Experimental Investigation on Pyrolysis of Domestic Plastic Wastes for Fuel Grade Hydrocarbons

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization of Feedstock

2.2.1. Proximate and Ultimate Analysis

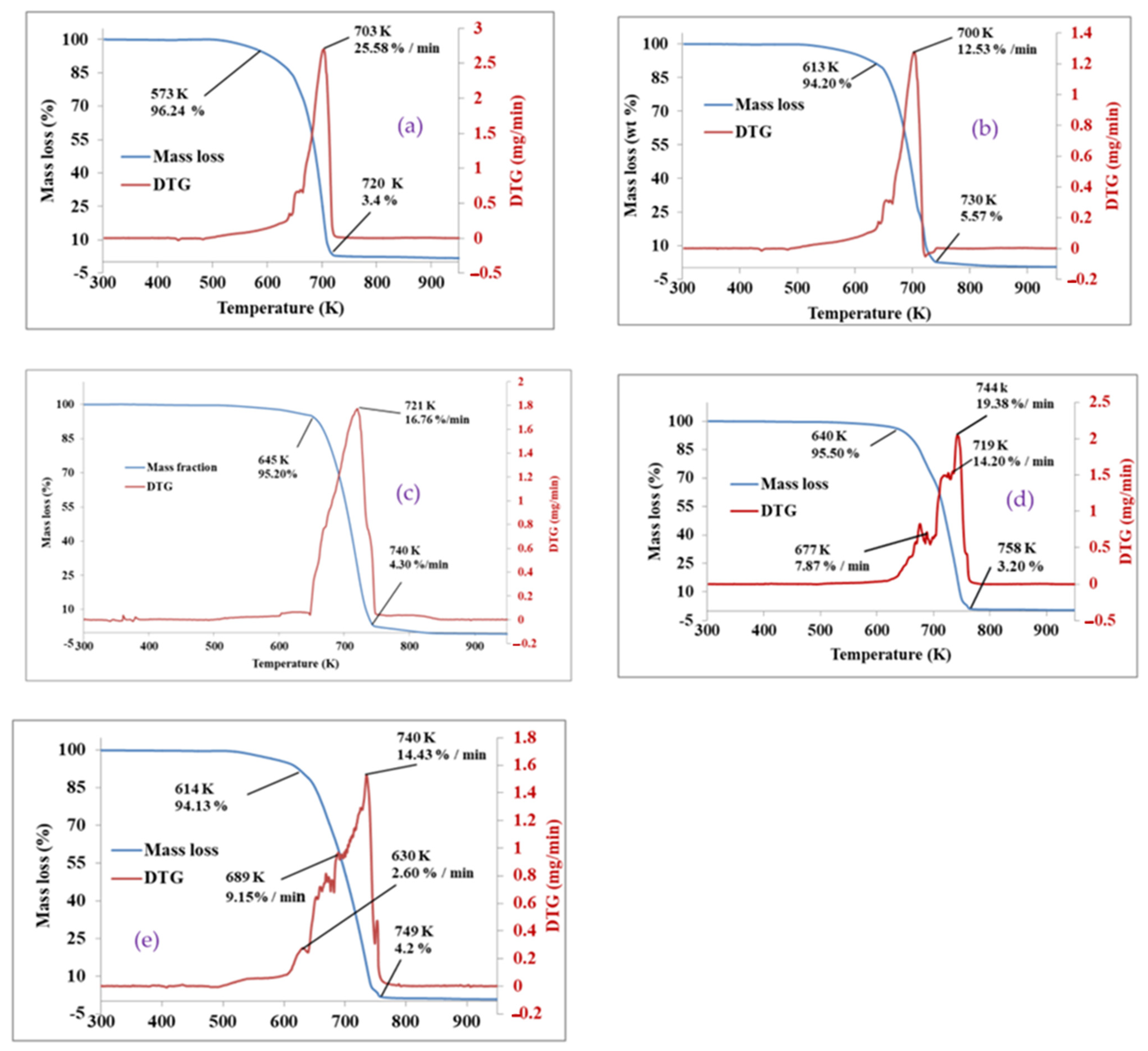

2.2.2. Thermogravimetric Analysis (TGA)

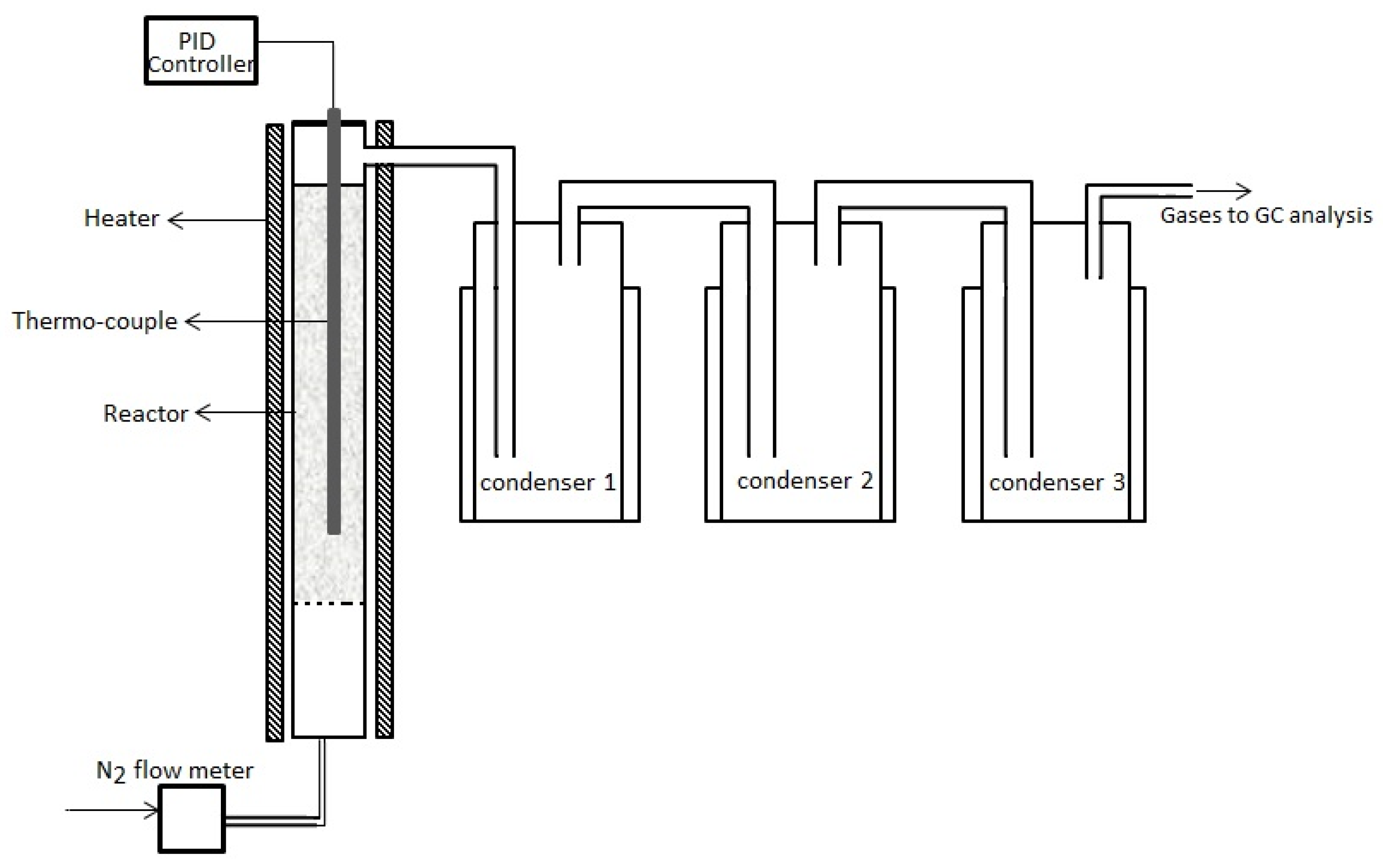

2.3. Experimental Set Up and Procedure

2.4. Product Analysis

3. Results and Discussion

3.1. Characterization of Plastic Feedstock

3.1.1. Thermogravimetric Analysis (TGA) Analysis of Plastic Waste

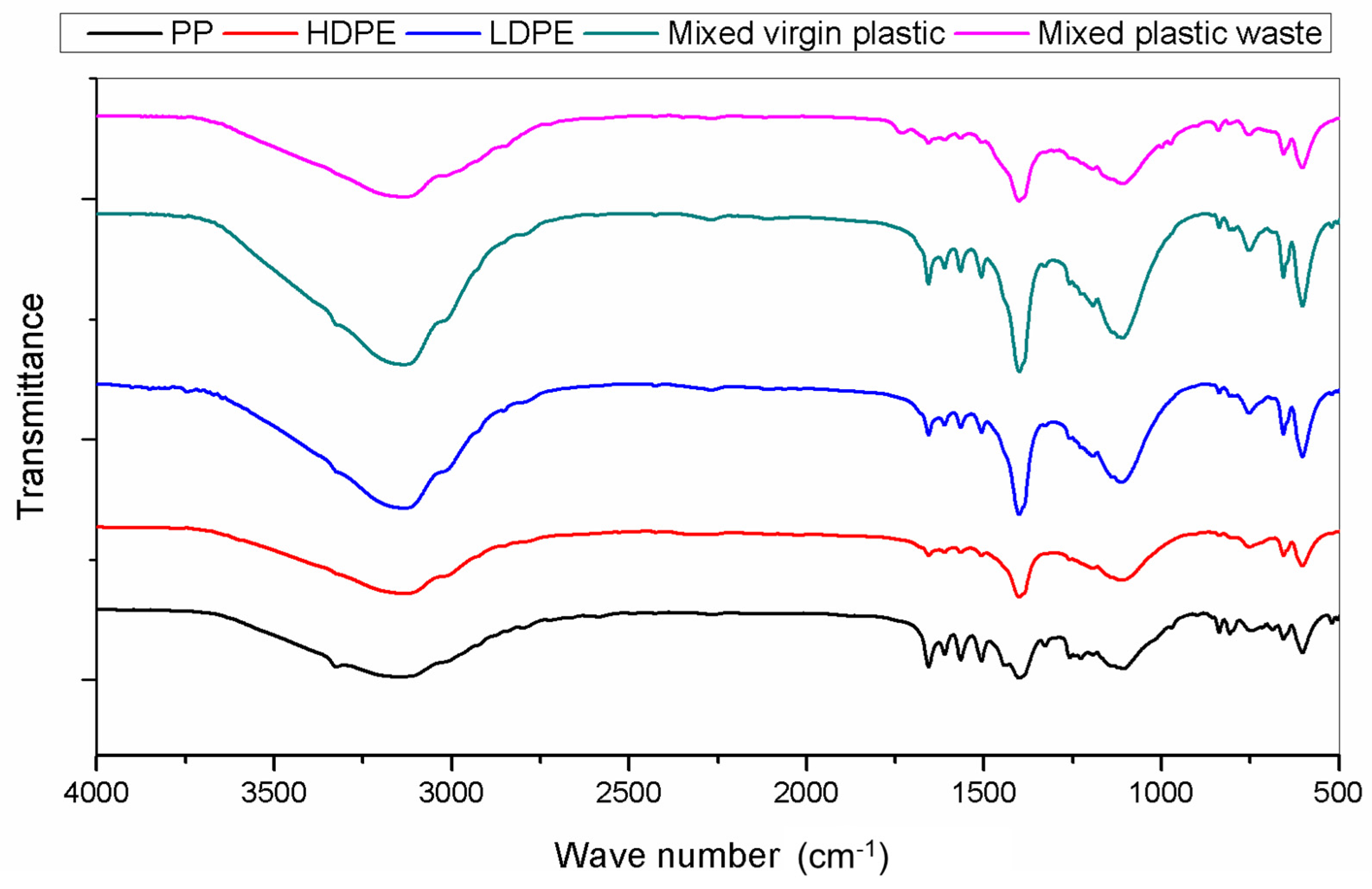

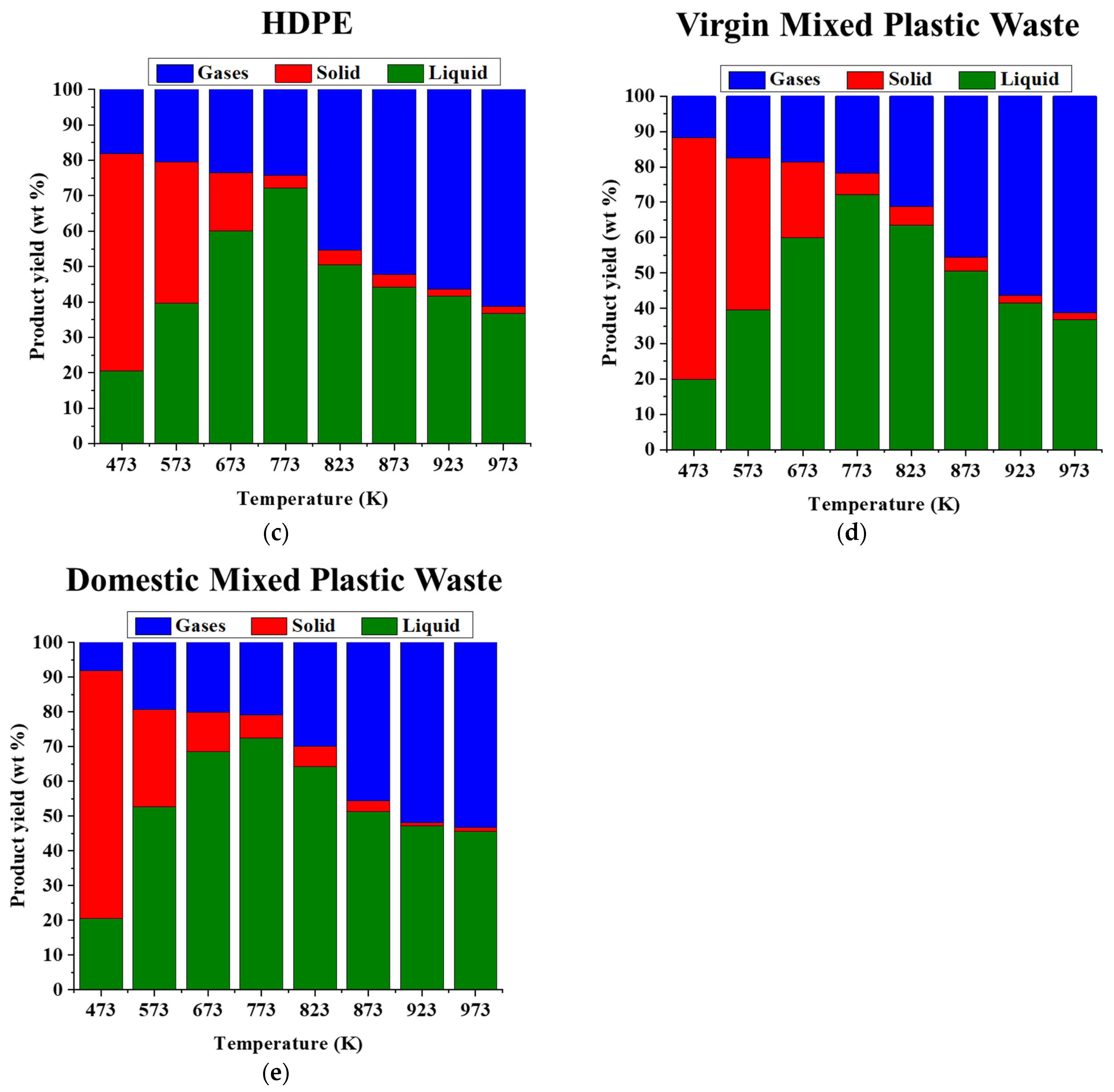

