Integration of Renewable Energy Systems in Desalination

Abstract

1. Introduction

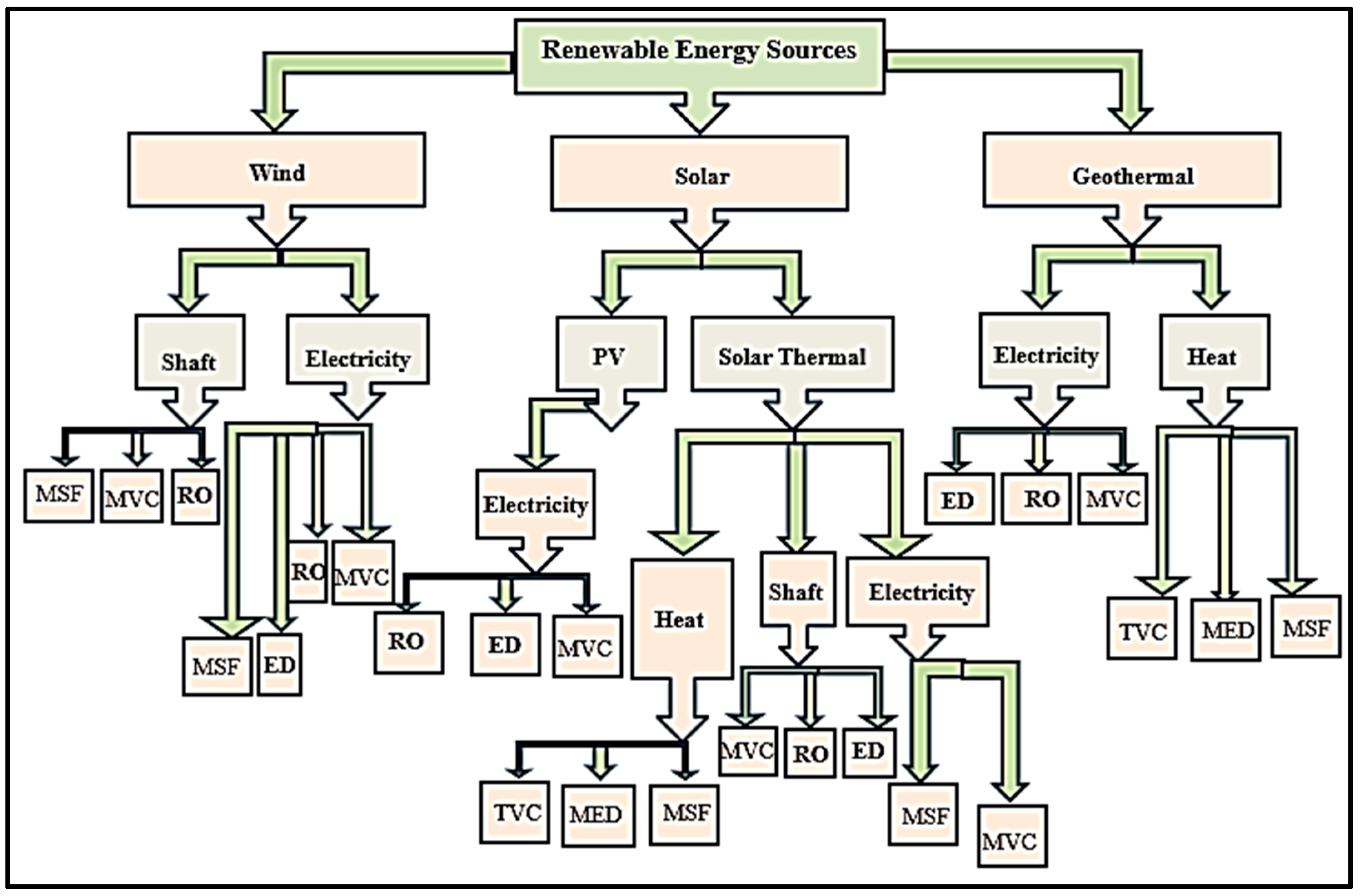

2. Renewable Energy Systems

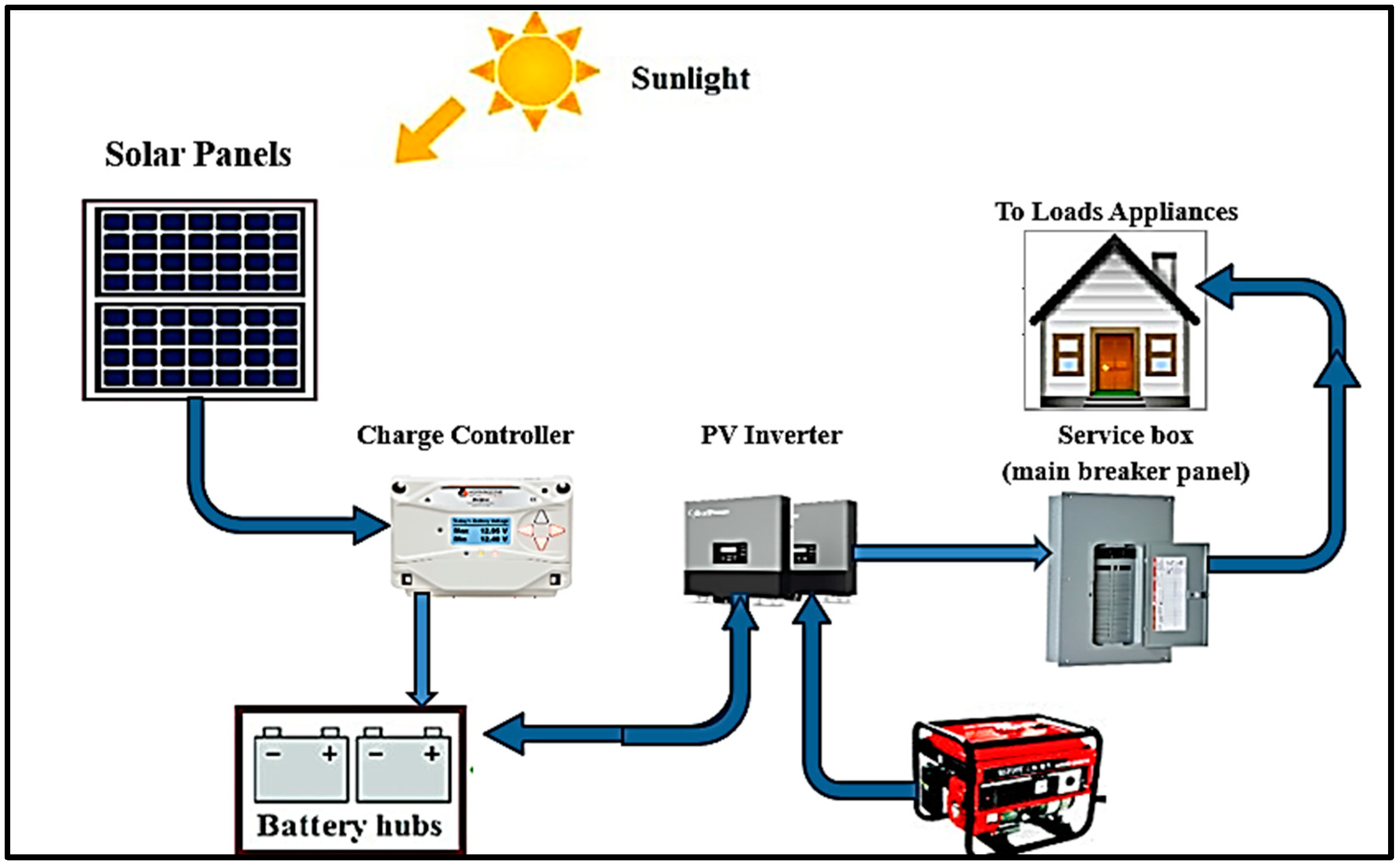

2.1. Solar Energy Systems

Description of a Solar Energy System

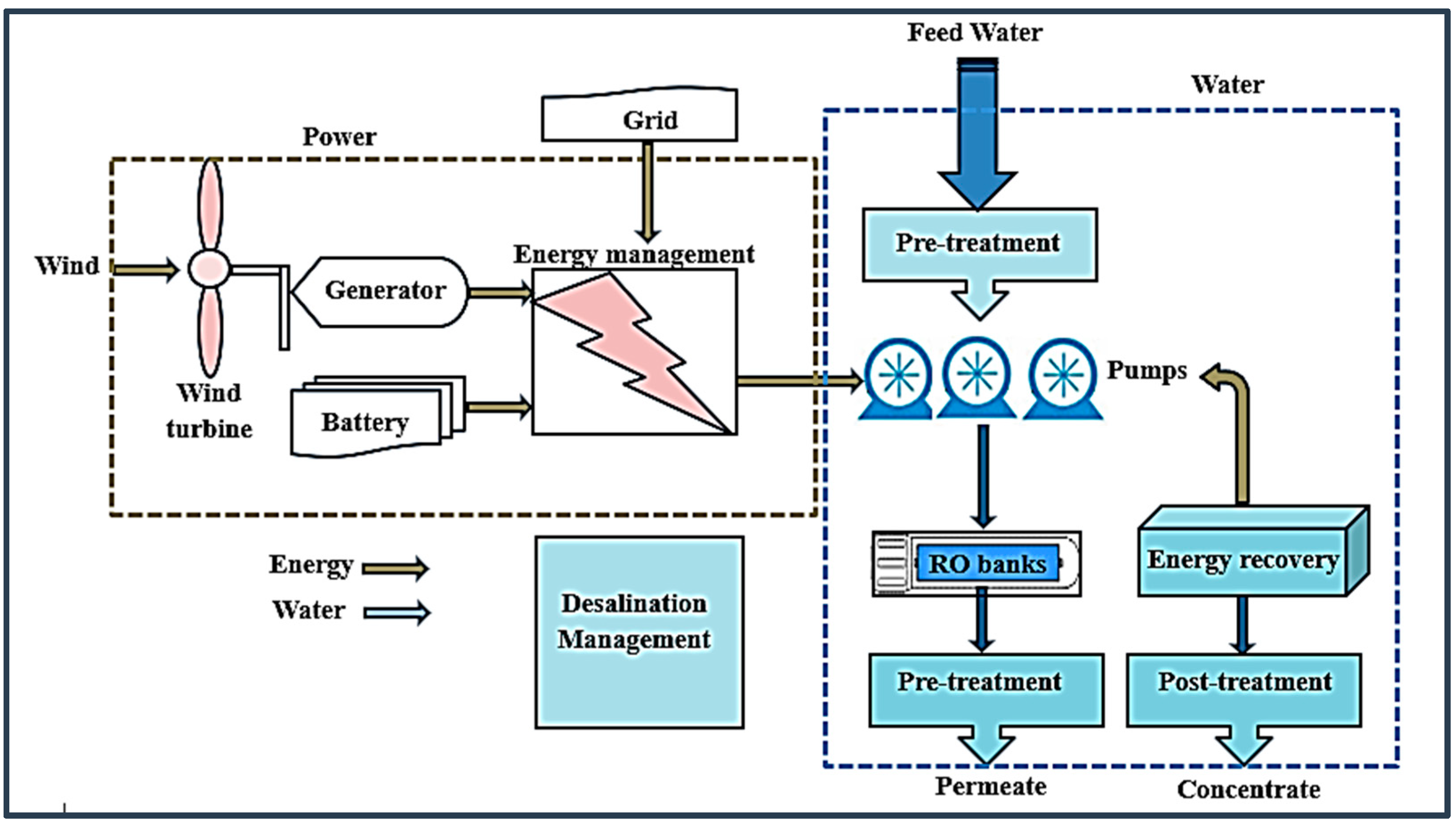

2.2. Wind Energy Systems

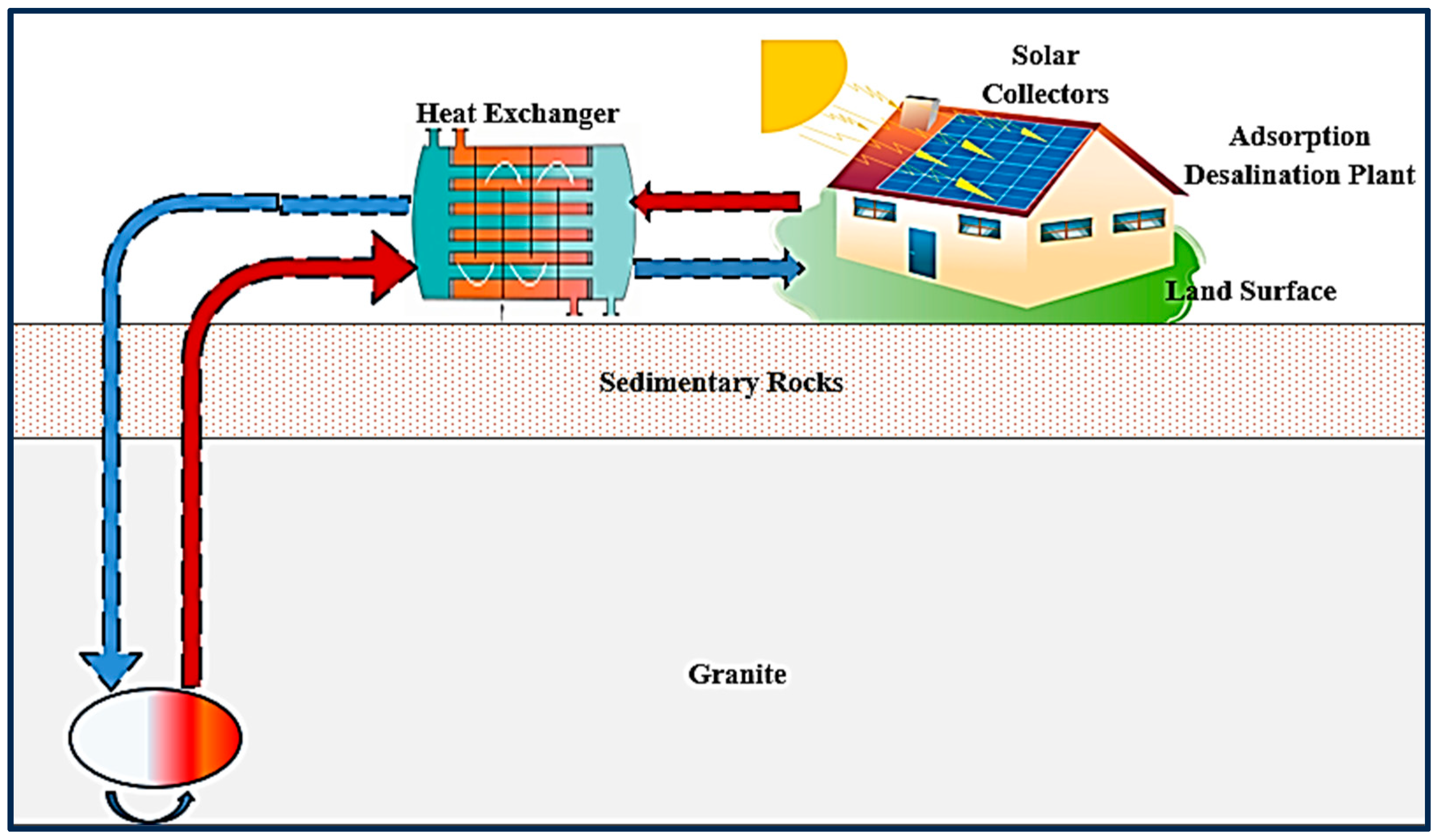

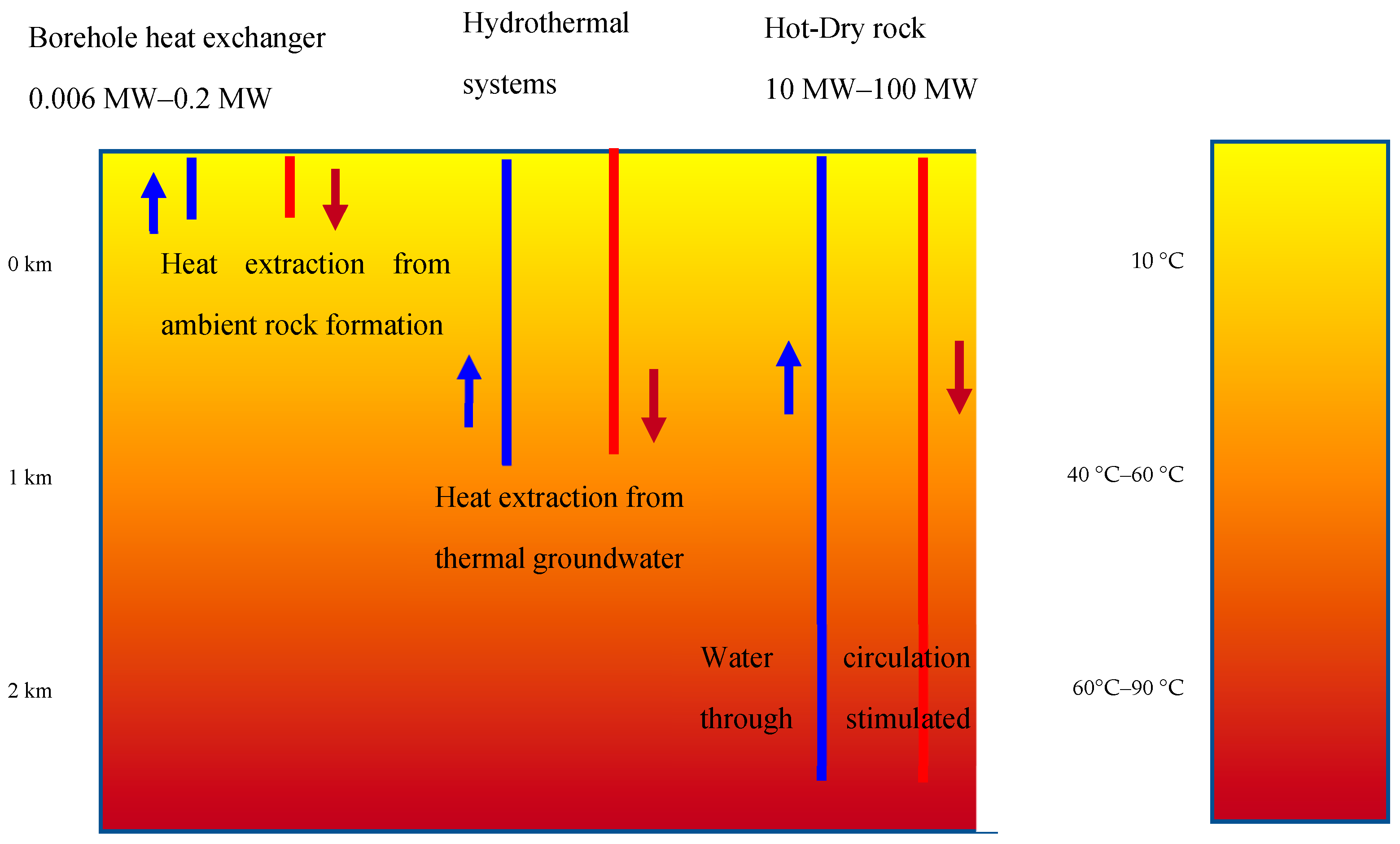

2.3. Geothermal Energy Systems

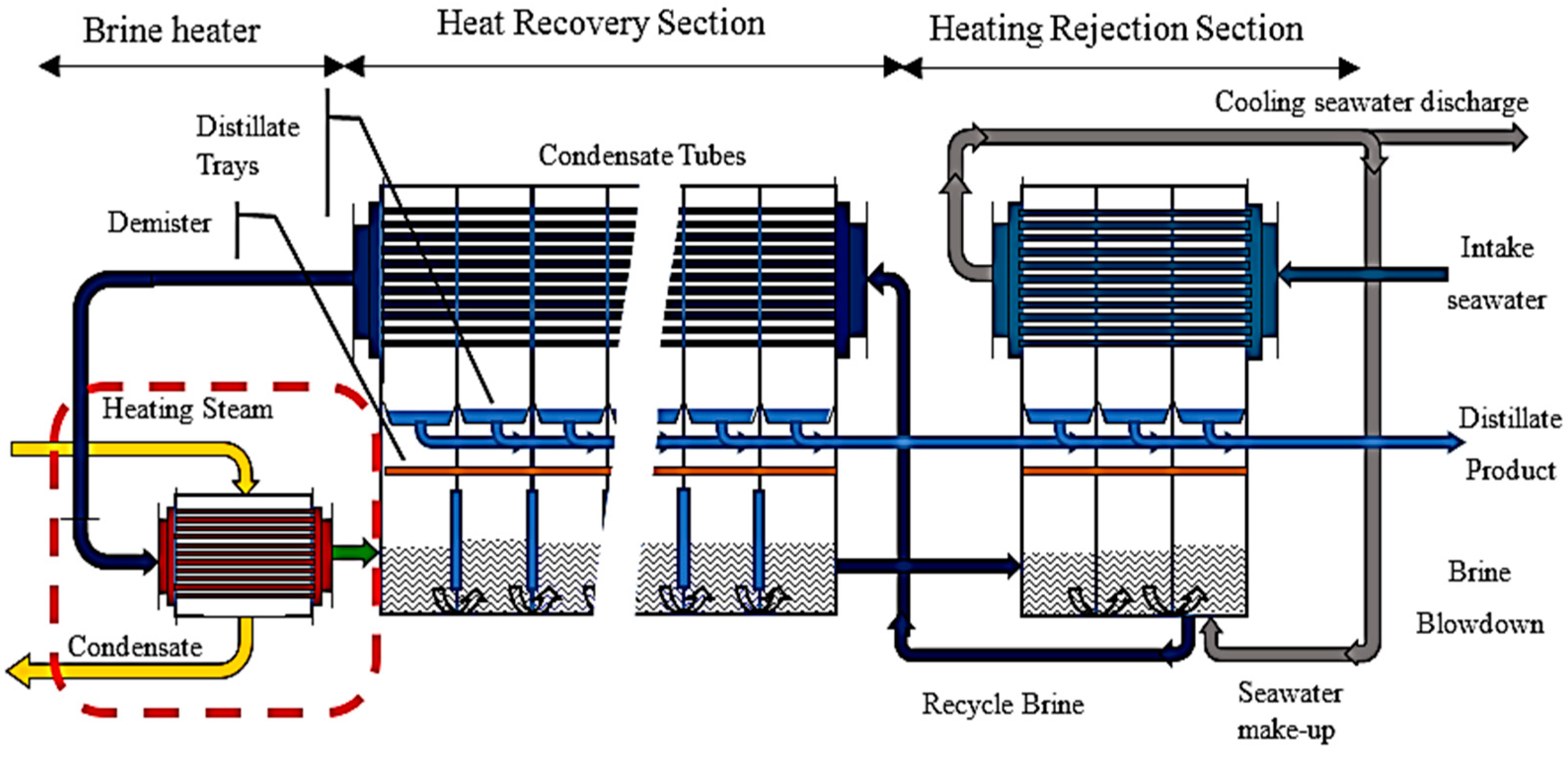

3. MSF Desalination and Renewable Energies

