An Integrated Approach of Fuzzy AHP-TOPSIS for Multi-Criteria Decision-Making in Industrial Robot Selection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fuzzy Numbers

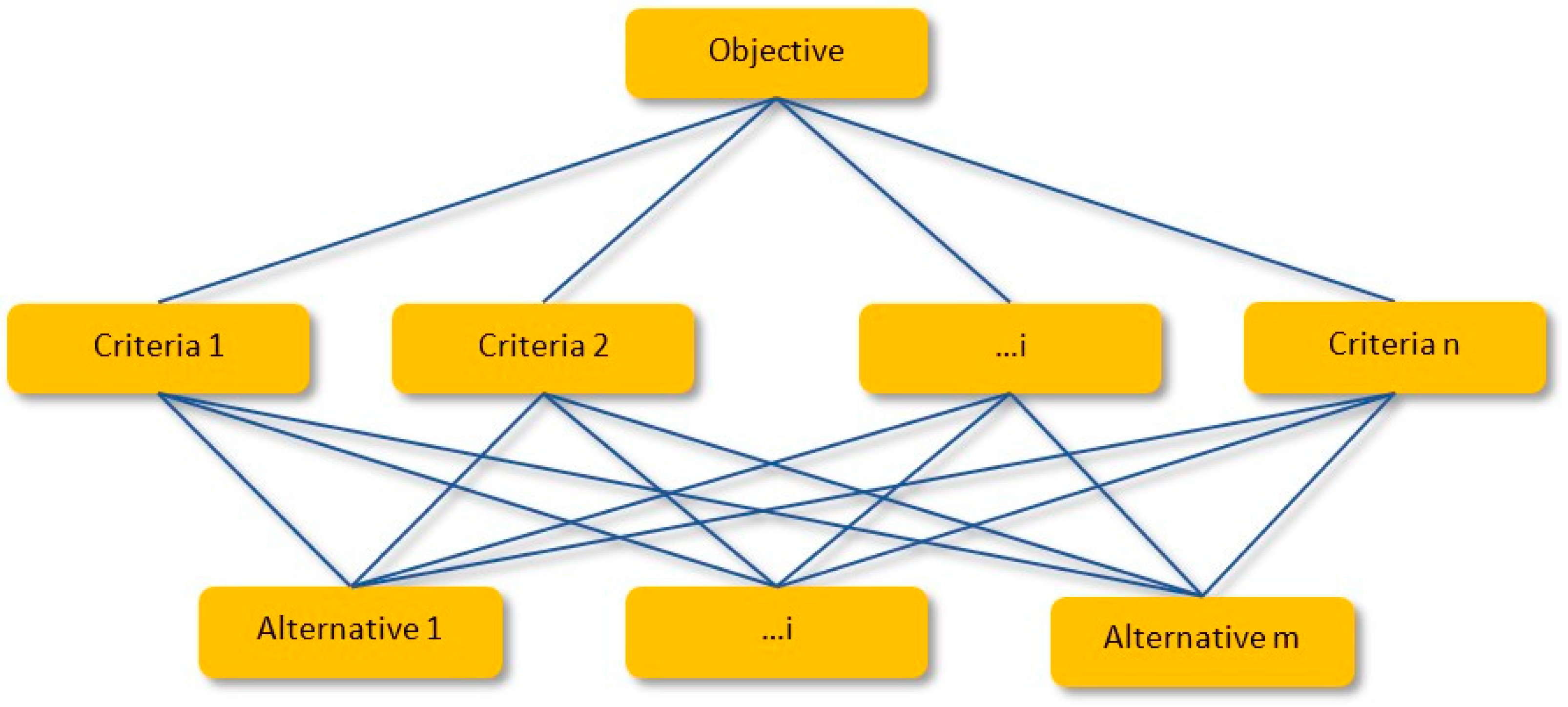

2.2. Fuzzy AHP

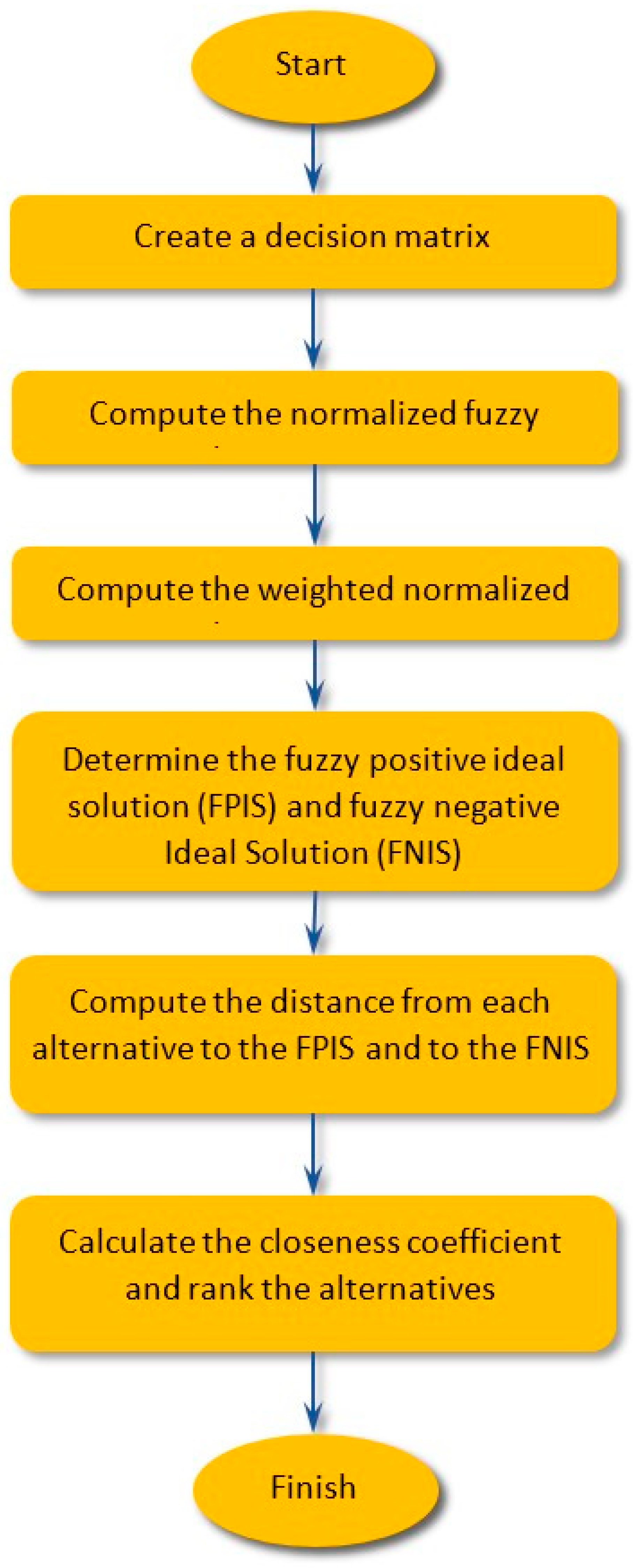

2.3. Fuzzy TOPSIS

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Criteria | Alternative | DM 1 | DM 2 | DM 3 | DM 4 | DM 5 |