3.1.2. FTIR Analysis of Plastic Feedstock

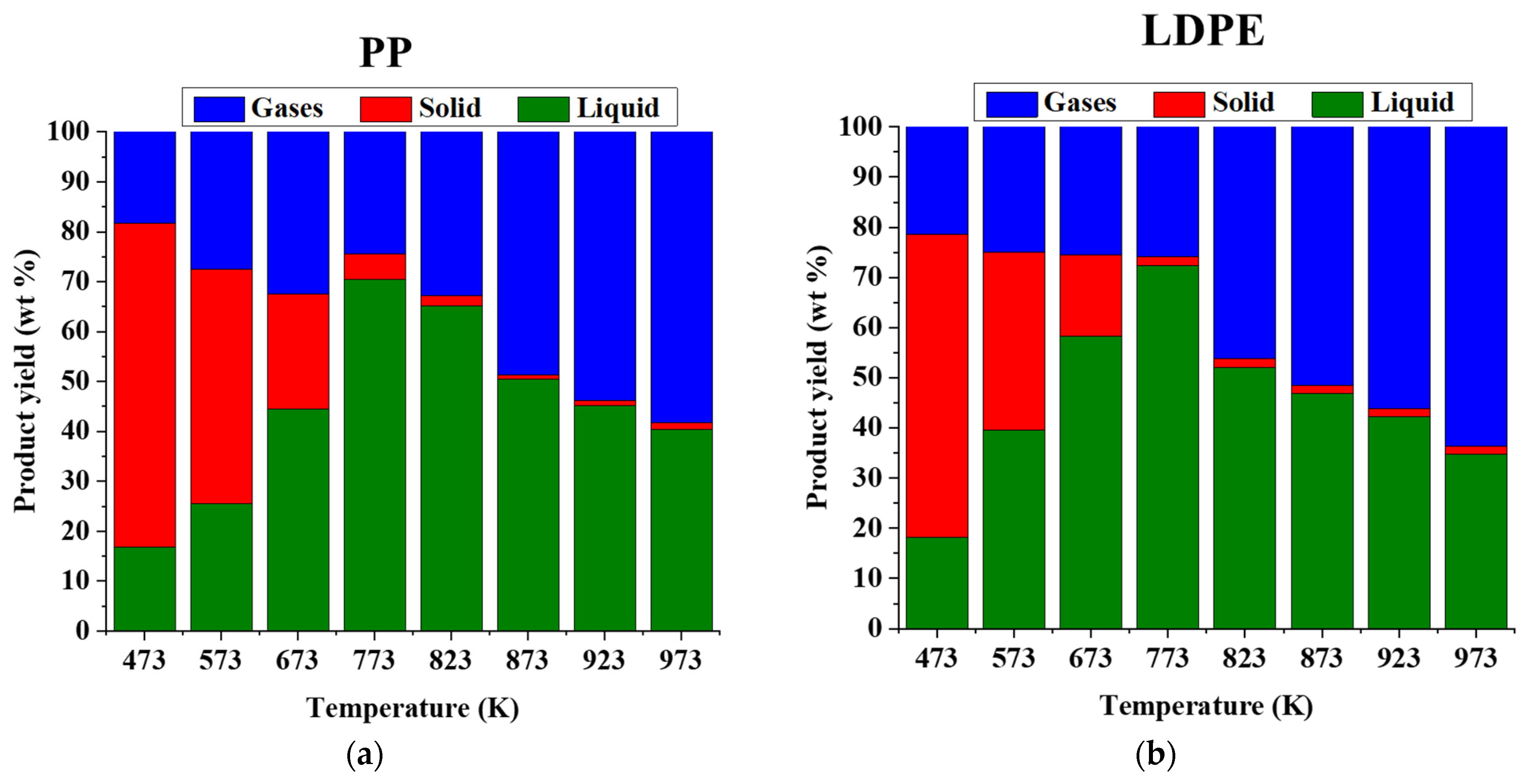

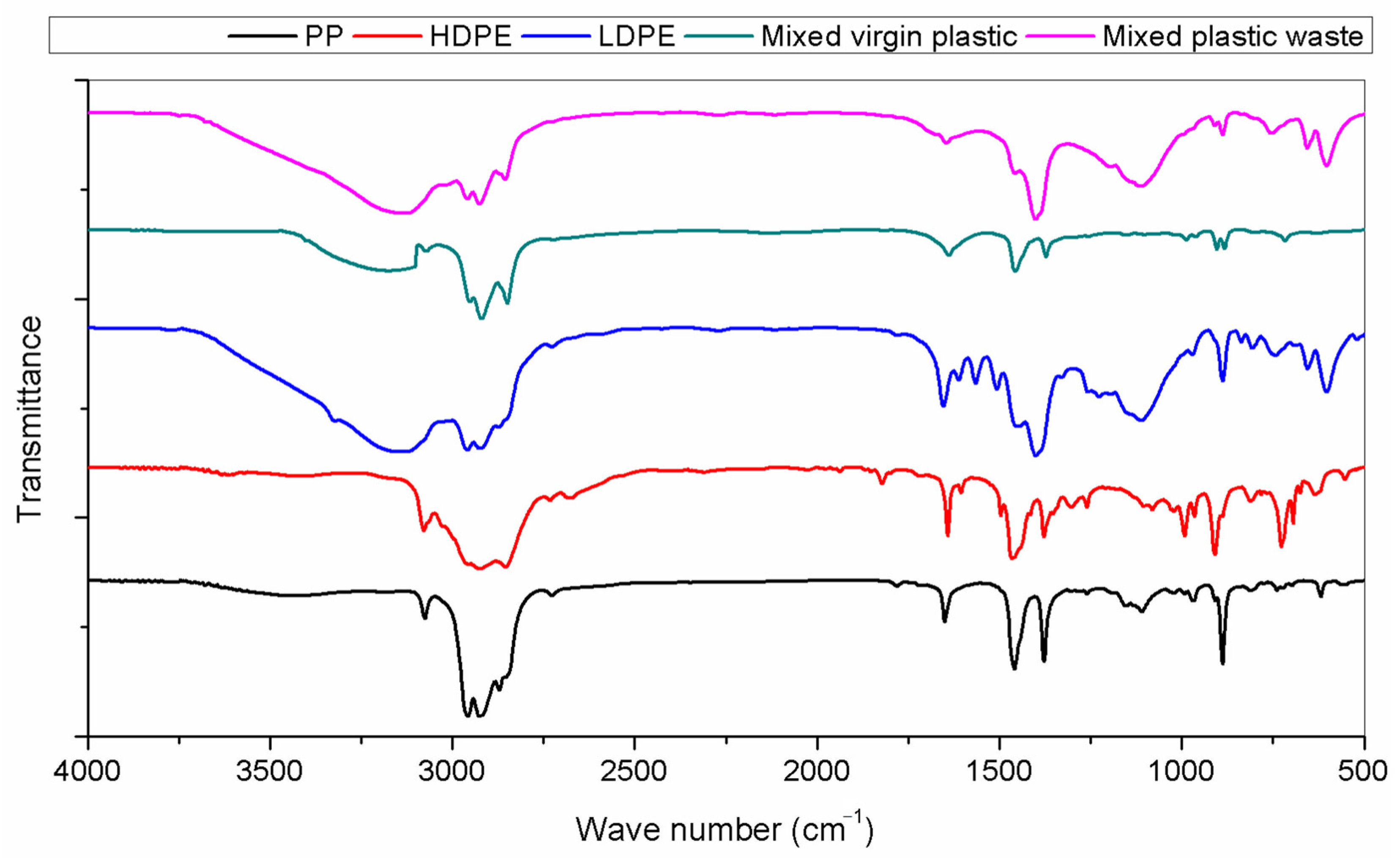

3.2. Product Distribution of Pyrolysis Reaction with Domestic Plastic Waste, PP, LDPE, HDPE, and Mixed Virgin Plastic

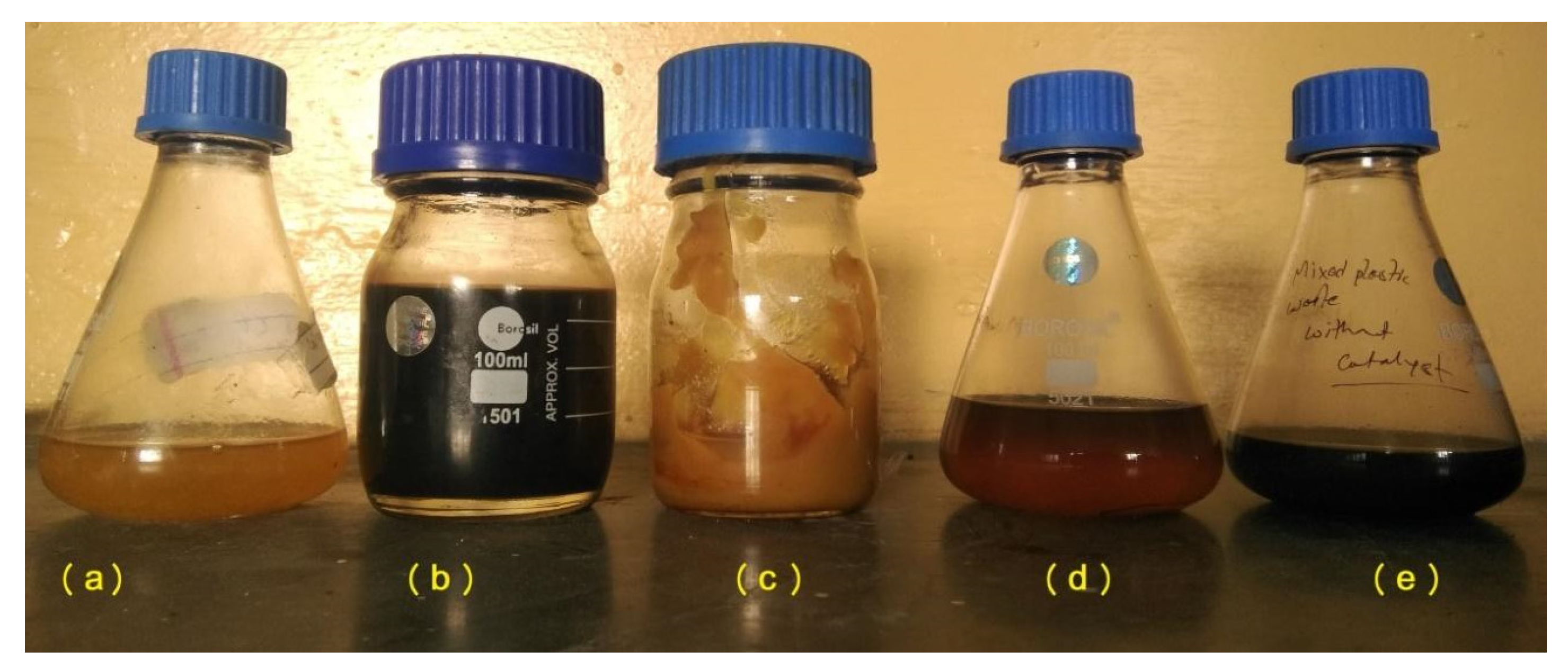

3.3. Analysis of Liquid Products Extracted from Plastic Feedstock by Pyrolysis Process

3.3.1. FTIR of Pyrolysis Liquid Fuels

3.3.2. GC-MS Analysis

3.3.3. Analysis of Physic-Chemical Properties of Liquid Fuels

3.4. Gas Analysis Obtained from Pyrolysis of Plastic Waste

