Path Planning of Rail-Mounted Logistics Robots Based on the Improved Dijkstra Algorithm

Abstract

:Featured Application

Abstract

1. Introduction

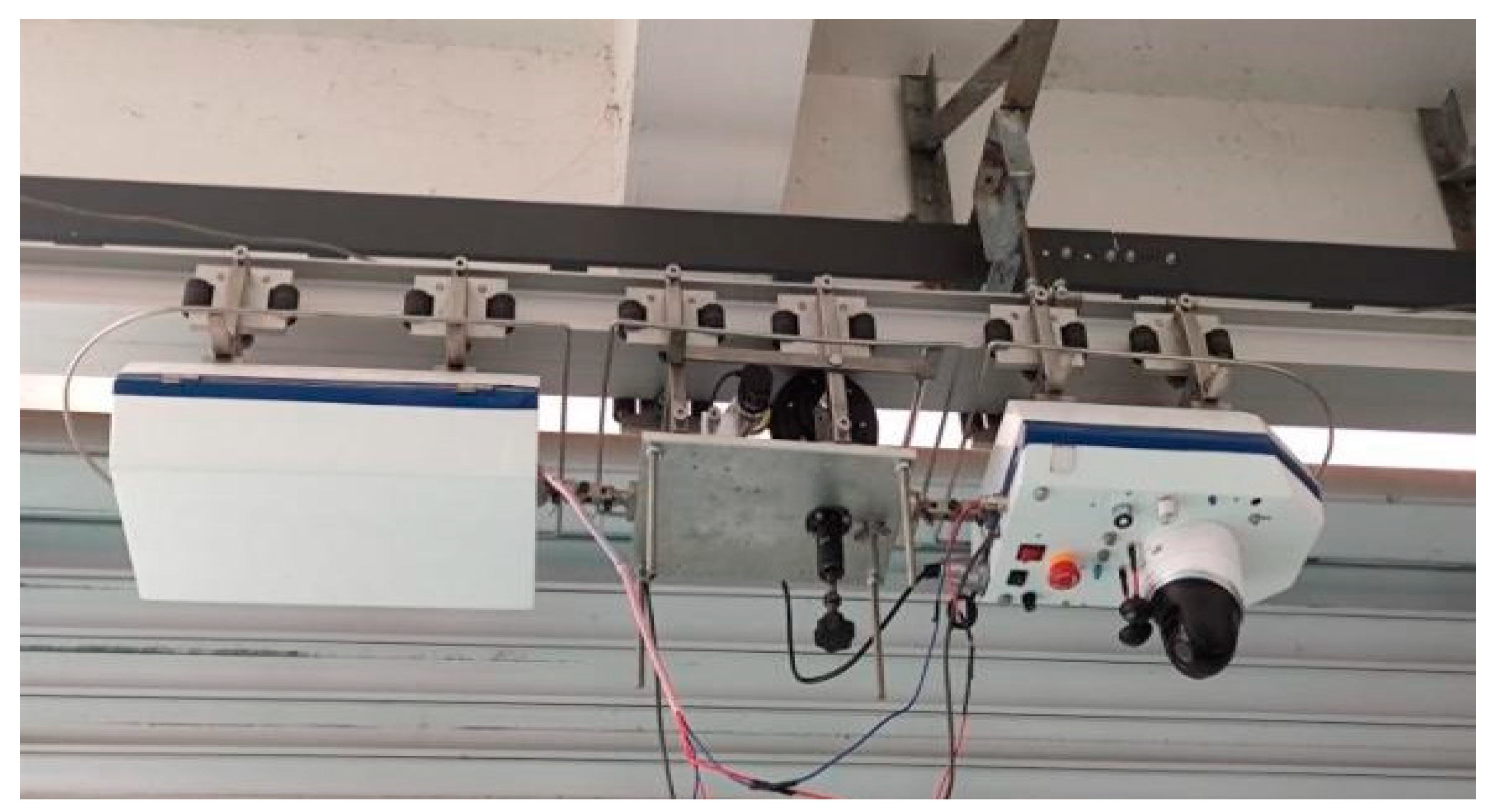

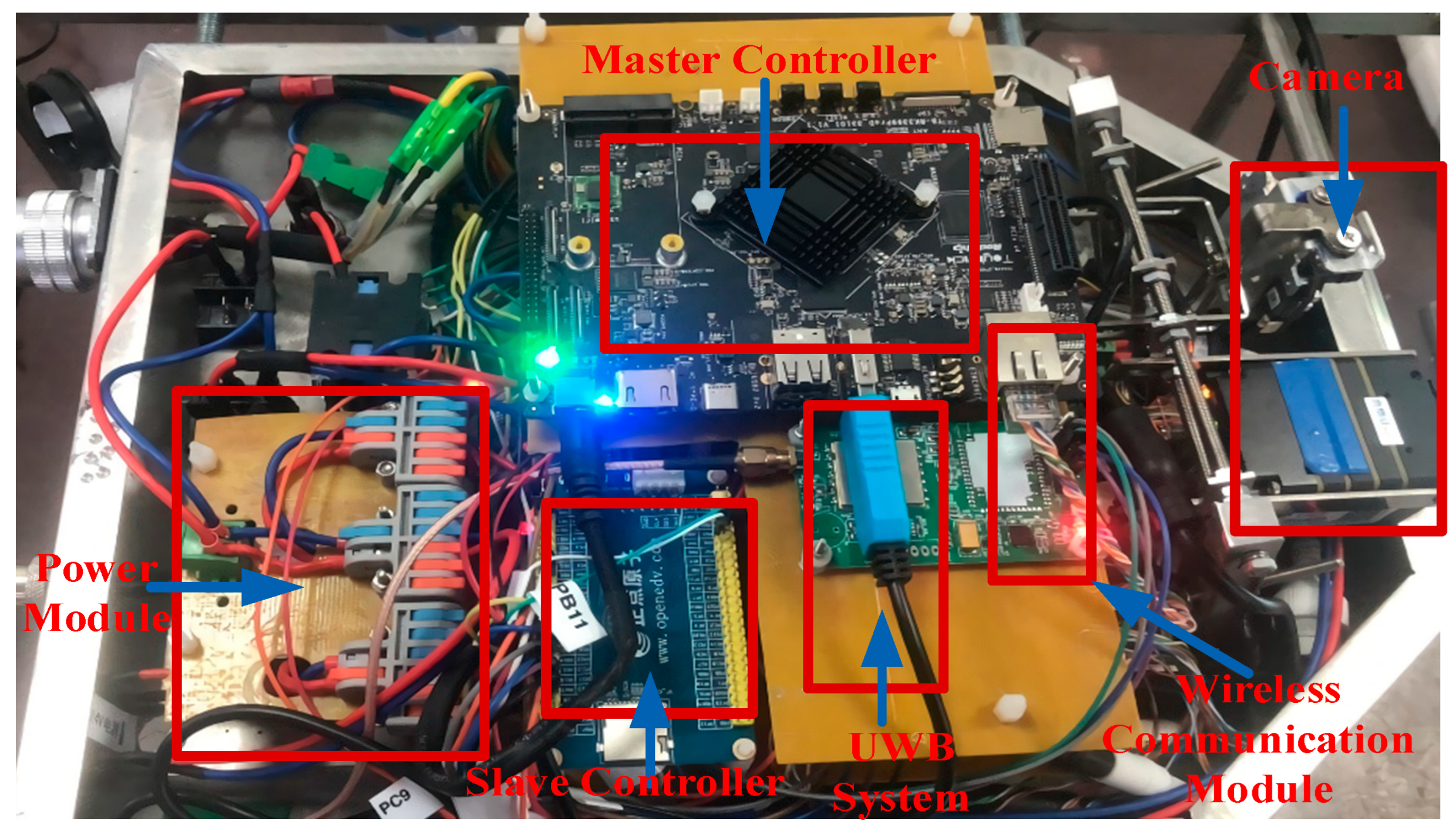

2. Materials and Methods

