Eco-Designing Cosmetic Products while Preserving the Sensorial-Application Properties: An Instrumental Approach toward Sustainable Formulations

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Emulsions

2.3. Stability Assessment

2.4. Rheological Analysis

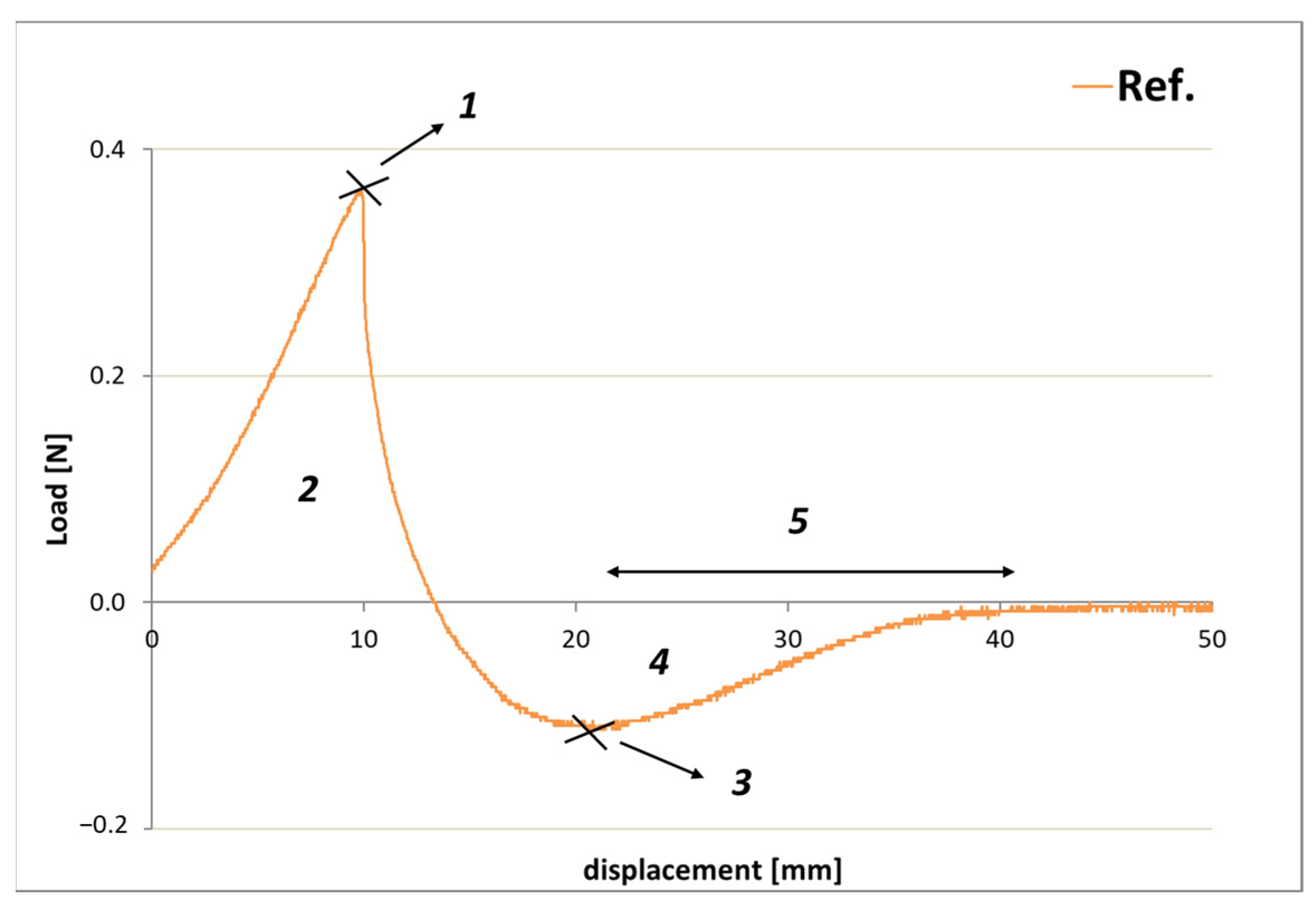

2.5. Texture Analysis

2.6. Sensory Analysis and Statistical Analysis

- -

- Color: from 1 (yellowish) to 7 (greyish) through 4 (white);

- -

- Consistency at first touch: from 1 (fluid) to 7 (very consistent);

- -

- Spreadability: from 1 (not spreadable) to 7 (very spreadable);

- -

- Rate of absorption: from 1 (very slow) to 7 (very fast);

- -

- Greasiness: from 1 (not greasy) to 7 (very greasy);

- -

- Stickiness: from 1 (not sticky) to 7 (very sticky);

- -

- Softness of the skin after application: from (not soft) to 7 (very soft).

