Mechanical Characteristics and Mechanisms of Destruction of Trapezoidal Sandstone Samples Under Uneven Loading

Abstract

:1. Introduction

2. Compression Test

3. Microscopic Characteristics

4. Particle Flow Analysis

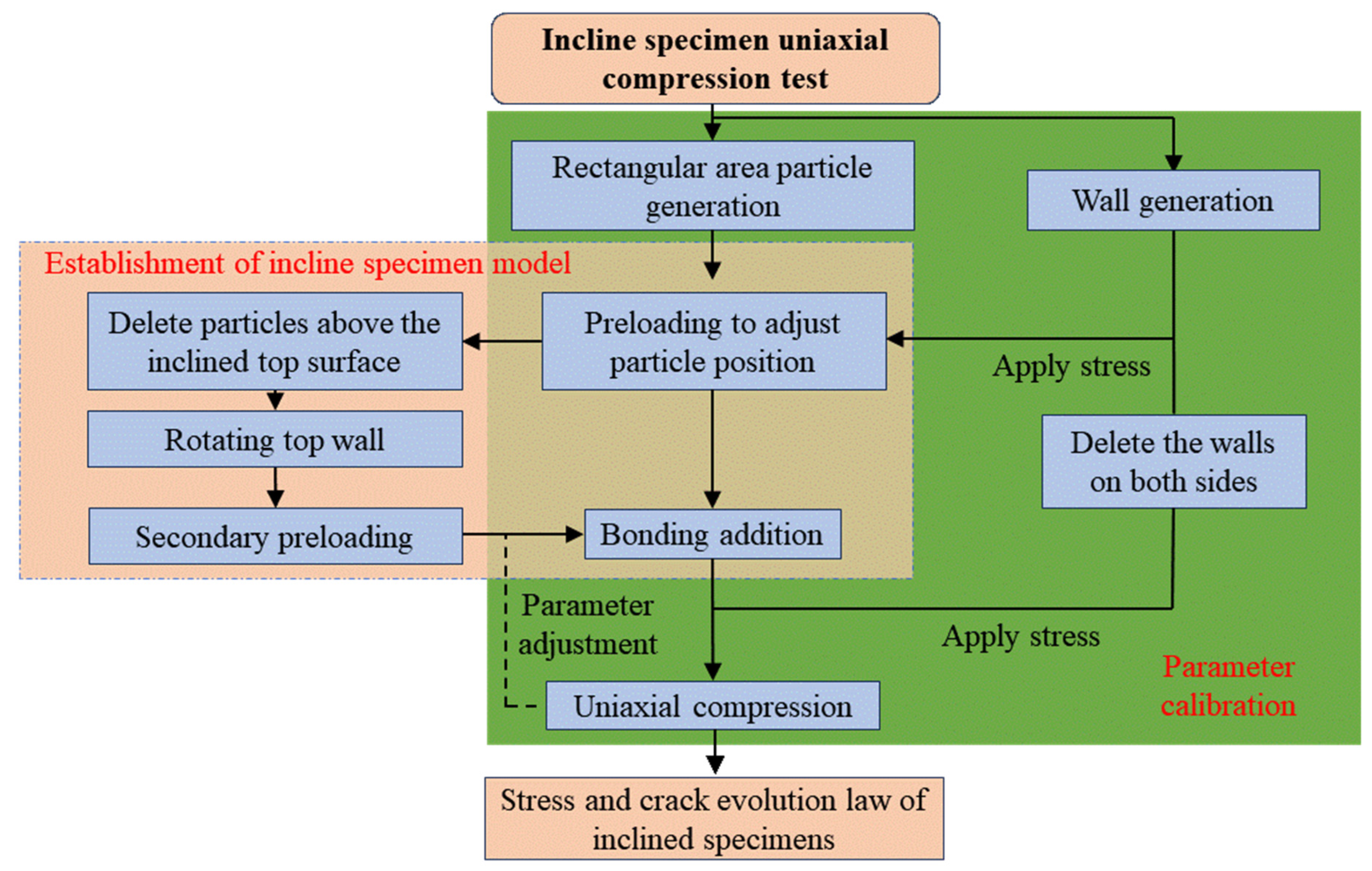

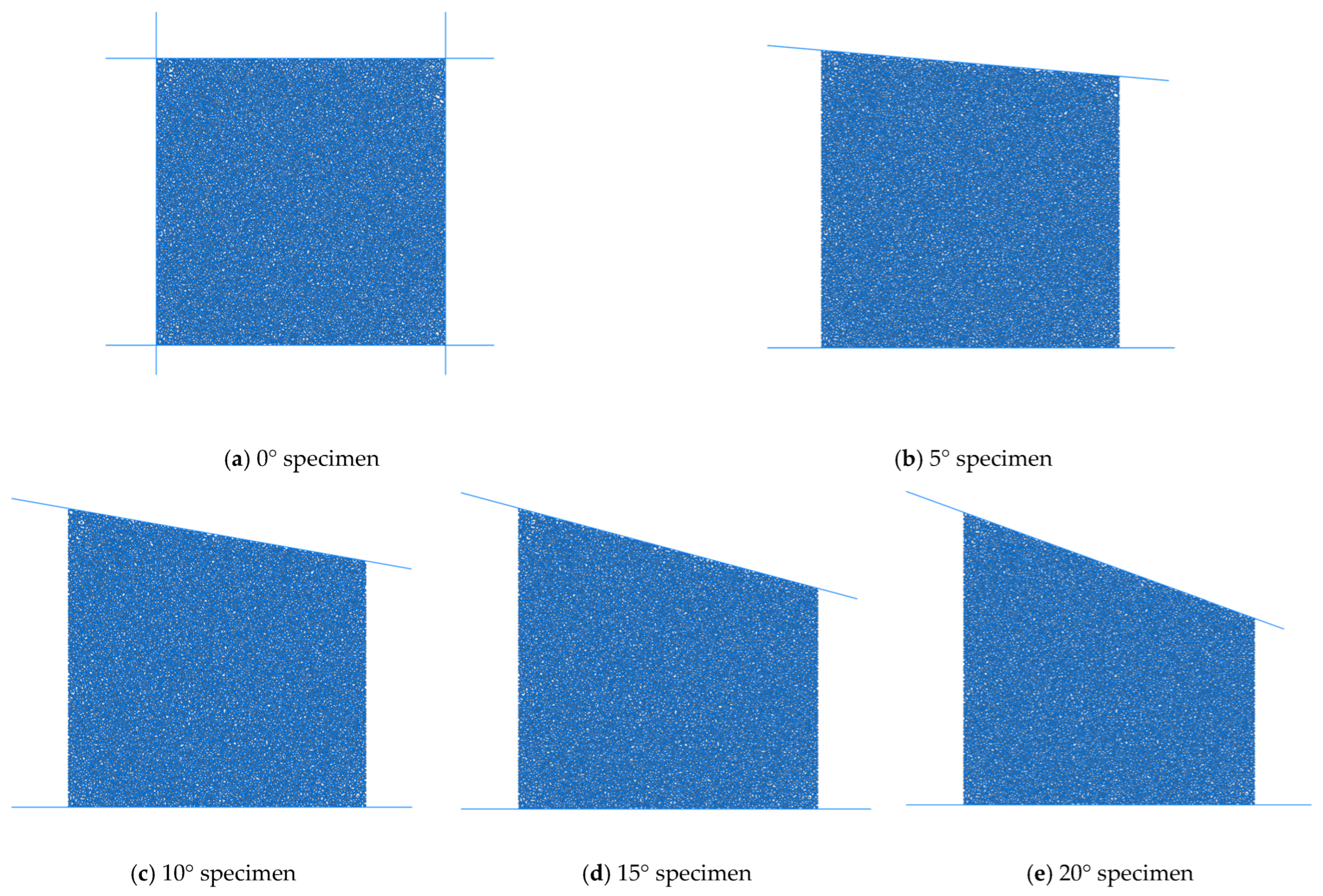

4.1. Establishment of Inclined Specimen Model

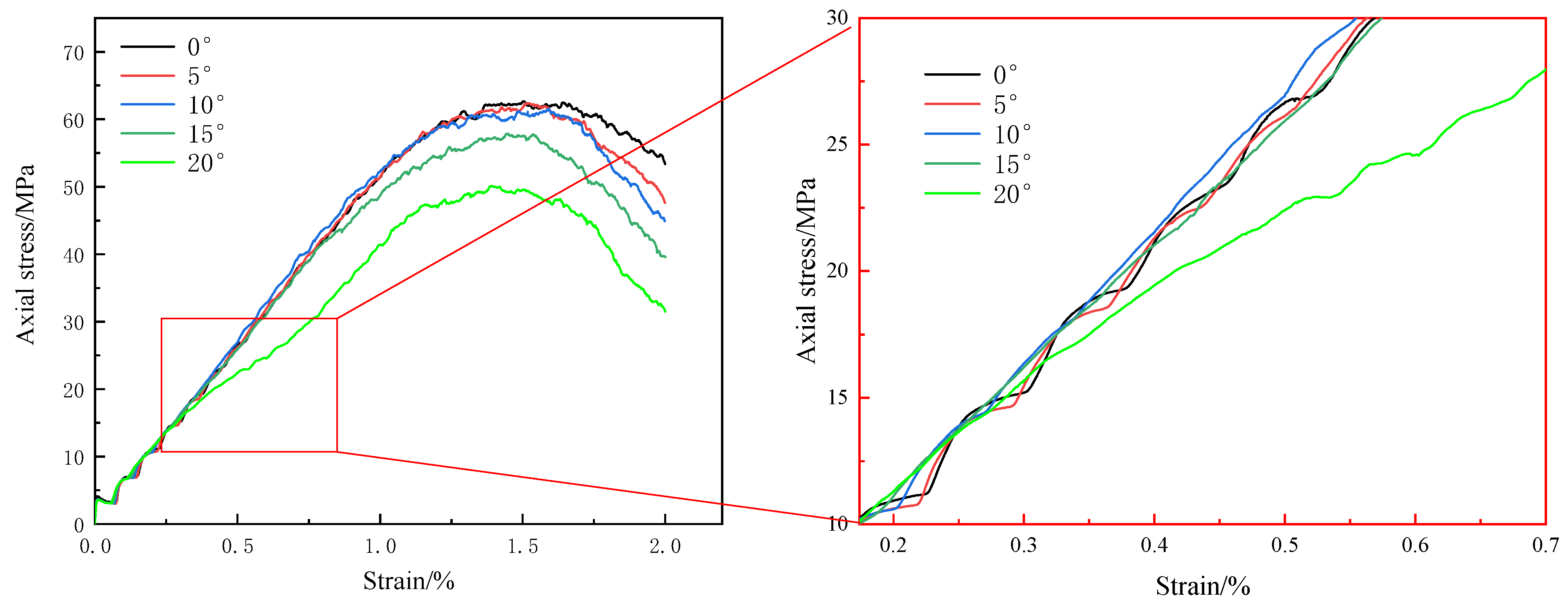

4.2. Mechanical Characteristics of Inclined Specimens

