A Comprehensive Review and Analysis of Nanosensors for Structural Health Monitoring in Bridge Maintenance: Innovations, Challenges, and Future Perspectives

Abstract

:1. Introduction

1.1. Background

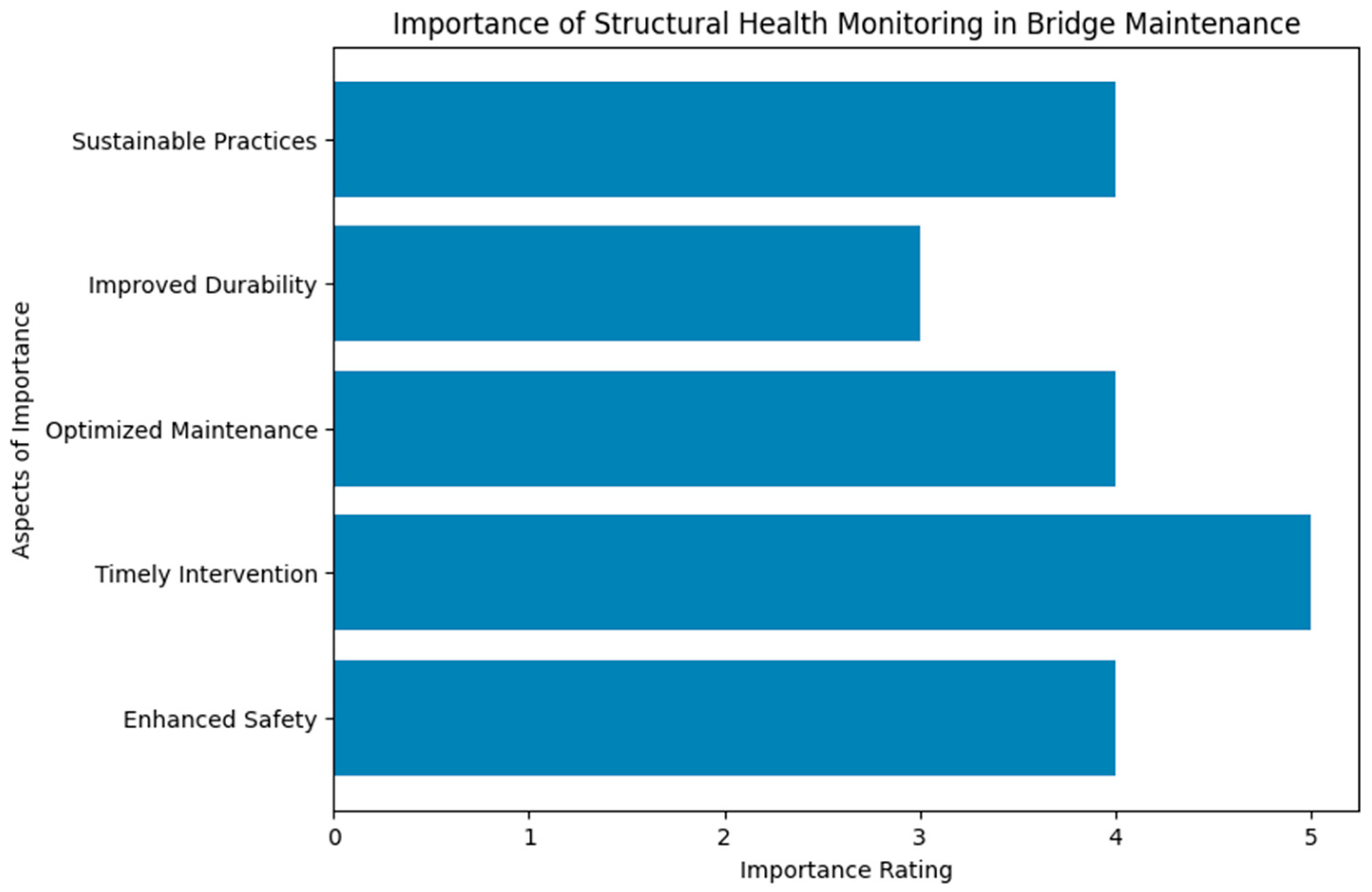

1.2. Importance of Structural Health Monitoring in Bridge Maintenance

1.3. Nanosensors: An Overview

2. Methods

- Literature Search: A thorough search was conducted using keywords and phrases related to nanosensors, bridge maintenance, structural health monitoring, and related topics. The search was limited to the Scopus and Web of Science databases to ensure access to high-quality, peer-reviewed academic literature.

- Inclusion Criteria: The search results were screened based on predefined inclusion criteria. Only research papers, review articles, and conference proceedings published in reputable journals or presented at recognized conferences were considered.

- Document Selection: The titles and abstracts of the search results were reviewed to identify documents relevant to the topic of nanosensors in bridge maintenance. Irrelevant or duplicate documents were excluded during this stage. The selected documents were then obtained in full-text format for detailed analysis.

- Data Extraction and Analysis: The selected documents were thoroughly read and analyzed to extract relevant information. Key findings, methodologies, case studies, and emerging trends were identified and documented. The information gathered from the literature was organized based on the different sections of the review paper.

- Critical Evaluation: The information extracted from the selected documents was critically evaluated to ensure accuracy, reliability, and relevance. The quality and impact of the studies were assessed based on the reputation of the authors, the journals or conferences in which the papers were published, and the rigor of the research methodology employed.

- Synthesis and Writing: The findings, insights, and key points from the selected documents were synthesized and incorporated into the corresponding sections of the review paper. The information was organized in a logical manner to present a comprehensive overview of the topic.

- Iterative Process: The methodology involved an iterative process, where additional searches and document selection were conducted based on the gaps identified during the analysis. This iterative process ensured a comprehensive coverage of the relevant literature and emerging trends in the field.

