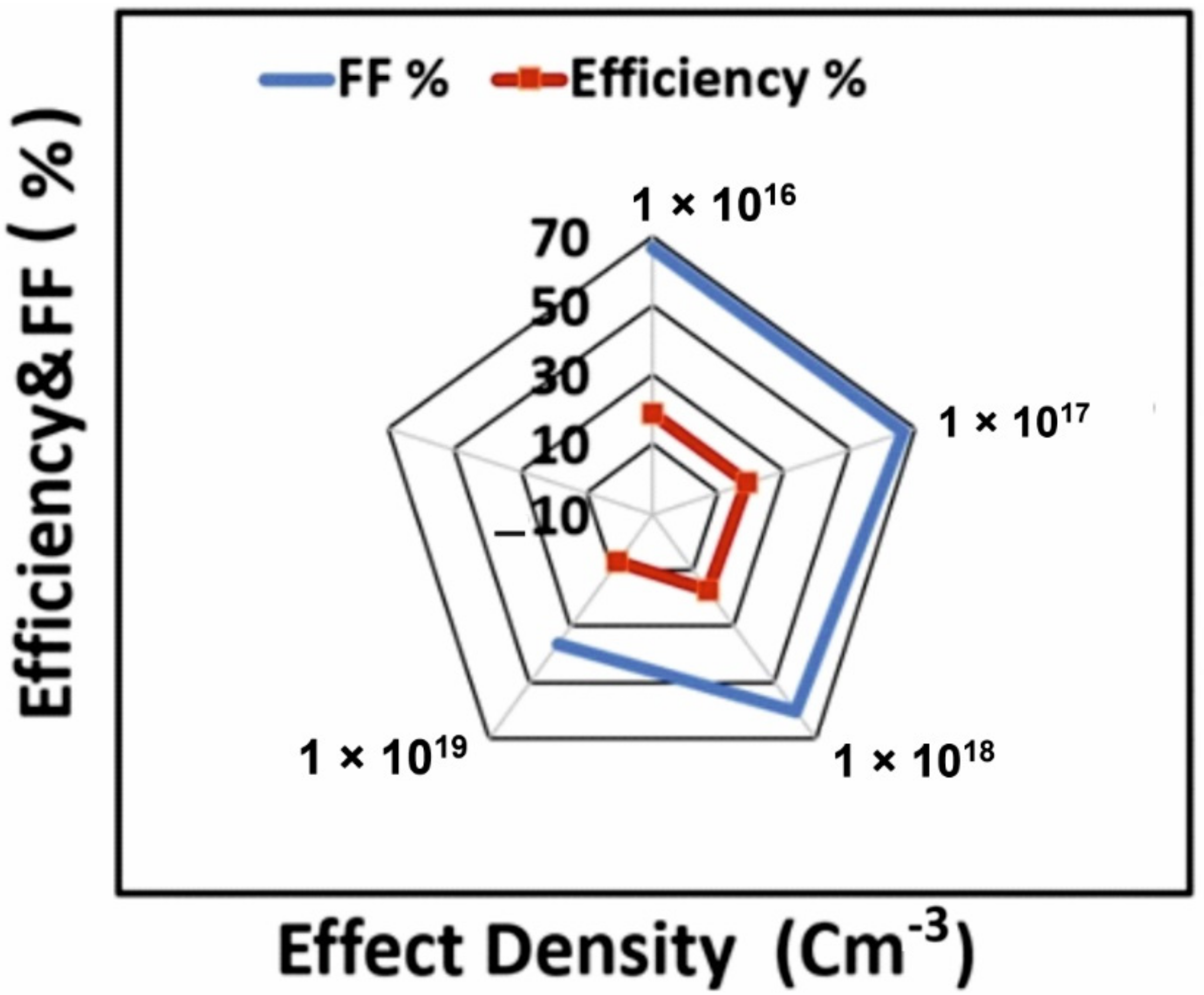

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hong, F.; Lin, W.; Meng, W.; Yan, Y. Trigonal Cu2-II-Sn-VI4 (II = Ba, Sr and VI = S, Se) quaternary compounds for earth-abundant photovoltaics. Phys. Chem. Chem. Phys. 2016, 18, 4828–4834. [Google Scholar] [CrossRef] [PubMed]

- Adachi, S. Earth-Abundant Materials for Solar Cells: Cu2-II-IV-VI4 Semiconductors; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Altamura, G. Development of CZTSSe Thin Films based Solar Cells. Ph.D. Thesis, Université Joseph-Fourier—Grenoble I: Material Chemistry, Grenoble, France, 2014. [Google Scholar]

