Tartary Buckwheat Bran: A Review of Its Chemical Composition, Processing Methods and Food Uses

Abstract

:1. Introduction

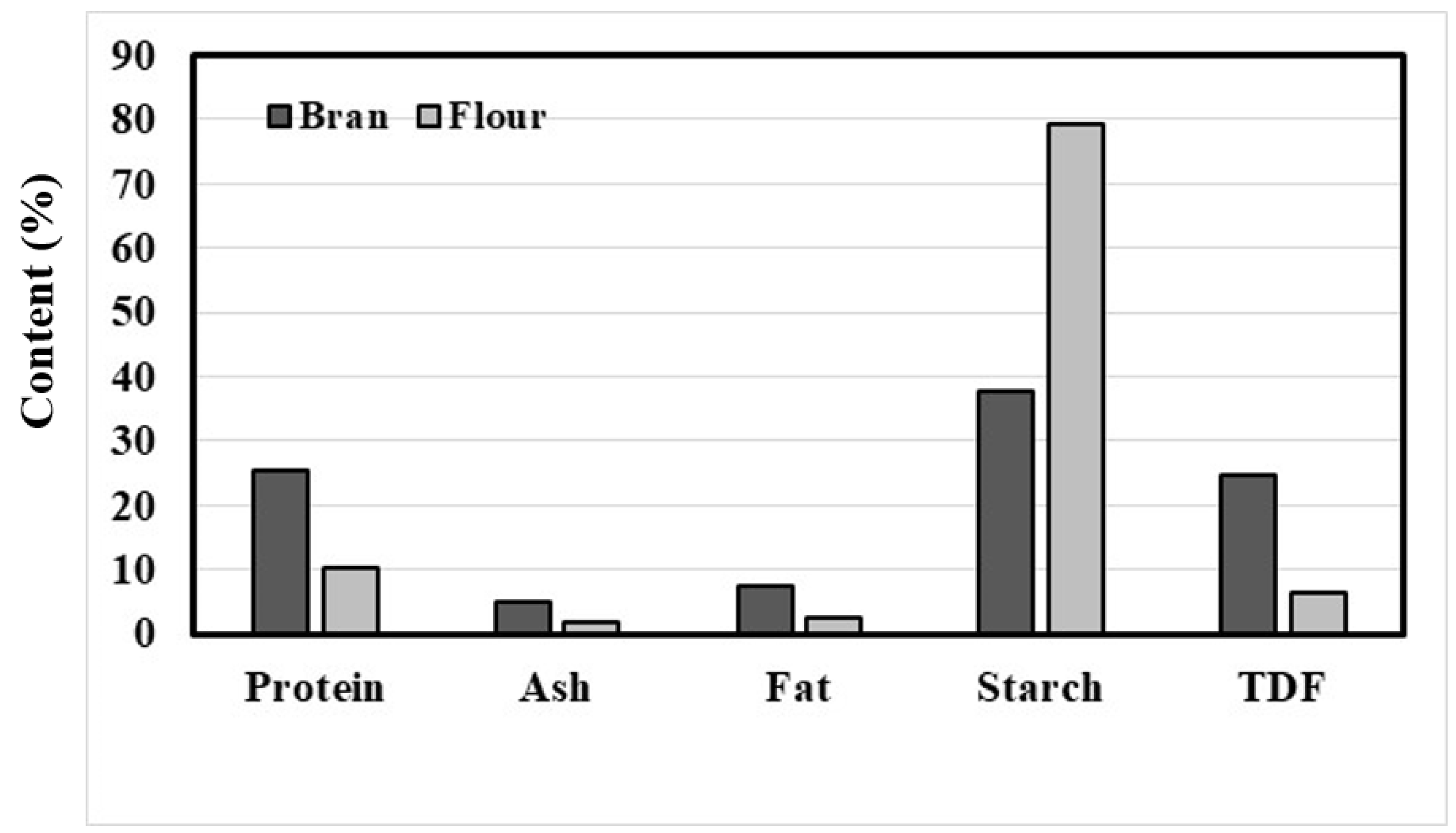

2. Nutritional Compounds of Tartary Buckwheat Bran

3. Functional Compounds of Tartary Buckwheat Bran

4. Processing Method of Tartary Buckwheat Bran

5. Food Uses of Tartary Buckwheat Bran

6. Our Studies on Tartary Buckwheat Bran Using a Novel Cultivar ‘Manten-Kirari’

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Luthar, Z.; Golob, A.; Germ, M.; Vombergar, B.; Kreft, I. Tartary Buckwheat in Human Nutrition. Plants 2021, 10, 700. [Google Scholar] [CrossRef]

- Zhu, F. Chemical composition and health effects of Tartary buckwheat. Food Chem. 2016, 203, 231–245. [Google Scholar] [CrossRef]

- Fabjan, T.; Rode, J.; Kosir, I.J.; Wang, Z.; Zhang, Z.; Kreft, I. Tartary buckwheat (Fagopyrum tataricum Gaertn.) as a source of dietary rutin and quercetin. J. Agric. Food Chem. 2003, 51, 6452–6455. [Google Scholar] [CrossRef]