3. Results

3.1. Carbon Nanotube-Based Sensors

3.1.1. Synthesis Methods and Fabrication Techniques

3.1.2. Sensing Mechanisms and Applications

3.2. Graphene-Based Sensors

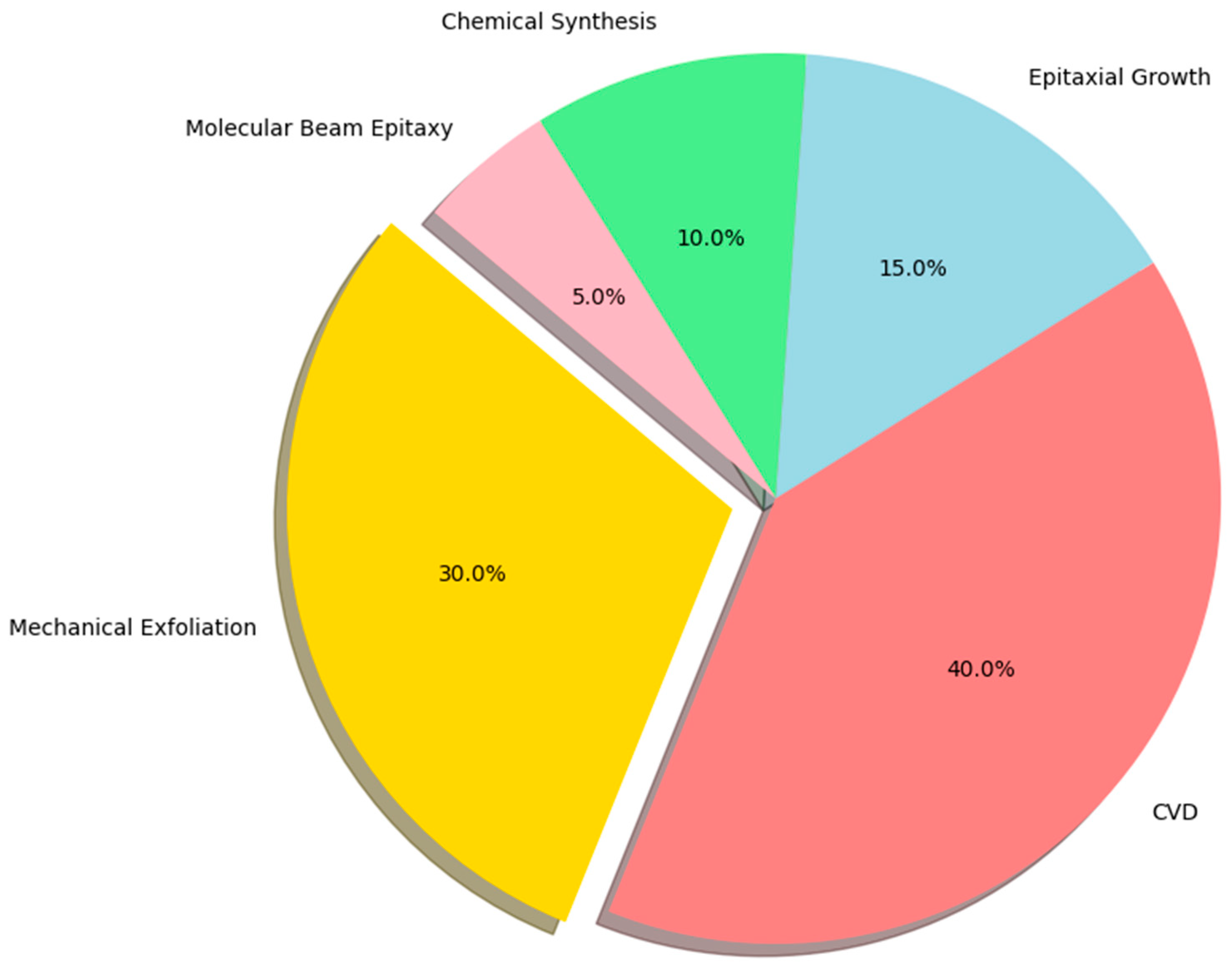

3.2.1. Fabrication Approaches and Growth Techniques

3.2.2. Sensing Properties and Potential Applications

3.3. Nanowire-Based Sensors

3.3.1. Growth Techniques and Sensor Design

3.3.2. Sensing Mechanisms and Performance Evaluation

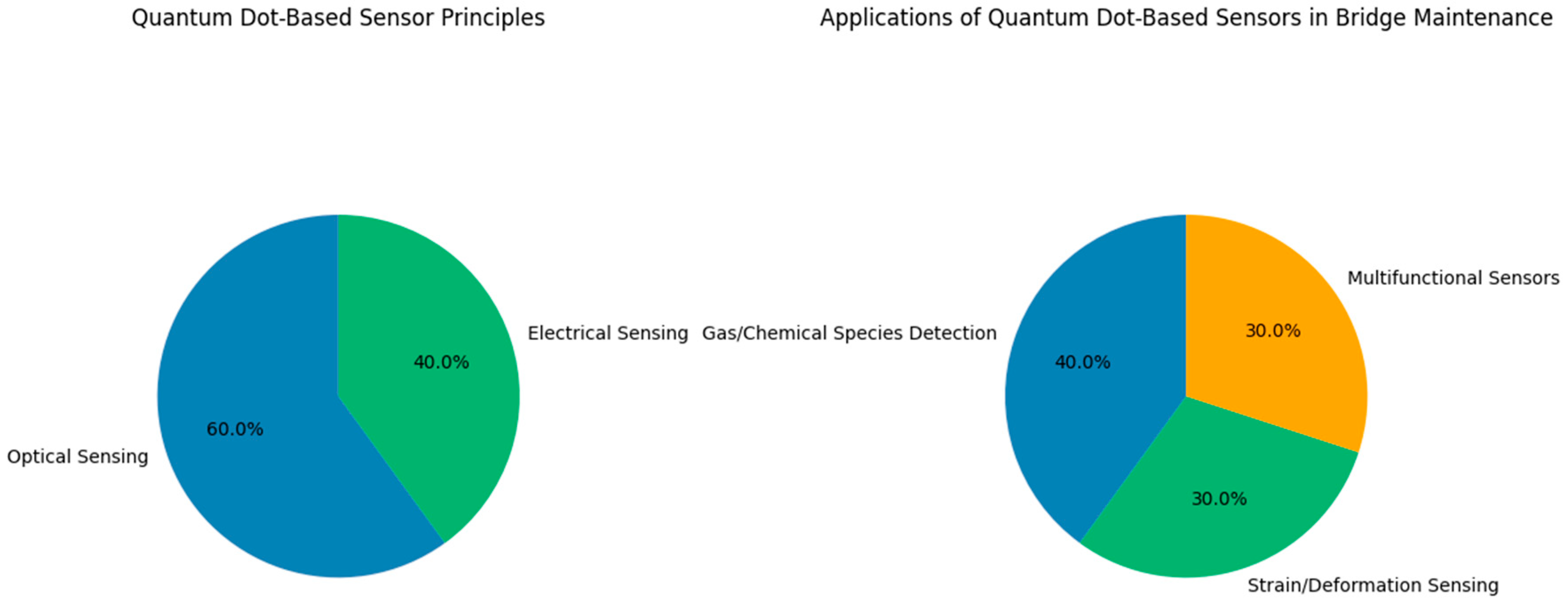

3.4. Quantum Dot-Based Sensors

3.4.1. Synthesis Approaches and Sensor Integration

3.4.2. Optical and Electrical Sensing Principles

3.5. Fabrication Techniques for Nanosensors

3.5.1. Top-Down Approaches

3.5.2. Bottom-Up Approaches

3.5.3. Hybrid Fabrication Techniques

3.6. Integration Strategies for Nanosensors in Bridge Maintenance

3.6.1. Sensor Placement and Distribution

3.6.2. Connection and Communication Infrastructure

3.6.3. Data Management and Analysis

- Data Pre-Processing and Calibration: Employ automated data pre-processing and calibration to manage noise and ensure accuracy in the data.

- Machine Learning and AI: Integrate machine learning algorithms and AI to derive predictive insights from the data, facilitating preemptive maintenance strategies.

- Visualization Tools: Develop intuitive visualization tools and dashboards that convey real-time and historical data in an accessible manner to various stakeholders.

3.6.4. Environmental and Long-Term Considerations

- Protective Coatings and Housings: Employ protective coatings and sensor housings that shield them from corrosive and abrasive elements without compromising data quality.

- Long-Term Calibration: Implement methods to ensure that sensors remain calibrated over extended periods and establish procedures for regular recalibration and maintenance.

- Material Compatibility: Ensure that the materials of the sensors are compatible with the bridge materials to prevent adverse reactions that could compromise structural integrity or sensor performance.

3.7. Power Supply Considerations

4. Challenges and Limitations of Nanosensor Deployment

4.1. Signal Processing and Data Interpretation

4.1.1. Unique Challenges in Nanosensor Data Management

4.1.2. High-Dimensional Data

4.2. Calibration and Sensor Reliability

4.2.1. Nanoscale Calibrations

4.2.2. Real-Time Monitoring and Reliability Assurance

4.3. Environmental Factors and Durability

4.3.1. Protecting Nanosensors from Environmental Nano-Particles

4.3.2. Durability against Nanoscale Wear and Tear

5. Case Studies and Applications

6. Discussion: Navigating the Expanse of Nanosensors in Structural Health Monitoring

7. Future Perspectives and Emerging Trends

7.1. Advancements in Sensing Materials and Nanofabrication Techniques

7.2. Internet of Things (IoT) Integration for Real-Time Monitoring

8. Conclusions

8.1. Summary of Key Findings

- -

- Nanosensors, such as carbon nanotube-based, graphene-based, nanowire-based, and quantum dot-based sensors, offer unique sensing capabilities for bridge maintenance, including strain monitoring, crack detection, corrosion sensing, and environmental monitoring.

- -

