Comparison of Physical, Sensorial, and Microstructural Properties to Assess the Similarity Between Plant- and Animal-Based Meat Products

Abstract

1. Introduction

2. Materials and Methods

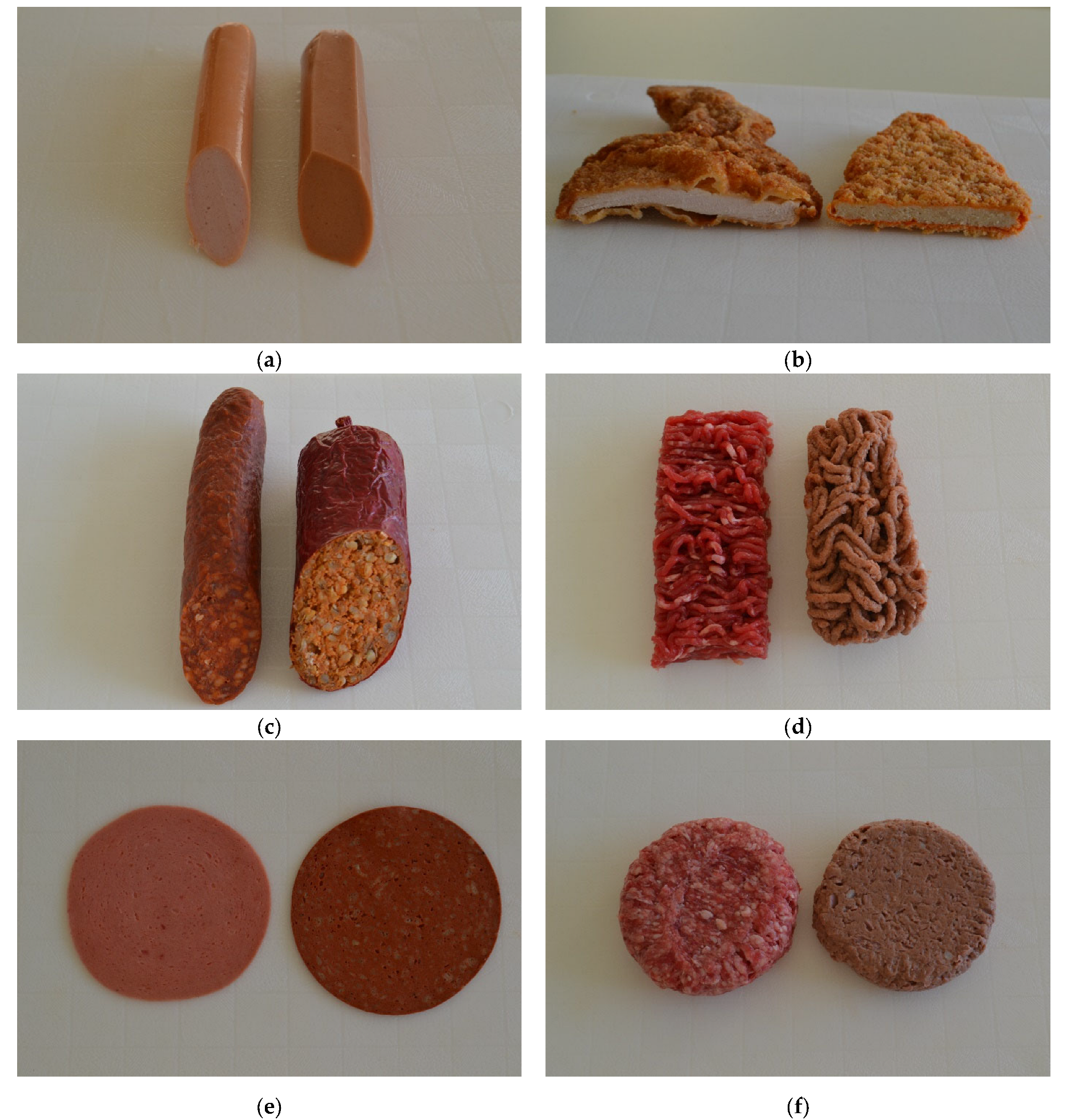

2.1. Sampling

2.2. Physical Properties Methodology

2.2.1. Colour Methodology

2.2.2. Texture Methodology

2.3. Sensory Analysis

2.4. Microstructural Characteristics

2.4.1. Light Microscopy

2.4.2. Electron Microscopy

2.5. Statistical Analysis

3. Results and Discussion

3.1. Physical Properties

3.1.1. Colour

3.1.2. Texture

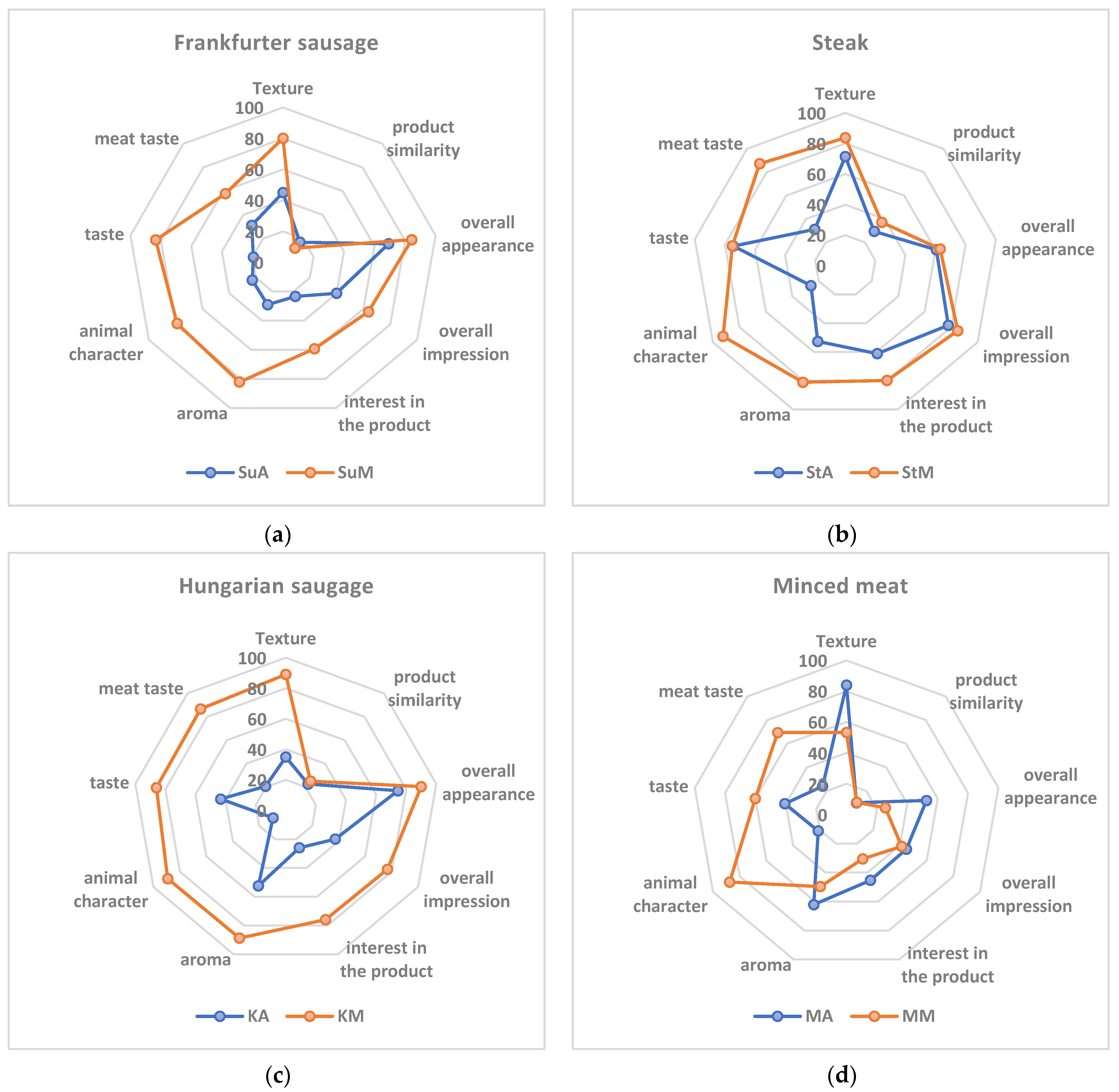

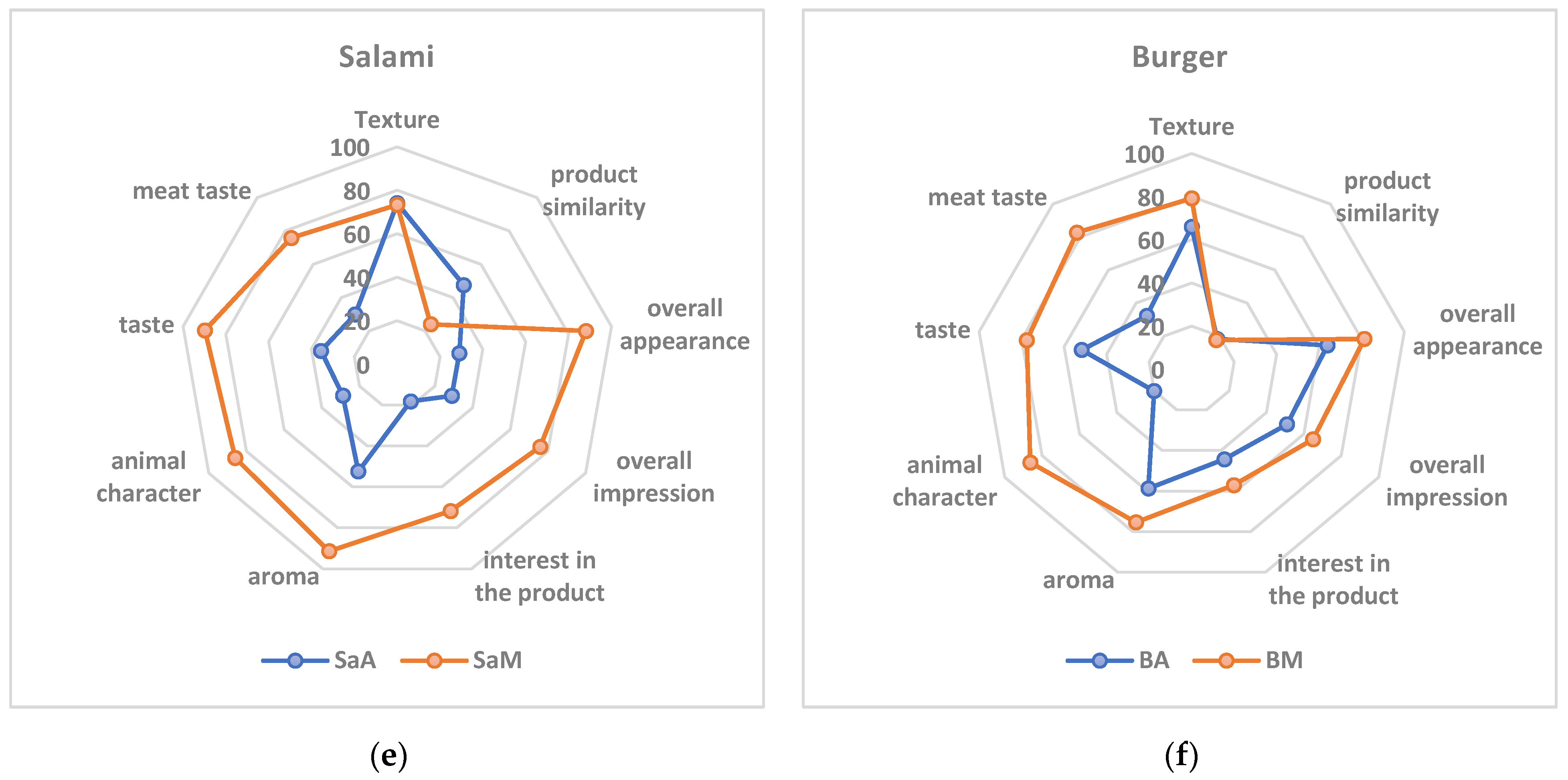

3.2. Sensorial Properties

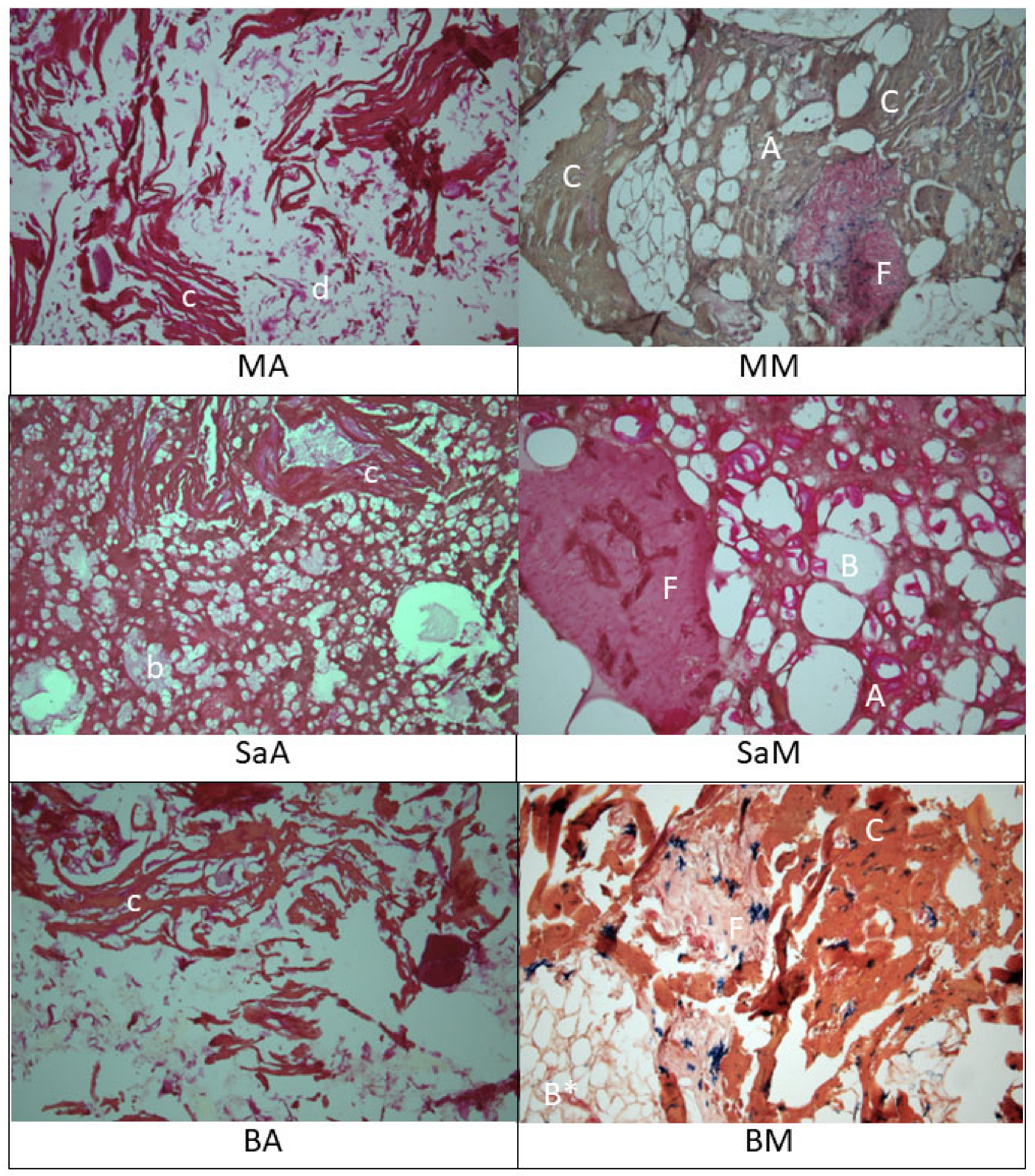

3.3. Microstructural Characteristics

3.3.1. Light Microscopy

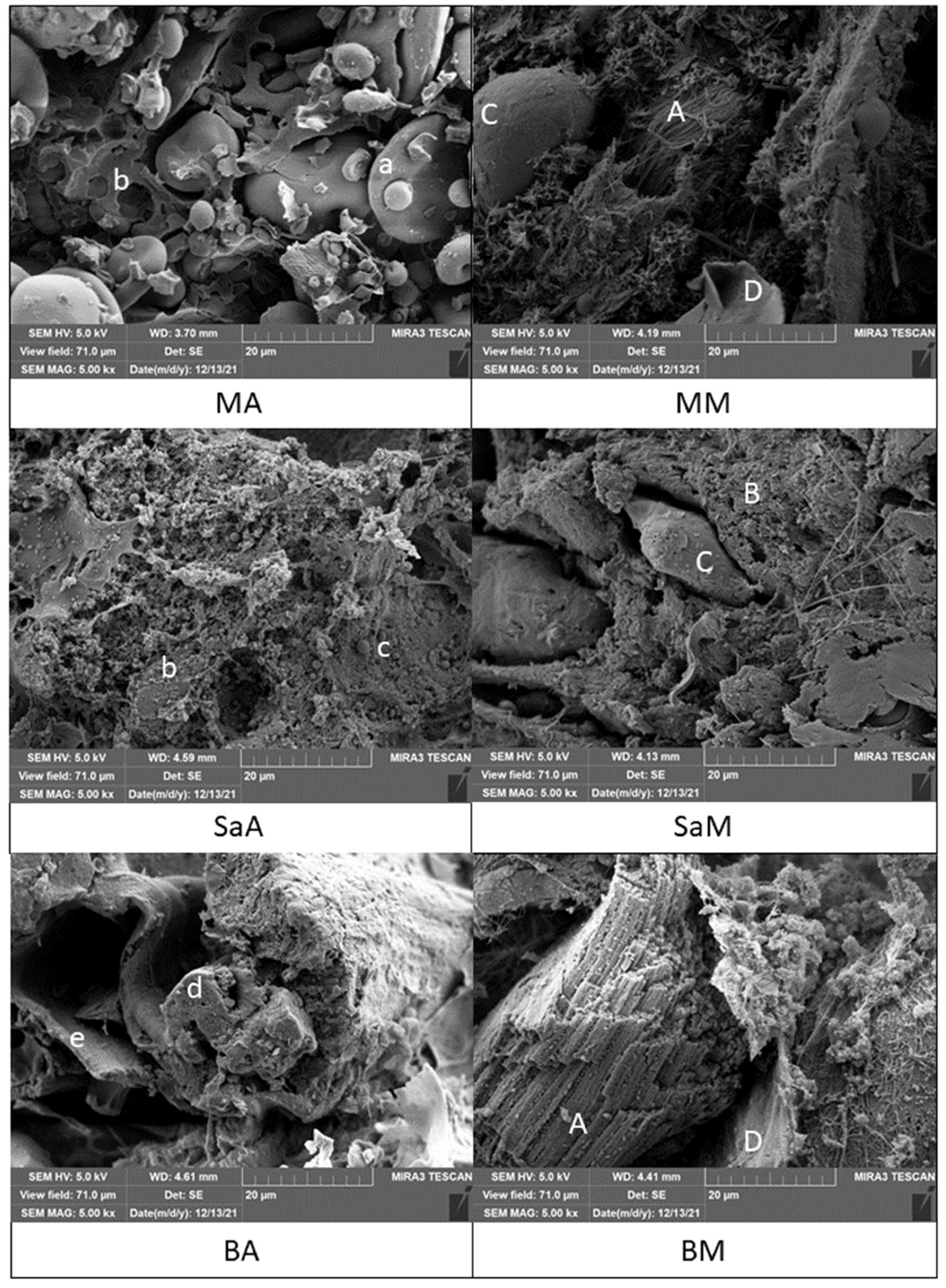

3.3.2. Electron Microscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Niva, M.; Vainio, A.; Jallinoja, P. Barriers to increasing plant protein consumption in western populations. In Vegetarian and Plant-Based Diets in Health and Disease Prevention; Elsevier: Amsterdam, The Netherlands, 2017; pp. 157–171. ISBN 9780128039694. [Google Scholar]