- Morishita, T.; Yamaguchi, H.; Degi, K. The Contribution of Polyphenols to Antioxidative Activity in Common Buckwheat and Tartary Buckwheat Grain. Plant Prod. Sci. 2007, 10, 99–104. [Google Scholar] [CrossRef]

- Griffith, J.Q.; Couch, J.F.; Lindauer, M.A. Effect of Rutin on Increased Capillary Fragility in Man. Proc. Soc. Exp. Biol. Med. 1944, 55, 228–229. [Google Scholar] [CrossRef]

- Matsubara, Y.; Kumamoto, H.; Iizuka, Y.; Murakami, T.; Okamoto, K.; Miyake, H.; Yokoi, K. Structure and hypotensive effect of flavonoid glycosides in Citrus unshiu peelings. Agric. Biol. Chem. 1985, 49, 909–914. [Google Scholar]

- Afanas’ev, I.B.; Ostrakhovitch, E.A.; Mikhal’chik, E.V.; Ibragimova, G.A.; Korkina, G.L. Enhancement of antioxidant and anti-inflammatory activities of bioflavonoid rutin by complexation with transition metals. Biochem. Pharmacol. 2001, 61, 677–684. [Google Scholar] [CrossRef]

- Jiang, P.; Burczynski, F.; Campbell, C.; Pierce, G.; Austria, J.A.; Briggs, C.J. Rutin and flavonoid contents in three buck-wheat species Fagopyrum esculentum, F. tataricum, and F. homotropicum and their protective effects against lipid peroxidation. Food Res. Int. 2007, 40, 356–364. [Google Scholar] [CrossRef]

- Lee, L.S.; Choi, E.J.; Kim, C.H.; Sung, J.M.; Kim, Y.B.; Seo, D.H.; Choi, H.W.; Choi, Y.S.; Kum, J.S.; Park, J.D. Contribution of flavonoids to the antioxidant properties of common and tartary buckwheat. J. Cereal Sci. 2016, 68, 181–186. [Google Scholar] [CrossRef]

- Li, Y.Q.; Zhou, F.C.; Gao, F.; Bian, J.S.; Shan, F. Comparative evaluation of quercetin, isoquercetin and rutin as inhibitors of α-glucosidase. J. Agric. Food Chem. 2009, 57, 11463–11468. [Google Scholar] [CrossRef]

- Luo, K.; Zhou, X.; Zhang, G. The impact of Tartary buckwheat extract on the nutritional property of starch in a whole grain context. J. Cereal Sci. 2019, 89, 102798. [Google Scholar] [CrossRef]

- Wieslander, G.; Fabjan, N.; Vogrincic, M.; Kreft, I.; Janson, C.; Spetz-Nyström, U.; Vombergar, B.; Tagesson, C.; Leanderson, P.; Norbäck, D. Eating Buckwheat Cookies Is Associated with the Reduction in Serum Levels of Myeloperoxidase and Cholesterol: A Double Blind Crossover Study in Day-Care Centre Staffs. Tohoku J. Exp. Med. 2011, 225, 123–130. [Google Scholar] [CrossRef]

- Bonafaccia, G.; Marocchini, M.; Kreft, I. Composition and technological properties of the flour and bran from common and tartary buckwheat. Food Chem. 2003, 80, 9–15. [Google Scholar] [CrossRef]

- Guo, X.-D.; Wu, C.-S.; Ma, Y.-J.; Parry, J.; Xu, Y.-Y.; Liu, H.; Wang, M. Comparison of milling fractions of tartary buckwheat for their phenolics and antioxidant properties. Food Res. Int. 2012, 49, 53–59. [Google Scholar] [CrossRef]

- Liu, B.; Zhu, Y. Extraction of flavonoids from flavonoid-rich parts in tartary buckwheat and identification of the main flavonoids. J. Food Eng. 2007, 78, 584–587. [Google Scholar] [CrossRef]

- Wang, M.; Liu, J.-R.; Gao, J.-M.; Parry, J.W.; Wei, Y.-M. Antioxidant Activity of Tartary Buckwheat Bran Extract and Its Effect on the Lipid Profile of Hyperlipidemic Rats. J. Agric. Food Chem. 2009, 57, 5106–5112. [Google Scholar] [CrossRef]

- Li, F.H.; Zhang, X.L.; Zheng, S.J.; Lu, K.; Zhao, G.H.; Ming, J. The composition, antioxidant and antiproliferative capacities of phenolic compounds extracted from tartary buckwheat bran [Fagopyrum tartaricum (L.) Gaerth]. J. Funct. Foods 2016, 22, 145–155. [Google Scholar] [CrossRef]

- Li, W.; Zhang, X.; He, X.; Li, F.; Zhao, J.; Yin, R.; Ming, J. Effects of steam explosion pretreatment on the composition and biological activities of tartary buckwheat bran phenolics. Food Funct. 2020, 11, 4648–4658. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, S.; Geng, S.; Liu, C.; Ma, H.; Liu, B. Effects of Tartary Buckwheat Bran Flour on Dough Properties and Quality of Steamed Bread. Foods 2021, 10, 2052. [Google Scholar] [CrossRef]

