Remote Monitoring and Diagnosis for Building Maintenance Units Based on Internet of Things System

Abstract

:1. Introduction

- Establishment of an IoT architecture to acquire and store operational data from distributed BMU systems, forming a comprehensive dataset that serves as the foundation for system status analysis and fault detection.

- Development of a KD fusion framework that integrates expert-system prior knowledge with real-time operational data, which constructs multi-source relational association rules based on operational parameters and fault samples, ensuring the reliability of the proposed fault diagnosis model.

- Implementation of a multi-BMU integrated test system to validate the approach’s effectiveness. Experimental results demonstrate that the method simultaneously satisfies both accuracy and timeliness requirements for equipment fault diagnosis while providing comprehensive and innovative fault maintenance strategies.

2. System Design and Application

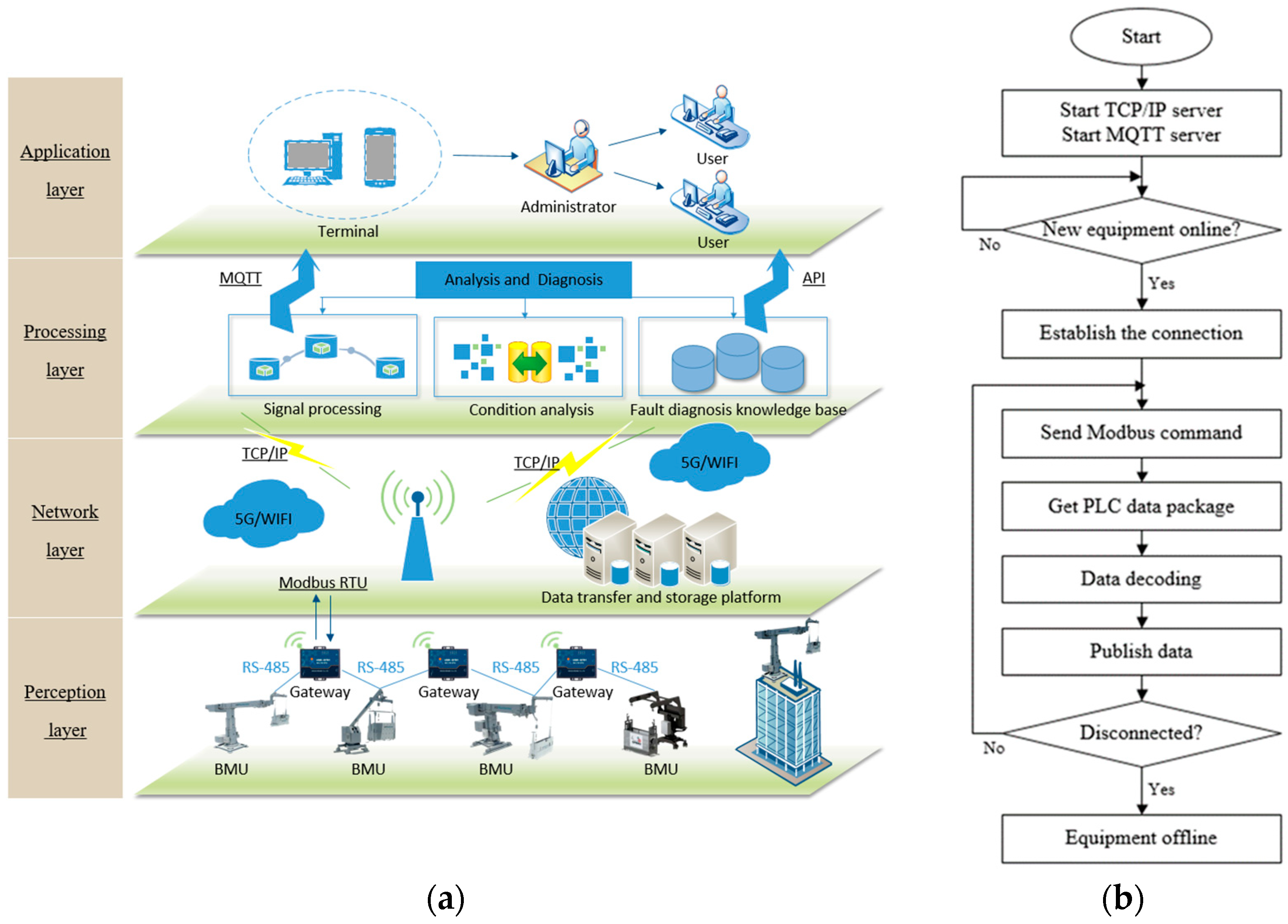

2.1. Overall System Architecture Design

| Algorithm 1: System data transmission and processing process |

| Input: client_socket Output: continuously monitor and process client requests 1. import socket 2. import MQTT 3. socket.socket() // Create a server-side socket object 4. bind((“ip”,port)) // Bind the host’s IP address and port number 5. Listen() 6. while True: 7. accept() // Wait for the client’s connection request 8. recv() // Receive gateway MAC ID 9. send() // Send MODBUS command to the client 10. recv() // Receive gateway return message 11. analy() // Data parsing function 12. mqtt_client.publish() // MQTT server publishes messages 12. if the device goes offline 13. close() // Close the connection 14. break |

