Development of an Inertial Linear Ultrasonic Motor with a Double-Stator Structure Based on Bending Mode

Abstract

1. Introduction

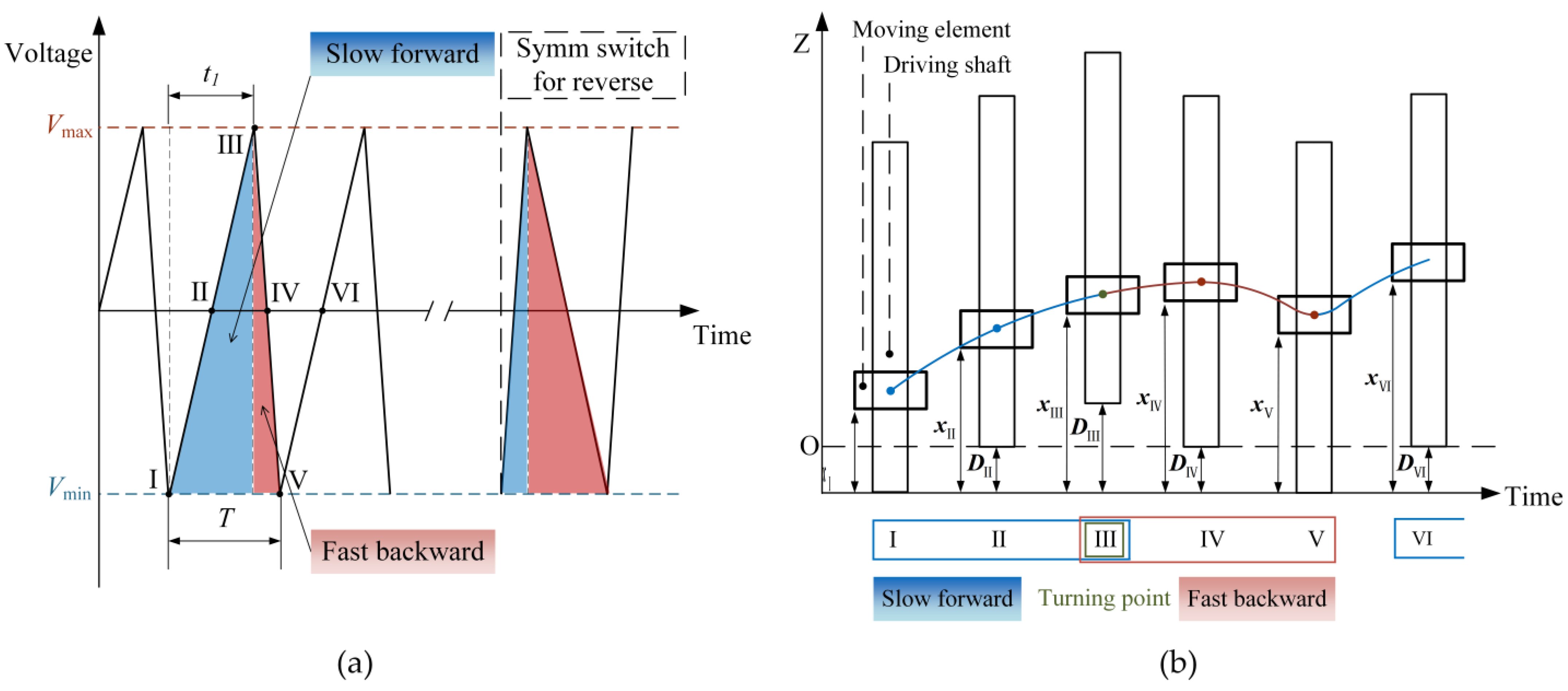

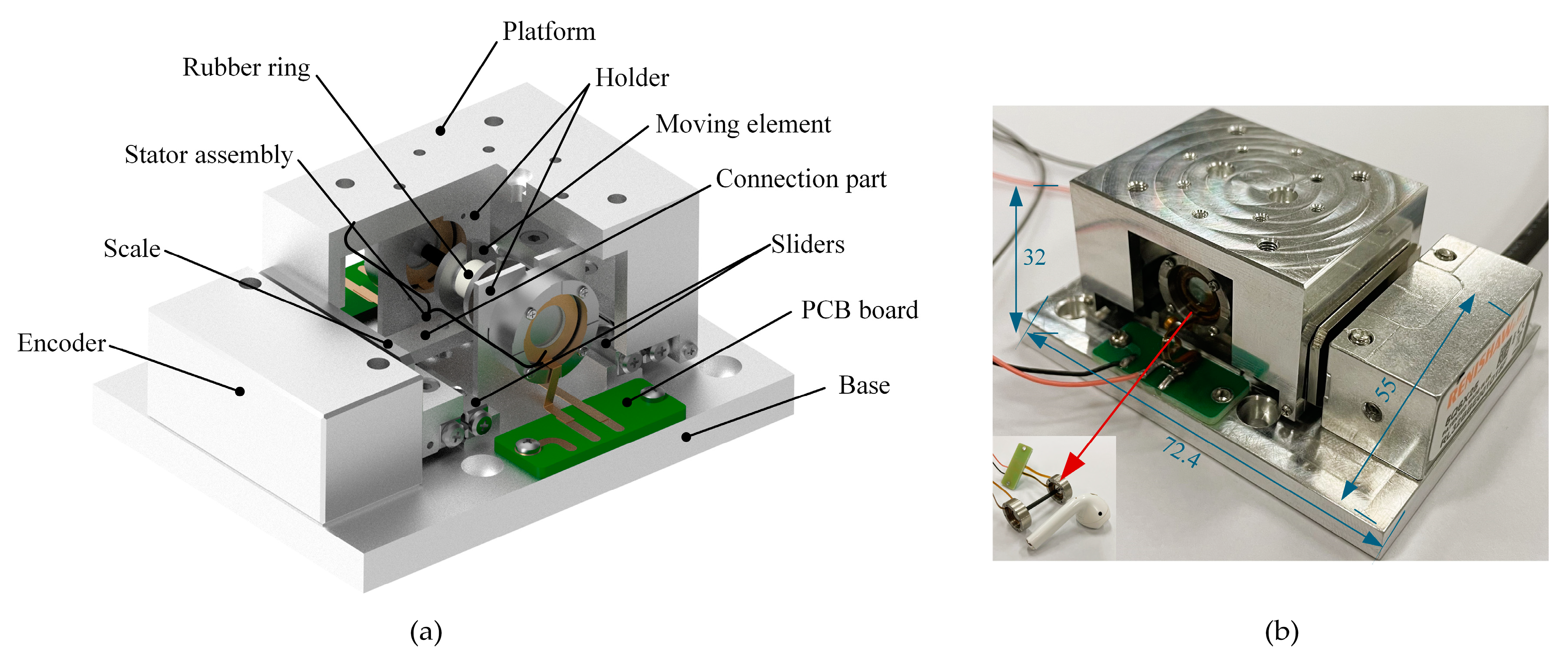

2. Configuration and Working Mechanism

3. Simulation and Analyses

3.1. Modal Analyses

| Component | Materials | Density (kg/m3) | Young’s Modulus (N/m2) | Poisson’s Ratio |