3.1. Solar Energy—MSF

3.2. Wind Energy—MSF

3.3. Geothermal Energy—MSF

4. RO Desalination and Renewable Energy

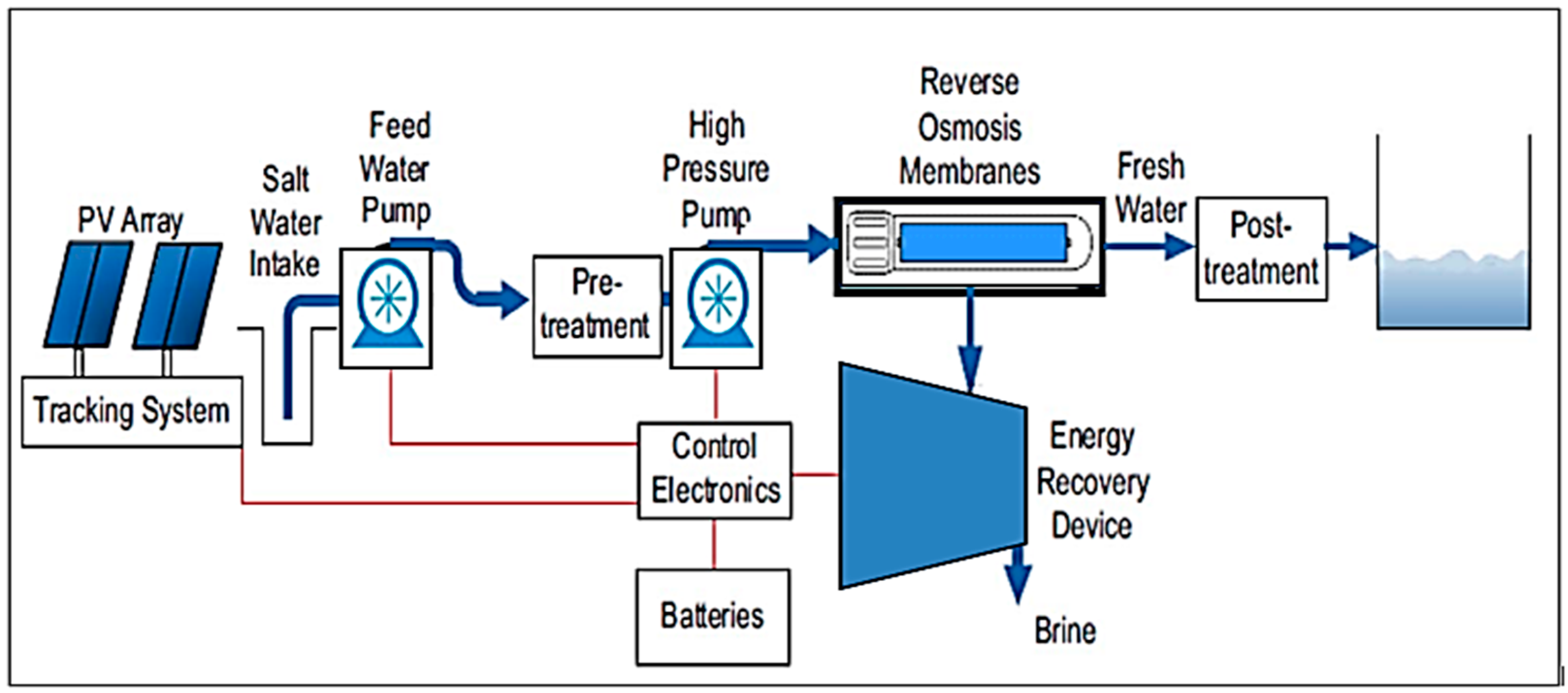

4.1. Solar Energy—RO

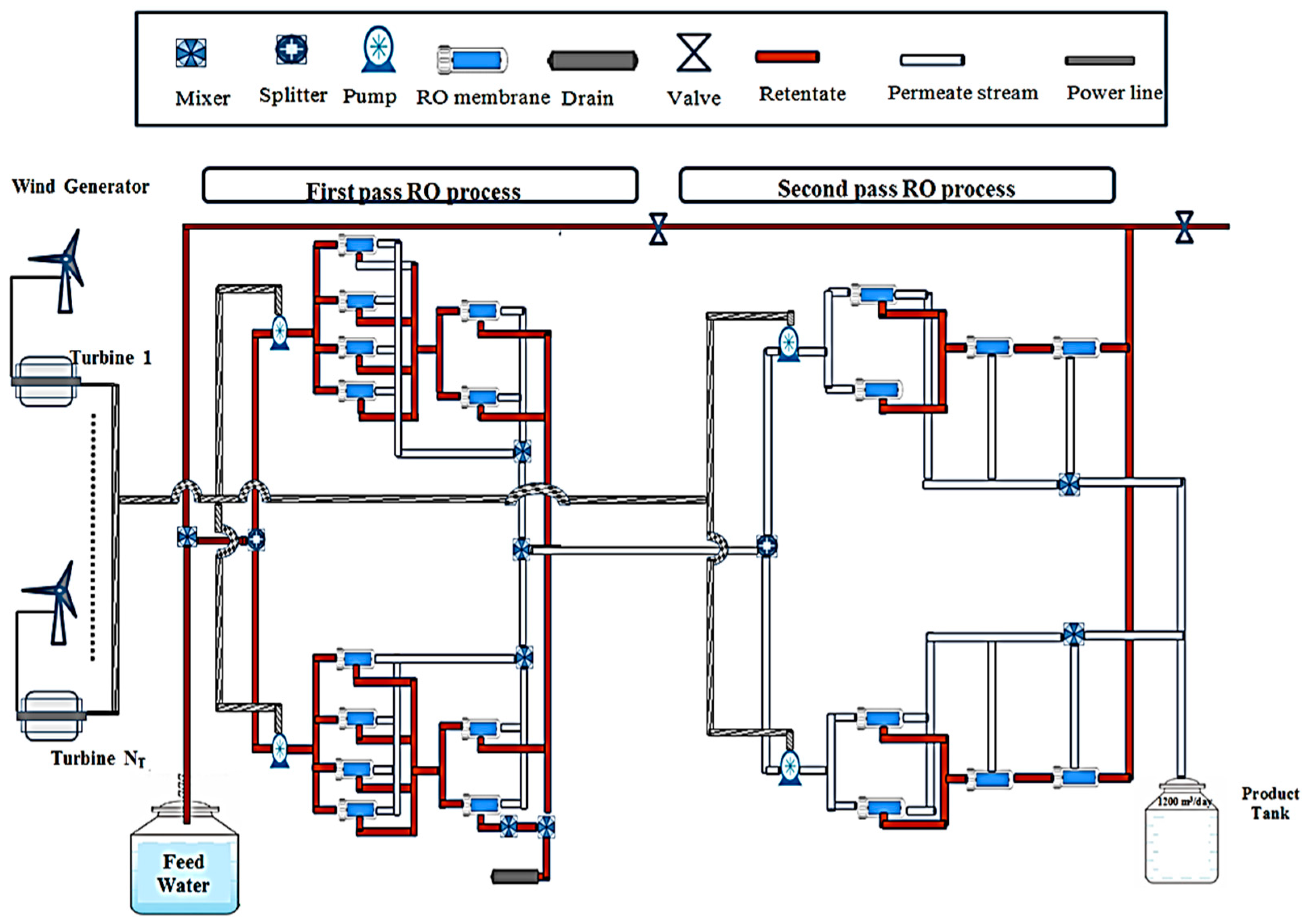

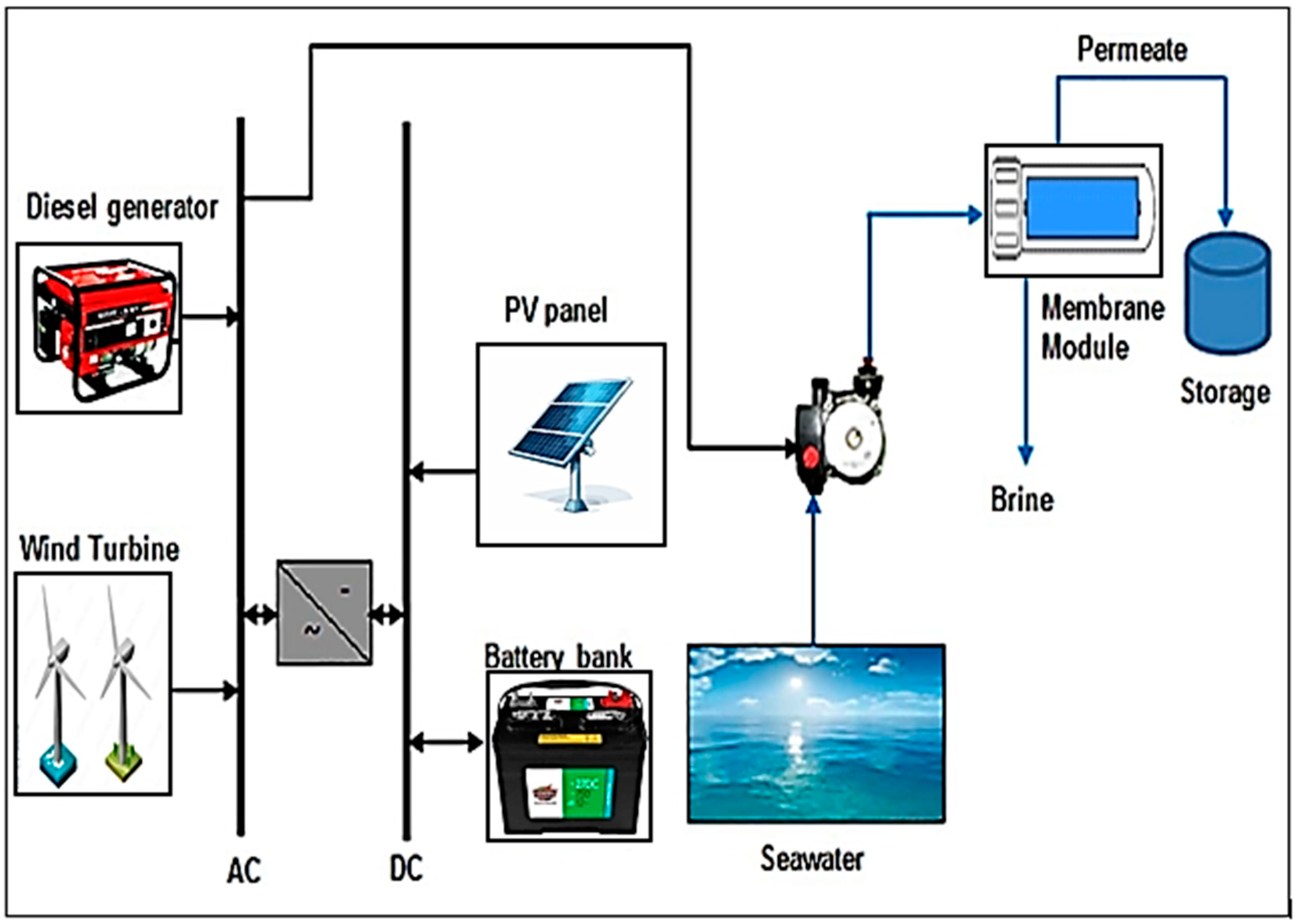

4.2. Wind Energy—RO

4.3. Geothermal Energy—RO

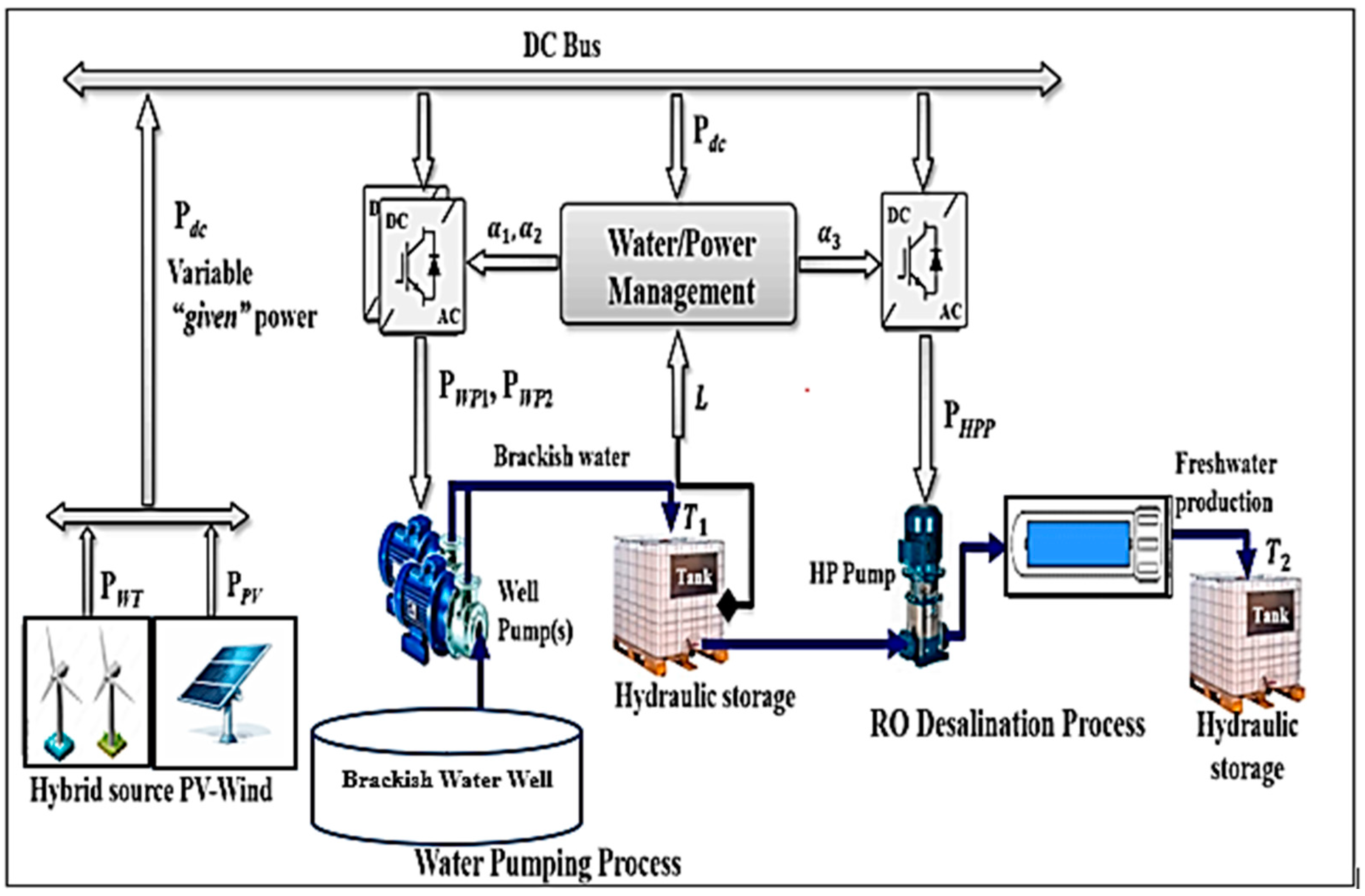

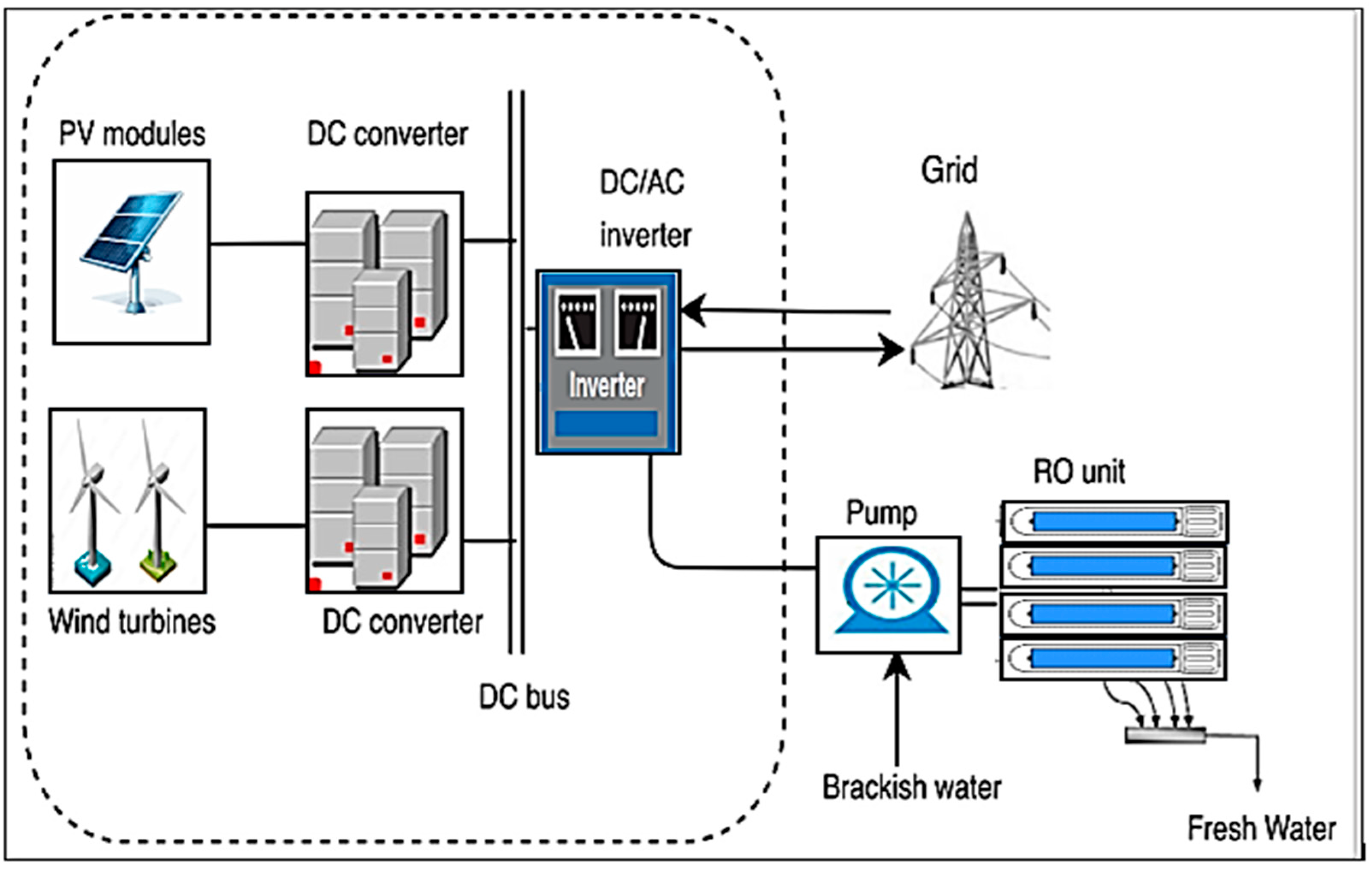

4.4. Solar Energy and Wind Energy—RO

4.5. Solar Energy and Geothermal Energy—RO

5. MED Desalination and Renewable Energy

5.1. Solar Energy—MED