- Haque, K.; Baten, M.Z. On the prospect of CZTSSe-based thin film solar cells for indoor photovoltaic applications: A simulation study. AIP Adv. 2019, 9, 55326. [Google Scholar] [CrossRef] [Green Version]

- Mebelson, T.J.; Elampari, K. A study of electrical and optical characteristics of CZTSe solar cell using Silvaco Atlas. Mater. Today Proc. 2021, 46, 2540–2543. [Google Scholar] [CrossRef]

- Jiang, M.; Yan, X. Cu2ZnSnS4 thin film solar cells: Present status and future prospects. In Solar Cells—Research and Application Perspectives; Morales-Acevedo, A., Ed.; Intech: Rijeka, Croatia, 2013. [Google Scholar]

- Ratz, T.; Brammertz, G.; Caballero, R.; Leon, M.; Canulescu, S.; Schou, J.; Gütay, L.; Pareek, D.; Taskesen, T.; Kim, D.-H.; et al. Physical routes for the synthesis of kesterite. J. Phys. Energy 2019, 1, 42003. [Google Scholar] [CrossRef]

- Tumbul, A.; Aslan, F.; Göktaş, A.; Mutlu, I. All solution processed superstrate type Cu2ZnSnS4 (CZTS) thin film solar cell: Effect of absorber layer thickness. J. Alloys Compd. 2019, 781, 280–288. [Google Scholar] [CrossRef]

- Guerra, N.; Guevara, M.; Palacios, C.; Crupi, F. Operation and physics of photovoltaic solar cells: An overview. I + D Tecnológico 2018, 14, 84–95. [Google Scholar] [CrossRef]

- Attafi, D.; Boumaraf, R.; Meftah, A.; Sengouga, N. Effect of a Back-Surface Field and Passivation Layer on a Silicon Schottky Solar Cell. Trans. Electr. Electron. Mater. 2021, 22, 357–362. [Google Scholar] [CrossRef]

- Boukortt, N.E.I.; AlAmri, A.M.; Bouhjar, F.; Bouhadiba, K. Investigation and optimization of ultrathin Cu (In, Ga) Se2 solar cells by using silvaco-TCAD tools. J. Mater. Sci. Mater. Electron. 2021, 32, 21525–21538. [Google Scholar] [CrossRef]

- Luque, A.; Hegedus, S. Handbook of Photovoltaic Science and Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Jabbar, H.; Jeong, T. Ambient Light Energy Harvesting and Numerical Modeling of Non-Linear Phenomena. Appl. Sci. 2022, 12, 2068. [Google Scholar] [CrossRef]

- Dwivedi, D.K. Modeling of Photovoltaic Solar Cell Based on CuSbS2 Absorber for the Enhancement of Performance. IEEE Trans. Electron Devices 2021, 68, 1121–1128. [Google Scholar] [CrossRef]

- Antolin, E.; Zehender, M.H.; Garcia-Linares, P.; Svatek, S.A.; Marti, A. Considerations for the Design of a Heterojunction Bipolar Transistor Solar Cell. IEEE J. Photovolt. 2019, 10, 2–7. [Google Scholar] [CrossRef] [Green Version]

- Verma, M.; Routray, S.R.; Mishra, G. Analysis and optimization of BSF layer for highly efficient GaInP single junction solar cell. Mater. Today Proc. 2021, 43, 3420–3423. [Google Scholar] [CrossRef]

- De Rossi, F.; Taheri, B.; Bonomo, M.; Gupta, V.; Renno, G.; Nia, N.Y.; Rech, P.; Frost, C.; Cazzaniga, C.; Quagliotto, P.; et al. Neutron irradiated perovskite films and solar cells on PET substrates. Nano Energy 2021, 93, 106879. [Google Scholar] [CrossRef]

- Girish, K.; Vishnumurthy, K.; Roopa, T. Role of conducting polymers in enhancing the stability and performance of perovskite solar cells: A brief review. Mater. Today Sustain. 2022, 17, 100090. [Google Scholar] [CrossRef]

- Basumatary, P.; Agarwal, P. A short review on progress in perovskite solar cells. Mater. Res. Bull. 2021, 149, 111700. [Google Scholar] [CrossRef]