- Xue, C.Q.; Guo, X.N.; Zhu, K.X. Effect of Tartary buckwheat bran substitution on the quality, bioactive compounds content, and in vitro starch digestibility of Tartary buckwheat dried noodles. Foods 2022, 11, 3696. [Google Scholar] [CrossRef]

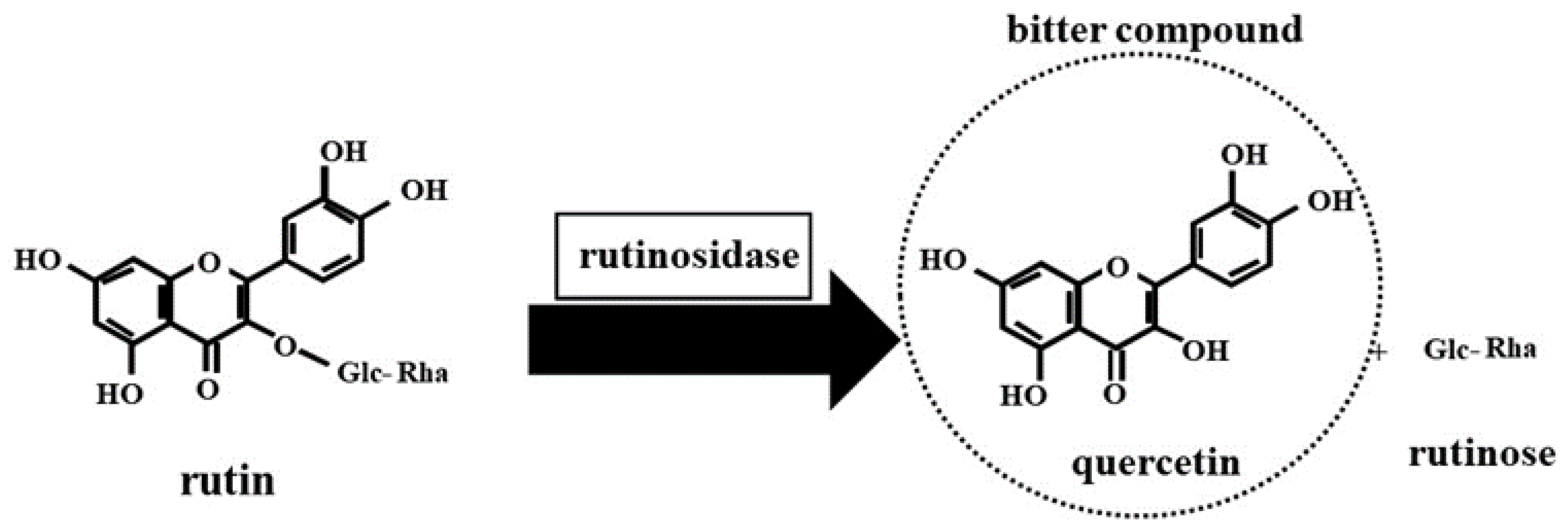

- Yasuda, T.; Nakagawa, H. Purification and characterization of the rutin-degrading enzymes in tartary buckwheat seeds. Phytochemistry 1994, 37, 133–136. [Google Scholar] [CrossRef]

- Suzuki, T.; Honda, Y.; Funatsuki, W.; Nakatsuka, K. Purification and characterization of flavonol 3-glucosidase, and its activity during ripening in tartary buckwheat seeds. Plant Sci. 2002, 163, 417–423. [Google Scholar] [CrossRef]

- Suzuki, T.; Morishita, T.; Mukasa, Y.; Takigawa, S.; Yokota, S.; Ishiguro, K.; Noda, T. Discovery and genetic analysis of non-bitter Tartary buckwheat (Fagopyrum tataricum Gaertn.) with trace-rutinosidase activity. Breed. Sci. 2014, 64, 339–343. [Google Scholar] [CrossRef]

- Suzuki, T.; Morishita, T.; Mukasa, Y.; Takigawa, S.; Yokota, S.; Ishiguro, K.; Noda, T. Breeding of ‘Manten-Kirari’, a non-bitter and trace-rutinosidase variety of Tartary buckwheat (Fagopyrum tataricum Gaertn.). Breed. Sci. 2014, 64, 344–350. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, T.; Morishita, T.; Noda, T.; Ishiguro, K.; Otsuka, S.; Katsu, K. Breeding of Buckwheat to Reduce Bitterness and Rutin Hydrolysis. Plants 2021, 10, 791. [Google Scholar] [CrossRef] [PubMed]

- Morishita, T.; Ishiguro, K.; Noda, T.; Suzuki, T. The effect of grain moisture contents on the roll milling characteristics of Tartary buckwheat cultivar ‘Manten-Kirari’. Plant Prod. Sci. 2020, 23, 539–546. [Google Scholar] [CrossRef]