- Allied Market Research. Meat Substitute Market Size, Share, Competitive Landscape and Trend Analysis Report, by Category, by Product Type, by Source: Global Opportunity Analysis and Industry Forecast, 2024–2035. 2024. Available online: https://www.alliedmarketresearch.com/meat-substitute-market (accessed on 28 August 2024).

- Centers for Disease Control and Prevention. CDC Estimates of Foodborne Illness in the United States. Atlanta: CDC. Available online: http://www.cdc.gov/foodborneburden/2011-foodborne-estimates.html (accessed on 5 November 2018).

- Rohrmann, S.; Overvad, K.; Bueno-de-Mesquita, H.B.; Jakobsen, M.U.; Egeberg, R.; Tjønneland, A.; Nailler, L.; Boutron-Ruault, M.-C.; Clavel-Chapelon, F.; Krogh, V.; et al. Meat consumption and mortality—Results from the European Prospective Investigation into Cancer and Nutrition. BMC Med. 2013, 11, 63. [Google Scholar] [CrossRef] [PubMed]

- Larsson, S.C.; Wolk, A. Meat consumption and risk of colorectal cancer: A meta-analysis of prospective studies. Int. J. Cancer 2006, 119, 2657–2664. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Ge, J.; He, J.; Gan, R.; Fang, Y. Processing, Quality, Safety, and Acceptance of Meat Analogue Products. Engineering 2021, 7, 674–678. [Google Scholar] [CrossRef]

- Schreuders, F.K.G.; Schlangen, M.; Kyriakopoulou, K.; Boom, R.M.; van der Goot, A.J. Texture methods for evaluating meat and meat analogue structures: A review. Food Control 2021, 127, 108103. [Google Scholar] [CrossRef]

- Arêas, J.A.G. Extrusion of food proteins. Crit. Rev. Food Sci. Nutr. 1992, 32, 365–392. [Google Scholar] [CrossRef]

- Cheftel, J.C.; Kitagawa, M.; Quéguiner, C. New protein texturization processes by extrusion cooking at high moisture levels. Food Rev. Int. 1992, 8, 235–275. [Google Scholar] [CrossRef]

- Hoek, A.C.; Luning, P.A.; Weijzen, P.; Engels, W.; Kok, F.J.; de Graaf, C. Replacement of meat by meat substitutes. A survey on person- and product-related factors in consumer acceptance. Appetite 2011, 56, 662–673. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Dekkers, B.; van der Goot, A.J. Plant-based meat analogues. In Sustainable Meat Production and Processing; Elsevier: Amsterdam, The Netherlands, 2019; pp. 103–126. ISBN 9780128148747. [Google Scholar]

- He, J.; Evans, N.M.; Liu, H.; Shao, S. A review of research on plant-based meat alternatives: Driving forces, history, manufacturing, and consumer attitudes. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2639–2656. [Google Scholar] [CrossRef]

- Abdullah, F.A.A.; Dordevic, D.; Kabourkova, E.; Zemancová, J.; Dordevic, S. Antioxidant and Sensorial Properties: Meat Analogues versus Conventional Meat Products. Processes 2022, 10, 1864. [Google Scholar] [CrossRef]

- Saláková, A.; Straková, E.; Válková, V.; Buchtová, H.; Steinhauserová, I. Quality Indicators of Chicken Broiler Raw and Cooked Meat Depending on Their Sex. Acta Vet. 2009, 78, 497–504. [Google Scholar] [CrossRef]

- ISO 8589:2007; Sensory Analysis—General Guidance for the Design of Test Rooms. International Organization for Standardization: Geneva, Switzerland, 2007.