3. Results and Discussions

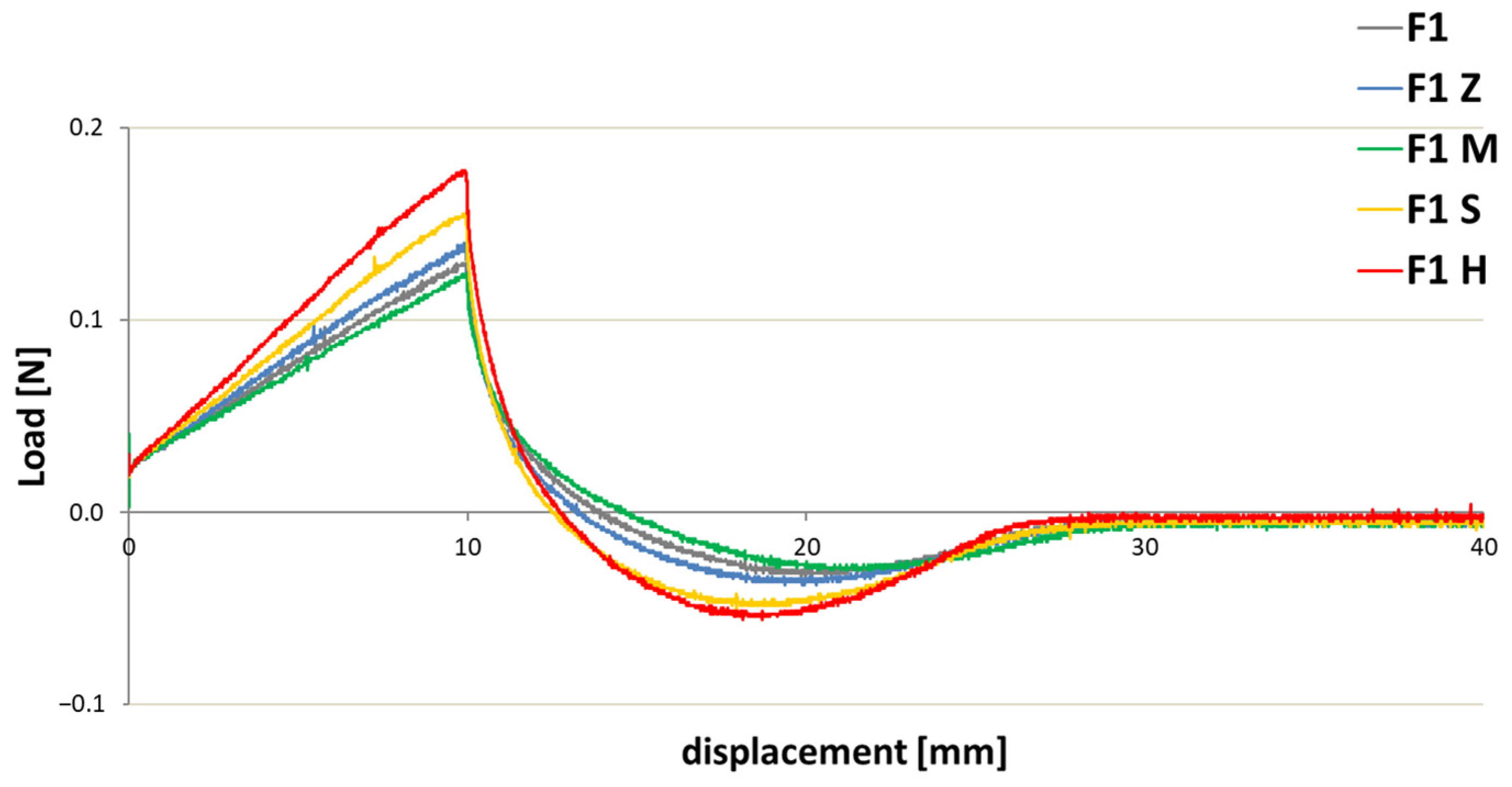

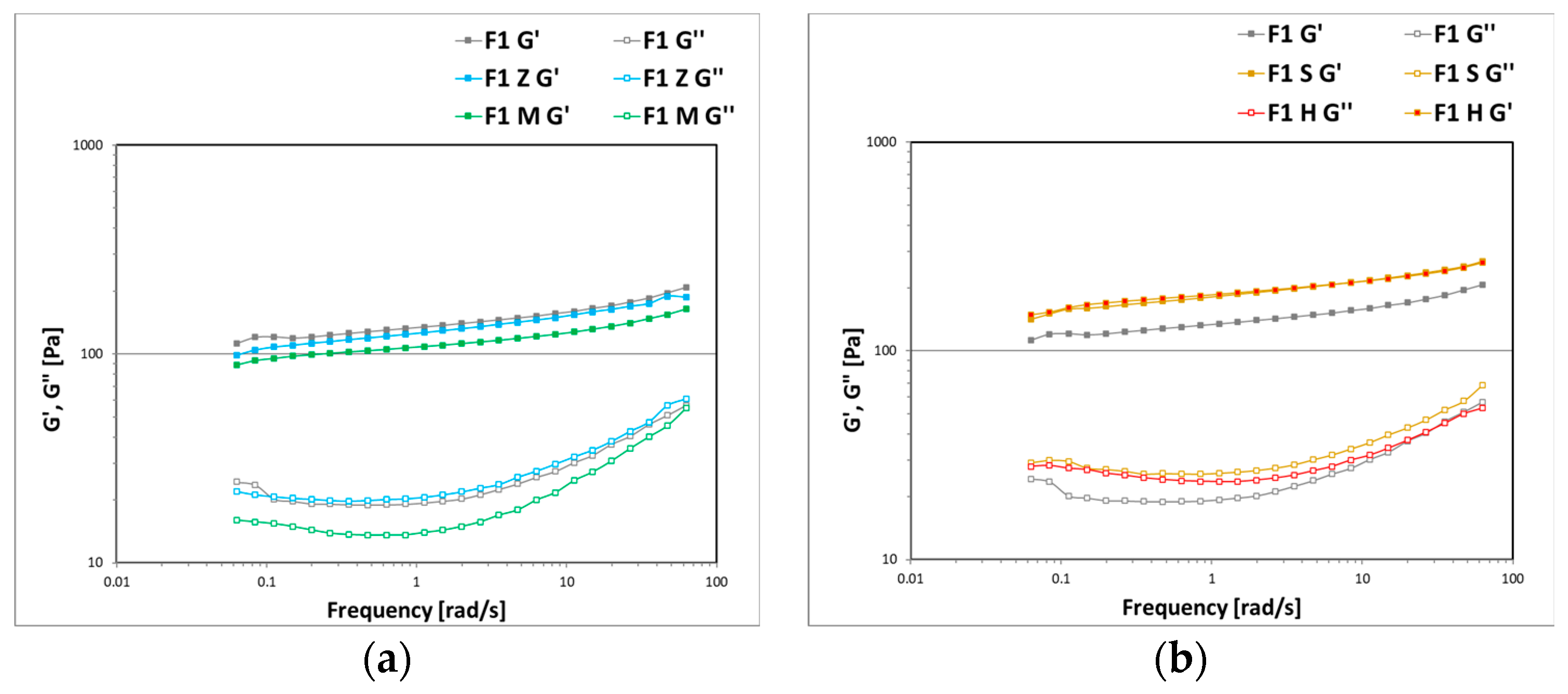

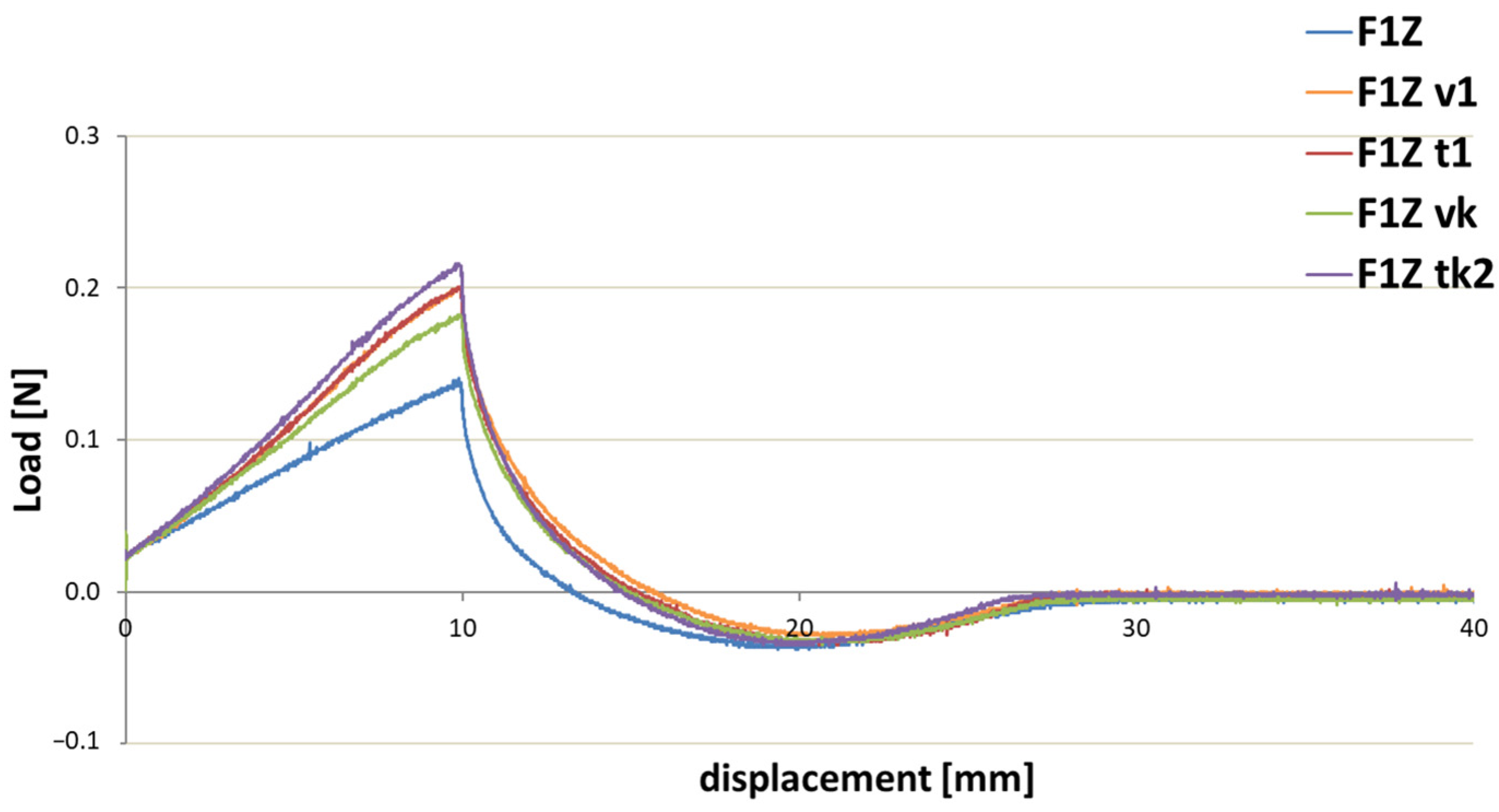

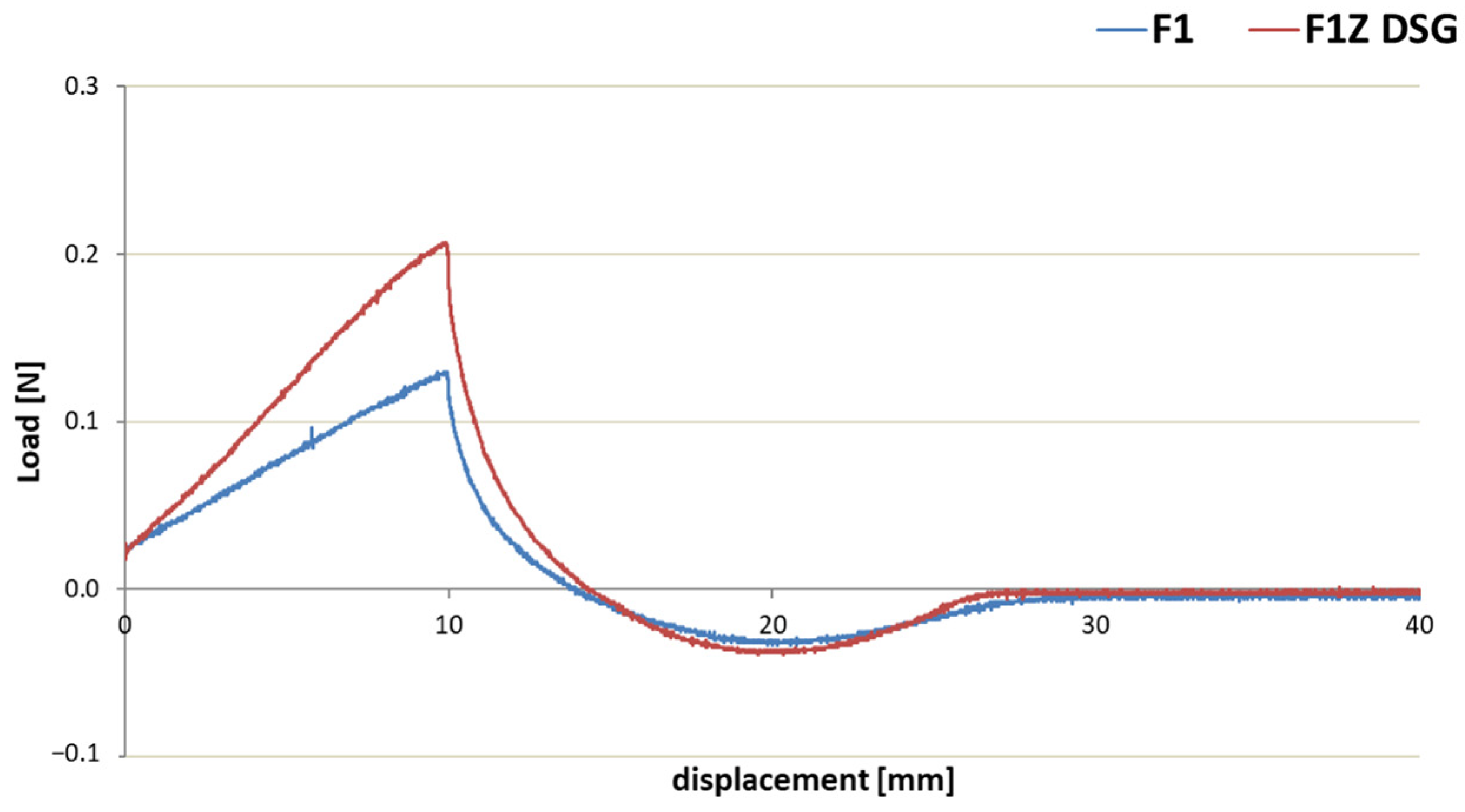

3.1. Reformulation of Product F1

3.1.1. Substitution of Synthetic Texturizers

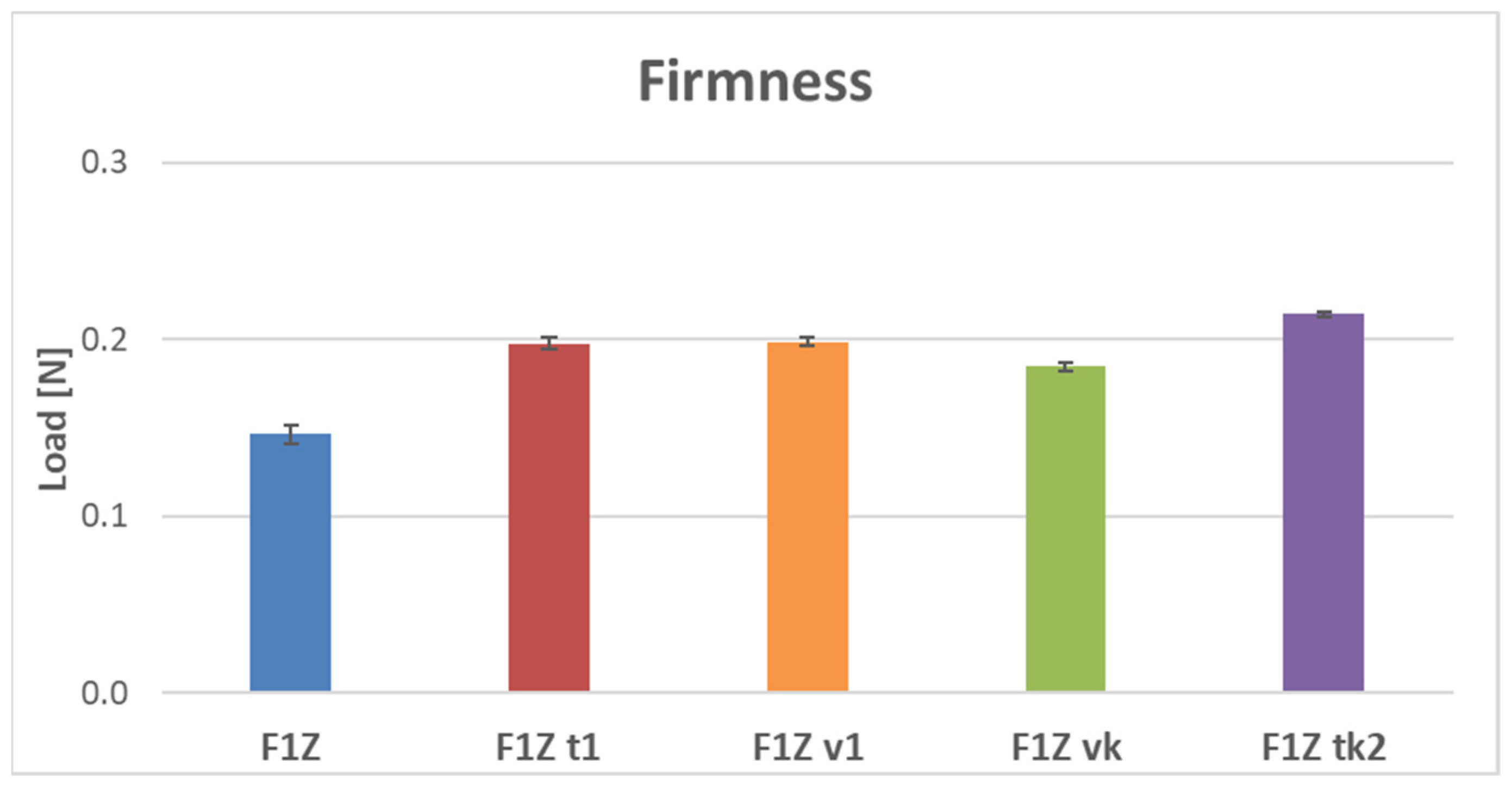

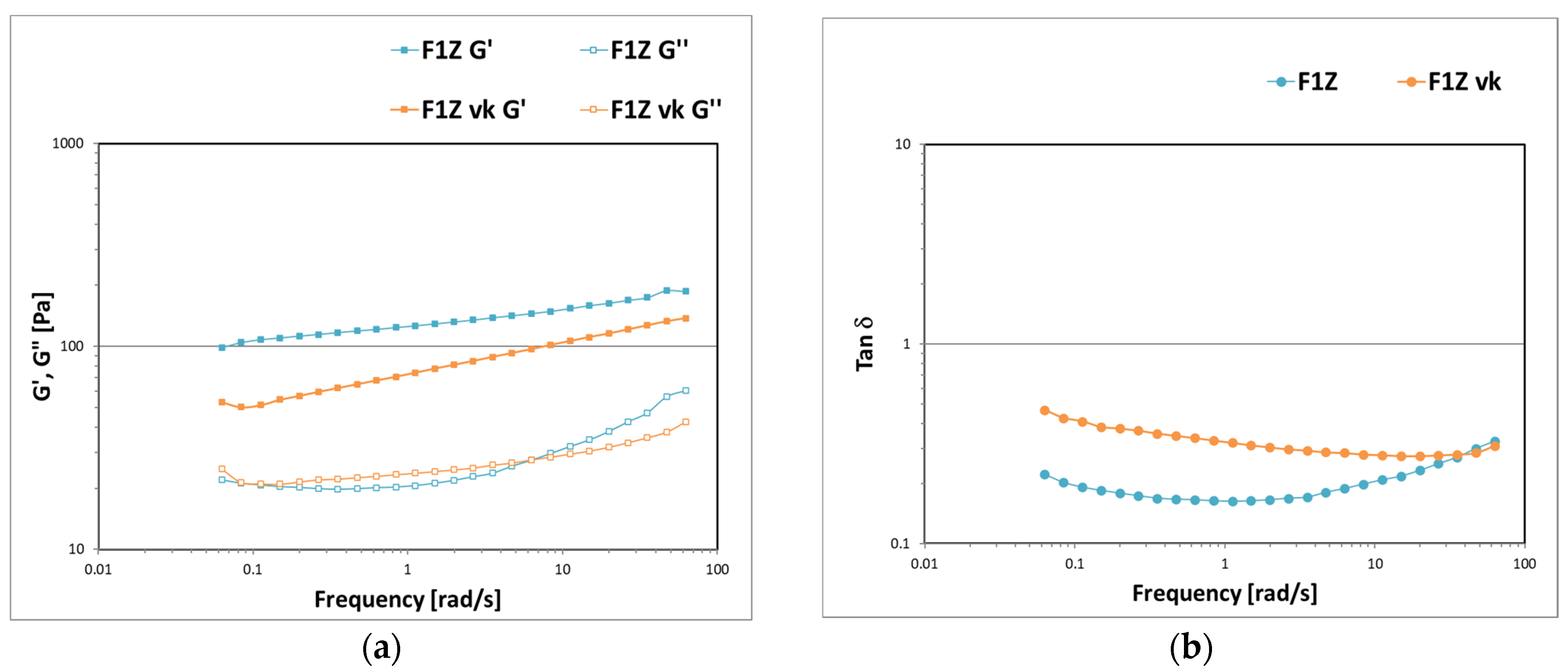

3.1.2. Substitution of Acrylic Rheological Modifiers

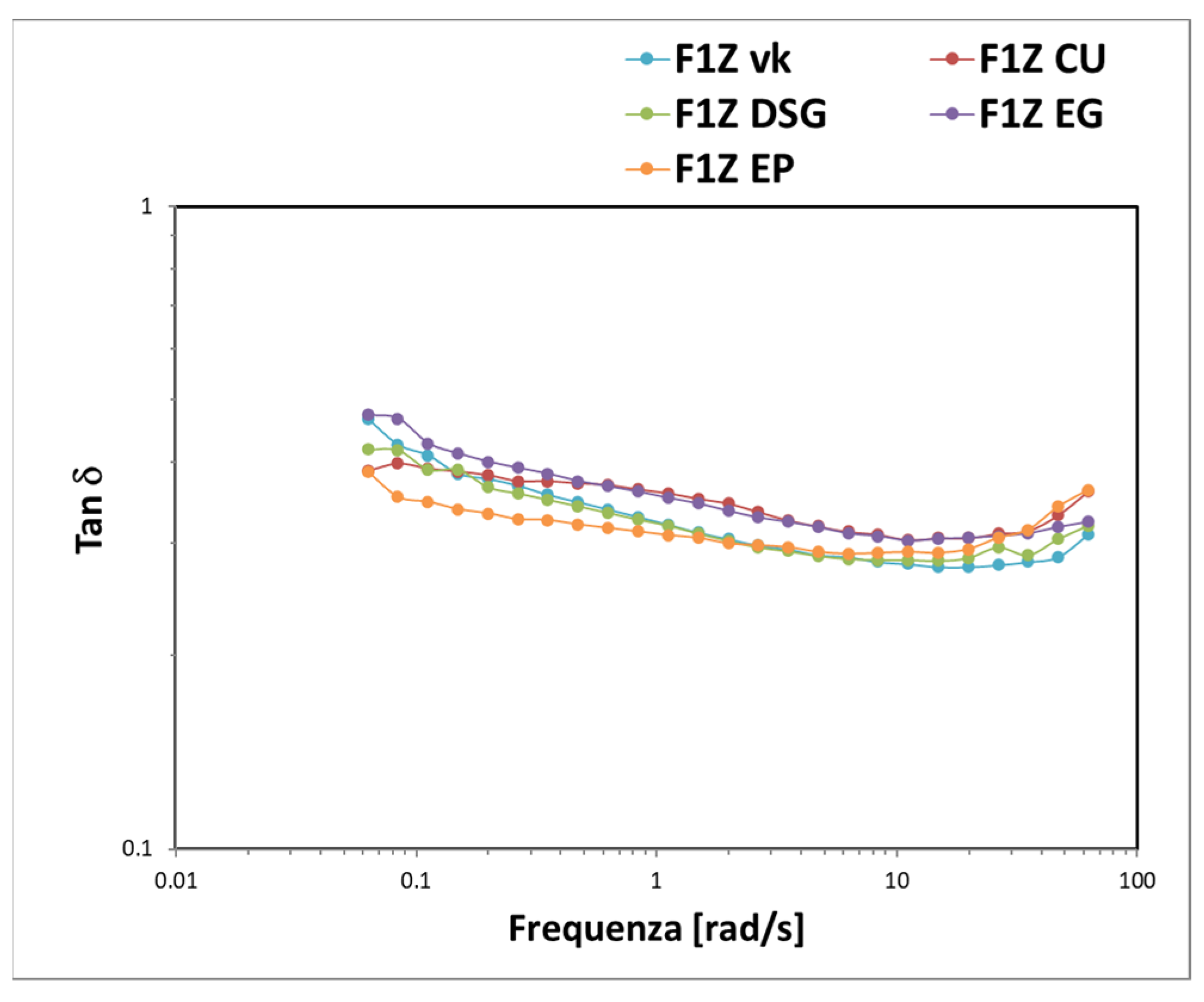

3.1.3. Substitution of Silicone Emollients

3.2. Reformulation of Product F2

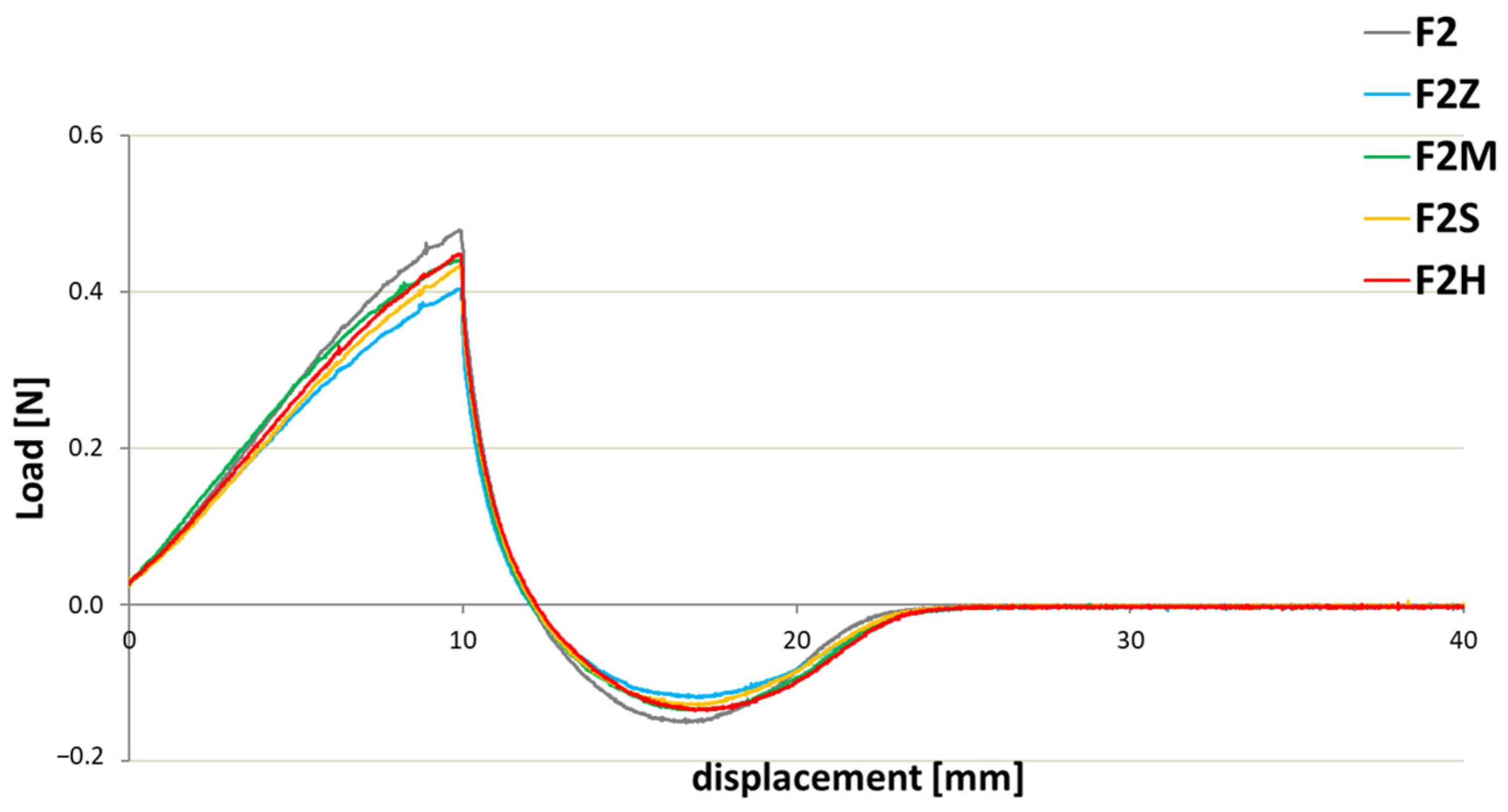

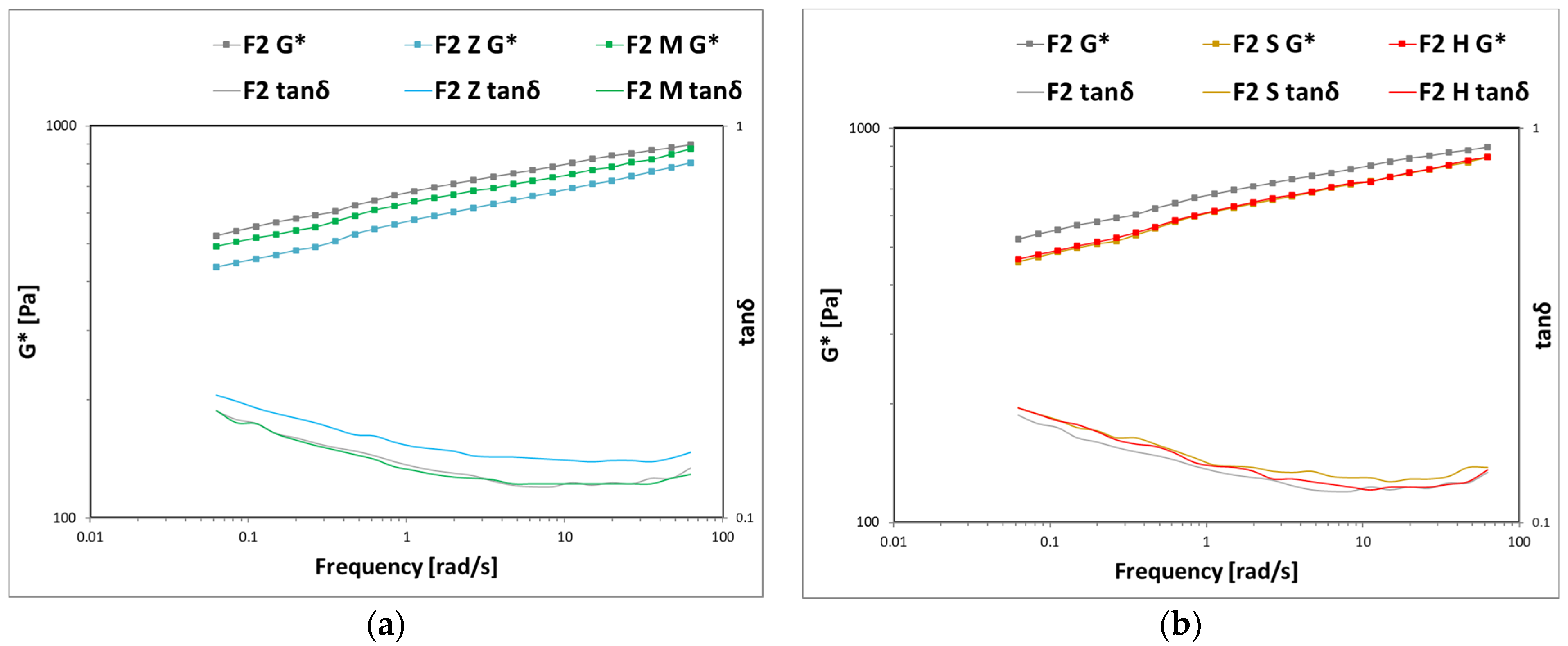

3.2.1. Substitution of Synthetic Texturizers

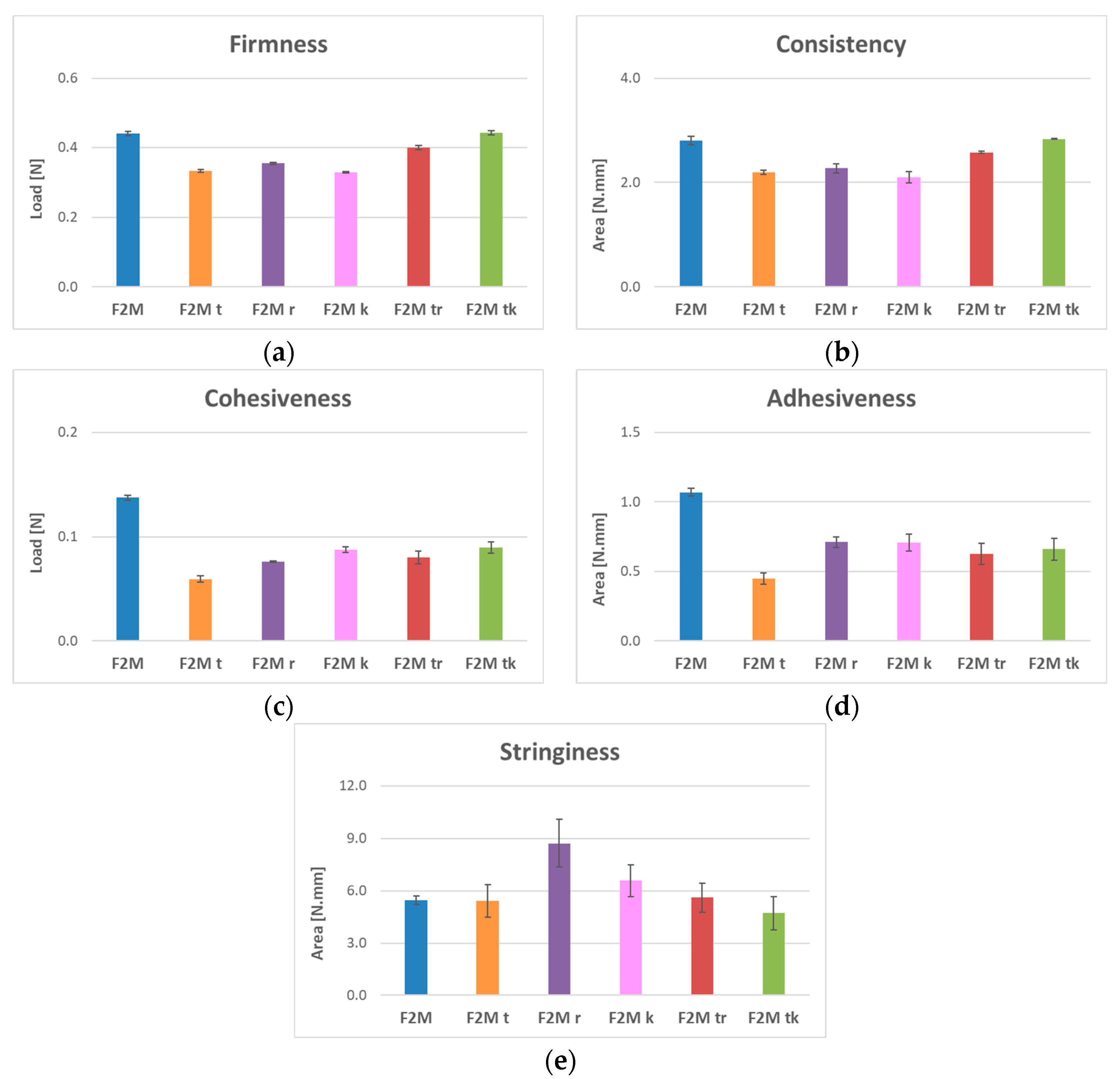

3.2.2. Substitution of Acrylic Rheological Modifiers

