Designing a Renewable Jet Fuel Supply Chain: Leveraging Incentive Policies to Drive Commercialization and Sustainability

Abstract

:1. Introduction and Literature Review

- What is the optimal corn-stover-based supply chain network design that can meet RJF demand in the Midwest?

- -

- Which regions are the optimal locations to supply biomass feedstock to biorefineries?

- -

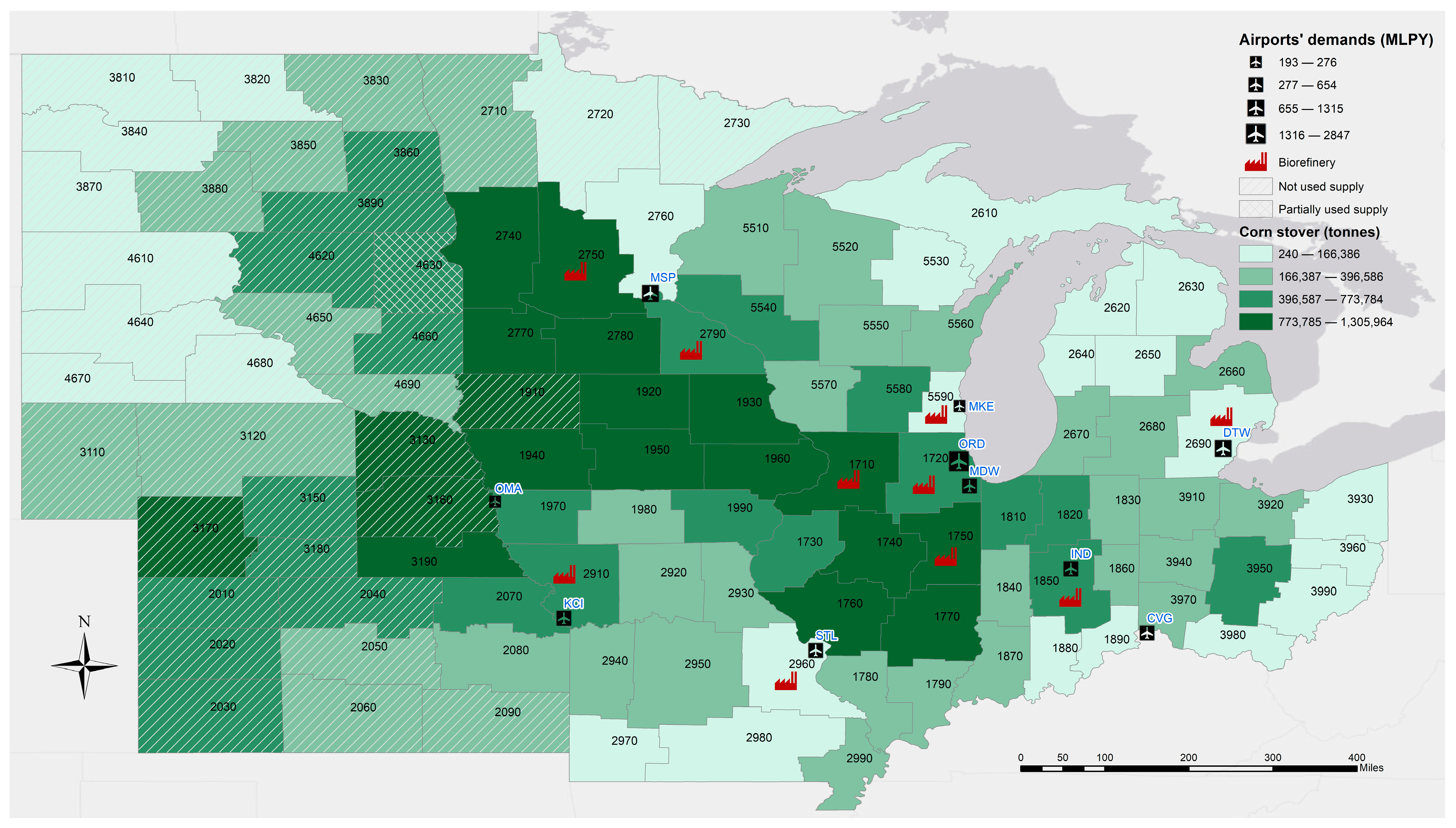

- How many and where should biorefineries be established to meet the demand at airports?