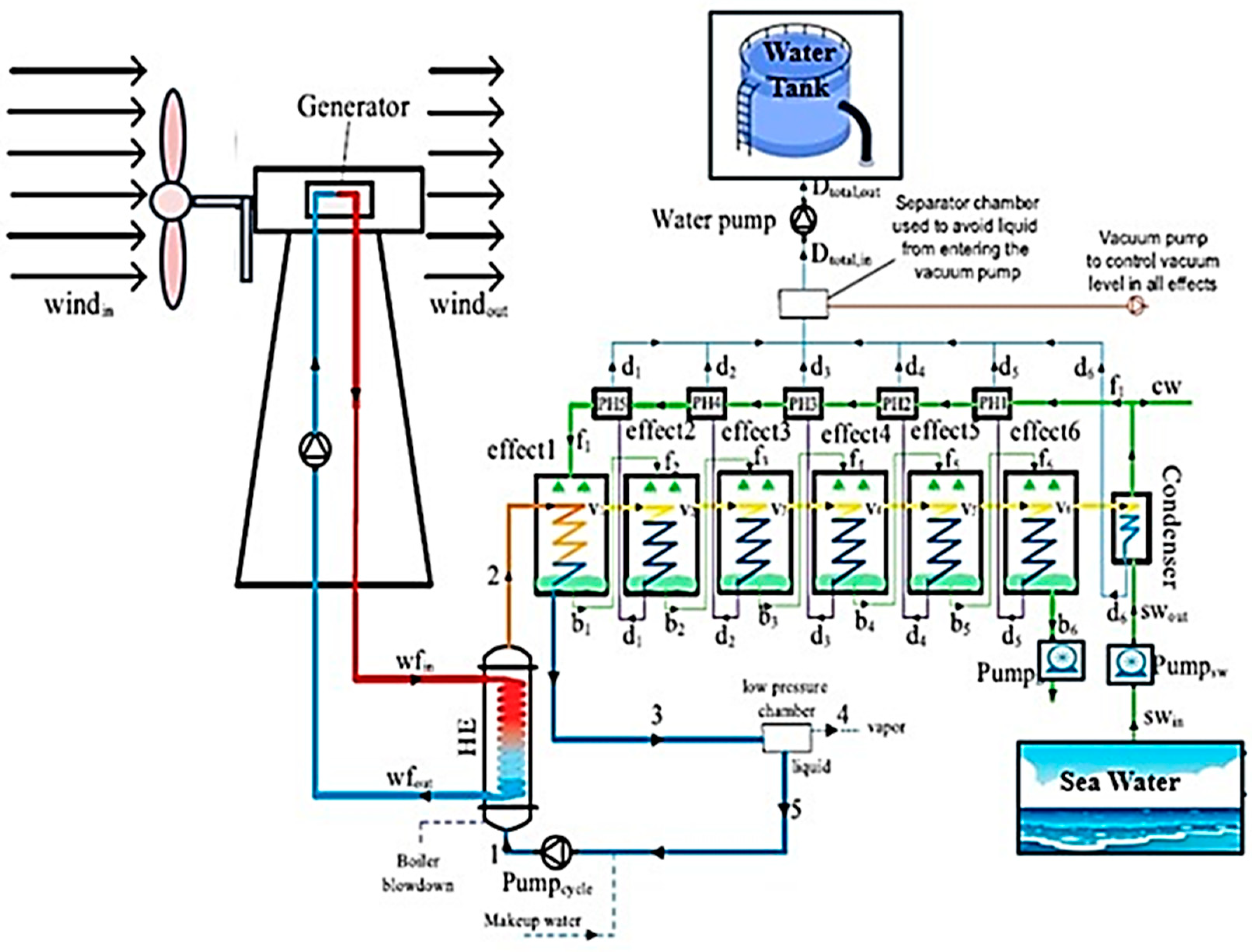

5.2. Wind Energy—MED

5.3. Geothermal Energy—MED

6. Challenges and Conceptual Ideas of Improvement of Utilization of Renewable Energy Seawater Treatment Systems

- Renewable energy sources are irregular, which means that they do not always exist when needed. Examples of irregular energy sources are solar and wind power. Because water desalination and wastewater treatment systems run around the clock, seven days a week, it may be challenging to rely solely on renewable energy to power them.