|---|---|---|---|---|

| Stator | Structural Steel | 7850 | 2.0 × 1011 | 0.3 |

| Moving element | Stainless Steel | 7760 | 2.1 × 1011 | 0.28 |

| Driving shaft | Carbon Fiber | 1800 | E1 = 1.6 × 1011 | ν12 = 0.33 |

| E1 = 9.7 × 109 | ν23 = 0.28 | |||

| E1 = 9.7 × 109 | ν13 = 0.33 |

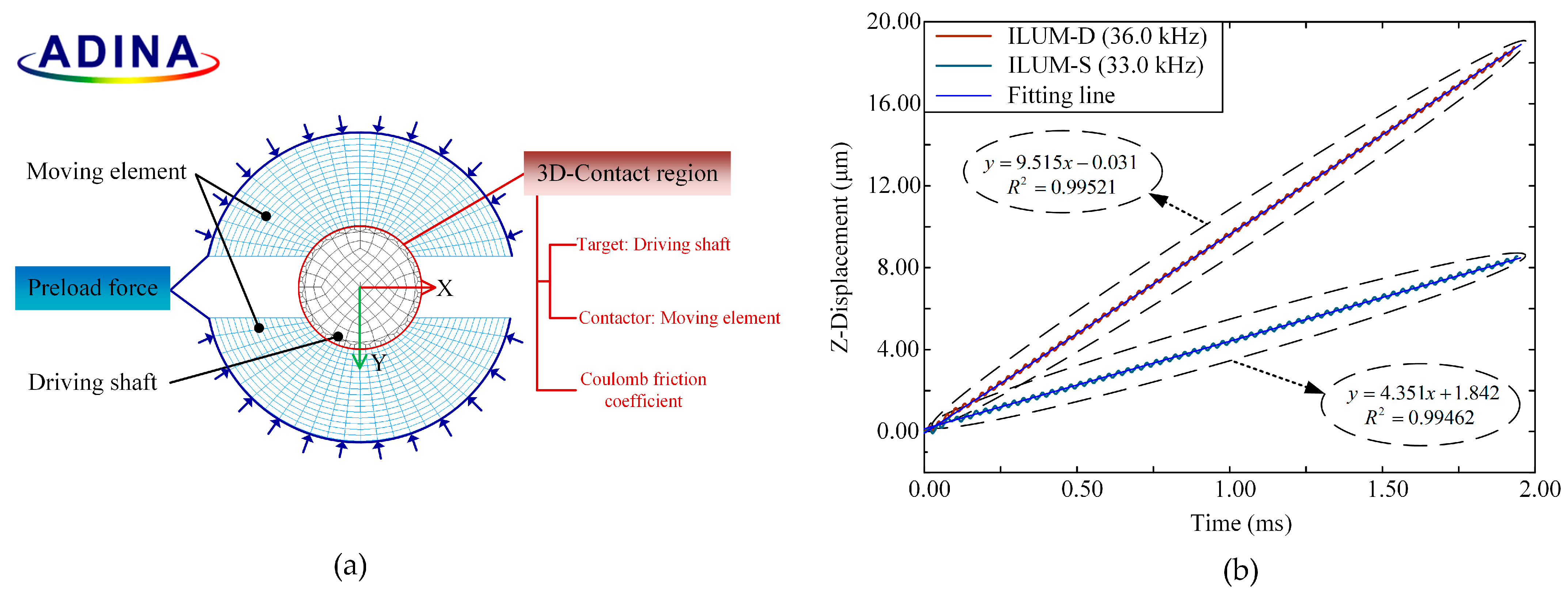

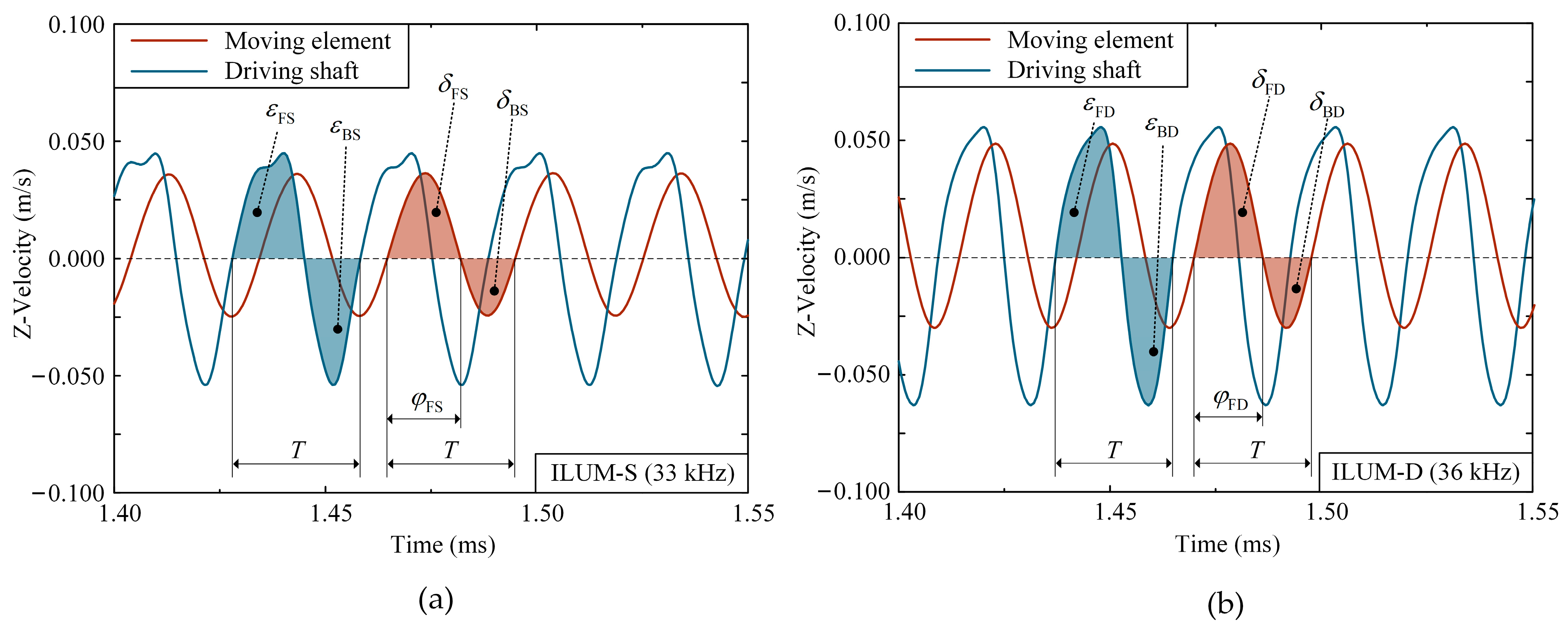

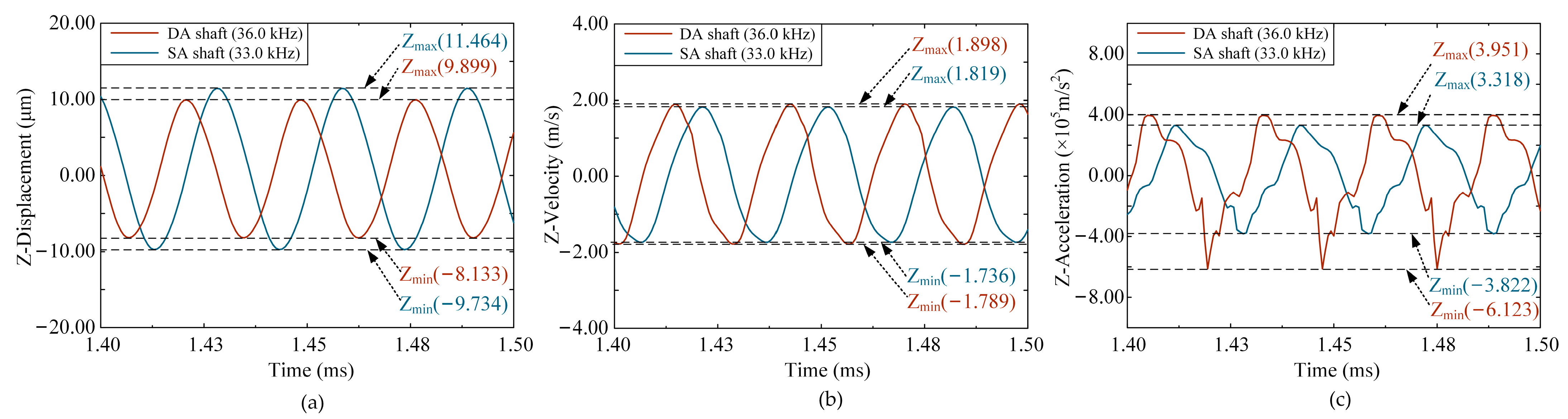

3.2. Transient Analyses

| Data | ILUM-S | ILUM-D |

|---|---|---|

| (μm) | 0.33623 | 0.40420 |

| (μm) | −0.19448 | −0.14609 |

| (μm) | 0.14175 | 0.25811 |

| 0.57612 | 0.58158 |

4. Experimental Results