- Noda, T.; Ishiguro, K.; Suzuki, T.; Morishita, T. Relationship between Color Change and Rutin Content in Roasted Tartary Buckwheat Bran. Food Sci. Technol. Res. 2020, 26, 709–716. [Google Scholar] [CrossRef]

- Noda, T.; Ishiguro, K.; Suzuki, T.; Morishita, T. Roasted Tartary Buckwheat Bran as a Material for Producing Rutin-Rich Tea Beverages. Plants 2021, 10, 2662. [Google Scholar] [CrossRef]

- Sinkovič, L.; Sinkovič, D.K.; Meglič, V. Milling Fractions Composition of Common (Fagopyrum esculentum Moench) and Tartary (Fagopyrum tataricum (L.) Gaertn.) Buckwheat. Food Chem. 2021, 365, 130459. [Google Scholar] [CrossRef]

- Sinkovič, L.; Deželak, M.; Kopinč, R.; Meglič, V. Macro/microelements, nutrients and bioactive components in common and Tartary buckwheat (Fagopyrum spp.) grain and stone-milling fractions. LWT 2022, 161, 113422. [Google Scholar] [CrossRef]

- Lu, L.; Murphy, K.; Baik, B.-K. Genotypic Variation in Nutritional Composition of Buckwheat Groats and Husks. Cereal Chem. 2013, 90, 132–137. [Google Scholar] [CrossRef]

- Zobel, H.F. Molecules to Granules: A Comprehensive Starch Review. Starch 1988, 40, 44–50. [Google Scholar] [CrossRef]

- Fredriksson, H.; Silverio, J.; Andersson, R.; Eliasson, A.C.; Åman, P. The influence of amylose and amylopectin characteristics on gelatinization and retrogradation properties of different starches. Carbohydr. Polym. 1998, 35, 119–134. [Google Scholar] [CrossRef]

- Noda, T.; Nishiba, Y.; Sato, T.; Suda, I. Properties of Starches from Several Low-Amylose Rice Cultivars. Cereal Chem. 2003, 80, 193–197. [Google Scholar] [CrossRef]

- Yoshimoto, Y.; Egashira, T.; Hanashiro, I.; Ohinata, H.; Takase, Y.; Takeda, Y. Molecular structure and some physico-chemical properties of buckwheat starches. Cereal Chem. 2004, 81, 515–520. [Google Scholar] [CrossRef]

- Gao, J.; Kreft, I.; Chao, G.; Wang, Y.; Liu, X.; Wang, L.; Wang, P.; Gao, X.; Feng, B. Tartary buckwheat (Fagopyrum tataricum Gaertn.) starch, a side product in functional food production, as a potential source of retrograded starch. Food Chem. 2016, 190, 552–558. [Google Scholar] [CrossRef]

- Zhu, F. Buckwheat starch: Structures, properties, and applications. Trends Food Sci. Technol. 2016, 49, 121–135. [Google Scholar] [CrossRef]

- Noda, T.; Ishiguro, K.; Suzuki, T.; Morishita, T. Physicochemical Properties and In Vitro Digestibility of Starch from a Trace-Rutinosidase Variety of Tartary Buckwheat ‘Manten-Kirari’. Molecules 2022, 27, 6172. [Google Scholar] [CrossRef]

- Dhingra, D.; Michael, M.; Rajput, H.; Patil, R.T. Dietary fibre in foods: A review. J. Food Sci. Technol. 2012, 49, 255–266. [Google Scholar] [CrossRef]

- Howarth, N.C.; Saltzman, E.; Roberts, S.B. Dietary Fiber and Weight Regulation. Nutr. Rev. 2001, 59, 129–139. [Google Scholar] [CrossRef]

- Anderson, J.W.; Baird, P.; Davis, R.H., Jr.; Ferreri, S.; Knudtson, M.; Koraym, A.; Waters, V.; Williams, C.L. Health benefits of dietary fiber. Nutr. Rev. 2009, 67, 188–205. [Google Scholar] [CrossRef] [PubMed]

- Elleuch, M.; Bedigian, D.; Roiseux, O.; Besbes, S.; Blecker, C.; Attia, H. Dietary fibre and fibre-rich by-products of food processing: Characterisation, technological functionality and commercial applications: A review. Food Chem. 2011, 124, 411–421. [Google Scholar] [CrossRef]

- Wang, X.-T.; Zhu, Z.-Y.; Zhao, L.; Sun, H.-Q.; Meng, M.; Zhang, J.-Y.; Zhang, Y.-M. Structural characterization and inhibition on α-dglucosidase activity of non-starch polysaccharides from Fagopyrum tartaricum. Carbohydr. Polym. 2016, 153, 679–685. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Li, Z.; Qin, F.; Qiu, J. Anti-diabetic effects of the soluble dietary fiber from tartary buckwheat bran in diabetic mice and their potential mechanisms. Food Nutr. Res. 2021, 65, 4998. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Yao, H. Fractionation and characterization of tartary buckwheat flour proteins. Food Chem. 2006, 98, 90–94. [Google Scholar] [CrossRef]