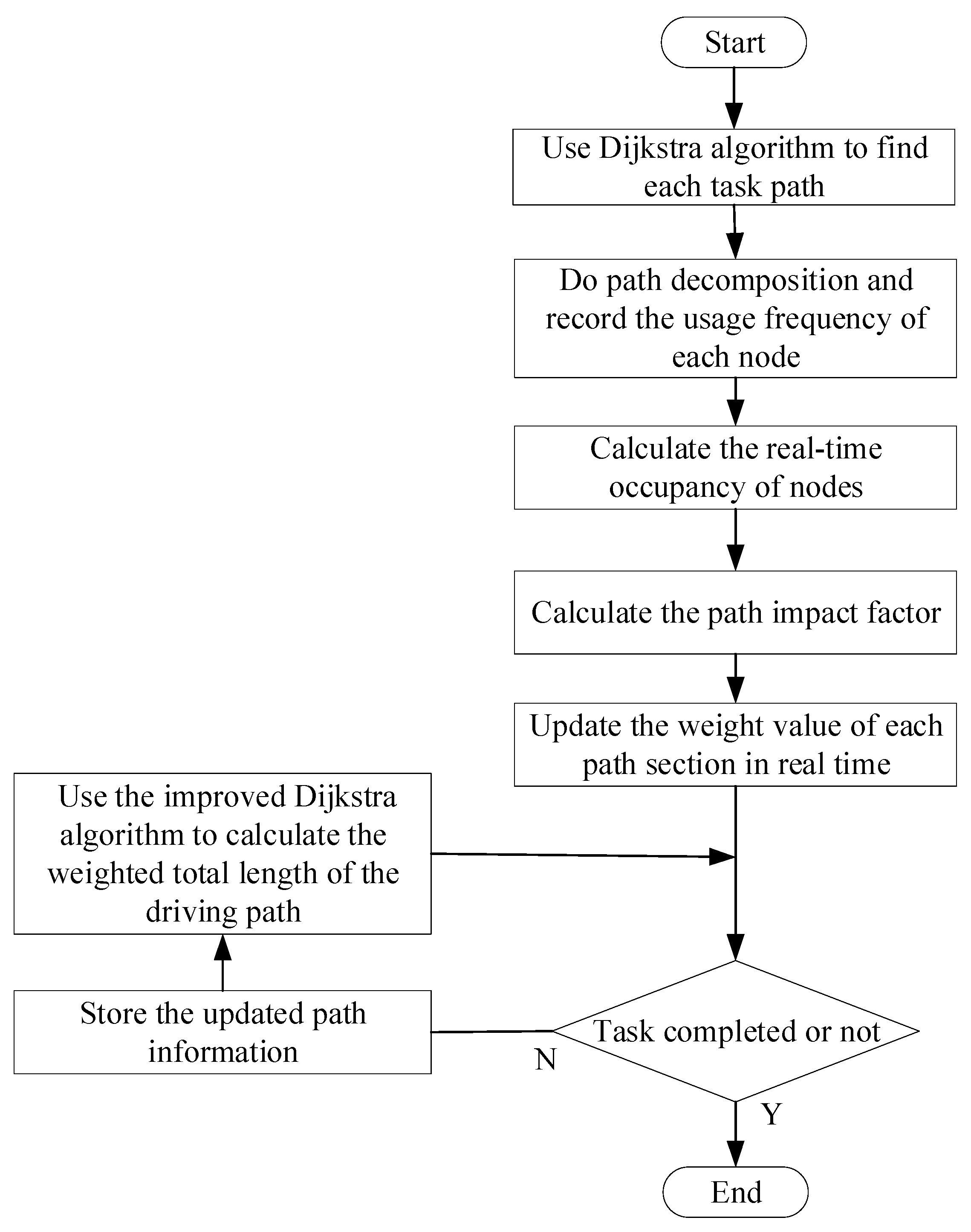

2.1. The Improved Dijkstra Algorithm

2.1.1. Dijkstra Algorithm Analysis

- Define the set sum and , perform initialization, letwhere is the shortest path target node set, is the set of nodes excluding , is the initial node, and is the target node.