- -

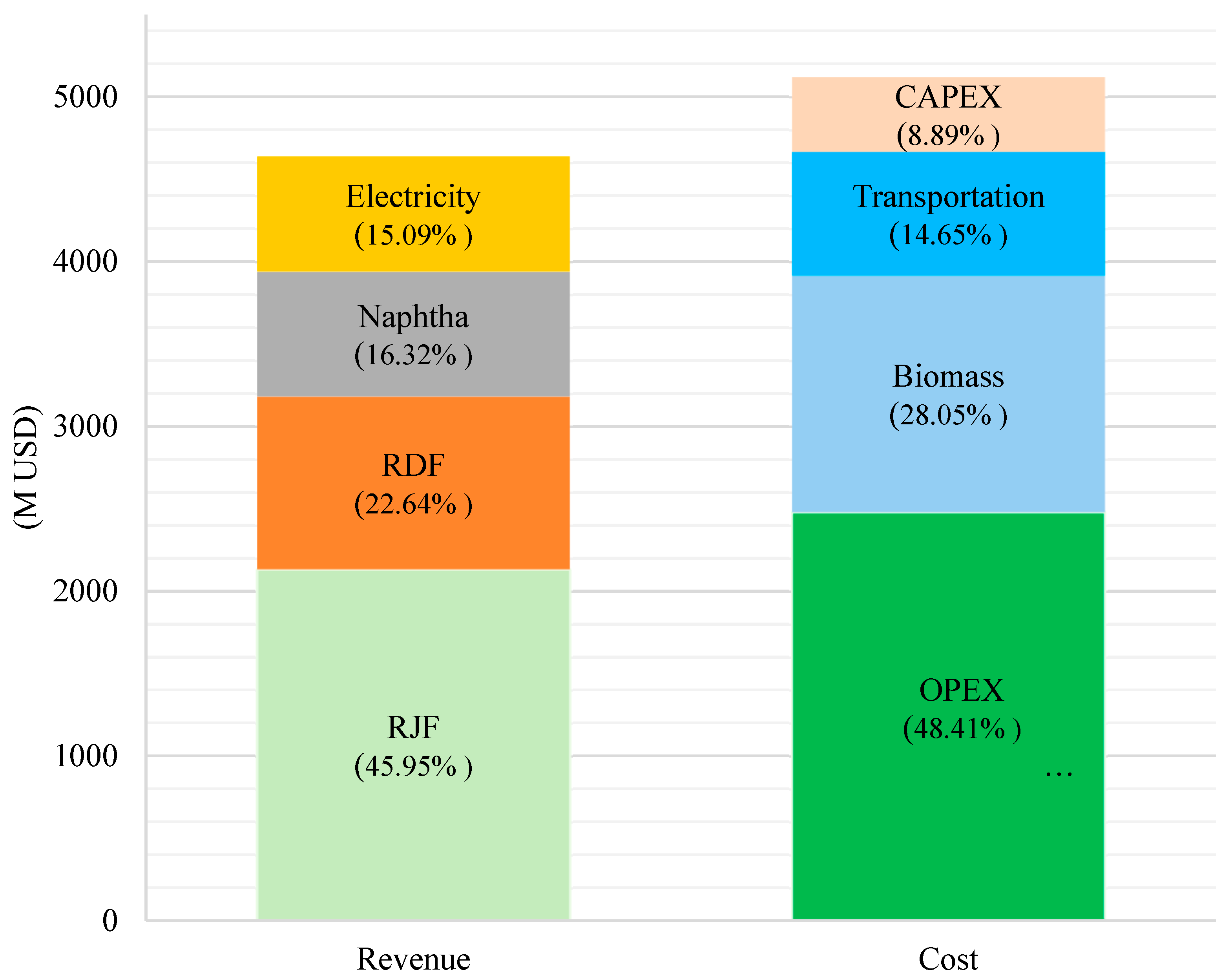

- How much are the costs and revenues generated by the supply chain?

- Can the four incentive programs cover the RJF supply chain costs?

- This study contributes to the literature by

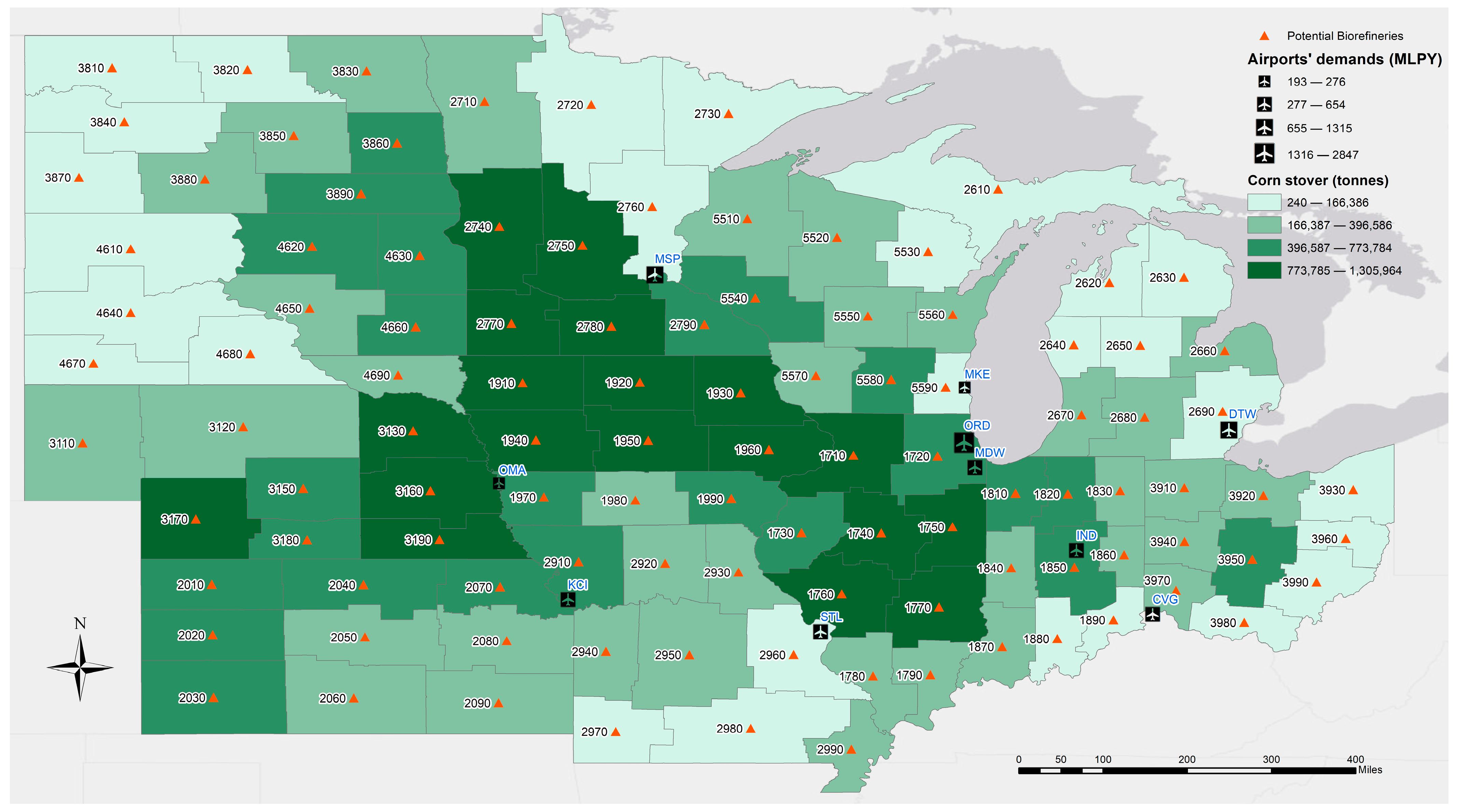

- Determining prospective agricultural sites in the Midwest where corn stover can be collected from lands planted by corn. In this study, we utilize agricultural statistics districts (ASDs) as more robust strategic-level supply regions compared to a previous study on RJF supply chain network design in the Midwest by Huang et al., which focused on counties as supply regions [34].