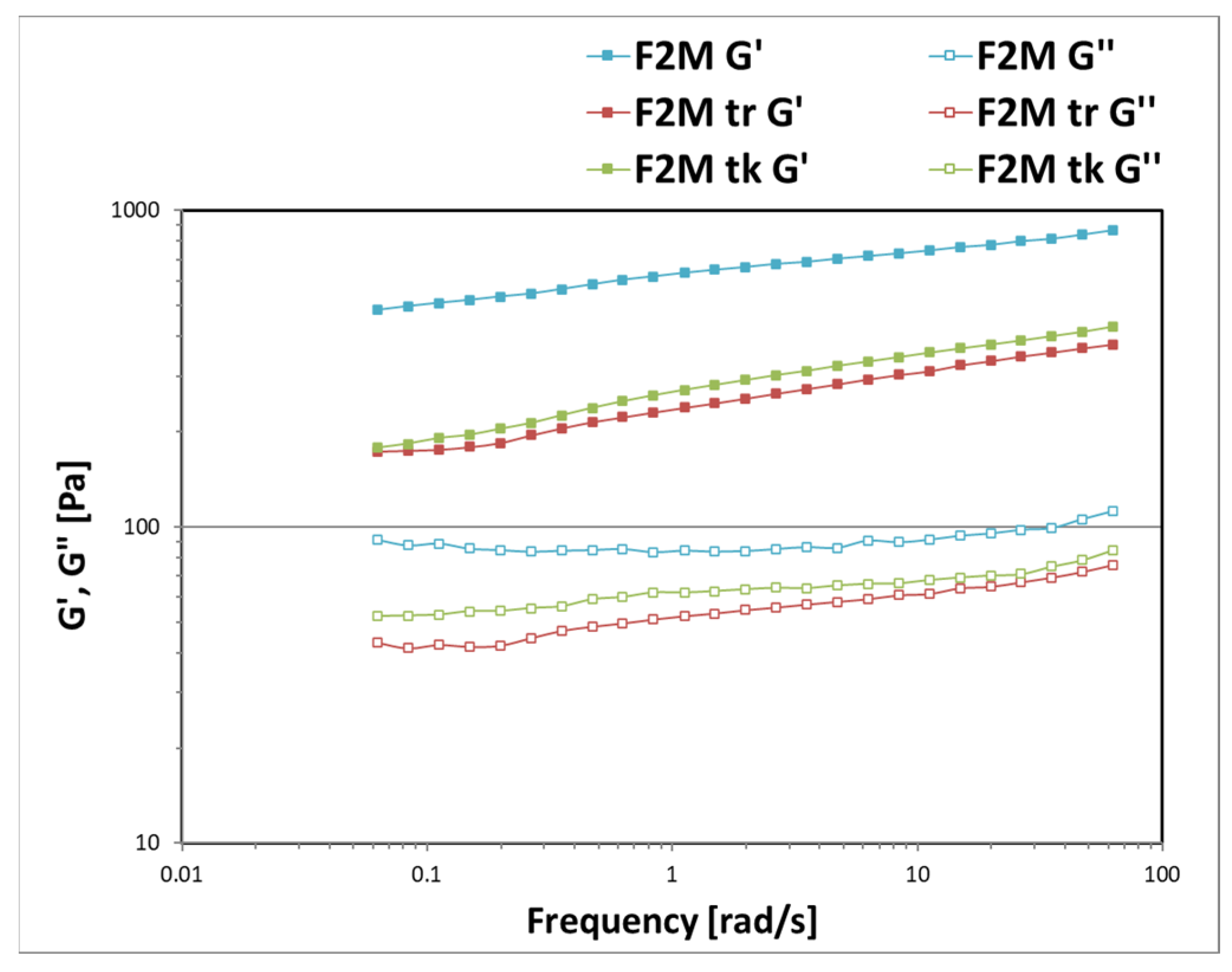

3.2.3. Substitution of Silicone Emollients

3.3. Reformulation of Product F3

3.3.1. Substitution of Synthetic Texturizers

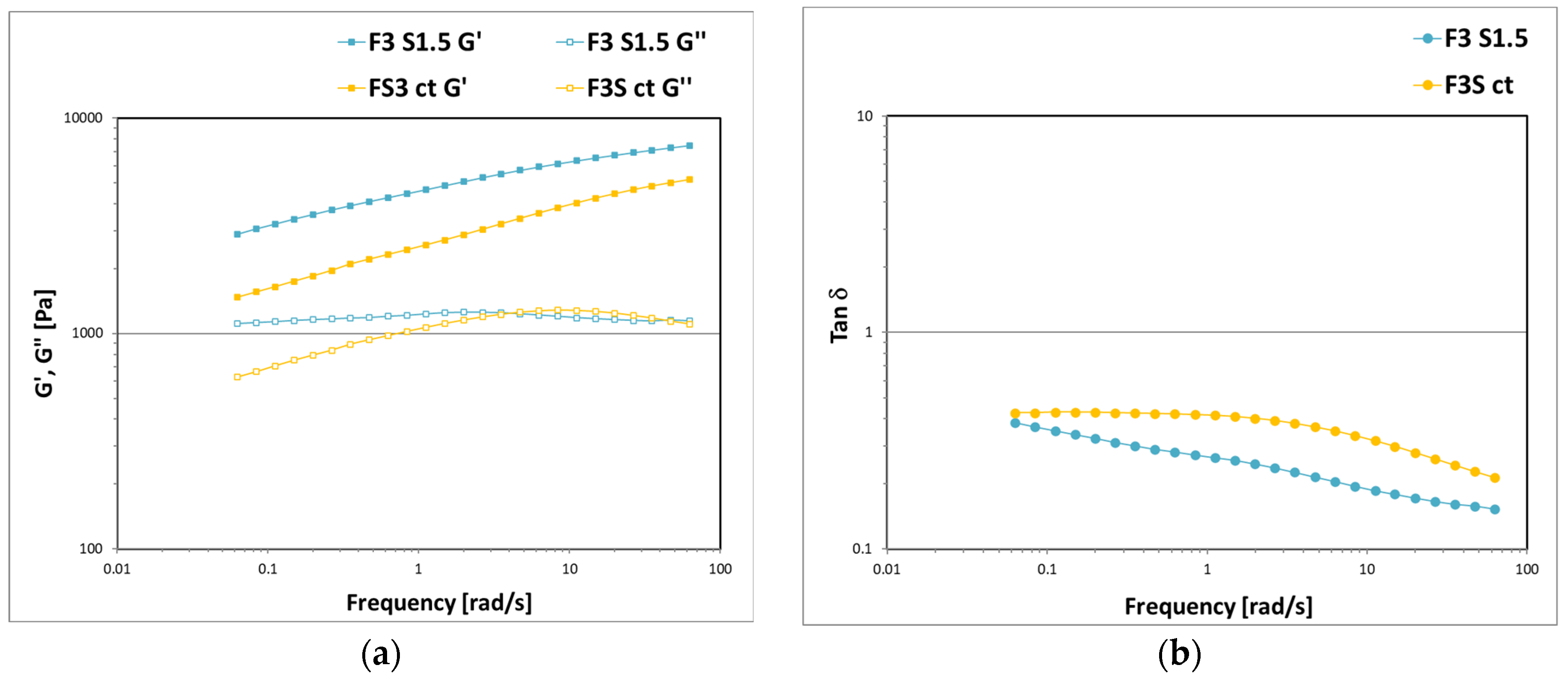

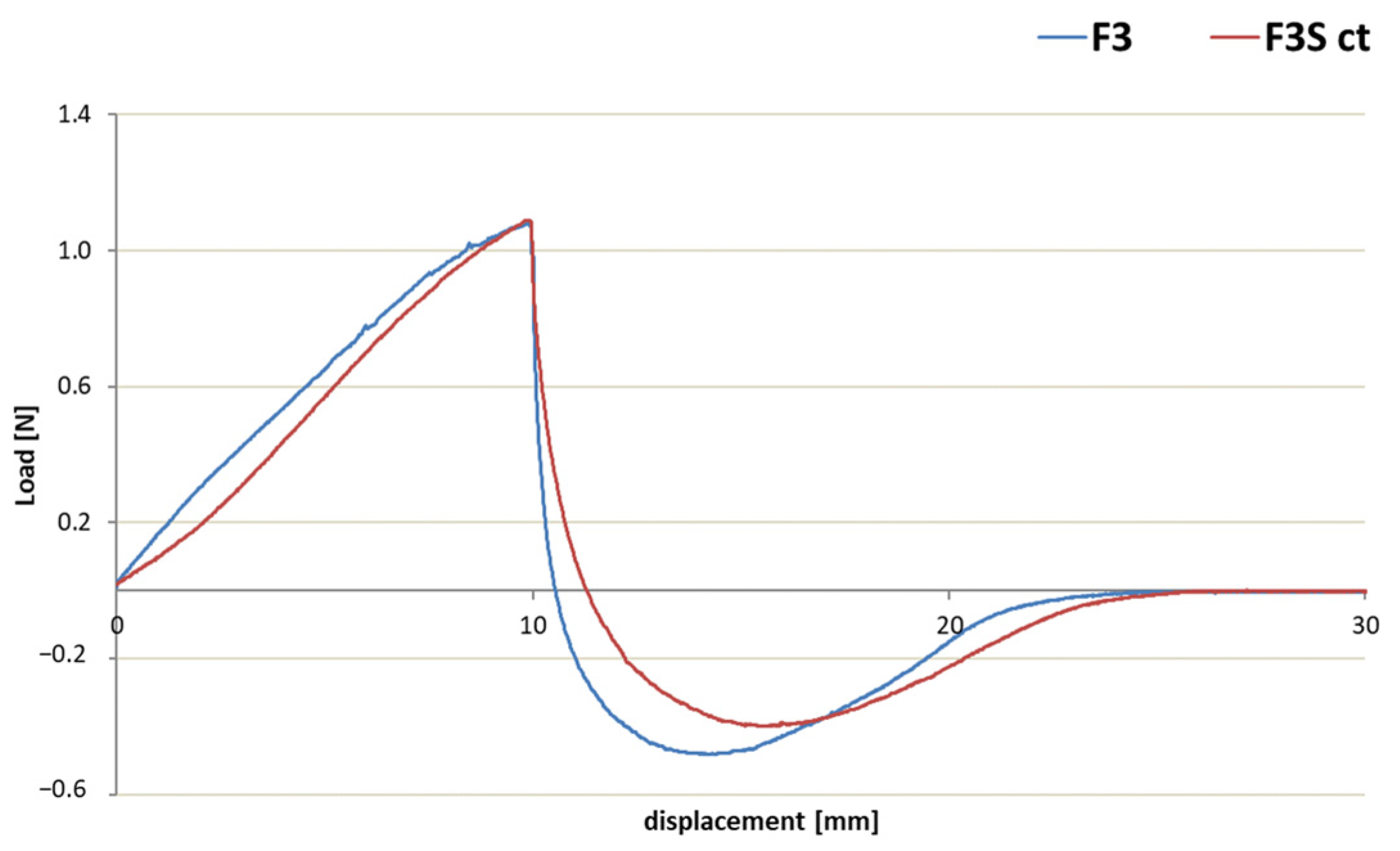

3.3.2. Substitution of Acrylic Rheological Modifiers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schneiders, B.; Anklin, F. The social impact of a cosmetics company. In Sustainability: How the Cosmetics Industry Is Greening up; Sahota, A., Ed.; John Wiley & Sons, Ltd.: London, UK, 2014; pp. 47–68. [Google Scholar]

- L’Haridon, J.L.; Martz, P.; Chenéble, J.C.; Campion, J.F.; Colombe, L. Ecodesign of cosmetic formulae: Methodology and application. Int. J. Cosmet. Sci. 2018, 40, 165–177. [Google Scholar] [CrossRef] [PubMed]