- Select the node closest to the initial node in set , so thatwhere is the distance matrix, and then the distance between any two nodes can be expressed as

- Update set and as

- Correct path length ifThen, L is amended as

- Judge whether all the target nodes are added to the shortest path set ; if not, jump to step 2; otherwise, output the shortest path node set .

2.1.2. Introducing the Real-Time Node Occupancy into Dijkstra’s Algorithm

- 1.

- The traditional Dijkstra algorithm is used to plan the initial distribution path for the robot, and the initial distribution path is decomposed in real time. The driving frequency of each robot on each node is recorded, and the real-time occupancy of this node is calculated according to

- 2.

- The real-time node occupancy is introduced into the weight function of the traditional Dijkstra algorithm, and the impact factor and real-time node occupancy of the traditional Dijkstra algorithm are considered at the same time. In this case, the weight function of Dijkstra’s algorithm is as follows:where the initial factor of the path node is 1, is the original length of the path, and is the weight after considering the real-time occupancy of the node.

2.1.3. Introducing the Time Window Model into Dijkstra’s Algorithm

- The traveling speed of the robot in orbit is 1 m/s;

- The maximum number of on-orbit robots in the same section of the track is 4;

- The start and stop times and reversing time of the robot are not considered;

- Each station can only be entered by one robot at the same time, and the other robots can only enter after occupying the right to contact.

2.1.4. Priority Rules and Conflict Coordination Strategy

- The on-orbit priority of the robot is determined by the system, and it is not allowed to reset the priority for the robot performing material distribution.

- The priority of the robot with a fault in orbit is the highest, and the track section is forbidden to pass, so its priority is 0. The priorities of the other robots performing tasks are set in advance.

- Node conflict: Multiple robots coming from different directions to the same site at the same time.

- Opposite direction conflict: Two robots are driving opposite each other on the same road at some point.

- Occupying conflict: The node that one robot will occupy the next moment is the node that the other robot is currently occupying.

- It is determined whether there is a common site for other orbiting robots on the initial path. If not, it will follow the initial planned path, or if there is a common station, then the priority of the robot is judged.

- The robot with high priority has a driving priority and passes according to the established route.

- The robot with low priority calculates the time required for waiting and replanning, choosing the strategy with a shorter time.