2.2. Establishment of the Real-Time Fault Diagnosis Model Based on Multi-Correlation Data

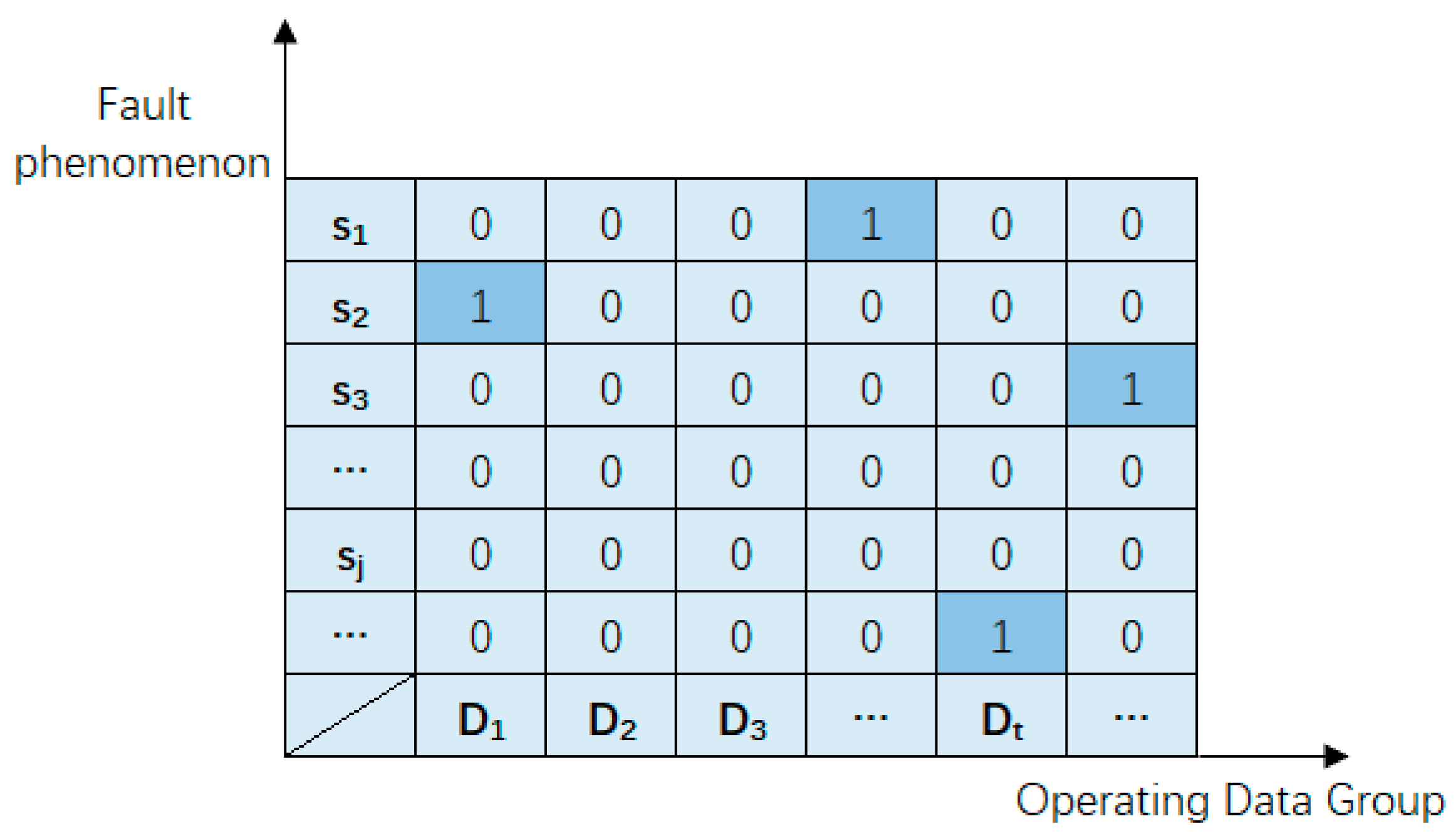

2.2.1. Construction of Data Layer Structure

2.2.2. Design of the Diagnostic Model Based on a Fault Constitutive Relationship

2.2.3. Construction of a Data Processing Layer Framework with a Real-Time Fault Diagnosis Model

3. The Simulation Test of the System

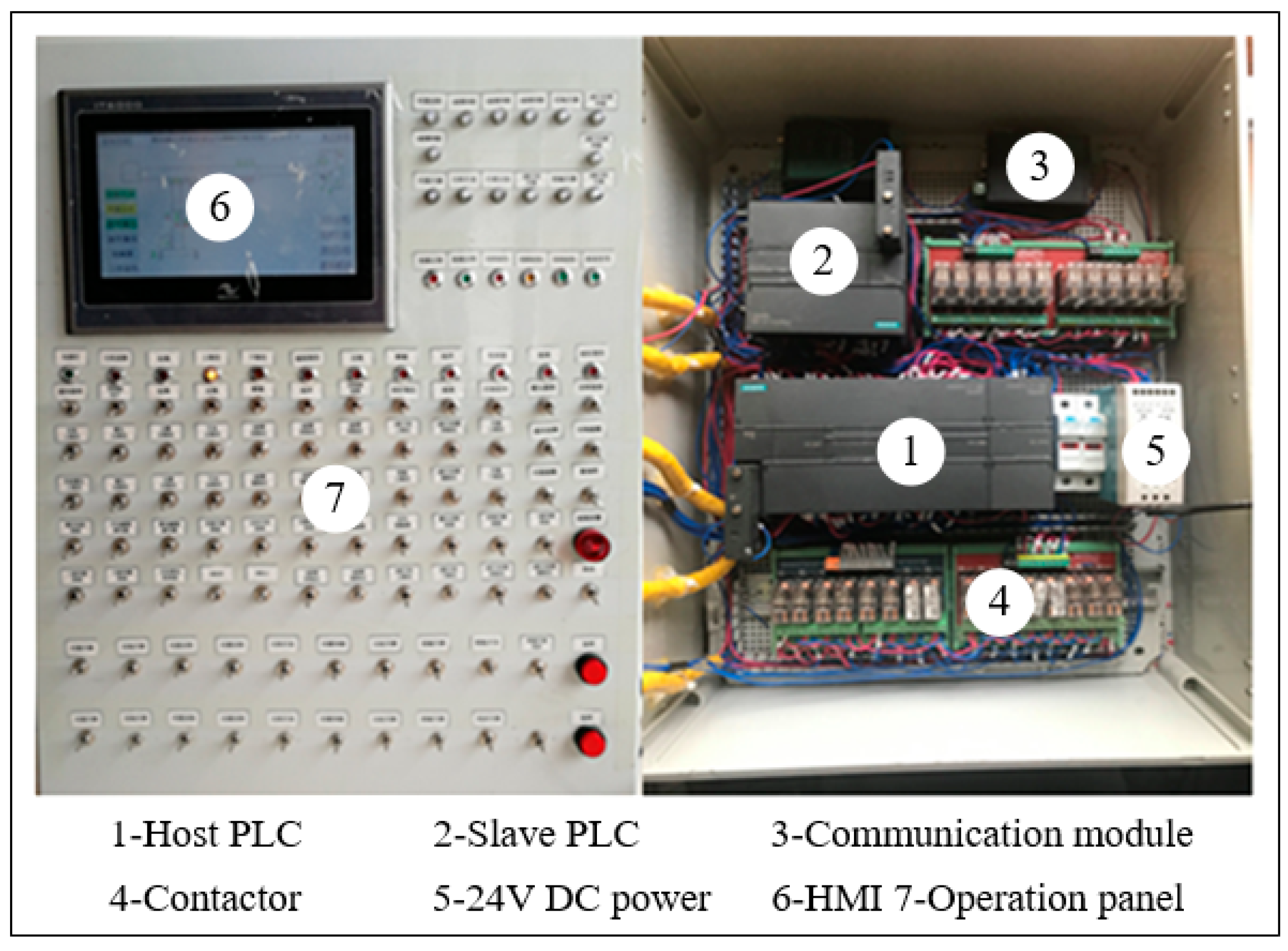

3.1. Establishment of the Testing System

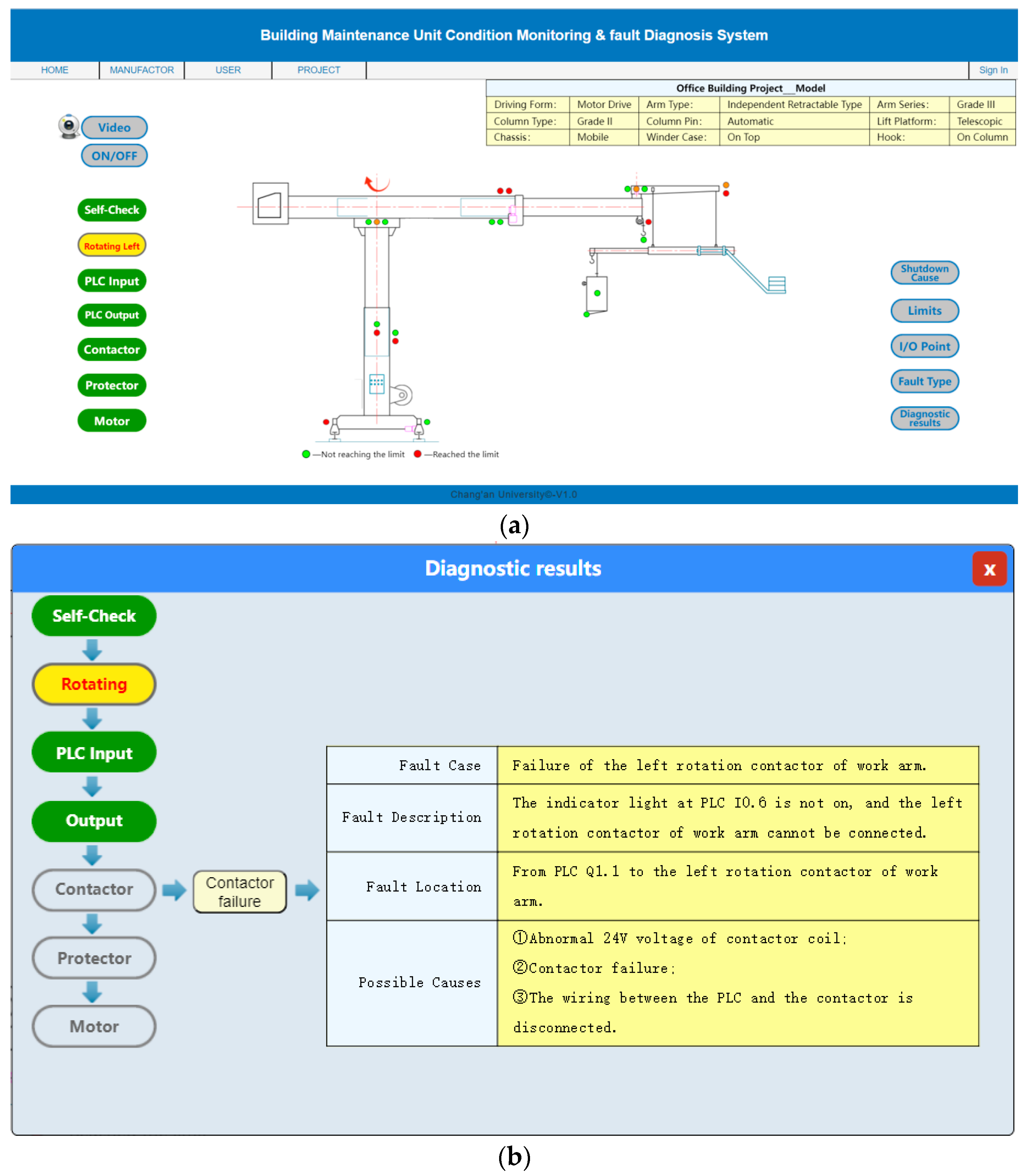

3.2. Application Simulation Analysis

