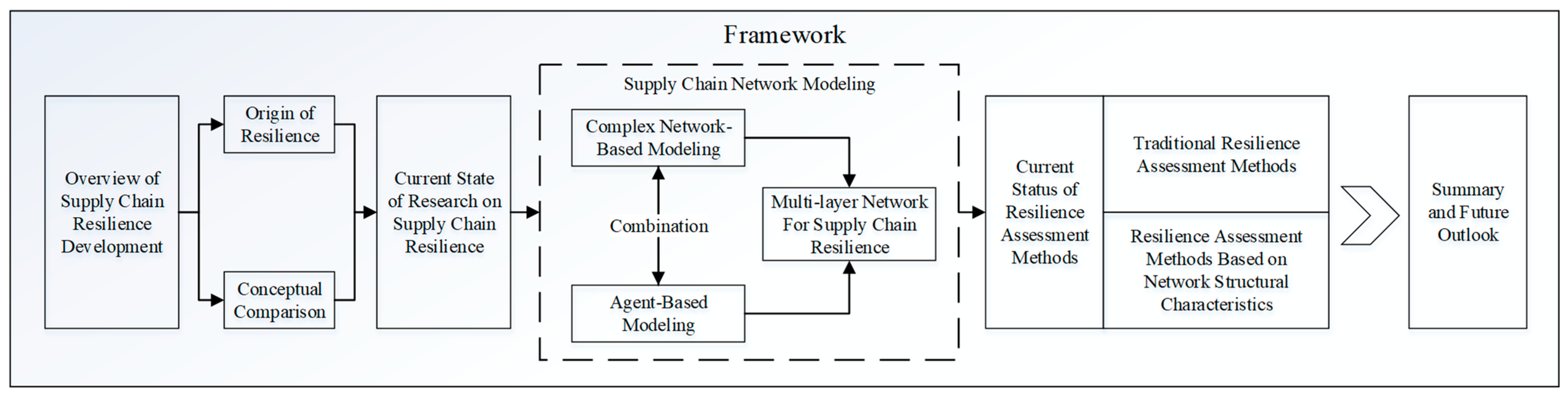

A Review of Supply Chain Resilience: A Network Modeling Perspective

Abstract

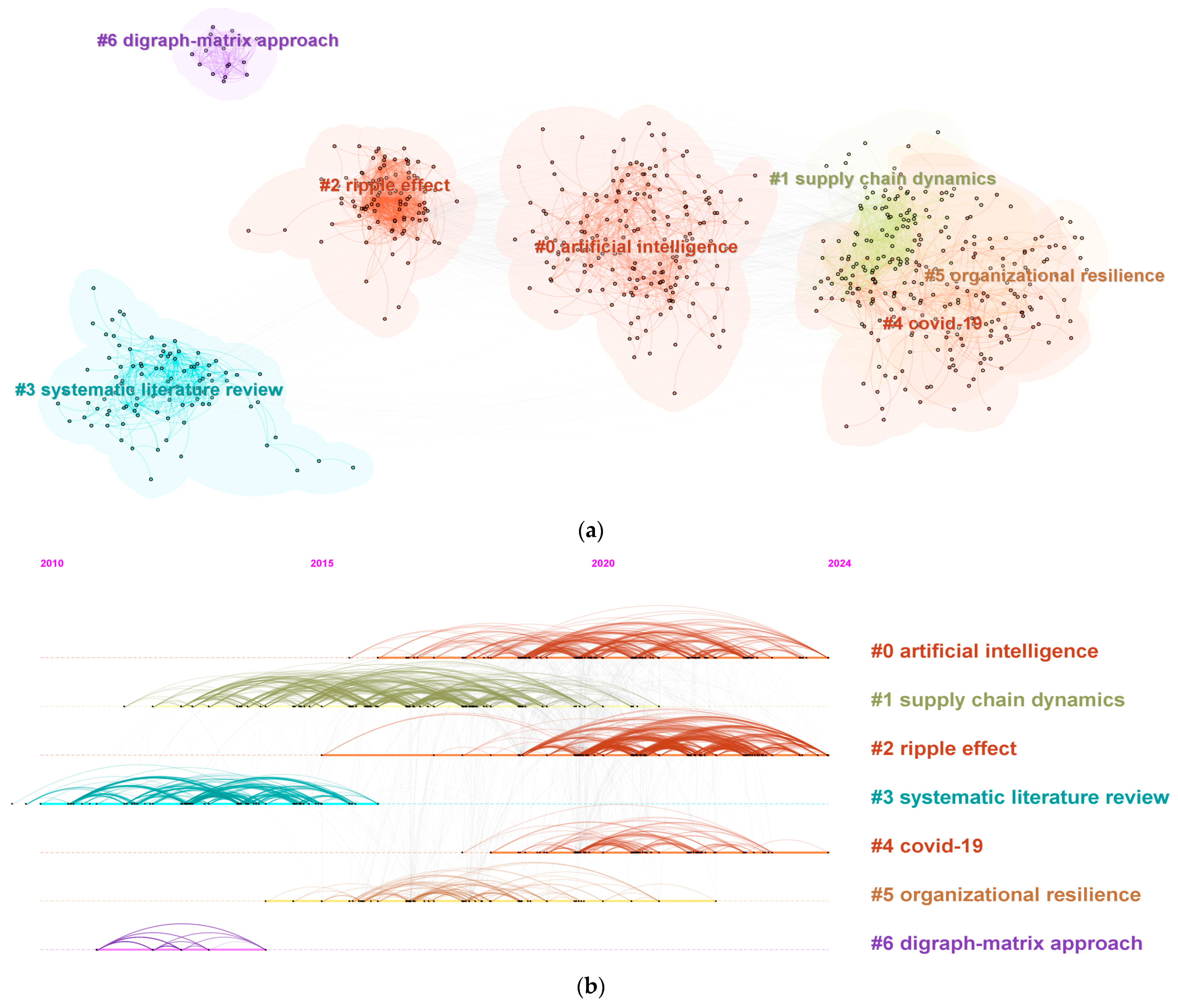

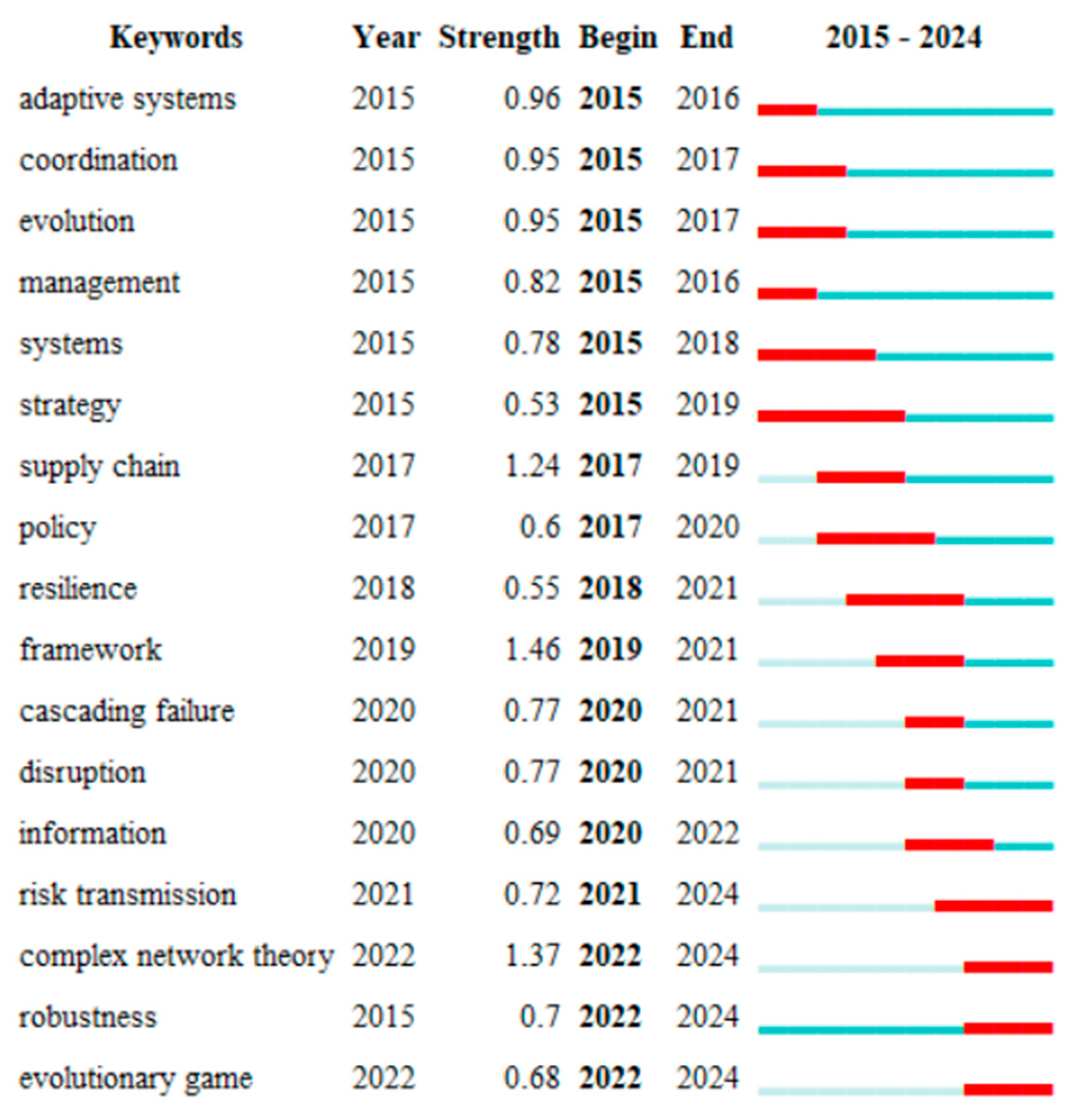

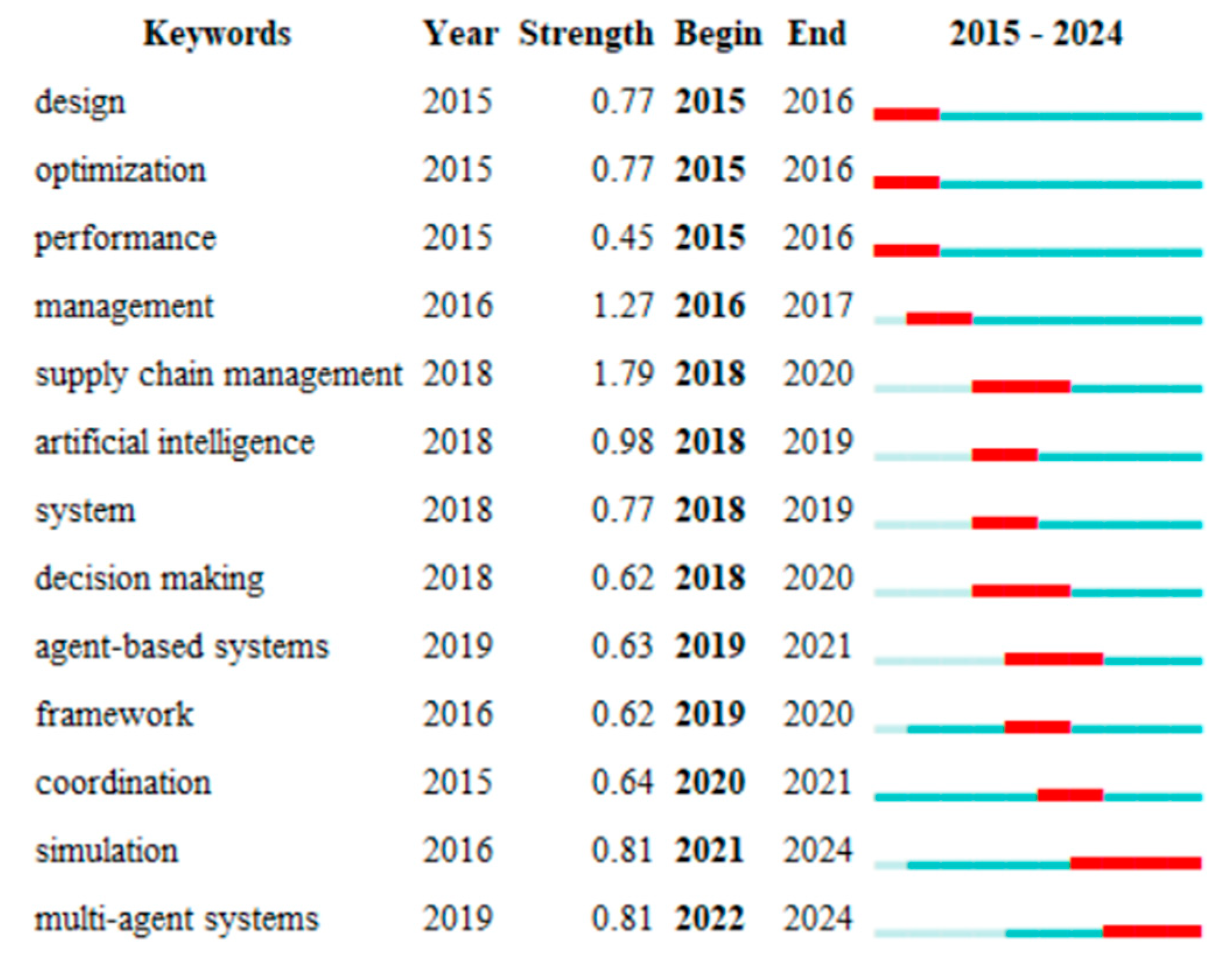

:1. Introduction

2. Overview of Supply Chain Resilience Development

2.1. Fundamental Concept of Resilience

2.1.1. The Concept and Origin of Resilience

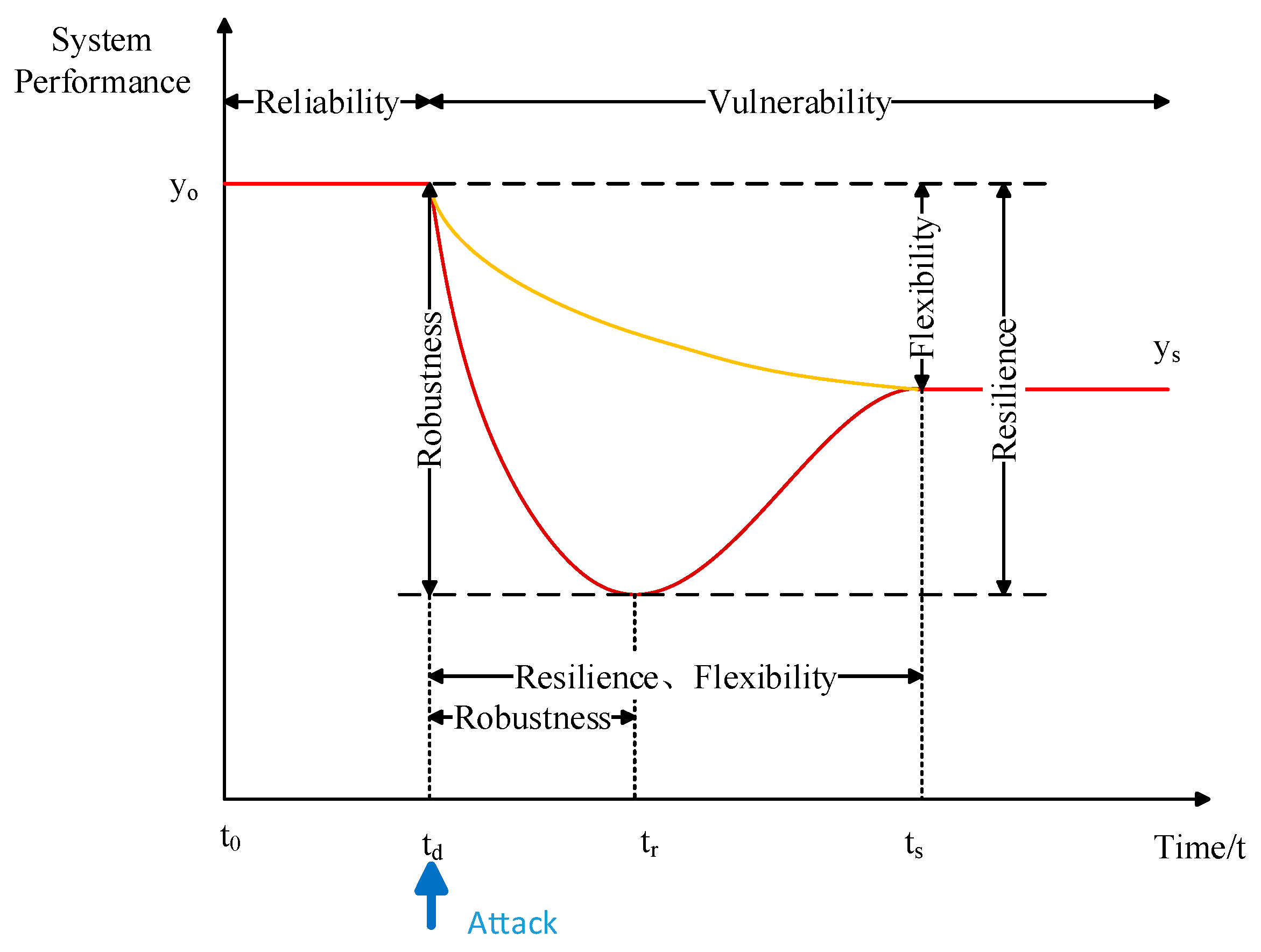

2.1.2. The Relationship Among Resilience, Flexibility, Robustness, Vulnerability, and Reliability

- Reliability refers to a system’s ability to perform its specified functions under predetermined conditions within a specified time frame. A reliable system maintains regular operation during the expected period, with a low probability of failure;