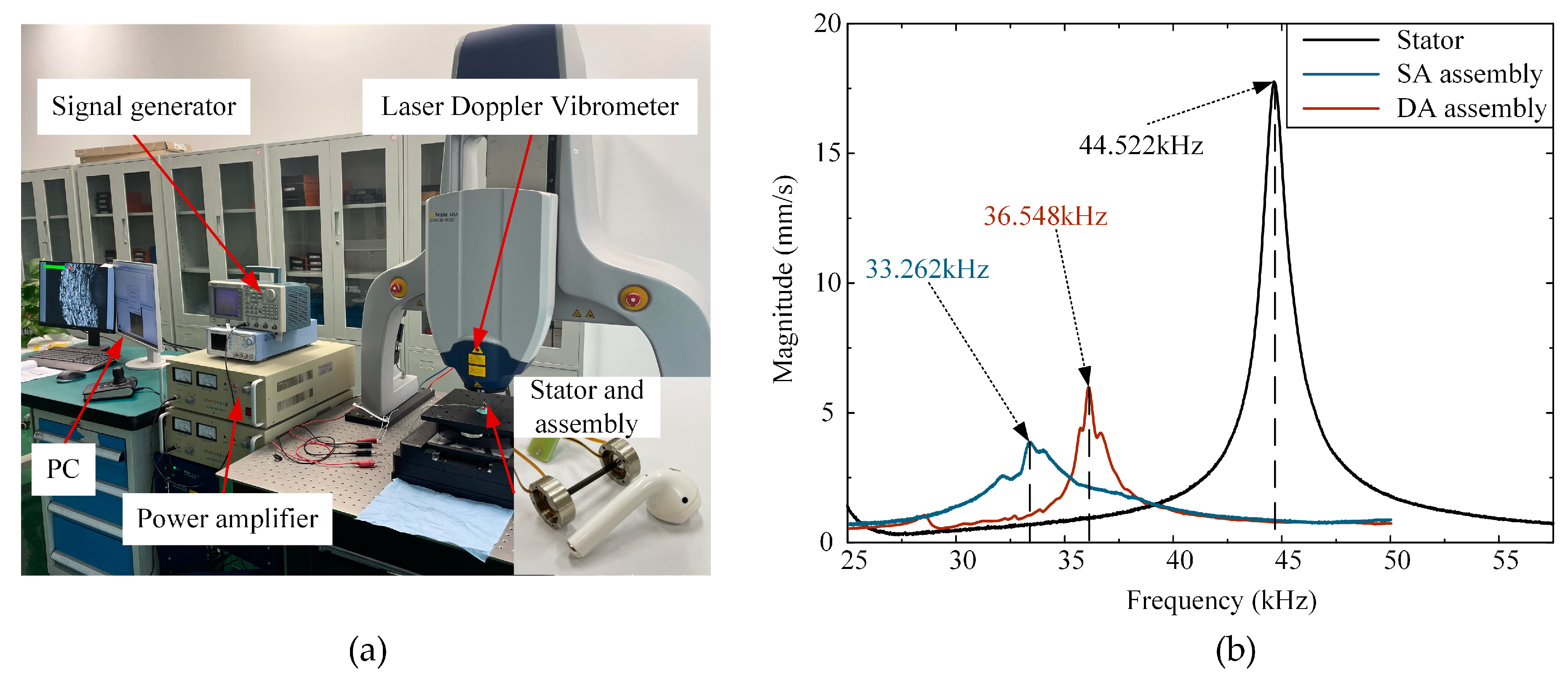

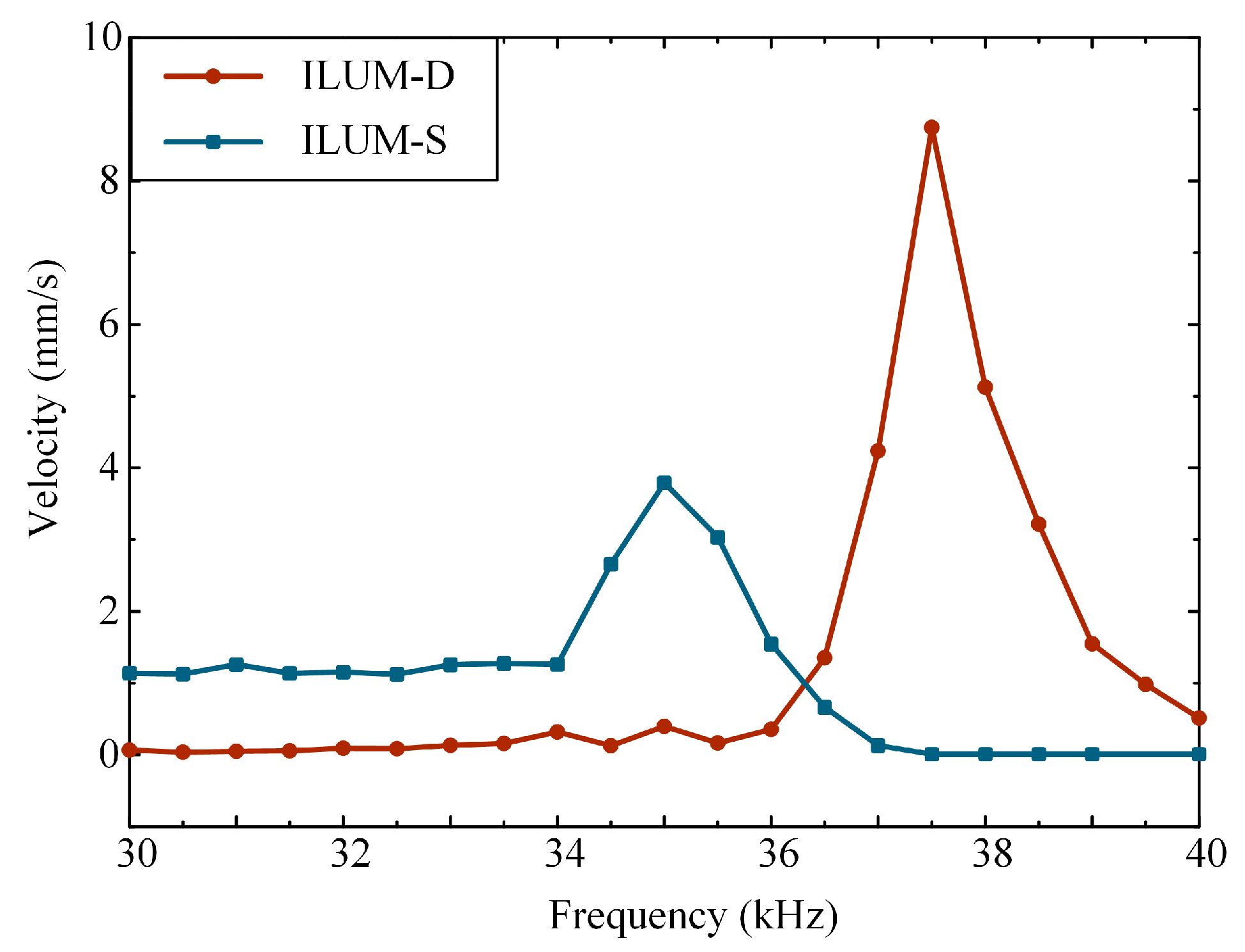

4.1. Vibration Characteristics Measurement

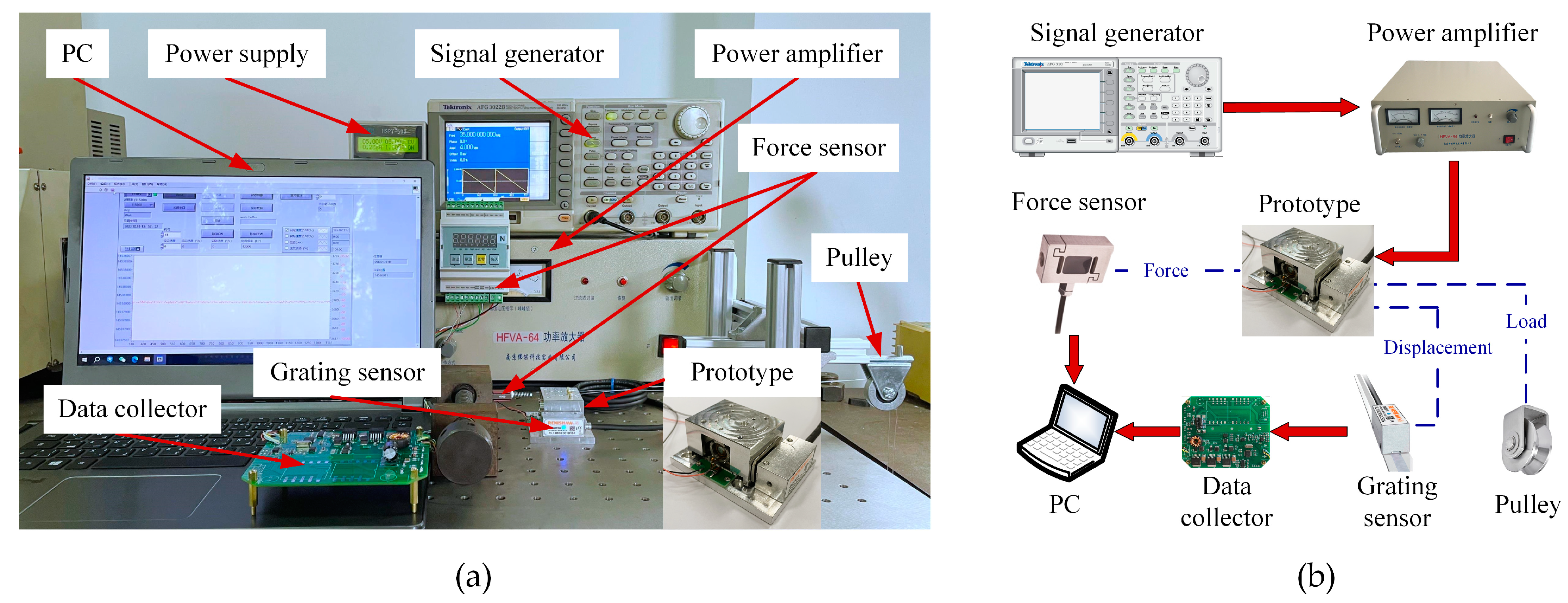

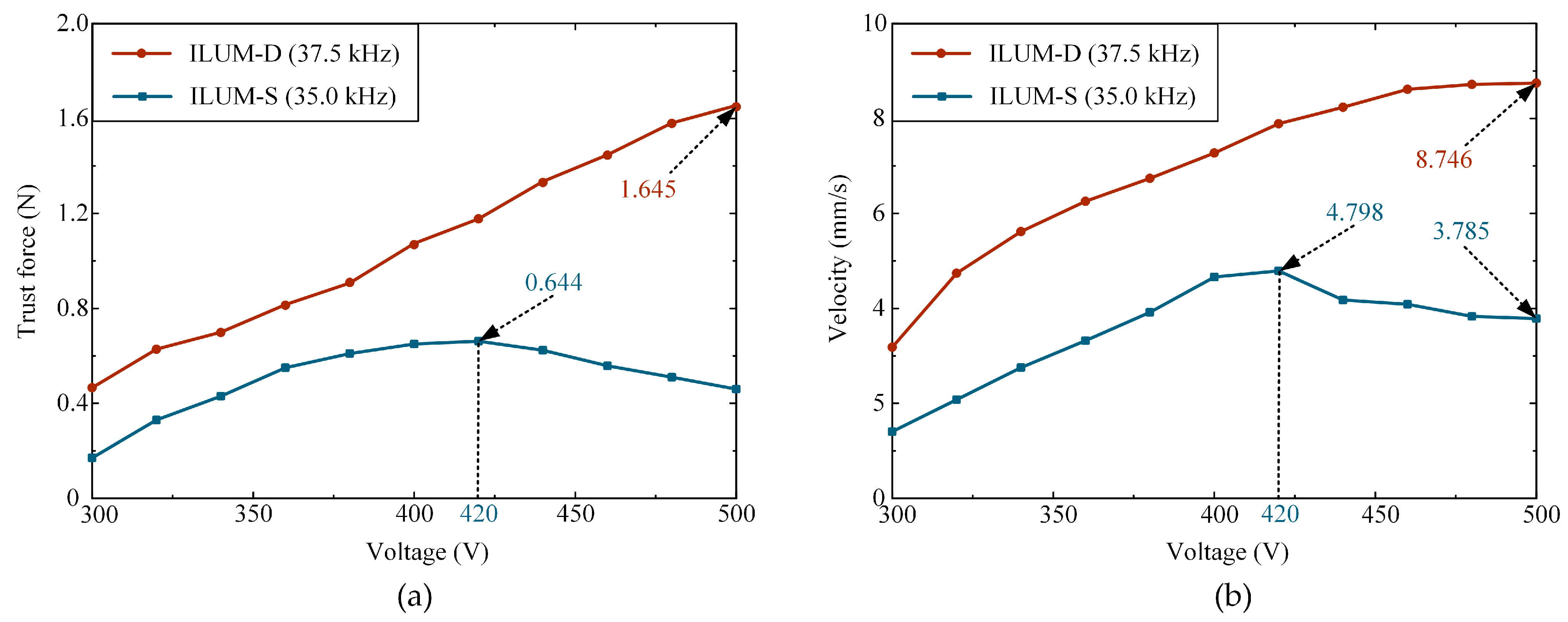

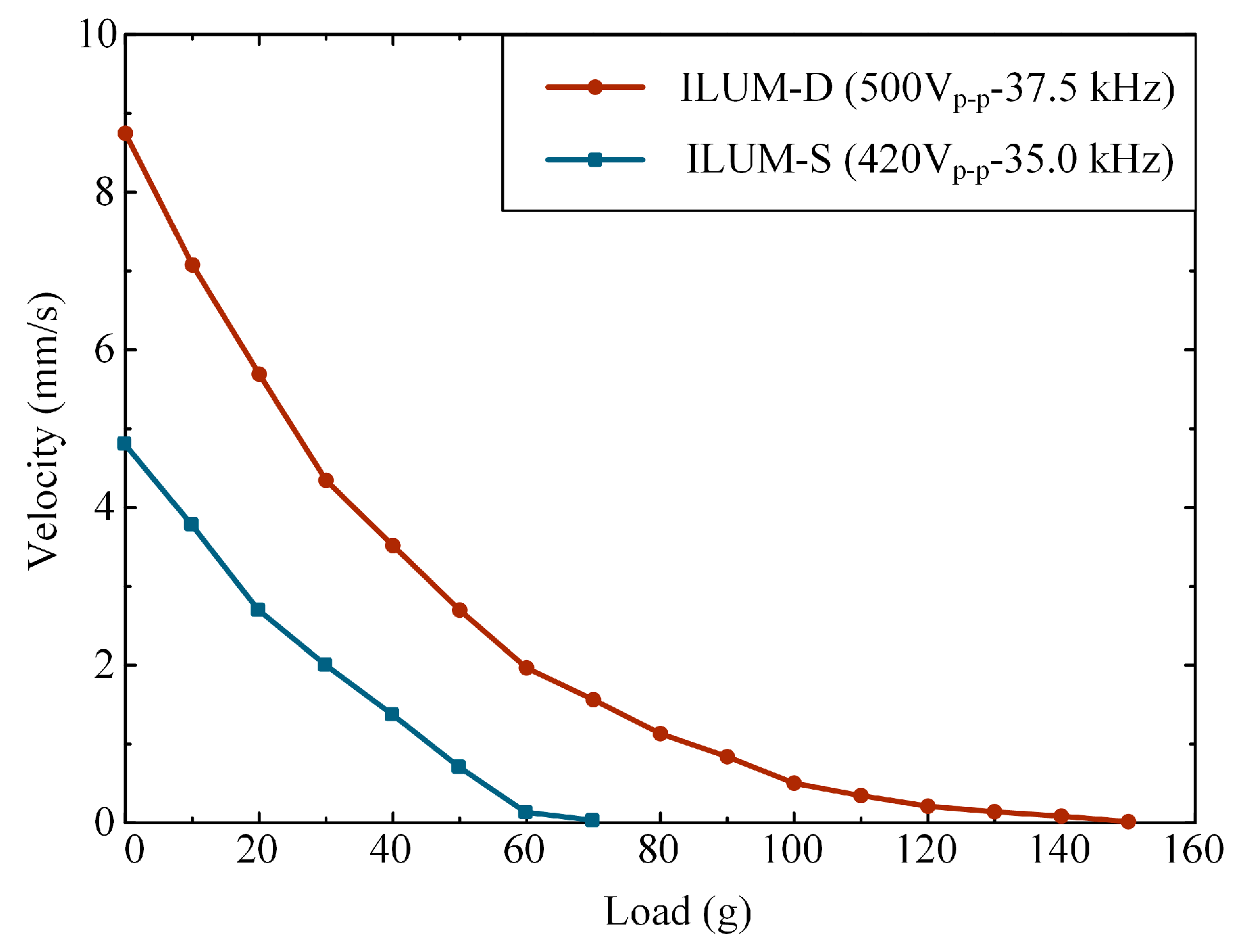

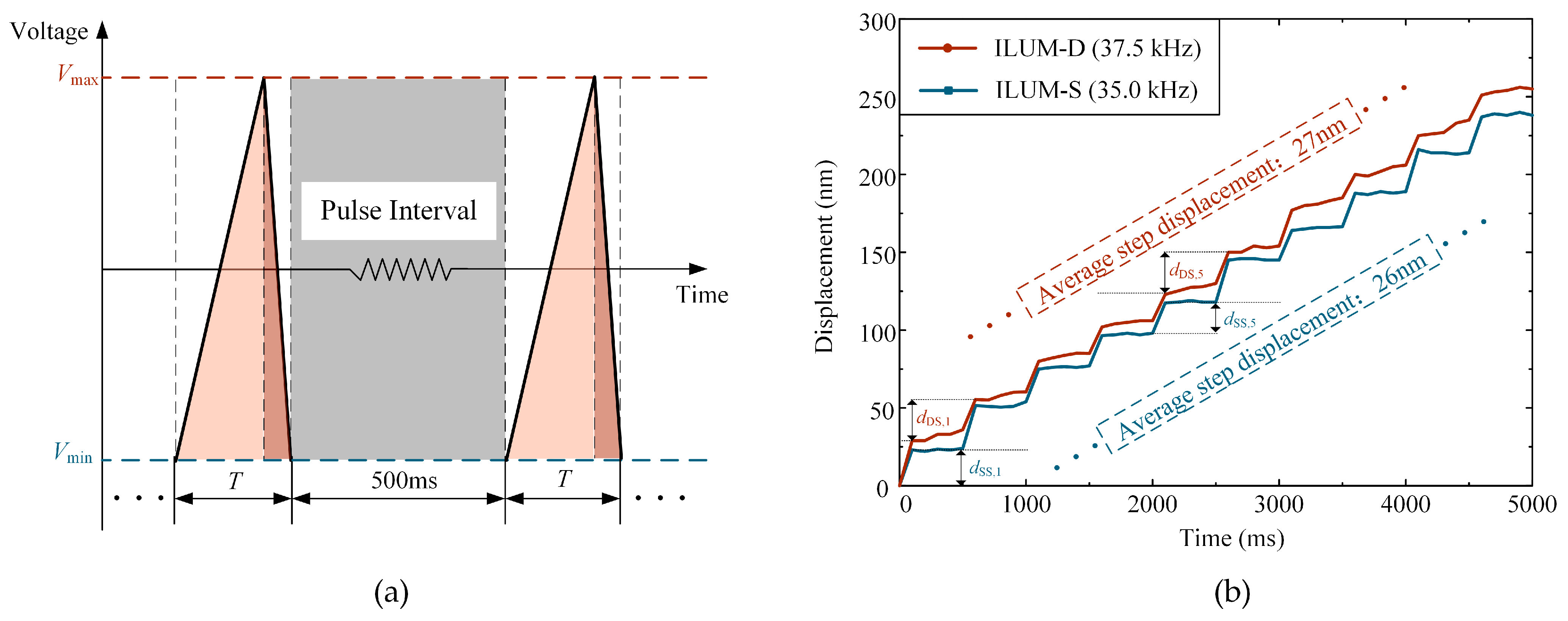

4.2. Mechanical Characteristics Measurement

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ko, H.-P.; Kim, S.; Borodinas, S.N.; Vasiljev, P.E.; Kang, C.-Y.; Yoon, S.-J. A Novel Tiny Ultrasonic Linear Motor Using the Radial Mode of a Bimorph. Sens. Actuators A Phys. 2006, 125, 477–481. [Google Scholar] [CrossRef]