- Tomotake, H.; Yamamoto, N.; Kitabayashi, H.; Kawakami, A.; Kayashita, J.; Ohinata, H.; Karasawa, H.; Kato, N. Preparation of tartary buckwheat protein product and its improving effect on cholesterol metabolism in rats and mice fed choles-terolenriched diet. J. Food Sci. 2007, 72, S528–S533. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, R.; Li, Y.M.; Liang, N.; Zhao, Y.; Zhu, H.; He, Z.; Liu, J.; Hao, W.; Jiao, R.; et al. Cholesterol-Lowering Activity of Tartary Buckwheat Protein. J. Agric. Food Chem. 2017, 65, 1900–1906. [Google Scholar] [CrossRef]

- Luthar, Z.; Zhou, M.; Golob, A.; Germ, M. Breeding Buckwheat for Increased Levels and Improved Quality of Protein. Plants 2021, 10, 14. [Google Scholar] [CrossRef]

- Sinkovič, L.; Kokalj, D.; Vidrih, R.; Meglič, V. Milling fractions fatty acid composition of common (Fagopyrum esculentum Moench) and tartary (Fagopyrum tataricum (L.) Gaertn) buckwheat. J. Stored Prod. Res. 2020, 85, 101551. [Google Scholar] [CrossRef]

- Dziedzic, K.; Kurek, S.; Mildner–Szkudlarz, S.; Kreft, I.; Walkowiak, J. Fatty acids profile, sterols, tocopherol and squalene content in Fagopyrum tataricum seed milling fractions. J. Cereal Sci. 2020, 96, 103118. [Google Scholar] [CrossRef]

- Peng, L.X.; Zou, L.; Tan, M.L.; Deng, Y.Y.; Yan, J.; Yan, Z.Y.; Zhao, G. Free amino acids, fatty acids and phenolic com-pounds in Tartary buckwheat of different hull colour. Czech J. Food Sci. 2017, 35, 214–222. [Google Scholar] [CrossRef]

- Bonafaccia, G.; Gambelli, L.; Fabjan, N.; Kreft, I. Trace elements in flour and bran from common and tartary buckwheat. Food Chem. 2003, 83, 1–5. [Google Scholar] [CrossRef]

- Zhou, X.; Hao, T.; Zhou, Y.; Tang, W.; Xiaoli, Z.; Meng, X.; Fang, X. Relationships between antioxidant compounds and antioxidant activities of tartary buckwheat during germination. J. Food Sci. Technol. 2015, 52, 2458–2463. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Wang, H.; Cui, L.; Zhou, X.; Tang, W.; Song, X. Evolution of nutrient ingredients in tartary buckwheat seeds during germination. Food Chem. 2015, 186, 244–248. [Google Scholar]

- Cai, Y.; Luo, Q.; Sun, M.; Corke, H. Antioxidant activity and phenolic compounds of 112 traditional Chinese medicinal plants associated with anticancer. Life Sci. 2004, 74, 2157–2184. [Google Scholar] [CrossRef]

- Qin, P.; Wang, Q.; Shan, F.; Hou, Z.; Ren, G. Nutritional composition and flavonoids content of flour from different buckwheat cultivars. Int. J. Food Sci. 2010, 45, 951–958. [Google Scholar] [CrossRef]

- Guo, X.-D.; Ma, Y.-J.; Parry, J.; Gao, J.-M.; Yu, L.-L.; Wang, M. Phenolics Content and Antioxidant Activity of Tartary Buckwheat from Different Locations. Molecules 2011, 16, 9850–9867. [Google Scholar] [CrossRef]

- Qin, P.Y.; Wu, L.; Yao, Y.; Ren, G.X. Changes in phytochemical compositions, antioxidant and α-glucosidase inhibitory activities during the processing of tartary buckwheat tea. Food Res. Int. 2013, 50, 562–567. [Google Scholar] [CrossRef]

- Guo, X.-D.; Wang, M.; Gao, J.-M.; Shi, X.-W. Bioguided Fraction of Antioxidant Activity of Ethanol Extract from Tartary Buckwheat Bran. Cereal Chem. 2012, 89, 311–315. [Google Scholar] [CrossRef]

- Wang, L.; Yang, X.; Qin, P.; Shan, F.; Ren, G. Flavonoid composition, antibacterial and antioxidant properties of tartary buckwheat bran extract. Ind. Crops Prod. 2013, 49, 312–317. [Google Scholar] [CrossRef]

- Ostlund, R.; McGill, J.B.; Herskowitz, I.; Kipnis, D.M.; Santiago, J.V.; Sherman, W.R. D-chiroinositol metabolism in diabetes mellitus. Proc. Natl. Acad. Sci. USA 1993, 90, 9988–9992. [Google Scholar] [CrossRef] [PubMed]