- Vulnerability describes the degree to which a system is susceptible to damage or functional failure when exposed to external or internal threats. A highly vulnerable system lacks resistance to disturbances or shocks and is prone to failure. High vulnerability indicates insufficient protective mechanisms or response strategies, making the system more susceptible to harm;

- Robustness is the ability of a system to maintain its normal functions in the face of uncertainty, disturbances, or environmental changes. A highly robust system can withstand a certain degree of shocks or failures without losing functionality. Robustness is often associated with system stability and strength, emphasizing the capacity to operate continuously even when subjected to certain levels of disruption;

- Flexibility refers to a system’s ability to adapt to changes in the environment or demands. A highly flexible system can adjust to maintain functionality or improve efficiency amidst change. Flexibility does not necessarily imply maintaining original functionality after a shock but involves reconfiguring strategies, structures, or configurations to adapt to new conditions;

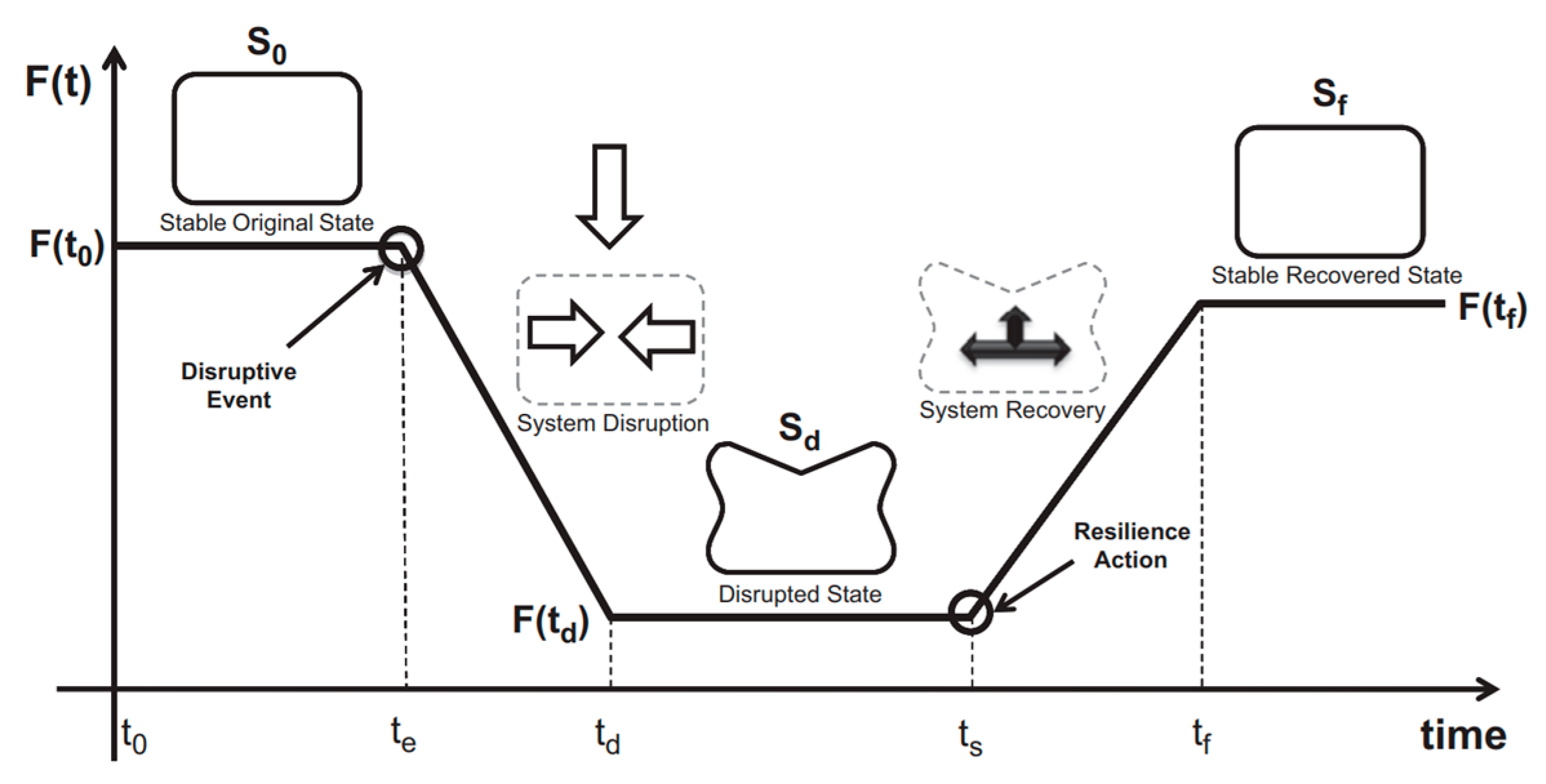

- Resilience is the ability of a system to recover from disturbances, shocks, or failures and return to its original state or adapt to a new environment. Resilience emphasizes recovery capacity and adaptability. It relates to a system’s self-repair and recovery mechanisms, particularly the ability to quickly return to normal or establish a new equilibrium after partial failures or disruptions [19,20,21].

