Featured Application

This paper describes the development of the constitutive model for early-aging viscoelastic concrete. And this paper provides the work related to material testing and modeling for identifying the required constitutive properties of early-age concrete.

Abstract

Short-term uniaxial tensile creep tests were conducted for early-age concrete at different ages in an effort to characterize early-age concrete as an aging viscoelastic material. Based on the test results, the viscoelastic material properties of the test concrete were characterized in terms of the Dirichlet series creep compliance and relaxation modulus functions. Applications of the model to the numerical analysis of the test samples showed a good agreement between the tests and computational results for the samples tested at different ages. This paper presents the test procedures and data analysis with a brief introduction of theoretical background.

1. Introduction

It is well recognized that under sustained loading conditions, concrete exhibits time-dependent viscoelastic behavior, such as creep or stress relaxation [1,2,3]. Concrete pavement is a special type of structure undergoing sustained environmental loads, causing thermal or drying shrinkage deformation from the ambient temperature and moisture conditions. In a newly placed concrete pavement, restrained shrinkage stress will gradually develop with time because the deformation becomes limited in concrete due to internal restraints from aggregate as well as hardening cement paste matrix [4,5]. However, early-age concrete subjected to restrained shrinkage will experience significant stress relaxation, which is beneficial with respect to concrete cracking. Cracking is expected to occur when the stress after relaxation exceeds the material’s resistance to cracking. But the cracking time might be delayed with the help of creep and relaxation, reducing the magnitude of tensile stresses, which consequently allows for a wider saw-cut-timing window [6]. It should be noted that saw cut timing is affected by various factors such as concrete mixtures, curing temperatures, and relative humidity, etc. In hot weather conditions, saw cutting may start as soon as a couple of hours after the concrete has been finished. In cooler weather, sawing may not start for 12 h after pouring [7].

The factors that can influence the creep of the concrete structures include concrete mix proportioning, ambient humidity and temperature, and concrete member shape and size, etc. [8,9]. Influential factors for the concrete mix that induce creep are the type and content of cementitious materials, slump, air content, fine aggregate percentage, aggregate type, and fibers [8,9,10,11]. The early-age deformation of high-performance concrete (HPC) is known to be higher than normal concrete, as HPC is mixed with high cement and supplementary cementitious materials [12]. In addition, lower ambient relative humidity increases the creep coefficient [8]. And the volume-to-surface ratio or minimum thickness of the concrete specimen affects the creep coefficient too because of resistance to moisture transport from the interior to the atmosphere [5].

To date, existing studies on concrete creep have been focused on the compressive creep of concrete [13,14,15], while few efforts have been carried out on issues concerning the tensile creep of concrete. The tensile creep of concrete is creep deformation under constant tensile loading conditions. Reviewing various research results on the compressive and tensile creep of concrete, Hilaire et al. [16] reported that the development of creep strain is different between compressive and tensile creep in most studies, while the ratio of compressive creep to tensile creep decreases with time. Under similar testing conditions, such as specimen geometry, curing conditions, and loading conditions, similar creep results in compression and tension were demonstrated by Klausen et al. [17]. Performing creep tests in tension is known to be more difficult than conducting those in compression, especially at early ages [10].

A number of aging creep models have been proposed, e.g., ACI equation [18], the triple power law [19], the microprestress–solidification theory (MPS) [20,21,22], and the Dischinger model [23]. However, the empirical constants and functional parameters in these models have been derived from long-term compressive creep test data for aged concrete. Other studies modified these models to fit the creep of early-age concrete [24,25]. These modified models provide a good basis for the description of aging effects on the creep behavior of early-age concrete. These models are generally formulated via production or summation of the power laws, each of which represents age-dependent and age-independent behavior. Due to this functional complexity, further approximation is required for the representation of the relaxation behavior and structural stress analysis.

Investigations of the creep and relaxation effect on the mechanical responses of pavements are very limited [6,26,27,28]. Yeon et al. [26] used the creep coefficient adopted from CEB-FIP Model Code 1990 [23] to analytically calculate the average stress at the mid-depth of a slab. Lim et al. [27] predicted the average stress generated in the pavement using the creep properties measured from a ring test. Wei et al. [6] considered the effect of concrete creep in pavement slab for analyzing moisture warping and warping stresses by using specimens under different drying conditions exposed to drying at the age of 7 days. The creep relaxation effect is most significant in the first 7 days and tends to be stable after 60 days [28].

For the stress analysis of concrete structures, a proper material model should be used that represents a realistic constitutive behavior of early-age concrete. In this study, the early-age concrete is assumed to conform to the linear viscoelastic behavior with a strong aging effect. Short-term uniaxial tensile creep tests were conducted for a minor concrete paving mixture with 25% fly ash at different ages in an effort to characterize early-age concrete as an aging viscoelastic material. Based on the test results, the viscoelastic material properties of the test concrete were characterized in terms of the Dirichlet series creep compliance and relaxation modulus functions. In order to verify the aging creep model and its conversion to an age-dependent relaxation modulus, the tensile creep tests at different ages were simulated using the finite element program, ABAQUS, with the estimated relaxation modulus at each age. This paper presents the test procedures and data analysis with a brief introduction of the theoretical background.

2. Theoretical Background

2.1. Constitutive Relations

The time-dependent behavior of concrete has been effectively explained by the linear viscoelastic theory with the principle of superposition [29]. The general constitutive relations for linear aging viscoelastic materials can be expressed with the superposition integral as follows [30]:

where σij is the stress tensor, εkl is the strain tensor, Cijkl is the fourth order tensor of relaxation modulus, xk is the position vector, t is the time of interest, and t′ is the initial loading time. The relaxation modulus Cijkl(t,t′) describes the stress at time t caused by a unit constant strain applied at time t′. Note that the relaxation modulus is a function of the current time, t, and the initial loading time, t′. For non-aging materials, it will be a function of the duration of the load (t − t′) only. It is also noted that thermal or shrinkage stresses are not included in Equation (1). Under the linear theory, these environmental stresses may be effectively considered by adding separate terms that consist of relevant mechanical properties relating the environmental effects and corresponding stress developments [5].

For isotropic materials, the fourth order modulus tensor can be expressed as Equation (2) [30], and, therefore, the constitutive equations reduce to Equation (3) for early-age concrete as an isotropic, linear aging viscoelastic material.

where λ(t) and μ(t) are independent relaxation moduli, and δij is the Kronecker delta. For an effective use of the constitutive equations to early-age concrete, it is crucial to properly define the related material properties, i.e., the time- and age-dependent relaxation modulus functions, and , for the early-age concrete.

These general isotropic relaxation moduli can then be expressed in terms of the uniaxial relaxation modulus, E(t), as shown in Equations (4) and (5). The Poisson’s ratio (ν) is assumed to be time-independent.

As shown, the relations of the material properties are very similar to those defined in elastic theory. By these relations, the constitutive equation given in Equation (3) can be used for the viscoelastic stress analysis of early-age concrete when the age-dependent uniaxial relaxation modulus, , is defined. One way to determine this viscoelastic material property is through a relaxation test [30]. However, due to the difficulties associated with the relaxation test, especially for early-age concrete in tension, a creep test that defines creep compliance is generally preferred. The relaxation modulus can be determined from the compliance by a unique relationship between those two properties.