- Top-down fabrication techniques, such as lithography-based fabrication and chemical etching methods, provide precise control over sensor dimensions and structures, while bottom-up approaches, such as chemical vapor deposition and molecular self-assembly, enable the growth or assembly of nanosensors from atomic or molecular building blocks.

- -

- Integration strategies for nanosensors in bridge maintenance encompass sensor placement and distribution, connection and communication infrastructure, and power supply considerations. These strategies ensure effective data collection, analysis, and monitoring of bridge structures.

- -

- Challenges and limitations of nanosensor deployment include signal processing and data interpretation, calibration and sensor reliability, as well as environmental factors and durability. Overcoming these challenges requires advanced data analytics, calibration protocols, and robust sensor design.

- -

- Case studies and performance evaluations have demonstrated the effectiveness of nanosensors in bridge monitoring systems and their reliability and accuracy in real-world scenarios. Nanosensors have shown potential in detecting structural anomalies, optimizing maintenance strategies, and improving bridge safety and longevity.

8.2. Recommendations for Future Research

- -

- Continued exploration of novel sensing materials and nanofabrication techniques to enhance the performance, stability, and functionality of nanosensors.

- -

- Further development of IoT integration for seamless data transmission, real-time monitoring, and data-driven decision-making in bridge maintenance.

- -

- Advancement in AI and ML algorithms for efficient analysis and interpretation of nanosensor data, enabling predictive maintenance and early anomaly detection.

- -

- Investigation of the long-term durability, reliability, and scalability of nanosensors under diverse environmental conditions and bridge operational parameters.

- -

- Exploration of cost-effective manufacturing processes and large-scale deployment strategies for nanosensors to facilitate their widespread adoption in bridge maintenance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jeong, Y.; Kim, W.; Lee, I.; Lee, J. Bridge inspection practices and bridge management programs in China, Japan, Korea, and U.S. J. Struct. Integr. Maint. 2018, 3, 126–135. [Google Scholar] [CrossRef]

- Norris, A.; Saafi, M.; Romine, P. Temperature and moisture monitoring in concrete structures using embedded nanotechnology/microelectromechanical systems (MEMS) sensors. Constr. Build. Mater. 2008, 22, 111–120. [Google Scholar] [CrossRef]

- Ko, J.M.; Ni, Y.Q. Technology developments in structural health monitoring of large-scale bridges. Eng. Struct. 2005, 27, 1715–1725. [Google Scholar] [CrossRef]

- Chan, B.; Guan, H.; Hou, L.; Jo, J.; Blumenstein, M.; Wang, J. Defining a conceptual framework for the integration of modelling and advanced imaging for improving the reliability and efficiency of bridge assessments. J. Civ. Struct. Health Monit. 2016, 6, 703–714. [Google Scholar] [CrossRef]

- Martinez-Luengo, M.; Kolios, A.; Wang, L. Structural health monitoring of offshore wind turbines: A review through the Statistical Pattern Recognition Paradigm. Renew. Sustain. Energy Rev. 2016, 64, 91–105. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Rab, S.; Suman, R. Exploring the potential of nanosensors: A brief overview. Sens. Int. 2021, 2, 100130. [Google Scholar] [CrossRef]