- Designing a three-echelon RJF supply chain network using corn stover in the Midwest. The region’s lands are abundantly planted with corn. The production of RJF from corn stover promises to improve the farming economy of the region and the sustainability of jet fuel used by airports. This study is the first to examine the entire Midwest (12 states) as a supply region for RJF production. Similar research by Huang et al. [34] also studied RJF supply chain network design but only considered seven states as the supply region.

- Analyzing the impact of four distinct monetary incentives on the profitability of a corn-stover-based RJF supply chain. There have been few studies comparing the profitability of RJF supply chains based on potential direct monetary incentives. This study offers one more incentive policy (CT) compared to the study by Ebrahimi et al. [21] in which they only applied PCP, BCAP, and BAP in their carinata-based RJF supply chain network.

2. Materials and Methods

2.1. The RJF Supply Chain Configuration

2.2. Model Formulation

2.2.1. RJF Supply Chain with no Monetary Incentives

2.2.2. RJF Supply Chain Incentivized with PCP

2.2.3. RJF Supply Chain Incentivized with BCAP

2.2.4. RJF Supply Chain Incentivized with BAP

2.2.5. RJF Supply Chain Incentivized with Cap-and-Trade Policy

2.3. Assumptions

- All the products, including RJF and coproducts, produced by the biorefineries will be sold.

- Transporting biomass feedstock from farms to biorefineries and transporting RJF from biorefineries to airports is carried out by trucks.

- RDF and naphtha are sold at biorefineries, with customers being responsible for transportation costs.

- For transportation purposes, each supply node at an ASD is considered to originate from the center of the ASD (centroid).

- For the case where the supply node and biorefinery are located in the same ASD, the transportation distance is assumed to be 2/3 of the radius of that ASD which is calculated using the area of each ASD [34].

- Preprocessing of corn stover is performed at biorefineries.

- The model utilizes the average demand for US domestic jet fuel spanning the years 2015 to 2019 for a robust and reliable estimate.

3. Results and Discussion

3.1. Supply Chain Analysis with no Monetary Incentives

3.2. Supply Chain Analysis with Application of Different Monetary Incentives and Their Corresponding Sensitivity Analyses