2.2. Current State of Research on Supply Chain Resilience

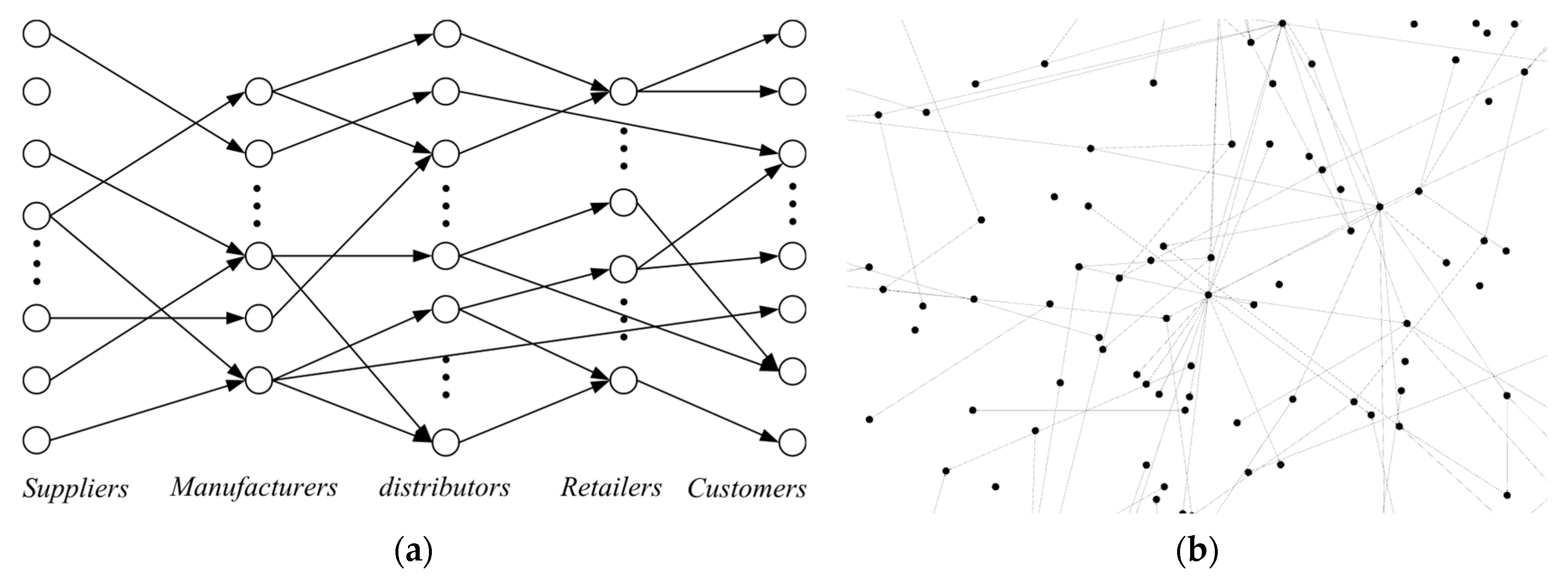

3. Current Status of Supply Chain Network Modeling Research

- Complex Network-Based Modeling: This approach adopts a top-down perspective, focusing on the static structure and relationships within the supply chain network;