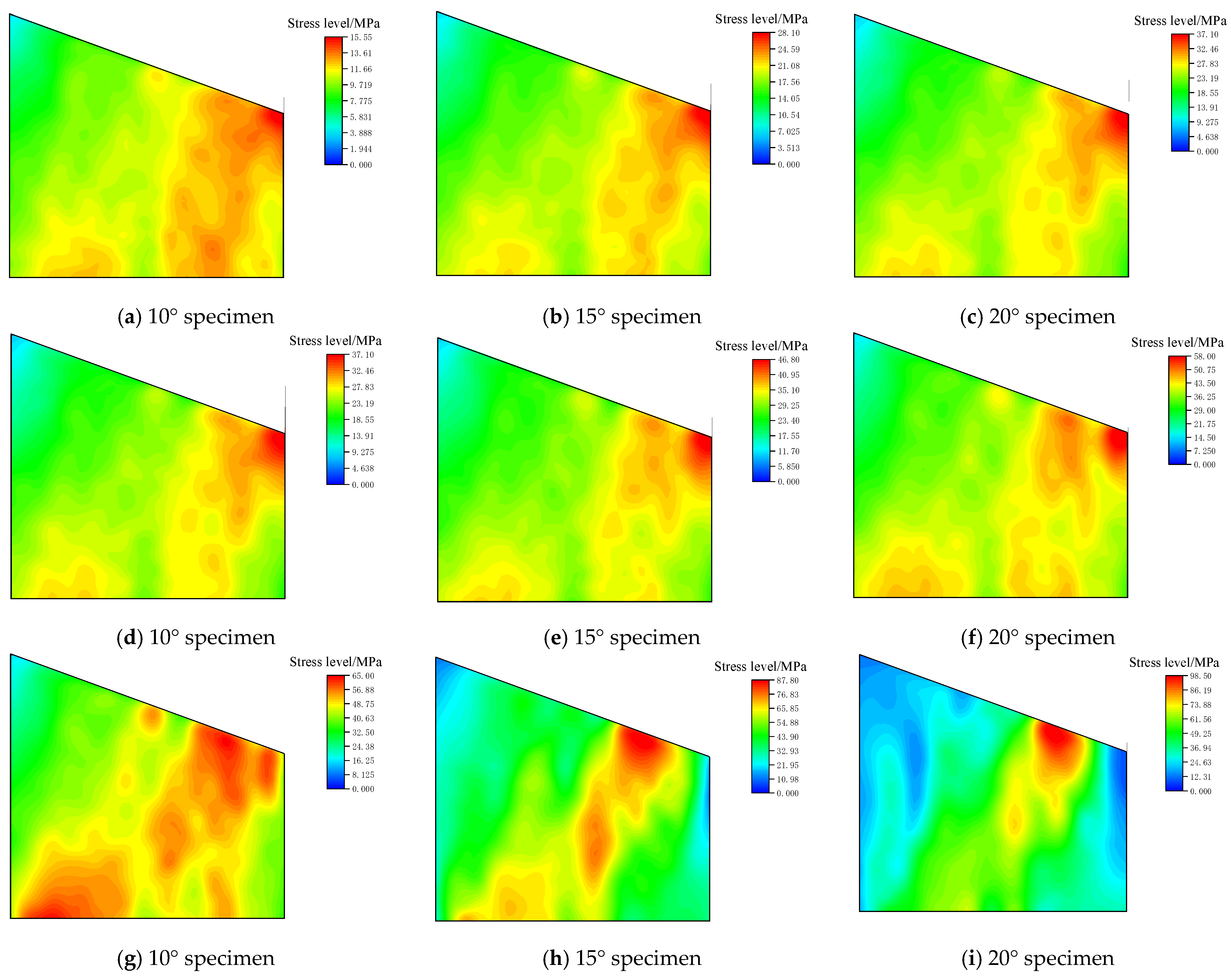

4.3. Stress Distribution Law of Inclined Specimen Loading

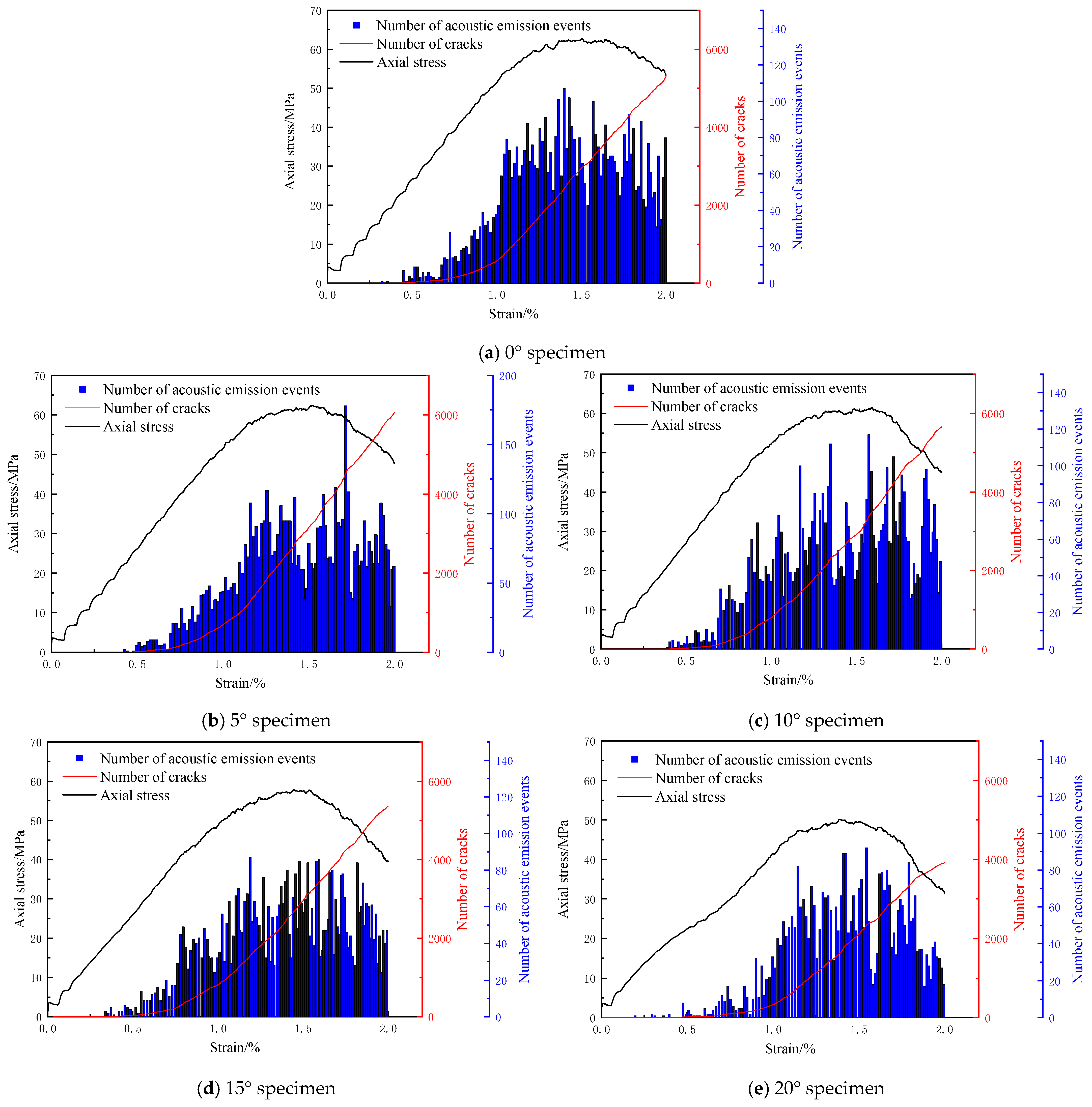

4.4. Damage Evolution

5. Discussion

6. Conclusions

- By adjusting top-surface inclination angles and employing customized rigid loading plates, gradient-based non-uniform loading on intact rock specimens was successfully achieved. Experimental and theoretical analyses confirm that this method effectively simulates asymmetric stress fields induced by excavation unloading, establishing a new paradigm for studying constitutive relationships in surrounding rock mechanics.

