1. Introduction

Additive manufacturing (AM) is revolutionizing production technologies by enabling the creation of components layer by layer without the limitations of traditional manufacturing methods. This technology also allows for the use of a variety of materials, making it highly attractive to industries such as the automotive, aircraft, and medical industries [

1,

2]. Material extrusion (ME) is a type of 3D printing process that involves selectively depositing material through a heated nozzle [

3] and is one of seven categories of additive printing processes defined by the ASTM/ISO 52900 standard [

3]. Extrusion-based technology can process a wide range of materials [

4], making it suitable also for constructing complex parts [

5,

6]. Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is a 3D printing process that uses a thermoplastic filament to create components layer by layer. The path of the nozzle is defined by the file codes generated during the design stage. The most used thermoplastic material for FDM is polylactic acid (PLA), made from plant-based sources.

To ensure that FFF-made components meet their functional requirements, critical process factors must be examined to determine their impact on mechanical qualities. Several studies have looked at the influence of the key process parameters. A Taguchi orthogonal array was used to define the level of each factor, and the experimental data were analyzed using analysis of variance (ANOVA) to quantify the main effects of the parameters on the responses [

6,

7,

8]. In a study using Taguchi’s L9, the effects of the printing speed, layer height, and extrusion temperature were analyzed, and the results showed that higher extrusion temperatures improved interlayer adhesion in the printed object. On the other hand, the use of printing speeds that are too high leads to a progressive reduction in the tensile strength because the deposition of the layers is not uniform. The optimal process parameters for this work are a layer height of 0.15 mm, a printing speed of 48 mm/s, and an extrusion temperature of 220 °C [

9]. By using lower melting temperatures, at which printing speeds do not affect the geometry of the part, the necessary integrity of the structure is maintained. For the maximum tensile strength, higher extruding temperatures provide better material bonding. Lower printing speeds combined with the printing temperature leads to higher strain and stiffness [

10]. Moreover, higher cooling speeds were found to improve the geometric accuracy but decrease the mechanical strength [

11]. A detailed analysis of the specimen’s internal structure was conducted to study the effects of infill type, percentage of part fill, number of perimeters, and shell thickness. The performance is influenced by the chosen infill pattern and the number of contours, with optimal values being a layer height of 0.1 mm, six perimeters, and a gyroid infill geometry [

12]. In contrast, ranked first in influence is the infill percentage, followed by the contour thickness and then the layer height. In Enemuoh et al.’s study, the most influential parameter for optimum printing was found to be the infill percentage, followed by the contour thickness and layer height. Specifically, an infill density of 100%, a shell thickness of 1.2 mm, a layer thickness of 0.2 mm, a cubic infill pattern, and a print speed of 40 mm/s were identified as optimal printing parameters [

13]. The results on layer thickness are mixed. Caminero et al. observed that on-edge and flat orientations result in the highest mechanical properties with intra-layer failure. The study found that the tensile strength was highest at a lower layer thickness, which also had a higher ductility. However, the ductility decreased as the layer thickness increased [

14]. Another study showed that increasing the layer height from 0.1 to 0.2 mm resulted in improving the tensile strength. Furthermore, the triangle pattern provides the optimal mechanical strength while minimizing material consumption [

15,

16].

Machine learning (ML) is a subfield of artificial intelligence (AI) that uses algorithms to analyze data, recognize patterns, and make decisions without explicit instructions. It is based on objective analysis and logical structure. Within the field of ML, artificial neural networks (ANNs) are modeled to simulate the working flow of the human brain and consist of interconnected nodes that mimic neurons. ANNs excel at learning intricate patterns and correlations in data, making them ideal for applications such as image identification, natural language processing, and predictive analytics. The development of deep neural networks has further improved the capability in processing various and complex datasets [

17]. ANNs have played a crucial role in image recognition tasks, including object detection, facial recognition, and image classification. This has resulted in significant progress in areas such as self-driving cars, medical imaging, and security systems [