- Steadman, K.J.; Burgoon, M.S.; Schuster, R.L.; Lewis, B.A.; Edwardson, S.E.; Obendorf, R.L. Fagopyritols, d-chiro-Inositol, and Other Soluble Carbohydrates in Buckwheat Seed Milling Fractions. J. Agric. Food Chem. 2000, 48, 2843–2847. [Google Scholar] [CrossRef] [PubMed]

- Yang, N.; Ren, G.X. Determination of D-chiro-inositol in tartary buckwheat using high-performance liquid chromatography with an evaporative light-scattering detector. J. Agric. Food Chem. 2008, 56, 757–760. [Google Scholar] [CrossRef] [PubMed]

- Yang, N.; Ren, G. Application of Near-Infrared Reflectance Spectroscopy to the Evaluation of Rutin and D-chiro-Inositol Contents in Tartary Buckwheat. J. Agric. Food Chem. 2008, 56, 761–764. [Google Scholar] [CrossRef]

- Horbowicz, M.; Brenac, P.; Obendorf, R.L. Fagopyritol B1, O-α-D-galactopyranosyl-(1→2)-D-chiro-inositol, a galactosyl cyclitol in maturing buckwheat seeds associated with desiccation tolerance. Planta 1998, 205, 1–11. [Google Scholar] [CrossRef]

- Cheng, F.; Ge, X.; Gao, C.; Li, Y.; Wang, M. The distribution of D-chiro-inositol in buckwheat and its antioxidative effect in HepG2. J. Cereal Sci. 2019, 89, 102808. [Google Scholar] [CrossRef]

- Kawa, J.M.; Taylor, C.G.; Przybylski, R. Buckwheat Concentrate Reduces Serum Glucose in Streptozotocin-Diabetic Rats. J. Agric. Food Chem. 2003, 51, 7287–7291. [Google Scholar] [CrossRef]

- Yao, Y.; Shan, F.; Bian, J.; Chen, F.; Wang, M.; Ren, G. d-chiro-Inositol-Enriched Tartary Buckwheat Bran Extract Lowers the Blood Glucose Level in KK-Ay Mice. J. Agric. Food Chem. 2008, 56, 10027–10031. [Google Scholar] [CrossRef]

- Hu, Y.; Zhao, Y.; Ren, D.; Guo, J.; Luo, Y.; Yang, X. Hypoglycemic and hepatoprotective effects of D-chiro-inositol-enriched tartary buckwheat extract in high fructose-fed mice. Food Funct. 2003, 6, 3360–3369. [Google Scholar] [CrossRef]

- Ge, R.H.; Wang, H. Nutrient components and bioactive compounds in tartary buckwheat bran and flour as affected by thermal processing. Int. J. Food Prop. 2020, 23, 127–137. [Google Scholar] [CrossRef]

- Chen, H.Z.; Liu, L.Y. Unpolluted fractionation of wheat straw by steam explosion and ethanol extraction. Bioresour. Technol. 2007, 98, 666–676. [Google Scholar]

- Wan, F.C.; Feng, C.F.; Luo, K.Y.; Cui, W.Y.; Xia, Z.H.; Cheng, A.W. Effect of steam explosion on phenolics and antioxidant activity in plants: A review. Trends Food Sci. Technol. 2022, 124, 13–24. [Google Scholar] [CrossRef]

- Li, W.; He, X.; Chen, Y.; Lei, L.; Li, F.; Zhao, J.; Zeng, K.; Ming, J. Improving antioxidant activity and modifying Tartary buckwheat bran by steam explosion treatment. LWT 2022, 170, 114106. [Google Scholar] [CrossRef]

- He, X.Q.; Li, W.Z.; Chen, Y.Y.; Lei, L.; Li, F.H.; Zhao, J.C.; Zeng, K.F.; Ming, J. Dietary fiber of Tartary buckwheat bran modified by steam explosion alleviates hyperglycemia and modulates gut microbiota in db/db mice. Food Res. Int. 2022, 157, 111386. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhang, J.; Zhang, L.F. Effect of superfine grinding on physicochemical properties and endogenous enzyme induced flavonoid transformations of Tartary buckwheat bran. LWT 2022, 162, 113420. [Google Scholar] [CrossRef]

- Zhu, K.; Huang, S.; Peng, W.; Qian, H.; Zhou, H. Effect of ultrafine grinding on hydration and antioxidant properties of wheat bran dietary fiber. Food Res. Int. 2010, 43, 943–948. [Google Scholar] [CrossRef]

- Xu, Q.; Huang, R.; Yang, P.; Wang, L.; Xing, Y.; Liu, H.; Wu, L.; Che, Z.; Zhang, P. Effect of different superfine grinding technologies on the physicochemical and antioxidant properties of tartary buckwheat bran powder. RSC Adv. 2021, 11, 30898–30910. [Google Scholar] [CrossRef]

- Cho, Y.J.; Bae, I.Y.; Inglett, G.E.; Lee, S. Utilization of tartary buckwheat bran as a source of rutin and its effect on the rheological and antioxidant properties of wheat-based products. Ind. Crops Prod. 2014, 61, 211–216. [Google Scholar] [CrossRef]