- Petrášová, M.; Zichová, E.; Pospiech, M.; Tremlová, B.; Javůrková, Z. Possibilities of microscopic detection of isolated porcine proteins in model meat products. Slovak J. Food Sci. Potravin. 2016, 10, 202–206. [Google Scholar] [CrossRef] [PubMed]

- Lukášková, Z.Ř.; Tremlová, B.; Pospiech, M.; Renčová, E.; Randulová, Z.; Steinhauser, L.; Reichová, A.; Bednář, J. Comparison of immunohistochemical, histochemical and immunochemical methods for the detection of wheat protein allergens in meat samples and cooked, dry, raw and fermented sausage samples. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2011, 28, 817–825. [Google Scholar] [CrossRef] [PubMed]

- Běhalová, H.; Tremlová, B.; Kalčáková, L.; Pospiech, M.; Dordevic, D. Assessment of the Effect of Secondary Fixation on the Structure of Meat Products Prepared for Scanning Electron Microscopy. Foods 2020, 9, 487. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Cai, W.; Li, L.; Gao, Y.; Lai, K.H. Recent advances in the processing and manufacturing of plant-based meat. J. Agric. Food Chem. 2023, 71, 1276–1290. [Google Scholar] [CrossRef]

- Youssef, M.K.; Barbut, S. Physicochemical Effects of the Lipid Phase and Protein Level on Meat Emulsion Stability, Texture, and Microstructure. J. Food Sci. 2010, 75, 108–114. [Google Scholar] [CrossRef]

- Youssef, M.K.; Barbut, S. Fat reduction in comminuted meat products-effects of beef fat, regular and pre-emulsified canola oil. Meat Sci. 2011, 87, 356–360. [Google Scholar] [CrossRef]

- Wi, G.; Bae, J.; Kim, H.; Cho, Y.; Choi, M.-J. Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives. Foods 2020, 9, 461. [Google Scholar] [CrossRef]

- Samard, S.; Ryu, G.H. A comparison of physicochemical characteristics, texture, and structure of meat analogue and meats. J. Sci. Food Agric 2019, 99, 2708–2715. [Google Scholar] [CrossRef]

- Ryu, K.K.; Kang, Y.K.; Jeong, E.W.; Baek, Y.; Lee, K.Y.; Lee, H.G. Applications of various natural pigments to a plant-based meat analog. LWT 2023, 174, 114431. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, C.H.; Zhang, X.H.; Wen, C.L.; Olatunji, O.J.; Lee, C.C.; Ashaolu, T.J. Plant-based Meat Analogs: Perspectives on Their Meatiness, Nutritional Profile, Environmental Sustainability, Acceptance and Challenges. Curr. Nutr. Rep. 2024, 13, 921–936. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J.; Chen, Q.; Hu, A.; Li, T.; Guo, F.; Wang, Q.; Liu, H.; Zhang, J.; Chen, Q.; et al. Preparation of Whole-Cut Plant-Based Pork Meat and Its Quality Evaluation with Animal Meat. Gels 2023, 9, 461. [Google Scholar] [CrossRef] [PubMed]

- Gasparre, N.; Rosell, C.M. Wheat gluten: A functional protein still challenging to replace in gluten-free cereal-based foods. Cereal Chem. 2023, 100, 243–255. [Google Scholar] [CrossRef]

- Novakovi, S.; Tomaševi, I. A comparison between warner-bratzler shear force measurement and texture profile analysis of meat and meat products: A review. IOP Conf. Ser. Earth Environ. Sci. 2017, 85, 012063. [Google Scholar] [CrossRef]

- Taghian Dinani, S.; Zhang, Y.; Vardhanabhuti, B.; van der Goot, A.J. Enhancing Textural Properties in Plant-Based Meat Alternatives: The Impact of Hydrocolloids and Salts on Soy Protein-Based Products. Curr. Res. Food Sci. 2023, 7, 100571. [Google Scholar] [CrossRef]

- Paneras, E.D.; Bloukas, J.G. Vegetable Oils Replace Pork Backfat for Low-Fat Frankfurters. J. Food Sci. 1994, 59, 725–728. [Google Scholar] [CrossRef]

- Barbut, S.; Marangoni, A. Organogels use in meat processing—Effects of fat/oil type and heating rate. Meat Sci. 2019, 149, 9–13. [Google Scholar] [CrossRef]

- Ishaq, A.; Irfan, S.; Sameen, A.; Khalid, N. Plant-Based Meat Analogs: A Review with Reference to Formulation and Gastrointestinal Fate. Curr. Res. Food Sci. 2022, 5, 973. [Google Scholar] [CrossRef]

- Benković, M.; Jurinjak Tušek, A.; Sokač Cvetnić, T.; Jurina, T.; Valinger, D.; Gajdoš Kljusurić, J. An Overview of Ingredients Used for Plant-Based Meat Analogue Production and Their Influence on Structural and Textural Properties of the Final Product. Gels 2023, 9, 921. [Google Scholar] [CrossRef]

- Lee, C.C.; Taştemir, İ.A. Direct heat exchangers in the food industry. In Thermal Processing of Food Products by Steam and Hot Water; Woodhead Publishing: Sawston, UK, 2023; pp. 181–208. [Google Scholar]

- Godschalk-Broers, L.; Sala, G.; Scholten, E. Meat Analogues: Relating Structure to Texture and Sensory Perception. Foods 2022, 11, 2227. [Google Scholar] [CrossRef]