3.1. Supply Chain Network Modeling Based on Complex Networks

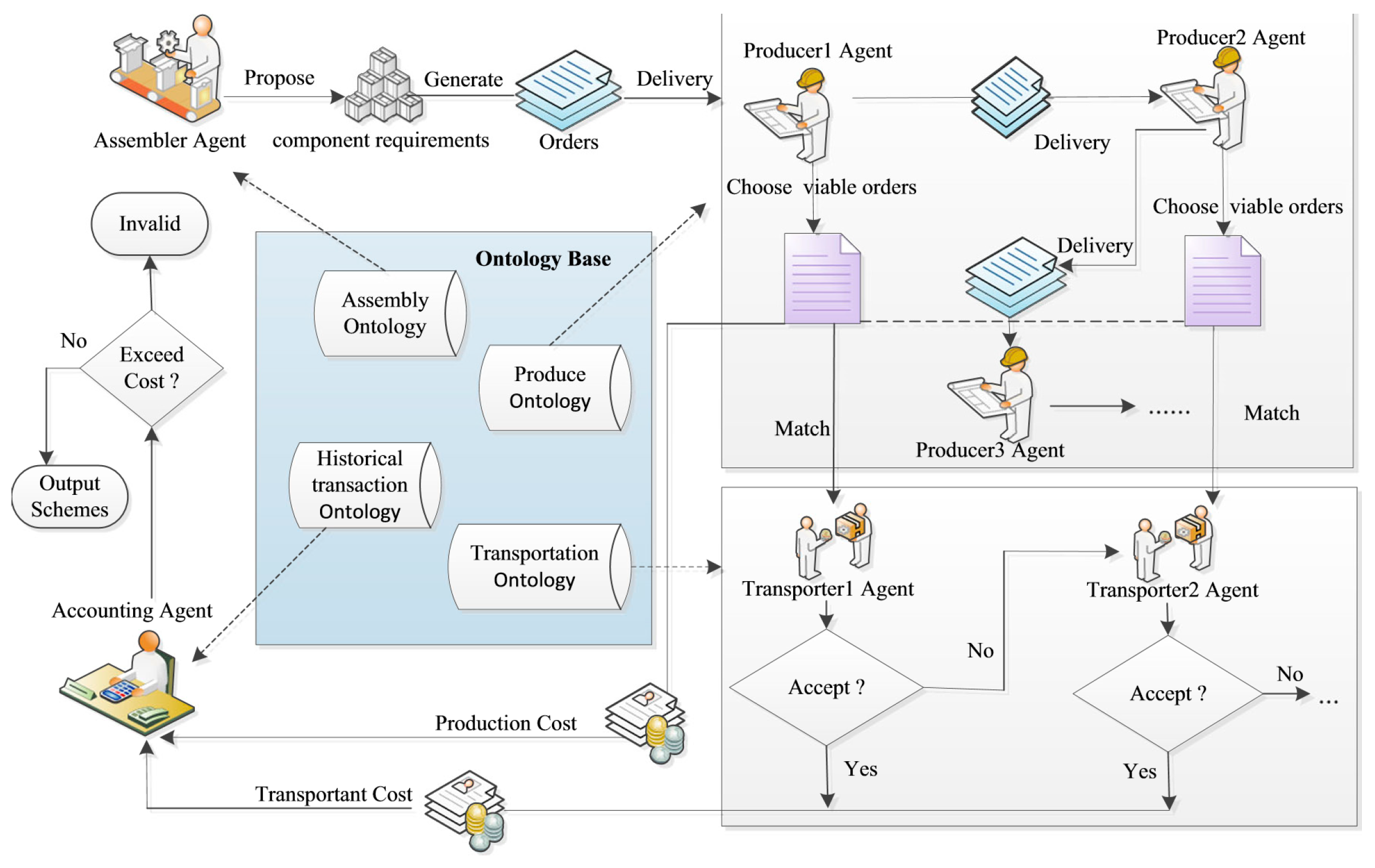

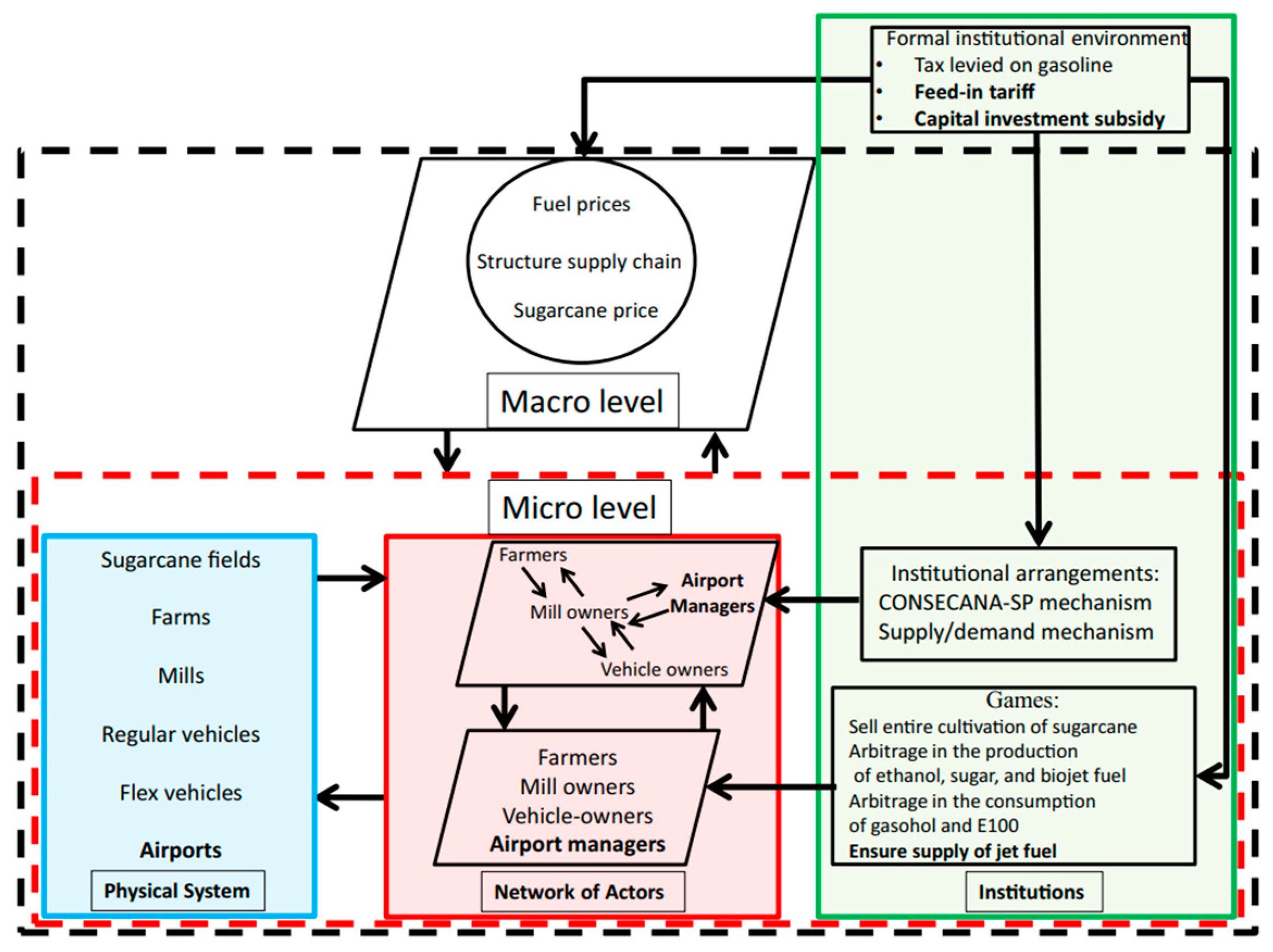

3.2. Agent-Based Modeling of Supply Chain Networks

3.3. Comment on Supply Chain Resilience Based on Network Modeling Methods

- Behavioral Modeling of Business Entities

- 2.

- Information Network Modeling as a Key Factor

- 3.

- Task Fulfillment as the Ultimate Objective

4. Resilience Assessment Methods: Current Research Status

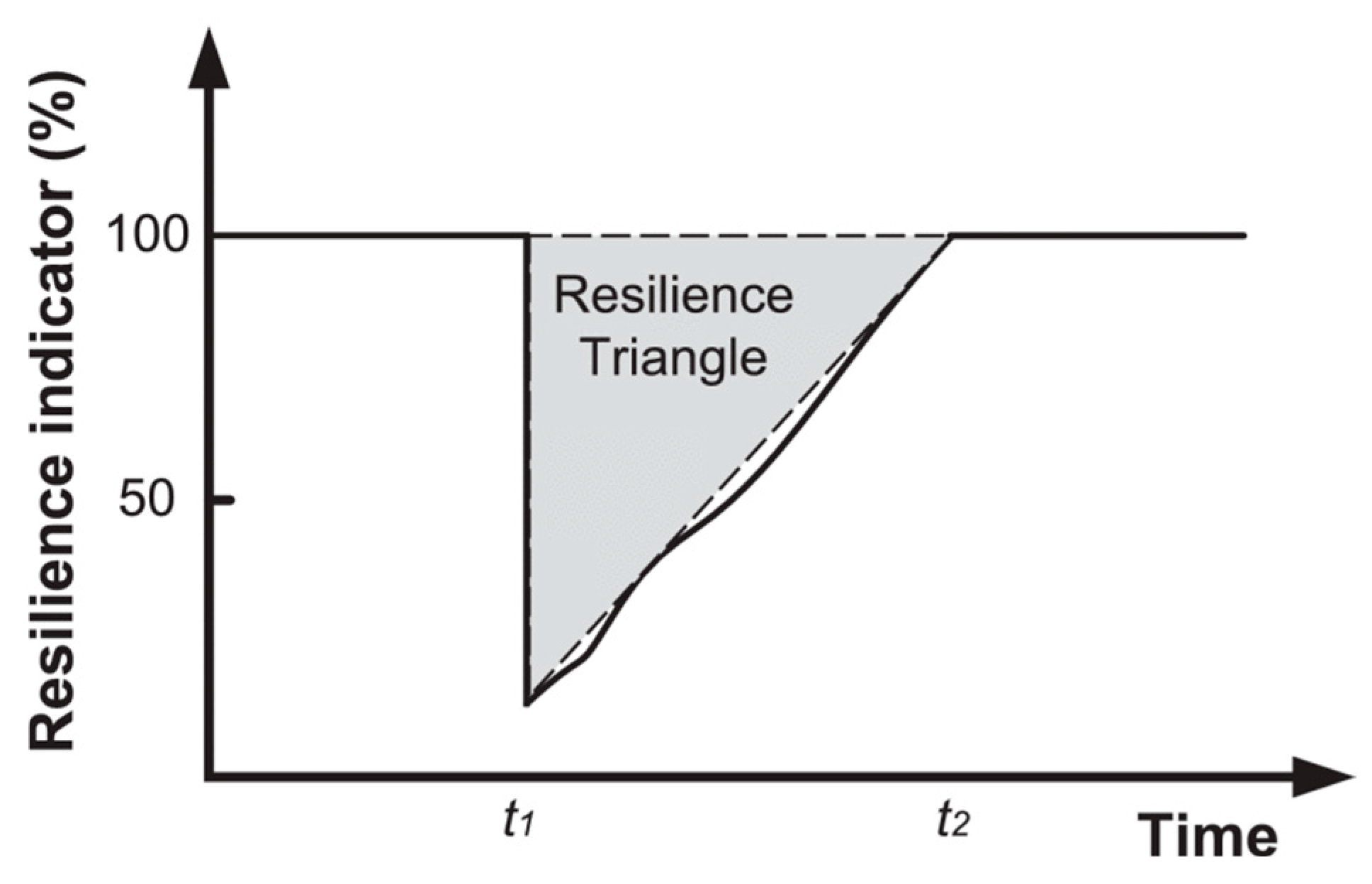

4.1. Traditional Resilience Assessment Methods

- Stage Division: From the perspective of stage categorization, different systems may exhibit variations in the refinement or overlap of stages. For instance, some studies divide the system task process into three stages: disruption, adaptation, and recovery, while others categorize it into only two stages: disruption and recovery;

- Capability Definition: From the perspective of capability categorization, there is no consensus on which specific capabilities resilience should include. Moreover, the qualitative descriptions and quantitative representations of various capabilities may overlap or intersect;

- Metric Construction: the construction of resilience metrics still faces unresolved issues, such as unclear quantification methods and the absence of rational integration approaches for various capability factors.

4.2. Resilience Assessment Methods Based on Network Structural Characteristics

5. Summary and Future Outlook

5.1. Key Points to Pay Attention to in the Study of Supply Chain Resilience

5.2. Further Directions

- Theoretical Foundations and Concept Definition: The concept of supply chain resilience is clarified, and its developmental trajectory is reviewed. Supply chain resilience encompasses not only the system’s ability to adapt to and absorb shocks but also its capability to recover to a normal state;

- Research Progress and Network Modeling Applications: the importance of network modeling techniques in supply chain resilience research is highlighted, particularly in the areas of risk propagation, simulation of supply chain evolution, and dynamic behavior analysis of individual entities;

- Methodological Advantages and Limitations: This paper examines the methods of supply chain network modeling based on complex networks and agent-based modeling, analyzing their strengths and limitations. While complex network models are suited for macro-level analyses, agent-based models focus on micro-level dynamic behavior simulations;

- The application of interdisciplinary methods in supply chain resilience research remains at an early stage. Future research can focus on the following directions [88,89,90]:

- Enhanced Representation of Individual Firm Behavior: as the complexity of supply chain networks increases, accurately depicting firm-level behaviors will become a critical research direction;

- Dynamic Analysis of Information Networks: The role of information networks in supply chains extends beyond information transmission. They also serve as critical enablers for decision-making and collaboration;

- Task-Oriented Model Design: in dynamic and highly uncertain environments, task-driven supply chain modeling, particularly for managing emergencies and ensuring the fulfillment of urgent demands, will be a key area of focus.