3.3. Result Analysis

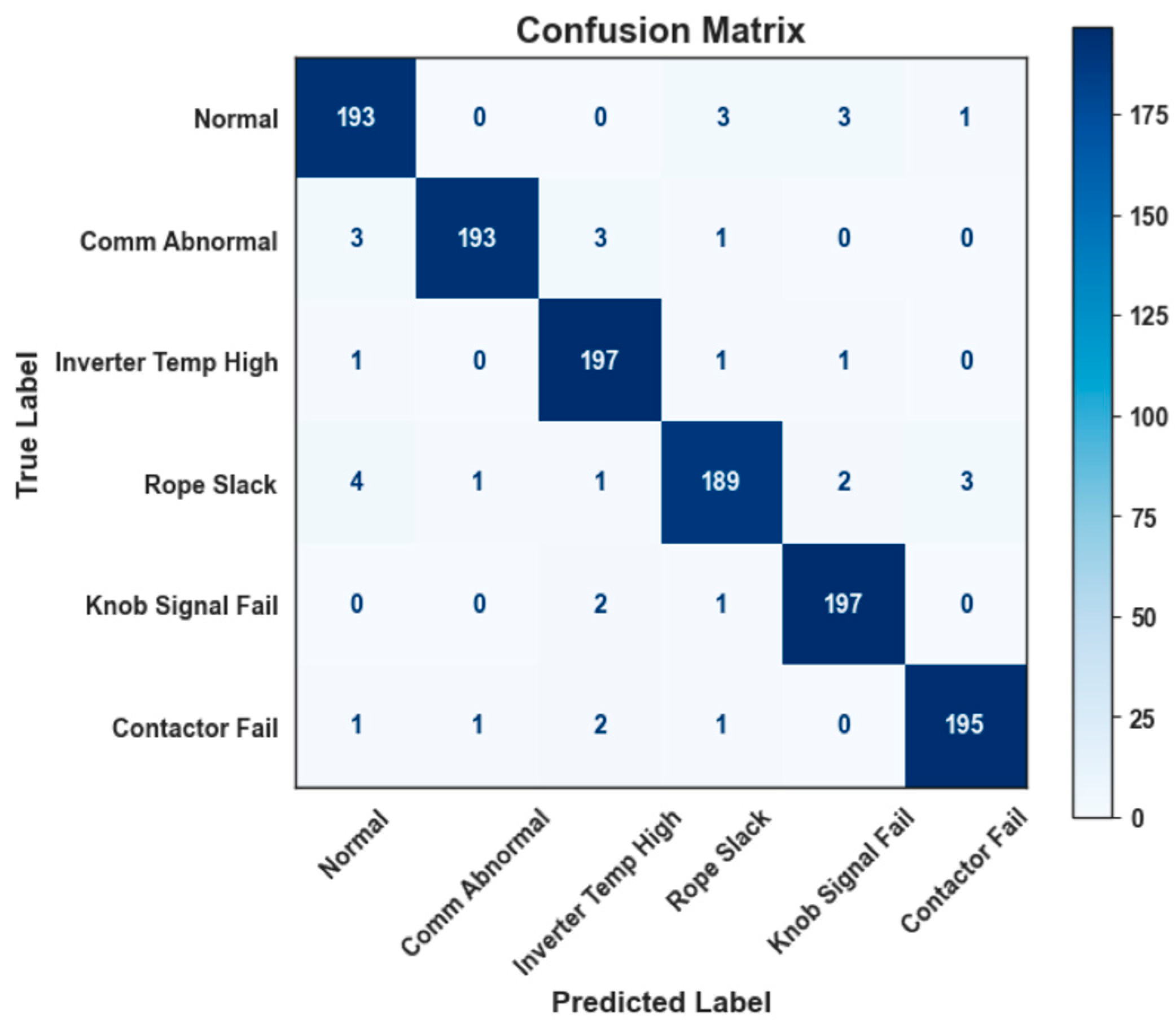

- Category 0: Normal Operation

- Category 1: Host Communication Abnormality

- Category 2: Inverter Fault—Excessive Temperature

- Category 3: Rope Slack Fault

- Category 4: No Input Signal—Knob Contact Malfunction

- Category 5: Contactor Failure—Left Rotate as an Example

3.3.1. Diagnostic Performance Evaluation

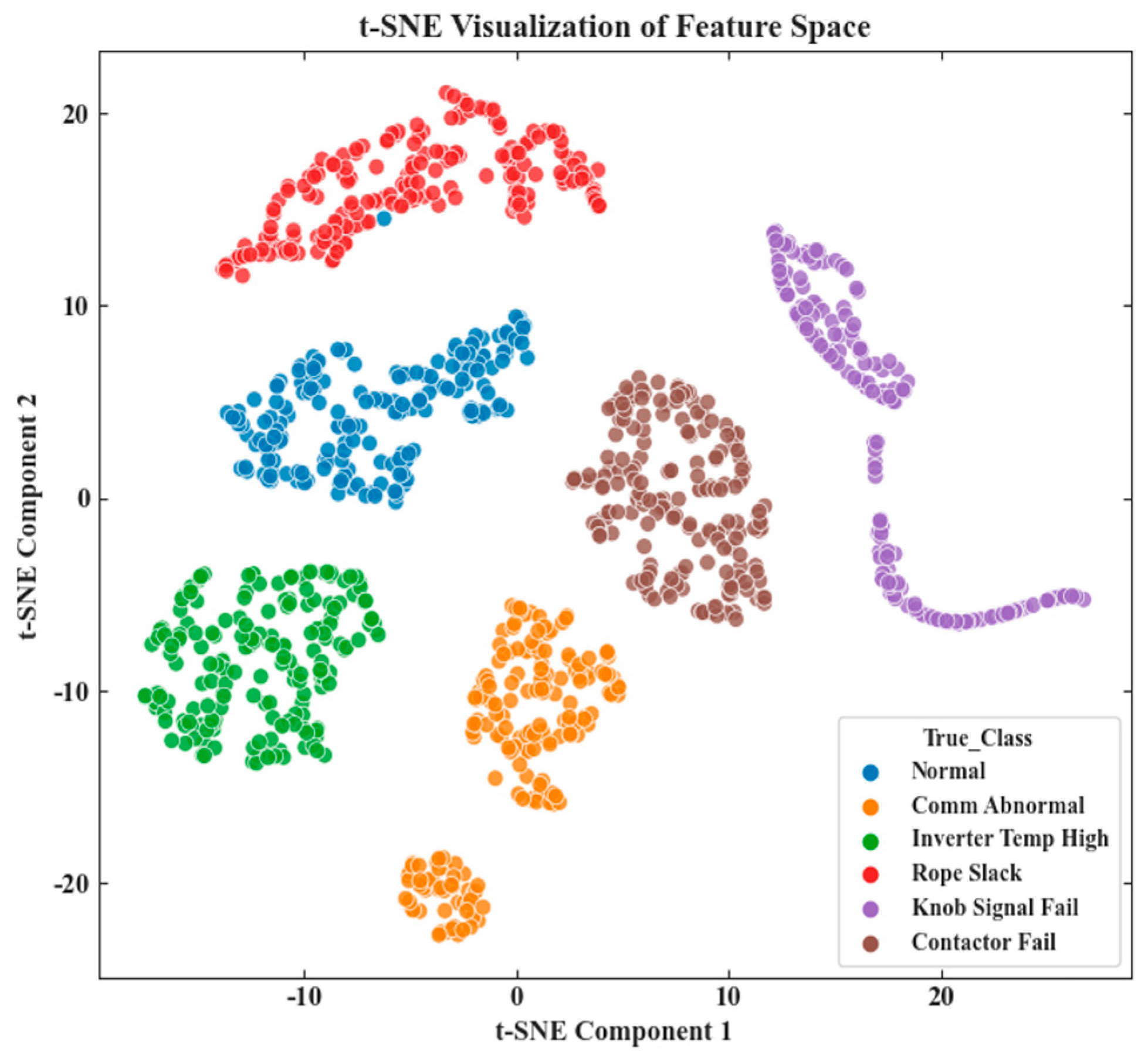

3.3.2. Feature Effectiveness Analysis

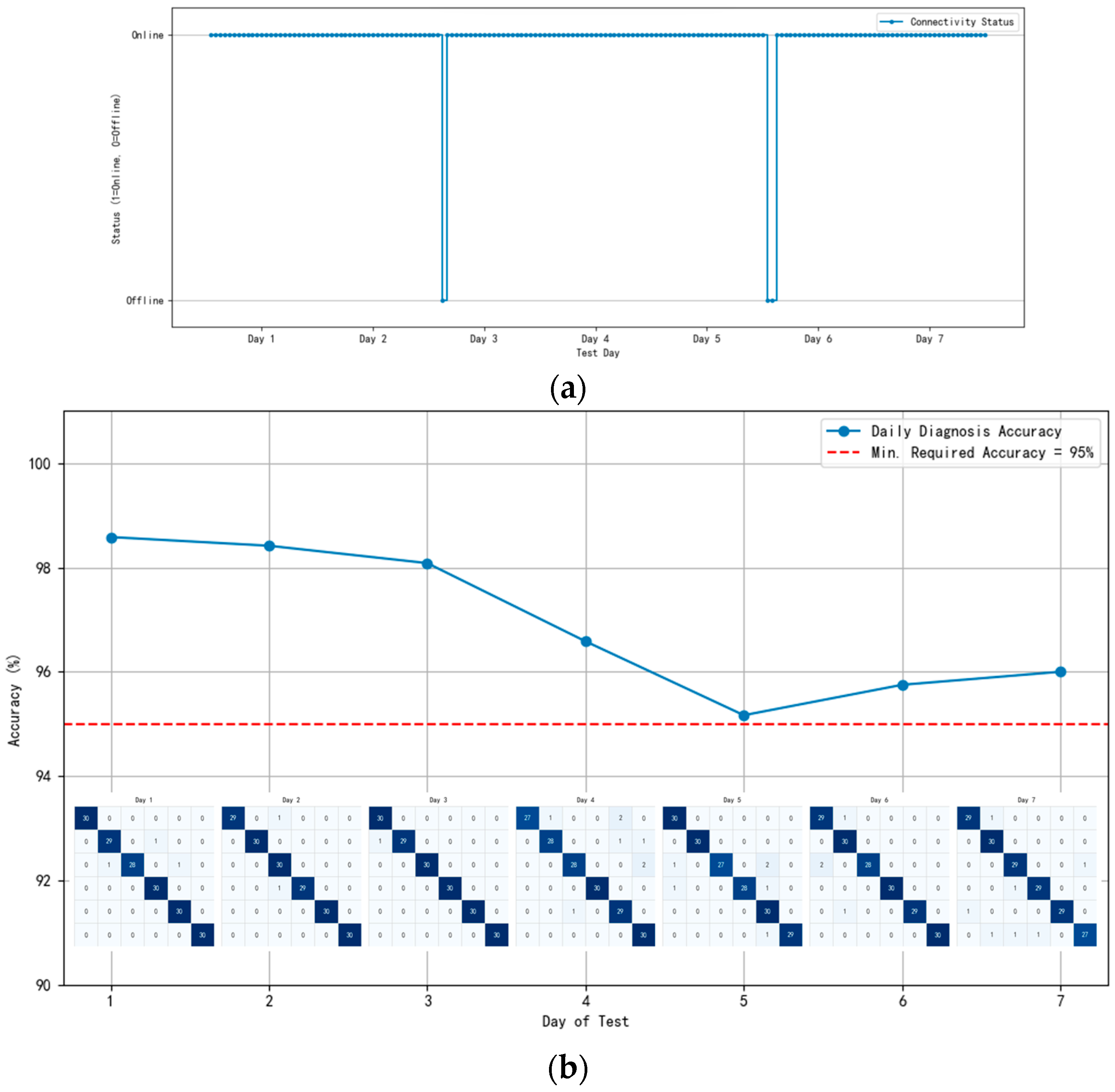

3.3.3. Stability Analysis

4. Conclusions