- Due to the discontinuous nature of solar and wind energy, efficient energy storage and management systems are necessary to maintain a steady and dependable power supply and meet the fluctuating energy demands of desalination operations. In this regard, finding economical and practical energy storage options for wastewater treatment plants is still a problem, especially for large-scale applications [108].

- Weather conditions can have a substantial influence on the affordability of renewable energy sources. This might make it thought-provoking for desalination facilities to bring a steady and dependable source of electricity.

- Intensive amounts of heat or power are required to run water desalination facilities, predominantly thermal desalination technologies, which require a high-energy procedure. Although renewable energy sources are environmentally friendly substitutes for fossil fuels, they do not always have the high-energy demand wanted for properly operating desalination technologies.

- Common industrial desalination plants are constructed to be large-scale operations necessitating considerable energy consumption. Regrettably, the majority of renewable energy technologies are still in the early phases of development and require additional investigation.

- The manufacture of renewable energy systems such as solar energy and wind energy is associated with large initial expenditures [109].

- Geographical location and environmental features affect the availability of proper renewable energy equipment, such as wind and direct sunlight. The handiness of local resources must be wisely considered in order to distinguish and assess the practicability of renewable energy choices for specific seawater desalination plants.

- For the time being, the freshwater production cost of seawater desalination technologies powered by renewable energy systems is typically greater than the freshwater production cost of seawater desalination systems powered by fossil fuels. Due to the intermittent nature of renewable energy, seawater desalination systems powered by renewable energy systems need more backup power than seawater desalination systems powered by fossil fuels. Table 4 illustrates a comparison of freshwater production costs for these systems for desalting seawater. Realizing the fact that fossil fuels are suspected to be depleted, using renewable energy systems is still a suitable option to drive desalination technologies, as well as enabling reductions in the harmful effects on the ecosystem.

- The intermittent nature and instability of single renewable energy sources can be reduced by combining numerous sources, such as solar, wind, and geothermal energy, into hybrid systems. This results in a more dependable and constant source of electricity for water desalination processes. Moreover, hybrid systems have synergistic advantages like an improved utilization of energy in both energy capture and consumption.

- Further studies are required to improve water desalination technologies to make them more compatible with renewable energy technologies. Advancing efficient energy desalination technologies would undoubtedly mitigate the overall energy consumption and enhance the reliability of their integration into renewable energy sources.

- The development of sophisticated energy storage technologies allows for excess renewable energy to be stored for use at a later time of low energy availability. Examples of these devices include batteries, thermal storage, and pumped hydro storage.

- Further techno-economic simulation and optimization studies are required to identify the most effective renewable energy sources to be integrated into water desalination systems, besides evaluating their life cycle cost.

7. Conclusions

- Due to the unstable nature of a single renewable energy source, the systematic incorporation of different renewable energy sources such as solar, wind, and geothermal energy into water desalination facilities would introduce a fixed source of electricity along with acquiring the lowest energy consumption and greenhouse gas emissions.

- The PV–RO system can unquestionably secure an economically practicable and environmentally friendly solution to water scarcity.

- The freshwater production cost of using MSF powered by concentrated solar power is about three times higher than that of using traditional MSF.

- Thermo-economic data revealed that the employment of MSF powered by parabolic trough concentrator solar power would consume more specific power of 5 kWh/m3, compared to a standalone desalination unit of 4.09 kWh/m3.

- Geothermal energy is unaffected by weather or seasonal changes, unlike solar or wind energy. Because of this, this energy source is chosen over wind and solar energy sources because it does not require thermal storage tanks or battery storage to preserve energy.

- To secure the target temperature for MSF, which is in the region of 90–110 °C, the extracted geo-fluid well should be between 2 and 3 km deep.

- It has been noted that producing water with geothermal energy is less expensive than conducting this with photovoltaic solar energy. Nonetheless, the primary obstacles to fully utilizing geothermal energy sources are the high upfront costs associated with discovery and well drilling, as well as the length of the payback time.

- Utilizing solar geothermal pre-heating units has an optimistic and significant impact by reducing the specific energy consumption, ranging between 24.33 and 35.79% and 18.69 and 22.87% in the scenarios of brackish water and seawater desalination, respectively.

- Using waste heat from large-scale wind turbines to power MED desalination units is a viable solution for producing freshwater in isolated and coastal areas at a reasonable cost.

- The solar-powered MED plant reduces the effects of climate change by 10 kg of CO2 equivalent for every m3 of freshwater produced. This is not like the standard MED plant.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Owusu, P.A.; Asumadu-Sarkodie, S. A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent Eng. 2016, 3, 1167990. [Google Scholar] [CrossRef]

- Saldivia, D.; Rosales, C.; Barraza, R.; Cornejo, L. Computational analysis for a multi-effect distillation (MED) plant driven by solar energy in Chile. Renew. Energy 2018, 132, 206–220. [Google Scholar] [CrossRef]

- Nassrullah, H.; Anis, S.F.; Hashaikeh, R.; Hilal, N. Energy for desalination: A state-of-the-art review. Desalination 2020, 491, 114569. [Google Scholar] [CrossRef]

- Rodríguez, R.; Espada, J.; Gallardo, M.; Molina, R.; López-Muñoz, M. Life cycle assessment and techno-economic evaluation of alternatives for the treatment of wastewater in a chrome-plating industry. J. Clean. Prod. 2018, 172, 2351–2362. [Google Scholar] [CrossRef]

- El-Emam, R.S.; Ozcan, H.; Bhattacharyya, R.; Awerbuch, L. Nuclear desalination: A sustainable route to water security. Desalination 2022, 542, 116082. [Google Scholar] [CrossRef]

- Eltawil, M.A.; Zhao, Z.; Yuan, L. A review of renewable energy technologies integrated with desalination systems. Renew. Sustain. Energy Rev. 2009, 13, 2245–2262. [Google Scholar] [CrossRef]

- Ghaffour, N.; Lattemann, S.; Missimer, T.; Ng, K.C.; Sinha, S.; Amy, G. Renewable energy-driven innovative energy-efficient desalination technologies. Appl. Energy 2014, 136, 1155–1165. [Google Scholar] [CrossRef]

- Esmaeilion, F. Hybrid renewable energy systems for desalination. Appl. Water Sci. 2020, 10, 1–47. [Google Scholar] [CrossRef]

- Gude, V.G.; Fthenakis, V. Energy efficiency and renewable energy utilization in desalination systems. Prog. Energy 2020, 2, 022003. [Google Scholar] [CrossRef]

- Bundschuh, J.; Kaczmarczyk, M.; Ghaffour, N.; Tomaszewska, B. State-of-the-art of renewable energy sources used in water desalination: Present and future prospects. Desalination 2021, 508, 115035. [Google Scholar] [CrossRef]

- Parida, B.; Iniyan, S.; Goic, R. A review of solar photovoltaic technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Yuan, W.; Liu, Z.; Su, C.; Wang, X. Photovoltaic capacity optimization of small and medium-sized hydro-photovoltaic hybrid energy systems considering multiple uncertainties. J. Clean. Prod. 2020, 276, 124170. [Google Scholar] [CrossRef]

- Batzelis, S.; Rather, Z.H.; Barton, J.; Naidu, B.R.; Wu, B.; Ul Nazir, F.; Nduka, O.S.; He, W.; Nsengiyaremye, J.; Pawar, B.; et al. Solar Integration in the UK and India: Technical Barriers and Future Directions. Loughborough University, 2021. Available online: https://eprints.soton.ac.uk/449751/1/JVCEC_White_Paper_revised.pdf (accessed on 14 February 2024).

- Khanzada, N.; Khan, S.J.; Davies, P. Performance evaluation of reverse osmosis (RO) pre-treatment technologies for in-land brackish water treatment. Desalination 2017, 406, 44–50. [Google Scholar] [CrossRef]

- Mustafa, R.J.; Gomaa, M.R.; Al-Dhaifallah, M.; Rezk, H. Environmental impacts on the performance of solar pho-tovoltaic systems. Sustainability 2020, 12, 608. [Google Scholar] [CrossRef]

- Obiwulu, A.U.; Erusiafe, N.; Olopade, M.A.; Nwokolo, S.C. Modeling and estimation of the optimal tilt angle, maximum incident solar radiation, and global radiation index of the photovoltaic system. Heliyon 2022, 8, e09598. [Google Scholar] [CrossRef] [PubMed]

- Abdelkareem, M.A.; Assad, M.E.H.; Sayed, E.T.; Soudan, B. Recent progress in the use of renewable energy sources to power water desalination plants. Desalination 2018, 435, 97–113. [Google Scholar] [CrossRef]

- Kaldellis, J.K. Stand-Alone and Hybrid Wind Energy Systems: Technology, Energy Storage and Applications; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Srikanth, M.; Muni, T.V.; Vardhan, M.V.; Somesh, D.J.J. Design and simulation of PV-wind hybrid energy system. J. Adv. Res. Dyn. Control. Syst. 2018, 10, 999–1005. [Google Scholar]

- Goosen, M.; Mahmoudi, H.; Ghaffour, N. Water desalination using geothermal energy. Energies 2010, 3, 1423–1442. [Google Scholar] [CrossRef]

- Missimer, T.M.; Kim, Y.-D.; Rachman, R.; Ng, K.C. Sustainable renewable energy seawater desalination using combined-cycle solar and geothermal energy sources. Desalination Water Treat. 2013, 51, 1161–1170. [Google Scholar] [CrossRef]

- Fan, R.; Jiang, Y.; Yao, Y.; Ma, Z. Theoretical study on the performance of an integrated ground-source heat pump system in a whole year. Energy 2008, 33, 1671–1679. [Google Scholar] [CrossRef]

- Shah, M.; Prajapati, M.; Sircar, A. A comprehensive and systematic study of geothermal energy-based desalination systems for sustainable development. Geothermics 2023, 115, 102829. [Google Scholar] [CrossRef]

- Prajapati, M.; Shah, M.; Soni, B.; Parikh, S.; Sircar, A.; Balchandani, S.; Thakore, S.; Tala, M. Geothermal-solar in-tegrated groundwater desalination system: Current status and future perspective. Groundw. Sustain. Dev. 2021, 12, 100506. [Google Scholar] [CrossRef]

- Ettouney, H.; El-Dessouky, H.; Al-Juwayhel, F. Performance of the once-through multistage flash desalination process. Proc. Inst. Mech. Eng. Part A J. Power Energy 2002, 216, 229–241. [Google Scholar] [CrossRef]

- Hasan, H.; Alsadaie, S.; Al-Obaidi, M.A.; Mujtaba, I.M. Dynamic modelling and simulation of industrial scale mul-tistage flash desalination process. Desalination 2023, 553, 116453. [Google Scholar] [CrossRef]

- Manesh, M.H.K.; Onishi, V.C. Energy, exergy, and thermo-economic analysis of renewable energy-driven polygeneration systems for sustainable desalination. Processes 2021, 9, 210. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Burhan, M.; Ang, L.; Ng, K.C. Energy-water-environment nexus underpinning future desalination sustainability. Desalination 2017, 413, 52–64. [Google Scholar] [CrossRef]

- Al-Karaghouli, A.; Renne, D.; Kazmerski, L.L. Solar and wind opportunities for water desalination in the Arab regions. Renew. Sustain. Energy Rev. 2009, 13, 2397–2407. [Google Scholar] [CrossRef]

- Alhaj, M.; Tahir, F.; Al-Ghamdi, S.G. Life-cycle environmental assessment of solar-driven Multi-Effect Desalination (MED) plant. Desalination 2022, 524, 115451. [Google Scholar] [CrossRef]

- Blanco, J.; Malato, S.; Fernández-Ibañez, P.; Alarcón, D.; Gernjak, W.; Maldonado, M. Review of feasible solar energy applications to water processes. Renew. Sustain. Energy Rev. 2009, 13, 1437–1445. [Google Scholar] [CrossRef]

- Dabwan, Y.N.; Gang, P.; Li, J.; Gao, G.; Feng, J. Development and assessment of integrating parabolic trough col-lectors with gas turbine trigeneration system for producing electricity, chilled water, and freshwater. Energy 2018, 162, 364–379. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Bostani, M.; Rashidi, S.; Valipour, M.S. Challenges and opportunities of desalination with renewable energy resources in Middle East countries. Renew. Sustain. Energy Rev. 2023, 184, 113543. [Google Scholar] [CrossRef]

- Zhang, Y.; Sivakumar, M.; Yang, S.; Enever, K.; Ramezanianpour, M. Application of solar energy in water treatment processes: A review. Desalination 2018, 428, 116–145. [Google Scholar] [CrossRef]

- Khalilzadeh, S.; Nezhad, A.H. Utilization of waste heat of a high-capacity wind turbine in multi effect distillation desalination: Energy, exergy and thermoeconomic analysis. Desalination 2018, 439, 119–137. [Google Scholar] [CrossRef]

- Lindblom, J. Solar Thermal Technologies for Seawater Desalination: State of the Art. Jenny Lindblom, Renewable Energy Systems, Luleå University of Technology: Luleå, Sweden, 2003. Available online: https://www.diva-portal.org/smash/get/diva2:995032/FULLTEXT01.pdf (accessed on 14 February 2024).