2.2. UWB Positioning

2.2.1. Chan Algorithm Based on TDOA

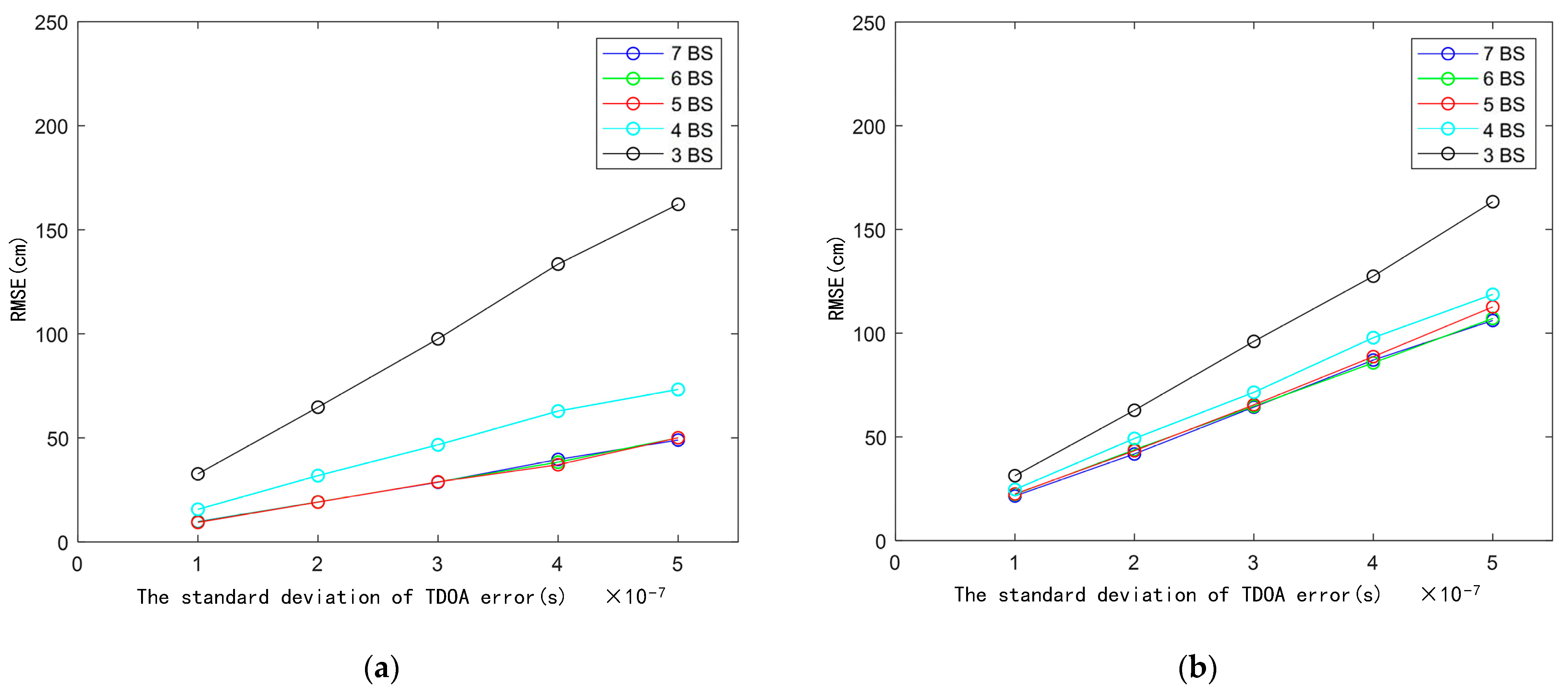

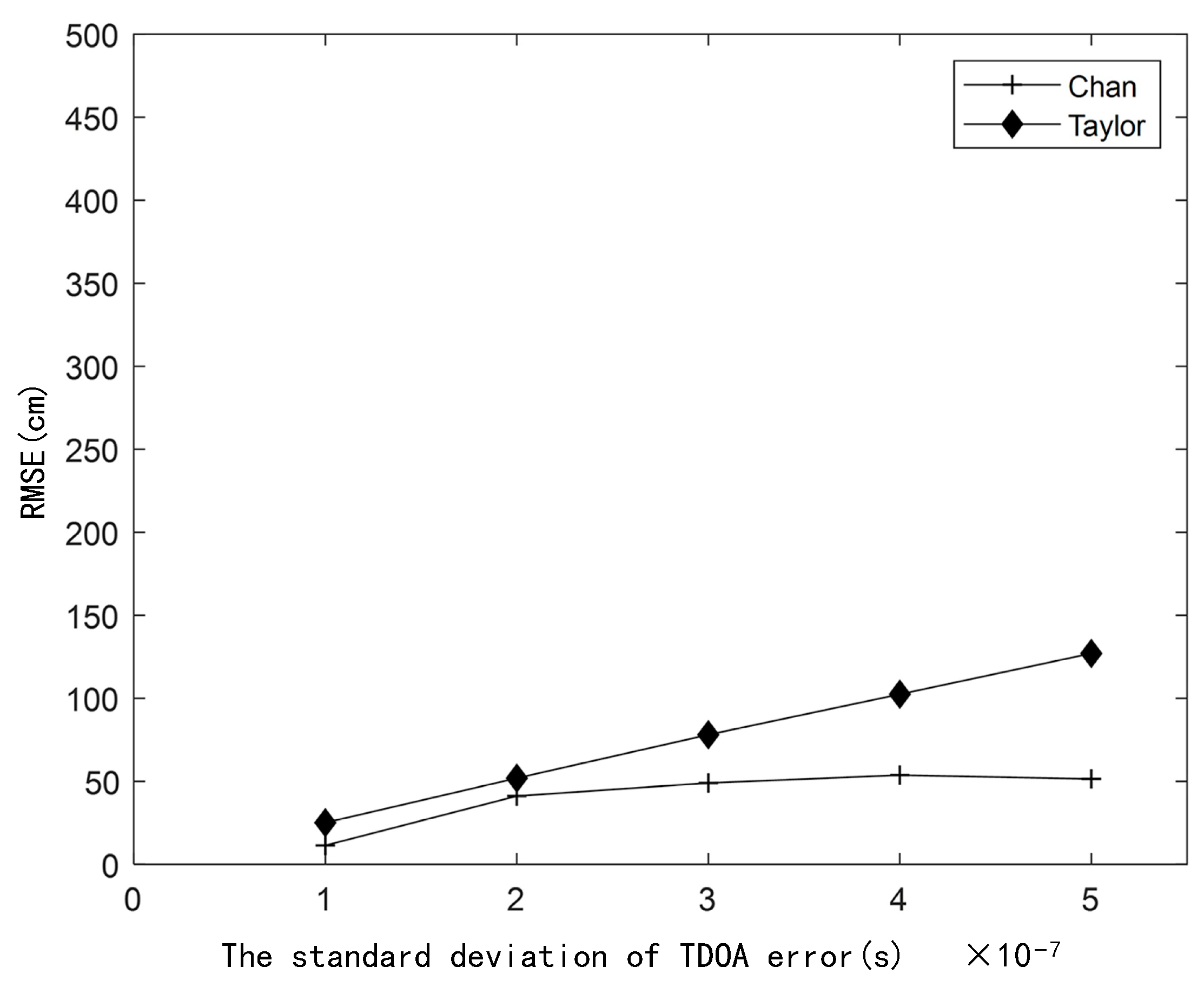

2.2.2. Performance Comparison Experiment between Chan Algorithm and Taylor Algorithm

3. Results and Discussion

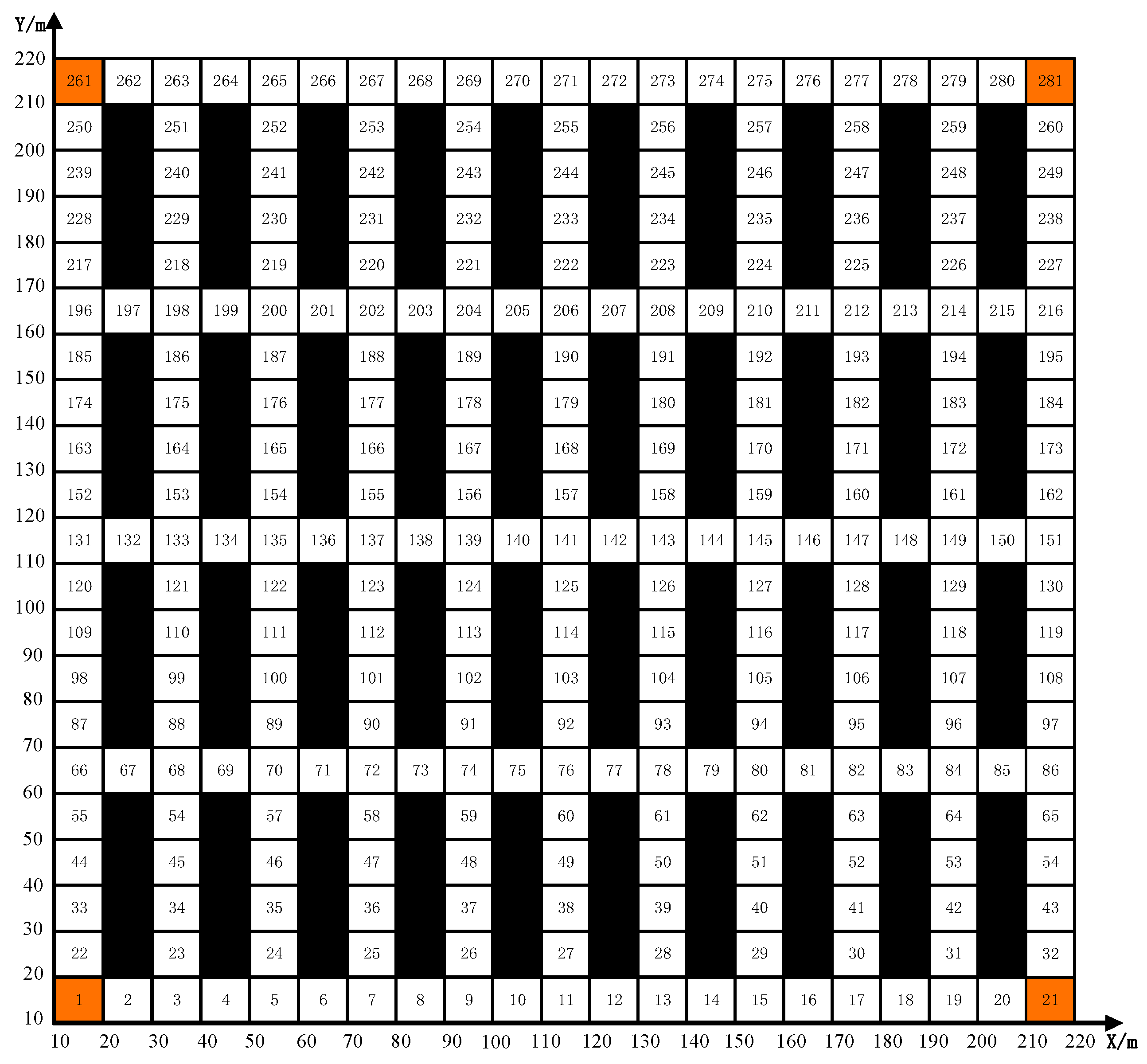

3.1. Experimental Scenarios

3.2. UWB Positioning Accuracy Test

3.2.1. The Ranging Test

3.2.2. The Positioning Test

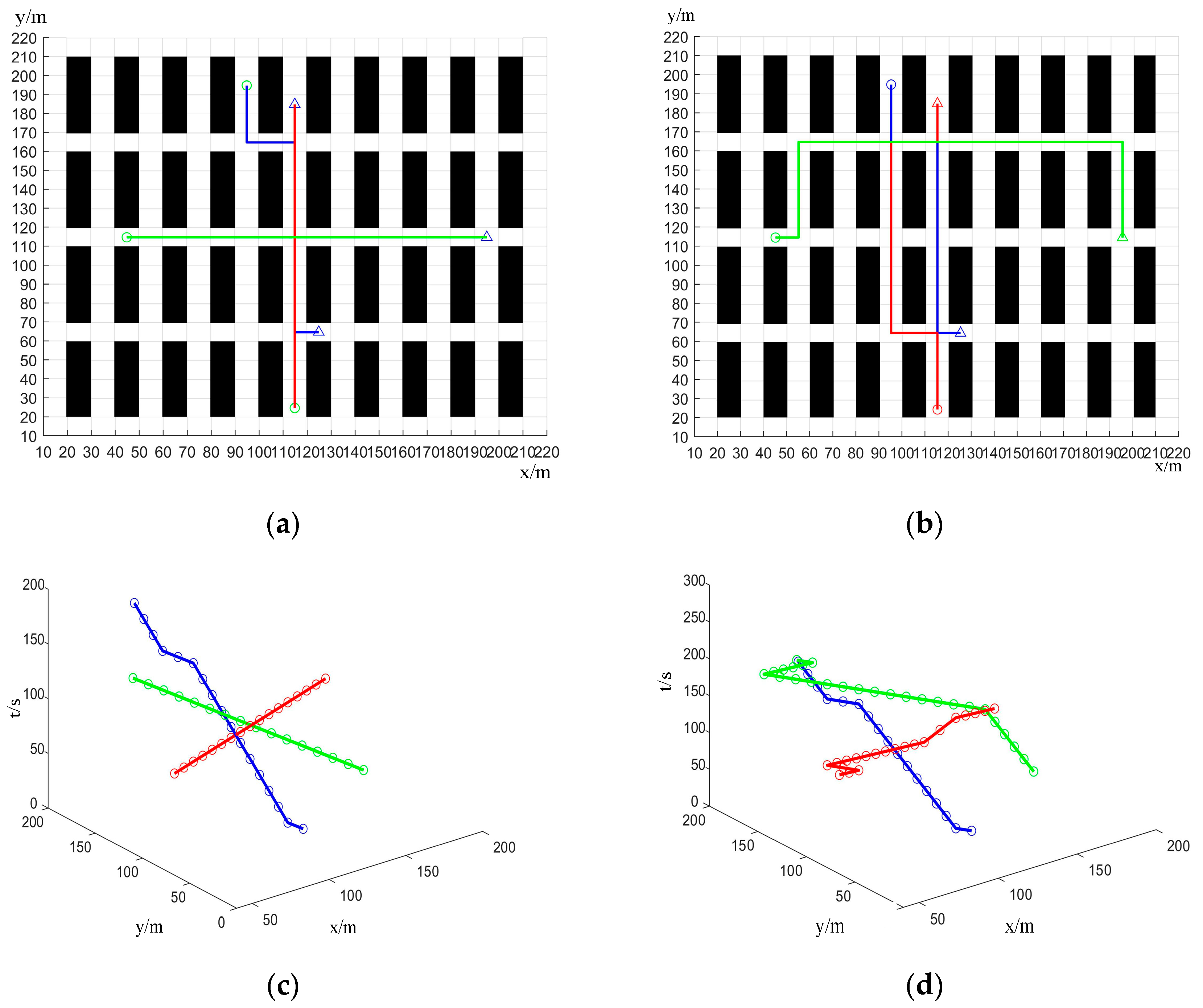

3.3. Dynamic Test Experiment

3.4. Formatting of Mathematical Components

- Delay waiting: As shown in Table 7, if the robot chooses to wait for a delay at station 60 before a conflict occurs, the robot can continue to pass when it passes through station 76. When the delay waiting strategy is adopted, the total traveling time of the robot is 221.4 s, the waiting time is 75.7 s, and the traveling distance remains unchanged. After the robot adopts the delay waiting strategy, the time of executing the distribution task increases by 48.62%, and the driving path does not change.

- Replanning: As shown in Table 7, after the replanning strategy is adopted, the robot’s traveling time is 197.1 s and its traveling distance is 150 m. After replanning, the delivery time and driving distance increase by 25.59% and 14.28%, respectively. Therefore, adopting the replanning strategy to solve the conflict between two robots can improve the efficiency of distribution.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lewis, R.H.; Papadimitriou, H.C. Elements of the Theory of Computation. ACM SIGACT News 1998, 29, 62–78. [Google Scholar] [CrossRef]