- Paik, D.-S.; Yoo, K.-H.; Kang, C.-Y.; Cho, B.-H.; Nam, S.; Yoon, S.-J. Multilayer Piezoelectric Linear Ultrasonic Motor for Camera Module. J. Electroceram. 2009, 22, 346–351. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, W.S.; Kim, K.-S.; Kim, S. A Novel Smooth Impact Drive Mechanism Actuation Method with Dual-Slider for a Compact Zoom Lens System. Rev. Sci. Instrum. 2011, 82, 085105. [Google Scholar] [CrossRef] [PubMed]

- Rakotondrabe, M.; Haddab, Y.; Lutz, P. Development, Modeling, and Control of a Micro-/Nanopositioning 2-DOF Stick–Slip Device. IEEE/ASME Trans. Mechatron. 2009, 14, 733–745. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, R.; Wen, J.; Liu, J.-Q. A Low-Frequency Structure-Control-Type Inertial Actuator Using Miniaturized Bimorph Piezoelectric Vibrators. IEEE Trans. Ind. Electron. 2019, 66, 6179–6188. [Google Scholar] [CrossRef]

- Mashimo, T.; Toyama, S. Micro rotary-linear ultrasonic motor for endovascular diagnosis and surgery. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; IEEE: Piscataway, NJ, USA, 2008. [Google Scholar]

- Delibas, B.; Koc, B.; Thielager, J.; Stiebel, C. A novel drive and control method for piezoelectric motors in microscopy stages. In Proceedings of the Euspen’s 21st International Conference & Exhibition, Copenhagen, Denmark, 7–10 June 2021; Volume 10. [Google Scholar]