- (1)

- Although this study proposes IoT-based data collection to address insufficient samples, the process remains time-consuming. Future improvements could incorporate evolutionary learning mechanisms and data augmentation techniques to expand the sample size, thereby obtaining more accurate real-time data and refining the fault diagnosis correlation model.

- (2)

- The current fault diagnosis method focuses on outputting real-time status results and root cause analysis for BMU but lacks preventive recommendations. The system could integrate multi-axis force sensors and machine learning algorithms to analyze structural wear, enabling predictive maintenance strategies and establishing a comprehensive intelligent maintenance framework for BMUs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| IOT | Internet of Things |

| BMUs | Building Maintenance Units |

| TCP/IP | Transmission Control Protocol/Internet Protocol |

| MQTT | Message Queuing Telemetry Transport |

| API | Application Programming Interface |

| KD | Knowledge Driven |

| DD | Data-Driven |

| CM | Condition Monitoring |

| FD | Fault Diagnosis |

| MASs | Multi-Agent Systems |

| HVAC | Heating, Ventilation and Air Conditioning |

| OAMP | Orthogonal Approximate Message Passing |

| JSON | JavaScript Object Notation |

| PLC | Programmable Logic Controller |

| HMI | Human Machine Interface |

References

- Lee, Y.S.; Kim, S.H.; Gil, M.S.; Lee, S.H.; Kang, M.S.; Jang, S.H.; Yu, B.H.; Ryu, B.G.; Hong, D.; Han, C.S. The study on the integrated control system for curtain wall building facade cleaning robot. Autom. Constr. 2018, 94, 39–46. [Google Scholar] [CrossRef]