- Dong, L.; Xu, X.; Sun, K.; Ding, Y.; Ouyang, P.; Wang, P. Sensing analysis based on fano resonance in arch bridge structure. J. Phys. Commun. 2018, 2, 105010. [Google Scholar] [CrossRef]

- Li, J. Nano Sensors and Devices for Space and Terrestrial Applications. In Proceedings of the Space 2005, Long Beach, CA, USA, 30 August–1 September 2005; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2015. [Google Scholar] [CrossRef]

- Qureshi, A.; Kang, W.P.; Davidson, J.L.; Gurbuz, Y. Review on carbon-derived, solid-state, micro and nano sensors for electrochemical sensing applications. Diam. Relat. Mater. 2009, 18, 1401–1420. [Google Scholar] [CrossRef]

- Rizzo, P.; Enshaeian, A. Challenges in Bridge Health Monitoring: A Review. Sensors 2021, 21, 4336. [Google Scholar] [CrossRef]

- Harms, T.; Sedigh, S.; Bastianini, F. Structural Health Monitoring of Bridges Using Wireless Sensor Networks. IEEE Instrum. Meas. Mag. 2010, 13, 14–18. [Google Scholar] [CrossRef]

- Kaya, Y.; Safak, E. Real-time analysis and interpretation of continuous data from structural health monitoring (SHM) systems. Bull. Earthq. Eng. 2014, 13, 917–934. [Google Scholar] [CrossRef]

- Sigurdardottir, D.H.; Glisic, B. On-site validation of fiber-optic methods for structural health monitoring: Streicker Bridge. J. Civ. Struct. Health Monit. 2015, 5, 529–549. [Google Scholar] [CrossRef]

- Drissi-Habti, M.; Betti, R.; Yanev, B. Structural Health Monitoring of Bridge Cables. ASNT NDT Library. 2009. Available online: https://ndtlibrary.asnt.org/2009/StructuralHealthMonitoringofBridgeCables (accessed on 27 May 2023).

- Farhoud, M. The Use of Nanosensors for Monitoring Civil Structures. 2018. Available online: https://pearl.plymouth.ac.uk/handle/10026.1/14186 (accessed on 27 May 2023).

- Drissi-Habti, M. Smart Composites for Durable Infrastructures—Importance of Structural Health Monitoring (SHM). In Advances in FRP Composites in Civil Engineering; Ye, L., Feng, P., Yue, Q., Eds.; Springer: Berlin, Heidelberg, 2011; pp. 264–267. [Google Scholar] [CrossRef]

- Lebental, B.; Ghaddab, B.; Michelis, F. Nanosensors for Embedded Monitoring of Construction Materials: The ‘2D Conformable’ Route. In Nanotechnology in Construction; Sobolev, K., Shah, S.P., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 383–388. [Google Scholar] [CrossRef]

- Lieber, C.M. Nanoscale Science and Technology: Building a Big Future from Small Things. MRS Bull. 2003, 28, 486–491. [Google Scholar] [CrossRef]

- Tang, R.; Shi, Y.; Hou, Z.; Wei, L. Carbon Nanotube-Based Chemiresistive Sensors. Sensors 2017, 17, 882. [Google Scholar] [CrossRef] [PubMed]

- Abdulhameed, A.; Halin, I.A.; Mohtar, M.N.; Hamidon, M.N. Airflow-assisted dielectrophoresis to reduce the resistance mismatch in carbon nanotube-based temperature sensors. RSC Adv. 2021, 11, 39311–39318. [Google Scholar] [CrossRef]

- Justino, C.I.L.; Gomes, A.R.; Freitas, A.C.; Duarte, A.C.; Rocha-Santos, T.A.P. Graphene based sensors and biosensors. TrAC Trends Anal. Chem. 2017, 91, 53–66. [Google Scholar] [CrossRef]

- Peña-Bahamonde, J.; Nguyen, H.N.; Fanourakis, S.K.; Rodrigues, D.F. Recent advances in graphene-based biosensor technology with applications in life sciences. J. Nanobiotechnol. 2018, 16, 1–17. [Google Scholar] [CrossRef]

- Ramgir, N.S.; Yang, Y.; Zacharias, M. Nanowire-Based Sensors. Small 2010, 6, 1705–1722. [Google Scholar] [CrossRef]

- Abdel-Karim, R.; Reda, Y.; Abdel-Fattah, A. Review—Nanostructured Materials-Based Nanosensors. J. Electrochem. Soc. 2020, 167, 037554. [Google Scholar] [CrossRef]

- Biswas, A.; Bayer, I.S.; Biris, A.S.; Wang, T.; Dervishi, E.; Faupel, F. Advances in top–down and bottom–up surface nanofabrication: Techniques, applications & future prospects. Adv. Colloid Interface Sci. 2012, 170, 2–27. [Google Scholar]

- Khanna, V.K. (Ed.) Bottom-up Nanofabrication. In Integrated Nanoelectronics: Nanoscale CMOS, Post-CMOS and Allied Nanotechnologies; NanoScience and Technology; Springer India: New Delhi, India, 2016; pp. 397–417. [Google Scholar]

- Teo, B.K.; Sun, X.H. From Top-Down to Bottom-Up to Hybrid Nanotechnologies: Road to Nanodevices. J. Clust. Sci. 2006, 17, 529–540. [Google Scholar] [CrossRef]

- Mustapha, S.; Lu, Y.; Ng, C.-T.; Malinowski, P. Sensor Networks for Structures Health Monitoring: Placement, Implementations, and Challenges—A Review. Vibration 2021, 4, 551–585. [Google Scholar] [CrossRef]

- Li, X.; Zhang, X.; Werschmoeller, D.; Choi, H.; Cheng, X. Embedded micro/nano sensors for harsh engineering environments. In Proceedings of the 2008 IEEE Sensors, Lecce, Italy, 26–29 October 2008; pp. 1273–1276. [Google Scholar] [CrossRef]

- Thammadi, S.P.D.; Pisini, S.K. Nanotechnology and building construction: Towards effective stakeholder engagement. IOP Conf. Ser. Earth Environ. Sci. 2022, 1084, 012074. [Google Scholar] [CrossRef]

- Kim, K.-H.; Hong, S.K.; Ha, S.-H.; Li, L.; Lee, H.W.; Kim, J.-M. Enhancement of linearity range of stretchable ultrasensitive metal crack strain sensor via superaligned carbon nanotube-based strain engineering. Mater. Horiz. 2020, 7, 2662–2672. [Google Scholar] [CrossRef]