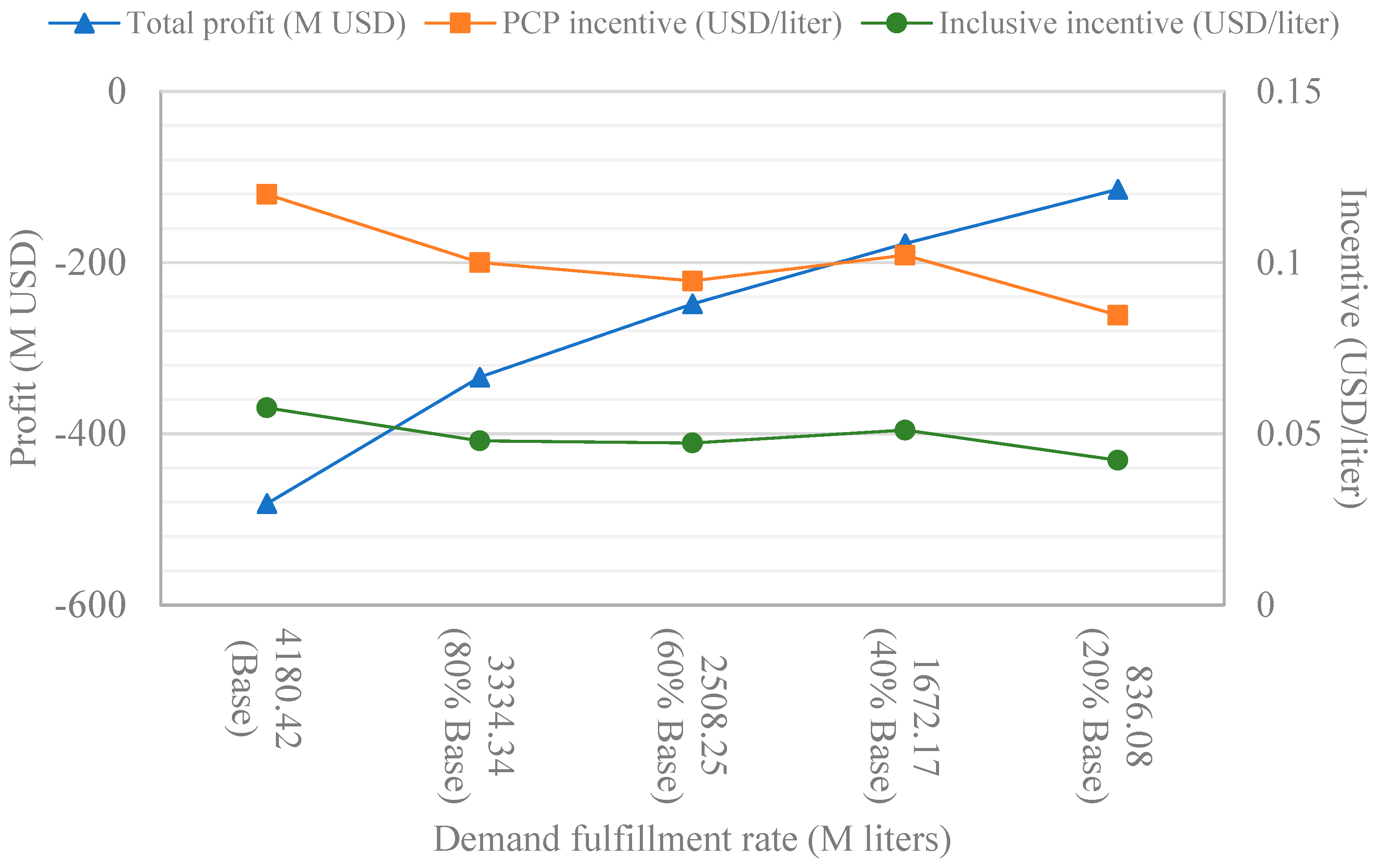

3.2.1. Supply Chain Incentivized with PCP and Its Sensitivity Analysis

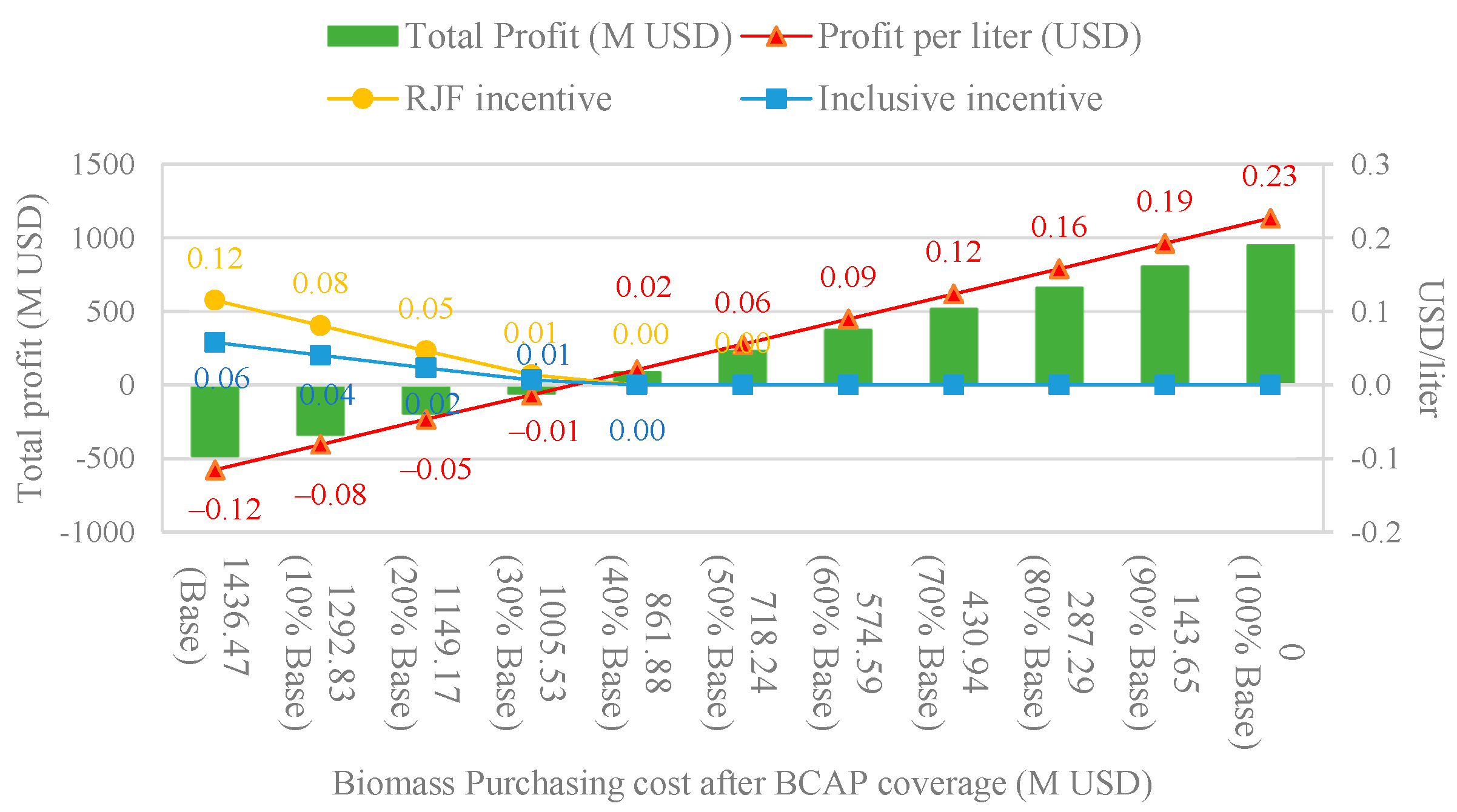

3.2.2. Supply Chain Incentivized with BCAP and Its Sensitivity Analysis

3.2.3. Supply Chain Incentivized with BAP and Its Sensitivity Analysis

3.2.4. Supply Chain Incentivized with the Carbon Cap-and-Trade Policy and Its Sensitivity Analysis

3.3. Sensitivity Analysis with Regard to Changes in Parameters

4. Managerial Implications

- Diversifying incentive policies: Managers can explore and implement various monetary incentive policies, such as PCP, BCAP, BAP, and CT, to make the RJF supply chain profitable. This provides flexibility and allows for the selection of incentives that align with specific organizational goals.

- Strategic use of carbon trading (CT): Recognizing CT as a reward-based mechanism opens avenues for supply chains to strategically focus on reducing carbon emissions. CT not only ensures profitability but also creates an opportunity to earn additional revenue by selling unused carbon credits. This highlights the importance of adopting environmentally sustainable practices.

- Cost-efficiency considerations: Understanding that different incentive policies require varying levels of coverage to achieve profitability can guide managers in selecting the most cost-effective approach. For instance, PCP, with the lowest coverage requirement, might be an attractive option for achieving commercialization thresholds.

- Cost allocation strategy: Managers should carefully consider the types of costs covered by different incentive programs. Whether it is total supply chain costs, biomass purchasing costs, or operational costs, aligning the incentive program with the specific cost components can optimize the impact on profitability.

- Sensitivity to external factors: Given the high sensitivity of RJF supply chain profitability to changes in biofuel prices and oil prices, managers should stay vigilant about market dynamics. Anticipating potential price increases, particularly in biofuels, allows for strategic decision-making even without the application of monetary incentives.

- Utilizing ASDs: Managers may explore the integration of ASDs as designated supply regions in the Midwest. This zoning strategy can enhance the efficiency of biomass feedstock sourcing by identifying regions with consistent and suitable sources. This approach aligns with sustainable and strategic sourcing practices, contributing to the reliability and stability of the RJF supply chain.