|---|---|---|---|---|---|---|

| MW | Robot 1 | P | P | P | VP | VP |

| Robot 2 | VP | VP | VP | VP | VP | |

| Robot 3 | P | P | P | P | P | |

| Robot 4 | G | G | G | G | MG | |

| Robot 5 | MG | MG | MG | G | MG | |

| Robot 6 | F | F | F | MP | MP | |

| Robot 7 | VG | VG | VG | G | VG | |

| Robot 8 | MP | MP | P | MP | P |

| Criteria | Alternative | DM 1 | DM 2 | DM 3 | DM 4 | DM 5 |

|---|---|---|---|---|---|---|

| VL | Robot 1 | VG | VG | G | VG | VG |

| Robot 2 | F | F | MP | F | MP | |

| Robot 3 | G | G | VG | G | G | |

| Robot 4 | P | VP | VP | VP | P | |

| Robot 5 | P | P | P | P | VP | |

| Robot 6 | VP | VP | VP | VP | VP | |

| Robot 7 | MP | MP | MP | P | P | |

| Robot 8 | MG | MG | MG | G | MG |

| Criteria | Alternative | DM 1 | DM 2 | DM 3 | DM 4 | DM 5 |

|---|---|---|---|---|---|---|

| PL | Robot 1 | MG | G | MG | MG | MG |

| Robot 2 | P | P | P | P | VP | |

| Robot 3 | VP | VP | P | P | P | |

| Robot 4 | G | VG | G | VG | G | |

| Robot 5 | VG | VG | VG | VG | G | |

| Robot 6 | F | F | F | F | MP | |

| Robot 7 | P | P | P | MP | P | |

| Robot 8 | MP | MP | MP | MP | MP |

| Criteria | Alternative | DM 1 | DM 2 | DM 3 | DM 4 | DM 5 |

|---|---|---|---|---|---|---|

| MR | Robot 1 | P | P | P | P | VP |

| Robot 2 | VP | VP | VP | VP | VP | |

| Robot 3 | P | P | P | P | P | |

| Robot 4 | MP | MP | MP | MP | F | |

| Robot 5 | G | G | G | MG | MG | |

| Robot 6 | MG | MG | MG | MG | MG | |

| Robot 7 | VG | VG | VG | VG | VG | |

| Robot 8 | F | F | F | MG | F |

| Criteria | Alternative | DM 1 | DM 2 | DM 3 | DM 4 | DM 5 |

|---|---|---|---|---|---|---|

| APC | Robot 1 | MG | G | G | MG | MG |

| Robot 2 | VG | VG | VG | VG | VG | |

| Robot 3 | G | VG | G | G | G | |

| Robot 4 | P | P | P | P | P | |

| Robot 5 | F | F | F | F | MP | |

| Robot 6 | VP | VP | VP | VP | P | |

| Robot 7 | MP | MP | MP | MP | F | |

| Robot 8 | VP | VP | VP | P | P |

| Criteria | Alternative | DM 1 | DM 2 | DM 3 | DM 4 | DM 5 |

|---|---|---|---|---|---|---|

| CO | Robot 1 | P | P | P | MP | MP |

| Robot 2 | MG | G | G | MG | MG | |

| Robot 3 | VP | VP | VP | VP | P | |

| Robot 4 | F | F | MP | F | MP | |

| Robot 5 | MP | MP | MP | MP | P | |

| Robot 6 | VG | VG | VG | VG | VG | |

| Robot 7 | G | VG | G | G | VG | |

| Robot 8 | F | F | MG | MG | F |

References

- Brecher, C.; Müller, A.; Dassen, Y.; Storms, S. Automation technology as a key component of the industry 4.0 production development path. Int. J. Adv. Manuf. Technol. 2021, 117, 2287–2295. [Google Scholar] [CrossRef]

- Papulová, Z.; Gažová, A.; Šufliarský, Ľ. Implementation of automation technologies of industry 4.0 in automotive manufacturing companies. Procedia Comput. Sci. 2022, 200, 1488–1497. [Google Scholar] [CrossRef]

- Pedersen, M.R.; Nalpantidis, L.; Andersen, R.S.; Schou, C.; Bøgh, S.; Krüger, V.; Madsen, O. Robot skills for manufacturing: From concept to industrial deployment. Robot. Comput.-Integr. Manuf. 2016, 37, 282–291. [Google Scholar] [CrossRef]

- Dean-Leon, E.; Ramirez-Amaro, K.; Bergner, F.; Dianov, I.; Lanillos, P.; Cheng, G. Robotic technologies for fast deployment of industrial robot systems. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society 2016, Florence, Italy, 23–26 October 2016. [Google Scholar]

- De Backer, K.; DeStefano, T.; Menon, C.; Suh, J.R. Industrial Robotics and the Global Organisation of Production. 2018. Available online: https://www.oecd-ilibrary.org/docserver/dd98ff58-en.pdf?expires=1723607367&id=id&accname=guest&checksum=AEE2669ACDD759EE9C1C92406FE64B4D (accessed on 15 July 2024).