- Fang, X.; Yang, X.; Xing, X.; Wang, J.; Umer, W.; Guo, W. Real-Time Monitoring of Mental Fatigue of Construction Workers Using Enhanced Sequential Learning and Timeliness. Autom. Constr. 2024, 159, 105267. [Google Scholar] [CrossRef]

- NU Ahmed, Optimal control and stabilization of building maintenance units based on minimum principle. J. Ind. Manag. Optim. 2021, 17, 1713–1727. [CrossRef]

- Pandithawatta, S.; Ahn, S.; Rameezdeen, R.; Chow, C.W.K.; Gorjian, N. Systematic Literature Review on Knowledge-Driven Approaches for Construction Safety Analysis and Accident Prevention. Buildings 2024, 14, 3403. [Google Scholar] [CrossRef]

- AlShorman, O.; Irfan, M.; Abdelrahman, R.E.; Masadeh, M.; Alshorman, A.; Sheikh, M.A.; Saad, N.; Rahman, S. Advancements in condition monitoring and fault diagnosis of rotating machinery: A comprehensive review of image-based intelligent techniques for induction motors. Eng. Appl. Artif. Intell. 2024, 130, 107724. [Google Scholar] [CrossRef]

- Cai, S.; Ma, Z.; Skibniewski, M.J.; Bao, S. Construction automation and robotics for high-rise buildings over the past decades: A comprehensive review. Adv. Eng. Inform. 2019, 42, 100989. [Google Scholar] [CrossRef]

- Es-sakali, N.; Zoubir, Z.; Kaitouni, S.I.; Mghazli, M.O.; Cherkaoui, M.; Pfafferott, J. Advanced predictive maintenance and fault diagnosis strategy for enhanced HVAC efficiency in buildings. Appl. Therm. Eng. 2024, 254, 123910. [Google Scholar] [CrossRef]

- Sahu, A.R.; Palei, S.K.; Mishra, A. Data-driven fault diagnosis approaches for industrial equipment: A review. Expert Syst. 2024, 41, e13360. [Google Scholar] [CrossRef]

- Yan, R.; Zhou, Z.; Shang, Z.; Wang, Z.; Hu, C.; Li, Y.; Yang, Y.; Chen, X.; Gao, R.X. Knowledge Driven Machine Learning Towards Interpretable Intelligent Prognostics and Health Management: Review and Case Study. Chin. J. Mech. Eng. 2025, 38, 5. [Google Scholar] [CrossRef]

- Hasan, S.M.; Lee, K.; Moon, D. Augmented reality and digital twin system for interaction with construction machinery. J. Asian Archit. Build. Eng. 2022, 21, 564–574. [Google Scholar] [CrossRef]

- Narasimhan, S.; Biswas, G. Model-based diagnosis of hybrid systems. IEEE Trans. Syst. Man Cybern.-Part A Syst. Hum. 2007, 37, 348–361. [Google Scholar] [CrossRef]

- Wilhelm, Y.; Reimann, P.; Gauchel, W.; Mitschang, B. Overview on hybrid approaches to fault detection and diagnosis: Combining data-driven, physics-based and knowledge-based models. Procedia Cirp 2021, 99, 278–283. [Google Scholar] [CrossRef]

- Li, R.; Jiang, B.; Zong, Y.; Lu, N.; Guo, L. Distributed Fault Diagnosis for Heterogeneous Multiagent Systems: A Hybrid Knowledge-Based and Data-Driven Method. IEEE Trans. Fuzzy Syst. 2024, 32, 4940–4949. [Google Scholar] [CrossRef]

- Hassanpour, H.; Hamedi, A.H.; Mhaskar, P.; House, J.M.; Salsbury, T.I. A hybrid clustering approach integrating first-principles knowledge with data for fault detection in HVAC systems. Comput. Chem. Eng. 2024, 187, 108717. [Google Scholar] [CrossRef]

- Li, H.; He, Y.; Zheng, S.; Zhou, F.; Yang, H. Dual-Driven Learning-Based Multiple-Input Multiple-Output Signal Detection for Unmanned Aerial Vehicle Air-to-Ground Communications. Drones 2024, 8, 180. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, M.; Wang, H.; Ye, X.; Ma, X. Sample-Evaluation-Enhanced Machine Learning Approach for Fault Diagnosis of Hybrid Systems. IEEE Trans. Instrum. Meas. 2024, 73, 3527313. [Google Scholar] [CrossRef]

- Peng, J.; Andreas, K.; Wang, D.; Niu, Z.; Zhi, F.; Wang, J.; Liu, X.; Ovtcharova, J. A systematic review of data-driven approaches to fault diagnosis and early warning. J. Intell. Manuf. 2023, 34, 3277–3304. [Google Scholar]

- Cheng, Y.; Gu, H.; Suo, M. A normal-fault sample translator for fault diagnosis with insufficient fault samples. Expert Syst. Appl. 2025, 266, 126109. [Google Scholar] [CrossRef]

- Gupta, V.; Sharma, M.; Pachauri, R.; Babu, K.D. Performance analysis of solar PV system using customize wireless data acquisition system and novel cleaning technique. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 2748–2769. [Google Scholar] [CrossRef]