2.2. Creep and Relaxation Characteristics

For one-dimensional loading, the constitutive equations reduce to

or equivalently in a stress formulation,

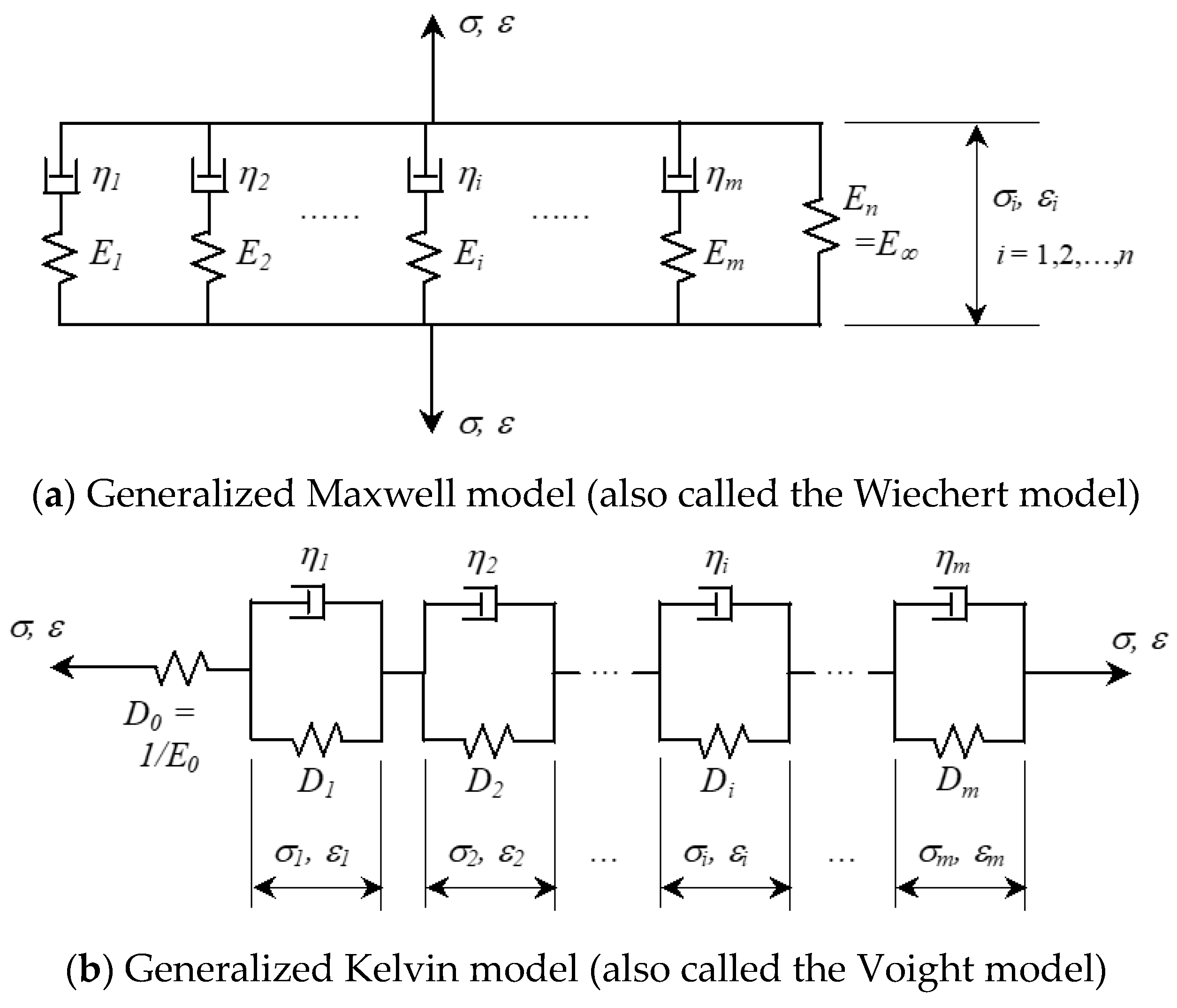

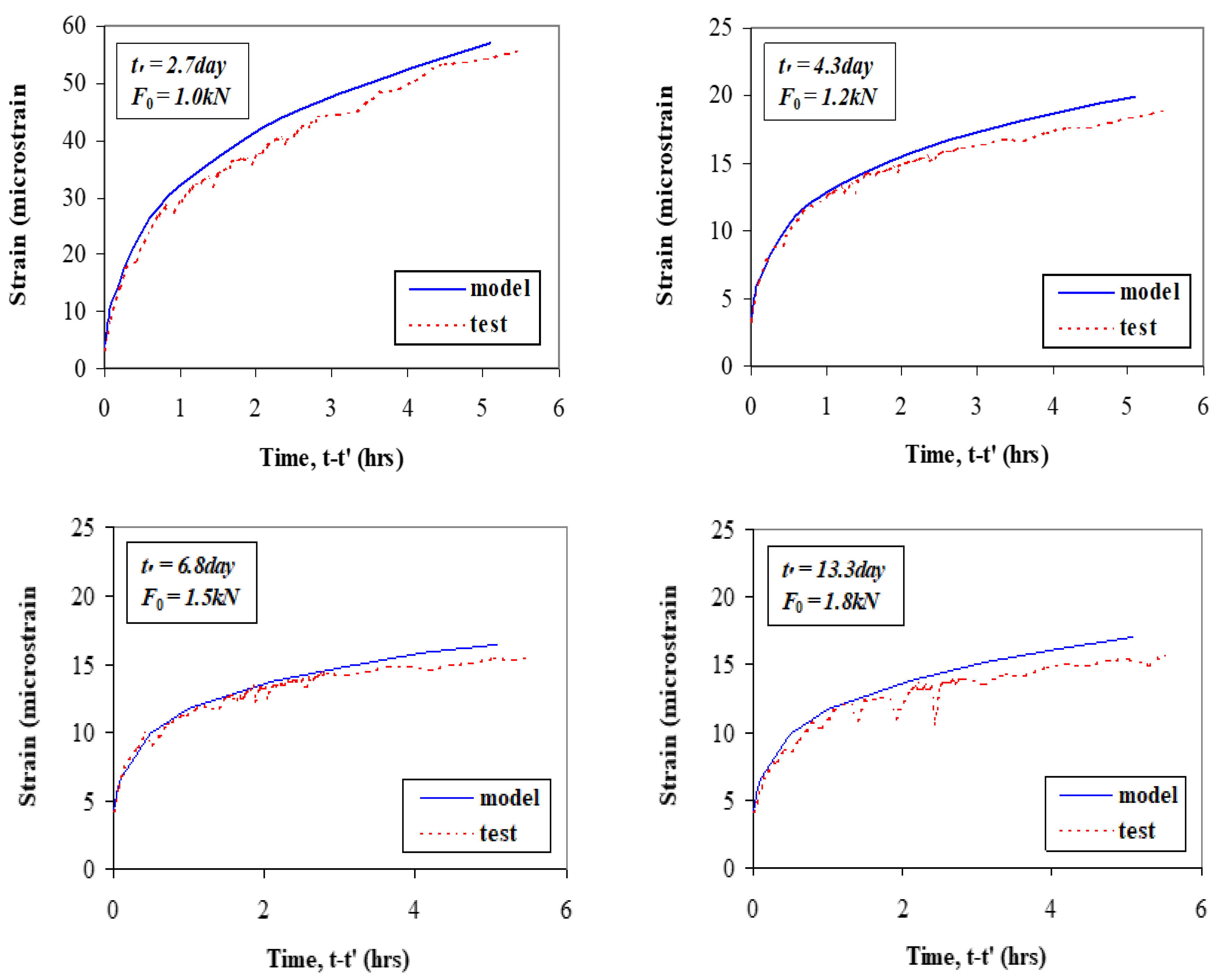

where and are the time- and age-dependent uniaxial relaxation modulus and creep compliance, respectively. As a counterpart of the relaxation modulus, creep compliance describes the strain at time t caused by a unit constant stress applied at time t′. Viscoelastic material behavior defined by the constitutive relations given in Equations (6) and (7) can be analogized by their mechanical models shown in Figure 1. These mechanical models, respectively, define the relaxation modulus and creep compliance in a series of real exponents referred to as the Dirichlet series or the Prony series [31]. Equations (8) and (9) represent the Dirichlet series relaxation modulus and creep compliance functions for aging concrete. Mathematical difficulties from the aging effect are simplified in these representations by formulating the functions in a sum of products of single time-dependent variables [32,33].

Figure 1.

Experimental mechanical models for viscoelastic materials.

Material parameters (E∞, Ei, D0, and Di) in Equations (8) and (9) correspond to the internal modulus and compliance of the spring units of the mechanical models in Figure 1. The internal viscosity (ηi) of each unit of the models characterizes the time-dependent viscous behavior of the material, which are involved in the exponents ρi and τi, referred to as the relaxation time and retardation time, respectively.

The two viscoelastic material properties, relaxation modulus and creep compliance, are uniquely related to each other as presented in Equation (10). Therefore, once one of the properties is identified, the other can be estimated by the relationship [30]. As will be seen later, the relationship can be verified by the Laplace transform of the relaxation and creep functions.

It is noted that the relationship above does not involve the age-dependency of the material properties. This means the interrelation applies for a particular age, t′, between D(t) and E(t). If the conversion of the material properties is required for an age-dependent stress or displacement analysis, therefore, the conversion scheme must be continuously incorporated into each time step of the analysis procedure.

3. Tensile Creep Tests

3.1. Materials

Conventional plain concrete was tested at different ages. The mixtures consisted of Type I Portland cement, crushed limestone aggregates with the maximum size of 25 mm, natural sand, and Class C fly ash. The gradation of coarse and fine aggregates conformed to ASTM C33 requirements. Table 1 presents the concrete mixture proportions used in this study.

Table 1.

Concrete mixture proportions.