Author Contributions

Funding

Conflicts of Interest

References

- Alicke, K.; Bayazit, C.; Beckhoff, T.; Foster, T.; Mysore, M. Supply chains: To build resilience, manage proactively. Available online: https://www.mckinsey.com/capabilities/operations/our-insights/supply-chains-to-build-resilience-manage-proactively (accessed on 22 March 2023).

- Arora, V.; Ventresca, M. Modeling topologically resilient supply chain networks. Appl. Netw. Sci. 2018, 3, 19. [Google Scholar] [CrossRef]

- Zhao, P.; Li, Z.; Han, X.; Duan, X. Supply chain network resilience by considering disruption propagation: Topological and operational perspectives. IEEE Syst. J. 2022, 16, 5305–5316. [Google Scholar] [CrossRef]

- Uday, P.; Marais, K.B. Resilience-based System Importance Measures for System-of-Systems. Procedia Comput. Sci. 2014, 28, 257–264. [Google Scholar] [CrossRef]

- Kim, Y.; Chen, Y.S.; Linderman, K. Supply network disruption and resilience: A network structural perspective. J. Oper. Manag. 2015, 33, 43–59. [Google Scholar] [CrossRef]

- Neches, R.; Madni, A.M. Towards affordably adaptable and effective systems. Syst. Eng. 2013, 16, 224–234. [Google Scholar] [CrossRef]

- Mallipeddi, R.; Gholaminezhad, I.; Saeedi, M.S.; Assimi, H.; Jamali, A. Robust controller design for systems with probabilistic uncertain parameters using multi-objective genetic programming. Soft Comput. 2021, 25, 233–249. [Google Scholar] [CrossRef]

- Huang, J.; Wang, Y.; Chen, Y.L. A Simplified Method for Quantifying Structural Robustness. Eng. Mech. 2013, 10, 46–53. [Google Scholar]

- Nagasawa, K.; Kinoshita, Y.; Morikawa, K.; Takahashi, K. Design of a robust closed-loop supply chain with backup suppliers under disruption scenarios. J. Adv. Mech. Des. Syst. Manuf. 2023, 17, JAMDSM0059. [Google Scholar] [CrossRef]

- Madni, A.M.; Jackson, S. Towards a Conceptual Framework for Resilience Engineering. IEEE Syst. J. 2009, 3, 181–191. [Google Scholar] [CrossRef]

- Holling, C.S. Resilience and Stability of Ecological Systems. Annu. Rev. Ecol. Syst. 1973, 4, 1–23. [Google Scholar] [CrossRef]

- USA Department of Homeland Security. National Infrastructure Protection Plan: Partnering to Enhance Protection and Resiliency; USA Department of Homeland Security: Washington, DC, USA, 2009; pp. 1–188.

- Dinh, L.; Pasman, H.; Gao, X.; Mannan, M.S. Resilience engineering of industrial processes: Principles and contributing factors. J. Loss Prev. Process Ind. 2012, 25, 233–241. [Google Scholar] [CrossRef]

- Luthar, S.S.; Becker, C.B. Research on Resilience: Response to Commentaries. Child Dev. 2010, 71, 573–575. [Google Scholar] [CrossRef]

- Cimellaro, G.P.; Reinhorn, A.M.; Bruneau, M. Seismic resilience of a hospital system. Struct. Infrastruct. Eng. 2010, 6, 127–144. [Google Scholar] [CrossRef]

- Li, L.G.; Zhang, P.Y.; Tan, J.T.; Guan, H.M. The Evolution of the Resilience Concept and Advances in Regional Economic Resilience Research. Hum. Geogr. 2019, 34, 1–7+151. [Google Scholar]

- Shao, Y.W.; Xu, J. Urban Resilience: A Conceptual Analysis Based on an International Literature Review. Int. Urban Plan. 2015, 30, 48–54. [Google Scholar]

- Rivera-Royero, D.; Galindo, G.; Jaller, M.; Reyes, J.B. Road network performance: A review on relevant concepts. Comput. Ind. Eng. 2022, 165, 107927. [Google Scholar] [CrossRef]

- Porse, E.; Lund, J. Network analysis and visualizations of water resources infrastructure in California: Linking connectivity and resilience. J. Water Resour. Plan. Manag. 2016, 142, 04015041. [Google Scholar] [CrossRef]

- Shela, V.; Danks, N.P.; Ramayah, T.; Ahmad, N.H. An application of the COA Framework: Building a sound foundation for organizational resilience. J. Bus. Res. 2024, 179, 114702. [Google Scholar] [CrossRef]

- Chalupnik, M.J.; Wynn, D.C.; Clarkson, P.J. Comparison of ilities for protection against uncertainty in system design. J. Eng. Des. 2013, 24, 814–829. [Google Scholar] [CrossRef]

- Oliveira, E.L.; Silva Portugal, L.; Junior, W.P. Indicators of reliability and vulnerability: Similarities and differences in ranking links of a complex road system. Transp. Res. Part A Policy Pract. 2016, 88, 195–208. [Google Scholar] [CrossRef]

- Liu, H.; Tian, Z.; Huang, A.; Yang, Z. Analysis of vulnerabilities in maritime supply chains. Reliab. Eng. Syst. Saf. 2018, 169, 475–484. [Google Scholar] [CrossRef]

- Van Landeghem, H.; Vanmaele, H. Robust Planning: A New Paradigm for Demand Chain Planning. J. Oper. Manag. 2002, 20, 769–783. [Google Scholar] [CrossRef]

- Liu, X.L. Research on Supply Network Resilience. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2007. [Google Scholar]

- Grzybowska, K.; Tubis, A.A. Supply chain resilience in reality VUCA—An international delphi study. Sustainability 2022, 14, 10711. [Google Scholar] [CrossRef]

- Achurra-Gonzalez, P.E.; Novati, M.; Foulser-Piggott, R.; Graham, D.J.; Bowman, G.; Bell, M.G.; Angeloudis, P. Modelling the impact of liner shipping network perturbations on container cargo routing: Southeast Asia to Europe application. Accid. Anal. Prev. 2019, 123, 399–410. [Google Scholar] [CrossRef]

- Nikookar, E.; Gligor, D.; Russo, I. Supply chain resilience: When the recipe is more important than the ingredients for managing supply chain disruptions. Int. J. Prod. Econ. 2024, 272, 109236. [Google Scholar] [CrossRef]

- Ashraf, M.; Eltawil, A.; Ali, I. Disruption detection for a cognitive digital supply chain twin using hybrid deep learning. Oper. Res. 2024, 24, 1–31. [Google Scholar] [CrossRef]

- Spiegler, V.L.M.; Naim, M.M.; Wikner, J. A control engineering approach to the assessment of supply chain resilience. Int. J. Prod. Res. 2012, 50, 6162–6187. [Google Scholar] [CrossRef]

- Rajesh, R.; Ravi, V.; Venkata Rao, R. Selection of risk mitigation strategy in electronic supply chains using grey theory and digraph-matrix approaches. Int. J. Prod. Res. 2015, 53, 238–257. [Google Scholar] [CrossRef]

- Jüttner, U.; Maklan, S. Supply chain resilience in the global financial crisis: An empirical study. Supply Chain Manag. Int. J. 2011, 16, 246–259. [Google Scholar] [CrossRef]

- Annarelli, A.; Nonino, F. Strategic and operational management of organizational resilience: Current state of research and future directions. Omega 2016, 62, 1–18. [Google Scholar] [CrossRef]

