Structural Performance of Reinforced Concrete Beams Retrofitted Using Modularized Steel Plates in Precast Concrete with Bolted Connections

Abstract

1. Introduction

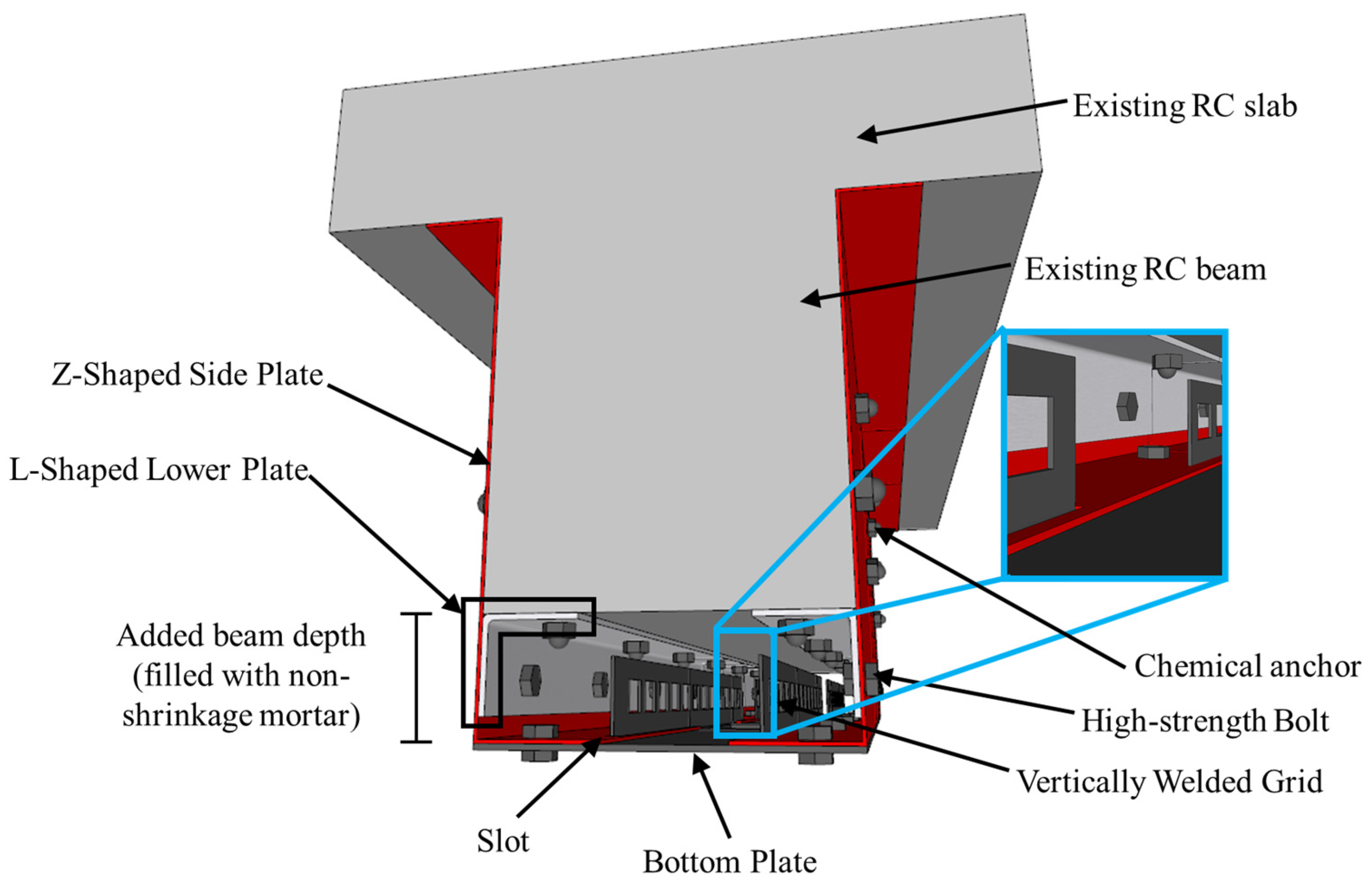

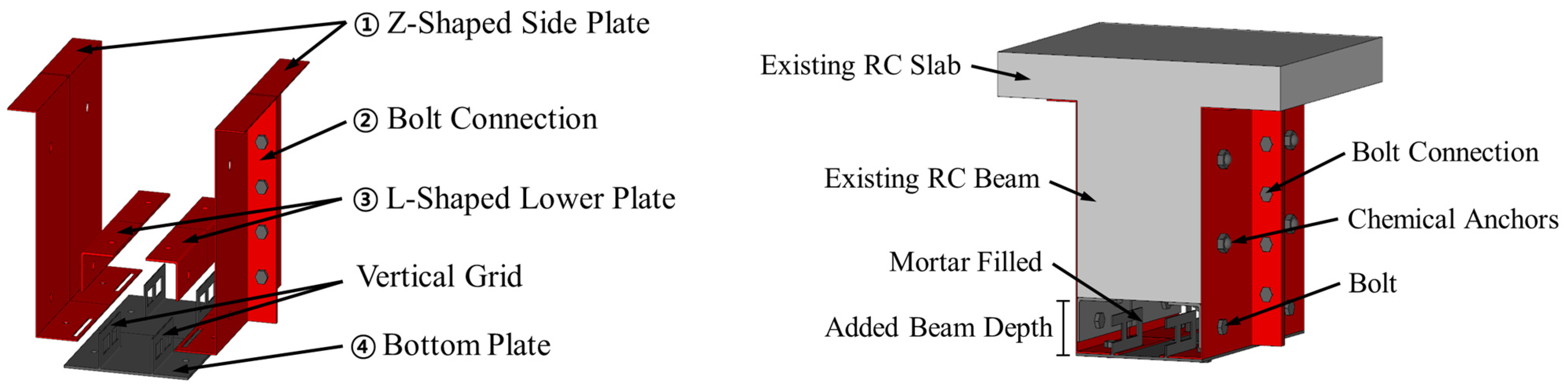

2. Concept of the Modularized Steel Plate with Bolt Connections

- (1)

- The surface preparation of the concrete, for example, removing surface contaminants, is conducted, and later, the L-shaped lower plate, with its protrusion, is affixed to the RC beam underside utilizing chemical anchors;

- (2)

- The L-shaped lower plate and the Z-shaped side plate are interconnected using high-strength bolts. The bottom plate is slotted into the designated groove at the Z-shaped side plate base. After aligning the bottom plate with the Z-shaped side plate, they are secured using high-strength bolts;

- (3)

- The Z-shaped side plate is anchored to the concrete beam side via chemical anchors;

- (4)

- The void between the L-shaped lower plate and the bottom plate is filled with non-shrinkage mortar, facilitating the formation of the added beam;

- (5)

- For instances incorporating joint details between modularized steel plates, high-strength bolts are employed for the connection.