- ISO/TR 14006:2020 Environmental Management Systems—Guidelines for Incorporating Ecodesign. 2020. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14006:ed-2:v1:en (accessed on 15 March 2024).

- Szaban, R. Internal factors influencing customer attitude, purchase intention and purchase behaviour with regard to green personal care products. A literature review. Argum. Oeconomica 2023, 2, 233–262. [Google Scholar] [CrossRef]

- Suphasomboon, T.; Vassanadumrongdee, S. Toward Sustainable Consumption of Green Cosmetics and Personal Care Products: The Role of Perceived Value and Ethical Concern. Sustain. Prod. Consum. 2022, 33, 230–243. [Google Scholar] [CrossRef]

- Fonseca-Santos, B.; Antonio Corrêa, M.; Chorilli, M. Sustainability, Natural and Organic Cosmetics: Consumer, Products, Efficacy, Toxicological and Regulatory Considerations. Braz. J. Pharm. Sci. 2015, 51, 17–26. [Google Scholar] [CrossRef]

- Amberg, N.; Fogarassy, C. Green Consumer Behavior in the Cosmetics Market. Resources 2019, 8, 137. [Google Scholar] [CrossRef]

- Bom, S.; Fitas, M.; Martins, A.M.; Pinto, P.; Ribeiro, H.M.; Marto, J. Replacing Synthetic Ingredients by Sustainable Natural Alternatives: A Case Study Using Topical O/W Emulsions. Molecules 2020, 25, 4887. [Google Scholar] [CrossRef]

- Fresneda, M.; Trujillo-Cayado, L.A.; García, M.C.; Alfaro-Rodriguez, M.C.; Muñoz, J. Production of more sustainable emulsions formulated with eco-friendly materials. J. Clean. Prod. 2020, 243, 118661. [Google Scholar] [CrossRef]

- Bom, S.; Ribeiro, H.M.; Marto, J. Sustainability Calculator: A Tool to Assess Sustainability in Cosmetic Products. Sustainability 2020, 12, 1437. [Google Scholar] [CrossRef]

- Faraca, G.; Vidal Abarca Garrido, C.; Kaps, R.B.; Fernandez Carretero, A.; Wolf, O. Revision of EU Ecolabel Criteria for Cosmetic Products and Animal Care Products (Previously Rinse-Off Cosmetic Products); EUR 30724 EN; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- European Chemical Agency. ECHA Proposes to Restrict Intentionally Added Microplastics. 2019. Available online: https://echa.europa.eu/it/-/echa-proposes-to-restrict-intentionally-added-microplastics#:~:text=ECHA’s%20proposed%20restriction%20targets%20intentionally,that%20resist%20(bio)degradation (accessed on 15 March 2024).