- Cook, S.A. The Complexity of Theorem Proving Procedures. In Proceedings of the 3rd Annual ACM Symposium on Theory of Computing, Shaker Heights, OH, USA, 3–5 May 1971; pp. 151–158. [Google Scholar]

- Wang, X.; Zhang, H.; Liu, S.; Wang, J.; Wang, Y.; Shangguan, D. Path planning of scenic spots based on improved A* algorithm. Sci. Rep. 2022, 12, 1320. [Google Scholar] [CrossRef] [PubMed]

- Sang, H.; You, Y.; Sun, X.; Zhou, Y.; Liu, F. The hybrid path planning algorithm based on improved A* and artificial potential field for unmanned surface vehicle formations. Ocean Eng. 2021, 223, 108709. [Google Scholar] [CrossRef]

- Hartomo, K.; Ismanto, B.; Nugraha, A.; Yulianto, S.; Laksono, B. Searching the shortest route to distribute disaster’s logistical assistance using Dijkstra method. J. Phys. Conf. Ser. 2019, 1402, 077014. [Google Scholar] [CrossRef]

- Ming, Y.; Li, Y.; Zhang, Z.; Yan, W. A survey of path planning algorithms for autonomous vehicles. Vehicles 2021, 3, 448–468. [Google Scholar] [CrossRef]

- Baoye, S.; Zidong, W.; Lei, Z. An improved PSO algorithm for smooth path planning of mobile robots using continuous high-degree Bezier curve. Appl. Soft Comput. J. 2021, 100, 106960. [Google Scholar]