5. Limitations and Future Scope of the Study

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASD | Agricultural statistics districts |

| ASTM | American Society for Testing and Materials |

| ATJ | alcohol-to-jet |

| BAP | Biorefinery assistance program |

| BCAP | Biomass crop assistance program |

| CO2e | Carbon dioxide equivalent |

| CT | Cap-and-trade |

| CVG | Cincinnati/Northern Kentucky International Airport |

| DOE | Department of Energy |

| DTW | Detroit Metropolitan Wayne County Airport |

| FT | Fischer Tropsch |

| GHG | Greenhouse gas |

| GIS | Geographic Information Systems |

| HEFA | Hydroprocessed esters and fatty acids |

| HTL | Hydrothermal liquefaction |

| IND | Indianapolis International Airport |

| IRS | Internal Revenue Service |

| KCI | Kansas City International Airport |

| LCA | life-cycle analysis |

| MDW | Chicago Midway International Airport |

| MILFP | Mixed-integer linear fractional programming |

| MILP | Mixed-integer Linear Programming |

| MKE | General Mitchell International Airport |

| MSP | Minneapolis-Saint Paul International Airport |

| OMA | Eppley Airfield |

| ORD | O’Hare International Airport |

| PCP | Producer credit program |

| RDF | Renewable diesel fuel |

| RFS | Renewable Fuel Standard |

| RJF | Renewable jet fuel |

| STL | St. Louis Lambert International Airport |

| TEA | Techno-economic analysis |

| USDA | US Department of Agriculture |

Appendix A

| Parameter and Value | Description | Reference |

|---|---|---|

| = 0.36 | Selling price of naphtha (USD/L) | [21] |

| = 0.50 | Selling price of RDF (USD/L) | [21] |

| 0.51 | Selling price of RJF (USD/L) | [34] |

| = 49.61 | Selling price of corn stover (USD/tonne) | [29] |

| = 0.59 | Production cost of RJF at biorefinery (USD/L) | [39] |

| = 144.38 | RJF conversion rate from corn stover (L/tonne) | [39] |

| = 72.25 | Fuel coproduct j (naphtha) conversion rate from corn stover (L/tonne) | [39] |

| = 72.25 | Fuel coproduct j (RDF) conversion rate from corn stover (L/tonne) | [39] |

| = 6.615 | Transportation fixed cost of corn stover via truck (USD/tonne) | [48] |

| = 0.0548 | Transportation variable cost of corn stover via truck (USD/tonne-km) | [48] |

| = 0.0031 | Transportation fixed cost of RJF via truck (USD/L) | [49] |

| = 0.000394 | Transportation variable cost of RJF via truck (USD/L-km) | [49] |

| = 0.0756 | Emission factor of transporting corn stover (kg CO2e/tonne-km) | [50] |

| = 0.00009235 | Emission factor of transporting RJF (kg CO2e/L-km) | [51] |

| = 0.0001654 | Emission factor of corn stover acquisition (kg CO2e/tonne) | [50] |

| −0.344 a | Emission factor of producing RJF through FT pathway from corn stover (kg CO2e/L) | [34] |

| = 45.51 | Annual fixed cost of biorefinery (M USD) | [34] |

| 0.59 | Production cost of RJF at biorefinery (USD/L) | [39] |

| Supplier District (Share of Supply Assignment) | Activated Biorefinery and Its Capacity | Demand Node (Share of Demand Fulfillment) |

|---|---|---|

| S b1940 (34.82%), S1950 (38.53%), S1960 (26.65%). | B c1710 | ORD (100%). |

| S1710 (34.07%), S1720 (16.16%), S1810 (17.09%), S1930 (5.30%), S1980 (10.40%), S1990 (16.98%). | B1720 | MDW (1.11%), ORD (98.89). |

| S1730 (19.75%), S1740 (29.67%), S1750 (28.36%), S1760 (21.18%), S1810 (1.04%). | B1750 | MDW (71.53%), DTW (28.47%). |

| S1770 (26.67%), S1820 (10.88%), S1840 (12.69%), S1850 (18.06%), S1860 (7.59%), S1870 (12.28%), S1880 (3.09%), S1890 (2.45%), S3790 (5.98%). | B1850 | CVG (40.60%), DTW (17.63%), IND (41.77%). |

| S1820 (3.03%), S1830 (8.21%), S2610 (0.38%), S2620 (1.10%), S2630 (0.83%), S2640 (1.78%), S2650 (5.34%), S2660 (8.19%), S2670 (7.53%), S2680 (12.20%), S2690 (3.76%), S3910 (6.09%), S3920 (7.08%), S3930 (4.12%), S3940 (11.77%), S3950 (13.56%), S3960 (1.67%), S3980 (2.03%), S3990 (1.32%). | B2690 | DTW (100%). |

| S2740 (31.79%), S2750 (29.97%), S2760 (3.18%), S2770 (25.42%), S4630 (3.06%), S5510 (6.58%). | B2750 | MSP (100%). |

| S1920 (40.24%), S2780 (34.29%), S2790 (23.51%), S5540 (1.96%). | B2790 | MSP (48.12%), ORD (51.88%). |

| S1970 (30.36%), S2070 (20.13%), S2080 (8.74%), S2910 (21.21%), S3190 (19.56%). | B2910 | OMA (31.73), KCI (68.27%). |

| S1760 (10.14%), S1780 (12.06%), S1790 (12.14%), S2080 (0.92%), S2920 (9.76%), S2930 (15.18%), S2940 (10.23%), S2950 (11.37%), S2960 (4.62%), S2970 (3.82%), S2980 (0.56%), S2990 (9.21%). | B2960 | STL (100%). |

| S1930 (27.65%), S5520 (6.59%), S5530 (3.97%), S5540 (11.67%), S5550 (8.04%), S5560 (10.36%), S5570 (11.36%), S5580 (16.32%), S5590 (4.06%). | B5590 | MKE (30.70%), ORD (69.30%). |

References

- Shahriar, M.F.; Khanal, A. The Current Techno-Economic, Environmental, Policy Status and Perspectives of Sustainable Aviation Fuel (SAF). Fuel 2022, 325, 124905. [Google Scholar] [CrossRef]

- Air Transport Action Group. Aviation Benefits beyond Borders. 2016. Volume 1, pp. 1–36. Available online: https://aviationbenefits.org/media/149668/abbb2016_full_a4_web.pdf (accessed on 10 September 2023).

- Wei, H.; Liu, W.; Chen, X.; Yang, Q.; Li, J.; Chen, H. Renewable Bio-Jet Fuel Production for Aviation: A Review. Fuel 2019, 254, 115599. [Google Scholar] [CrossRef]

- Chao, H.; Agusdinata, D.B.; DeLaurentis, D.A. The Potential Impacts of Emissions Trading Scheme and Biofuel Options to Carbon Emissions of U.S. Airlines. Energy Policy 2019, 134, 110993. [Google Scholar] [CrossRef]

- Mousavi-Avval, S.H.; Shah, A. Techno-Economic Analysis of Hydroprocessed Renewable Jet Fuel Production from Pennycress Oilseed. Renew. Sustain. Energy Rev. 2021, 149, 111340. [Google Scholar] [CrossRef]

- Escalante, E.S.R.; Ramos, L.S.; Rodriguez Coronado, C.J.; de Carvalho Júnior, J.A. Evaluation of the Potential Feedstock for Biojet Fuel Production: Focus in the Brazilian Context. Renew. Sustain. Energy Rev. 2022, 153, 111716. [Google Scholar] [CrossRef]

- Aviation Benefits beyond Borders. Powering the Future of Flight: The Six Easy Steps to Growing a Viable Aviation Biofuels Industry. 2011. Available online: https://seors.unfccc.int/applications/seors/attachments/get_attachment?code=GRPR31ZA287D3KAP5XOXQO2WP1JE9SQQ (accessed on 10 September 2023).