- Van der Bruggen, B.; Vandecasteele, C. Distillation vs. membrane filtration: Overview of process evolutions in sea-water desalination. Desalination 2002, 143, 207–218. [Google Scholar] [CrossRef]

- Hassabou, A.H.; Spinnler, M.; Polifke, W. Tecnoeconomic analysis of medium and large-sacle desalination plants driven by concentrated solar systems in the MENA region. Energy Procedia 2013, 42, 735–744. [Google Scholar] [CrossRef]

- Eldean, M.A.S.; Fath, H. Exergy and thermo-economic analysis of solar thermal cycles powered multi-stage flash desalination process. Desalination Water Treat. 2013, 51, 7361–7378. [Google Scholar] [CrossRef]

- Abdunnabi, M.; Ramadan, A. Simulation Study of the Thermal Performance of MSF Desalination Unit Operating by Solar Vacuum Tube Collectors. Sol. Energy Sustain. Dev. J. 2015, 4, 1–10. [Google Scholar] [CrossRef]

- Ozlu, S.; Dincer, I. Performance assessment of a new solar energy-based multigeneration system. Energy 2016, 112, 164–178. [Google Scholar] [CrossRef]

- Alsehli, M.; Choi, J.-K.; Aljuhan, M. A novel design for a solar powered multistage flash desalination. Sol. Energy 2017, 153, 348–359. [Google Scholar] [CrossRef]

- Al-Othman, A.; Tawalbeh, M.; Assd, M.E.H.; Alkayyali, T.; Eisa, A. Novel multi-stage flash (MSF) desalination plant driven by parabolic trough collectors and a solar pond: A simulation study in UAE. Desalination 2018, 443, 237–244. [Google Scholar] [CrossRef]

- Garg, K.; Khullar, V.; Das, S.K.; Tyagi, H. Performance evaluation of a brine-recirculation multistage flash desalination system coupled with nanofluid-based direct absorption solar collector. Renew. Energy 2018, 122, 140–151. [Google Scholar] [CrossRef]

- Shaaban, S. Performance optimization of an integrated solar combined cycle power plant equipped with a brine circu-lation MSF desalination unit. Energy Convers. Manag. 2019, 198, 111794. [Google Scholar] [CrossRef]

- Darawsheh, I.; Islam, M.D.; Banat, F. Experimental characterization of a solar powered MSF desalination process performance. Therm. Sci. Eng. Prog. 2019, 10, 154–162. [Google Scholar] [CrossRef]

- Méndez, C.; Bicer, Y. Integration of solar chimney with desalination for sustainable water production: A thermo-dynamic assessment. Case Stud. Therm. Eng. 2020, 21, 100687. [Google Scholar] [CrossRef]

- Babaeebazaz, A.; Gorjian, S.; Amidpour, M. Integration of a Solar Parabolic Dish Collector with a Small-Scale Multi-Stage Flash Desalination Unit: Experimental Evaluation, Exergy and Economic Analyses. Sustainability 2021, 13, 11295. [Google Scholar] [CrossRef]

- Mussati, S.; Aguirre, P.; Scenna, N. Dual-purpose desalination plants. Part II. Optimal configuration. Desalination 2003, 153, 185–189. [Google Scholar] [CrossRef]

- Kabiri, S.; Manesh, M.K.; Yazdi, M.; Amidpour, M. New procedure for optimal solar repowering of thermal power plants and integration with MSF desalination based on environmental friendliness and economic benefit. Energy Convers. Manag. 2021, 240, 114247. [Google Scholar] [CrossRef]

- Ziyaei, M.; Jalili, M.; Chitsaz, A.; Nazari, M.A. Dynamic simulation and life cycle cost analysis of a MSF desalination system driven by solar parabolic trough collectors using TRNSYS software: A comparative study in different world regions. Energy Convers. Manag. 2021, 243, 114412. [Google Scholar] [CrossRef]

- Al bkoor Alrawashdeh, K.; Al-Zboon, K.K.; Momani, R.; Momani, T.; Gul, E.; Bartocci, P.; Fantozzi, F. Performance of dual multistage flashing-recycled brine and solar power plant, in the framework of the water-energy nexus. Energy Nexus 2022, 5, 100046. [Google Scholar] [CrossRef]

- Yadav, K.; Gudjonsdottir, M.; Axelsson, G.; Ómarsdóttir, M.; Sircar, A.; Shah, M.; Yadav, A. Geothermal-solar inte-grated Multistage Flash Distillation Cogeneration system: A cleaner and sustainable solution. Desalination 2023, 566, 116897. [Google Scholar] [CrossRef]

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.-H. Solar energy: Potential and future prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- García-Rodríguez, L. Desalination by Wind Power. Wind. Eng. 2004, 28, 453–463. [Google Scholar] [CrossRef]

- Mentis, D.; Karalis, G.; Zervos, A.; Howells, M.; Taliotis, C.; Bazilian, M.; Rogner, H. Desalination using renewable energy sources on the arid islands of South Aegean Sea. Energy 2016, 94, 262–272. [Google Scholar] [CrossRef]

- Nakatake, Y.; Tanaka, H. A new maritime lifesaving distiller driven by wind. Desalination 2005, 177, 31–42. [Google Scholar] [CrossRef]

- Cheboxarov, V.V.; Cheboxarov, V.V. Research of Wind Turbine with Low-speed Floating Rotor. Pac. Sci. Rev. 2007, 9, 134–139. [Google Scholar]

- Noorollahi, Y.; Taghipoor, S.; Sajadi, B. Geothermal sea water desalination system (GSWDS) using abandoned oil/gas wells. Geothermics 2017, 67, 66–75. [Google Scholar] [CrossRef]

- Loutatidou, S.; Arafat, H.A. Techno-economic analysis of MED and RO desalination powered by low-enthalpy geothermal energy. Desalination 2015, 365, 277–292. [Google Scholar] [CrossRef]

- Shelare, S.; Kumar, R.; Gajbhiye, T.; Kanchan, S. Role of Geothermal Energy in Sustainable Water Desalination—A Review on Current Status, Parameters, and Challenges. Energies 2023, 16, 2901. [Google Scholar] [CrossRef]

- Karagiannis, I.C.; Soldatos, P.G. Water desalination cost literature: Review and assessment. Desalination 2008, 223, 448–456. [Google Scholar] [CrossRef]

- Alawad, S.M.; Ben Mansour, R.; Al-Sulaiman, F.A.; Rehman, S. Renewable energy systems for water desalination applications: A comprehensive review. Energy Convers. Manag. 2023, 286, 117035. [Google Scholar] [CrossRef]

- Missimer, T.M.; Ng, K.C.; Thuw, K.; Shahzad, M.W. Geothermal electricity generation and desalination: An integrated process design to conserve latent heat with operational improvements. Desalination Water Treat. 2016, 57, 23110–23118. [Google Scholar] [CrossRef]

- Sasikumar, M.P.D.S.S.; Panchal, J.M.S.J. Performance Evaluation of Geothermal Integrated Desalination Double Effect Evaporator (DEE) with or without Steam Jet Ejector with Software Simulation. In Proceedings of the 46th Workshop on Geothermal Reservoir Engineering Stanford University, Stanford, California, 16–18 February 2021. SGP-TR-218. [Google Scholar]

- Karytsas, C.; Mendrinos, D.; Radoglou, G. The current geothermal exploration and development of the geothermal field of Milos Island in Greece. GHC Bulletin. June 2004, pp. 17–21. Available online: https://www.researchgate.net/profile/Dimitrios-Mendrinos/publication/237237284_THE_CURRENT_GEOTHERMAL_EXPORATION_AND_DEVELOPMENT_OF_THE_GEOTHERMAL_FIELD_OF_MILOS_ISLAND_IN_GREECE/links/0c9605296f339c17a0000000/THE-CURRENT-GEOTHERMAL-EXPORATION-AND-DEVELOPMENT-OF-THE-GEOTHERMAL-FIELD-OF-MILOS-ISLAND-IN-GREECE.pdf (accessed on 14 February 2024).

- Ali, A.; Tufa, R.A.; Macedonio, F.; Curcio, E.; Drioli, E. Membrane technology in renewable-energy-driven desali-nation. Renew. Sustain. Energy Rev. 2018, 81, 1–21. [Google Scholar] [CrossRef]

- Al-Obaidi, M.; Kara-Zaïtri, C.; Mujtaba, I. Simulation and optimisation of a two-stage/two-pass reverse osmosis system for improved removal of chlorophenol from wastewater. J. Water Process. Eng. 2018, 22, 131–137. [Google Scholar] [CrossRef]

- Al-Obaidi, M.; Zaïtri, C.K.; Mujtaba, I. Optimum design of a multi-stage reverse osmosis process for the production of highly concentrated apple juice. J. Food Eng. 2017, 214, 47–59. [Google Scholar] [CrossRef]

- Sun, X.; Duan, L.; Liu, Z.; Gao, Q.; Liu, J.; Zhang, D. The mechanism of silica and transparent exopolymer particles (TEP) on reverse osmosis membranes fouling. J. Environ. Manag. 2024, 349, 119634. [Google Scholar] [CrossRef]

- Gao, Q.; Duan, L.; Liu, J.; Zhang, H.; Zhao, Y. Evaluation and optimization of reverse osmosis pretreatment tech-nology using the modified intermediate blocking model. J. Clean. Prod. 2023, 417, 138029. [Google Scholar] [CrossRef]

- Feria-Díaz, J.J.; Correa-Mahecha, F.; López-Méndez, M.C.; Rodríguez-Miranda, J.P.; Barrera-Rojas, J. Recent de-salination technologies by hybridization and integration with reverse osmosis: A review. Water 2021, 13, 1369. [Google Scholar] [CrossRef]

- Li, C.; Goswami, Y.; Stefanakos, E. Solar assisted sea water desalination: A review. Renew. Sustain. Energy Rev. 2013, 19, 136–163. [Google Scholar] [CrossRef]

- Alghoul, M.A.; Poovanaesvaran, P.; Mohammed, M.H.; Fadhil, A.M.; Muftah, A.F.; Alkilani, M.M.; Sopian, K. De-sign and experimental performance of brackish water reverse osmosis desalination unit powered by 2 kW photovoltaic system. Renew. Energy 2016, 93, 101–114. [Google Scholar] [CrossRef]

- Mostafaeipour, A.; Qolipour, M.; Rezaei, M.; Babaee-Tirkolaee, E. Investigation of off-grid photovoltaic systems for a reverse osmosis desalination system: A case study. Desalination 2019, 454, 91–103. [Google Scholar] [CrossRef]

- Karavas, C.-S.; Arvanitis, K.G.; Papadakis, G. Optimal technical and economic configuration of photovoltaic powered reverse osmosis desalination systems operating in autonomous mode. Desalination 2019, 466, 97–106. [Google Scholar] [CrossRef]

- Abdelgaied, M.; Abdullah, A.; Kabeel, A.; Abosheiasha, H. Assessment of an innovative hybrid system of PVT-driven RO desalination unit integrated with solar dish concentrator as preheating unit. Energy Convers. Manag. 2022, 258, 115558. [Google Scholar] [CrossRef]

- Ma, Q.; Lu, H. Wind energy technologies integrated with desalination systems: Review and state-of-the-art. Desalination 2011, 277, 274–280. [Google Scholar] [CrossRef]

- García-Rodríguez, L. Renewable energy applications in desalination: State of the art. Sol. Energy 2003, 75, 381–393. [Google Scholar] [CrossRef]

- Raluy, R.; Serra, L.; Uche, J. Life cycle assessment of desalination technologies integrated with renewable energies. Desalination 2005, 183, 81–93. [Google Scholar] [CrossRef]

- Pestana, I.d.l.N.; Latorre, F.J.G.; Espinoza, C.A.; Gotor, A.G. Optimization of RO desalination systems powered by renewable energies. Part I: Wind energy. Desalination 2004, 160, 293–299. [Google Scholar] [CrossRef]

- Forstmeier, M.; Mannerheim, F.; D’Amato, F.; Shah, M.; Liu, Y.; Baldea, M.; Stella, A. Feasibility study on wind-powered desalination. Desalination 2007, 203, 463–470. [Google Scholar] [CrossRef]

- Carta, J.A.; González, J.; Cabrera, P.; Subiela, V.J. Preliminary experimental analysis of a small-scale prototype SWRO desalination plant, designed for continuous adjustment of its energy consumption to the widely varying power generated by a stand-alone wind turbine. Appl. Energy 2015, 137, 222–239. [Google Scholar] [CrossRef]

- Alsarayreh, A.A.; Al-Obaidi, M.A.; Patel, R.; Mujtaba, I.M. Enhancement of energy saving of reverse osmosis system of Arab Potash Company via a wind energy system. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2021; Volume 50, pp. 95–100. [Google Scholar]

- Abusharkh, A.; Giwa, A.; Hasan, S. Wind and geothermal energy in desalination: A short review on progress and sustainable commercial processes. Ind. Eng. Manag. 2015, 4, 1000175. [Google Scholar]

- Ghaffour, N.; Bundschuh, J.; Mahmoudi, H.; Goosen, M.F.A. Renewable energy-driven desalination technologies: A comprehensive review on challenges and potential applications of integrated systems. Desalination 2015, 356, 94–114. [Google Scholar] [CrossRef]

- Assad, M.E.H.; Al-Shabi, M.; Khaled, F. Reverse osmosis with an energy recovery device for seawater desalination powered by Geothermal energy. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 4 February–9 April 2020; IEEE: Piscataway, NJ, USA; pp. 1–5. [Google Scholar]

- Mokheimer, E.M.; Sahin, A.Z.; Al-Sharafi, A.; Ali, A.I. Modeling and optimization of hybrid wind–solar-powered reverse osmosis water desalination system in Saudi Arabia. Energy Convers. Manag. 2013, 75, 86–97. [Google Scholar] [CrossRef]

- Sigarchian, S.G.; Malmquist, A.; Fransson, T. Modeling and control strategy of a hybrid PV/Wind/Engine/Battery system to provide electricity and drinkable water for remote applications. Energy Procedia 2014, 57, 1401–1410. [Google Scholar] [CrossRef]

- Gökçek, M. Integration of hybrid power (wind-photovoltaic-diesel-battery) and seawater reverse osmosis systems for small-scale desalination applications. Desalination 2018, 435, 210–220. [Google Scholar] [CrossRef]

- Mito, M.T.; Ma, X.; Albuflasa, H.; Davies, P.A. Reverse osmosis (RO) membrane desalination driven by wind and solar photovoltaic (PV) energy: State of the art and challenges for large-scale implementation. Renew. Sustain. Energy Rev. 2019, 112, 669–685. [Google Scholar] [CrossRef]

- Leijon, J.; Salar, D.; Engström, J.; Leijon, M.; Boström, C. Variable renewable energy sources for powering reverse osmosis desalination, with a case study of wave powered desalination for Kilifi, Kenya. Desalination 2020, 494, 114669. [Google Scholar] [CrossRef]

- Ben Ali, I.; Turki, M.; Belhadj, J.; Roboam, X. Systemic design and energy management of a standalone battery-less PV/Wind driven brackish water reverse osmosis desalination system. Sustain. Energy Technol. Assess. 2020, 42, 100884. [Google Scholar] [CrossRef]

- Ghaithan, A.M.; Mohammed, A.; Al-Hanbali, A.; Attia, A.M.; Saleh, H. Multi-objective optimization of a photovol-taic-wind-grid connected system to power reverse osmosis desalination plant. Energy 2022, 251, 123888. [Google Scholar] [CrossRef]

- Ba-Alawi, A.H.; Nguyen, H.-T.; Yoo, C. Sustainable design of a solar/wind-powered reverse osmosis system with cooperative demand-side water management: A coordinated sizing approach with a fuzzy decision-making model. Energy Convers. Manag. 2023, 295, 117624. [Google Scholar] [CrossRef]

- Shalaby, S.; Elfakharany, M.; Mujtaba, I.; Moharram, B.; Abosheiasha, H. Development of an efficient nano-fluid cooling/preheating system for PV-RO water desalination pilot plant. Energy Convers. Manag. 2022, 268, 115960. [Google Scholar] [CrossRef]

- Ben Bacha, H.; Abdullah, A.S.; Aljaghtham, M.; Salama, R.S.; Abdelgaied, M.; Kabeel, A.E. Thermo-Economic Assessment of Photovoltaic/Thermal Pan-Els-Powered Reverse Osmosis Desalination Unit Combined with Preheating Using Geothermal Energy. Energies 2023, 16, 3408. [Google Scholar] [CrossRef]

- Filippini, G.; Al-Obaidi, M.; Manenti, F.; Mujtaba, I. Design and economic evaluation of solar-powered hybrid multi effect and reverse osmosis system for seawater desalination. Desalination 2019, 465, 114–125. [Google Scholar] [CrossRef]

- Al-hotmani, O.M.A.; Al-Obaidi, M.A.; John, Y.M.; Patel, R.; Mujtaba, I.M. An integrated system of multi effect dis-tillation and wind power system-Evaluation of total energy saving. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2021; Volume 50, pp. 81–86. [Google Scholar]