- Hu, Y.; Yang, S.X.; Xu, L.Z.; Meng, M.H. A Knowledge Based Genetic Algorithm for Path Planning in Unstructured Mobile Robot Environments. In Proceedings of the 2004 IEEE International Conference on Robotics and Biomimetics, Shenyang, China, 22–26 August 2004; pp. 767–772. [Google Scholar]

- Roberge, V.; Tarbouchi, M.; Labonté, G. Comparison of Parallel Genetic Algorithm and Particle Swarm Optimization for Real-Time UAV Path Planning. IEEE Trans. Ind. Inform. 2013, 9, 132–141. [Google Scholar] [CrossRef]

- Nazarahari, M.; Khanmirza, E.; Doostie, S. Multi-objective multi-robot path planning in continuous environment using an enhanced genetic algorithm. Expert Syst. Appl. 2019, 115, 106–120. [Google Scholar] [CrossRef]

- Garcia, M.P.; Montiel, O.; Castillo, O.; Sepulveda, R.; Melin, P. Path planning for autonomous mobile robot navigation with ant colony optimization and fuzzy cost function evaluation. Appl. Soft Comput. 2009, 9, 1102–1110. [Google Scholar] [CrossRef]

- Miao, C.; Chen, G.; Yan, C.; Wu, Y. Path planning optimization of indoor mobile robot based on adaptive ant colony algorithm. Comput. Ind. Eng. 2021, 156, 107230. [Google Scholar] [CrossRef]

- Sharkawy, A.-N.; Papakonstantinou, C.; Papakostopoulos, V.; Moulianitis, V.C.; Aspragathos, N. Task Location for High Performance Human-Robot Collaboration. J. Intell. Robot. Syst. 2020, 100, 183–202. [Google Scholar] [CrossRef]