- Diniz, A.P.M.M.; Sargeant, R.; Millar, G.J. Stochastic Techno-Economic Analysis of the Production of Aviation Biofuel from Oilseeds. Biotechnol. Biofuels 2018, 11, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Perkis, D.F.; Tyner, W.E. Developing a Cellulosic Aviation Biofuel Industry in Indiana: A Market and Logistics Analysis. Energy 2018, 142, 793–802. [Google Scholar] [CrossRef]

- U.S. Department of Energy. U.S. Billion-Ton Update: Biomass Supply for a Bioenergy and Bioproducts Industry; Oak Ridge National Lab.: Oak Ridge, TN, USA, 2011. [Google Scholar]

- Wang, W.-C.; Tao, L. Bio-Jet Fuel Conversion Technologies. Renew. Sustain. Energy Rev. 2016, 53, 801–822. [Google Scholar] [CrossRef]

- Geleynse, S.; Brandt, K.; Garcia-Perez, M.; Wolcott, M.; Zhang, X. The Alcohol-to-Jet Conversion Pathway for Drop-In Biofuels: Techno-Economic Evaluation. ChemSusChem 2018, 11, 3728–3741. [Google Scholar] [CrossRef]

- Ail, S.S.; Dasappa, S. Biomass to Liquid Transportation Fuel via Fischer Tropsch Synthesis–Technology Review and Current Scenario. Renew. Sustain. Energy Rev. 2016, 58, 267–286. [Google Scholar] [CrossRef]

- Kargbo, H.; Harris, J.S.; Phan, A.N. “Drop-in” Fuel Production from Biomass: Critical Review on Techno-Economic Feasibility and Sustainability. Renew. Sustain. Energy Rev. 2021, 135, 110168. [Google Scholar] [CrossRef]

- Peters, M.A.; Alves, C.T.; Onwudili, J.A.; Rakopoulos, D.; Peters, M.A.; Alves, C.T.; Onwudili, J.A. A Review of Current and Emerging Production Technologies for Biomass-Derived Sustainable Aviation Fuels. Energies 2023, 16, 6100. [Google Scholar] [CrossRef]

- de Jong, S.; Hoefnagels, R.; Faaij, A.; Slade, R.; Mawhood, R.; Junginger, M. The Feasibility of Short-Term Production Strategies for Renewable Jet Fuels–A Comprehensive Techno-Economic Comparison. Biofuels Bioprod. Biorefin. 2015, 9, 778–800. [Google Scholar] [CrossRef]

- Natelson, R.H.; Wang, W.-C.; Roberts, W.L.; Zering, K.D. Technoeconomic Analysis of Jet Fuel Production from Hydrolysis, Decarboxylation, and Reforming of Camelina Oil. Biomass Bioenergy 2015, 75, 23–34. [Google Scholar] [CrossRef]

- Pearlson, M.; Wollersheim, C.; Hileman, J. A Techno-Economic Review of Hydroprocessed Renewable Esters and Fatty Acids for Jet Fuel Production. Biofuels Bioprod. Biorefin. 2013, 7, 89–96. [Google Scholar] [CrossRef]

- Pham, V.; Holtzapple, M.; El-Halwagi, M. Techno-Economic Analysis of Biomass to Fuel Conversion via the MixAlco Process. J. Ind. Microbiol. Biotechnol. 2010, 37, 1157–1168. [Google Scholar] [CrossRef] [PubMed]

- de Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Life-Cycle Analysis of Greenhouse Gas Emissions from Renewable Jet Fuel Production. Biotechnol. Biofuels 2017, 10, 64. [Google Scholar] [CrossRef]

- Ebrahimi, S.; Haji Esmaeili, S.A.; Sobhani, A.; Szmerekovsky, J. Renewable Jet Fuel Supply Chain Network Design: Application of Direct Monetary Incentives. Appl. Energy 2022, 310, 118569. [Google Scholar] [CrossRef]

- Haji Esmaeili, S.A.; Sobhani, A.; Ebrahimi, S.; Szmerekovsky, J.; Dybing, A.; Keramati, A. Location Allocation of Biorefineries for a Switchgrass-Based Bioethanol Supply Chain Using Energy Consumption and Emissions. Logistics 2023, 7, 5. [Google Scholar] [CrossRef]

- Grimme, W. The Introduction of Sustainable Aviation Fuels—A Discussion of Challenges, Options and Alternatives. Aerospace 2023, 10, 218. [Google Scholar] [CrossRef]

- Zheng, T.; Wang, B.; Rajaeifar, M.A.; Heidrich, O.; Zheng, J.; Liang, Y.; Zhang, H. How Government Policies Can Make Waste Cooking Oil-to-Biodiesel Supply Chains More Efficient and Sustainable. J. Clean. Prod. 2020, 263, 121494. [Google Scholar] [CrossRef]

- Noh, H.M.; Benito, A.; Alonso, G. Study of the Current Incentive Rules and Mechanisms to Promote Biofuel Use in the EU and Their Possible Application to the Civil Aviation Sector. Transp. Res. Part D Transp. Environ. 2016, 46, 298–316. [Google Scholar] [CrossRef]

- Ng, K.S.; Farooq, D.; Yang, A. Global Biorenewable Development Strategies for Sustainable Aviation Fuel Production. Renew. Sustain. Energy Rev. 2021, 150, 111502. [Google Scholar] [CrossRef]

- Malladi, K.T.; Sowlati, T. Impact of Carbon Pricing Policies on the Cost and Emission of the Biomass Supply Chain: Optimization Models and a Case Study. Appl. Energy 2020, 267, 115069. [Google Scholar] [CrossRef]