3.2. Procedures

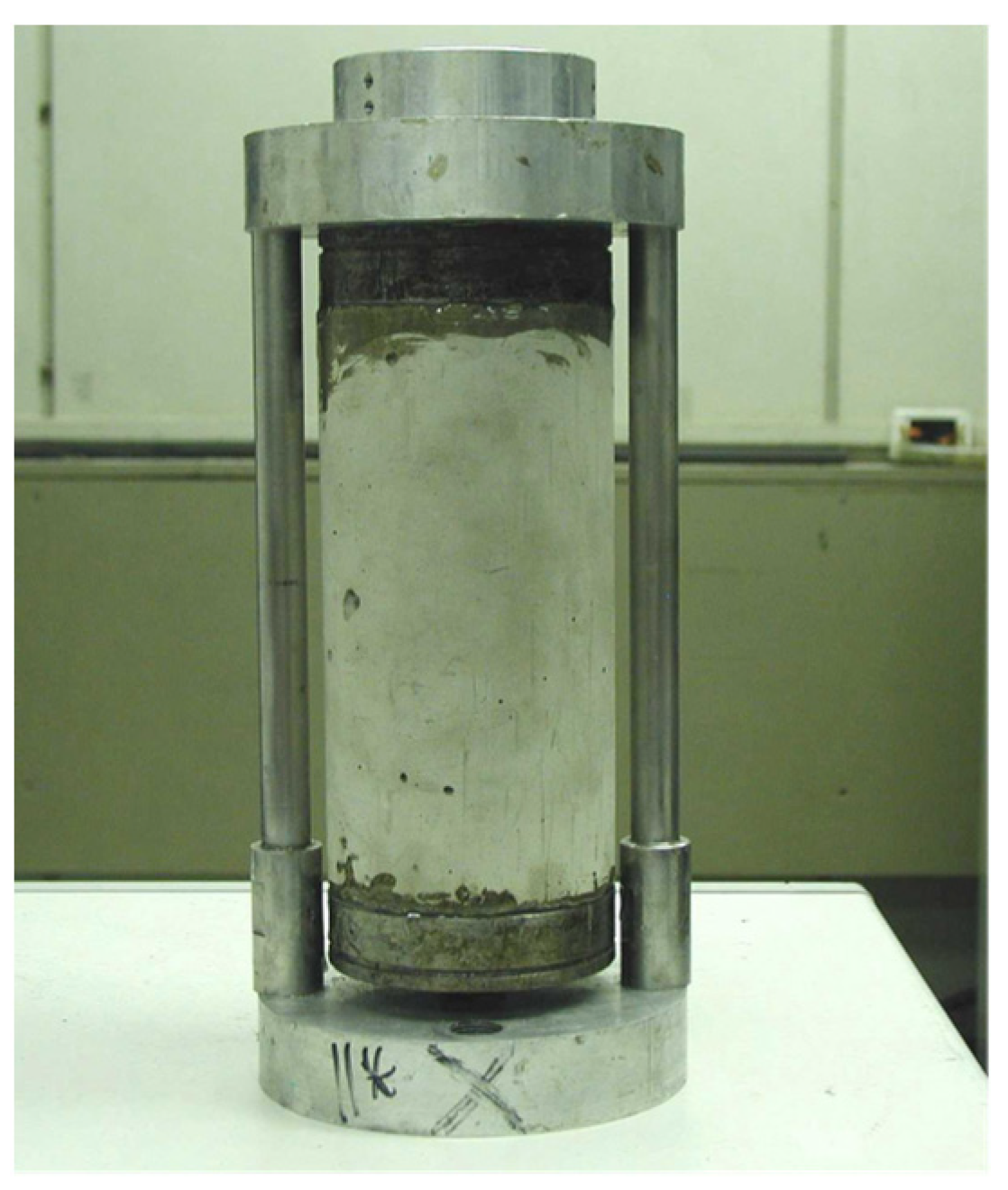

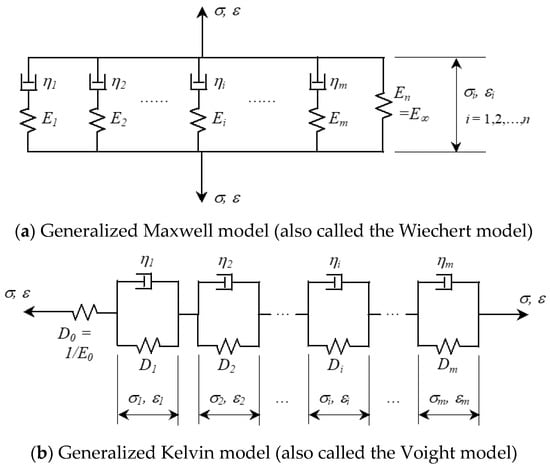

Uniaxial tensile creep tests were conducted with standard concrete cylinders (100 × 200 mm) at the ages of 2.7, 4.3, 6.8, and 13.3 days using a servo-controlled MTS testing machine. One sample per age was used to verify the modeling approach. Immediately after casting, the concrete cylinders were moved to a moisture curing room with a controlled temperature and humidity at 25 °C and 100%. The cylinder specimens were moved to the testing room (25 °C and 40% RH) for instrumentation at 24 h before the respective ages of testing. A pair of steel connections for direct tensioning of the test specimen was epoxy-bonded at each end of the cylinder. In order to provide a surface for epoxy bonding, both ends of the concrete cylinder were ground by approximately 5 mm in depth. The epoxy work was performed with a specially prepared concentric jig as shown in Figure 2. After the epoxy work, the specimens were kept in the testing room until the time of testing in order for the epoxy to develop its full bond strength.

Figure 2.

Alignment of test specimen and the end fixtures.

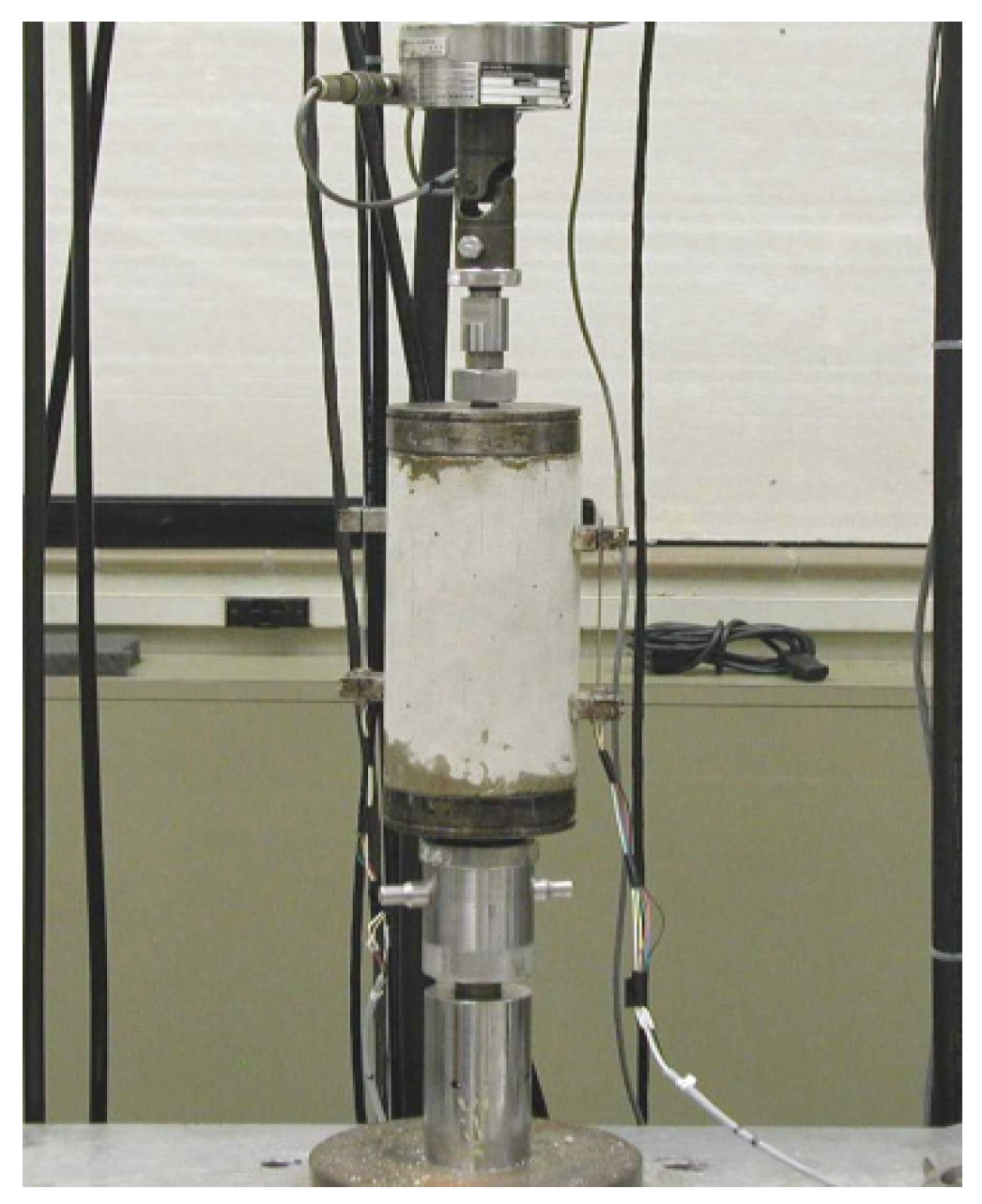

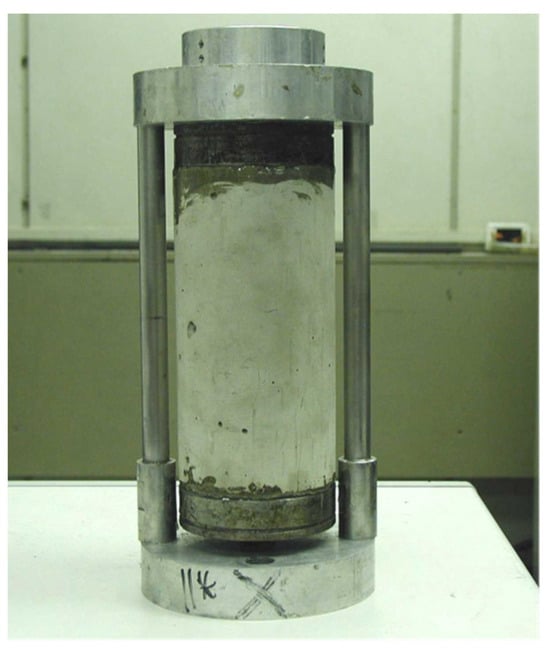

A designated level of tensile load was introduced to the specimen within 0.1 s, and subsequent changes in displacement as a function of time was monitored up to 20,000 s (5.5 h), while keeping the load constant. The level of load was controlled with a 4.5 kN capacity load cell. The load level ranged from 1 to 2 kN depending on the ages of the specimens. Displacement data were traced by the two LVDTs installed on the mid-surface of the cylinder specimens with 100 mm gage lengths. Figure 3 shows the test set-up.