- Day, L.; Swanson, B.G. Functionality of Protein-Fortified Extrudates. Compr. Rev. Food Sci. Food Saf. 2013, 12, 546–564. [Google Scholar] [CrossRef]

- Michel, F.; Hartmann, C.; Siegrist, M. Consumers’ associations, perceptions and acceptance of meat and plant-based meat alternatives. Food Qual. Prefer. 2021, 87, 104063. [Google Scholar] [CrossRef]

- Flores, M.; Piornos, J.A. Fermented meat sausages and the challenge of their plant-based alternatives: A comparative review on aroma-related aspects. Meat Sci. 2021, 182, 108636. [Google Scholar] [CrossRef] [PubMed]

- Van Loo, E.J.; Caputo, V.; Lusk, J.L. Consumer preferences for farm-raised meat, lab-grown meat, and plant-based meat alternatives: Does information or brand matter? Food Policy 2020, 95, 101931. [Google Scholar] [CrossRef]

- Belleggia, L.; Milanovic, V.; Ferrocino, I.; Cocolin, L.; Haouet, M.N.; Scuota, S.; Maolonia, L.; Garofaloa, C.; Cardinalia, F.; Aquilanti, L.; et al. Is there any still undisclosed biodiversity in Ciauscolo salami? A new glance into the microbiota of an artisan production as revealed by high-throughput sequencing. Meat Sci. 2020, 165, 108128. [Google Scholar] [CrossRef]

- Ettinger, L.; Falkeisen, A.; Knowles, S.; Gorman, M.; Barker, S.; Moss, R.; McSweeney, M.B. Consumer Perception and Acceptability of Plant-Based Alternatives to Chicken. Foods 2022, 11, 2271. [Google Scholar] [CrossRef]

- Roesch, R.R.; Corredig, M. Texture and microstructure of emulsions prepared with soy protein concentrate by high-pressure homogenization. LWT Food Sci. Technol. 2003, 36, 113–124. [Google Scholar] [CrossRef]

- Liu, W.; Lanier, T.C. Combined use of variable pressure scanning electron microscopy and confocal laser scanning microscopy best reveal microstructure of comminuted meat gels. LWT 2015, 62, 1027–1033. [Google Scholar] [CrossRef]

- Noguchi, S.; Saio, A. Microstructural Studies of Texturized Vegetable Protein Products: Effects of Oil Addition and Transformation of Raw Materials in Various Sections of a Twin Screw Extruder. Food Struct. 1987, 6, 57–61. [Google Scholar]

- Petrášová, M.; Král, M.; Pospiech, M.; Halamová, P.; Tremlová, B.; Walczycka, M. Pork protein addition effect on structural and qualitative parameters of frankfurter-type sausage. J. Sci. Food Agric. 2019, 99, 1888–1897. [Google Scholar] [CrossRef]

- Zhu, L.J.; Shukri, R.; de Mesa-Stonestreet, N.J.; Alavi, S.; Dogan, H.; Shi, Y.C. Mechanical and microstructural properties of soy protein—High amylose corn starch extrudates in relation to physiochemical changes of starch during extrusion. J. Food Eng. 2010, 100, 232–238. [Google Scholar] [CrossRef]

- Sadeghi-Mehr, A.; Raudsepp, P.; Brüggemann, D.A.; Lautenschlaeger, R.; Drusch, S. Dynamic rheology, microstructure and texture properties of model porcine meat batter as affected by different cold-set binding systems. Food Hydrocoll. 2018, 77, 937–944. [Google Scholar] [CrossRef]

| Sample Type | Product No. | Batch No. | Weight of Product (g) | Storage Temperature (°C) | Packaging Type | Producer |

|---|---|---|---|---|---|---|

| SuA | 15 | 1 | 200 | 1–7 | Vacuum | Soya frankfurtes classic: from Well Well potraviny s.r.o. Hrabinská 498/19 73701 Český Těšín, Czech Republic |

| SuM | 15 | 2 | 750 | Up to 6 | Protective atmosphere | Pork sausages: from Tesco Stores CZ a.s., Vršovická 1527/68b, 100 00 P Prague 10, Czech Republic |

| StA | 15 | 1 | 180 | Up to 8 | Modified atmosphere | Garden Gourment: from Nestlé Česko s.r.o., Mezi Vodami 2035/31, 143 20 Praha 4 |

| StM | 15 | 1 | 300 | Up to 4 | Modified atmosphere | Pork steak: from Matušák Agrion s.r.o. Kunčina 27, 569 24, Czech Repblic |

| KA | 10 | 2 | 300 | Up to 8 | Vacuum | Hungarian klobaňa smoked classic—vegan: from Good Nature s.r.o., Kollárova 88, 036 01 Martin, Slovakia |

| KM | 10 | 2 | 400 | Up to 20 | Protective atmosphere | Hungarian sausages Mives hot: from Pick Szeged Zrt. H-6725 Szeged Szabadkai út 18., Hungary |

| MA | 10 | 1 | 200 | Up to 4 | Modified atmosphere | Garden Gourment: from Nestlé Česko s.r.o., Mezi Vodami 2035/31, 143 20 Praha 4, Czech Republic |

| MM | 10 | 2 | 500 | Up to 8 | Modified atmosphere | Lean ground beef: from Bidfood Kralupy s.r.o., V Růžovém údolí 553, 278 01 Kralupy nad Vltavou, Czech Republic |

| SaA | 10 | 1 | 100 | 1–5 | Protective atmosphere | Soy salami: from KALMA, k.s., Ostravská 256,739 25 Sviadnov, Czech Republic |

| SaM | 10 | 1 | 100 | 1–7 | Protective atmosphere | Junior salami: from Kostelecké uzeniny a.s., č.p. 588 61 Kostelec, Czech Republic |

| BA | 10 | 1 | 150 | Up to 8 | Modified atmosphere | Garden Gourment: from Nestlé Česko s.r.o., Mezi Vodami 2035/31, 143 20 Praha 4, Czech Republic |