- Hong, L.; Zhao, X.B.; Wang, S.Y. Key scientific issues in supply chain resilience and security. China Sci. Found. 2023, 37, 418–428. [Google Scholar]

- Modgil, S.; Singh, R.K.; Hannibal, C. Artificial intelligence for supply chain resilience: Learning from COVID-19. Int. J. Logist. Manag. 2022, 33, 1246–1268. [Google Scholar] [CrossRef]

- Modgil, S.; Gupta, S.; Stekelorum, R.; Laguir, I. AI technologies and their impact on supply chain resilience during COVID-19. Int. J. Phys. Distrib. Logist. Manag. 2022, 52, 130–149. [Google Scholar] [CrossRef]

- Belhadi, A.; Mani, V.; Kamble, S.S.; Khan, S.A.R.; Verma, S. Artificial intelligence-driven innovation for enhancing supply chain resilience and performance under the effect of supply chain dynamism: An empirical investigation. Ann. Oper. Res. 2024, 333, 627–652. [Google Scholar] [CrossRef]

- Sawik, T. Stochastic optimization of supply chain resilience under ripple effect: A COVID-19 pandemic related study. Omega 2022, 109, 102596. [Google Scholar] [CrossRef]

- Lei, Z.; Cui, L.; Tang, J.; Chen, L.; Liu, B. Supply chain resilience in the context of I4.0 and I5.0 from a multilayer network ripple effect perspective. Ann. Oper. Res. 2023, 1, 1–44. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D. Ripple effect and supply chain disruption management: New trends and research directions. Int. J. Prod. Res. 2021, 59, 102–109. [Google Scholar] [CrossRef]

- Li, Y.; Zobel, C.W.; Seref, O.; Chatfield, D. Network characteristics and supply chain resilience under conditions of risk propagation. Int. J. Prod. Econ. 2020, 223, 107529. [Google Scholar] [CrossRef]

- Habibi, F.; Chakrabortty, R.K.; Abbasi, A. Evaluating supply chain network resilience considering disruption propagation. Comput. Ind. Eng. 2023, 183, 109531. [Google Scholar] [CrossRef]

- Saisridhar, P.; Thuerer, M.; Avittathur, B. Assessing supply chain responsiveness, resilience, and robustness (Triple-R) by computer simulation: A systematic review of the literature. Int. J. Prod. Res. 2024, 62, 1458–1488. [Google Scholar] [CrossRef]

- Coşkun, A.E.; Erturgut, R. How do uncertainties affect supply-chain resilience? The moderating role of information sharing for sustainable supply-chain management. Sustainability 2023, 16, 131. [Google Scholar] [CrossRef]

- Amio, M.G.A.N.; Ahmed, H.N.; Ali, S.M.; Ahmed, S.; Majumdar, A. Key determinants to supply chain resilience to face pandemic disruption: An interpretive triple helix framework. PLoS ONE 2024, 19, 299778. [Google Scholar] [CrossRef] [PubMed]

- Korder, B.; Maheut, J.; Konle, M. Simulation methods and digital strategies for supply chains facing disruptions: Insights from a systematic literature review. Sustainability 2024, 16, 5957. [Google Scholar] [CrossRef]

- Liu, T.; Meidani, H. Supply chain network extraction and entity classification leveraging large language models. arXiv 2024, arXiv:2410.13051. [Google Scholar]

- Cheng, C.C. Task-Oriented Resilience Evaluation of UAV Clusters. Ph.D. Thesis, National University of Defense Technology, Changsha, China, 2020. [Google Scholar]

- Cui, J.Y.; Xu, S.Q.; Na, X.; Pan, L.M.; Lue, L.Y. Research on supply chains based on complex network theory. Acta Phys. Sin. 2024, 73, 161–183. [Google Scholar] [CrossRef]

- Perera, S.; Bell, M.G.H.; Bliemer, M.C.J. Network science approach to modelling the topology and robustness of supply chain networks: A review and perspective. Appl. Netw. Sci. 2017, 2, 1–25. [Google Scholar] [CrossRef]

- Choudhary, N.A.; Ramkumar, M.; Schoenherr, T.; Rana, N.P. Assessing supply chain resilience during the pandemic using network analysis. IEEE Trans. Eng. Manag. 2021, 71, 12297–12310. [Google Scholar] [CrossRef]

- Hearnshaw, E.J.S.; Wilson, M.M.J. A complex network approach to supply chain network theory. Int. J. Oper. Prod. Manag. 2013, 33, 442–469. [Google Scholar] [CrossRef]

- Wiedmer, R.; Griffis, S.E. Structural characteristics of complex supply chain networks. J. Bus. Logist. 2021, 42, 264–290. [Google Scholar] [CrossRef]

- Watson, M. Supply Chain Network Design: Applying Optimization and Analytics to the Global Supply Chain; Pearson Education: London, UK, 2013. [Google Scholar]

- Ioannou, I.; Demirel, G. Blockchain and supply chain finance: A critical literature review at the intersection of operations, finance, and law. J. Bank. Financ. Technol. 2022, 6, 83–107. [Google Scholar] [CrossRef]

- Guo, H.; Cheng, Y.; Xie, X. A new model for supply chain risk propagation considering herd mentality and risk preference under warning information on multiplex networks. Phys. A Stat. Mech. Appl. 2020, 545, 123506. [Google Scholar]

- Yao, Q.; Fan, R.; Chen, R.; Qian, R. A model of the enterprise supply chain risk propagation based on partially mapping two-layer complex networks. Phys. A Stat. Mech. Appl. 2023, 613, 128506. [Google Scholar] [CrossRef]

- Bellamy, M.A.; Basole, R.C. Network analysis of supply chain systems: A systematic review and future research. Syst. Eng. 2013, 16, 235–249. [Google Scholar] [CrossRef]

- Batwa, A.B.; Norrman, A. A framework for exploring blockchain technology in supply chain management. Oper. Supply Chain Manag. Int. J. 2020, 13, 294–306. [Google Scholar] [CrossRef]

- Basole, R.C.; Bellamy, M.A. Supply network structure, visibility, and risk diffusion: A computational approach. Decis. Sci. 2014, 45, 753–789. [Google Scholar] [CrossRef]

- Tang, L.; Jing, K.; He, J.; Stanley, H.E. Complex interdependent supply chain networks: Cascading failure and robustness. Phys. A Stat. Mech. Appl. 2016, 443, 58–69. [Google Scholar] [CrossRef]

- Mari, S.I.; Lee, Y.H.; Memon, M.S. Complex network theory-based approach for designing resilient supply chain networks. Int. J. Logist. Syst. Manag. 2015, 21, 365–384. [Google Scholar] [CrossRef]

- Guo, N.; Guo, P.; Dong, H.; Zhao, J.; Han, Q. Modeling and analysis of cascading failures in projects: A complex network approach. Comput. Ind. Eng. 2019, 127, 1–7. [Google Scholar] [CrossRef]

- Liu, H.; Han, Y.; Zhu, A. Modeling supply chain viability and adaptation against underload cascading failure during the COVID-19 pandemic. Nonlinear Dyn. 2022, 110, 2931–2947. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, Z. Identification of key risk nodes and invulnerability analysis of construction supply chain networks. Buildings 2024, 14, 1997. [Google Scholar] [CrossRef]

- Yu, W.; Chen, G.; Cao, M.; Lü, J.; Zhang, H.T. Swarming behaviors in multi-agent systems with nonlinear dynamics. Chaos Interdiscip. J. Nonlinear Sci. 2013, 23. [Google Scholar] [CrossRef] [PubMed]

- Giuliani, M.; Castelletti, A. Assessing the value of cooperation and information exchange in large water resources systems by agent-based optimization. Water Resour. Res. 2013, 49, 3912–3926. [Google Scholar] [CrossRef]

- Du, J.; Jing, H.; Choo, K.K.R.; Sugumaran, V.; Castro-Lacouture, D. An ontology and multi-agent based decision support framework for prefabricated component supply chain. Inf. Syst. Front. 2020, 22, 1467–1485. [Google Scholar] [CrossRef]