- Dashputre, A.; Kaushik, A.; Pal, A.; Jariwala, D.; Yadav, K.; Shah, M. Geothermal energy integrated multi-effect evaporator (MEE) and multi-effect distillation (MED)-based desalination systems: An ecofriendly and sustainable solutions. Environ. Sci. Pollut. Res. 2023, 30, 67941–67952. [Google Scholar] [CrossRef] [PubMed]

- Iaquaniello, G.; Salladini, A.; Mari, A.; Mabrouk, A.A.; Fath, H.E.S. Concentrating solar power (CSP) system inte-grated with MED–RO hybrid desalination. Desalination 2014, 336, 121–128. [Google Scholar] [CrossRef]

- Weiner, A.M.; Blum, D.H.; Lienhard, V.J.H.; Ghoniem, A.F. Design of a hybrid RO-MED solar desalination system for treating agricultural drainage water in California. In The International Desalination Association World Congress on Desalination and Water Reuse; IDA: San Diego, CA, USA, 2015; pp. 1–15. [Google Scholar]

- Askari, I.B.; Ameri, M. Solar Rankine Cycle (SRC) powered by Linear Fresnel solar field and integrated with Multi Effect Desalination (MED) system. Renew. Energy 2018, 117, 52–70. [Google Scholar] [CrossRef]

- Birney, C.I.; Jones, M.C.; Webber, M.E. A spatially resolved thermodynamic assessment of geothermal powered multi-effect brackish water distillation in texas. Resources 2019, 8, 65. [Google Scholar] [CrossRef]

- Farsi, A.; Rosen, M.A. Assessment of a geothermal combined system with an organic rankine cycle and multi-effect distillation desalination. Earth Syst. Environ. 2022, 6, 15–27. [Google Scholar] [CrossRef]

- Liu, H.; Joseph, A.; Elsayad, M.M.; Elshernoby, B.; Awad, F.; Elsharkawy, M.; Kandeal, A.; Hussien, A.; An, M.; Sharshir, S.W. Recent advances in heat pump-coupled desalination systems: A systematic review. Desalination 2022, 543, 116081. [Google Scholar] [CrossRef]

- Baccioli, A.; Antonelli, M.; Desideri, U.; Grossi, A. Thermodynamic and economic analysis of the integration of Organic Rankine Cycle and Multi-Effect Distillation in waste-heat recovery applications. Energy 2018, 161, 456–469. [Google Scholar] [CrossRef]

- Dehghani-Sanij, A.R.; Tharumalingam, E.; Dusseault, M.B.; Fraser, R. Study of energy storage systems and environmental challenges of batteries. Renew. Sustain. Energy Rev. 2019, 104, 192–208. [Google Scholar] [CrossRef]

- Lee, D.; Joo, S.-K. Economic Analysis of Large-Scale Renewable Energy (RE) Source Investment Incorporating Power System Transmission Costs. Energies 2023, 16, 7407. [Google Scholar] [CrossRef]

| Authors and Year | MSF Design | Renewable Energy Process Design | Aim of the Research | Operating Conditions | Highlights |

|---|---|---|---|---|---|

| Hassabou et al. [38] | Unknown number of stages | Concentrated solar | To conduct a numerical analysis and techno economic evaluation of a concentrated solar thermal system to power a large MSF desalination plant | Seawater temp. of 25 °C -Seawater salinity of 35,000 ppm -TBT of 112 °C | -Productivity of 5000 m3/day |

| Eldean and Fath [39] | 40 flashing stages MSF unit | Parabolic trough concentrator solar | To carry out exergic and thermo-economic analyses for large MSF desalination process powered by solar thermal energy | -Seawater temp. of 28 °C -Salinity of 47,300 ppm -TBT of 90 °C | -Productivity of 5000 m3/day -GOR of 12 |

| Abdunnabi and Ramadan [40] | 14 flashing stages MSF unit | Vacuum tubes solar collectors | To investigate the finest use of solar thermal collectors to run the MSF desalination unit using TRNSYS software | -Seawater temp. of 20 °C -Seawater salinity of 35,000 ppm -TBT of 80 °C | -Productivity of 5 m3/day |

| Ozlu and Dincer [41] | 15 flashing stages MSF unit | Parabolic solar collector | To carry out a thermodynamic analysis of a new multi-generation system powered by solar energy and to generate electricity, heat, freshwater, and hydrogen | -Seawater temp. of 18 °C -Seawater salinity of 35,000 ppm | -Productivity around 3.45 m3/day |

| Alsehli et al. [42] | 20 flashing stages MSF unit | Concentrating solar collectors | To develop a new design of a solar desalination approach with smaller solar collectors area | -Seawater temp. of 25 °C -TBT of 90 °C | -Productivity of 2230 m3/day -GOR of 6.8 -Fresh water production cost of USD 2.72 /m3 |

| Al-Othman et al. [43] | 4 flashing stages MSF unit | Parabolic trough collectors and solar pond | To investigate the utilization of parabolic tough collectors and solar ponds driven an MSF plant using ASPEN HYSYS V8.8 | -Seawater temp. of 25 °C -TBT of 96 °C | -Product 1880 m3/day -Fresh water production cost of USD 2.23/m3 |

| Garg et al. [44] | 20 flashing stages MSF unit | Direct absorption solar collector | To measure the thermal performance of an MSF system via a mathematical model of an MSF system integrated with a nano-fluid-based direct absorption solar collector | -Seawater temp. of 25 °C -Seawater salinity of 42,000 ppm -TBT of 90 °C | -GOR between 11 and 14 |

| Shaaban [45] | 24 flashing stages MSF unit | Integrated solar combined cycle | To enhance the power output and reduce the MSF size via an optimization of a combined solar cycle that is used to power an MSF desalination process | -Seawater temp. of 25 °C -Seawater salinity of 42,000 ppm -TBT of 105 °C | -Productivity of 16,364.2 m3/day |

| Darawsheh et al. [46] | Two flashing stages MSF unit | Plate solar collectors | To optimize the process performance and cost effectiveness of the MSF desalination process by integrating flat-plate solar collectors with multi-stage flash (MSF) | -Feed flow rate of 0.5 L/min -Pressure 20 kPa | -Productivity of 0.3 L/h/m2 |

| Méndez and Bicer [47] | 16 flashing stages MSF unit | Solar chimney | To conduct a thermal assessment of the feasibility of integrating a solar chimney with MSF for workable water production | -Seawater temp. of 25 °C -Seawater salinity of 35,000 ppm -TBT of 96.55 °C | -Productivity of 8.3 kg/s -GOR of 8.91 |

| Babaeebazaz et al. [48] | Small-scale two flashing stages MSF unit | Solar parabolic dish collector | To examine the feasibility of using solar parabolic collectors as the main heating source for a small-scale two-stage MSF system | -Feed flow rate 0.7 L/min -Pressure 10 kPa -TBT between 94.25 °C | -Productivity of 0.644 L/h |

| Kabiri et al. [50] | 22 flashing stages MSF unit | Parabolic trough collectors | To examine the thermodynamics of the MSF process to be powered with a solar energy source based on environmental friendliness and economic benefit | -Seawater salinity of 45,000 ppm -TBT of 110.6 °C | -Productivity of 115.4 kg/s -GOR of 9.62. -Fresh water production cost of USD 0.21/m3 |

| Dabwan et al. [32] | -- | Parabolic trough collectors | To examine the probable adjustments of a gas turbine tri-generation plant via combining it with a parabolic trough collector for producing electricity, chilled water, and freshwater | -- | -Productivity of 45,461 m3/day -Fresh water production cost of 0.8 USD/m3 |

| Ziyaei et al. [51] | 24 flashing stages MSF unit | Parabolic trough collectors | To develop a dynamic simulation and carry out a life cycle cost analysis for an MSF plant powered by solar parabolic trough collectors using TRNSYS software | -Seawater temp. of 25 °C -Seawater salinity of 42,000 ppm -TBT of 106 °C | -GOR of 7.18 -Fresh water production cost varies between USD 2.21/m3 and USD 4.32/m3 |

| Al bkoor Alrawashdeh et al. [52] | 24 flashing stages MSF unit | Poly PV array | To develop a model to examine the performance ratio of MSF powered by a solar energy source utilizing a poly PV array type | -Seawater temp. of 25 °C -Seawater salinity of 42,000 ppm -TBT of 110 °C | -Productivity of 63.3 kg/s -GOR of 10.3 |

| Yadav et al. [53] | 3 flashing stages MSF unit | Solar evacuated tubes | To design an MSF system to desalt geothermal water and produce potable fresh drinking water using solar evacuated tubes as the main heating source | -Geothermal temp. of 40 °C -Water salinity of 4205 ppm -TBT of 143.5 °C | -Productivity of 0.66 kg/s -Fresh water production cost of 0.1034 USD/m3 |

| Authors (Year) | RO Process Design | Renewable Energy Process Design | Operating Conditions | Results | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| Alghoul et al. [74] | A small-scale BWRO unit | 2 kWp PV system | -Water salinity of up to 2000 ppm -Feed pressure of 8.3 bar | -5.1 m3 of fresh water for 10 h a day -Specific energy consumption of 1.1 kWh/m3 -Permeate salinity of less than 50 ppm -The initial investment cost of the PV–brackish water RO system is around USD 30,000 | PV–RO-systems-based brackish water can be assumed as a favorable desalination option in isolated areas | -It was established that there are numerous hours when the PV module operates at high temperatures (above 45 °C) and in the battery room (above 35 °C), both of which have the potential to have a detrimental impact on power production and battery autonomy |

| Mostafaeipour et al. [75] | RO desalination system in districts of Bushehr, Iran | PV unit | -Seawater salinity of 39,600 ppm -Feed flow rate of 8.33 m3/h | -Maximum and minimum productivity of 228 m3/day and 148 m3/day, respectively, for Daylam Port -Specific energy consumption of 0.83 kWh/m3 -The cost of production per cubic meter of fresh water is approximately USD 2.43 -The freshwater production cost of PV–RO desalination systems in different areas ranges between 1.96 and 3.02 USD/m3. | -PV cells are much cheaper than diesel generators in spite of the higher initial investment costs -The system reduces CO2 emissions and the dependability on the import of fossil energy sources | --- |

| Karavas et al. [76] | A small-scale seawater RO, island in Cyclades, Aegean sea, Greece | PV system | -Feed pressure of 42 bar -Feed flow rate of 3.333 m3/h | -Productivity of 20 m3/month -The freshwater production cost can be up to 2.18 EUR/m3 | The PV–RO system presents a promising solution for water scarcity, offering both economic viability and environmental sustainability | |

| Abdelgaied et al. [77] | A standalone RO desalination system in remote areas with an ERD | PV–geothermal energy | -Feed pressure of 150 kpa -Brackish water salinity of 2000 ppm -Seawater salinity of 40,000 ppm -Water temperature of 30 °C -Feed flow rate of 1.4 m3/h | -Specific energy consumption of 0.475 kWh/m3 -The freshwater production cost of the hybrid system of PVT-driven RO desalination unit integrated with a solar dish concentrator is calculated to be 1.07 USD/m3 -The economic analysis depicts that the utilization of solar dish concentrators as preheating units reduced the freshwater cost by 33.1% compared to other desalination plants | Incorporating solar pre-heating units significantly reduces the specific power consumption of the desalination system. This reduction ranges from 24.33% to 35.79% for brackish water treatment and 18.69% to 22.87% for seawater treatment | The salt concentration permeation rate is significantly higher (between 490 and 510 ppm) when using geothermal pre-heating units, compared to only 170 ppm without pre-heating |

| Assad et al. [87] | A single-stage single pass RO system integrated with a dry steam geothermal energy system | A dry steam geothermal energy system | -Seawater salinity of 48,787 ppm -Feed flowrate of 31 m3/day -Feed pressure of 74.96 bar | -Specific energy consumption of 3.33 kWh/m3 -Product salinity of 335.85 ppm -Productivity of 450 m3/day | -The existence of a pressure exchanger reduces the specific energy consumption from 6.51 kWh/m3 to 3.33 kWh/m3. | The study has not provided detailed information for utilizing the dry steam of geothermal energy system |

| Mokheimer et al. [88] | A standalone RO desalination plant in Saudi Arabia | -Hybrid wind/solar-powered RO desalination plant -1 to 10 wind turbines with rated power of 1 kW each -1 to 400 of PV modules with rated power of 50 W each | -Seawater temperature of 25 °C. -Solar radiation: 1000 W/m2 | -Max. power output for PV module of 50 W -The freshwater production cost of the hybrid wind/solar system ranges between USD 3.693/m3 and USD 3.812/m3 | The optimized design of the proposed hybrid wind/solar system significantly reduces the cost of freshwater production | -Solar energy can be effectively utilized for water desalination, but it requires backup systems to ensure continuous operation -The intermittent nature of solar energy generation poses challenges, necessitating quick-start backup units to compensate for shortfalls or absorb excess energy production |

| Sigarchian et al. [89] | A small-scale RO system in Sudan | -Hybrid PV/wind/engine energy-powered RO desalination system that is designed in a parallel configuration with AC coupling -22 solar PV modules with a rated power of 5 kW -A wind turbine with a rated power of 1 kW -A diesel generator with a rated power of 1.5 kW | -Provide electricity and drinkable water for 1000 individuals in disaster situations | The hybrid system addresses environmental concerns compared to relying solely on diesel engines, a common solution in disaster scenarios | -Parallel configurations offer advantages over series configurations but requires a well-designed energy management system and a more complex control system | |

| Gökçek [90] | Small-scale RO system in Turkey | Wind/PV of the various off-grid power systems | -Seawater salinity of 37,864.4 ppm -Wind speed has a range of 4.78–7.35 m/s -Solar radiation varies between 1.56 kWh/m2/day and 7.80 kWh/m2/day, and its annual average value is 4.62 kWh/m2/day | -A capacity of 24 m3/day -The freshwater production cost is estimated to be USD 2.20/m3. | The study demonstrated that utilizing a hybrid power system instead of a diesel generator resulted in a substantial 90% reduction in annual carbon dioxide (CO2) emissions | -This study focused on assessing the operational emissions of the hybrid power system, excluding the emissions related to the manufacturing of the equipment used |

| Mito et al. [91] | RO system | Hybrid solar-wind renewable system | -The plant capacity: 4800 m3/day -Optimum total 20 installed capacities for RO-based desalination are 500 kw, PV panels of 100 kW, and wind turbines of 3000 kW | -A hybrid power and water supply system with RO desalination is the most cost-effective option -The RO desalination system has the greatest renewable energy penetration and lowermost energy cost. This will reduce environmental consequences and improve cost affordability | -While it is mathematically feasible to eliminate or minimize capacity shortages, this approach would result in a substantial increase in project expenses | |

| Leijon et al. [92] | Brackish water RO system in Kenya | A hybrid solar and wave desalination system | -Seawater salinity of 4000 ppm Minimum and maximum feed pressure of 8.4 bar and 16.2 bar, respectively -Water temperature of 20 °C | -Capacity of 24 m3/day -Maximum power output of 7 kW -Product water salinity of 433.93 ppm. -Specific energy consumption of 4.38 kWh/m3 | Increasing the quantity of wave energy converters increased the production of freshwater. However, this results in a higher total system cost and an increase in the power surplus production | Wave power is still in a pre-commercial state |