- Haites, E. Carbon Taxes and Greenhouse Gas Emissions Trading Systems: What Have We Learned? Climate Policy 2018, 18, 955–966. [Google Scholar] [CrossRef]

- Haji Esmaeili, S.A.; Sobhani, A.; Szmerekovsky, J.; Dybing, A.; Pourhashem, G. First-Generation vs. Second-Generation: A Market Incentives Analysis for Bioethanol Supply Chains with Carbon Policies. Appl. Energy 2020, 277, 115606. [Google Scholar] [CrossRef]

- Haji Esmaeili, S.A.; Szmerekovsky, J.; Sobhani, A.; Dybing, A.; Peterson, T.O. Sustainable Biomass Supply Chain Network Design with Biomass Switching Incentives for First-Generation Bioethanol Producers. Energy Policy 2020, 138, 111222. [Google Scholar] [CrossRef]

- Yazdanparast, R.; Jolai, F.; Pishvaee, M.S.; Keramati, A. A Resilient Drop-in Biofuel Supply Chain Integrated with Existing Petroleum Infrastructure: Toward More Sustainable Transport Fuel Solutions. Renew. Energy 2022, 184, 799–819. [Google Scholar] [CrossRef]

- United States Department of Agriculture National Agricultural Statistics Service. Available online: https://www.nass.usda.gov/ (accessed on 10 September 2023).

- Leila, M.; Whalen, J.; Bergthorson, J. Strategic Spatial and Temporal Design of Renewable Diesel and Biojet Fuel Supply Chains: Case Study of California, USA. Energy 2018, 156, 181–195. [Google Scholar] [CrossRef]

- Huang, E.; Zhang, X.; Rodriguez, L.; Khanna, M.; de Jong, S.; Ting, K.C.C.; Ying, Y.; Lin, T. Multi-Objective Optimization for Sustainable Renewable Jet Fuel Production: A Case Study of Corn Stover Based Supply Chain System in Midwestern U.S. Renew. Sustain. Energy Rev. 2019, 115, 109403. [Google Scholar] [CrossRef]

- Tong, K.; You, F.; Rong, G. Robust Design and Operations of Hydrocarbon Biofuel Supply Chain Integrating with Existing Petroleum Refineries Considering Unit Cost Objective. Comput. Chem. Eng. 2014, 68, 128–139. [Google Scholar] [CrossRef]

- Ullah, K.M.; Masum, F.H.; Field, J.L.; Dwivedi, P. Designing a GIS-Based Supply Chain for Producing Carinata-Based Sustainable Aviation Fuel in Georgia, USA. Biofuels Bioprod. Biorefin. 2023, 17, 786–802. [Google Scholar] [CrossRef]

- Elia, J.A.; Baliban, R.C.; Floudas, C.A.; Gurau, B.; Weingarten, M.B.; Klotz, S.D. Hardwood Biomass to Gasoline, Diesel, and Jet Fuel: Supply Chain Optimization Framework for a Network of Thermochemical Refineries. Energy Fuels 2013, 27, 4325–4352. [Google Scholar] [CrossRef]

- Masum, F.H.; Coppola, E.; Field, J.L.; Geller, D.; George, S.; Miller, J.L.; Mulvaney, M.J.; Nana, S.; Seepaul, R.; Small, I.M.; et al. Supply Chain Optimization of Sustainable Aviation Fuel from Carinata in the Southeastern United States. Renew. Sustain. Energy Rev. 2023, 171, 113032. [Google Scholar] [CrossRef]

- Pereira, L.G.; MacLean, H.L.; Saville, B.A. Financial Analyses of Potential Biojet Fuel Production Technologies. Biofuels, Bioprod. Biorefin. 2017, 11, 665–681. [Google Scholar] [CrossRef]

- Guo, C.; Hu, H.; Wang, S.; Rodriguez, L.F.; Ting, K.C.; Lin, T. Multiperiod Stochastic Programming for Biomass Supply Chain Design under Spatiotemporal Variability of Feedstock Supply. Renew. Energy 2022, 186, 378–393. [Google Scholar] [CrossRef]

- NASS Cropland Data. Available online: https://www.nass.usda.gov/Data_and_Statistics/ (accessed on 13 June 2021).

- Mohamed Abdul Ghani, N.M.A.; Vogiatzis, C.; Szmerekovsky, J. Biomass Feedstock Supply Chain Network Design with Biomass Conversion Incentives. Energy Policy 2018, 116, 39–49. [Google Scholar] [CrossRef]

- Zetterholm, J.; Pettersson, K.; Leduc, S.; Mesfun, S.; Lundgren, J.; Wetterlund, E. Resource Efficiency or Economy of Scale: Biorefinery Supply Chain Configurations for Co-Gasification of Black Liquor and Pyrolysis Liquids. Appl. Energy 2018, 230, 912–924. [Google Scholar] [CrossRef]

- Osmani, A.; Zhang, J. Economic and Environmental Optimization of a Large Scale Sustainable Dual Feedstock Lignocellulosic-Based Bioethanol Supply Chain in a Stochastic Environment. Appl. Energy 2014, 114, 572–587. [Google Scholar] [CrossRef]

- Bureau of Transportation Statistics (BTS) Airlines, Airports, and Aviation. Available online: https://www.bts.gov/topics/airlines-airports-and-aviation (accessed on 13 June 2023).

- Mixed-Integer Programming (MIP). Available online: https://www.gurobi.com/resources/mixed-integer-programming-mip-a-primer-on-the-basics/ (accessed on 29 November 2023).

- EIA US Jet Fuel Wholesale/Resale Price by Refiners. Available online: www.eia.gov (accessed on 13 June 2021).