- Chowdhury, R.; Adhikari, S.; Mitchell, J. Vibrating carbon nanotube based bio-sensors. Phys. Low Dimens. Syst. Nanostruct. 2009, 42, 104–109. [Google Scholar] [CrossRef]

- Zhao, N.; Wu, Q.; Zhang, X.; Yang, T.; Li, D.; Zhang, X.; Ma, C.; Liu, R.; Xin, L.; He, M. Chemical vapor deposition growth of single-walled carbon nanotubes from plastic polymers. Carbon 2022, 187, 29–34. [Google Scholar] [CrossRef]

- Klimin, V.S.; Rezvan, A.A.; Ageev, O.A. Study of the effect of carbon-containing gas pressure on the geometric parameters of an array of carbon nanostructures. J. Phys. Conf. Ser. 2018, 1124, 022035. [Google Scholar] [CrossRef]

- Kohls, A.; Ditty, M.M.; Dehghandehnavi, F.; Zheng, S.-Y. Vertically Aligned Carbon Nanotubes as a Unique Material for Biomedical Applications. ACS Appl. Mater. Interfaces 2022, 14, 6287–6306. [Google Scholar] [CrossRef]

- Corletto, A.; Shapter, J.G. Discontinuous Dewetting, Template-Guided Self-Assembly, and Liquid Bridge-Transfer Printing of High-Resolution Single-Walled Carbon Nanotube Lines for Next-Generation Electrodes and Interconnects. ACS Appl. Nano Mater. 2020, 3, 8148–8160. [Google Scholar] [CrossRef]

- Prajapati, S.K.; Agnihotri, T.; Gomte, S.S.; Jain, A. Surface Modification Strategies for the Carbon Nanotubes. In Chemically Modified Carbon Nanotubes for Commercial Applications; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2023; pp. 51–74. [Google Scholar] [CrossRef]

- Tang, Z.-H.; Li, Y.-Q.; Huang, P.; Wang, H.; Hu, N.; Fu, S.-Y. Comprehensive evaluation of the piezoresistive behavior of carbon nanotube-based composite strain sensors. Compos. Sci. Technol. 2021, 208, 108761. [Google Scholar] [CrossRef]

- Hur, O.-N.; Ha, J.-H.; Park, S.-H. Strain-Sensing Properties of Multi-Walled Carbon Nanotube/Polydimethylsiloxane Composites with Different Aspect Ratio and Filler Contents. Materials 2020, 13, 2431. [Google Scholar] [CrossRef]

- Zhao, B.; Sivasankar, V.S.; Subudhi, S.K.; Dasgupta, A.; Das, S. Printed Carbon Nanotube-Based Humidity Sensors Deployable on Surfaces of Widely Varying Curvatures. ACS Appl. Nano Mater. 2023, 6, 1459–1474. [Google Scholar] [CrossRef]

- Abdulla, S.; Dhakshinamoorthy, J.; Mohan, V.; Ponnuvelu, D.V.; Kallidaikuruchi, V.K.; Thalakkotil, L.M.; Pullithadathil, B. Development of low-cost hybrid multi-walled carbon nanotube-based ammonia gas-sensing strips with an integrated sensor read-out system for clinical breath analyzer applications. J. Breath Res. 2019, 13, 046005. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Zhang, X.; Puthirath, A.B.; Meiyazhagan, A.; Bhattacharyya, S.; Rahman, M.M.; Babu, G.; Susarla, S.; Saju, S.K.; Tran, M.K.; et al. Structure, Properties and Applications of Two-Dimensional Hexagonal Boron Nitride. Adv. Mater. 2021, 33, 2101589. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, A.A.; Sakib, N.; Iqbal, A.P.; Nuruzzaman, D.M. Graphene-based nanocomposites and their fabrication, mechanical properties and applications. Materialia 2020, 12, 100815. [Google Scholar] [CrossRef]

- Chen, J.; Duan, M.; Chen, G. Continuous mechanical exfoliation of graphene sheets via three-roll mill. J. Mater. Chem. 2012, 22, 19625–19628. [Google Scholar] [CrossRef]

- Zhu, F.-F.; Chen, W.-J.; Xu, Y.; Gao, C.-L.; Guan, D.-D.; Liu, C.-H.; Qian, D.; Zhang, S.-C.; Ji, J.-F. Epitaxial growth of two-dimensional stanene. Nat. Mater. 2015, 14, 1020–1025. [Google Scholar] [CrossRef]

- Zhan, N.; Olmedo, M.; Wang, G.; Liu, J. Layer-by-layer synthesis of large-area graphene films by thermal cracker enhanced gas source molecular beam epitaxy. Carbon 2011, 49, 2046–2052. [Google Scholar] [CrossRef]

- Yusof, N.M.; Ibrahim, S.; Rozali, S. Advances on graphene-based gas sensors for acetone detection based on its physical and chemical attributes. J. Mater. Res. 2022, 37, 405–423. [Google Scholar] [CrossRef]

- Mathew, R.; Ajayan, J. Material processing, performance and reliability of MoS2 field effect transistor (FET) technology—A critical review. Mater. Sci. Semicond. Process. 2023, 160, 107397. [Google Scholar] [CrossRef]

- Mehmood, A.; Mubarak, N.M.; Khalid, M.; Walvekar, R.; Abdullah, E.C.; Siddiqui, M.T.H.; Baloch, H.A.; Nizamuddin, S.; Mazari, S. Graphene based nanomaterials for strain sensor application—A review. J. Environ. Chem. Eng. 2020, 8, 103743. [Google Scholar] [CrossRef]

- Zhao, G.; Li, X.; Huang, M.; Zhen, Z.; Zhong, Y.; Chen, Q.; Zhao, X.; He, Y.; Hu, R.; Yang, T.; et al. The physics and chemistry of graphene-on-surfaces. Chem. Soc. Rev. 2017, 46, 4417–4449. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Duan, S.; Zhao, H. Advances in constructing silver nanowire-based conductive pathways for flexible and stretchable electronics. Nanoscale 2022, 14, 11484–11511. [Google Scholar] [CrossRef] [PubMed]

- Sunkara, M.K.; Sharma, S.; Miranda, R.; Lian, G.; Dickey, E.C. Bulk synthesis of silicon nanowires using a low-temperature vapor–liquid–solid method. Appl. Phys. Lett. 2001, 79, 1546–1548. [Google Scholar] [CrossRef]