3. Experimental Program

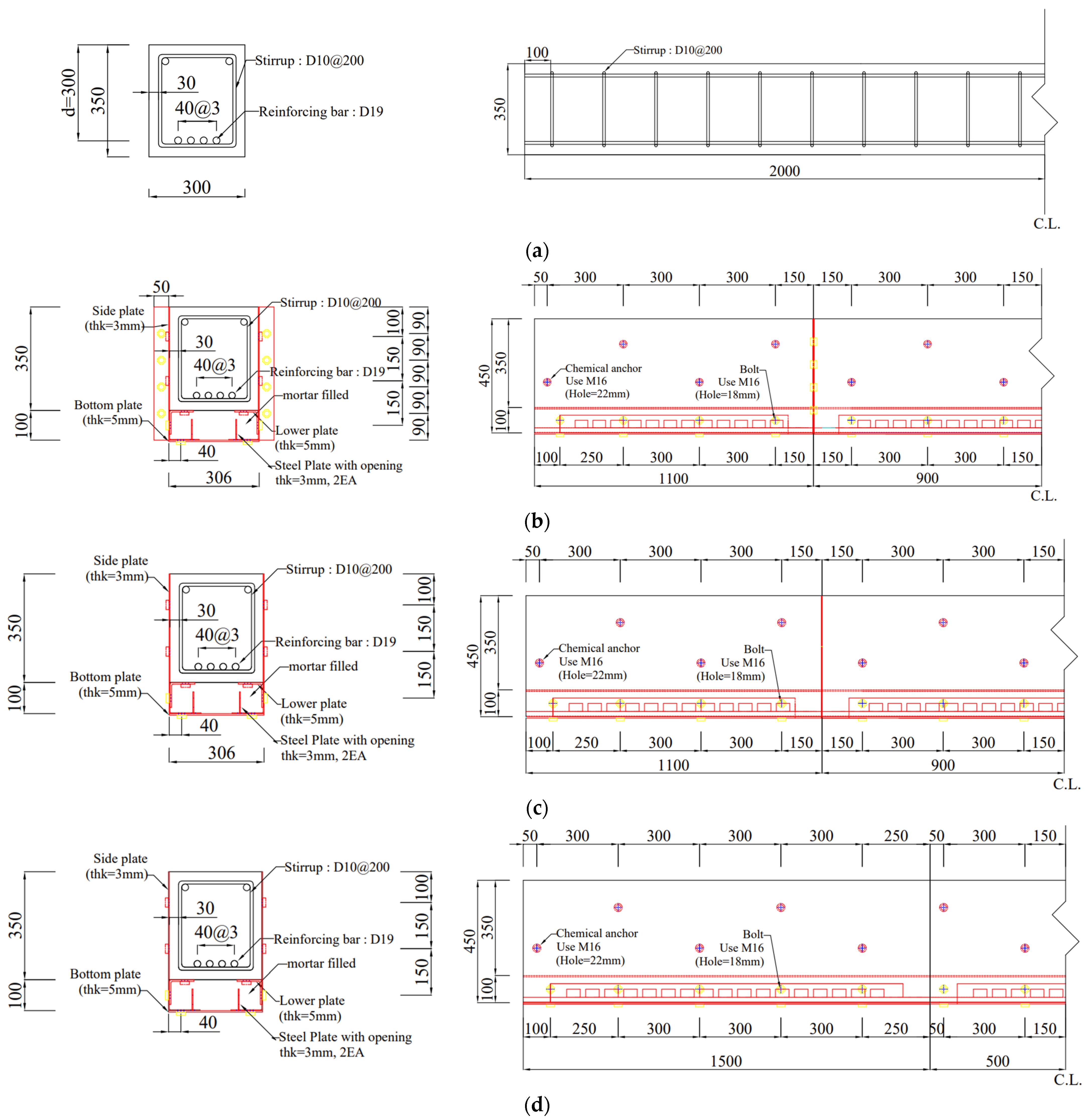

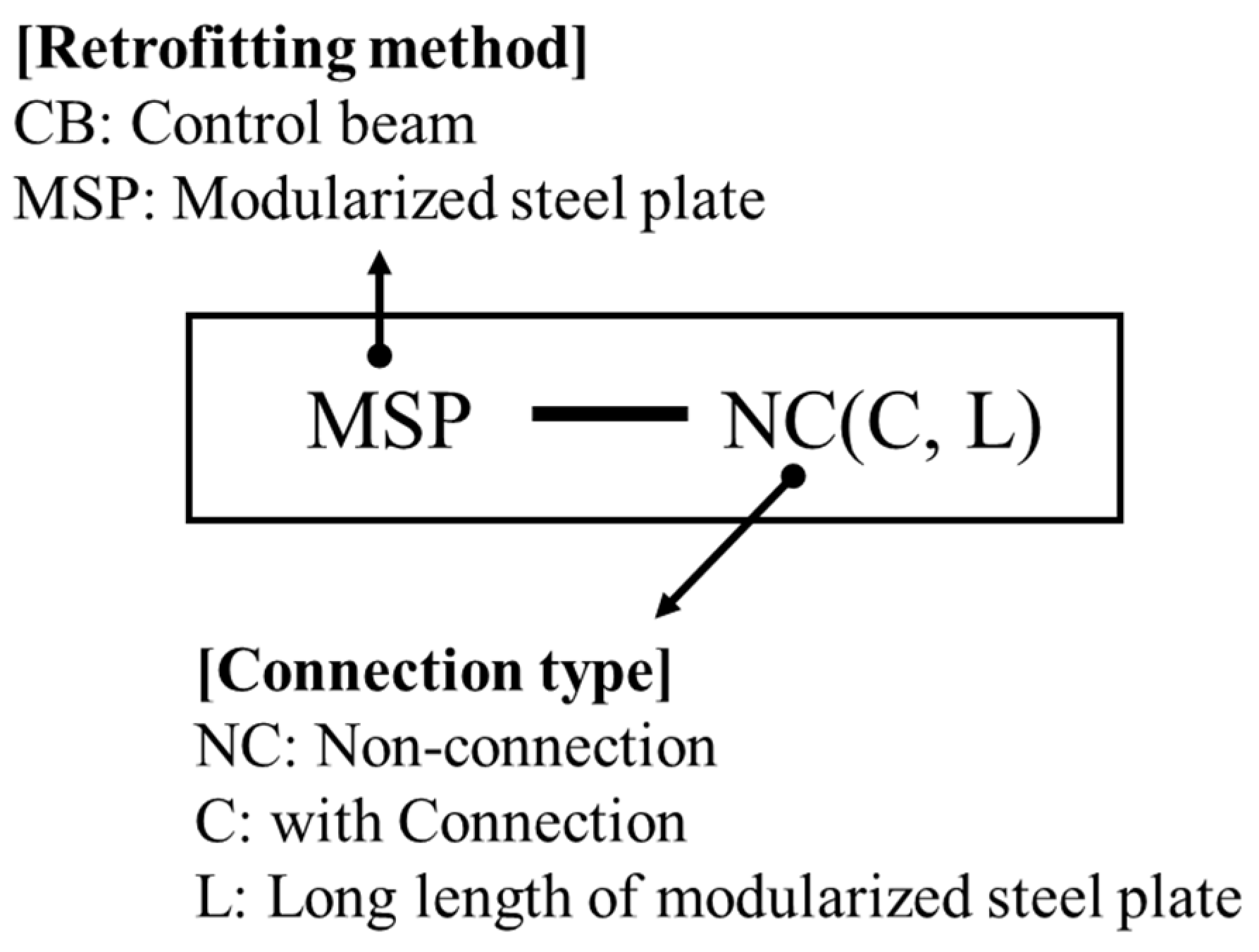

3.1. Specimen Details

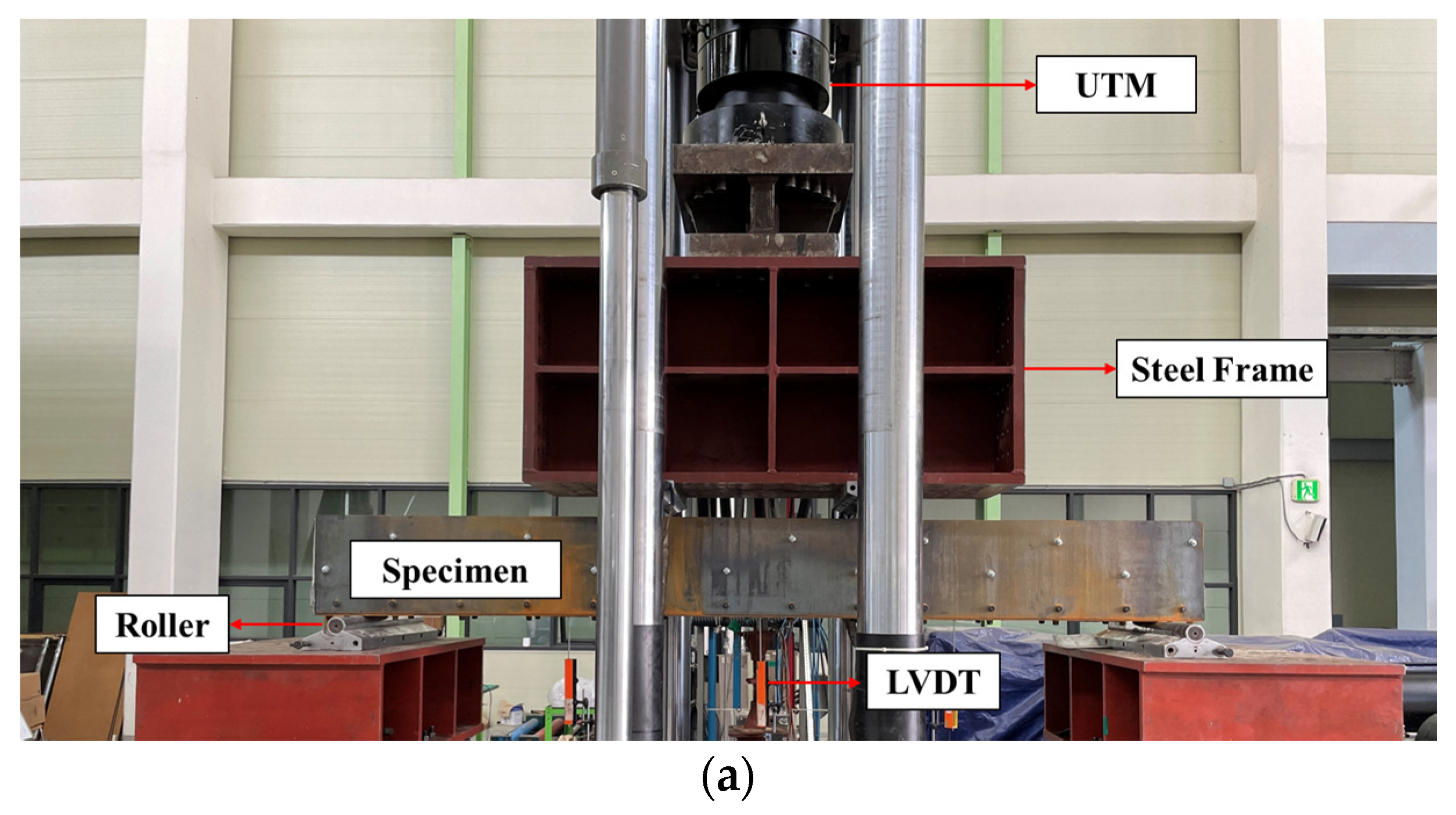

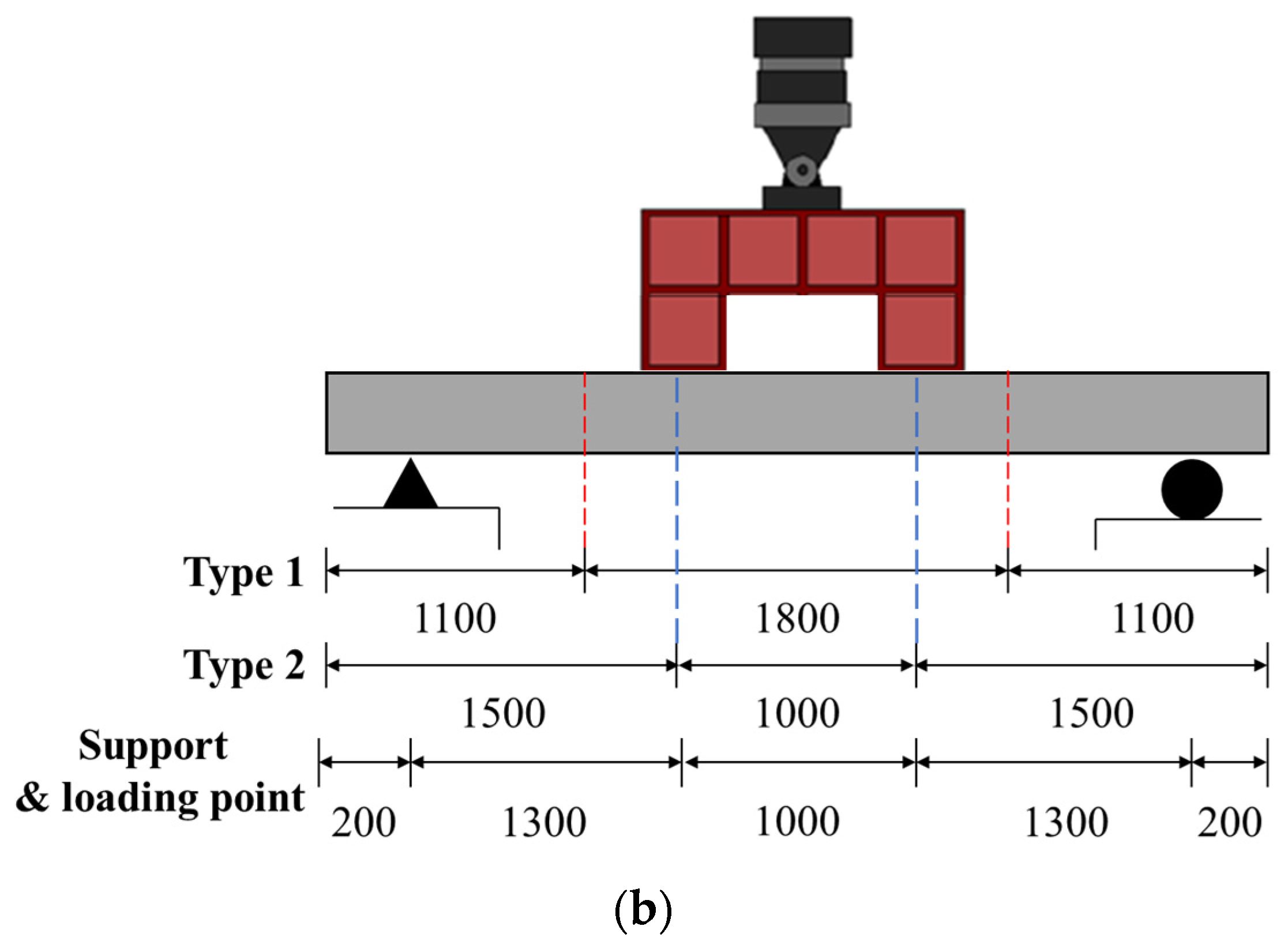

3.2. Test Setup

4. Experimental Results and Analysis

4.1. Crack Propagation and Failure Modes

4.2. Load–Displacement Relationships and Initial Stiffness

4.3. Ductility Capacity

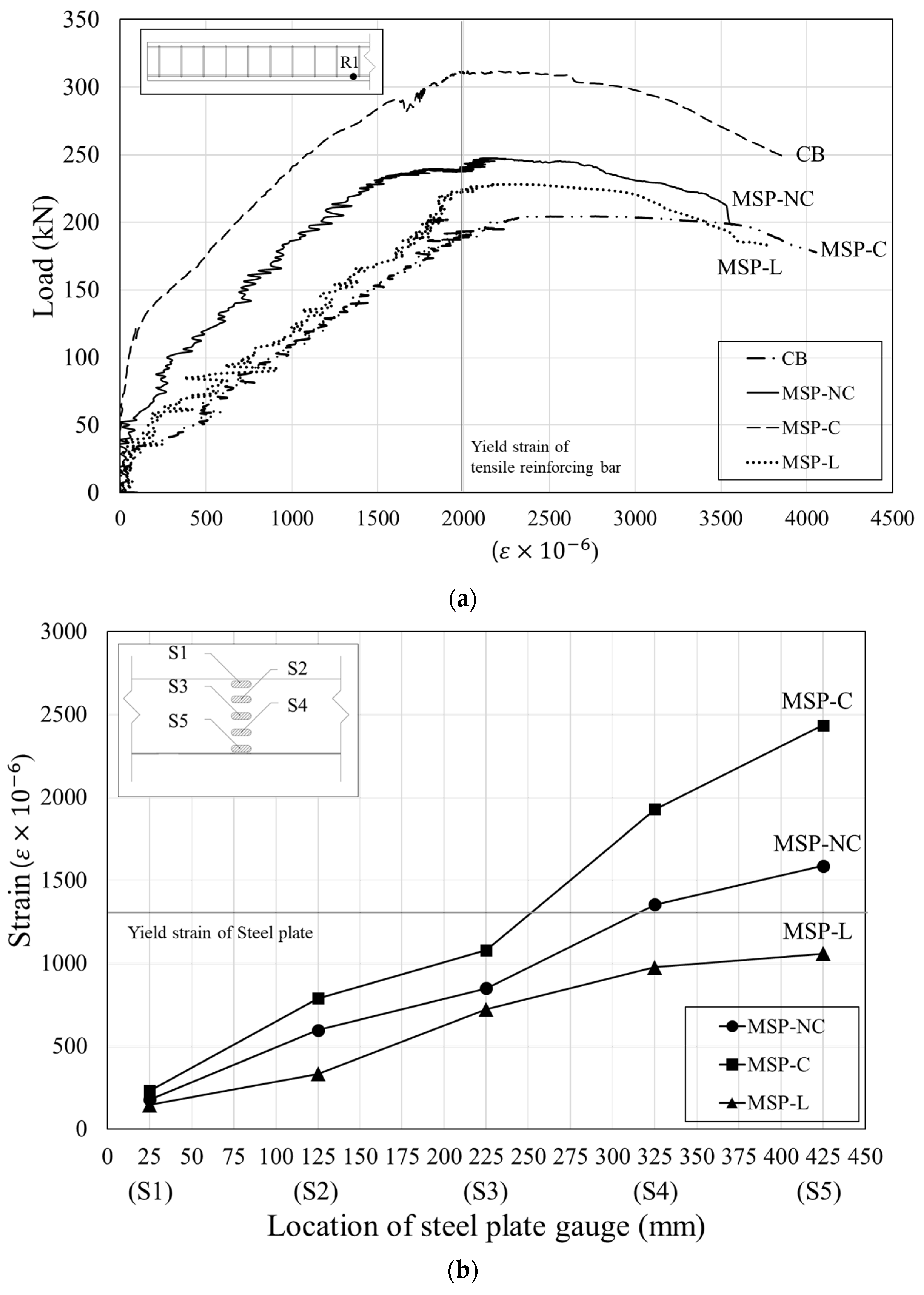

4.4. Load-Strain Behavior

5. Conclusions

- (1)

- The modularized steel plate retrofitting technique was effective in influencing crack propagation in retrofitted RC beams. Specimens