| Ghaithan et al. [94] | Brackish water RO desalination plant in Saudi Arabia. | A hybrid solar–wind energy and grid-connected system of 100 photovoltaic modules and 94 wind turbines | -Seawater temperature varies between 10 °C and 42 °C -Standard solar radiation of 1000 W/m2 | -Productivity of 800 m3/day -Specific energy consumption of 3 kWh/m3 -The freshwater production cost is USD 1.572/m3, USD 1.911/m3 and USD 1.639/ m3 for the first, second, and third plant, respectively | The energy shortfall of the RO system is met by the utility grid and, to some extent, by the wind turbine system | Significant energy shortages occur during April, May, August, and October due to either limited renewable energy resources or high energy consumption |

| Ba-Alawi et al. [95] | RO system | A hybrid system of PV–wind | Feed flow rate of 9.537 m3/h | -The integration of distributed seawater membrane (DSWM) technology has led to significant improvements in various aspects of the system’s performance -Compared to the scenario without DSWM, the total annual cost, total environmental cost, scheduling profit, and potential loss of power supply probability are enhanced by 5.37%, 32.4438%, 57.9311%, and 23.78%, respectively | -The integrated sizing model that takes into account DSWM can aid in optimizing the sizing of renewable energy–RO systems, ensuing in noteworthy cost savings, adaptive demand satisfaction, lower emissions, and a higher level of sustainability | To address the constraints of short-term battery storage in power storage systems, long-term energy storage is necessary to enable flexible electricity loading |

| Shalaby et al. [96] | RO desalination system in Egypt | PV–geothermal energy | -Productivity of 600 gallons /day of freshwater -Feed Temp.: 30 °C -PV cells of 0.25 kW | -Salt rejection of 97% -Product water flow rate of 300 L/day -The freshwater production cost is reported to be in the range of 0.74–1.12 USD/m3 | The benefits of the geothermal pre-heating of the feed water are particularly evident when the salinity of the water is high. Additionally, the proposed PV–RO desalination system has a high potential for commercialization due to its ability to produce fresh water at a very low cost | Geothermal water is not available in all locations with the existence pf a number of influential parameters. In turn, this would limit the viability of integrating RO systems with geothermal energy systems in some districts |

| Bacha et al. [97] | RO desalination unit with an energy recovery device | A hybrid system of PV–geothermal | -Feed water flow rate of 1.4 m3/h -Feed water temperature of 25 °C | -Reducing the energy consumption rates by 29.1% for seawater treatment and 40.75% for brackish water -The freshwater production cost was found to be 0.966 USD/m3. | -An improvement of the water productivity of RO plants, in addition to dropping their specific energy consumption compared to traditional technologies | High exploration costs, high investment risk, and high installation costs are the most highlighted disadvantages |

| Authors (Year) | MED Process Design | Renewable Energy Process Design | Operating Conditions | Results | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

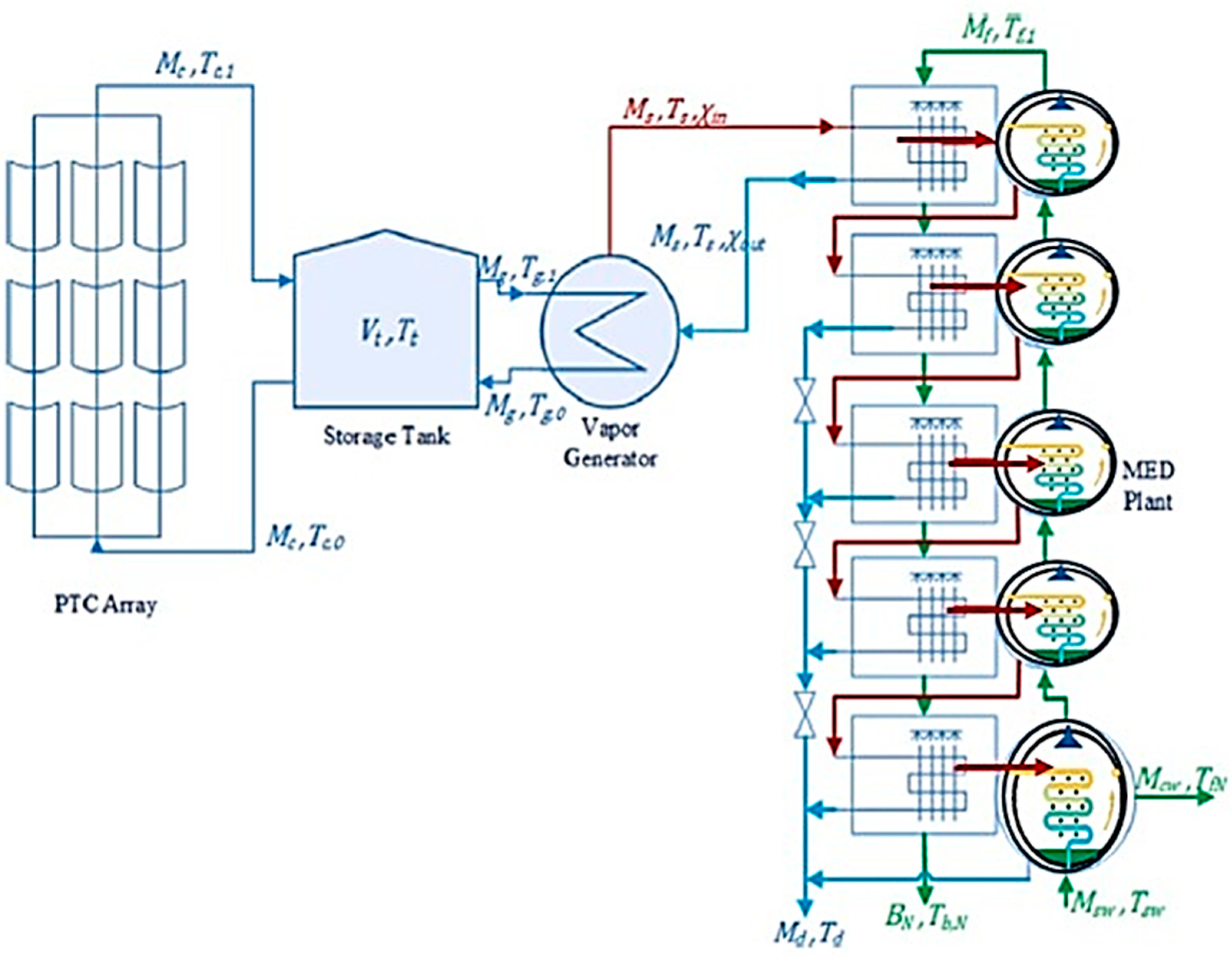

| Saldivia et al. [2] | Forward-feed MED Steam temperature of less than 70.8 °C Feed flow rate of 8 m3/h | Parabolic trough collector (PTC) | -Feed flow rate of 8 m3/h | -Productivity of 3000 m3 of fresh water each day | -The study offers a thorough numerical model for a solar-powered MED plant that can be applied to planning, enhancing, and evaluating the system -The study offers insightful information about the technological viability of solar-powered MED plants in Chile | -Because the study is focused on a particular MED plant design and location, it is possible that the findings will not apply to other MED plants or places -The economics of solar MED plants, which are crucial for determining their commercial feasibility, are not taken into account in this study -Due to an absence of thorough experimental data, the study encountered difficulties when predicting the heat transfer coefficients for the preheaters and evaporators |

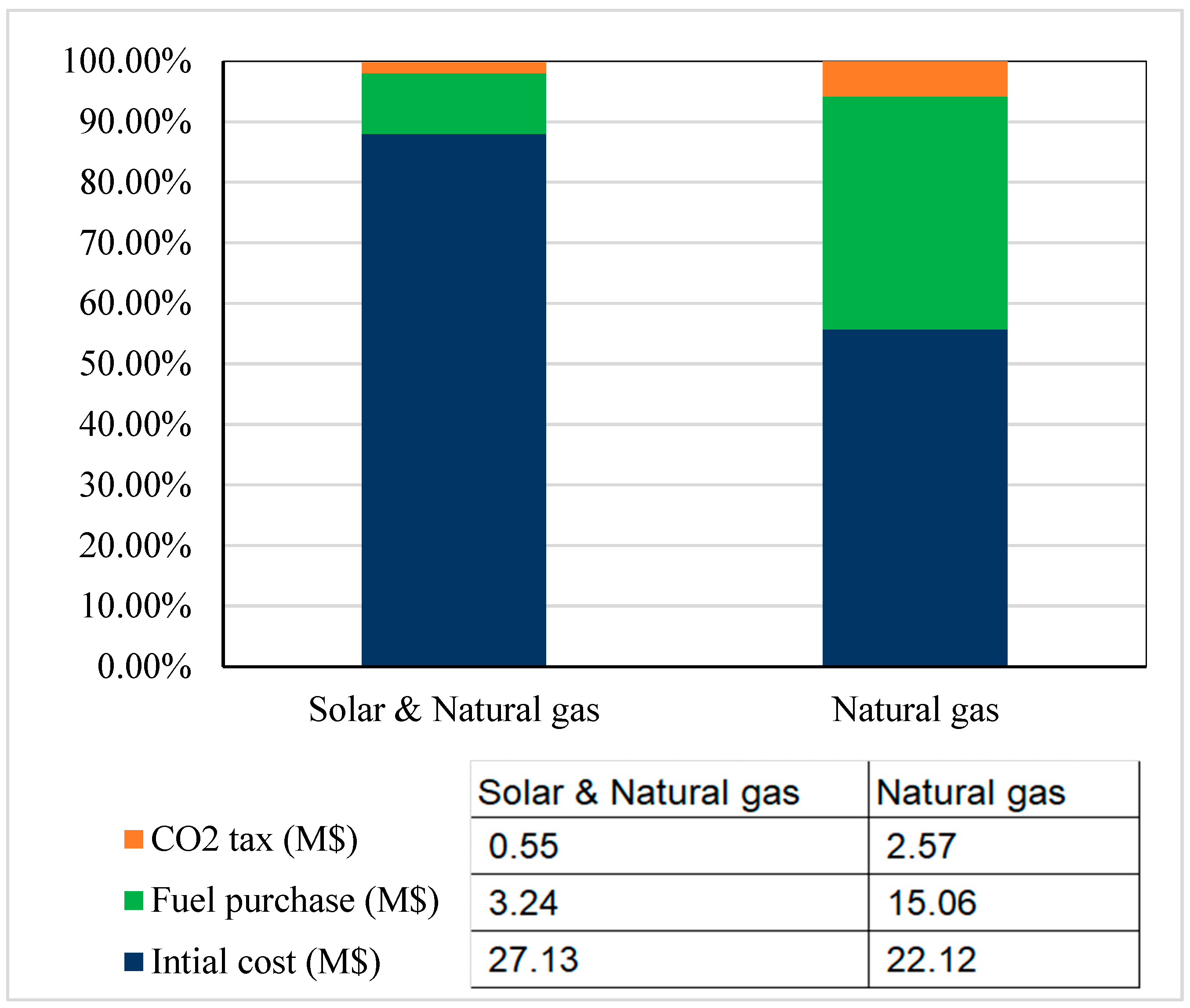

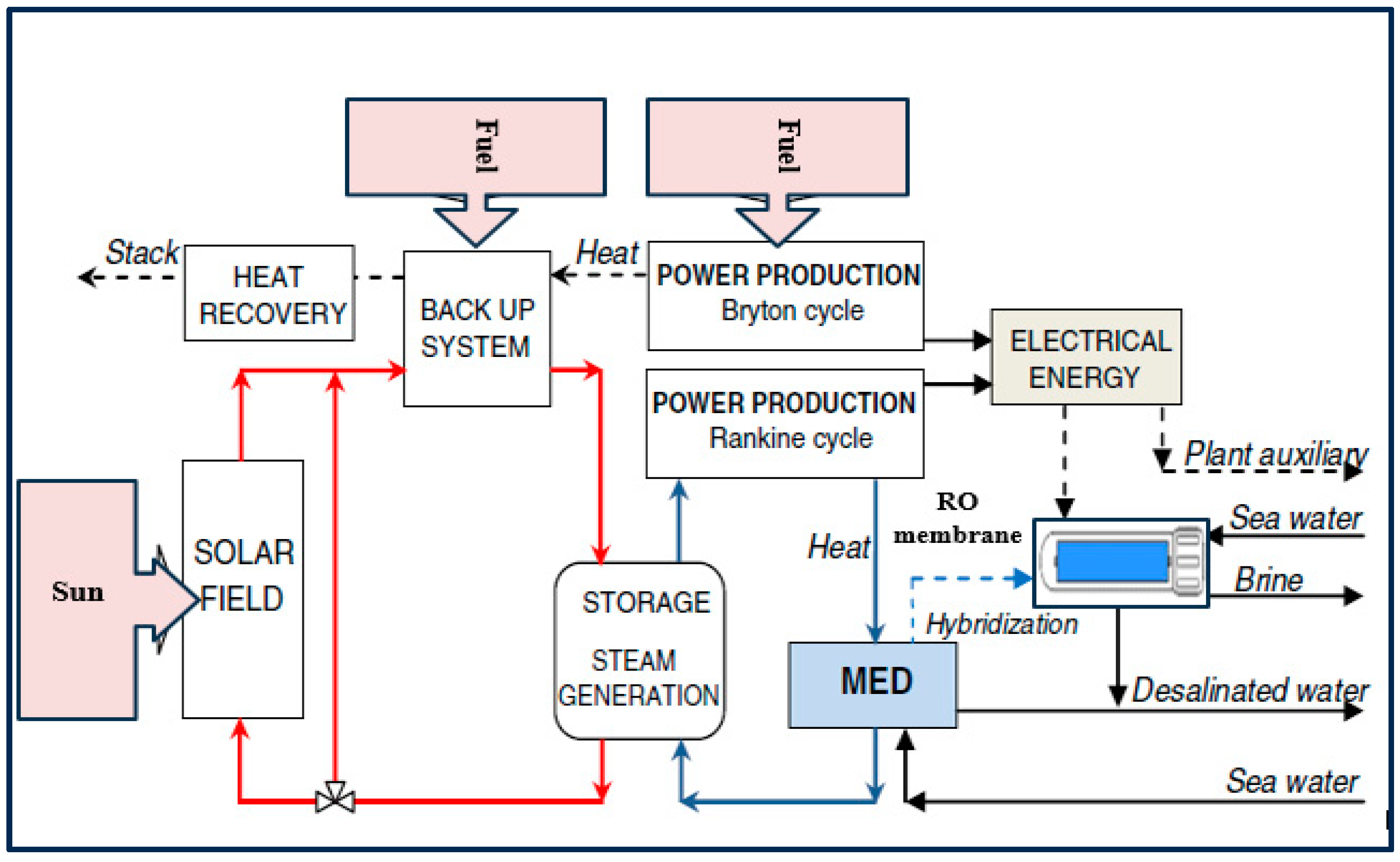

| Iaquaniello et al. [101] | 10 effects of MED at 70 °C of top brine temperature | To extend the operating time beyond the direct heat irradiation period, the CSP system uses molten salts as its thermal medium, which is fitted with a thermal storage unit. A continuous operating mode is made possible by a backup system that functions as a heat recovery device on flue gas supplied by a gas turbine (GT) | Seawater salinity of 35,000 ppm, temperature of 25 °C, heating steam temperature of 69 °C | -Freshwater production cost is USD 0.97/m3 -The annual productivity is 6,864,000 m3 -The specific energy consumption is 2.52 kWe/m3 -CO2 emission of 1.53 kg/m3 of freshwater | -The price of natural gas and the plant’s lifespan have an impact on the cost of producing water -The suggested method has the potential to drastically lower greenhouse gas emissions when compared to traditional desalination facilities | -A significant obstacle to the proposed scheme’s deployment is the CSP system’s high capital cost -Because solar radiation is irregular, the desalination plant needs a dependable backup system to keep running continuously |

| Weiner et al. [102] | Five MED effects at 70 °C of top brine temperature. To raise the temperature and pressure of the resultant mixture to the levels needed by the first effect, some of the vapor from the final effect is fed into a TVC, where high-pressure motive steam is introduced | -In order to heat a circulating heat transfer fluid, solar radiation is collected and concentrated using trough collectors | Brackish water salinity of 15,000 ppm | -At a levelized cost of USD 0.45/m3, the hybrid RO–MED system may generate water at a 41% cheaper cost than a standalone MED system -The product salinity of 500 ppm | -In California, the hybrid RO–MED system is a viable technological solution for purifying agricultural drainage water -The optimal number of MED effects is five, and the ideal RO working flux is 18.2 LMH -The number of effects used in the MED system has the greatest impact on the hybrid RO-MED system | -Because of the high capital cost of the CSP plant, the hybrid RO-MED system implementation is hindered -Solar radiation availability affects the system as well -Fouling and scaling of the RO and MED membranes may lead to reduced system performance |