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rafey, A.; Siddiqui, F.Z. A Review of Plastic Waste Management in India–Challenges and Opportunities. Int. J. Environ. Anal. Chem. 2021, 1–17. [Google Scholar] [CrossRef]

- Damodharan, D.; Sathiyagnanam, A.P.; Rana, D.; Saravanan, S.; Rajesh Kumar, B.; Sethuramasamyraja, B. Effective Utilization of Waste Plastic Oil in a Direct Injection Diesel Engine Using High Carbon Alcohols as Oxygenated Additives for Cleaner Emissions. Energy Convers. Manag. 2018, 166, 81–97. [Google Scholar] [CrossRef]

- Tulashie, S.K.; Boadu, E.K.; Dapaah, S. Plastic Waste to Fuel via Pyrolysis: A Key Way to Solving the Severe Plastic Waste Problem in Ghana. Therm. Sci. Eng. Prog. 2019, 11, 417–424. [Google Scholar] [CrossRef]

- Chandran, M.; Tamilkolundu, S.; Murugesan, C. Conversion of Plastic Waste to Fuel; Academic Press: Cambridge, MA, USA, 2020; ISBN 9780128178805. [Google Scholar]

- Dobó, Z.; Jakab, Z.; Nagy, G.; Koós, T.; Szemmelveisz, K.; Muránszky, G. Transportation Fuel from Plastic Wastes: Production, Purification and SI Engine Tests. Energy 2019, 189, 116353. [Google Scholar] [CrossRef]

- Bharathy, S.; Gnanasikamani, B.; Radhakrishnan Lawrence, K. Investigation on the Use of Plastic Pyrolysis Oil as Alternate Fuel in a Direct Injection Diesel Engine with Titanium Oxide Nanoadditive. Environ. Sci. Pollut. Res. 2019, 26, 10319–10332. [Google Scholar] [CrossRef] [PubMed]

- Honus, S.; Kumagai, S.; Němček, O.; Yoshioka, T. Replacing Conventional Fuels in USA, Europe, and UK with Plastic Pyrolysis Gases—Part I: Experiments and Graphical Interchangeability Methods. Energy Convers. Manag. 2016, 126, 1128–1145. [Google Scholar] [CrossRef]

- Miandad, R.; Barakat, M.A.; Aburiazaiza, A.S.; Rehan, M.; Ismail, I.M.I.; Nizami, A.S. Effect of Plastic Waste Types on Pyrolysis Liquid Oil. Int. Biodeterior. Biodegrad. 2017, 119, 239–252. [Google Scholar] [CrossRef]