Figure 3.

Uniaxial tensile creep test.

The level of test load was determined to be 15% of the tensile strength of the concrete at the respective ages of testing. Tensile strength was assumed to be 1/8 of the compressive strength at all ages of testing. Development of the compressive strength of the concrete was estimated by the ACI equation [18] shown in Equation (11). The average 28-day compressive strength of the test concrete was 15.51 MPa, found by separate strength tests. Table 2 summarizes the determination of the test load for the respective ages of testing.

where fc(t) = compressive strength at time t, and fc′ = reference compressive strength at the age of 28 days.

Table 2.

Determination of load levels for the tensile creep tests.

Earlier studies on the creep of aged concrete suggested that the principle of superposition would be valid within the service range of stresses (up to ½ of the strength) under a monotonically increasing strain condition [29,34]. Recent studies found that early-age concrete also shows proportional creep responses to the stress level below 50% of static strength, regardless of mixture characteristics [25,35,36]. Based on these previous observations, no additional linearity check was conducted in this study.

4. Test Results

4.1. Creep Compliance

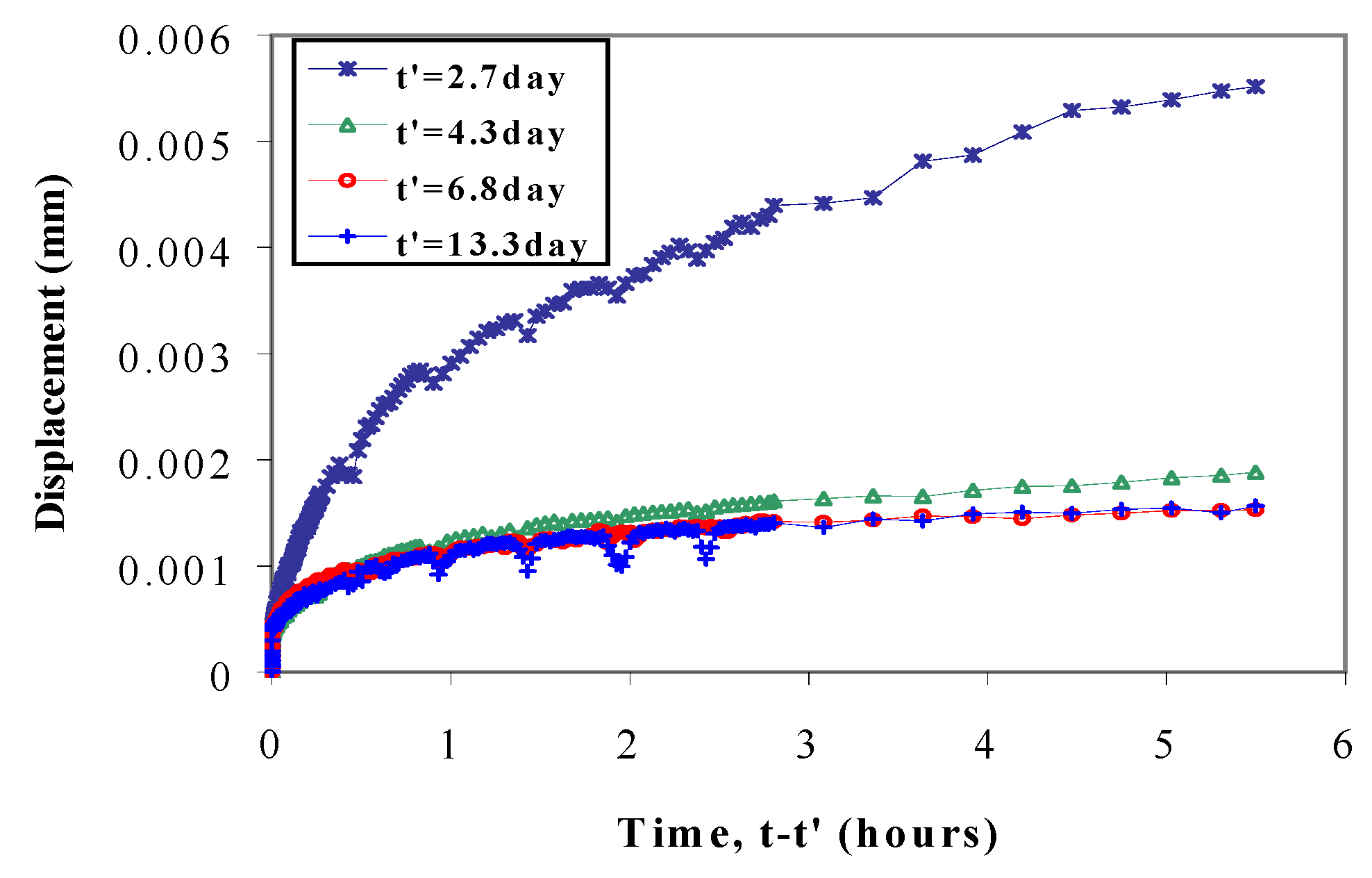

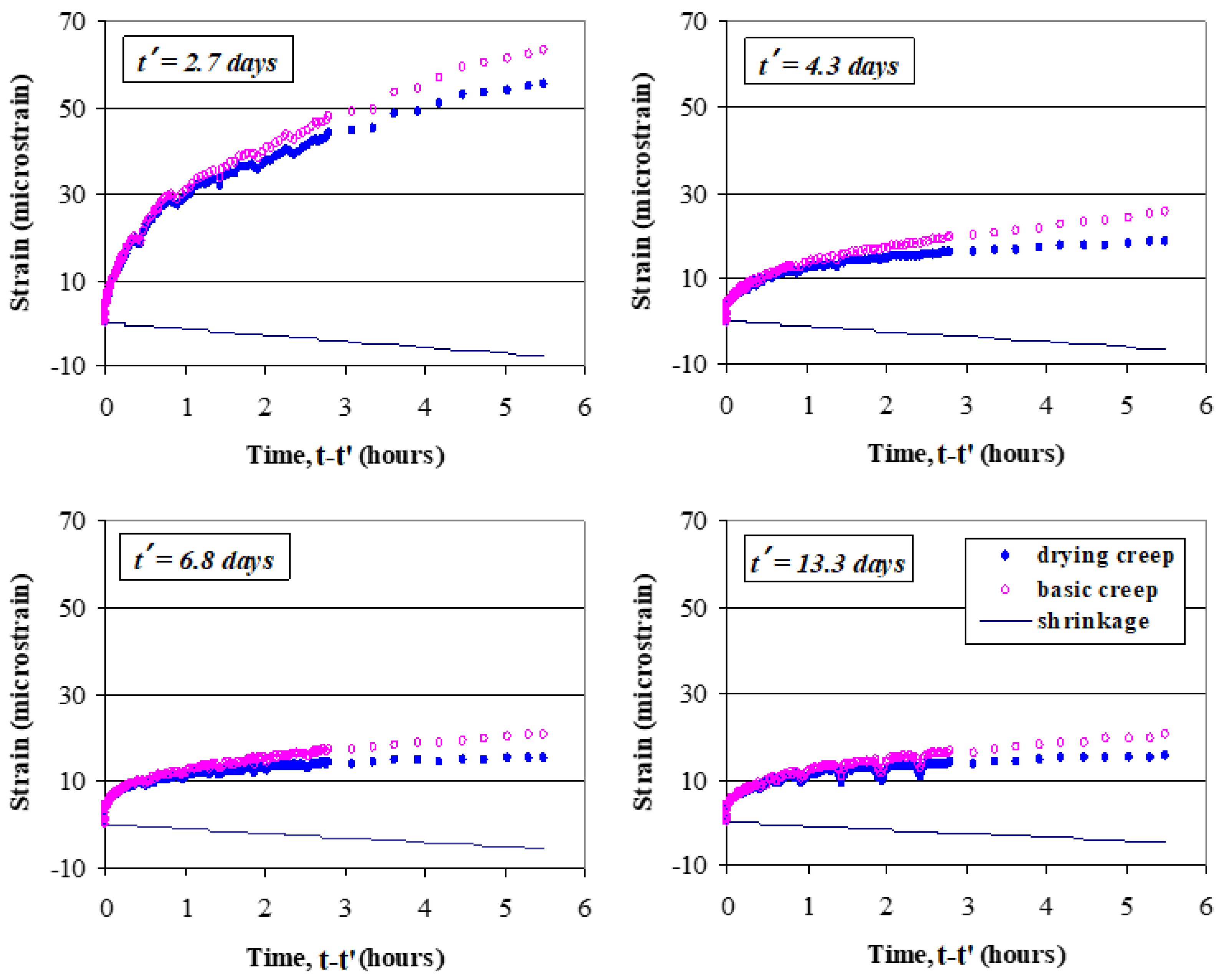

Figure 4 shows the time-dependent displacement of the test specimens placed under constant tensile load at the designated testing ages. It is noted that the measured deformation is the drying creep under the effect of drying shrinkage that occurred during the test period. Drying creep is known to induce a non-linear effect, particularly in long-term response; as such, it is always greater than the sum of separate measurements of creep under sealed conditions (basic creep) and drying shrinkage under load-free conditions (free shrinkage) [37,38]. However, this study focuses on short-term creep in early-age