- Ogbemhe, J.; Mpofu, K.; Tlale, N.; Ramatsetse, B. Application of robotics in rail car manufacturing learning factory: A case of welding complex joints. Procedia Manuf. 2019, 31, 316–322. [Google Scholar] [CrossRef]

- Iqbal, J.; Khan, Z.H.; Khalid, A. Prospects of robotics in food industry. Food Sci. Technol. 2017, 37, 159–165. [Google Scholar] [CrossRef]

- Tran, N.T.; Ngo, T.D.; Nguyen, D.K.; Son, P.X.; Thai, N.H. Mapping and path planning for the differential drive wheeled mobile robot in unknown indoor environments using the rapidly exploring random tree method. In Lecture Notes in Mechanical Engineering 2021, Proceedings of the RCTEMME 2021, Hanoi, Vietnam, 10–12 December 2021; Springer Nature: Singapore, 2021; pp. 516–527. [Google Scholar]

- Fosch-Villaronga, E.; Drukarch, H. Accounting for diversity in robot design, testbeds, and safety standardization. Int. J. Soc. Robot. 2023, 15, 1871–1889. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; Silva, F.J.G. Industrial process improvement by automation and robotics. Machines 2023, 11, 1011. [Google Scholar] [CrossRef]

- Barosz, P.; Gołda, G.; Kampa, A. Efficiency analysis of manufacturing line with industrial robots and human operators. Appl. Sci. 2020, 10, 2862. [Google Scholar] [CrossRef]

- Amici, C.; Pellegrini, N.; Tiboni, M. The robot selection problem for mini-parallel kinematic machines: A task-driven approach to the selection attributes identification. Micromachines 2020, 11, 711. [Google Scholar] [CrossRef]

- Rao, R.V.; Patel, B.K.; Parnichkun, M. Industrial robot selection using a novel decision making method considering objective and subjective preferences. Robot. Auton. Syst. 2011, 59, 367–375. [Google Scholar] [CrossRef]

- Chatterjee, P.; Mondal, S.; Chakraborty, S. A comparative study of preference dominance-based approaches for selection of industrial robots. Adv. Prod. Eng. Manag. 2014, 9, 5. [Google Scholar] [CrossRef]

- Villa Silva, A.J.; Pérez-Domínguez, L.; Martínez Gómez, E.; Luviano-Cruz, D.; Valles-Rosales, D. Dimensional analysis under linguistic pythagorean fuzzy set. Symmetry 2021, 13, 440. [Google Scholar] [CrossRef]

- Ic, Y.T.; Yurdakul, M.; Dengiz, B. Development of a decision support system for robot selection. Robot. Comput.-Integr. Manuf. 2013, 29, 142–157. [Google Scholar]

- Choe, M.S.; Yang, W.C. A reasonable method for industrial robot selection combined with several multi-attribute decision making methods. Int. J. Interact. Des. Manuf. 2024, 18, 2481–2489. [Google Scholar] [CrossRef]

- Khan, N.A.; Kumar, A.; Rao, N. A hybrid robot selection model for efficient decisive support system using fuzzy logic and genetic algorithm. Int. J. Syst. Assur. Eng. Manag. 2024, 15, 2120–2129. [Google Scholar] [CrossRef]

- Garg, C.P.; Görçün, Ö.F.; Kundu, P.; Küçükönder, H. An integrated fuzzy MCDM approach based on Bonferroni functions for selection and evaluation of industrial robots for the automobile manufacturing industry. Expert Syst. Appl. 2023, 213, 118863. [Google Scholar] [CrossRef]

- Ketipi, M.; Koulouriotis, D.; Karakasis, E. Robot evaluation and selection part b: A comparative analysis. Int. J. Adv. Manuf. Technol. 2014, 71, 1395–1417. [Google Scholar] [CrossRef]

- Bhangale, P.P.; Saha, S.; Agrawal, V. A dynamic model based robot arm selection criterion. Multibody Syst. Dyn. 2004, 12, 95–115. [Google Scholar] [CrossRef]

- Bader, F.; Rahimifard, S. A methodology for the selection of industrial robots in food handling. Innov. Food Sci. Emerg. Technol. 2020, 64, 102379. [Google Scholar] [CrossRef]

- Zhang, Y.; Abdullah, S.; Ullah, I.; Ghani, F. A new approach to neural network via double hierarchy linguistic information: Application in robot selection. Eng. Appl. Artif. Intell. 2024, 129, 107581. [Google Scholar] [CrossRef]

- Khouja, M.; Booth, D.E. A decision model for the robot selection problem using robust regression. Decis. Sci. 1991, 22, 656–662. [Google Scholar] [CrossRef]

- Rao, R.V.; Padmanabhan, K. Selection, identification and comparison of industrial robots using digraph and matrix methods. Robot. Comput.-Integr. Manuf. 2006, 22, 373–383. [Google Scholar] [CrossRef]

- Sen, D.K.; Datta, S.; Patel, S.K.; Mahapatra, S.S. Multi-criteria decision making towards selection of industrial robot: Exploration of promethee ii method. Benchmarking Int. J. 2015, 22, 465–487. [Google Scholar] [CrossRef]

- Sampathkumar, S.; Augustin, F.; Narayanamoorthy, S.; Ahmadian, A.; Ferrara, M.; Kang, D. Centroid and graded mean ranking methods for intuitionistic trapezoidal dense fuzzy set to solve mcdm problems of robot selection. Int. J. Fuzzy Syst. 2024, 1–24. [Google Scholar] [CrossRef]

- Athawale, V.M.; Chakraborty, S. A comparative study on the ranking performance of some multi-criteria decision-making methods for industrial robot selection. Int. J. Ind. Eng. Comput. 2011, 2, 831–850. [Google Scholar] [CrossRef]

- Fu, Y.; Li, M.; Luo, H.; Huang, G.Q. Industrial robot selection using stochastic multicriteria acceptability analysis for group decision making. Robot. Auton. Syst. 2019, 122, 103304. [Google Scholar] [CrossRef]

- Bui, H.A.; Tran, N.T.; Nguyen, D.L. Multi-criteria decision making in the powder-mixed electrical discharge machining process based on the cocoso, spotis algorithms and the weighting methods. Int. J. Mod. Manuf. Technol. 2023, 15, 69–79. [Google Scholar] [CrossRef]

- Garg, H.; Sharaf, I.M. A new spherical aggregation function with the concept of spherical fuzzy difference for spherical fuzzy EDAS and its application to industrial robot selection. Comput. Appl. Math. 2022, 41, 212. [Google Scholar] [CrossRef]

- Goh, C.-H. Analytic hierarchy process for robot selection. J. Manuf. Syst. 1997, 16, 381–386. [Google Scholar] [CrossRef]