- Rochman, C.M.; Kross, S.M.; Armstrong, J.B.; Bogan, M.T.; Darling, E.S.; Green, S.J.; Smyth, A.R.; Veríssimo, D. Scientific Evidence Supports a Ban on Microbeads. Environ. Sci. Technol. 2015, 49, 10759–10761. [Google Scholar] [CrossRef]

- Scudo, A.; Liebmann, B.; Corden, C.; Tyrer, D.; Kreissig, J.; Warwick, O. Intentionally Added Microplastics in Products; Amec Foster Wheeler Environ. & Infrastruct.: London, UK, 2017. [Google Scholar]

- Zheng, Y.J.; Loh, X.J. Natural Rheological Modifiers for Personal Care. In Polymers for Personal Care Products and Cosmetics; Loh, X.J., Ed.; Royal Society of Chemistry: London, UK, 2016; pp. 60–89. [Google Scholar]

- Kulawik-Pióro, A.; Ptaszek, A.; Kruk, G. Effective tool for assessment of the quality of barrier creams—Relationships between rheological, textural and sensory properties. Regul. Toxicol. Pharmacol. 2019, 103, 113–123. [Google Scholar] [CrossRef]

- Calixto, M.S.; Maia Campos, P.M.B.G. Physical–Mechanical characterization of cosmetic formulations and correlation between instrumental measurements and sensorial properties. Int. J. Cosmet. Sci. 2017, 39, 527–534. [Google Scholar] [CrossRef] [PubMed]

- de Araujo Silva, R.; Morais Ruela, A.L.; de Oliveira Mamede, M.E.; de Paula Pereira, N. Preparation and sensory evaluation of gels based on silicone copolymers/acrylic copolymers incorporating different vegetable oils. Ind. Crops Prod. 2023, 193, 116147. [Google Scholar] [CrossRef]

- Gilbert, L.; Picard, C.; Savary, G.; Grisel, M. Rheological and textural characterization of cosmetic emulsions containing natural and synthetic polymers: Relationships between both data. Colloids Surf. A Physiochem. Eng. Asp. 2013, 421, 150–163. [Google Scholar] [CrossRef]

- Tadros, T. Application of rheology for assessment and prediction of the long-term physical stability of emulsions. Adv. Colloid Interface Sci. 2004, 108–109, 227–258. [Google Scholar] [CrossRef] [PubMed]

- Terescenco, D.; Picard, C.; Clemenceau, F.; Grisel, M.; Savary, G. Influence of the emollient structure on the properties of cosmetic emulsion containing lamellar liquid crystals. Colloids Surf. A Physicochem. Eng. Asp. 2018, 536, 10–19. [Google Scholar] [CrossRef]

- Adejokun, D.A.; Dodou, K. Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation. Cosmetics 2020, 7, 2. [Google Scholar] [CrossRef]

- Vieira, G.S.; Lavarde, M.; Fréville, V.; Rocha-Filho, P.A.; Pensé-Lhéritier, A. Combining sensory and texturometer parameters to characterize different type of cosmetic ingredients. Int. J. Cosmet. Sci. 2020, 42, 156–166. [Google Scholar] [CrossRef]

- César, F.C.S.; Campos, P.M.B.G.M. Influence of vegetable oils in the rheology, texture profile and sensory properties of cosmetic formulations based on organogel. Int. J. Cosmet. Sci. 2020, 42, 494–500. [Google Scholar] [CrossRef] [PubMed]

- Imbart, S.; Laplanche, A.; Ruzic, C.; Lavarde, M.; Marull-Tufeu, S.; Bernard, C.; Pensé-Lhéritier, A.-M. Aoussat Design of a Sensorial-Instrumental Correlation Methodology for a Category of Cosmetic Products: O/W Emulsions. Cosmetics 2022, 9, 84. [Google Scholar] [CrossRef]

- Bashir, S.M.; Kimiko, S.; Mak, C.W.; Fang, J.K.H.; Gonçalves, D. Personal Care and Cosmetic Products as a Potential Source of Environmental Contamination by Microplastics in a Densely Populated Asian City. Front. Mar. Sci. 2021, 8, 683482. [Google Scholar] [CrossRef]

- Georgalas, A. Are Silicones Safe and Sustainable? What Are the Alternatives? Cosmet. & Toilet.: Northbrook, IL, USA, 2014; p. 129. [Google Scholar]

- Martins, A.M.; Marto, J.M. A sustainable life cycle for cosmetics: From design and development to post-use phase. Sustain. Chem. Pharm. 2023, 35, 101178. [Google Scholar] [CrossRef]

- Yasuda, K.; Armstrong, R.C.; Cohen, R.E. Shear flow properties of concentrated solutions of linear and star branched poly-styrenes. Rheol. Acta 1981, 20, 163–178. [Google Scholar] [CrossRef]

- Tai, A.; Bianchini, R.; Jachowicz, J. Texture analysis of cosmetic/pharmaceutical raw materials and formulations. Int. J. Cosmet. Sci. 2014, 36, 291–304. [Google Scholar] [CrossRef] [PubMed]

- Estanqueiro, M.; Amarak, M.H.; Sousa Lobo, J.M. Comparison between sensory and instrumental characterization of topical formulations: Impact of thickening agent. Int. J. Cosmet. Sci. 2016, 38, 389–398. [Google Scholar] [CrossRef] [PubMed]

- Marku, D.; Wahlgren, M.; Rayner, M.; Sjöö, M.; Timgren, A. Characterization of starch Pickering emulsions for potential applications in topical formulations. Int. J. Pharm. 2012, 428, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Lapasin, R.; Pricl, S. Rheology of Industrial Polysaccarides, Theory and Application; Blackie Academic & Professional: London, UK, 1995. [Google Scholar]

- Tafuro, G.; Costantini, A.; Baratto, G.; Francescato, S.; Busata, L.; Semenzato, A. Characterization of Polysaccharidic Associations for Cosmetic Use: Rheology and Texture Analysis. Cosmetics 2021, 8, 62. [Google Scholar] [CrossRef]

- Pressi, G.; Barbieri, E.; Rizzi, R.; Tafuro, G.; Costantini, A.; Di Domenico, E.; Semenzato, A. Formulation and Physical Characterization of a Polysaccharidic Gel for the Vehiculation of an Insoluble Phytoextract for Mucosal Application. Polysaccharides 2022, 3, 728–744. [Google Scholar] [CrossRef]

- Lapasin, R.; Abrami, M.; Grassi, M.; Sebenik, U. Rheology of laponite-scleroglucan hydrogels. Carbohydr. Polym. 2017, 168, 290–300. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.; Kim, Y.; Hu, Y.; Jung, S. Bacterial Succinoglycans: Structure, Physical Properties, and Applications. Polymers 2022, 14, 276. [Google Scholar] [CrossRef]

- Xu, L.; Gong, H.; Dong, M.; Li, Y. Rheological properties and thickening mechanism of aqueous diutan gum solution: Effects of temperature and salts. Carbohydr. Polym. 2015, 132, 620–629. [Google Scholar] [CrossRef]

- Blakemore, W.R.; Harpell, A.R. Carrageenan. In Food Stabilizers, Thickeners and Gelling Agents; Imeson, A., Ed.; Wiley-Blackwell: Oxford, UK, 2010; pp. 73–94. [Google Scholar]

| Phase | Ingredients | Composition % w/w |

|---|---|---|

| Aqueous Phase | Water | Add until reaching 100 |

| Chelating agent | 0.1 | |

| Humectants | 5 | |

| Preservatives | 0.7 | |

| Hydrophilic active ingredients | 5 | |

| Ammonium acryloyldimethyltaurate/VP copolymer | 0.9 | |

| Anionic emulsifier | 0.3 | |

| Nylon-12 Polymethylmethacrylate | 2.5 | |

| Lipidic Phase | Oils | 2 |

| Dimethicone | 1 | |

| Non-ionic emulsifier system | 3.5 | |

| Lipophilic active ingredients | 0.2 | |

| Antioxidant | 0.1 |

| Phase | Ingredients | Composition % w/w |

|---|---|---|

| Aqueous Phase | Water | Add until reaching 100 |

| Chelating agent | 0.1 | |

| Humectants | 3 | |

| Preservatives | 0.7 | |

| Hydrophilic active ingredients | 3 | |

| Natural gums | 1 | |

| Carbomer | 0.3 | |

| Non-ionic emulsifier system | 3 | |

| Polymethylmethacrylate | 1 | |

| Buffering agent | 0.5 | |

| Lipidic Phase | Coemulsifier | 0.6 |

| Oils | 5 | |

| Dimethicone Polysilicone-11 Dimethiconol | 5.5 | |

| Antioxidant | 0.1 |

| Phase | Ingredients | Composition % w/w |

|---|---|---|

| Aqueous Phase | Water | Add until reaching 100 |

| Chelating agent | 0.3 | |

| Humectants | 6 | |

| Preservatives | 0.6 | |

| Hydrophilic active ingredients | 0.1 | |

| Sodium polyacrylate Acrylates/beheneth-25 methacrylate copolymer | 1.3 | |

| Anionic emulsifier | 0.5 | |

| Polymethylmethacrylate | 3 | |

| Buffering agent | 0.03 | |

| Lipidic Phase | Non-ionic emulsifier system | 4 |

| Emollients | 36 | |

| Fragrance | 0.7 |

| Category | Code | Name | Inci Name | Origin | Supplier |

|---|---|---|---|---|---|

| Texturizers | ORGASOL® 2002 D NAT COS | Nylon-12 | synthetic | Arkema (Colombes, France) | |