| BM | 10 | 2 | 620 | 0 ± 4 | Modified atmosphere | Beef burger: from CHOVSERVIS a.s., TORO Hlavečník, Hlavečník u Kladrub nad Labem, Czech Republic |

| Types | Nutritional Values per 100 g | Ingredients | ||||

|---|---|---|---|---|---|---|

| Protein | Saccharides | Fat | Salt | Fibre | ||

| SuA | 18.0 | 4.9 including 1.0 sugars | 10 including 0.9 saturated fatty acids | 1.9 | 0.7 | Soya protein (10.86%), rapeseed oil, wheat protein (7.28%), modified starch (E1422), salt, aromas, thickener—carrageenan (E407), ground red pepper, colourant—iron oxides and hydroxides (E172), smoky aroma |

| SuM | 13.2 | 2.2 including 1.7 sugars | 23.3 including 8.2 saturated fatty acids | 2.7 | Pork (83%), water, salt, glucose, stabilisers (diphosphates, sodium citrates), aromas, spices, spice extracts, antioxidant (sodium erythorbate), preservative (sodium nitrite) | |

| StA | 16.0 | 16.0 including 2.4 sugars | 12.0 including 1.3 saturated fatty acids | 1.3 | 5.5 | Breadcrumbs (16.4%) (wheat flour, water, rapeseed oil, yeast, salt, spice extracts: sweet pepper, turmeric), vegetable oils in various proportions (rapeseed, sunflower), wheat protein (5.8%), soy protein (5.5%), dried egg proteins, mayonnaise (sunflower oil; fermented alcohol vinegar; dried egg yolks; mustard; iodised table salt: table salt, potassium iodate; sugar), corn starch, citrus fibre, fermented alcohol vinegar, dried yeast extract, wheat flour, spice mix (sweet pepper, cumin, chili pepper, oregano), onion powder, tomato concentrate, salt, garlic, garlic powder |

| StM | Pork (20%), breadcrumbs, egg, flour, milk, salt, rapeseed oil, butter | |||||

| KA | 9.6 | 12.48 including 1.52 sugars | 7.2 including 1.32 saturated fatty acids | 2.03 | Wheat, soy, ground barley, oatmeal, sunflower oil, garlic, ground pepper, salt, spices | |

| KM | 22.0 | <0.5 including <0.5 sugars | 42.0 including 17.0 saturated fatty acids | 3.7 | Pork, lard, salt, spices, ground hot pepper (1.2%), sweet ground pepper (1.0%), spice extract, colour (E160c), sugar, preservative (E250, E202), smoke Stuffed into edible pork intestine | |

| MA | 17.3 | 3.6 including 1.0 sugars | 7.9 including 2.9 saturated fatty acids | 1.0 | 5.0 | Soy protein (22.9%), vegetable oils (rapeseed, coconut), stabiliser (methylcellulose), natural aromas, fermented alcohol vinegar, garlic and onion powder, fruit and vegetable concentrates (beets, carrots, peppers, blackcurrants), malted barley extract, black pepper |

| MM | 18.2 | 0.15 including 0.01 sugars | 14.2 including 7.38 saturated fatty acids | 1.55 | Beef (94.5%), water, salt, stabiliser—sodium acetate | |

| SaA | 17.0 | 5.1 including 1.3 sugars | 6.9 including 0.6 saturated fatty acids | 1.9 | 2.1 | Soy protein (9%), textured soy protein (7%), rapeseed oil, wheat protein (5%), modified corn starch, salt, thickeners: carrageenan and spices, powdered vinegar, barley sweet extract, colour E172 |

| SaM | 10.7 | 5.2 including <0.3 sugars | 14.7 including 6.2 saturated fatty acids | 2.4 | 0.7 | Pork (28%), water, pork skin, beef (12%), lard, potato starch, salt, pork protein, stabilisers (E250, E450, and E451), modified starch (E1422), thickeners (E407a, E415, and E412), emulsifier (E471), antioxidants (E301 and E330), acidity regulators E500, Vegetable fibre, flavour enhancers (E621 and E635), colour (E120, E150c, and E162), spices, garlic, spice extracts |

| BA | 17.3 | 2.8 including 0.5 sugars | 13.0 including 3.6 saturated fatty acids | 0.73 | 6.0 | Soy protein (19.9%), vegetable oils, rapeseed coconut, fermented alcohol vinegar, aromas, stabiliser (E461—methylcellulose), plant concentrates (apple, beet, carrot, hibiscus), malted barley extract |

| BM | 20.0 | 0 including 0 sugars | 9.6 including 4.0 saturated fatty acids | 1.1 | Beef (99%), salt | |

| Descriptor | Verbal Description Provided | Lowest Point | Highest Point |

|---|---|---|---|

| Texture | Soft consistency 1,4; stiff consistency, solid, cohesive 2,3,6; cohesive 4; brittle 5 | Too soft or too stiff 1,6; incoherent 6; too soft or stiff 2,3,4; solid parts 5 | Optimally soft 1;solid, cohesive 2,3,6; soft, cohesive 4; brittle 5 |

| Product similarity | They resemble each other * | Completely different * | Absolutely identical * |

| Overall appearance | Surface discolouration, air bubbles, surface stains 1,3; uniform golden brown colour 2; uniform colouration, typical 4,6; flesh-pink colour 5 | Obvious numerous defects * | No deviations * |

| Overall impression | overall impression with regard to the evaluated parameters * | Disgusting * | Delicious * |

| Interest in the product | - | Definitely would not buy it * | Would definitely buy it * |

| Aroma | Typical, moderately intense, pleasant 1,3,4,6; typical, soft, after frying, pleasant, without foreign odours 2; smoked, mildly spiced 3,5 | Weak, strong foreign odour 1,3,4,5,6; bland, unsalted, with a foreign flavour 2 | Typical, without any foreign smell *; typical, optimally salty 2 |