- Dijkstra, E.W. A note on two problems in connexion with graphs. Numer. Math. 1959, 1, 269–271. [Google Scholar] [CrossRef]

- Zhang, F.B. Three fastest shortest path algorithms on real road networks. J. Geogr. Inf. Decis. Anal. 1997, 1, 69–82. [Google Scholar]

- Ab Wahab, M.N.; Nefti-Meziani, S.; Atyabi, A. A comparative review on mobile robot path planning: Classical or meta-heuristic methods? Annu. Rev. Control 2020, 20, 50. [Google Scholar] [CrossRef]

- Sunita; Garg, D. Dynamizing Dijkstra: A solution to dynamic shortest path problem through retroactive priority queue. J. King Saud Univ. Comput. Inf. Sci. 2021, 33, 364–373. [Google Scholar] [CrossRef]

- Huang, Y.; Sun, J. Research on improved Dijkstra algorithm path planning based on automated wharf. Electron. Des. Eng. 2023, 31, 37–41. [Google Scholar]

- Qing, G.; Zheng, Z.; Yue, X. Path-Planning of Automated Guided Vehicle Based on Improved Dijkstra algorithm. In Proceedings of the 2017 29th Chinese Control and Decision Conference (CCDC), Chongqing, China, 28–30 May 2017. [Google Scholar]

- Yulan, Z.; Nannan, H. Airport AGV Path Optimization Model Based on Ant Colony Algorithm to Optimize Dijkstra Algorithm in Urban Systems. Sustain. Comput. Inform. Syst. 2022, 35, 100716. [Google Scholar]

- Duraklı, Z.; Nabiyev, V. A new approach based on bezier curves to solve path planning problems for mobile robots. J. Comput. Sci. 2021, 58, 101540. [Google Scholar] [CrossRef]

- Akram, M.; Habib, A.; Alcantud, R.C.J. An optimization study based on Dijkstra algorithm for a network with trapezoidal picture fuzzy numbers. Neural Comput. Appl. 2021, 20, 33. [Google Scholar] [CrossRef]

- Liu, L.S.; Lin, J.F.; Yao, J.X.; He, D.W.; Zheng, J.S.; Huang, J.; Shi, P. Path Planning for Smart Car Based on Dijkstra Algorithm and Dynamic Window Approach. Wirel. Commun. Mob. Comput. 2021, 2021, 8881684. [Google Scholar] [CrossRef]

- Szczesniak, I.; Wozna, B. Generic Dijkstra: Correctness and tractability. In Proceedings of the NOMS 2023–2023 IEEE/IFIP Network Operations and Management Symposiu, Miami, FL, USA, 8–12 May 2023; pp. 1–7. [Google Scholar]

- Reed, J.; Rappaport, T. An overview of the challenges and progress in meeting the E-911requirement for locaation. IEEE Commun. Mag. 1998, 36, 30–37. [Google Scholar] [CrossRef]

- Smolic-Rocak, N.; Bogdan, S.; Kovacic, Z.; Petrovic, T. Time Windows Based Dynamic Routing in Multi-AGV Systems. IEEE Trans. Autom. Sci. Eng. 2009, 7, 151–155. [Google Scholar] [CrossRef]