- Hayashi, Y.; Li, D.; Ogura, A.; Ohshita, Y. Role of i-aSi: H layers in aSi: H/cSi heterojunction solar cells. IEEE J. Photovolt. 2013, 3, 1149–1155. [Google Scholar] [CrossRef]

- Noge, H.; Saito, K.; Sato, A.; Kaneko, T.; Kondo, M. Two-dimensional simulation of interdigitated back contact silicon heterojunction solar cells having overlapped p/i and n/i a-Si: H layers. Jpn. J. Appl. Phys. 2015, 54, 8KD17. [Google Scholar] [CrossRef]

- Moulé, A.J.; Meerholz, K. Morphology Control in Solution-Processed Bulk-Heterojunction Solar Cell Mixtures. Adv. Funct. Mater. 2009, 19, 3028–3036. [Google Scholar] [CrossRef]

- Kumar, D.; Krishnan, N.S.; Ilango, M.S.; Ramasesha, S.K. Device simulations of a novel nanostructured CdS/CdTe solar cell with back contacts. J. Comput. Electron. 2021, 20, 324–329. [Google Scholar] [CrossRef]

- Ergen, O.; Celik, E.; Unal, A.H.; Erdolu, M.Y. Screen Engineered Field Effect Cu2O Based Solar Cells. IEEE Electron Device Lett. 2020, 41, 1138–1140. [Google Scholar] [CrossRef]

- Chee, K.W.; Hu, Y. Design and optimization of ARC less InGaP/GaAs single-/multi-junction solar cells with tunnel junction and back surface field layers. Superlattices Microstruct. 2018, 119, 25–39. [Google Scholar] [CrossRef]

- Hoehn, O.; Niemeyer, M.; Weiss, C.; Lackner, D.; Predan, F.; Franke, A.; Beutel, P.; Schachtner, M.; Müller, R.; Siefer, G.; et al. Development of Germanium-based wafer-bonded four-junction solar cells. IEEE J. Photovolt. 2019, 9, 1625–1630. [Google Scholar] [CrossRef]

- Trahms, M.; Jost, M.; Trinh, C.T.; Preissler, N.; Albrecht, S.; Schlatmann, R.; Rech, B.; Amkreutz, D. All-Thin-Film Tandem Cells Based on Liquid Phase Crystallized Silicon and Perovskites. IEEE J. Photovolt. 2019, 9, 621–628. [Google Scholar] [CrossRef]

- Paswan, S.K.; Chandra, D.; Bhatt, U.M.; Kumar, B. Performance Enhancement of CZTS and CZTSSe Solar Cells using CdS as Buffer Layer. In Proceedings of the 2020 International Conference on Electrical and Electronics Engineering (ICE3), Gorakhpur, India, 14–15 February 2020. [Google Scholar]

- Latrous, A.R.; Mahamdi, R.; Touafek, N.; Pasquinelli, M. Performance Enhancement in CZTS Solar Cells by SCAPS-1D. Int. J. Thin Film. Sci. Technol. 2021, 10, 1. [Google Scholar]

- Madan, J.; Pandey, R.; Sharma, R. Designing of CZTSSe Based SnS thin film solar cell for improved conversion efficiency: A simulation study with SCAPS. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019. [Google Scholar]

- Bao, W.; Qiu, F.Y.; Bai, S.; Li, Y.; Chen, D.M. Study of band offset at ZnS/Cu2ZnIVS4 (IV = Si, Ge, Sn) heterointerfaces. Optoelectron. Adv. Mater. Rapid Commun. 2018, 12, 327–331. [Google Scholar]

- Braly, I.L.; de Quilettes, D.W.; Pazos-Outón, L.W.; Burke, S.; Ziffer, M.E.; Ginger, D.S.; Hillhouse, H.W. Hybrid perovskite films approaching the radiative limit with over 90% photoluminescence quantum efficiency. Nat. Photonics 2018, 12, 355–361. [Google Scholar] [CrossRef]

- Tripathi, S.; Maurya, S.; Kumar, B.; Dwivedi, D.K. Comparative analysis of CZTS/CZTSe/CZTSSe absorber layer for solar cell applications. In Proceedings of the 2020 International Conference on Electrical and Electronics Engineering (ICE3), Gorakhpur, India, 14–15 February 2020. [Google Scholar]

- Gohri, S.; Sharma, S.; Pandey, R.; Madan, J.; Sharma, R. Influence of SnS and Sn2S3 based BSF layers on the performance of CZTSSe solar cell. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 15 June–21 August 2020. [Google Scholar]