retrofitted with this method displayed more flexural cracks in tension zones and exhibited narrower shear crack widths compared to non-retrofitted beams. A key observation was deviation of the flexural behavior due to insufficient connections between the steel plates. This highlighted the significance of robust interconnections to ensure cohesive behavior and to prevent debonding. Furthermore, the interplay between module dimensions and their corresponding loading points became apparent. Concentrated loading at the end of a module increased susceptibility to forces that could lead to debonding. This emphasizes the necessity of aligning module dimensions with anticipated loads and the mechanism of load transfer;

- (2)

- Retrofitting using the modularized steel plate method significantly enhances the maximum load and stiffness of existing RC beams. Specimens retrofitted with these plates demonstrated maximum load 1.6 times that of non-retrofitted beams. Additionally, interconnected steel plates increased the load capacity by about 25% compared to isolated plates. Both the load application point and module size were crucial in determining modularized steel plate performance;

- (3)

- The use of modularized steel plates for retrofitting RC beams resulted in a marked increase in ductility, with certain specimens showing almost double the ductility. Specimens with interconnected plates had a ductility index approximately 1.6 times that of those without. Tensile forces were shared between the steel plate and the original RC beam, indicating that the modularized steel plate effectively handles tensile forces. Additionally, the strain levels within these plates increased as they neared the beam’s tension zone, emphasizing the importance of effective bonding;

- (4)

- The evident differences of load, stiffness, and ductility between specimens with interconnected steel plates and those without highlight the necessity for shear and flexural strength formulas tailored to the connection method. While this research focused on a limited set of specimens to study the effects of steel plate interconnections, future research should include a broader specimen range for a more comprehensive assessment of flexural and shear performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, J.; Shin, H. Seismic loss assessment of a structure retrofitted with slit-friction hybrid dampers. Eng. Struct. 2017, 130, 336–350. [Google Scholar] [CrossRef]