concrete within the context of linear theory. Creep tests were accordingly conducted where the non-linear effect during the 5 h testing period is assumed negligible. With these assumptions, the measured total strain (εtest) can be expressed by the sum of basic creep (εcreep) and shrinkage (εsh) as shown in Equation (12). Note that the drying shrinkage occurs in the opposite direction to the tensile creep. The basic creep (εcreep) is the test load-induced time-dependent deformation of the concrete that can be determined by the constitutive relations shown in Equation (13). Substituting Equation (13) into Equation (12) gives Equation (14), which was used for the estimation of the creep compliance of each test specimen.

where = uniaxial creep compliance, = constant testing load in terms of stress, and = step function (0 for and 1 for ).

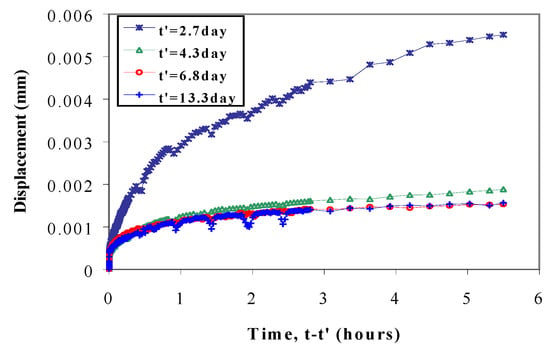

Figure 4.

Time-dependent displacements as the result of tensile creep tests.

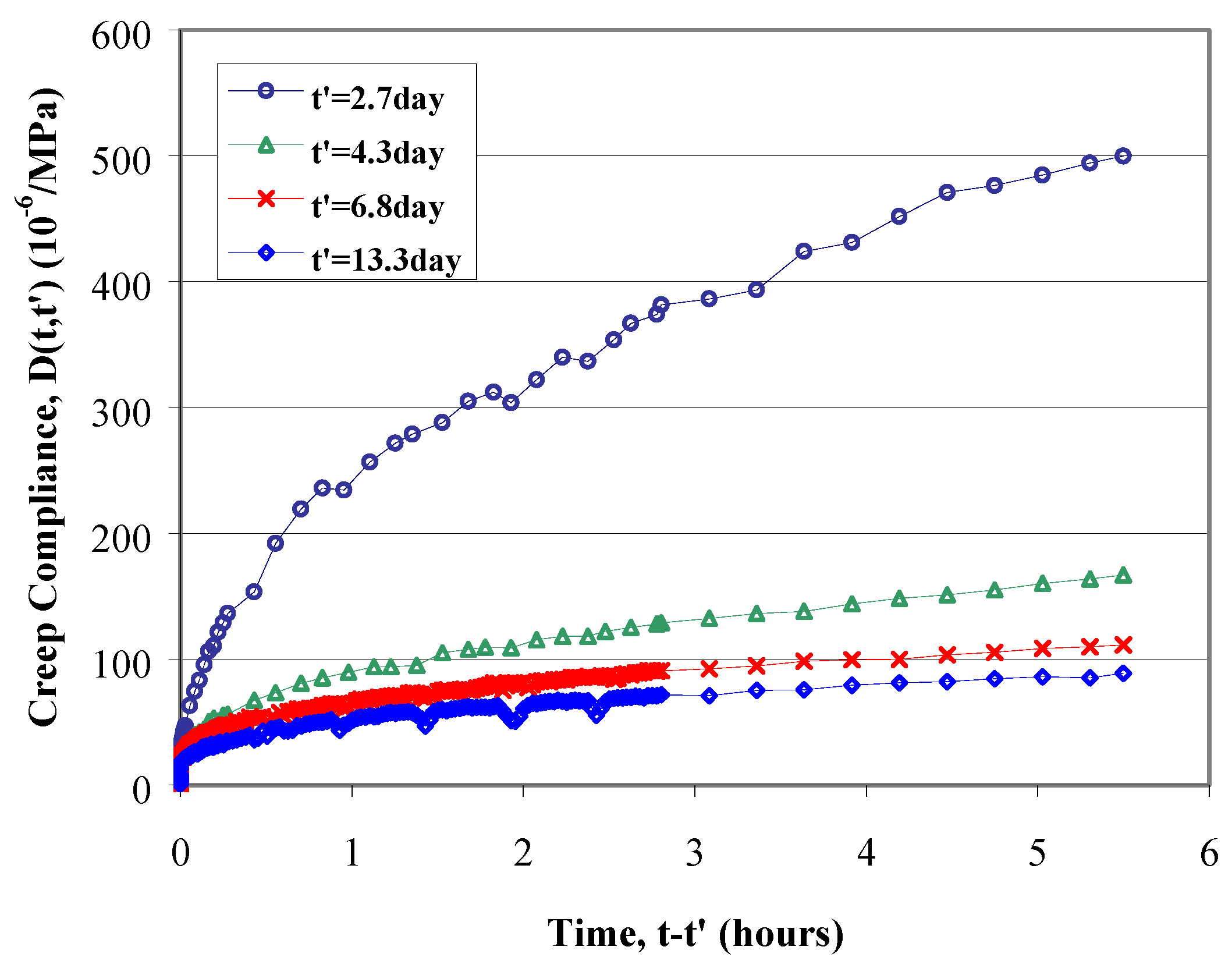

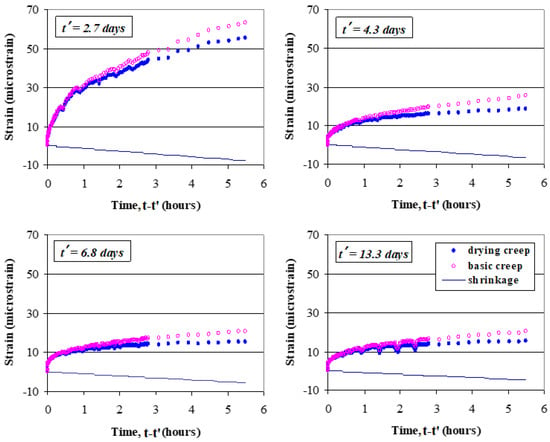

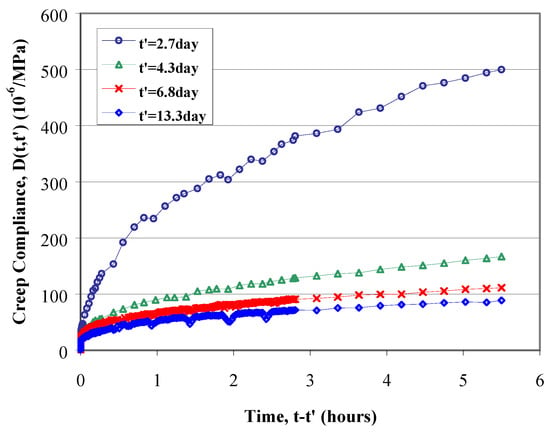

The magnitude of drying shrinkage (εsh) of the test concrete was estimated by the BP model [39]. Estimated maximum shrinkage after the 5 h testing period at the ages of 2.7, 4.3, 6.8, and 13.3 days were 7.72, 6.55, 5.71, and 4.76 microstrains, respectively. The basic creep was then calculated by Equation (12). Figure 5 shows the three components of deformation for the respective test samples. Creep compliance curves estimated by Equation (14) for the test concrete at different ages are shown in Figure 6. As shown, there is a sharp reduction in the creep response of the concrete between the samples aged 2.7 and 4.3 days. Much stiffer responses were observed from the samples at later ages. The difference in the response is not so pronounced between the 6.8- and 13.3-day-old samples, suggesting the aging effect on the creep response may not be significant for concrete aged more than 7 days.