- Zhao, K.; Zuo, Z.; Blackhurst, J.V. Modelling supply chain adaptation for disruptions: An empirically grounded complex adaptive systems approach. J. Oper. Manag. 2019, 65, 190–212. [Google Scholar] [CrossRef]

- Moncada, J.A.; Verstegen, J.A.; Posada, J.A.; Junginger, M.; Lukszo, Z.; Faaij, A.; Weijnen, M. Exploring the emergence of a biojet fuel supply chain in Brazil: An agent-based modeling approach. GCB Bioenergy 2019, 11, 773–790. [Google Scholar] [CrossRef]

- Maltseva, S.; Kornilov, V.; Barakhnin, V.; Gorbunov, A. Self-Organization in network sociotechnical systems. Complexity 2022, 2022, 5714395. [Google Scholar] [CrossRef]

- Shim, J.; Bliemel, M. Ignition of new product diffusion in entrepreneurship: An agent-based approach. Entrep. Res. J. 2018, 8, 20160014. [Google Scholar] [CrossRef]

- Bertani, F.; Ponta, L.; Raberto, M.; Teglio, A.; Cincotti, S. The complexity of the intangible digital economy: An agent-based model. J. Bus. Res. 2021, 129, 527–540. [Google Scholar] [CrossRef]

- Wears, R.L. Resilience engineering: Concepts and precepts. Qual. Saf. Health Care 2006, 15, 447–458. [Google Scholar] [CrossRef]

- Cimellaro, G.P.; Renschler, C.; Reinhorn, A.M.; Arendt, L. PEOPLES: A framework for evaluating resilience. J. Struct. Eng. 2016, 142, 63–76. [Google Scholar] [CrossRef]

- Bruneau, M.; Chang, S.E.; Eguchi, R.T.; Lee, G.C.; O’Rourke, T.D.; Reinhorn, A.M. A framework to quantitatively assess and enhance the seismic resilience of communities. Earthq. Spectra 2012, 19, 733–752. [Google Scholar] [CrossRef]

- Panteli, M.; Mancarella, P.; Trakas, D.N.; Kyriakides, E.; Hatziargyriou, N.D. Metrics and quantification of operational and infrastructure resilience in power systems. IEEE Trans. Power Syst. 2017, 32, 4732–4742. [Google Scholar] [CrossRef]

- Henry, D.; Ramirez-Marquez, J.E. Generic metrics and quantitative approaches for system resilience as a function of time. Reliab. Eng. Syst. Saf. 2017, 99, 114–122. [Google Scholar] [CrossRef]

- Ayyub, B.M. Systems resilience for multihazard environments: Definition, metrics, and valuation for decision making. Risk Anal. 2014, 34, 340–355. [Google Scholar] [CrossRef] [PubMed]

- Basole, R.C.; Ghosh, S.; Hora, M.S. Supply network structure and firm performance: Evidence from the electronics industry. IEEE Trans. Eng. Manag. 2017, 65, 141–154. [Google Scholar] [CrossRef]

- Akgul, B.K.; Ozorhon, B.; Dikmen, I.; Birgonul, M.T. Social network analysis of construction companies operating in international markets: Case of Turkish contractors. J. Civ. Eng. Manag. 2017, 23, 327–337. [Google Scholar] [CrossRef]

- Kazemian, I.; Torabi, S.A.; Zobel, C.W.; Li, Y.; Baghersad, M. A multi-attribute supply chain network resilience assessment framework based on SNA-inspired indicators. Oper. Res. 2022, 22, 1853–1883. [Google Scholar]

- Zhang, X.; Miller-Hooks, E.; Denny, K. Assessing the role of network topology in transportation network resilience. J. Transp. Geogr. 2015, 46, 35–45. [Google Scholar] [CrossRef]

- Kao, T.W.D.; Simpson, N.C.; Shao, B.B.M.; Lin, W.T. Relating supply network structure to productive efficiency: A multi-stage empirical investigation. Eur. J. Oper. Res. 2017, 259, 469–485. [Google Scholar] [CrossRef]

- Shao, B.B.M.; Shi, Z.M.; Choi, T.Y.; Chae, S. A data-analytics approach to identifying hidden critical suppliers in supply networks: Development of nexus supplier index. Decis. Support Syst. 2018, 114, 37–48. [Google Scholar] [CrossRef]

- Zhao, K.; Scheibe, K.; Blackhurst, J.; Kumar, A. Supply chain network robustness against disruptions: Topological analysis, measurement, and optimization. IEEE Trans. Eng. Manag. 2018, 66, 127–139. [Google Scholar] [CrossRef]

- Dixit, V.; Verma, P.; Tiwari, M.K. Assessment of pre- and post-disaster supply chain resilience based on network structural parameters with CVaR as a risk measure. Int. J. Prod. Econ. 2020, 227, 107655. [Google Scholar] [CrossRef]

- Adobor, H. Supply chain resilience: A multi-level framework. Int. J. Logist. Res. Appl. 2019, 22, 533–556. [Google Scholar] [CrossRef]

- Chen, Y.; Li, B.; Huo, B. Building operational resilience through digitalization: The roles of supply chain network position. Technol. Forecast. Soc. Chang. 2025, 211, 123918. [Google Scholar] [CrossRef]

- Richey, R.G.; Roath, A.S.; Adams, F.G.; Wieland, A. A responsiveness view of logistics and supply chain management. J. Bus. Logist. 2022, 43, 62–91. [Google Scholar] [CrossRef]

| Type | Equilibrium State | Research Focus | Connotation | Target System |

|---|---|---|---|---|

| Engineering Resilience | Pursues a single equilibrium state | Stability, robustness | The system adapts and recovers to its normal state after disturbances, emphasizing adaptability and recovery speed and extent. | Physical systems |

| Ecological Resilience | Pursues multiple equilibrium states | Maximum disturbance a system can withstand before changing its equilibrium state | The system shifts from one equilibrium state to another after disturbances, emphasizing the stability of the system structure and function. | Ecological systems |

| Evolutionary Resilience | Abandons equilibrium pursuit, emphasizes continuous evolution | Complex adaptive systems, dynamic evolution | Resilience is a continuously evolving process, with the potential to create new development pathways, emphasizing the adaptive transformation of the system structure and function. | Economic systems |

| Type | Metric | Definition |

|---|---|---|

| Diameter | Network Diameter | The maximum shortest path length between any two nodes in the network. |

| Average Path Length | The average number of steps along the shortest paths for all pairs of nodes. | |

| Degree | Node Degree | The number of links associated with a node. |

| Network Density | Defined as the ratio of total actual links to the total potential links in the network. | |

| Flow Complexity | Represents the average number of outgoing flows from any node. | |

| Centrality | Closeness Centrality | Measures how close a given node is to all other nodes in the network. |

| Degree Centrality | A metric of the positional significance of a given node based on its degree. | |

| Betweenness Centrality | How often does a node act as a bridge on the shortest paths between other nodes. | |

| Clustering | Clustering Coefficient | A measure of the tendency of nodes to form tightly knit groups, calculated as the ratio of the number of closed triplets (triangles) to the total triplets. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; Zhang, L.; You, L.; Tian, W. A Review of Supply Chain Resilience: A Network Modeling Perspective. Appl. Sci. 2025, 15, 265. https://doi.org/10.3390/app15010265

Ma C, Zhang L, You L, Tian W. A Review of Supply Chain Resilience: A Network Modeling Perspective. Applied Sciences. 2025; 15(1):265. https://doi.org/10.3390/app15010265

Chicago/Turabian StyleMa, Chuhan, Lei Zhang, Liang You, and Wenjie Tian. 2025. "A Review of Supply Chain Resilience: A Network Modeling Perspective" Applied Sciences 15, no. 1: 265. https://doi.org/10.3390/app15010265

APA StyleMa, C., Zhang, L., You, L., & Tian, W. (2025). A Review of Supply Chain Resilience: A Network Modeling Perspective. Applied Sciences, 15(1), 265. https://doi.org/10.3390/app15010265