- Bairagi, B.; Dey, B.; Sarkar, B.; Sanyal, S. Selection of robotic systems in fuzzy multi criteria decision-making environment. Int. J. Comput. Syst. Eng. 2015, 2, 32–42. [Google Scholar] [CrossRef]

- Hung, C.-Y.; Chang, P.Y.; Huang, Y.-H. Comparison of fuzzy-based mcdm and non-fuzzy mcdm in setting a new fee schedule for orthopedic procedures in taiwan’s national health insurance program. In Proceedings of the 8th WSEAS International Conference on APPLIED MATHEMATICS, Tenerife, Spain, 16–18 December 2005; Volume 3, pp. 321–332. [Google Scholar]

- Dubois, D.; Prade, H. Fuzzy numbers: An overview. In Readings in Fuzzy Sets for Intelligent Systems; Morgan Kaufmann: Cambridge, MA, USA, 1993; pp. 112–148. [Google Scholar] [CrossRef]

- Petrović, G.; Mihajlović, J.; Ćojbašić, Ž.; Madić, M.; Marinković, D. Comparison of three fuzzy mcdm methods for solving the supplier selection problem. Facta Univ. Ser. Mech. Eng. 2019, 17, 455–469. [Google Scholar] [CrossRef]

- Kahar, N. Comparative study of smart and fmcdm methods in smartphone selection decision support system. Int. J. Image Graph. Signal Process. 2021, 13, 1. [Google Scholar] [CrossRef]

- Chen, L.; Pan, W. Review fuzzy multi-criteria decision-making in construction management using a network approach. Appl. Soft Comput. 2021, 102, 107103. [Google Scholar] [CrossRef]

- Bellman, R.E.; Zadeh, L.A. Decision-making in a fuzzy environment. Manag. Sci. 1970, 17, B-141–B-164. [Google Scholar] [CrossRef]

- Kumar, R.; Khepar, J.; Yadav, K.; Kareri, E.; Alotaibi, S.D.; Viriyasitavat, W.; Gulati, K.; Kotecha, K.; Dhiman, G. A systematic review on generalized fuzzy numbers and its applications: Past, present and future. Arch. Comput. Methods Eng. 2022, 29, 5213–5236. [Google Scholar] [CrossRef]

- Gurukumaresan, D.; Duraisamy, C.; Srinivasan, R. Optimal solution of fuzzy transportation problem using octagonal fuzzy numbers. Comput. Syst. Sci. Eng. 2021, 37, 415–421. [Google Scholar] [CrossRef]

- Wang, F. Preference degree of triangular fuzzy numbers and its application to multi-attribute group decision making. Expert Syst. Appl. 2021, 178, 114982. [Google Scholar] [CrossRef]

- Nayagam, V.L.G.; Murugan, J. Hexagonal fuzzy approximation of fuzzy numbers and its applications in mcdm. Complex Intell. Syst. 2021, 7, 1459–1487. [Google Scholar] [CrossRef]

- Liu, Y.; Eckert, C.M.; Earl, C. A review of fuzzy ahp methods for decision-making with subjective judgements. Expert Syst. Appl. 2020, 161, 113738. [Google Scholar] [CrossRef]

- Stanković, M.; Stević, Ž.; Das, D.K.; Subotić, M.; Pamučar, D. A new fuzzy marcos method for road traffic risk analysis. Mathematics 2020, 8, 457. [Google Scholar] [CrossRef]

- Makki, A.A.; Abdulaal, R.M.S. A hybrid MCDM approach based on Fuzzy MEREC-G and Fuzzy RATMI. Mathematics 2023, 11, 3773. [Google Scholar] [CrossRef]

- Gürbüz, F.; Erdinç, G. Selecting the best hotel using the Fuzzy-Moora method with a new combined weight approach. In Proceedings of the International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), Ankara, Turkey, 19–21 October 2018; pp. 1–8. [Google Scholar]

- Kahraman, C.; Kaya, I.; Evik, S.; Ates, N.Y.; Gülbay, M. Fuzzy multi-criteria evaluation of industrial robotic systems using topsis. In Fuzzy Multi-Criteria Decision Making: Theory and Applications with Recent Developments; Springer: Boston, MA, USA, 2008; pp. 159–186. [Google Scholar]

- Kutlu Gündoğdu, F.; Kahraman, C. Spherical fuzzy analytic hierarchy process (AHP) and its application to industrial robot selection. In Intelligent and Fuzzy Techniques in Big Data Analytics and Decision Making, Proceedings of the INFUS 2019 Conference, Istanbul, Turkey, 23–25 July 2019; Springer International Publishing: Cham, Switzerland, 2020; pp. 988–996. [Google Scholar]

- Tan, T.; Mills, G.; Papadonikolaki, E.; Liu, Z. Combining multi-criteria decision making (mcdm) methods with building information modelling (bim): A review. Autom. Constr. 2021, 121, 103451. [Google Scholar] [CrossRef]

- Shyur, H.-J.; Shih, H.-S. A hybrid mcdm model for strategic vendor selection. Math. Comput. Model. 2006, 44, 749–761. [Google Scholar] [CrossRef]

- Hu, S.-K.; Lu, M.-T.; Tzeng, G.-H. Exploring smart phone improvements based on a hybrid mcdm model. Expert Syst. Appl. 2014, 41, 4401–4413. [Google Scholar] [CrossRef]

- Wu, H.-Y.; Chen, J.-K.; Chen, I.-S.; Zhuo, H.-H. Ranking universities based on performance evaluation by a hybrid mcdm model. Measurement 2012, 45, 856–880. [Google Scholar] [CrossRef]

- Zarei, E.; Ramavandi, B.; Darabi, A.H.; Omidvar, M. A framework for resilience assessment in process systems using a fuzzy hybrid mcdm model. J. Loss Prev. Process Ind. 2021, 69, 104375. [Google Scholar] [CrossRef]

- Roshanaei, V.; Vahdani, B.; Mousavi, S.M.; Mousakhani, M.; Zhang, G. Cad/cam system selection: A multi-component hybrid fuzzy mcdm model. Arab. J. Sci. Eng. 2013, 38, 2579–2594. [Google Scholar] [CrossRef]