Figure 5.

Strain components of the test concrete at different ages.

Figure 6.

Creep compliance of the test concrete at different ages.

4.2. Dirichlet Series Creep Function

The creep compliance data shown in Figure 6 were fitted with the Dirichlet series functions given in Equation (9) by the collocation method. The method of fitting the data with the Dirichlet series may be found elsewhere [32]. In this study, six collocation points were selected from 10−3 to 102 h at decimal spacing. This means the Kelvin model used in this study consists of six Kelvin units in addition to the initial spring unit. The initial compliance (D0) was selected; as such, it corresponds to the instantaneous response of the specimen to loading within 1 s (2.8 × 10−4 h). The last two collocation values were extrapolated from the test data referring to the creep rate reported in the previous studies for the long-term creep in compression [39,40]. The material retardation time (τi) for each Kelvin unit was determined at six points from 5 × 10−4 to 50 h at decimal intervals. With these pre-selected variables, the internal compliance (Di) of the Kelvin model was determined using Equation (15), which is a matrix formulation of Equation (9) rearranged for Di. Since the model has six Kelvin units, the number of collocation points (i, j) varies from 1 to 6.

where {Di} = the compliance vector to be determined for the respective Kelvin units, and D(tj) = compliance at the jth collocation point (tj).

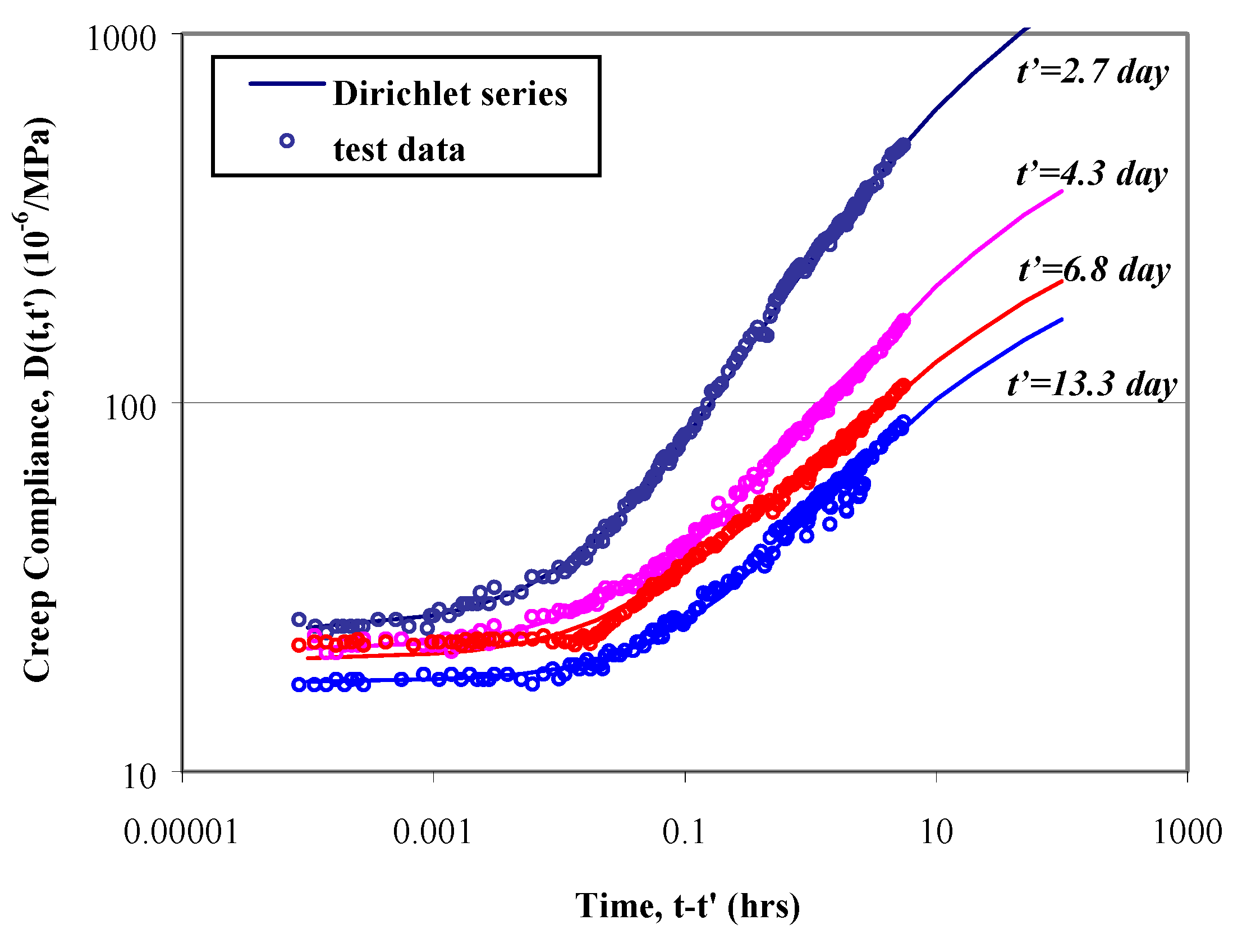

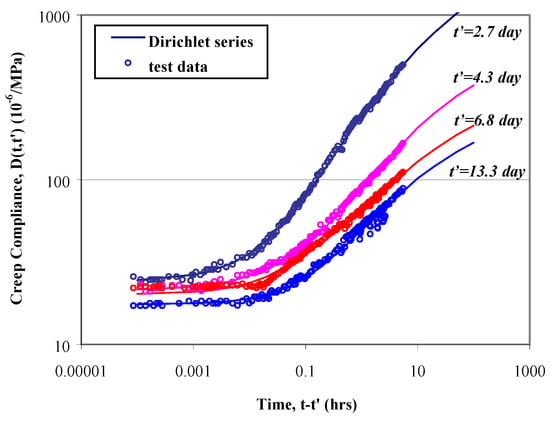

Figure 7 shows the fitted creep compliance curves compared to the respective test data. The internal parameters, D0 and Di, determined from the fitting process, are presented in Table 3. The aging effect, represented by the dependency of the response to the initial loading time, may be explained by the changes in the internal compliance of the concrete at different ages.

Figure 7.

Dirichlet series fitting of the creep compliance data.

Table 3.

Material parameters determined for the Dirichlet series creep compliance function.

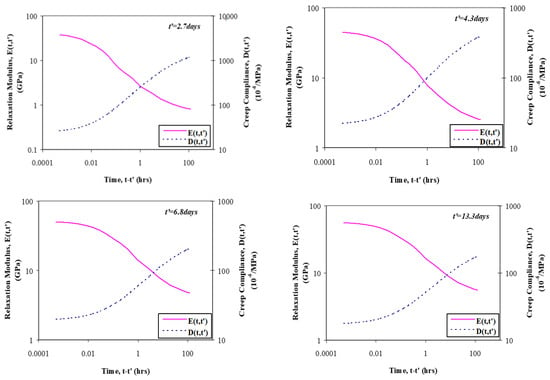

4.3. Relaxation Modulus

As previously mentioned, the relaxation modulus function (E(t,t′)) can be estimated by converting creep compliance function (D(t,t′)) using their relationship given in Equation (10). The conversion procedure can be simplified with the Laplace transform (L). The Laplace transform with respect to time is defined by

where s is the transform parameter. The transform of the relationship, Equation (10), is

By introducing the Carson transform, , Equation (17) becomes

The Carson transform of the uniaxial relaxation modulus (Equation (8)) and creep compliance (Equation (9)) are

The substitution of Equations (19) and (20) into Equation (18) gives

By the final value theorem, , the infinite modulus can be found from Equation (21) as