- Cho, Y.J.; Lee, S.Y. Extraction of rutin from Tartary buckwheat milling fractions and evaluation of its thermal stability in an instant fried noodle system. Food Chem. 2015, 176, 40–44. [Google Scholar] [CrossRef]

- Hoover, R. The Impact of Heat-Moisture Treatment on Molecular Structures and Properties of Starches Isolated from Different Botanical Sources. Crit. Rev. Food Sci. Nutr. 2010, 50, 835–847. [Google Scholar] [CrossRef]

- Punchaarnon, S.; Uttapap, D. Rice starch vs. rice flour: Differences in their properties when modified by heat–moisture treatment. Carbohydr. Polym. 2013, 91, 85–91. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Lv, M.; Peng, Q.; Shan, F.; Wang, M. Physicochemical and textural properties of tartary buckwheat starch after heat-moisture treatment at different moisture levels. Starch 2015, 67, 276–284. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, H.; Wei, T.; Shen, J.; Wang, M. Differences in physicochemical properties and in vitro digestibility between tartary buckwheat flour and starch modified by heat-moisture treatment. LWT 2017, 86, 285–292. [Google Scholar]

- Zhang, S.; Zhou, W.; Chen, C. Application of Tartary buckwheat bran flour modified by heat-moisture treatment in steamed bread processing. Food Sci. Technol. 2022, 42, e71622. [Google Scholar] [CrossRef]

- Capron, I.; Cathala, B. Surfactant-Free High Internal Phase Emulsions Stabilized by Cellulose Nanocrystals. Biomacromolecules 2013, 14, 291–296. [Google Scholar] [CrossRef]

- Zhang, S.; Geng, S.; Shi, Y.; Ma, H.; Liu, B. Fabrication and characterization of Pickering high internal phase emulsions stabilized by Tartary buckwheat bran flour. Food Chem. X 2022, 16, 100513. [Google Scholar] [CrossRef]

- Guo, H.; Yang, X.; Zhou, H.; Luo, X.; Qin, P.; Li, J.; Ren, G. Comparison of Nutritional Composition, Aroma Compounds, and Biological Activities of Two Kinds of Tartary Buckwheat Tea. J. Food Sci. 2017, 82, 1735–1741. [Google Scholar] [CrossRef]

- Zhao, G.; Peng, L.; Zou, L.; Wang, J.; Zhao, J.; Xiang, D. Flavonoids, antioxidant activity and aroma compounds analysis from different kinds of Tartary Buckwheat Tea. Indian J. Pharm. Sci. 2015, 77, 661–667. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Huang, Y.; Jiang, Y.; Liu, Y.; Wen, W.; Li, H.; Shao, J.; Wang, C.; Zhu, X. Antioxidant Capacity, Metal Contents, and Their Health Risk Assessment of Tartary Buckwheat Teas. ACS Omega 2020, 5, 9724–9732. [Google Scholar] [CrossRef]

- Suzuki, T.; Morishita, T.; Kim, S.-J.; Park, S.-U.; Woo, S.-H.; Noda, T.; Takigawa, S. Physiological Roles of Rutin in the Buckwheat Plant. JARQ 2015, 49, 37–43. [Google Scholar] [CrossRef]

- Ohara, T.; Ohinata, H.; Muramatsu, N.; Oike, T.; Matsuhashi, T. Enzymatic degradation of rutin in buckwheat noodle. J. Jpn. Soc. Food Sci. 1989, 36, 121–126. [Google Scholar]

- Yasuda, T.; Masaki, K.; Kashiwagi, T. An Enzyme Degrading Rutin in Tartary Buckwheat Seeds. J. Jpn. Soc. Food Sci. 1992, 39, 994–1000. [Google Scholar] [CrossRef]

- Vogrinčič, M.; Timoracka, M.; Melichacova, S.; Vollmannova, A.; Kreft, I. Degradation of Rutin and Polyphenols during the Preparation of Tartary Buckwheat Bread. J. Agric. Food Chem. 2010, 58, 4883–4887. [Google Scholar] [CrossRef] [PubMed]

- Kawakami, A.; Kayahara, H.; Ujihara, A. Properties and Elimination of Bitter Components Derived from Tartary Buckwheat (Fagopyrum tataricum) Flour. J. Jpn. Soc. Food Sci. 1995, 42, 892–898. [Google Scholar] [CrossRef]

- Yoo, J.; Kim, Y.; Yoo, S.H.; Inglett, G.E.; Lee, S. Reduction of rutin loss in buckwheat noodles and their physicochemical characterization. Food Chem. 2012, 132, 2107–2111. [Google Scholar] [CrossRef]

- Fujita, K.; Yoshihashi, T. Heat-treatment of Tartary buckwheat (Fagopyrum tataricum Gaertn.) provides dehulled and gelatinized product with denatured rutinosidase. Food Sci. Technol. Res. 2019, 25, 613–618. [Google Scholar] [CrossRef]