- Park, K.B.; Jeong, Y.S.; Guzelciftci, B.; Kim, J.S. Characteristics of a New Type Continuous Two-Stage Pyrolysis of Waste Polyethylene. Energy 2019, 166, 343–351. [Google Scholar] [CrossRef]

- Thahir, R.; Altway, A.; Juliastuti, S.R. Susianto Production of Liquid Fuel from Plastic Waste Using Integrated Pyrolysis Method with Refinery Distillation Bubble Cap Plate Column. Energy Rep. 2019, 5, 70–77. [Google Scholar] [CrossRef]

- Jahnavi, N.; Kanmani, K.; Kumar, P.S.; Varjani, S. Conversion of Waste Plastics into Low Emissive Hydrocarbon Fuel Using Catalyst Produced from Biowaste. Environ. Sci. Pollut. Res. 2020, 28, 63638–63645. [Google Scholar] [CrossRef]

- Achilias, D.S.; Roupakias, C.; Megalokonomos, P.; Lappas, A.A.; Antonakou, V. Chemical Recycling of Plastic Wastes Made from Polyethylene (LDPE and HDPE) and Polypropylene (PP). J. Hazard. Mater. 2007, 149, 536–542. [Google Scholar] [CrossRef] [PubMed]

- Adrados, A.; de Marco, I.; Caballero, B.M.; López, A.; Laresgoiti, M.F.; Torres, A. Pyrolysis of Plastic Packaging Waste: A Comparison of Plastic Residuals from Material Recovery Facilities with Simulated Plastic Waste. Waste Manag. 2012, 32, 826–832. [Google Scholar] [CrossRef] [PubMed]

- Quesada, L.; Calero, M.; Martín-Lara, M.A.; Pérez, A.; Blázquez, G. Characterization of Fuel Produced by Pyrolysis of Plastic Film Obtained of Municipal Solid Waste. Energy 2019, 186, 115874. [Google Scholar] [CrossRef]

- Dogu, O.; Pelucchi, M.; van de Vijver, R.; van Steenberge, P.H.M.; D’hooge, D.R.; Cuoci, A.; Mehl, M.; Frassoldati, A.; Faravelli, T.; van Geem, K.M. The Chemistry of Chemical Recycling of Solid Plastic Waste via Pyrolysis and Gasification: State-of-the-Art, Challenges, and Future Directions. Prog. Energy Combust. Sci. 2021, 84, 100901. [Google Scholar] [CrossRef]

- Dao Thi, H.; Djokic, M.R.; van Geem, K.M. Detailed Group-Type Characterization of Plastic-Waste Pyrolysis Oils: By Comprehensive Two-Dimensional Gas Chromatography Including Linear, Branched, and Di-Olefins. Separations 2021, 8, 103. [Google Scholar] [CrossRef]

- Pal, S.; Kumar, A.; Sharma, A.K.; Ghodke, P.K.; Pandey, S.; Patel, A. Recent Advances in Catalytic Pyrolysis of Municipal Plastic Waste for the Production of Hydrocarbon Fuels. Processes 2022, 10, 1497. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Dai, L.; Fan, L.; Duan, D.; Ruan, R.; Wang, Y.; Liu, Y.; Zhou, Y.; Yu, Z.; Liu, Y.; Jiang, L. Production of Hydrocarbon-Rich Bio-Oil from Soapstock via Fast Microwave-Assisted Catalytic Pyrolysis. J. Anal. Appl. Pyrolysis 2017, 125, 356–362. [Google Scholar] [CrossRef]

- Abdy, C.; Zhang, Y.; Wang, J.; Yang, Y.; Artamendi, I.; Allen, B. Pyrolysis of polyolefin plastic waste and potential applications in asphalt road construction: A technical review. Resour. Conserv. Recycl. 2022, 180, 106213. [Google Scholar] [CrossRef]

- Rajamohan, S.; Kasimani, R. Analytical Characterization of Products Obtained from Slow Pyrolysis of Calophyllum Inophyllum Seed Cake: Study on Performance and Emission Characteristics of Direct Injection Diesel Engine Fuelled with Bio-Oil Blends. Environ. Sci. Pollut. Res. 2018, 25, 9523–9538. [Google Scholar] [CrossRef]

- Hazrat, M.A.; Rasul, M.G.; Khan, M.M.K.; Azad, A.K.; Bhuiya, M.M.K. Utilization of Polymer Wastes as Transport Fuel Resources—A Recent Development. Energy Procedia 2014, 61, 1681–1685. [Google Scholar] [CrossRef] [Green Version]

- Williams, P.T.; Slaney, E. Analysis of Products from the Pyrolysis and Liquefaction of Single Plastics and Waste Plastic Mixtures. Resour. Conserv. Recycl. 2007, 51, 754–769. [Google Scholar] [CrossRef]

- Shah, S.H.; Khan, Z.M.; Raja, I.A.; Mahmood, Q.; Bhatti, Z.A.; Khan, J.; Farooq, A.; Rashid, N.; Wu, D. Low Temperature Conversion of Plastic Waste into Light Hydrocarbons. J. Hazard. Mater. 2010, 179, 15–20. [Google Scholar] [CrossRef]

- Siddiqui, M.N.; Redhwi, H.H. Pyrolysis of Mixed Plastics for the Recovery of Useful Products. Fuel Process. Technol. 2009, 90, 545–552. [Google Scholar] [CrossRef]

- Ahmad, N.; Ahmad, N.; Maafa, I.M.; Ahmed, U.; Akhter, P.; Shehzad, N.; Amjad, U.e.s.; Hussain, M. Thermal Conversion of Polystyrene Plastic Waste to Liquid Fuel via Ethanolysis. Fuel 2020, 279, 118498. [Google Scholar] [CrossRef]

- Abbas, A.S.; Shubar, S.D.A. Pyrolysis of High-Density Polyethylene for the Production of Fuel-like Liquid Hydrocarbon. Iraqi J. Chem. Pet. Eng. 2008, 99, 23–29. [Google Scholar]