18]. Deep learning (DL) differs from traditional ANNs in its ability to automatically learn complex data representations through the use of deep neural networks with many hidden layers. Compared with traditional ML, DL can learn complicated representations of datasets automatically, without the need to manually extract relevant features. It enables more efficient and accurate learning from raw data, automatically uncovering complex patterns and relationships that may not be apparent upon initial analysis. Additionally, it can handle large amounts of data and adapt dynamically to changes, making it particularly suitable for applications with high data complexity and dimensionality [

19]. On the other hand, Deep Belief Networks (DBNs) are hierarchically structured ANNs that learn complex representations of input data using probabilistic methods. They have been used successfully in areas such as computer vision, natural language recognition, bioinformatics, and financial data analysis. Recent developments include hybrid architectures that combine DBNs with other deep learning techniques, such as Convolutional Neural Networks (CNNs) for image processing and Recurrent Neural Networks (RNNs) for sequential data processing. This combination improves model performance and increases flexibility when learning data representations. DBNs are increasingly being used on cloud platforms, allowing for more efficient data management and faster neural network training [

19]. One of its applications is in smart cities to improve security and efficiency. It enables anomaly detection, data encryption, intrusion detection, behavior analysis, and secure communication with significantly improved overall security by providing effective tools for data protection and cyber threat prevention [

20]. Moreover, to enhance the planning and administration of urban tunnel building projects, DBNs are utilized to predict the performance of cantilever roadheaders in challenging terrain. This enables the precise and timely control of factors that affect roadheader performance. The use of DBNs allows one to address issues related to the complexity of geological data and the nonlinear correlations between excavation factors, resulting in more accurate projections that are adaptive to changing ground conditions [

21]. High-resolution image processing is crucial in various industries, including medical analysis, satellite image processing, and computer graphics. Rehman et al. [

22] proposed a cascade approach, where a CNN extracts DNN-based features from input image patches. These features are then fed into the DBN model for high-resolution image quality prediction. This study aims to improve the objective assessment of super-resolution image quality by providing an advanced, accurate approach without reference images. Bayesian neural networks (BNNs) are a type of neural network that treat model weights as random variables with probability distributions, rather than fixed parameters. This approach captures the uncertainty associated with the model weights and input data, resulting in more informative and robust predictions. Bayesian approaches enable the estimation of the posterior distribution of model parameters from observed data. This estimation can be used for model selection, prediction, and uncertainty quantification. Additionally, Bayesian approaches can improve the generalization performance of ANNs by reducing overfitting and providing a principled method for selecting the appropriate model complexity. Bayesian methods have the advantage of incorporating prior knowledge into the model, which is useful when training data are limited. They are also robust to outliers and less sensitive to overfitting than non-Bayesian methods due to constraints on model complexity [

23,

24]. The transition from the traditional Bayesian approach to Bayesian regularization (BR) is a significant advancement in the field of neural networks and machine learning. This approach improves network performance, making it more robust and better able to generalize to new data, without the full complexity of traditional Bayesian methods [

25,

26]. Bayesian analysis is a suitable approach for addressing uncertainties in civil engineering problems such as materials, excitation, modeling, and emission for damage prediction [

24]. Moreover, the approach has been utilized to address various challenges in the medical field, including predicting disease progression, identifying diagnostic biomarkers, and customizing treatments to individual patient characteristics [

27].

Nowadays, digital technologies and solutions for calibration, prediction, learning, and self-optimization have been implemented in manufacturing to eliminate inefficiencies [

28]. The combination of AM and ML techniques offers the ability to identify relationships in large manufacturing datasets, providing the possibility of obtaining components with improved performance [

29]. Charalampous et al. [

30] investigated tensile strength optimization by adopting an ML regression algorithm. The layer thickness, printing speed, and printing temperature were the process parameters considered. The results showed that a medium printing speed, temperature, and low layer thickness improved the tensile strength. The layer height, infill percentage, printing temperature, and printing speed were used as input to train an ML model for simultaneously predicting the minimum weight, minimum printing time, and maximum tensile strength. Although no unique optimal solution exists, the Pareto front provides an appropriate combination of input parameters to obtain the best trade-off between the outputs to meet the user’s requirements [