- Li, H.; Wang, W.; Fan, L.; Li, Q.; Chen, X. A novel hybrid mcdm model for machine tool selection using fuzzy dematel, entropy weighting and later defuzzification vikor. Appl. Soft Comput. 2020, 91, 106207. [Google Scholar] [CrossRef]

- Alizadeh, R.; Soltanisehat, L.; Lund, P.D.; Zamanisabzi, H. Improving renewable energy policy planning and decision-making through a hybrid mcdm method. Energy Policy 2020, 137, 111174. [Google Scholar] [CrossRef]

- Goswami, S.S.; Behera, D.K. Developing fuzzy-AHP-integrated hybrid mcdm system of copras-aras for solving an industrial robot selection problem. Int. J. Decis. Support Syst. Technol. (IJDSST) 2023, 15, 1–38. [Google Scholar] [CrossRef]

- Soltan, H.; Janada, K.; Omar, M. FAQT-2: A customer-oriented method for MCDM with statistical verification applied to industrial robot selection. Expert Syst. Appl. 2023, 226, 120106. [Google Scholar] [CrossRef]

- Chodha, V.; Dubey, R.; Kumar, R.; Singh, S.; Kaur, S. Selection of industrial arc welding robot with TOPSIS and Entropy MCDM techniques. Mater. Today: Proc. 2022, 50, 709–715. [Google Scholar] [CrossRef]

- Rashid, T.; Ali, A.; Chu, Y.-M. Hybrid BW-EDAS MCDM methodology for optimal industrial robot selection. PLoS ONE 2021, 16, e0246738. [Google Scholar] [CrossRef]

- Yalçın, N.; Uncu, N. Applying EDAS as an applicable MCDM method for industrial robot selection. Sigma J. Eng. Nat. Sci. 2019, 37, 779–796. [Google Scholar]

- Goswami, S.S.; Behera, D.K.; Afzal, A.; Razak Kaladgi, A.; Khan, S.A.; Rajendran, P.; Subbiah, R.; Asif, M. Analysis of a robot selection problem using two newly developed hybrid MCDM models of TOPSIS-ARAS and COPRAS-ARAS. Symmetry 2021, 13, 1331. [Google Scholar] [CrossRef]

- Shanmugasundar, G.; Kalita, K.; Čep, R.; Chohan, J.S. Decision models for selection of industrial Robots—A comprehensive comparison of multi-criteria decision making. Processes 2023, 11, 1681. [Google Scholar] [CrossRef]

- Ahmad, S.; BİNGÖL, S.; Wakeel, S. A hybrid multi-criteria decision making method for robot selection in flexible manufacturing system. Middle East J. Sci. 2020, 6, 68–77. [Google Scholar]

- Büyüközkan, G.; Ilıcak, Ö.; Feyzioğlu, O. An integrated QFD approach for industrial robot selection. In Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems, Proceedings of the IFIP WG 5.7 International Conference, APMS 2021, Nantes, France, 5–9 September 2021; Proceedings, Part III, 2021; Springer: Berlin/Heidelberg, Germany, 2021; pp. 561–570. [Google Scholar]

- Eisa, A.; Fattouh, M. The significance of weighting in multicriteria decision-making methods: A case study on robot selection. ERJ. Eng. Res. J. 2023, 46, 339–352. [Google Scholar] [CrossRef]

- Kumar, V.; Kalita, K.; Chatterjee, P.; Zavadskas, E.K.; Chakraborty, S. A SWARA-CoCoSo-based approach for spray painting robot selection. Informatica 2022, 33, 35–54. [Google Scholar] [CrossRef]

- Agarwal, S.; Chakraborty, S.; Prasad, K.; Chakraborty, S. A rough multi-attributive border approximation area comparison approach for arc welding robot selection. Jordan J. Mech. Ind. Eng. 2021, 15, 169–180. [Google Scholar]

- Kumar, V.; Gupta, P.; Mohata, A.; Das, P.P. Selection of industrial arc welding robot using integrated PIPRECIA-TOPSIS model. In AIP Conference Proceedings 2023; AIP Publishing: Melville, NY, USA, 2023; Volume 2786. [Google Scholar]

- Ali, A.; Rashid, T. Best–worst method for robot selection. Soft Comput. 2021, 25, 563–583. [Google Scholar] [CrossRef]

- Zhao, J.; Sui, Y.; Xu, Y.; Lai, K. Industrial robot selection using a multiple criteria group decision making method with individual preferences. PLoS ONE 2021, 16, e0259354. [Google Scholar] [CrossRef]

- Shanmugasundar, G.; Sapkota, G.; Čep, R.; Kalita, K. Application of MEREC in multi-criteria selection of optimal spray-painting robot. Processes 2022, 10, 1172. [Google Scholar] [CrossRef]

- Mecheri, S.S.; Greene, C.M. Collaborative robot selection using analytical hierarchical process. Int. J. Rapid Manuf. 2019, 8, 326–344. [Google Scholar] [CrossRef]

- Karande, P.; Zavadskas, E.; Chakraborty, S. A study on the ranking performance of some MCDM methods for industrial robot selection problems. Int. J. Ind. Eng. Comput. 2016, 7, 399–422. [Google Scholar] [CrossRef]

- Mondal, S.; Kuila, S.; Singh, A.K.; Chatterjee, P. A complex proportional assessment method-based framework for industrial robot selection problem. Int. J. Res. Sci. Eng. 2017, 3, 368–378. [Google Scholar]

- Breaz, R.E.; Bologa, O.; Racz, S.G. Selecting industrial robots for milling applications using AHP. Procedia Comput. Sci. 2017, 122, 346–353. [Google Scholar] [CrossRef]

- Muduli, K.; Pumwa, J.; Yadav, D.K.; Kumar, R.; Tripathy, S. A grey relation approach for selection of industrial robot. In Proceedings of the 2018 International Conference on Information Technology (ICIT) 2018, Bhubaneswar, India, 19–21 December 2018; pp. 141–144. [Google Scholar]

- Simion, M.; Socaciu, L.; Giurgiu, O.; PETRIŞOR, S.M. The selection of industrial robots for military industry using AHP method: A case study. Acta Tech. Napoc.-Ser. Appl. Math. Mech. Eng. 2018, 61. Available online: https://atna-mam.utcluj.ro/index.php/Acta/article/view/987 (accessed on 9 August 2024).