- Miskolczi, N.; Bartha, L.; Deák, G.; Jóver, B. Thermal Degradation of Municipal Plastic Waste for Production of Fuel-like Hydrocarbons. Polym. Degrad. Stab. 2004, 86, 357–366. [Google Scholar] [CrossRef]

- Rajendran, K.M.; Chintala, V.; Sharma, A.; Pal, S.; Pandey, J.K.; Ghodke, P. Review of Catalyst Materials in Achieving the Liquid Hydrocarbon Fuels from Municipal Mixed Plastic Waste (MMPW). Mater. Today Commun. 2020, 24, 100982. [Google Scholar] [CrossRef]

- Singh, R.K.; Ruj, B. Time and Temperature Depended Fuel Gas Generation from Pyrolysis of Real World Municipal Plastic Waste. Fuel 2016, 174, 164–171. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, D.; Lei, H.; Villota, E.; Ruan, R. Jet Fuel Production from Waste Plastics via Catalytic Pyrolysis with Activated Carbons. Appl. Energy 2019, 251, 113337. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, Y.; Ke, L.; Dai, L.; Wu, Q.; Kirk, C.; Yuan, Z.; Zou, R.; Liu, Y.; Roger, R. A review on catalytic pyrolysis of plastic wastes to high-value products. Energy Con. Manag. 2022, 254, 115243. [Google Scholar] [CrossRef]

- Ruiz, M.; Martin, E.; Blin, J.; Van De Steene, L.; Broust, F. Understanding the Secondary Reactions of Flash Pyrolysis Vapors inside a Hot Gas Filtration Unit. Energy Fuels 2017, 31, 13785–13795. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S.; Zayoud, A.; Kusenberg, M.; Roosen, M.; Vermeire, F.; Yazdani, P.; Van Waeyenberg, J.; Eschenbacher, A.; Hernandez, F.J.A.; Kuzmanović, M.; et al. Thermochemical recycling of end-of-life and virgin HDPE: A pilot-scale study. J. Anal. Appl. Pyrolysis 2022, 166, 105614. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. Valorization of Packaging Plastic Waste by Slow Pyrolysis. Resour. Conserv. Recycl. 2018, 128, 69–77. [Google Scholar] [CrossRef]

- Budsaereechai, S.; Hunt, A.J.; Ngernyen, Y. Catalytic Pyrolysis of Plastic Waste for the Production of Liquid Fuels for Engines. RSC Adv. 2019, 9, 5844–5857. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pal, S.; Chintala, V.; Sharma, A.K.; Ghodke, P.; Kumar, S.; Kumar, P. Effect of Injection Timing on Performance and Emission Characteristics of Single Cylinder Diesel Engine Running on Blends of Diesel and Waste Plastic Fuels. Mater. Today Proc. 2019, 17, 209–215. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sharma, P.K.; Chintala, V.; Khatri, N.; Patel, A. Environment-Friendly Biodiesel/Diesel Blends for Improving the Exhaust Emission and Engine Performance to Reduce the Pollutants Emitted from Transportation Fleets. Int. J. Environ. Res. Public Health 2020, 17, 3896. [Google Scholar] [CrossRef] [PubMed]

| Properties | Virgin Plastic | Mixed Virgin Plastic | Domestic Plastic Waste | ||

|---|---|---|---|---|---|

| PP | HDPE | LDPE | |||

| Volatile matter (wt.%) | 99.9 | 97.7 | 98.78 | 98.72 | 93.45 |

| Fixed carbon (wt.%) | 0.09 | 2.12 | 1.12 | 1.17 | 5.34 |

| Ash (wt.%) | 0.01 | 0.18 | 0.1 | 0.11 | 1.21 |

| Bulk Density (kg m−3) | 0.574 | 0.584 | 0.552 | 0.56 | 0.862 |

| Conradson Carbon residue | 0.2 | 0.68 | 0.61 | 0.51 | 1.34 |

| Heating value (MJ kg−1) | 41.1 | 42.1 | 45.7 | 42.04 | 40.42 |

| Carbon (wt.%) | 83.49 | 85.26 | 85.85 | 84.88 | 84.43 |

| Hydrogen (wt.%) | 16.13 | 14.65 | 14.15 | 14.83 | 12.45 |

| Nitrogen (wt.%) | 0.28 | 0.09 | 0 | 0.26 | 2.71 |

| Sulfur (wt.%) | 0.1 | 0 | 0 | 0.03 | 0.41 |

| H/C ratio | 0.19 | 0.17 | 0.16 | 0.17 | 0.15 |

| Wavelength | Remark |

|---|---|

| 3200–3000 cm−1 | =C−H stretch, −C−H stretch, CH3, CH2 & CH (strong) |

| 2962 cm−1 | −C−H stretch, CH3, CH2 & CH (strong) |

| 1650 cm−1 | C=C stretch |

| 1458, 1377 cm−1 | −C−H bending, C=C bending. |

| Below 1000 cm−1 | =C−H bending and fingerprint region |

| Compound | Molecular Formula | LDPE | HDPE | PP | Mixed Virgin | Domestic Plastic Waste (wt.%) |