- Basha, A.; Fayed, S.; Elsamak, G. Flexural behavior of cracked RC beams retrofitted with strain hardening cementitious composites. KSCE J. Civ. Eng. 2019, 23, 2644–2656. [Google Scholar] [CrossRef]

- Hong, S.G.; Lim, W.Y. Strengthening of shear-dominant reinforced concrete beams with ultra-high-performance concrete jacketing. Constr. Build. Mater. 2023, 365, 130043. [Google Scholar] [CrossRef]

- Sener, K.C.; Varma, A.H.; Seo, J. Experimental and numerical investigation of the shear behavior of steel-plate composite (SC) beams without shear reinforcement. Eng. Struct. 2016, 127, 495–509. [Google Scholar] [CrossRef]

- Zou, G.P.; Xia, P.X.; Shen, X.H.; Wang, P. Investigation on the failure mechanism of steel-concrete steel composite beam. Steel Compos. Struct. 2016, 20, 1183–1191. [Google Scholar] [CrossRef]

- Rasheed, H.A.; Abdalla, J.; Hawileh, R.; Al-Tamimi, A.K. Flexural behavior of reinforced concrete beams strengthened with externally bonded Aluminum Alloy plates. Eng. Struct. 2017, 147, 473–485. [Google Scholar] [CrossRef]

- Wang, J.J.; Tao, M.X.; Zhou, M.; Nie, X. Force transfer mechanism in RC beams strengthened in shear by means of steel plated concrete. Eng. Struct. 2018, 171, 56–71. [Google Scholar] [CrossRef]

- Shen, D.; Jiao, Y.; Li, M.; Liu, C.; Wang, W. Behavior of a 60-year-old reinforced concrete box beam strengthened with Basalt fiber-reinforced polymers using steel plate anchorage. J. Adv. Concr. Technol. 2021, 19, 1100–1119. [Google Scholar] [CrossRef]

- Luder, D.; Ariely, S.; Yalin, M. Stress corrosion cracking and brittle failure in a fiber-reinforced plastic (FRP) insulator from a 400 kV transmission line in humid environment. Eng. Fail. Anal. 2019, 95, 206–213. [Google Scholar] [CrossRef]

- Baena, M.; Jahani, Y.; Torres, L.; Barris, C.; Perera, R. Flexural performance and end debonding prediction of NSM Carbon FRP-strengthened reinforced concrete beams under different service temperatures. Polymers 2023, 15, 851. [Google Scholar] [CrossRef]

- Tiwary, A.K.; Singh, S.; Kumar, R.; Sharma, K.; Chohan, J.S.; Sharma, S.; Singh, J.; Kumar, J.; Deifalla, A.F. Comparative Study on the Behavior of Reinforced Concrete Beam Retrofitted with CFRP Strengthening Techniques. Polymers 2022, 14, 4024. [Google Scholar] [CrossRef]

- Eslami, A.; Moghavem, A.; Shayegh, H.R.; Ronagh, H.R. Effect of FRP stitching anchors on ductile performance of shear-deficient RC beams retrofitted using FRP U-wraps. Structures 2020, 23, 407–414. [Google Scholar] [CrossRef]

- Yang, X.; Yuan, H.; Li, C.; Wu, L.; Wang, P.; Liu, Y.; Jiang, B.; Wang, Q.; Zhang, X.; Liu, F.; et al. Experimental studies on behavior of failed CRB750 steel bars reinforced concrete beams retrofitted with steel plate. Eng. Struct. 2021, 243, 112539. [Google Scholar] [CrossRef]

- Rageh, B.O.; El-Mandouh, M.A.; Elmasry, A.H.; Attia, M.M. Flexural behavior of RC beams strengthened with GFRP laminate and retrofitting with novelty of adhesive material. Buildings 2022, 12, 1444. [Google Scholar] [CrossRef]

- Hanifehzadeh, M.; Aryan, H.; Gencturk, B.; Akyniyazov, D. Structural response of steel jacket-uhpc retrofitted reinforced concrete columns under blast loading. Materials 2021, 14, 1521. [Google Scholar] [CrossRef] [PubMed]

- Shang, X.Y.; Yu, J.T.; Li, L.Z.; Lu, Z.D. Strengthening of RC structures by using engineered cementitious composites: A review. Sustainability 2019, 11, 3384. [Google Scholar] [CrossRef]

- Ramezani, M.; Ozbulut, O.E.; Sherif, M.M. Mechanical characterization of high-strength and ultra-high-performance engineered cementitious composites reinforced with polyvinyl alcohol and polyethylene fibers subjected to monotonic and cyclic loading. Cem. Concr. Compos. 2024, 148, 105472. [Google Scholar] [CrossRef]