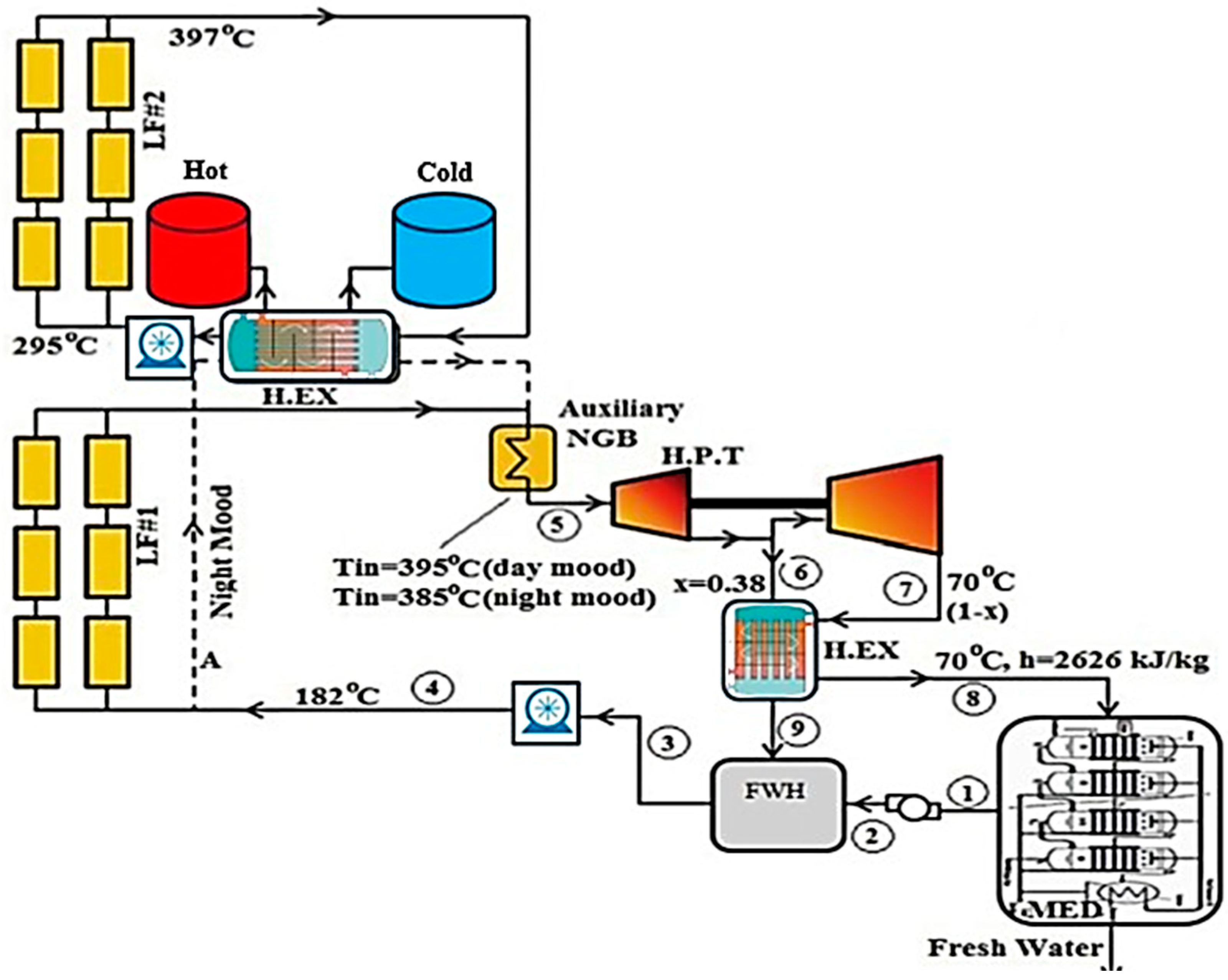

| Askari and Ameri [103] | 14 effects of MED Top brine temperature of 70.8 °C | In order to improve the charging and discharging procedure and enhance the thermal energy storage capacity of the Thermal Storage System (TES), two Linear Fresnel (LF) solar fields were employed | Seawater temperature between 35 and 66 °C | -Specific heat consumptions are 66 and 54 kWht/m3 for 9.8 and 12 of DOR, respectively | -The study concluded that a viable substitute for producing both water and electricity is to use an LF solar field as the thermal source of an SRC/MED plant -The research additionally discovered that the LCOW of the SRC/MED plant and the number of loops in the solar field are reduced with an increase in the MED unit GOR -The study also discovered that the solar share and LCOE of the SRC/MED plant rise with an increased TES capacity | -The impact of the solar field orientations on the solar share and LCOE of the SRC/MED plant was not taken into account in the analysis -Additionally, the impact of the MED unit design on the LCOW of the SRC/MED plant was not taken into account in this study -It is possible that the study overestimated the mass flow rate in the LF1 solar field |

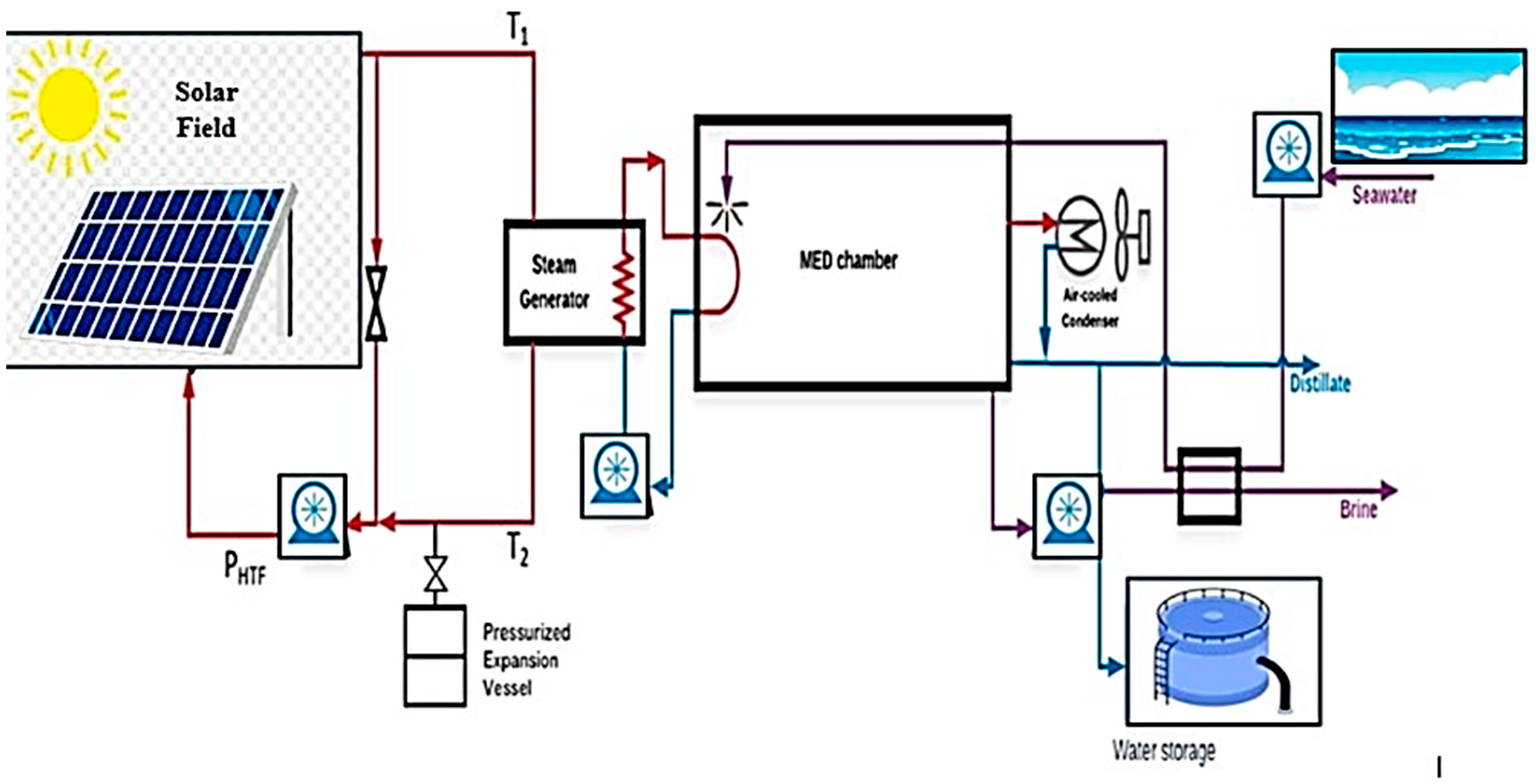

| Alhaj et al. [30] | 10 effects of MED at 70 °C of top brine temperature | Solar collectors (parabolic trough collector (PTC) and linear Fresnel collector (LFC) | Seawater salinity of 48,000 ppm, temperature of 30 °C | -Specific energy consumption of 4.2 kWh/m3 | For each m3 of freshwater generated, the solar-driven MED plant offsets the impact of climate change by 10 kg of CO2 equivalent. This is in contrast to the regular MED plant | -The absence of thorough data on the effects of desalination procedures on the environment is the primary obstacle to doing LCA studies on desalination plants -Comparing the findings of several studies can be challenging since the assumptions and methodologies employed in LCA research can have a significant impact on the findings -The social and economic advantages of desalination, such as the supply of clean drinking water and the generation of jobs, are sometimes overlooked in LCA studies |

| Khalilzadeh and Nezhad [35] | Six effects MED unit | Wind turbine of 7580 kW Enercon-E126 model | Seawater salinity and temperature of 42,000 ppm and 25 °C | -When steam is created at 100 °C and 101.3 kPa, 45.069 m3/day of drinkable water may be produced -An estimated 16.676 USD/m3 is the cost of fresh water | The study proved that it is feasible to run MED desalination machines with waste heat from high-capacity wind turbines, providing a cost-effective and environmentally friendly option for freshwater production in isolated and coastal places | The short-term nature of wind energy makes it difficult for the desalination system to run continuously. The combined system’s expensive initial investment cost could prevent it from being widely adopted, especially in lower-income nations |

| Birney et al. [104] | Top brine temperature of 70 °C | Geothermal temperature 90–150 °C and geothermal gradient of 36 °C/km | Brackish water salinity between 1000 and 10,000 ppm | -Freshwater from wells in these fairways may provide 232–2133 persons with a daily yield of 121–1132 m3/day | -It is possible to construct a geothermal-powered MED plant in southeast Texas’ geopressured Frio and Wilcox fairways that would function independently of the grid’s electricity -In every other part of Texas, a geothermal-energy-driven micro-engineering system would need to buy extra electricity from the grid or be constructed in combination with another renewable energy source, like solar or wind power | -It takes a lot of energy to pump water out of deep sea; hence, the binary-MED system struggles to become energy independent on its own -The environmental issues associated with brine disposal and the financial aspects of constructing a geothermal MED plant are not covered in the paper |

| Farsi and Rosen [105] | Six effects of MED and Organic Rankine cycle (ORC) Top brine temperature of MED of 63 °C Steam flowrate of MED of 9.02 kg/s | Geothermal energy of 180 °C of water temperature | Seawater salinity and temperature of 42,000 ppm and 20 °C, respectively | -Freshwater production rate of 32.7 kg/s -Fresh water salinity of 0.0 ppm -Overall exergy efficiency of 38% -ORC exergy efficiency of 34% -MED exergy efficiency of 20.5% | -Geothermal energy-powered ORC and MED combination may boost energy effectiveness, lower energy destruction, and lessen environmental effects | -The geothermal-based combination system’s economics were not taken into account in the research. -The study made the assumption that saltwater and geothermal hot water were easily accessible in appropriate amounts and temperatures -The study did not take into account the greenhouse gas emissions from the geothermal-based combination system or its effects on the environment |

| Energy Type | Productivity (m3/day) | Freshwater Production Cost (USD$/m3) |

|---|---|---|

| Fossil fuel | 0.46–3.5 | |

| Photovoltaic | Less than 100 | 11.7–15.6 |

| Wind energy | 1.3–6.5 | |

| Solar collectors | 4.55–10.40 | |

| Solar still | Less than 0.1 | 1.3–6.5 |

| Solar/CSP + MED | More than 5000 | 2.3–2.8 |

| Solar + MED | 1–100 | 2.6–6.5 |

| Solar + MSF | 1 | 1.0–5.0 |

| PV + RO | Less than 100 | 11.7–15.6 |

| Geothermal + MED | 80 | 2.0–2.8 |

| Wind + RO | 50–2000 | Small capacity: 6.6–9.0 High capacity: 1.95–5.2 |

| Wind + Mechanical Vapor Compression (MVC) | Less than 100 | 5.2–7.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Obaidi, M.A.; Alsadaie, S.; Alsarayreh, A.; Sowgath, M.T.; Mujtaba, I.M. Integration of Renewable Energy Systems in Desalination. Processes 2024, 12, 770. https://doi.org/10.3390/pr12040770

Al-Obaidi MA, Alsadaie S, Alsarayreh A, Sowgath MT, Mujtaba IM. Integration of Renewable Energy Systems in Desalination. Processes. 2024; 12(4):770. https://doi.org/10.3390/pr12040770

Chicago/Turabian StyleAl-Obaidi, Mudhar A., Salih Alsadaie, Alanood Alsarayreh, Md. Tanvir Sowgath, and Iqbal M. Mujtaba. 2024. "Integration of Renewable Energy Systems in Desalination" Processes 12, no. 4: 770. https://doi.org/10.3390/pr12040770

APA StyleAl-Obaidi, M. A., Alsadaie, S., Alsarayreh, A., Sowgath, M. T., & Mujtaba, I. M. (2024). Integration of Renewable Energy Systems in Desalination. Processes, 12(4), 770. https://doi.org/10.3390/pr12040770