|---|---|---|---|---|---|---|

| 1-Octene | C8H16 | 1.78 | 1.35 | 0.81 | ||

| Toluene | C10H20 | 0 | 4.05 | 5.26 | 1.01 | |

| Nonane | C9H20 | 3.01 | 2.41 | 1.08 | ||

| 1-Nonene | C9H18 | 1.06 | 2.62 | 3.16 | 3.52 | |

| 1-Decene | C10H20 | 12.43 | 4.14 | 2.57 | 6.8 | 3.84 |

| Decane | C10H22 | 8.58 | 5.21 | 2.24 | 5.42 | 3.17 |

| cyclodecane | C10H20 | 5.76 | 3.9 | |||

| 1-Undecene | C11H22 | 5.47 | 1.7 | 6.06 | ||

| Undecane | C11H24 | 12.31 | 5.6 | 3.27 | 1.2 | 2.41 |

| 1-Dodecene | C12H24 | 9.13 | 5.78 | 4.74 | 4.15 | 3.61 |

| Dodecane | C12H26 | 6.65 | 3.65 | 5.49 | 12.63 | |

| Tridecane | C13H28 | 1.93 | 5.32 | |||

| 1-Tridecene | C13H26 | 5.32 | 1.97 | 5.73 | 3.58 | 9.96 |

| 1-Tetradecene | C14H28 | 2.02 | 5.23 | 6.83 | 8.31 | |

| Tetradecane | C14H30 | 6.55 | 4.66 | 5.09 | 5.83 | 5.97 |

| 1-Pentadecene | C15H30 | 6.12 | 10.58 | 3.65 | 9.08 | 2.28 |

| Pentadecane | C15H32 | 11.71 | 6.82 | 9.16 | 10.21 | |

| 1-Hexadecene | C16H32 | 5.08 | 11.61 | 8.32 | 5.24 | |

| 1-Heptadecene | C17H34 | 8.56 | 9.09 | 10.06 | 5.71 | 0.17 |

| Hexadecane | C16H34 | 3.61 | 8.19 | 12.46 | 8.52 | 2.62 |

| Dibutyl adipate | C14H26O4 | 5.9 | ||||

| Heptadance | C17H36 | 3.66 | 5.48 | 4.38 | 3.01 | 3.08 |

| 1-Octadecene | C18H36 | 0 | 2.45 | 13.46 | 1.31 | |

| 1-Nonadecene | C19H38 | 2.06 | 1.52 | 2.02 | 0.94 | |

| Eicosane | C20H42 | 2.07 | 1.52 | 2.02 | 2.94 |

| Parameter | PP | LDPE | HDPE | Mixed Virgin Plastic | Domestic Plastic Waste | Gasoline | Diesel |

|---|---|---|---|---|---|---|---|

| Appearance | Pale yellow | Pale yellow | Dark brown | Brown | Dark brown | No color | Pale yellow |

| Moisture (% v/v) (ASTM D95) | 0 | 0 | 0 | 0 | 2.4 | 0.4–0.5 | 0.1–0.3 |

| API gravity @ 60 °F (ASTM D287) | 33.03 | 27.48 | 34.21 | 36.72 | 39.6 | 55 | 38 |

| Density @ 15 °C g/cc (ASTM D4052—16) | 0.86 | 0.89 | 0.92 | 0.91 | 0.86 | 0.78 | 0.807 |

| Kinematic viscosity @ 40 °C (cSt) (ASTM D445) | 4.09 | 3.98 | 5.08 | 4.53 | 4.48 | 1.17 | 2–4.5 |

| Gross heat of combustion (MJ/kg) (ASTM D240—17) | 45.72 | 45.59 | 43.63 | 44.61 | 43.92 | 47.64 | 45.21 |

| Conradson carbon residue (wt.%) (ASTM D189) | 0.12 | 0.19 | 0.11 | 0.15 | 0.15 | 0.14 | 0.35 |

| Ash (wt.%) (ASTM D482) | 0.013 | 0 | 0 | 0.11 | 0.013 | 0.001 | 0.01 |

| Pour point (°C) (ASTM D97) | −9 | −10 | 35 | 30 | 18 | − | 6 |

| Flash Point (°C) (ASTM D93) | 30 | 48 | 29 | 40 | 35 | 42 | 52 |

| Aniline point (°C) | 40 | 45 | 50 | 50 | 60 | 71 | 77.5 |

| Diesel index | 42.5 | 38.01 | 40.23 | 38.54 | 35.34 | − | 40 |

| Plastic | LDPE | HDPE | PP | Mixed Virgin Plastic | Domestic Plastic Waste |

|---|---|---|---|---|---|

| Hydrogen | 0.31 | 0.46 | 0.96 | 1.58 | 0.45 |

| Carbon dioxide | 0 | 0 | 0 | 0 | 0.82 |

| Carbon monoxide | 0 | 0 | 0 | 0 | 0.44 |

| Methane | 7.47 | 9.28 | 1.48 | 6.07 | 7.6 |

| Ethane | 12.1 | 11.56 | 14.42 | 11.69 | 12.12 |

| Ethene | 27.99 | 26.41 | 38.65 | 31.02 | 27.41 |

| Propane | 8.1 | 8.67 | 8.87 | 8.55 | 8.44 |

| Propene | 26.34 | 26.74 | 29.9 | 27.66 | 26.71 |

| Butane | 2.52 | 1.51 | 1.67 | 1.9 | 1.98 |

| Butene | 15.17 | 15.37 | 4.05 | 11.53 | 14.03 |

| Gross calorific value (MJ nm−3) | 69.99 | 69.02 | 75.61 | 70.97 | 69.38 |

| Net calorific value (MJ nm−3) | 67.49 | 66.60 | 71.02 | 67.84 | 66.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghodke, P.K.; Sharma, A.K.; Moorthy, K.; Chen, W.-H.; Patel, A.; Matsakas, L. Experimental Investigation on Pyrolysis of Domestic Plastic Wastes for Fuel Grade Hydrocarbons. Processes 2023, 11, 71. https://doi.org/10.3390/pr11010071

Ghodke PK, Sharma AK, Moorthy K, Chen W-H, Patel A, Matsakas L. Experimental Investigation on Pyrolysis of Domestic Plastic Wastes for Fuel Grade Hydrocarbons. Processes. 2023; 11(1):71. https://doi.org/10.3390/pr11010071

Chicago/Turabian StyleGhodke, Praveen Kumar, Amit Kumar Sharma, Krishna Moorthy, Wei-Hsin Chen, Alok Patel, and Leonidas Matsakas. 2023. "Experimental Investigation on Pyrolysis of Domestic Plastic Wastes for Fuel Grade Hydrocarbons" Processes 11, no. 1: 71. https://doi.org/10.3390/pr11010071

APA StyleGhodke, P. K., Sharma, A. K., Moorthy, K., Chen, W.-H., Patel, A., & Matsakas, L. (2023). Experimental Investigation on Pyrolysis of Domestic Plastic Wastes for Fuel Grade Hydrocarbons. Processes, 11(1), 71. https://doi.org/10.3390/pr11010071