- Vermang, B.; Ren, Y.; Donzel-Gargand, O.; Frisk, C.; Joel, J.; Salomé, P.; Borme, J.; Sadewasser, S.; Platzer-Björkman, C.; Edoff, M. Rear Surface Optimization of CZTS Solar Cells by Use of a Passivation Layer With Nanosized Point Openings. IEEE J. Photovolt. 2015, 6, 332–336. [Google Scholar] [CrossRef] [Green Version]

- Courel, M.; Andrade-Arvizu, J.A.; Vigil-Galán, O. The role of buffer/kesterite interface recombination and minority carrier lifetime on kesterite thin film solar cells. Mater. Res. Express 2016, 3, 95501. [Google Scholar] [CrossRef]

- Pandey, R.; Shimpi, T.; Munshi, A.; Sites, J.R. Impact of Carrier Concentration and Carrier Lifetime on MgZnO/CdSeTe/CdTe Solar Cells. IEEE J. Photovolt. 2020, 10, 1918–1925. [Google Scholar] [CrossRef]

- Shah, D.K.; Kc, D.; Muddassir, M.; Akhtar, M.S.; Kim, C.Y.; Yang, O.-B. A simulation approach for investigating the performances of cadmium telluride solar cells using doping concentrations, carrier lifetimes, thickness of layers, and band gaps. Sol. Energy 2021, 216, 259–265. [Google Scholar] [CrossRef]

- Shin, D.; Saparov, B.; Mitzi, D.B. Defect Engineering in Multinary Earth-Abundant Chalcogenide Photovoltaic Materials. Adv. Energy Mater. 2017, 7, 1602366. [Google Scholar] [CrossRef]

- Tampo, H.; Kim, K.M.; Kim, S.; Shibata, H.; Niki, S. Improvement of minority carrier lifetime and conversion efficiency by Na incorporation in Cu2ZnSnSe4 solar cells. J. Appl. Phys. 2017, 122, 023106. [Google Scholar] [CrossRef]

- Sun, R.; Zhuang, D.; Zhao, M.; Gong, Q.; Scarpulla, M.; Wei, Y.; Ren, G.; Wu, Y. Beyond 11% efficient Cu2ZnSn (Se, S)4 thin film solar cells by cadmium alloying. Sol. Energy Mater. Sol. Cells 2018, 174, 494–498. [Google Scholar] [CrossRef]

- Katagiri, H.; Jimbo, K.; Yamada, S.; Kamimura, T.; Maw, W.S.; Fukano, T.; Ito, T.; Motohiro, T. Enhanced Conversion Efficiencies of Cu2ZnSnS4-Based Thin Film Solar Cells by Using Preferential Etching Technique. Appl. Phys. Express 2008, 1, 041201. [Google Scholar] [CrossRef]

- Shooshtari, M.; Salehi, A. An electronic nose based on carbon nanotube -titanium dioxide hybrid nanostructures for detection and discrimination of volatile organic compounds. Sens. Actuators B Chem. 2022, 357, 131418. [Google Scholar] [CrossRef]

- Ge, J.; Yan, Y. Controllable Multinary Alloy Electrodeposition for Thin-Film Solar Cell Fabrication: A Case Study of Kesterite Cu2ZnSnS4. iScience 2018, 1, 55–71. [Google Scholar] [CrossRef] [Green Version]

- Tiwari, K.J.; Chetty, R.; Mallik, R.C.; Malar, P. Solid state synthesis and e-beam evaporation growth of Cu2ZnSnSe4 for solar energy absorber applications. Sol. Energy 2017, 153, 173–180. [Google Scholar] [CrossRef]

- Cazzaniga, A.; Crovetto, A.; Yan, C.; Sun, K.; Hao, X.; Estelrich, J.R.; Canulescu, S.; Stamate, E.; Pryds, N.; Hansen, O.; et al. Ultra-thin Cu2ZnSnS4 solar cell by pulsed laser deposition. Sol. Energy Mater. Sol. Cells 2017, 166, 91–99. [Google Scholar] [CrossRef] [Green Version]