- Fedai, Y. Optimization of drilling parameters in drilling of mwcnt-reinforced gfrp nanocomposites using fuzzy AHP-weighted Taguchi-based MCDM methods. Processes 2023, 11, 2872. [Google Scholar] [CrossRef]

- Luyen, L.A.; Thanh, N.V. Logistics service provider evaluation and selection: Hybrid SERVQUAL–FAHP–TOPSIS model. Processes 2022, 10, 1024. [Google Scholar] [CrossRef]

- Hien, D.N.; Thanh, N.V. Optimization of cold chain logistics with fuzzy MCDM model. Processes 2022, 10, 947. [Google Scholar] [CrossRef]

- Zhu, X.; Xiao, Y.; Xiao, G.; Deng, X. Research on driving factors of collaborative integration implementation of lean-green manufacturing system with industry 4.0 based on Fuzzy AHP-DEMATEL-ISM: From the Perspective of Enterprise Stakeholders. Processes 2022, 10, 2714. [Google Scholar] [CrossRef]

- Alhakami, W. Computational study of security risk evaluation in energy management and control systems based on a fuzzy MCDM method. Processes 2023, 11, 1366. [Google Scholar] [CrossRef]

- Alojaiman, B. A multi-criteria decision-making process for the selection of an efficient and reliable IOT application. Processes 2023, 11, 1313. [Google Scholar] [CrossRef]

- Liu, R.; Solangi, Y.A. An analysis of renewable energy sources for developing a sustainable and low-carbon hydrogen economy in China. Processes 2023, 11, 1225. [Google Scholar] [CrossRef]

- Abdullah, F.M.; Al-Ahmari, A.M.; Anwar, S. An integrated fuzzy dematel and fuzzy TOPSIS method for analyzing smart manufacturing technologies. Processes 2023, 11, 906. [Google Scholar] [CrossRef]

- Thanh, N.V. A dynamic decision support system for sustainable supplier selection under fuzzy environment. Processes 2022, 10, 1576. [Google Scholar] [CrossRef]

| MCDM Method | Criteria for Evaluating Robots | Results | Reference |

|---|---|---|---|

| Entropy, TOPSIS | Mechanical Weight, Repeatability, Payload, Maximum Reach, Average Power Consumption. | The study determined that Robot-7 is the optimal selection for arc welding tasks. This robot has a mechanical weight of 501 kg, a repeatability of 0.15 mm, a load capacity of 6 kg, a maximum reach of 4368 mm, and a power consumption of 2.5 kW. | [60] |

| BW, EDAS | Load Capacity, Repeatability, Velocity Ratio, Degree of Freedom. | The proposed method offers several advantages, including increased consistency and reduced computational requirements. | [61] |

| EDAS | Purchase Cost, Load Capacity, Repeatability, Man–Machine Interface, Man–Machine Interface, Vendor’s Service Contract. | Compared with other MCDM methods (such as AHP, TOPSIS, VIKOR, ELECTRE, PROMETHEE, MOORA, WASPAS, GRA, ROV, and OCRA), the EDAS method is simpler and easier to apply in selecting industrial robots. | [62] |

| TOPSIS-ARAS, COPRAS-ARAS | Load Capacity, Repeatability Error, Handling Coefficient, Velocity, Cost. | Based on the evaluation, Robot-12 achieved the highest rating and was identified as the optimal choice. This study validates the effectiveness of the hybrid models TOPSIS-ARAS and COPRAS-ARAS in enhancing the accuracy of rankings and delivering consistent and dependable results in the selection of industrial robots. | [63] |

| SAW, TOPSIS, LINMAP, VIKOR, ELECTRE-III and NFM | Load Capacity, Repeatability Error, Cost, Vendor’s Service Quality, Programming Flexibility. | In case study 1, Robot 2 and Robot 3 emerged as the top choices for pick-and-place tasks. Case study 2 revealed that Robot 1 and Robot 3 received the highest ratings among the considered robots. In case study 3, Robot 2 was consistently identified as the optimal selection among the four robots considered by most MCDM methods. | [64] |

| CRITIC, MABAC | Load Capacity, Memory Capacity, Manipulator Reach, Maximum Tip Speed, Repeatability. | Robot R3 attained the highest ranking, signifying its suitability for pick-and-place operations in flexible manufacturing systems. Among the evaluated robots, Robot R1 received the lowest ranking. The study also conducted a comparison of the ranking results with other MCDM methods to validate the accuracy and reliability of the proposed method. | [65] |

| QFD, MPR | Payload Capacity, Workspace, Accuracy, Repeatability, Life Expectancy, Programmable Flexibility, Safety and Security, Purchase Cost, Maintenance Cost, Operation Cost. | The key criterion in the selection of an industrial robot is load capacity, and the most critical technical requirement is the drive system. | [66] |

| COCOSO, TOPSIS, VIKOR, MOORA | Load Capacity, Repeatability, Maximum Tip Speed, Memory Capacity, Manipulator Reach. | According to the COCOSO method, R3 emerges as the best robot based on the MW, SD, and CRITIC weight distribution methods. However, R1 is considered the best robot according to the EM method, and R3 is favored according to the AHP method. | [67] |

| SWARA, CoCoSo | Payload, Mechanical weight, Repeatability, Reach, Cost, Power Consumption. | The Fanuc P-350iA/45 robot has been selected as the most suitable robot for painting applications. These results have also been compared and cross-referenced with other popular MCDM methods such as TOPSIS, VIKOR, COPRAS, PROMETHEE, and MOORA, demonstrating a high degree of similarity in the ranking patterns among these methods, affirming the effectiveness of the SWARA-CoCoSo method. | [68] |

| Rough-MABAC | Payload, Horizontal Reach, Vertical Reach, Repeatability, Weight, Power Rating, Cost, Flexibility, Safety, Welding Performance, Maintainability, Ease of Programming. | The research findings indicate that Robot A6 is the most suitable choice, ranking at the top of the list, followed by Robots A3, A13, A10, A5, A9, A4, A11, A1, A14, A7, A12, A8, and finally Robot A2. The robots are categorized into two main groups, efficient and inefficient, based on their positions in the approximate boundary regions. | [69] |

| PIPRECIA-TOPSIS | Payload, Weight of Robot, Repeatability, Reach. | The PIPRECIA technique identifies payload as the most crucial criterion based on a predefined priority order, and the TOPSIS method recommends the FANUC 100iD/10L model as the best arc welding robot. | [70] |