Therefore, when the creep compliance is defined, the material parameters D0, Di, and E∞ are known, and the only unknown is the internal spring moduli, Ei. This set of unknown variables may be effectively defined by the collocation method within the Carson domain. The collocation points, si, in the Carson domain may be selected at 1/ti, where ti represents the properly selected collocation points in the time domain. By definition, the material relaxation time (ρi) should be the same as the retardation time (τi). However, different material times can be selected for better fitting purposes. With the properly selected collocation points and the material relaxation times, Equation (21), can be rearranged for the unknown variables Ei as

in which

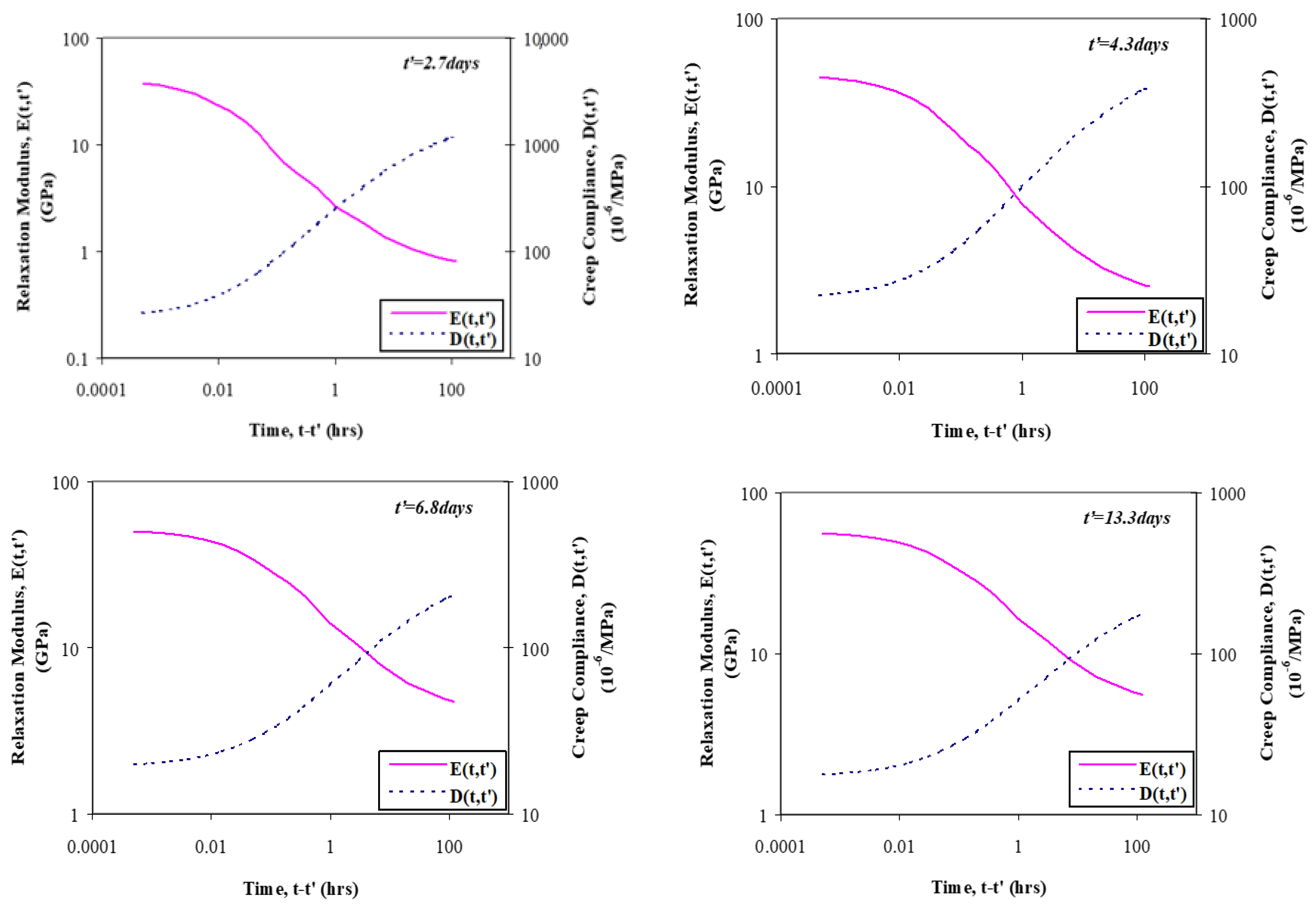

Solutions of Equations (22) and (23) will provide the material parameters constructing the Dirichlet series relaxation modulus function (Equation (8)). For converting the creep function of the test concrete, the material relaxation time (ρi) and the collocation points (tj) were selected at ρi = 0.8τi and tj = 0.5ρi, respectively. These values are selected to obtain a smooth curve fitting through the whole testing time span. Table 4 shows the converted internal parameters for the Dirichlet series relaxation function of the test concrete. Relaxation times are selected considering the test duration and goodness of curve fitting. Corresponding relaxation curves are plotted with the creep curves in Figure 8. As shown, symmetric relationships exist between the creep and relaxation responses with respect to the loading time (t − t′).

Table 4.

Material parameters converted for the Dirichlet series relaxation modulus function.

Figure 8.

Conversion of creep compliance to relaxation modulus.

5. Application

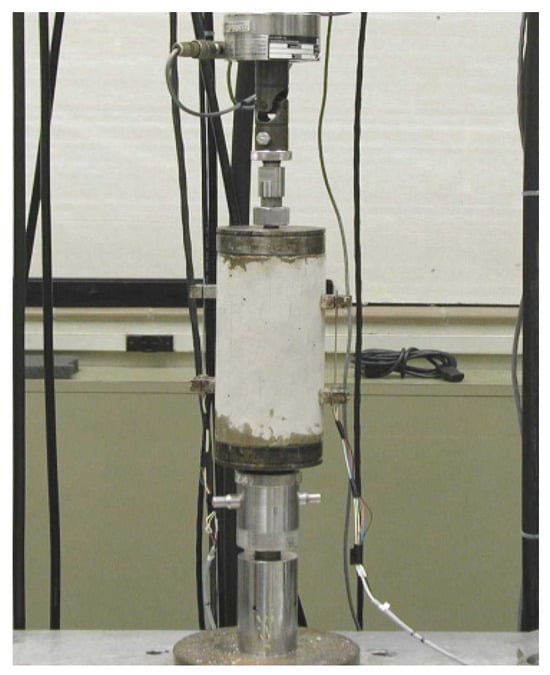

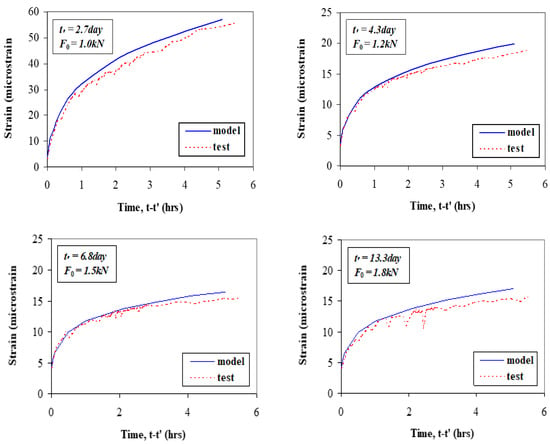

Using the estimated relaxation modulus, which is shown in Table 4, the creep tests conducted were simulated with the finite element program ABAQUS (Hibbitt, Karlsson & Sorensen, Inc., Providence, RI, USA). Continuum material properties were specified for a viscoelastic material option with the Prony series parameters in ABAQUS. And a constant Poisson’s ratio (ν = 0.17) was used for the analysis. Since the tests lasted less than 6 h, the aging effect during the test was ignored in this simulation, and the relaxation modulus determined for each age of testing was regarded as a constant during the test periods. The upper half (50 × 100 mm) of the creep test cylinders was modeled with bilinear axisymmetric solid elements (CAX8R element in ABAQUS). The stress level applied for each test was applied as a distributed pressure load on the surface of the top layer elements. The analysis was performed up to 5.1 h after the initial loading. The total analysis time was divided into 4 sub-steps at the time of 0.1, 0.5, 1.5, and 5.1 h with varying time steps (∆t) of 0.0001, 0.001, 0.005, and 0.01 h, respectively. Results of the finite element analysis are plotted with test results in Figure 9. As shown, the result of computational analysis agrees well with the result of tests at all ages of testing. In Figure 9, Fo denotes an applied test load at each age. Note again that, when the concrete experiences significant hardening during the analysis period, the material properties must be updated throughout the analysis in accordance with the relevant aging dependencies. This continuous update of material properties could be accomplished by an incremental analysis scheme [5].

Figure 9.

Computational simulation of the creep test data.

6. Conclusions

In this study, the early-age concrete is assumed to conform to linear viscoelastic behavior with a strong aging effect. Short-term uniaxial tensile creep tests were conducted for a minor concrete paving mixture with 25% fly ash at different ages in an effort to characterize early-age concrete as an aging viscoelastic material. Introduced in this paper is a method of determining viscoelastic properties of early-age concrete. Tensile creep tests have been conducted with concrete cylinders of four different ages between 2.7 and 13.3 days. Test results indicated that the effect of aging on the short-term creep responses of early-age concrete is pronounced especially for hardening concrete aged 7 days or younger. The time-dependent displacement of the youngest concrete tested at 2.7 days was 4 to 5 times greater than those of the other concrete specimens tested at 4.3, 6.8 and 13.3 days. The difference in the creep responses was found to not be so significant between the 6.8- and 13.3-day-old specimens. Based on the test results, creep compliance functions of the concrete were formulated in the Dirichlet series functions. The creep functions were then converted to a series of relaxation modulus functions, which is more useful for stress analysis. The results of computational analysis using these estimated viscoelastic properties agreed well with the results of the creep tests at all ages of testing. For future research, the tensile creep behavior of various mix proportions, such as fiber-reinforced concrete or supplementary cementitious materials, can be studied at early ages.