| Animal character | Origin of the product * | Plant-based * | Animal-based * |

| Taste | Typical, moderately intense, pleasant 1,3,4,6; typical, soft, after frying, pleasant, without foreign odours 2; smoked, mildly spiced 3,5 | Bland, with a foreign flavour 1,2,3,4,6; unsalted 1,2,3,5; not spicy 5 | Typical, without foreign flavours 1,2,3,4,5,6; optimally salty 1,2,3 |

| Meat taste | Presence of meat taste * | Absolutely not meaty taste * | Absolutely meaty taste * |

| Sample Type | L* | a* | b* | C* | h° |

|---|---|---|---|---|---|

| SuA | 57.63 ± 1.10 b | 15.30 ± 0.31 | 25.13 ± 0.42 b | 29.42 ± 0.50 b | 58.67 ± 0.24 b |

| SuM | 64.63 ± 1.75 a | 14.94 ± 0.96 | 32.90 ± 1.35 a | 36.14 ± 1.55 a | 65.60 ± 0.90 a |

| SuA ˣ | 62.19 ± 0.57 b | 14.00 ± 0.28 a | 22.71 ± 0.23 a | 26.67 ± 0.33 a | 58.35 ± 0.31 b |

| SuM ˣ | 79.10 ± 0.89 a | 5.82 ± 0.38 b | 12.49 ± 0.18 b | 13.78 ± 0.21 b | 65.02 ± 1.51 a |

| StA | 58.06 ± 1.19 a | 15.64 ± 1.58 a | 30.18 ± 2.57 a | 34.00 ± 2.92 a | 62.62 ± 1.29 |

| StM | 51.88 ± 3.07 b | 10.61 ± 0.65 b | 20.56 ± 2.09 b | 23.15 ± 1.98 b | 62.59 ± 2.16 |

| KA | 29.75 ± 3.06 b | 23.32 ± 2.53 | 10.54 ± 0.89 b | 25.59 ± 2.66 | 24.40 ± 0.82 b |

| KM | 34.05 ± 0.77 a | 21.70 ± 0.79 | 15.38 ± 0.96 a | 26.60 ± 1.16 | 35.31 ± 1.02 a |

| KA ˣ | 52.47 ± 1.00 a | 17.69 ± 1.39 b | 26.19 ± 2.21 a | 31.61 ± 2.48 a | 55.93 ± 1.52 a |

| KM ˣ | 44.92 ± 1.58 b | 21.15 ± 1.13 a | 18.36 ± 1.12 b | 28.02 ± 1.56 b | 40.95 ± 0.69 b |

| MA | 51.84 ± 0.85 a | 12.96 ± 0.40 b | 16.31 ± 0.48 a | 20.84 ± 0.59 | 51.52 ± 0.58 a |

| MM | 43.90 ± 1.62 b | 15.39 ± 1.19 a | 13.05 ± 1.02 b | 20.19 ± 1.40 | 40.30 ± 1.96 b |

| SaA | 45.12 ± 0.32 b | 21.93 ± 0.48 a | 21.71 ± 0.27 a | 30.86 ± 0.51 a | 44.72 ± 0.39 b |

| SaM | 57.61 ± 0.27 a | 12.54 ± 0.29 b | 14.09 ± 0.18 b | 18.86 ± 0.31 b | 48.34 ± 0.37 a |

| BA | 53.92 ± 1.04 a | 10.58 ± 0.47 a | 12.98 ± 0.53 a | 16.75 ± 0.66 a | 50.83 ± 0.91 b |

| BM | 47.27 ± 3.08 b | 7.33 ± 0.96 b | 10.91 ± 0.92 b | 13.16 ± 1.20 b | 56.16 ± 2.55 a |

| Sample Type | Hardness | Cohesiveness |

|---|---|---|

| SuA | 8.70 ± 0.59 b | 1.19 ± 0.01 |

| SuM | 13.89 ± 1.92 a | 1.19 ± 0.03 |

| KA | 7.36 ± 1.07 b | 1.05 ± 0.01 b |

| KM | 25.22 ± 3.70 a | 1.28 ± 0.02 a |

| MA | 2.05 ± 0.18 | 1.00 ± 0.04 b |

| MM | 2.04 ± 0.22 | 1.11 ± 0.04 a |

| BA | 1.25 ± 0.15 b | 0.96 ± 0.06 b |

| BM | 2.98 ± 0.33 a | 1.12 ± 0.02 a |

| Shear force | Toughness | |

| StA | 13.12 ± 2.35 b | 61.79 ± 13.33 b |

| StM | 21.09 ± 2.70 a | 72.55 ± 6.57 a |

| Sample types | Hardness | Cohesiveness |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdullah, F.A.A.; Pospiech, M.; Dordevic, D.; Kabourkova, E. Comparison of Physical, Sensorial, and Microstructural Properties to Assess the Similarity Between Plant- and Animal-Based Meat Products. Appl. Sci. 2024, 14, 11513. https://doi.org/10.3390/app142411513

Abdullah FAA, Pospiech M, Dordevic D, Kabourkova E. Comparison of Physical, Sensorial, and Microstructural Properties to Assess the Similarity Between Plant- and Animal-Based Meat Products. Applied Sciences. 2024; 14(24):11513. https://doi.org/10.3390/app142411513

Chicago/Turabian StyleAbdullah, Fouad Ali Abdullah, Matej Pospiech, Dani Dordevic, and Eliska Kabourkova. 2024. "Comparison of Physical, Sensorial, and Microstructural Properties to Assess the Similarity Between Plant- and Animal-Based Meat Products" Applied Sciences 14, no. 24: 11513. https://doi.org/10.3390/app142411513

APA StyleAbdullah, F. A. A., Pospiech, M., Dordevic, D., & Kabourkova, E. (2024). Comparison of Physical, Sensorial, and Microstructural Properties to Assess the Similarity Between Plant- and Animal-Based Meat Products. Applied Sciences, 14(24), 11513. https://doi.org/10.3390/app142411513