| BWM, G-BWM | Velocity, Repeatability, Load Capacity, Cost, Quality, Memory Capacity, Manipulator Reach. | The results indicate that Robot 2 is the best robot. The G-BWM (group best–worst method) demonstrates greater effectiveness compared to the G-AHP (Group Analytic Hierarchy Process) method due to its lower overall violation and deviation, as well as requiring fewer comparisons, resulting in reduced computational requirements. | [71] |

| MCGDM-IP | Cost, Handling Coefficient, Load Capacity, Repeatability, Velocity. | Robot R11 achieved the highest ranking among the evaluated robots, while Robot R4 received the lowest ranking. The MCGDM-IP method improved the satisfaction level of the group by 2.12% compared to the simple additive weighting (SAW) method. | [72] |

| CODAS, COPRAS, COCOSO, MABAC, VIKOR | Payload, Speed, Reach, Mechanical Weight, Repeatability, Cost, Power Consumption. | The results indicate that the HY1010A-143 robot is evaluated as the most suitable for painting applications according to four out of the five methods used. The KF121 robot is evaluated as the least suitable for painting applications by all of the MCDM methods. | [73] |

| AHP | General Criteria, Structure/Architecture Criteria, Reliability Criteria, Application Criteria, Performance Criteria, Safety Criteria. | The AHP method is applied to evaluate the cobots based on the predefined criteria. The cobot with the highest overall priority weight (A1) is considered the most suitable based on the given criteria and AHP evaluation. | [74] |

| WSM, WPM, WASPAS, MOORA, MULTIMOORA | Load Capacity, Maximum Tip Speed, Repeatability, Memory Capacity, Manipulator Reach. | The results indicate that among the applied MCDM methods, the MULTIMOORA (MOORA with Complete Multiplicative Form) method is the most robust and less affected by changes in the criteria weights. The robot ranking results show that the Cybotech V15 Electric Robot (R3) is often the best choice in most of the methods. | [75] |

| COPRAS | Repeatability Error, Load Capacity, Maximum Tip Speed, Memory Capacity, Manipulator Reach. | The Cincinnati Milacrone T3-726 Robot (A2) achieved the highest ranking with a Qi value of 0.1946 and a Ui value of 100.00, securing first position. The COPRAS method has been demonstrated to be effective in the evaluation and selection of industrial robots, aligning well with the results from previous studies. | [76] |

| AHP | Load Capacity, Reach, Weight, Repeatability, Power Consumption, Dexterity, Service | Based on the AHP method, the robot structure R2 is selected as the most optimal choice. | [77] |

| GRA | Load Capacity, Repeatability Error, Velocity Ratio, Degrees of Freedom. | Robot R3 achieved the highest score with a grey relational grade of 0.9434 and was ranked first. | [78] |

| AHP | Technical Criteria: Movement, Shaft Speed, Reach, Repeatability, Allowable Moment, Load: Robot Mass, Robot Reach, Vertical Reach, Horizontal reach Other Criteria: Capacity, Cost, Flexibility, Mounting Type, Welding Type. | Among the analyzed 15 industrial robots, the robot with code A4 achieved the highest weight of approximately 16%, followed by A5 with approximately 15%, and A2 and A9 both scoring ≈ 10%. Robot A4 excelled in criteria such as repeatability (C1.2), robot weight (C2.2), and power (C3.1), obtaining the highest score in these aspects. | [79] |

| No. | Criteria | Units | Symbol |

|---|---|---|---|

| 1 | Mechanical Weight | Kg | MW |

| 2 | Velocity | m/s | VL |

| 3 | Payload | Kg | PL |

| 4 | Maximum Reach | Mm | MR |

| 5 | Average Power Consumption | Kw | APC |

| 6 | Cost | $ | CO |

| Alternative | MW | VL | PL | MR | APC | CO |

|---|---|---|---|---|---|---|

| Robot 1 | 145 | 1.33 | 12 | 1441 | 1.0 | 722 |

| Robot 2 | 27 | 1.11 | 8 | 911 | 0.5 | 485 |

| Robot 3 | 170 | 1.26 | 4 | 1500 | 0.6 | 965 |

| Robot 4 | 272 | 0.65 | 20 | 1650 | 3.4 | 671 |

| Robot 5 | 250 | 0.04 | 25 | 2409 | 2 | 690 |

| Robot 6 | 230 | 0.25 | 10 | 1925 | 5.6 | 325 |

| Robot 7 | 501 | 1.01 | 6 | 4368 | 2.5 | 400 |

| Robot 8 | 215 | 1.21 | 8 | 1801 | 5.05 | 690 |

| Linguistic Terms | Scale of Fuzzy Number | Units |

|---|---|---|

| Absolutely strong (AS) | (2, 2.5, 3) | |

| Very strong (VS) | (1.5, 2, 2.5) | |

| Fairly strong (FS) | (1, 1.5, 2) | |

| Slightly strong (SS) | (1, 1, 1.5) | |

| Equal (E) | (1, 1, 1) | |

| Slightly weak (SW) | (2/3, 1, 1) | |

| Fairly weak (FW) | (0.5, 2/3, 1) | |

| Very weak (VW) | (0.4, 0.5, 2/3) | |

| Absolutely weak (AW) | (1/3, 0.4, 0.5) |

| Experts | Age | Education | Experience in the Field (Years) |

|---|---|---|---|

| Decision maker 1 (DM 1) | 58 | Associate Professor of Mechanical Engineering | >15 |

| Decision maker 2 (DM 2) | 62 | Associate Professor of Robotics Engineering | >20 |

| Decision maker 3 (DM 3) | 58 | Associate Professor of Manufacturing Processes | >25 |

| Decision maker 4 (DM 4) | 65 | Professor of Management Science and Engineering Management | >20 |

| Decision maker 5 (DM 5) | 66 | Professor of Mechatronics Engineering | >30 |

| Criteria | DM 1 | DM 2 | DM 3 | DM 4 | DM 5 |

|---|---|---|---|---|---|

| MW | FS | FS | FS | VS | FS |

| VL | AS | VS | VS | AS | VS |

| PL | AS | AS | AS | AS | AS |

| MR | VS | VS | VS | VS | AS |

| APC | VW | VW | VW | FW | VW |

| CO | FW | FW | FW | FW | FW |

| Criteria | High Priority | Equal | Low Priority | Criteria | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | |||||||||