- Desplanque, L.; Bucamp, A.; Troadec, D.; Patriarche, G.; Wallart, X. In-plane InSb nanowires grown by selective area molecular beam epitaxy on semi-insulating substrate. Nanotechnology 2018, 29, 305705. [Google Scholar] [CrossRef]

- Varghese, S.S.; Lonkar, S.; Singh, K.K.; Swaminathan, S.; Abdala, A. Recent advances in graphene based gas sensors. Sens. Actuators B Chem. 2015, 218, 160–183. [Google Scholar] [CrossRef]

- Huang, J.; Wang, H.; Liang, B.; Etim, U.J.; Liu, Y.; Li, Y.; Yan, Z. Oriented freeze-casting fabrication of resilient copper nanowire-based aerogel as robust piezoresistive sensor. Chem. Eng. J. 2019, 364, 28–36. [Google Scholar] [CrossRef]

- Chang, S.M.; Palanisamy, S.; Wu, T.H.; Chen, C.Y.; Cheng, K.H.; Lee, C.Y.; Yuan, S.S.-F.; Wang, Y.-M. Utilization of silicon nanowire field-effect transistors for the detection of a cardiac biomarker, cardiac troponin I and their applications involving animal models. Sci. Rep. 2020, 10, 22027. [Google Scholar] [CrossRef]

- Yang, Y.; Duan, S.; Xiao, W.; Zhao, H. Silver nanowire-based stretchable strain sensors with hierarchical wrinkled structures. Sens. Actuators A Phys. 2022, 343, 113653. [Google Scholar] [CrossRef]

- Ning, H.; Ye, X.; Sada, A.B.; Mao, L.; Daneshmand, M. An Attention Mechanism Inspired Selective Sensing Framework for Physical-Cyber Mapping in Internet of Things. IEEE Internet Things J. 2019, 6, 9531–9544. [Google Scholar] [CrossRef]

- Mele, L.J.; Palestri, P.; Selmi, L. Modeling Selectivity and Cross-sensitivity in membrane-based potentiometric sensors. In Proceedings of the 2020 Joint International EUROSOI Workshop and International Conference on Ultimate Integration on Silicon (EUROSOI-ULIS), Caen, France, 1–30 September 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Sivasankarapillai, V.S.; Jose, J.; Shanavas, M.S.; Marathakam, A.; Uddin, M.S.; Mathew, B. Silicon Quantum Dots: Promising Theranostic Probes for the Future. Curr. Drug Targets 2019, 20, 1255–1263. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Ye, Z.; Yang, L.; Li, J.; Qin, H.; Peng, X. Synthesis of Colloidal Quantum Dots with an Ultranarrow Photoluminescence Peak. Chem. Mater. 2021, 33, 1799–1810. [Google Scholar] [CrossRef]

- De Arquer, F.P.G.; Talapin, D.V.; Klimov, V.I.; Arakawa, Y.; Bayer, M.; Sargent, E.H. Semiconductor quantum dots: Technological progress and future challenges. Science 2021, 373, aaz8541. [Google Scholar] [CrossRef] [PubMed]

- Aubert, T.; Golovatenko, A.A.; Samoli, M.; Lermusiaux, L.; Zinn, T.; Abécassis, B.; Rodina, A.V.; Hens, Z. General Expression for the Size-Dependent Optical Properties of Quantum Dots. Nano Lett. 2022, 22, 1778–1785. [Google Scholar] [CrossRef] [PubMed]

- Jorns, M.; Pappas, D. A Review of Fluorescent Carbon Dots, Their Synthesis, Physical and Chemical Characteristics, and Applications. Nanomaterials 2021, 11, 1448. [Google Scholar] [CrossRef] [PubMed]

- Cornia, S.; Demontis, V.; Zannier, V.; Sorba, L.; Ghirri, A.; Rossella, F.; Affronte, M. Calibration-Free and High-Sensitivity Microwave Detectors Based on InAs/InP Nanowire Double Quantum Dots. Adv. Funct. Mater. 2023, 33, 2212517. [Google Scholar] [CrossRef]

- Kahmann, S.; Shulga, A.; Loi, M.A. Quantum Dot Light-Emitting Transistors—Powerful Research Tools and Their Future Applications. Adv. Funct. Mater. 2019, 30, 1904174. [Google Scholar] [CrossRef]

- Li, D.; Wang, J. Semiconductor/Carbon Quantum Dot-based Hue Recognition Strategy for Point of Need Testing: A Review. ChemistryOpen 2023, 12, e202200165. [Google Scholar] [CrossRef]

- Domonkos, M.; Kromka, A. Nanosphere Lithography-Based Fabrication of Spherical Nanostructures and Verification of Their Hexagonal Symmetries by Image Analysis. Symmetry 2022, 14, 2642. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, J.; Wang, T.; Su, X.; Yang, S.; Chen, W.; Wang, J.; Sun, J.; Peng, J. High-performance microwave absorption epoxy composites filled with hollow nickel nanoparticles modified graphene via chemical etching method. Compos. Sci. Technol. 2019, 176, 54–63. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, F.; Shenoy, V.B.; Tang, M.; Lou, J. Towards controlled synthesis of 2D crystals by chemical vapor deposition (CVD). Mater. Today 2020, 40, 132–139. [Google Scholar] [CrossRef]

- Zhang, X.; Li, N.; Zhang, S.; Sun, B.; Chen, Q.; He, Z.; Luo, C.; Sun, J. Emerging carrier-free nanosystems based on molecular self-assembly of pure drugs for cancer therapy. Med. Res. Rev. 2020, 40, 1754–1775. [Google Scholar] [CrossRef] [PubMed]

- Seo, M.; Yoo, J.; Jo, M.; Yoon, J. Geometrically Structured Nanomaterials for Nanosensors, NEMS, and Nanosieves. Adv. Mater. 2020, 32, e190708. [Google Scholar] [CrossRef] [PubMed]

- Young, C.; Yi, B.-Y.; Chen, H.-T. Template-assisted fabrication of CuxS–C hybrid-structure-based electrodes for electrochemical applications. Chem. Eng. J. 2022, 428, 132549. [Google Scholar] [CrossRef]