- Zhao, C. Linear Ultrasonic Motor Using Inertia Mass. In Ultrasonic Motors: Technologies and Applications, 1st ed.; Science Press: Beijing, China, 2007; pp. 342–348. [Google Scholar]

- Hunstig, M. Piezoelectric Inertia Motors—A Critical Review of History, Concepts, Design, Applications, and Perspectives. Actuators 2017, 6, 7. [Google Scholar] [CrossRef]

- Zhang, Z.M.; An, Q.; Li, J.W.; Zhang, W.J. Piezoelectric Friction–Inertia Actuator—A Critical Review and Future Perspective. Int. J. Adv. Manuf. Technol. 2012, 62, 669–685. [Google Scholar] [CrossRef]

- Xu, D.; Liu, Y.; Shi, S.; Liu, J.; Chen, W.; Wang, L. Development of a Nonresonant Piezoelectric Motor With Nanometer Resolution Driving Ability. IEEE/ASME Trans. Mechatron. 2018, 23, 444–451. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.-D.; Choi, S.-B. A Hybrid Inchworm Linear Motor. Mechatronics 2002, 12, 525–542. [Google Scholar] [CrossRef]

- Wang, Y.; Pan, S.; Huang, W. A Linear Stepping Piezoelectric Motor Using Inertial Impact Driving. In Proceedings of the 2011 Symposium on Piezoelectricity, Acoustic Waves and Device Applications (SPAWDA), Shenzhen, China, 9–11 December 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 357–360. [Google Scholar]