- Sokhansanj, S.; Mani, S.; Turhollow, A.; Kumar, A.; Bransby, D.; Lynd, L.; Laser, M. Large-Scale Production, Harvest and Logistics of Switchgrass (Panicum virgatum L.)–Current Technology and Envisioning a Mature Technology. Biofuels Bioprod. Biorefin. 2009, 3, 124–141. [Google Scholar] [CrossRef]

- Searcy, E.; Flynn, P.; Ghafoori, E.; Kumar, A. The Relative Cost of Biomass Energy Transport. In Applied Biochemistry and Biotechnology; Springer: New York, NY, USA, 2007; Volume 137–140, pp. 639–652. [Google Scholar]

- You, F.; Wang, B. Life Cycle Optimization of Biomass-to-Liquid Supply Chains with Distributed–Centralized Processing Networks. Ind. Eng. Chem. Res. 2011, 50, 10102–10127. [Google Scholar] [CrossRef]

- Zhang, F.; Johnson, D.M.; Wang, J. Life-Cycle Energy and GHG Emissions of Forest Biomass Harvest and Transport for Biofuel Production in Michigan. Energies 2015, 8, 3258–3271. [Google Scholar] [CrossRef]

| Reference | Zoning | Region | Incentive Policies | Feedstocks | Method |

|---|---|---|---|---|---|

| [33] | County | California | BAP | Wheat straw, Corn stover, forest residues, and camelina | MILP |

| [34] | County | Midwest (7 states) | - | Corn stover | MILP |

| [35] | County | Illinois | BAP and PCP | crop residues, wood residues, and energy crops | MILFP |

| [36] | County | Georgia | - | Carinata | GIS + MILP |

| [37] | County | USA | - | Hardwood biomass | MILP |

| [38] | County | Alabama, Florida, and Georgia | - | Carinata | MILP |

| [21] | ASD | Alabama, Florida, and Georgia | BCAP, BAP, and PCP | Carinata | MILP |

| Current study | ASD | Midwest (12 states) | BCAP, BAP, PCP, and CT | Corn stover | MILP |

| Airports | Total Jet Fuel Demand (MLPY) | Estimated RJF Demand (MLPY) |

|---|---|---|

| O’Hare International Airport (ORD) | 2846.51 | 1423.25 |

| Minneapolis-Saint Paul International Airport (MSP) | 1301.50 | 650.75 |

| Detroit Metropolitan Wayne County Airport (DTW) | 1314.88 | 657.44 |

| Chicago Midway International Airport (MDW) | 653.79 | 326.90 |

| St. Louis Lambert International Airport (STL) | 618.58 | 309.29 |

| Kansas City International Airport (KCI) | 415.03 | 207.51 |

| Indianapolis International Airport (IND) | 375.96 | 187.98 |

| Cincinnati/Northern Kentucky International Airport (CVG) | 365.37 | 182.69 |

| General Mitchell International Airport (MKE) | 276.33 | 138.16 |

| Eppley Airfield (OMA) | 192.90 | 96.45 |

| Total | 8360.84 | 4180.42 |

| Indices | Description | Indices | Description |

|---|---|---|---|

| Sets | Parameters | ||

| Set of suppliers, indexed by i | Transportation fixed cost of corn stover via truck (USD/tonne) | ||

| Set of biorefineries, indexed by k | Transportation variable cost of corn stover via truck (USD/tonne km) | ||

| Set of demand zones, indexed by e | Transportation fixed cost of RJF via truck (USD/L) | ||

| Set of byproducts, indexed by j; naphtha, RDF, and electricity | Transportation variable cost of RJF via truck (USD/L km) | ||

| Variables | Selling price of byproduct j (USD/L) | ||

| 1 if a biorefinery is activated at location k; 0 otherwise | Annual RJF demand level at demand node e (L) | ||

| Quantity of biomass transported from supply area i to biorefinery k (tonnes) | Production cost of RJF at biorefinery (USD/L) | ||

| Quantity of RJF transported from biorefinery k to demand zone e (L) | Buying price of one kg of carbon () in the carbon market (USD) | ||

| Quantity of byproduct j produced at biorefinery k (L) | Selling price of one kg of carbon () in the carbon market (USD) | ||

| Number of carbon credits purchased | Emission factor of transporting corn stover (kg /tonne km) | ||

| Number of carbon credits sold | Emission factor of transporting RJF (kg /L km) | ||

| RJF selling price (USD/L) | Emission factor of corn stover acquisition (kg /tonne) | ||

| BAP discount rate | Emission factor of producing RJF from corn stover (kg /L) | ||

| BCAP discount rate | Distance from supplier i to biorefinery k (km) | ||

| Monetary incentive for PCP program (USD/L) | Distance from biorefinery k to demand zone e (km) | ||

| Selling price of corn stover (USD/tonne) | Capacity of a biorefinery (tonne) | ||

| Quantity of corn stover available at supply node i | Annualized fixed cost of biorefinery (USD) | ||

| RJF conversion rate from corn stover (L/tonne) | Annualized variable cost of biorefinery (USD) | ||

| Conversion rate of fuel byproduct j from corn stover (L/tonne) | Carbon capacity allowed for the RJF supply chain (kg ) | ||

| Carbon Cap with Regard to Emission Created by Fossil-Based Jet Fuel | |||||

|---|---|---|---|---|---|

| Base | 25% | 50% | 75% | 100% | |

| Total profit (USD M) | −481.65 | 126.59 | 826.27 | 1526.82 | 2210.26 |

| Sold carbon credit (Mg) | 0 | 2795 | 6013 | 9236 | 12,442 |

| Profit per liter (USD) | −0.12 | 0.03 | 0.19 | 0.37 | 0.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ebrahimi, S.; Szmerekovsky, J.; Golkar, B.; Haji Esmaeili, S.A. Designing a Renewable Jet Fuel Supply Chain: Leveraging Incentive Policies to Drive Commercialization and Sustainability. Mathematics 2023, 11, 4915. https://doi.org/10.3390/math11244915

Ebrahimi S, Szmerekovsky J, Golkar B, Haji Esmaeili SA. Designing a Renewable Jet Fuel Supply Chain: Leveraging Incentive Policies to Drive Commercialization and Sustainability. Mathematics. 2023; 11(24):4915. https://doi.org/10.3390/math11244915

Chicago/Turabian StyleEbrahimi, Sajad, Joseph Szmerekovsky, Bahareh Golkar, and Seyed Ali Haji Esmaeili. 2023. "Designing a Renewable Jet Fuel Supply Chain: Leveraging Incentive Policies to Drive Commercialization and Sustainability" Mathematics 11, no. 24: 4915. https://doi.org/10.3390/math11244915

APA StyleEbrahimi, S., Szmerekovsky, J., Golkar, B., & Haji Esmaeili, S. A. (2023). Designing a Renewable Jet Fuel Supply Chain: Leveraging Incentive Policies to Drive Commercialization and Sustainability. Mathematics, 11(24), 4915. https://doi.org/10.3390/math11244915