31]. The same printing processes were investigated by Jatti et al. using an ML nonlinear regression algorithm only for tensile strength prediction. The results were able to predict the tensile strength with a percentage error of less than 2.977 [

32]. Models for predicting the ultimate tensile strength were developed using an ANN. The regression curve had a correlation coefficient of 0.999782. The input combinations between the print speed, infill density, build orientation, temperature, and layer thickness were evaluated based on the Taguchi orthogonal array. Having considered for each input three control levels, 33 experiments were performed for the training and evaluation of a neural network. The error percentage value for the neural network is 1.10. The validation parameter indicates an error of 1.57 when comparing the actual and predicted outcomes using the ML method [

33]. In the majority of the current study’s results, the best combination of process parameters was discovered through independent experimental trials, with the experimental outcome that produced a better solution being classified as the optimum solution [

34]. However, the optimal process parameter combination may differ from the experimental combinations, and it must fall within the permitted range of process parameters [

35]. Additionally, FFF involves a large number of process parameters that must be carefully controlled to ensure the proper formation of components. Therefore, it is essential to control the parameters that have an impact on mechanical performance [

36].

This work aims to explore the complex relationship between process parameters and mechanical performance in FFF through the integration of ANNs. This study employs a fractional Taguchi design to systematically vary seven key process parameters and generate a comprehensive dataset for model training. The primary objective is to develop an accurate ANN model capable of predicting tensile strength in FFF-produced parts. The gained knowledge should contribute to the optimization and quality assurance of 3D-printed parts. This investigation is structured as follows:

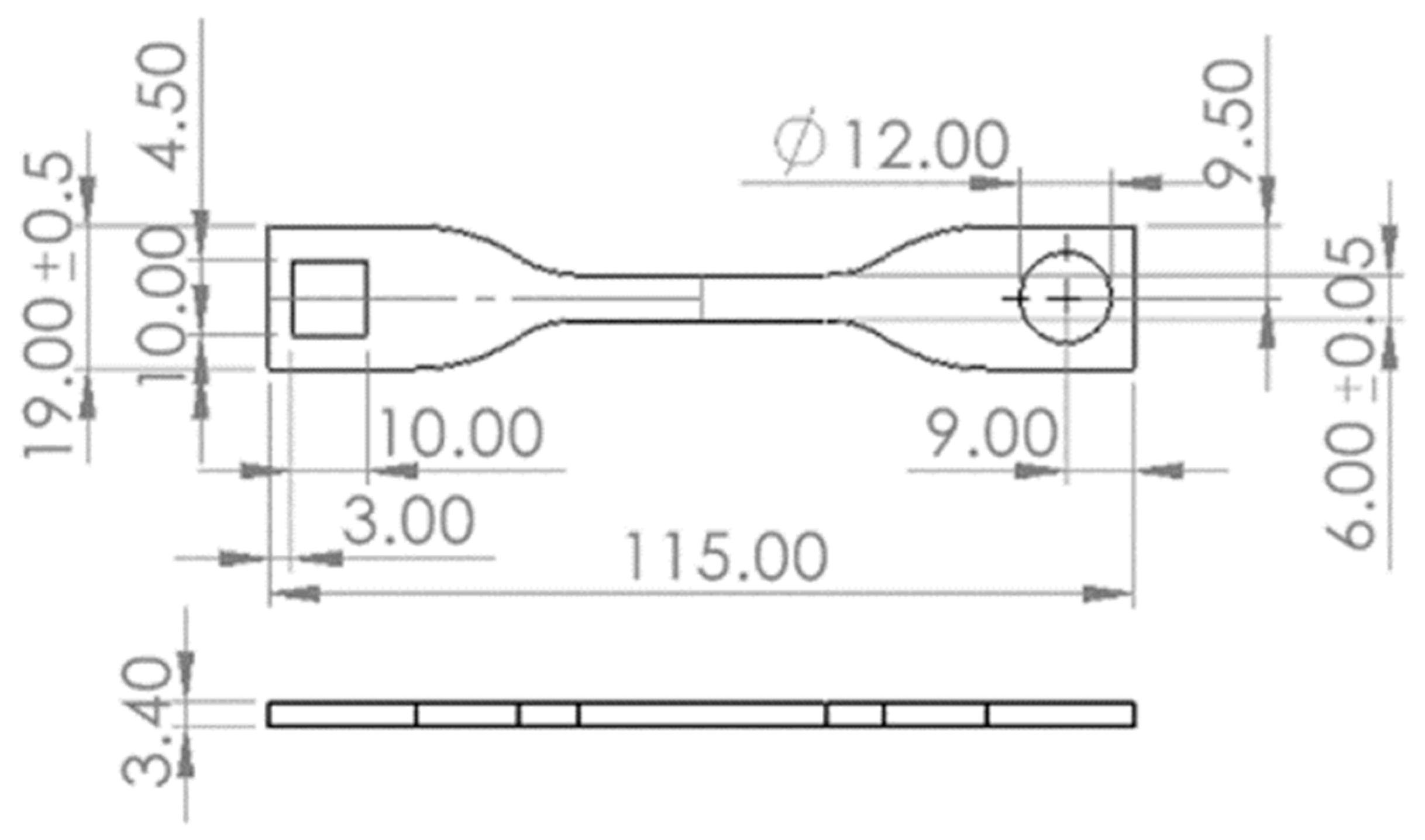

Section 2 discusses the materials, the benchmarks utilized in the experiments, and the manufacturing method along with the measuring procedure of the manufactured parts.

Section 3 reports the mechanical tests carried out and the performance metrics for the evaluation of the ANN model.

Section 4 shows the validation through additional data points to assess the prognosis.

Section 6 concludes by summarizing the findings and discussing prospective future studies on the issue.

6. Conclusions

In the field of additive manufacturing, FFF stands out as a transformative technology that enables the layer-by-layer construction of components without the constraints of traditional manufacturing methods. Its versatility in material usage, particularly with thermoplastics such as PLA, has attracted attention in the automotive, aerospace, and medical industries. However, the ever-increasing demand for the improved performance of 3D-printed components has spurred the integration of advanced techniques, and this study explores the pivotal role of ML in achieving this goal.

The primary objective of this work was to exploit the capabilities of ANN to predict the mechanical performance of FFF-manufactured parts. As part of a comprehensive investigation, experiments were designed using Taguchi’s parametric approach, with seven key process parameters carefully varied to study their influence on tensile strength. A fractional Taguchi L16 DOE was implemented, and the manufactured parts were tested to assess the mechanical performance of each combination.

The ANN showed the ability to predict tensile strength with an R2 greater than 90%. In addition, the LOO cross-validation approach provided a robust evaluation of the stability and generalization capabilities of the model with the MSE and MAE of 0.002 and 0.024.

The ANN model, trained and evaluated on the dataset, demonstrated its effectiveness in predicting unknown values. The low margin of error observed on the subsequent independent test dataset further underscored the reliability of the developed model.

The neural network with the highest R2 value, equal to approximately 97%, was used to check the percentage variation between the predicted and actual values. The best model has been selected according to the score on the training and validation. The variations on the UTS remain stable within a range of −1.17% to 2.56%.

In conclusion, this study not only advances our understanding of the intricate dynamics within FFF-manufactured parts but also underscores the transformative potential of ML in optimizing and predicting mechanical performance. As industries increasingly embrace additive manufacturing, the insights gained from this work serve as a beacon to guide the path toward more efficient, reliable, and precisely engineered 3D-printed components. As demonstrated, the fusion of FFF and ML technologies drives toward a future where additive manufacturing is at the forefront of innovation and quality assurance.

Future works will include a wider range of combinations and a greater expansion of input ranges to promote a more comprehensive and complete dataset. In this way, it will be possible to increase the representativeness of the database.