- Li, X.-Z.; Tian, C.-B.; Sun, Q.-F. Coordination-Directed Self-Assembly of Functional Polynuclear Lanthanide Supramolecular Architectures. Chem. Rev. 2022, 122, 6374–6458. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.-J.; Zhang, D.-L.; Hua, P.-R. Ultra-narrow and ultra-strong nanojet for nanopatterning and nanolithography. Optik 2022, 255, 168726. [Google Scholar] [CrossRef]

- Yang, C. An adaptive sensor placement algorithm for structural health monitoring based on multi-objective iterative optimization using weight factor updating. Mech. Syst. Signal Process. 2021, 151, 107363. [Google Scholar] [CrossRef]

- Hansen, M. Determination and assessment of fatigue stresses on concrete bridges. Struct. Concr. 2020, 21, 1286–1297. [Google Scholar] [CrossRef]

- Jeong, J.-H.; Jo, H.; Laflamme, S.; Li, J.; Downey, A.; Bennett, C.; Collins, W.; Taher, S.A.; Liu, H.; Jung, H.-J. Automatic control of AC bridge-based capacitive strain sensor interface for wireless structural health monitoring. Measurement 2022, 202, 111789. [Google Scholar] [CrossRef]

- Shitharth, S.; Meshram, P.; Kshirsagar, P.R.; Manoharan, H.; Tirth, V.; Sundramurthy, V.P. Impact of Big Data Analysis on Nanosensors for Applied Sciences Using Neural Networks. J. Nanomater. 2021, 2021, e4927607. [Google Scholar] [CrossRef]

- Zeinali, M.; Barenji, R.V. Communication Networks Characteristics Impact on Cyber-Physical Systems. In Control Engineering in Mechatronics; Azizi, A., Ed.; Emerging Trends in Mechatronics; Springer Nature: Singapore, 2023; pp. 189–202. [Google Scholar] [CrossRef]

- Wilson, A.N.; Kumar, A.; Jha, A.; Cenkeramaddi, L.R. Embedded Sensors, Communication Technologies, Computing Platforms and Machine Learning for UAVs: A Review. IEEE Sens. J. 2022, 22, 1807–1826. [Google Scholar] [CrossRef]

- Abdulzahra, A.M.K.; Al-Qurabat, A.K.M.; Abdulzahra, S.A. Optimizing energy consumption in WSN-based IoT using unequal clustering and sleep scheduling methods. Internet Things 2023, 22, 100765. [Google Scholar] [CrossRef]

- Haroun, A.F.; Le, X.; Gao, S.; Dong, B.; He, T.; Zhang, Z.; Wen, F.; Xu, S.; Lee, C. Progress in micro/nano sensors and nanoenergy for future AIoT-based smart home applications. Nano Express 2021, 2, 022005. [Google Scholar] [CrossRef]

- Boitier, V.; Estibals, B.; Huet, F.; Seguier, L. Battery-Free Power Supply for Wireless Sensor Combining Photovoltaic Cells and Supercapacitors. Energy Power Eng. 2023, 15, 151–179. [Google Scholar] [CrossRef]

- Hiran, K.K.; Khazanchi, D.; Vyas, A.K.; Padmanaban, S. Machine Learning for Sustainable Development; Walter de Gruyter GmbH & Co KG: Berlin, Germany, 2021. [Google Scholar]

- Giouroukis, D.; Dadiani, A.; Traub, J.; Zeuch, S.; Markl, V. A survey of adaptive sampling and filtering algorithms for the internet of things. In Proceedings of the 14th ACM International Conference on Distributed and Event-Based Systems, Montreal, QC, Canada, 13–17 July 2020; Available online: https://dl.acm.org/doi/abs/10.1145/3401025.3403777 (accessed on 29 May 2023).

- Leong, Y.X.; Tan, E.X.; Leong, S.X.; Koh, C.S.L.; Nguyen, L.B.T.; Chen, J.R.T.; Xia, K.; Ling, X.Y. Where Nanosensors Meet Machine Learning: Prospects and Challenges in Detecting Disease X. ACS Nano 2022, 16, 13279–13293. [Google Scholar] [CrossRef]

- Zhang, C.; Mousavi, A.A.; Masri, S.F.; Gholipour, G.; Yan, K.; Li, X. Vibration feature extraction using signal processing techniques for structural health monitoring: A review. Mech. Syst. Signal Process. 2022, 177, 109175. [Google Scholar] [CrossRef]

- Qiu, S.; Zhao, H.; Jiang, N.; Wang, Z.; Liu, L.; An, Y.; Zhao, H.; Miao, X.; Liu, R.; Fortino, G. Multi-sensor information fusion based on machine learning for real applications in human activity recognition: State-of-the-art and research challenges. Inf. Fusion 2022, 80, 241–265. [Google Scholar] [CrossRef]

- Ye, C.; Butler, L.; Calka, B.; Iangurazov, M.; Lu, Q.; Gregory, A.; Girolami, M.; Middleton, C. A Digital Twin of Bridges for Structural Health Monitoring; DEStech Publications, Inc.: Lancaster, PA, USA, 2019; Available online: https://www.repository.cam.ac.uk/handle/1810/316786 (accessed on 29 May 2023).

- Hosamo, H.H.; Hosamo, M.H. Digital Twin Technology for Bridge Maintenance Using 3D Laser Scanning: A Review. Adv. Civ. Eng. 2022, 2022, e2194949. [Google Scholar] [CrossRef]

- Tien, T.; Saccomano, S.C.; Martin, P.A.; Armstrong, M.S.; Prud’homme, R.K.; Cash, K.J. Sensors in a Flash! Oxygen Nanosensors for Microbial Metabolic Monitoring Synthesized by Flash Nanoprecipitation. ACS Sensors 2022, 7, 2606–2614. [Google Scholar] [CrossRef]

- Pu, H.; Xu, Y.; Sun, D.-W.; Wei, Q.; Li, X. Optical nanosensors for biofilm detection in the food industry: Principles, applications and challenges. Crit. Rev. Food Sci. Nutr. 2021, 61, 2107–2124. [Google Scholar] [CrossRef]

- Giordano, P.F.; Quqa, S.; Limongelli, M.P. Value of information analysis accounting for data quality. In Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2023; SPIE: Bellingham, WA, USA, 2023; pp. 235–245. [Google Scholar] [CrossRef]