Author Contributions

S.L. conceived, designed, and performed the experiments and wrote the paper; S.Y. analyzed the data and summarized the literature reviews. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by 2021 Hongik University Research Fund.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Powers, T. The thermodynamics of volume change and creep. Mater. Struct. 1968, 1, 487–507. [Google Scholar] [CrossRef]

- Neville, A. Creep of Concrete: Plain, Reinforced, and Prestressed; Elsevier: New York, NY, USA, 1970. [Google Scholar]

- Wittmann, F.; Roelfstra, P. Total deformation of loaded drying concrete. Cem. Concr. Res. 1980, 10, 601–610. [Google Scholar] [CrossRef]

- Yang, S.; Lee, H. Coefficient of thermal expansion of RCA concretre made by equivalent mortar volume. Appl. Sci. 2021, 11, 8214. [Google Scholar] [CrossRef]

- Lim, S. Viscoelastic Age-Dependent Analysis of Restrained Shrinkage Stress Development in Early-Age Concrete. Ph.D. Dissertation, Department of Civil Engineering, Texas A&M University, College Station, TX, USA, 2002. [Google Scholar]

- Wei, Y.; Liang, S.; Huang, J. Concrete creep modeling: Application to slabs on ground. J. Eng. Mech. 2019, 145, 04019078. [Google Scholar] [CrossRef]

- Krstulovich, J.; Dam, T.; Smith, K.; Gawedzinski, M. Evaluation of potential long-term durability of joints cut with early-entry saws on rigid pavements. Tranp. Res. Rec. 2011, 2235, 103–112. [Google Scholar] [CrossRef]

- Mehta, P.; Monteiro, P. Concrete Structure, Properties, and Materials; Prentice Hall: Englewood Cliffs, NJ, USA, 1993. [Google Scholar]

- Mindess, S.; Young, J.; Darwin, D. Concrete, 2nd ed.; Prentice Hall: Hoboken, NJ, USA, 2003. [Google Scholar]

- Chen, J.; Zhou, L.; Zhu, Z.; Ma, L.; Wang, M.; Deng, Z. Crack propagation analysis and mechanical properties of basalt fibre reinforced cement composites with changing fibre surface characteristics. Constr. Build. Mater. 2023, 392, 131738. [Google Scholar] [CrossRef]

- Kanstard, G.; Bjøntegaard, Ø.; Sellevold, E. Tensile and compressive creep deformations of hardening concrete containing mineral additives. Mater. Struct. 2013, 46, 1167–1182. [Google Scholar]

- Wei, Y.; Liang, L.; Guo, W. Decoupling of autogenous shrinkage and tensile creep strain in high strength concrete at early ages. Exp. Mech. 2017, 57, 475–485. [Google Scholar] [CrossRef]

- Charpin, L.; Pape, Y.; Coustabeau, É.; Toppani, É.; Heinfling, G.; Bellego, C.; Masson, B.; Montalvo, L.; Courtois, A.; Sanahuja, J.; et al. A 12 year EDF study of concrete creep under uniaxial and biaxial loading. Cem. Concr. Res. 2018, 103, 140–159. [Google Scholar] [CrossRef]

- Huynh, T.; Hwang, C.; Limongan, A. The long-term creep and shrinkage behaviors of green concrete designed for bridge girder using a densified mixture design algorithm. Cem. Concr. Compos. 2018, 87, 79–88. [Google Scholar] [CrossRef]

- Roy, R.; Maou, F.; Torrenti, J. Long term basic creep behavior of high performance concrete: Data and modelling. Mater. Struct. 2017, 50, 85. [Google Scholar] [CrossRef]

- Hilaire, A.; Benboudjema, F.; Darquennes, A.; Berthaud, Y.; Nahas, G. Modeling basic creep in concrete at early-age under compressive and tensile loading. Nucl. Eng. Des. 2014, 269, 222–230. [Google Scholar] [CrossRef]

- Klausen, A.; Kanstad, T.; Bjøntegaard, Ø.; Sellevold, E. Comparison of tensile and compressive creep of fly ash concretes in the hardening phase. Cem. Concr. Res. 2017, 95, 188–194. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI Manual of Concrete Practice 209R-92. Prediction of Creep, Shrinkage, and Temperature Effects in Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 1997; pp. 1–47. [Google Scholar]

- Bazant, Z.; Chern, J. Triple power law for concrete creep. J. Eng. Mech. 1985, 111, 63–84. [Google Scholar] [CrossRef][Green Version]

- Bazant, Z.; Prasannan, S. Solidification theory for concrete creep: I. Formulation. J. Eng. Mech. 1989, 115, 1691–1703. [Google Scholar] [CrossRef]

- Bazant, Z.; Prasannan, S. Solidification theory for concrete creep: II. Verification and application. J. Eng. Mech. 1989, 115, 1704–1725. [Google Scholar] [CrossRef]

- Bazant, Z.; Havlásek, P.; Jirásek, M. Microprestress-solidification theory: Modeling of size effect on drying creep. In Computational Modelling of Concrete Structures; Taylor & Francis Group: London, UK, 2014; pp. 749–758. [Google Scholar]

- Muller, H.; Hilsdorf, H. CEB 1990, “Evaluation of the Time Dependent Behavior of Concrete”, Bulletin d’Information No.199; Comite European du Be-ton/Federation Internationale de la Precontrainte: Lausanne, Switzerland, 1991. [Google Scholar]

- Westman, G. Basic creep and relaxation of young concrete. In Thermal Cracking in Concrete at Early Ages; E&FN Spon: London, UK, 1994; pp. 87–94. [Google Scholar]

- Ostergaard, L.; Lange, D.; Altoubat, S.; Stang, H. Tensile basic creep of early-age concrete under constant load. Cem. Concr. Res. 2001, 31, 1895–1899. [Google Scholar] [CrossRef]

- Yeon, J.; Choi, S.; Ha, S.; Won, M. Effects of creep and built-in curling on stress development of Portland cement concrete pavement under environmental loadings. J. Transp. Eng. 2012, 139, 147–155. [Google Scholar] [CrossRef]

- Lim, J.; Kim, S.; Jeong, J. Testing and analysis of viscoelastic characteristics of solidifying concrete pavement slabs. KSCE J. Civ. Eng. 2014, 18, 1063–1071. [Google Scholar] [CrossRef]

- Hu, C.; Sun, Z.; Wang, L. Early-age creep effects of cement concrete pavement. Eng. Mech. 2022, 39, 123–137. [Google Scholar]

- Bazant, Z. Mathematical models for creep and shrinkage of concrete. In Creep and Shrinkage in Concrete Structures; Bazant, Z., Wittmann, F., Eds.; John Wiley and Sons: New York, NY, USA, 1982; pp. 163–256. [Google Scholar]

- Christensen, R. Theory of Viscoelasticity: An Introduction, 2nd ed.; Academic Press: New York, NY, USA, 1982. [Google Scholar]

- Schapery, R. Approximate methods of transform inversion for viscoelastic stress analysis. In Proceedings of the 4th US National Congress on Applied Mechanics, Berkeley, CA, USA, 18–21 June 1962; ASME: New York, NY, USA, 1962; Volume 2, pp. 1075–1085. [Google Scholar]

- Bazant, Z.; Wu, S. Dirichlet series creep function for aging concrete. J. Eng. Mech. Div. 1973, 99, 367–387. [Google Scholar] [CrossRef]

- Bazant, Z.; Wu, S. Rate-type creep law of aging concrete based on Maxwell chain. Mater. Struct. 1974, 7, 45–60. [Google Scholar]

- Illston, J. The creep of concrete under uniaxial tension. Mag. Concr. Res. 1965, 17, 77–84. [Google Scholar] [CrossRef]

- Hauggaard, A.; Damkilde, L.; Hansen, P. Transitional thermal creep of early age concrete. J. Eng. Mech. 1999, 125, 458–465. [Google Scholar] [CrossRef]

- Bissonnette, M.; Boily, D.; Bastien, J.; Fafard, M. Tensile creep of concrete repair materials: Recent experimental findings towards optimization. In Proceedings of the Creep, Shrinkage and Durability Mechanics of Concrete and Other Quasi-Brittle Materials, Proceedings of the 6th International Conference, RILEM, Cambridge, MA, USA, 20–22 August 2001; pp. 599–604. [Google Scholar]

- Picket, G. Shrinkage stresses in concrete. J. Amer. Concr. Inst. Proc. 1946, 42, 165–204. [Google Scholar]

- Wittmann, F. Creep and Shrinkage Mechanisms. In Creep and Shrinkage in Concrete Structures; Bazant, Z.P., Wittmann, F.H., Eds.; John Wiley and Sons: New York, NY, USA, 1982; pp. 129–161. [Google Scholar]

- Bazant, Z.; Panula, L. Practical prediction of time-dependent deformations of concrete; Part I: Shrinkage, Part II: Basic creep. Mater. Struct. 1978, 11, 307–328. [Google Scholar]

- Bazant, Z.; Kim, J. Improved prediction model for time-dependent deformations of concrete: Part 2-Basic creep. Mater. Struct. 1991, 24, 409–421. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).