| Criteria | MW | VL | PL | MR | APC | CO |

|---|---|---|---|---|---|---|

| MW | (1, 1, 1) | (1, 15/14, 30/19) | (1, 15/13, 5/3) | (15/14, 30/19, 25/12) | (1, 8/5, 21/10) | (1, 11/10, 8/5) |

| VL | (19/30, 14/15, 1) | (1, 1, 1) | (1, 11/10, 8/5) | (1, 6/5, 17/10) | (8/5, 21/10, 13/5) | (1, 8/5, 21/10) |

| PL | (3/5, 13/15, 1) | (5/8, 10/11, 1) | (1, 1, 1) | (1, 15/14, 30/19) | (13/10, 9/5, 13/10) | (13/10, 9/5, 23/10) |

| MR | (12/25, 19/30, 14/15) | (10/17, 5/6, 1) | (19/30, 14/15, 1) | (1, 1, 1) | (1, 7/5, 19/10) | (1, 13/10, 9/5) |

| APC | (10/21, 5/8, 1) | (5/13, 10/21, 5/8) | (10/13, 5/9, 10/13) | (10/19, 5/7, 1) | (1, 1, 1) | (1, 7/5, 19/10) |

| CO | (5/8, 10/11, 1) | (10/21, 5/8, 1) | (10/23, 5/9, 10/13) | (5/9, 10/13, 1) | (10/19, 5/7, 1) | (1, 1, 1) |

| Value | |

|---|---|

| (0.132, 0.2, 0.33) | |

| (0.131, 0.206, 0.3190) | |

| (0.121, 0.192, 0.263) | |

| (0.098, 0.16, 0.247) | |

| (0.085, 0.121, 0.2) | |

| (0.076, 0.121, 0.195) |

| Linguistic Terms | Fuzzy Core |

|---|---|

| Very poor (VP) | (0, 0, 1) |

| Poor (P) | (0, 1, 3) |

| Medium poor (MP) | (1, 3, 5) |

| Fair (F) | (3, 5, 7) |

| Medium good (MG) | (5, 7, 9) |

| Good (G) | (7, 9, 10) |

| Very good (VG) | (9, 10, 10) |

| Alternative | MW | VL | PL | MR | APC | CO |

|---|---|---|---|---|---|---|

| Robot 1 | (0, 0.6, 2.2) | (8.6, 9.8, 10) | (5.4, 7.4, 9.2) | (0, 0.8, 2.6) | (5.8, 7.8, 9.4) | (0, 0.6, 2.2) |

| Robot 2 | (0, 0, 1) | (2.2, 4.2, 6.2) | (0, 0.8, 2.6) | (0, 0, 1) | (9, 10, 10) | (5.8, 7.8, 9.4) |

| Robot 3 | (0, 1, 3) | (7.4, 9.2, 10) | (0, 0.6, 2.2) | (0, 1, 3) | (7.4, 9.2, 10) | (0, 0.2, 1.4) |

| Robot 4 | (6.6, 8.6, 9.8) | (0, 0.4, 1.8) | (7.8, 9.4, 10) | (1.4, 3.4, 5.4) | (0, 1, 3) | (2.2, 4.2, 6.2) |

| Robot 5 | (5.4, 7.4, 9.2) | (0, 0.8, 2.6) | (8.6, 9.8, 10) | (7.8, 9.4, 10) | (2.6, 4.6, 6.6) | (0.8, 2.6, 4.6) |

| Robot 6 | (2.2, 4.2, 6.2) | (0, 0, 1) | (2.6, 4.6, 6.6) | (5, 7, 9) | (0, 0.2, 1.4) | (9, 10, 10) |

| Robot 7 | (8.6, 9.8, 10) | (0.6, 2.2, 4.2) | (0.2, 1.4, 3.4) | (9, 10, 10) | (1.4, 3.4, 5.4) | (7.8, 9.4, 10) |

| Robot 8 | (0.6, 2.2, 4.2) | (5.4, 7.4, 9.2) | (1, 3, 5) | (3.4, 5.4, 7.4) | (0, 0.4, 1.8) | (3.8, 5.8, 7.8) |

| Alternative | Robot 1 | Robot 2 | Robot 3 | Robot 4 | Robot 5 | Robot 6 | Robot 7 | Robot 8 |

|---|---|---|---|---|---|---|---|---|

| 0.2656 | 0.4608 | 0.3525 | 0.2307 | 0.1653 | 0.3168 | 0.2131 | 0.2673 | |

| 0.2803 | 0.0819 | 0.1953 | 0.3183 | 0.3835 | 0.2319 | 0.3301 | 0.2843 |

| Alternative | Robot 1 | Robot 2 | Robot 3 | Robot 4 | Robot 5 | Robot 6 | Robot 7 | Robot 8 |

|---|---|---|---|---|---|---|---|---|

| 0.5134 | 0.1508 | 0.3565 | 0.5798 | 0.6987 | 0.4227 | 0.6077 | 0.5154 | |

| Rank | 5 | 8 | 7 | 3 | 1 | 6 | 2 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, N.-T.; Trinh, V.-L.; Chung, C.-K. An Integrated Approach of Fuzzy AHP-TOPSIS for Multi-Criteria Decision-Making in Industrial Robot Selection. Processes 2024, 12, 1723. https://doi.org/10.3390/pr12081723

Tran N-T, Trinh V-L, Chung C-K. An Integrated Approach of Fuzzy AHP-TOPSIS for Multi-Criteria Decision-Making in Industrial Robot Selection. Processes. 2024; 12(8):1723. https://doi.org/10.3390/pr12081723

Chicago/Turabian StyleTran, Ngoc-Tien, Van-Long Trinh, and Chen-Kuei Chung. 2024. "An Integrated Approach of Fuzzy AHP-TOPSIS for Multi-Criteria Decision-Making in Industrial Robot Selection" Processes 12, no. 8: 1723. https://doi.org/10.3390/pr12081723

APA StyleTran, N.-T., Trinh, V.-L., & Chung, C.-K. (2024). An Integrated Approach of Fuzzy AHP-TOPSIS for Multi-Criteria Decision-Making in Industrial Robot Selection. Processes, 12(8), 1723. https://doi.org/10.3390/pr12081723