- Naderi, A.; Behdad, S.; Fakher, M.; Hosseini-Hashemi, S. Vibration analysis of mass nanosensors with considering the axial-flexural coupling based on the two-phase local/nonlocal elasticity. Mech. Syst. Signal Process. 2020, 145, 106931. [Google Scholar] [CrossRef]

- Singh, A.R.; Desu, P.K.; Nakkala, R.K.; Kondi, V.; Devi, S.; Alam, M.S.; Hamid, H.; Athawale, R.B.; Kesharwani, P. Nanotechnology-based approaches applied to nutraceuticals. Drug Deliv. Transl. Res. 2022, 12, 485–499. [Google Scholar] [CrossRef] [PubMed]

- Theka, T.J.; Motaung, D.E. Chapter 6—Smart and autonomous (self-powered) nanosensor networks. In Nanotechnology-Based Smart Remote Sensing Networks for Disaster Prevention; Denizli, A., Alencar, M.S., Nguyen, T.A., Motaung, D.E., Eds.; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2022; pp. 105–121. [Google Scholar] [CrossRef]

- Alabdulatif, A.; Thilakarathne, N.N.; Lawal, Z.K.; Fahim, K.E.; Zakari, R.Y. Internet of Nano-Things (IoNT): A Comprehensive Review from Architecture to Security and Privacy Challenges. Sensors 2023, 23, 2807. [Google Scholar] [CrossRef] [PubMed]

- Chen, R. Preparation, property determination and bridge health monitoring applications of self-sensing cement nanocomposites. Alex. Eng. J. 2023, 66, 891–900. [Google Scholar] [CrossRef]

- Mubarak, S.; Dhamodharan, D.; Ghoderao, P.N.P.; Byun, H.-S. A systematic review on recent advances of metal–organic frameworks-based nanomaterials for electrochemical energy storage and conversion. Coord. Chem. Rev. 2022, 471, 214741. [Google Scholar] [CrossRef]

- Li, X.; Ming, P.; Ao, S.; Wang, W. Review of additive electrochemical micro-manufacturing technology. Int. J. Mach. Tools Manuf. 2022, 173, 103848. [Google Scholar] [CrossRef]

- Xie, H.; Liu, J. Design of multi-parameter real-time acquisition system of human movement based on nanosensor. Measurement 2022, 194, 111056. [Google Scholar] [CrossRef]

- Alshamrani, M. IoT and artificial intelligence implementations for remote healthcare monitoring systems: A survey. J. King Saud Univ. Comput. Inf. Sci. 2022, 34, 4687–4701. [Google Scholar] [CrossRef]

| Technique | Description | Advantages | Disadvantages | Reference |

|---|---|---|---|---|

| Lithography-Based Fabrication | Involves using a mask or template to selectively expose a photosensitive material, followed by subsequent processing steps to create desired nanoscale features. | Offers high precision and allows the creation of complex sensor geometries and patterns. | Time-consuming and requires specialized equipment. Limitations in scalability and cost-effectiveness for large-scale production. | [68] |

| Chemical Etching Methods | Selectively removes material from a substrate, using chemical reactions, resulting in the formation of nanoscale features. | Offers flexibility in creating various sensor structures on planar substrates and allows for the formation of nanochannels, nanogaps, or nanostructures. | Control over the selectivity of the etching process and uniformity of etching can be challenging. | [69] |

| Technique | Description | Advantages | Disadvantages | Reference |

|---|---|---|---|---|

| Chemical Vapor Deposition (CVD) | Involves the growth of thin films or nanostructures by introducing precursor gases into a reaction chamber, where they undergo chemical reactions. | Provides precise control of overgrowth parameters and tailored properties. | Requires specialized equipment and careful optimization of growth conditions. | [70] |

| Molecular Self-Assembly Techniques | Utilizes spontaneous organization of molecules or nanoparticles into ordered structures driven by intermolecular forces and surface interactions. | Enables precise control over composition and structure of nanosensors. | Stability and robustness of assembled structures need to be considered. Assembly process may be sensitive to pH, temperature, and concentration. | [71] |

| Fabrication Technique | Description | Reference |

|---|---|---|

| Template-Assisted Fabrication | Involves using a template or scaffold as a guide or mold to direct the growth or deposition of nanoscale materials. The template can be created using lithography-based techniques or self-assembly methods. This approach allows for the creation of nanosensors with complex architectures and high reproducibility. | [73] |

| Directed Self-Assembly | Combines bottom-up self-assembly processes with external forces or templates to control the assembly and arrangement of nanoscale building blocks. External fields, such as electric or magnetic fields, are used to direct the self-assembly of nanoparticles or nanowires into specific patterns or structures. This technique enables the fabrication of nanosensors with precise positioning and controlled orientations. | [74] |

| Nanopatterning and Nanolithography | Combines traditional nanopatterning or nanolithography methods with self-assembly or growth processes. Nanopatterning techniques, such as electron beam lithography or nanoimprint lithography, are used to create patterns on a substrate. These patterns serve as a template or mask for subsequent deposition or growth of nanoscale materials, resulting in complex and precisely controlled nanosensors with well-defined patterns and structures. | [75] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, D.; Hosamo, H.; Ying, C.; Nie, R. A Comprehensive Review and Analysis of Nanosensors for Structural Health Monitoring in Bridge Maintenance: Innovations, Challenges, and Future Perspectives. Appl. Sci. 2023, 13, 11149. https://doi.org/10.3390/app132011149

Han D, Hosamo H, Ying C, Nie R. A Comprehensive Review and Analysis of Nanosensors for Structural Health Monitoring in Bridge Maintenance: Innovations, Challenges, and Future Perspectives. Applied Sciences. 2023; 13(20):11149. https://doi.org/10.3390/app132011149

Chicago/Turabian StyleHan, Daguang, Haidar Hosamo, Chunli Ying, and Ruimin Nie. 2023. "A Comprehensive Review and Analysis of Nanosensors for Structural Health Monitoring in Bridge Maintenance: Innovations, Challenges, and Future Perspectives" Applied Sciences 13, no. 20: 11149. https://doi.org/10.3390/app132011149

APA StyleHan, D., Hosamo, H., Ying, C., & Nie, R. (2023). A Comprehensive Review and Analysis of Nanosensors for Structural Health Monitoring in Bridge Maintenance: Innovations, Challenges, and Future Perspectives. Applied Sciences, 13(20), 11149. https://doi.org/10.3390/app132011149