- Huang, Y.; Lee, M.G.; Kan, Y.C.; Wang, W.C.; Wang, Y.C.; Pan, W.B. Reinforced concrete beams retrofitted with UHPC or CFRP. Case Stud. Constr. Mater. 2022, 17, e01507. [Google Scholar] [CrossRef]

- Ramezani, M.; Dehghani, A.; Sherif, M.M. Carbon nanotube reinforced cementitious composites: A comprehensive review. Constr. Build. Mater. 2022, 315, 125100. [Google Scholar] [CrossRef]

- Barham, W.S.; Irshidat, M.R.; Awawdeh, A. Repair of Heat-Damaged RC Beams Using Micro-concrete Modified with Carbon Nanotubes. KSCE J. Civ. Eng. 2021, 25, 2534–2543. [Google Scholar] [CrossRef]

- Teguh, M. Structural behaviour of precast reinforced concrete frames on a non-engineered building subjected to lateral loads. Int. J. Eng. Technol. Innov. 2016, 6, 152–164. [Google Scholar]

- Hu, T.; Zhang, H.; Zhou, J. Prediction of the debonding failure of beams strengthened with FRP through machine learning models. Buildings 2023, 13, 608. [Google Scholar] [CrossRef]

- Alam, M.A.; Onik, S.A.; Mustapha, K.N.B. Crack based bond strength model of externally bonded steel plate and CFRP laminate to predict debonding failure of shear strengthened RC beams. J. Build. Eng. 2020, 27, 100943. [Google Scholar] [CrossRef]

- Kim, M.S.; Lee, Y.H. Flexural behavior of reinforced concrete beams retrofitted with modularized steel plates. Appl. Sci. 2021, 11, 2348. [Google Scholar] [CrossRef]

- Kim, M.S.; Lee, Y.H. Shear behavior of reinforced concrete beam retrofitted with modularized steel plates. Materials 2023, 16, 3419. [Google Scholar] [CrossRef]

| No. | Name | Retrofitted Method | Bolted Connection Detail | Length of Modularized Steel Plate (m) | ||

|---|---|---|---|---|---|---|

| Left | Middle | Right | ||||

| 1 | CB | None | None | None | ||

| 2 | MSP-NC | Modularized steel plate | Absence | 1.1 | 1.8 | 1.1 |

| 3 | MSP-C | Presence | 1.1 | 1.8 | 1.1 | |

| 4 | MSP-L | Absence | 1.5 | 1 | 1.5 | |

| No. | Name | (kN) | (mm) | (kN/mm) |

|---|---|---|---|---|

| 1 | CB | 204.40 | 40.39 | 8.87 |

| 2 | MSP-NC | 247.65 | 82.33 | 9.74 |

| 3 | MSP-C | 311.95 | 116.27 | 11.86 |

| 4 | MSP-L | 228.24 | 78.65 | 9.37 |

| No. | Name | (kN) | (kN) | (mm) | (mm) | |

|---|---|---|---|---|---|---|

| 1 | CB | 199.40 | 204.40 | 26.87 | 40.39 | 1.50 |

| 2 | MSP-NC | 232.75 | 247.65 | 27.70 | 82.33 | 2.97 |

| 3 | MSP-C | 290.45 | 311.95 | 25.38 | 116.27 | 4.58 |

| 4 | MSP-L | 201.83 | 228.24 | 27.47 | 78.65 | 2.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ro, K.M.; Kim, M.S.; Lee, Y.H. Structural Performance of Reinforced Concrete Beams Retrofitted Using Modularized Steel Plates in Precast Concrete with Bolted Connections. Appl. Sci. 2024, 14, 3137. https://doi.org/10.3390/app14083137

Ro KM, Kim MS, Lee YH. Structural Performance of Reinforced Concrete Beams Retrofitted Using Modularized Steel Plates in Precast Concrete with Bolted Connections. Applied Sciences. 2024; 14(8):3137. https://doi.org/10.3390/app14083137

Chicago/Turabian StyleRo, Kyong Min, Min Sook Kim, and Young Hak Lee. 2024. "Structural Performance of Reinforced Concrete Beams Retrofitted Using Modularized Steel Plates in Precast Concrete with Bolted Connections" Applied Sciences 14, no. 8: 3137. https://doi.org/10.3390/app14083137

APA StyleRo, K. M., Kim, M. S., & Lee, Y. H. (2024). Structural Performance of Reinforced Concrete Beams Retrofitted Using Modularized Steel Plates in Precast Concrete with Bolted Connections. Applied Sciences, 14(8), 3137. https://doi.org/10.3390/app14083137