- Jang, J.; Park, S.; Huh, J.; Lee, K.H.; Lee, H.-Y.; Choi, J.-J.; Min, Y.; Yoon, W.-H. Design, Fabrication, and Characterization of Piezoelectric Single Crystal Stack Actuators Based on PMN-PT. Sens. Actuators A Phys. 2022, 342, 113617. [Google Scholar] [CrossRef]

- Tang, J.; Fan, H.; Liu, J.; Huang, H. Suppressing the Backward Motion of a Stick–Slip Piezoelectric Actuator by Means of the Sequential Control Method (SCM). Mech. Syst. Signal Process. 2020, 143, 106855. [Google Scholar] [CrossRef]

- Li, X.; Xu, Z.; Sun, W.; Wei, D.; Wu, H.; Huang, H. A Miniature Impact Drive Mechanism with Spatial Interdigital Structure. Int. J. Mech. Sci. 2023, 240, 107933. [Google Scholar] [CrossRef]

- Mazeika, D.; Vasiljev, P. Linear Inertial Piezoelectric Motor with Bimorph Disc. Mech. Syst. Signal Process. 2013, 36, 110–117. [Google Scholar] [CrossRef]

- Yokozawa, H.; Doshida, Y.; Kishimoto, S.; Morita, T. Resonant-Type Smooth Impact Drive Mechanism Actuator Using Lead-Free Piezoelectric Material. Sens. Actuators A Phys. 2018, 274, 179–183. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Zhao, L.; Xu, D.; Chen, W.; Deng, J. Design and Experiments of a Single-Foot Linear Piezoelectric Actuator Operated in a Stepping Mode. IEEE Trans. Ind. Electron. 2018, 65, 8063–8071. [Google Scholar] [CrossRef]

- Cheng, T.; Li, H.; He, M.; Zhao, H.; Lu, X.; Gao, H. Investigation on Driving Characteristics of a Piezoelectric Stick–Slip Actuator Based on Resonant/off-Resonant Hybrid Excitation. Smart Mater. Struct. 2017, 26, 035042. [Google Scholar] [CrossRef]

- Nishimura, T.; Hosaka, H.; Morita, T. Resonant-Type Smooth Impact Drive Mechanism (SIDM) Actuator Using a Bolt-Clamped Langevin Transducer. Ultrasonics 2012, 52, 75–80. [Google Scholar] [CrossRef] [PubMed]

- DeAngelis, D.A. Performance of PZT8 Versus PZT4 Piezoceramic Materials in Ultrasonic Transducers. Phys. Procedia 2016, 87, 85–92. [Google Scholar] [CrossRef]

- Yang, L.; Hu, X.; Yang, M.; Huan, Y.; Ren, W.; Xiong, Y.; Li, H. A Novel Traveling Wave Rotary Ultrasonic Motor with Piezoelectric Backup Function. J. Intell. Mater. Syst. Struct. 2023, 34, 2414–2427. [Google Scholar] [CrossRef]

- Polytec, MSA-100-3D. Vibrometry Products-MSA-100-3D Micro System Analyzer-Polytec. Available online: https://www.polytec.com/cn/vibrometry/products/microscope-based-vibrometers/msa-100-3d-micro-system-analyzer (accessed on 9 September 2024).

- Renishaw Plc, RL32BBE001D15F. Available online: https://www.renishaw.com/resourcecentre/zh/details/--105836 (accessed on 9 September 2024).

- Technohands, TULA (Tiny Ultrasonic Linear Actuator) 70. 2024. Available online: https://www.technohands.co.jp/ch/download-3 (accessed on 19 April 2024).

- Koc, B.; Delibas, B. Impact Force Analysis in Inertia-Type Piezoelectric Motors. Actuators 2023, 12, 52. [Google Scholar] [CrossRef]

| Parameters | Ultrasonic Motor [17] | Ultrasonic Motor [2] | TULA70 [26] | Piezoelectric Motor [27] | Proposed ILUM-D |

|---|---|---|---|---|---|

| Size (mm3) | 2.8 × 2.8 × 10 | 4 × 11 × 22 | 7 × 7 × 22 | 3 × 6 × 18 | 14.6 × 14.6 × 29 |

| Frequency (kHz) | 152 | 50 | 30~70 | 0~30 | 36.5~39 |

| Voltage (Vp-p) | 40 | 10 | 20~35 | 50 | 500 |

| PZT type | Multilayer | Multilayer | Multilayer | Multilayer | Single-layer |

| Maximum thrust force (N) | 0.08 | 0.12 | 0.392 | 3.3 | 1.645 |

| Maximum velocity (mm/s) | 20 | 14.8 | 10 | 16 | 8.746 |

| Resolution (nm) | Not mentioned | Not mentioned | 100 | 800 | 27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Xiong, Y.; Hong, X.; Wen, J.; Zhang, J.; Zhao, R. Development of an Inertial Linear Ultrasonic Motor with a Double-Stator Structure Based on Bending Mode. Appl. Sci. 2024, 14, 8533. https://doi.org/10.3390/app14188533

Yang L, Xiong Y, Hong X, Wen J, Zhang J, Zhao R. Development of an Inertial Linear Ultrasonic Motor with a Double-Stator Structure Based on Bending Mode. Applied Sciences. 2024; 14(18):8533. https://doi.org/10.3390/app14188533

Chicago/Turabian StyleYang, Lin, Yue Xiong, Xinwei Hong, Jiaquan Wen, Jie Zhang, and Rongcheng Zhao. 2024. "Development of an Inertial Linear Ultrasonic Motor with a Double-Stator Structure Based on Bending Mode" Applied Sciences 14, no. 18: 8533. https://doi.org/10.3390/app14188533

APA StyleYang, L., Xiong, Y., Hong, X., Wen, J., Zhang, J., & Zhao, R. (2024). Development of an Inertial Linear Ultrasonic Motor with a Double-Stator Structure Based on Bending Mode. Applied Sciences, 14(18), 8533. https://doi.org/10.3390/app14188533