| JURYMER MB-1 | Polymethyl methacrylate | synthetic | Kowa (Dusseldorf, Germany) | ||

| Z | ECOTOUCH® POWDER | Zea mays starch, polyvinyl alcohol, and glycerin | natural | Roelmi HPC (Origgio, VA, Italy) | |

| M | AGENAMALT 20.222 | Maltodextrin | natural | Agrana (Vienna, Austria) | |

| S | RONAFLAIR® LDP WHITE | Sodium potassium aluminum silicate, titanium dioxide, and silica | natural | Merck (Darmstadt, Germany) | |

| H | SERICA 5 | Mica | natural | Sensient (Saint-Ouen-l’Aumône, France) | |

| Rheological modifiers | CARBOPOL® ULTREZ 10 | Acrylates/C10-30 alkyl acrylate crosspolymer | synthetic | Lubrizol (Wickliffe, OH, USA) | |

| ARISTOFLEX® AVC | Ammonium acyloyldimethyltaurate/VP copolymer | synthetic | Clariant (Muttenz, Switzerland) | ||

| COSMEDIA® SP | Sodium polyacrylate | synthetic | Eurotrading (Veggiano, PD, Italy) | ||

| ACULYNTM 28 POLYMER | Acqua and acrylates/beheneth-25 methacrylate copolymer | synthetic | Dow Chemical (Midland, MI, USA) | ||

| t | ACTIGUMTM CS 11 QD | Sclerotium gum | natural | Cargill (Paris, France) | |

| v | ACTIGUMTM VSX 20 | Sclerotium gum and xanthan gum | natural | Cargill (Paris, France) | |

| k | KELCO CARETM DIUTAN GUM | Sphingomonas Ferment Extract | natural | CP-kelco (Atlanta, GA, USA) | |

| r | RHEOZAN® SH | Succynoglycan | natural | Solvay (Bruxelles, Belgium) | |

| c | GENUVISCO® CG-131 | Carrageenan | natural | CP-kelco (Atlanta, GA, USA) | |

| Emollients | BRBTM DM 5 | Dimethicone | synthetic | Lehvoss (Origgio, VA, Italy) | |

| X-21-5849 | Dimethiconol | synthetic | Shin-etsu (Chiyoda, Tokyo, Japan) | ||

| XIAMETERTM PMX-200 | Dimethicone | synthetic | Dow Chemical (Midland, MI, USA) | ||

| GRANSIL DMG-2 | Dimethicone and polysilicone-11 | synthetic | IMCD (Milan, MI, Italy) | ||

| CU | CETIOL® ULTIMATE | Undecane and tridecane | natural | Eurotrading (Veggiano, PD, Italy) | |

| EG | EMOGREENTM L15 | C15-19 alkanes | natural | Seppic (Courbevoie, Francia) | |

| DSG | DUBTM SOGREEN | Ethyl olivate and triheptanoin | natural | Stearinerie Dubois (Boulogne-Billancourt, Francia) | |

| EP | EUTRADERM® PENTA | Palm/kernel alkanes | natural | Eurotrading (Veggiano, PD, Italy) | |

| P | GRANSENSETM TC-18X | Coco-caprylate/caprate, triheptanoin, C9-12 alkane, dilinoleic acid/butanediol copolymer, and castor oil/IPDI copolymer | natural | Grant Industries (Elmwood Park, NJ, USA) |

| Sample Name | Texturizer | % w/w | η0 (Pa·s) |

|---|---|---|---|

| F1 | Nylon-12 and PMMA | 2.5 | 6547 |

| F1 Z | Zea mays starch, polyvinyl alcohol, and glycerin | 2.5 | 6180 |

| F1 M | Maltodextrin | 2.5 | 5671 |

| F1 S | Sodium potassium aluminum silicate, titanium dioxide, and silica | 2.5 | 9610 |

| F1 H | Mica | 2.5 | 10,582 |

| Sample Name | v % w/w | t % w/w | r % w/w | k % v | 4800 rpm; 30′ | η0 (Pa·s) |

|---|---|---|---|---|---|---|

| F1Z v075 | 0.75 | - | - | - | separation | - |

| F1Z v1 | 1 | - | - | - | stable | 5609 |

| F1Z t075 | - | 0.75 | - | - | separation | - |

| F1Z t1 | - | 1 | - | - | stable | 5650 |

| F1Z r075 | - | - | 0.75 | - | separation | - |

| F1Z r1 | - | - | 1 | - | separation | - |

| F1Z vk | 0.75 | - | - | 0.1 | stable | 3852 |

| F1Z tk | - | 0.75 | - | 0.1 | separation | - |

| F1Z tk2 | - | 0.75 | - | 0.2 | stable | 6929 |

| Sample Name | tanδ 10 rad/s | tanδ 0.5 rad/s | η0 (Pa·s) |

|---|---|---|---|

| F1Z vk | 0.278 | 0.347 | 3852 |

| F1Z CU | 0.303 | 0.371 | 3151 |

| F1Z DSG | 0.282 | 0.342 | 4407 |

| F1Z EG | 0.302 | 0.374 | 3677 |

| F1Z EP | 0.290 | 0.321 | 2677 |

| Sample Name | Texturizer | % w/w | η0 (Pa·s) |

|---|---|---|---|

| F2 | PMMA | 1 | 48,554 |

| F2 Z | Zea mays starch, polyvinyl alcohol, and glycerin | 1 | 36,186 |

| F2 M | Maltodextrin | 1 | 51,676 |

| F2 S | Sodium potassium aluminum silicate, titanium dioxide, and silica | 1 | 42,613 |

| F2 H | Mica | 1 | 48,589 |

| Sample Name | t % w/w | r % w/w | k % w/w | 4800 rpm; 30′ | η0 (Pa·s) |

|---|---|---|---|---|---|

| F2M t | 1.5 | - | - | stable | 18,434 |

| F2M t2 | 1.75 | - | - | stable | 29,121 |

| F2M t3 | 2 | - | - | stable | 20,052 |

| F2M r | - | 1.5 | - | stable | 12,576 |

| F2M k | - | - | 1.5 | stable | 9494 |

| F2M tr | 1.5 | 0.5 | - | stable | 17,331 |

| F2M tk | 1.5 | - | 0.5 | stable | 18,413 |

| Sample Name | P % w/w | DSG % w/w | 4800 rpm; 30′ | η0 (Pa·s) |

|---|---|---|---|---|

| F2M P | 5.5 | - | stable | 18,962 |

| F2M P DSG 1 | 4.5 | 1 | stable | 19,501 |

| F2M P DSG 1.5 | 4 | 1.5 | stable | 16,592 |

| Name | Texturizer | % w/w | η0 (Pa·s) | tanδ (10 rad/s) | tanδ (0.5 rad/s) |

|---|---|---|---|---|---|

| F3 | PMMA | 3 | 210,510 | 0.187 | 0.291 |

| F3 Z | Zea mays starch, polyvinyl alcohol, and glycerin | 3 | 204,930 | 0.240 | 0.360 |

| F3 M | Maltodextrin | 3 | 111,900 | 0.223 | 0.333 |

| F3 H | Mica | 3 | 187,190 | 0.211 | 0.302 |

| F3 S | Sodium potassium aluminum silicate, titanium dioxide, and silica | 3 | 260,830 | 0.198 | 0.274 |

| F3 S1.5 | 1.5 | 184,800 | 0.186 | 0.289 |

| Sample Name | c % w/w | t % w/w | 4800 rpm; 30′ | η0 (Pa·s) |

|---|---|---|---|---|

| F3S c1 | 1 | - | stable | 47,516 |

| F3S c1.5 | 1.5 | - | stable | 100,150 |

| F3S c2 | 2 | - | stable | 113,920 |

| F3S ct | 1.5 | 0.5 | stable | 126,410 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tafuro, G.; Costantini, A.; Piatto, M.; Lucchetti, S.; Francescato, S.; Busata, L.; Baratto, G.; Semenzato, A. Eco-Designing Cosmetic Products while Preserving the Sensorial-Application Properties: An Instrumental Approach toward Sustainable Formulations. Cosmetics 2024, 11, 60. https://doi.org/10.3390/cosmetics11020060

Tafuro G, Costantini A, Piatto M, Lucchetti S, Francescato S, Busata L, Baratto G, Semenzato A. Eco-Designing Cosmetic Products while Preserving the Sensorial-Application Properties: An Instrumental Approach toward Sustainable Formulations. Cosmetics. 2024; 11(2):60. https://doi.org/10.3390/cosmetics11020060

Chicago/Turabian StyleTafuro, Giovanni, Alessia Costantini, Mario Piatto, Silvia Lucchetti, Stefano Francescato, Laura Busata, Giovanni Baratto, and Alessandra Semenzato. 2024. "Eco-Designing Cosmetic Products while Preserving the Sensorial-Application Properties: An Instrumental Approach toward Sustainable Formulations" Cosmetics 11, no. 2: 60. https://doi.org/10.3390/cosmetics11020060

APA StyleTafuro, G., Costantini, A., Piatto, M., Lucchetti, S., Francescato, S., Busata, L., Baratto, G., & Semenzato, A. (2024). Eco-Designing Cosmetic Products while Preserving the Sensorial-Application Properties: An Instrumental Approach toward Sustainable Formulations. Cosmetics, 11(2), 60. https://doi.org/10.3390/cosmetics11020060