- Agawane, G.L.; Vanalakar, S.A.; Kamble, A.S.; Moholkar, A.V.; Kim, J.H. Fabrication of Cu2 (ZnxMg1-x) SnS4 thin films by pulsed laser deposition technique for solar cell applications. Mater. Sci. Semicond. Process. 2018, 76, 50–54. [Google Scholar] [CrossRef]

| Parameters | Cu2ZnSiSe4 | Cu2ZnGeSe4 | CZTS | CZTSe | CdS | ZnO | ITO |

|---|---|---|---|---|---|---|---|

| Band gap (eV) | 3 | 2.1 | 1.5 | 1.04 | 2.4 | 3.3 | 3.6 |

| Electron affinity (eV) | 2.4 | 3.4 | 4.1 | 4.15 | 4.5 | 4.6 | 4.2 |

| Dielectric permittivity | 7.5 | 6.8 | 7 | 10 | 10 | 9 | 10 |

| Electron mobility (cm2/Vs) | 60 | 60 | 60 | 100 | 100 | 100 | 100 |

| Hole mobility (cm2/Vs) | 20 | 20 | 20 | 25 | 10 | 10 | 10 |

| Effective conductance band density (cm/s) | 2.2 × 1018 | ||||||

| Effective valence band density (cm/s) | 1.8 × 1019 | ||||||

| Defect density (cm−3) | 1 × 1013 | 1 × 1013 | 1 × 1013 | 1 × 1013 | 6 × 1016 | - | - |

| Case 1 | Case 2 | Case 3-CSLO | Case 4-CSLO | Case 5-CSLO | Case 6-CSLO | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | T | C | T | C | T | C | T | C | T | C | T | C |

| ITO | 0.03 | 1 × 1019 | 0.03 | 1 × 1019 | 0.02 | 1 × 1019 | 0.02 | 1 × 1019 | 0.02 | 1 × 1019 | 0.02 | 1 × 1019 |

| ZnO | 0.08 | 1 × 1018 | 0.08 | 1 × 1018 | 0.08 | 1 × 1018 | 0.08 | 1 × 1018 | 0.08 | 1 × 1018 | 0.08 | 1 × 1018 |

| CdS | 0.03 | 1 × 1017 | 0.03 | 1 × 1017 | 0.03 | 1 × 1017 | 0.03 | 1 × 1017 | 0.03 | 1 × 1017 | 0.03 | 1 × 1017 |

| CZTSe (Cu2ZnSnSe4) | 2 | 1 × 1015 | 2 | 1 × 1018 | 0.5 1.5 | 1 × 1016 1 × 1019 | - | - | - | - | - | - |

| Cu2ZnSnS4 | - | - | - | - | - | - | 0.5 1.5 | 1 × 1016 1 × 1019 | - | - | - | - |

| Cu2ZnSiSe4 | - | - | - | - | - | - | - | - | 0.5 1.5 | 1 × 1016 1 × 1019 | - | - |

| Cu2ZnGeSe4 | - | - | - | - | - | - | - | - | - | - | 0.5 1.5 | 1 × 1016 1 × 1019 |

| Efficiency (η%) | 18.86 | 32 | 32.66 | 68 | 62.31 | 70.64 | ||||||

| Voc (v) | 0.378 | 0.548 | 0.537 | 0.99 | 1.2 | 1.31 | ||||||

| Jsc (A/cm2) | 0.074 | 0.073 | 0.076 | 0.078 | 0.074 | 0.075 | ||||||

| Fill Factor (%) | 66.79 | 79.44 | 79.55 | 86.03 | 69.73 | 71.67 | ||||||

| Pmax (W) | 0.018 | 0.032 | 0.0326 | 0.068 | 0.062 | 0.07 | ||||||

| Solar Cell | Fill Factor (%) | Efficiency (%) |

|---|---|---|

| hybrid structure (CZTSe and CZTS) | 66 | 41.54 |

| hybrid structure (CZTSe and Cu2ZnSiSe4) | 42 | 33.61 |

| hybrid structure (CZTSe and Cu2ZnGeSe4) | 54.82 | 50.112 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahimi, S.; Shooshtari, M. CZTSe-Based Solar Cell Performance Improvement Using the CSLO Technique. Appl. Sci. 2022, 12, 4119. https://doi.org/10.3390/app12094119

Rahimi S, Shooshtari M. CZTSe-Based Solar Cell Performance Improvement Using the CSLO Technique. Applied Sciences. 2022; 12(9):4119. https://doi.org/10.3390/app12094119

Chicago/Turabian StyleRahimi, Serveh, and Mostafa Shooshtari. 2022. "CZTSe-Based Solar Cell Performance Improvement Using the CSLO Technique" Applied Sciences 12, no. 9: 4119. https://doi.org/10.3390/app12094119