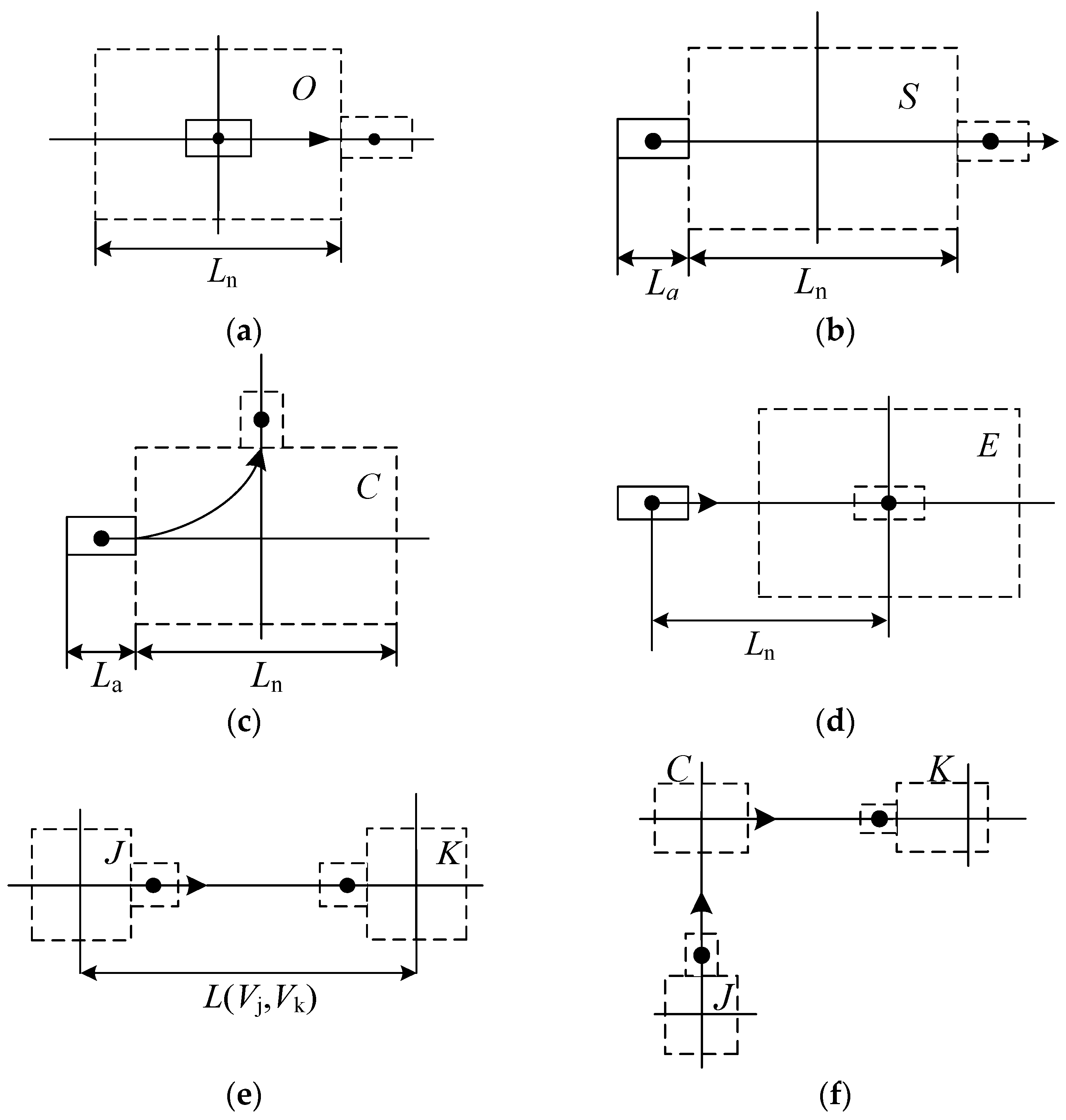

| Types of Time Window | Calculation |

|---|---|

| Drive out of the initial site | |

| Go straight through a station | |

| Turn to pass a station | |

| Pull into the target station | |

| Drive straight into from | |

| Turn into from |

| Constrained Object | Constraints |

|---|---|

| Number of robots from site to site | |

| Number of robots from site to site | |

| The number of robots on the path from site to must not exceed the maximum capacity | |

| No robot driving conflicts from site to site |

| Serial Number | The Mean Value of the UWB Measurements (m) | Actual Distance (m) | Error (m) |

|---|---|---|---|

| 1 | 206.41 | 206.27 | 0.14 |

| 2 | 211.37 | 211.23 | 0.13 |

| 3 | 222.12 | 222.33 | 0.21 |

| 4 | 231.99 | 231.80 | 0.19 |

| 5 | 246.87 | 246.69 | 0.18 |

| 6 | 248.52 | 248.67 | 0.15 |

| 7 | 261.80 | 261.62 | 0.18 |

| 8 | 271.59 | 271.44 | 0.15 |

| 9 | 281.71 | 281.54 | 0.17 |

| 10 | 284.03 | 284.13 | 0.10 |

| Serial Number | The Mean Coordinates of the UWB Measurements (m) | Actual Coordinates (m) | Error (m) |

|---|---|---|---|

| 1 | (101.22, 101.22) | (101.10, 101.10) | (0.12, 0.12) |

| 2 | (100.31, 131.64) | (100.01, 131.48) | (0.03, 0.16) |

| 3 | (121.76, 111.51) | (121.59, 111.36) | (0.17, 0.15) |

| 4 | (128.70, 128.63) | (128.83, 128.77) | (−0.13, −0.14) |

| 5 | (141.89, 171.22) | (141.71, 171.10) | (0.18, 0.12) |

| 6 | (151.99, 151.38) | (151.80, 151.25) | (0.19, 0.13) |

| 7 | (161.52, 111.61) | (161.02, 111.45) | (0.50, 0.16) |

| 8 | (171.75, 181.52) | (171.58, 181.37) | (0.17, 0.15) |

| 9 | (190.98, 151.46) | (190.89, 151.32) | (0.09, 0.14) |

| 10 | (181.55, 181.75) | (181.40, 181.58) | (0.15, 0.17) |

| Robots Serial Number | Priority | Initial Site | Target Site | The Planned Path before the Dynamic Adjustment | The Planned Path after the Dynamic Adjustment |

|---|---|---|---|---|---|

| Blue | P1 | 116 | 231 | 77-76-206-204-243 | 77-76-206-204-243 |

| Red | P2 | 168 | 236 | 233-27 | 233-206-204-74-76-27 |

| Green | P3 | 274 | 102 | 149-134 | 149-214-200-135-134 |

| Robots Serial Number | Priority | Initial Site | Target Site | The Planned Path before the Dynamic Adjustment |

|---|---|---|---|---|

| P1 | 222 | 51 | 222-141-76-80-51 | |

| P2 | 12 | 168 | 12-11-76-168 |

| Adjusting Policies | Path | Travel Time (s) | Distance (m) |

|---|---|---|---|

| Initial planning | 12-11-76-168 | 155.7 | 140 |

| Delay waiting | 12-11-76-168 | 231.4 | 140 |

| Replanning | 168-143-141-12-13-78 | 197.1 | 160 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Yan, J.; Yan, M.; Mao, K.; Yang, R.; Liu, W. Path Planning of Rail-Mounted Logistics Robots Based on the Improved Dijkstra Algorithm. Appl. Sci. 2023, 13, 9955. https://doi.org/10.3390/app13179955

Zhou X, Yan J, Yan M, Mao K, Yang R, Liu W. Path Planning of Rail-Mounted Logistics Robots Based on the Improved Dijkstra Algorithm. Applied Sciences. 2023; 13(17):9955. https://doi.org/10.3390/app13179955

Chicago/Turabian StyleZhou, Xiwei, Jingwen Yan, Mei Yan, Kaihao Mao, Ruizhe Yang, and Weiyu Liu. 2023. "Path Planning of Rail-Mounted Logistics Robots Based on the Improved Dijkstra Algorithm" Applied Sciences 13, no. 17: 9955. https://doi.org/10.3390/app13179955