- Yousuf, M.; Alsuwian, T.; Amin, A.A.; Fareed, S.; Hamza, M. IoT-based health monitoring and fault detection of industrial AC induction motor for efficient predictive maintenance. Meas. Control. 2024, 57, 1146–1160. [Google Scholar] [CrossRef]

- Jacome, F.; Andagoya-Alba, L.D.; Osorio, H.; Paredes, E. Real-time fault identification of photovoltaic systems based on remote monitoring with IoT. Int. J. Electr. Comput. Eng. Syst. 2024, 15, 225–234. [Google Scholar] [CrossRef]

- Lu, X.; Lu, Y.; Luo, L.; Lin, W.; Zhang, J. Remote data acquisition and management technology of power equipment based on Internet of Things. Mob. Inf. Syst. 2022, 2022, 3902541. [Google Scholar] [CrossRef]

- Hirsch, V.; Reimann, P.; Mitschang, B. Data-Driven Fault Diagnosis in End-of-Line Testing of Complex Products. In Proceedings of the 2019 IEEE International Conference on Data Science and Advanced Analytics (DSAA), Washington, DC, USA, 5–8 October 2019; pp. 492–503. [Google Scholar]

- Yusri, I.K. Solar panel remote monitoring and control system on miniature weather stations based on web server and ESP32. Int. J. Recent Technol. Appl. Sci. 2020, 2, 1–24. [Google Scholar]

- Li, W.J.; Li, H.; Gu, S.; Chen, T. Process fault diagnosis with model- and knowledge-based approaches: Advances and opportunities. Buildings 2020, 105, 104637. [Google Scholar] [CrossRef]

- Nayeri, M.R.; Araabi, B.N.; Yazdanpanah, M.; Moshiri, B. Design, implementation and evaluation of an expert system for operating regime detection in industrial gas turbine. Expert Syst. Appl. 2022, 203, 117332. [Google Scholar] [CrossRef]

- Motawa, I.; Almarshad, A. A knowledge-based BIM system for building maintenance. Autom. Constr. 2013, 29, 173–182. [Google Scholar] [CrossRef]

- Farooqi, N. Tackling Approach for Transferring Database to Knowledge Base via Practical Algorithm. Life Sci. J. 2019, 16, 6. [Google Scholar]

- Van Glabbeek, R.; Deac, D.; Perale, T.; Steenhaut, K.; Braeken, A. Flexible and Efficient Security Framework for Many-to-Many Communication in a Publish/Subscribe Architecture. Sensors 2022, 22, 7391. [Google Scholar] [CrossRef]

| Fault Type | Phenomenon | Cause |

|---|---|---|

| Abnormal self-check | Host communication abnormality | Communication line disconnected; the communication module is damp. |

| Inverter fault | Voltage too high; excessive temperature; excessive humidity leads to internal short circuit. | |

| Rope slack fault | Wear and tear of the rope-loosening mechanism. | |

| Overspeed protection failure | Brake disk wear; overspeed detection failure. | |

| Chain breakage | Wear and tear; overload; improper installation leads to unstable splicing. | |

| No input signal | Knob contact malfunction | Poor contact of contacts caused by moisture, arcing, and dust. |

| The wiring is disconnected | Loose joints; broken due to external force. | |

| No output signal | The device has no action | Equipment action output conditions not met. |

| Action limit switch failure | Internal short circuit or open circuit caused by water ingress and aging. | |

| Contactor failure | Contactor failure | Excessive loads lead to arc breakdown; high humidity causes internal moisture. |

| Motor protector failure | Motor protector failure | Long-term high temperatures lead to aging; excessive humidity on the rooftop leads to a decrease in insulation performance. |

| Motor failure | Motor failure | Unstable voltage, high temperature, and moisture. |

| Hydraulic system failure | Hydraulic valve malfunction | Poor assembly quality and clogged valve core. |

| Hydraulic pipeline damage | External damage and corrosion. | |

| Hydraulic joint leakage | Damaged seals; improper installation; corrosion; high-voltage impact. |

| Item | Quantity | Description |

|---|---|---|

| Simulation control system of the BMU | 1 | The control system simulating the working state of the BMU. |

| Communication module | 1 | The gateway to transfer data to the cloud server. |

| Cloud server | 1 | The platform for providing cloud services. |

| Laptop | 1 | The device to log in to the client for monitoring. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, B.; Liu, K.; Lei, C.; Song, R. Remote Monitoring and Diagnosis for Building Maintenance Units Based on Internet of Things System. Appl. Sci. 2025, 15, 4829. https://doi.org/10.3390/app15094829

Dong B, Liu K, Lei C, Song R. Remote Monitoring and Diagnosis for Building Maintenance Units Based on Internet of Things System. Applied Sciences. 2025; 15(9):4829. https://doi.org/10.3390/app15094829

Chicago/Turabian StyleDong, Boqian, Kai Liu, Chunli Lei, and Ruizhe Song. 2025. "Remote Monitoring and Diagnosis for Building Maintenance Units Based on Internet of Things System" Applied Sciences 15, no. 9: 4829. https://doi.org/10.3390/app15094829

APA StyleDong, B., Liu, K., Lei, C., & Song, R. (2025). Remote Monitoring and Diagnosis for Building Maintenance Units Based on Internet of Things System. Applied Sciences, 15(9), 4829. https://doi.org/10.3390/app15094829