- Germ, M.; Árvay, J.; Vollmannová, A.; Tóth, T.; Golob, A.; Luthar, Z.; Kreft, I. The temperature threshold for the transformation of rutin to quercetin in Tartary buckwheat dough. Food Chem. 2019, 283, 28–31. [Google Scholar] [CrossRef]

- Oh, M.; Oh, I.; Jeong, S.; Lee, S. Optical, rheological, thermal, and microstructural elucidation of rutin enrichment in Tartary buckwheat flour by hydrothermal treatments. Food Chem. 2019, 300, 125193. [Google Scholar] [CrossRef]

- Suzuki, T.; Morishita, T.; Takigawa, S.; Noda, T.; Ishiguro, K. Characterization of Rutin-rich Bread Made with ‘Manten-Kirari’, a Trace-rutinosidase Variety of Tartary Buckwheat (Fagopyrum tataricum Gaertn.). Food Sci. Technol. Res. 2015, 21, 733–738. [Google Scholar] [CrossRef]

- Ishiguro, K.; Morishita, T.; Ashizawa, J.; Suzuki, T.; Noda, T. Antioxidative activities in rutin-rich noodles and cookies made with a trace-rutinosidase variety of Tartary buckwheat (Fagopyrum tataricum Gaertn.), ‘Mantenkirari’. Food Sci. Technol. Res. 2016, 22, 557–562. [Google Scholar] [CrossRef]

- Suzuki, T.; Morishita, T.; Takigawa, S.; Noda, T.; Ishiguro, K. Development of rutin-rich noodles using trace-rutinosidase variety of Tartary buckwheat (Fagopyrum tataricum Gaertn.) ‘Mantenkirari’. Food Sci. Technol. Res. 2019, 25, 915–920. [Google Scholar] [CrossRef]

- Suzuki, T.; Morishita, T.; Takigawa, S.; Noda, T.; Ishiguro, K.; Otsuka, S. Effect of Sodium Bicarbonate on Rutin Residual Ratio in Tartary Buckwheat (Fagopyrum tataricum Gaertn.) Dough. Food Sci. Technol. Res. 2020, 26, 597–603. [Google Scholar] [CrossRef]

- Suzuki, T.; Morishita, T.; Noda, T.; Ishiguro, K. Acute and Subacute Toxicity Studies on Rutin-Rich Tartary Buckwheat Dough in Experimental Animals. J. Nutr. Sci. Vitaminol. 2015, 61, 175–181. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, T.; Morishita, T.; Takigawa, S.; Noda, T.; Ishiguro, K. Evaluation of the Mutagenicity Potential of Trace-Rutinosidase Variety of Tartary Buckwheat (Fagopyrum tataricum Gaertn.) Using the Ames Test. J. Agric. Chem. Environ. 2016, 5, 100–105. [Google Scholar] [CrossRef]

- Nishimura, M.; Ohkawara, T.; Sato, Y.; Satoh, H.; Suzuki, T.; Ishiguro, K.; Noda, T.; Morishita, T.; Nishihira, J. Effectiveness of rutin-rich Tartary buckwheat (Fagopyrum tataricum Gaertn.) ‘Manten-Kirari’ in body weight reduction related to its antioxidant properties: A randomised, double-blind, placebo-controlled study. J. Funct. Foods 2016, 26, 460–469. [Google Scholar] [CrossRef]

- Katsu, K.; Suzuki, T.; Fujino, K.; Morishita, T.; Noda, T. Development of a DNA marker for variety discrimination specific to ‘Manten-Kirari’ based on an NGS-RNA sequence in Tartary buckwheat (Fagopyrum tataricum). Food Chem. 2019, 295, 51–57. [Google Scholar] [CrossRef]

| Rutin Content (mg/g DW) | Reference |

|---|---|

| 65.00–85.00 | Morishita et al. [26] |

| 74.31 | Guo et al. [14] |

| 34.03–38.47 | Sinkovič et al. [30] |

| 40.79–51.86 | Peng et al. [51] |

| 33.29 | Ge and Wang [70] |

| 28.00 | Xiao et al. [75] |

| 51.70 | Cho et al. [78] |

| 36.10 | Cho and Lee [79] |

| 36.80 | Oh et al. [98] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noda, T.; Ishiguro, K.; Suzuki, T.; Morishita, T. Tartary Buckwheat Bran: A Review of Its Chemical Composition, Processing Methods and Food Uses. Plants 2023, 12, 1965. https://doi.org/10.3390/plants12101965

Noda T, Ishiguro K, Suzuki T, Morishita T. Tartary Buckwheat Bran: A Review of Its Chemical Composition, Processing Methods and Food Uses. Plants. 2023; 12(10):1965. https://doi.org/10.3390/plants12101965

Chicago/Turabian StyleNoda, Takahiro, Koji Ishiguro, Tatsuro Suzuki, and Toshikazu Morishita. 2023. "Tartary Buckwheat Bran: A Review of Its Chemical Composition, Processing Methods and Food Uses" Plants 12, no. 10: 1965. https://doi.org/10.3390/plants12101965