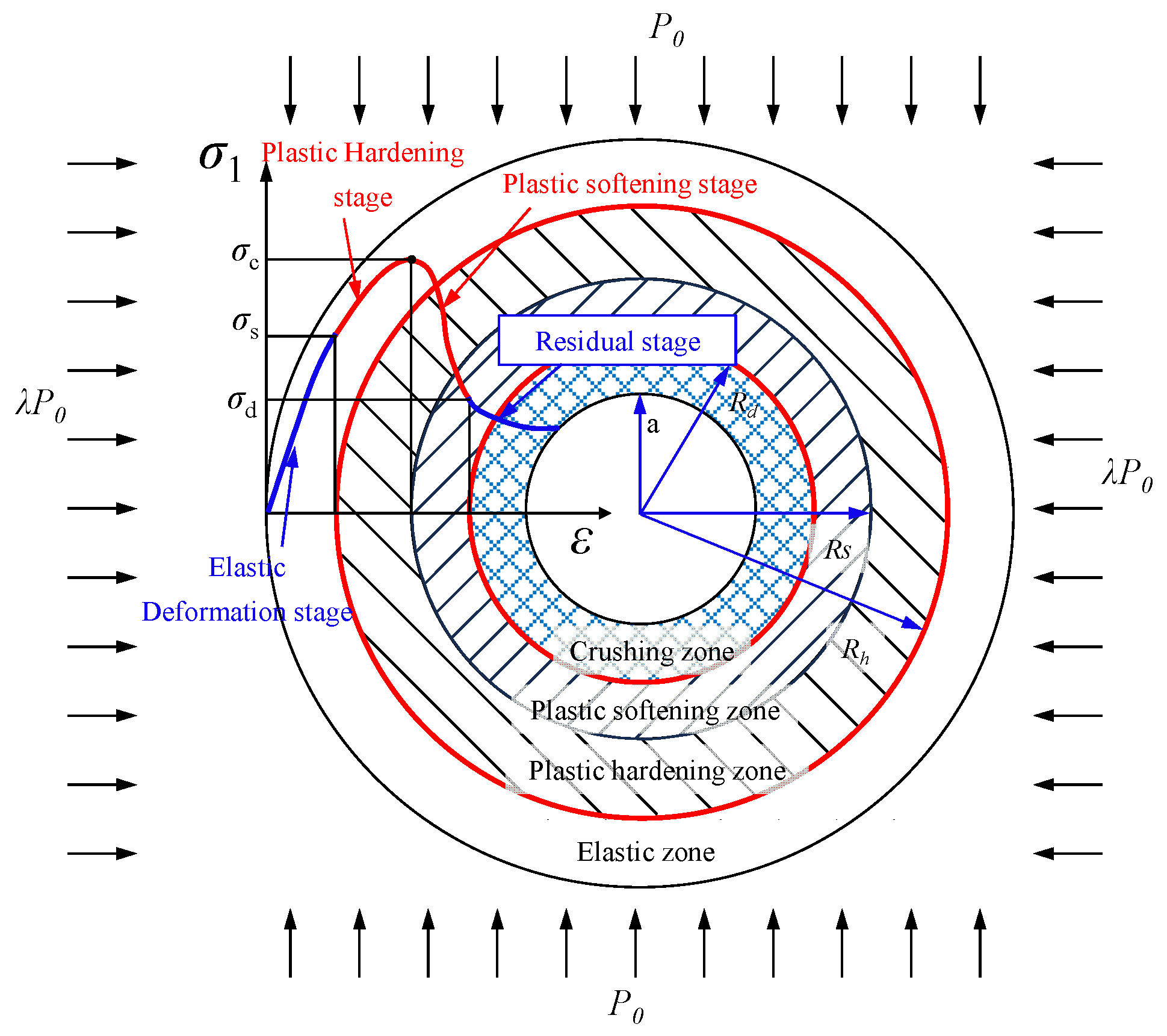

- Increasing inclination angles critically alter stress states and failure patterns. For S75 specimens, the left flank remains elastic during failure, while S85 specimens exhibit plastic hardening, highlighting stress gradient-driven expansion of plastic softening zones (38% larger in 20° specimens compared to 0°). PFC simulations further reveal that inclination amplifies shear stress contributions (up to 67%), shifting failure modes from vertical tensile fracturing (0°) to oblique shear localization (20°, θ = 52° ± 3°).

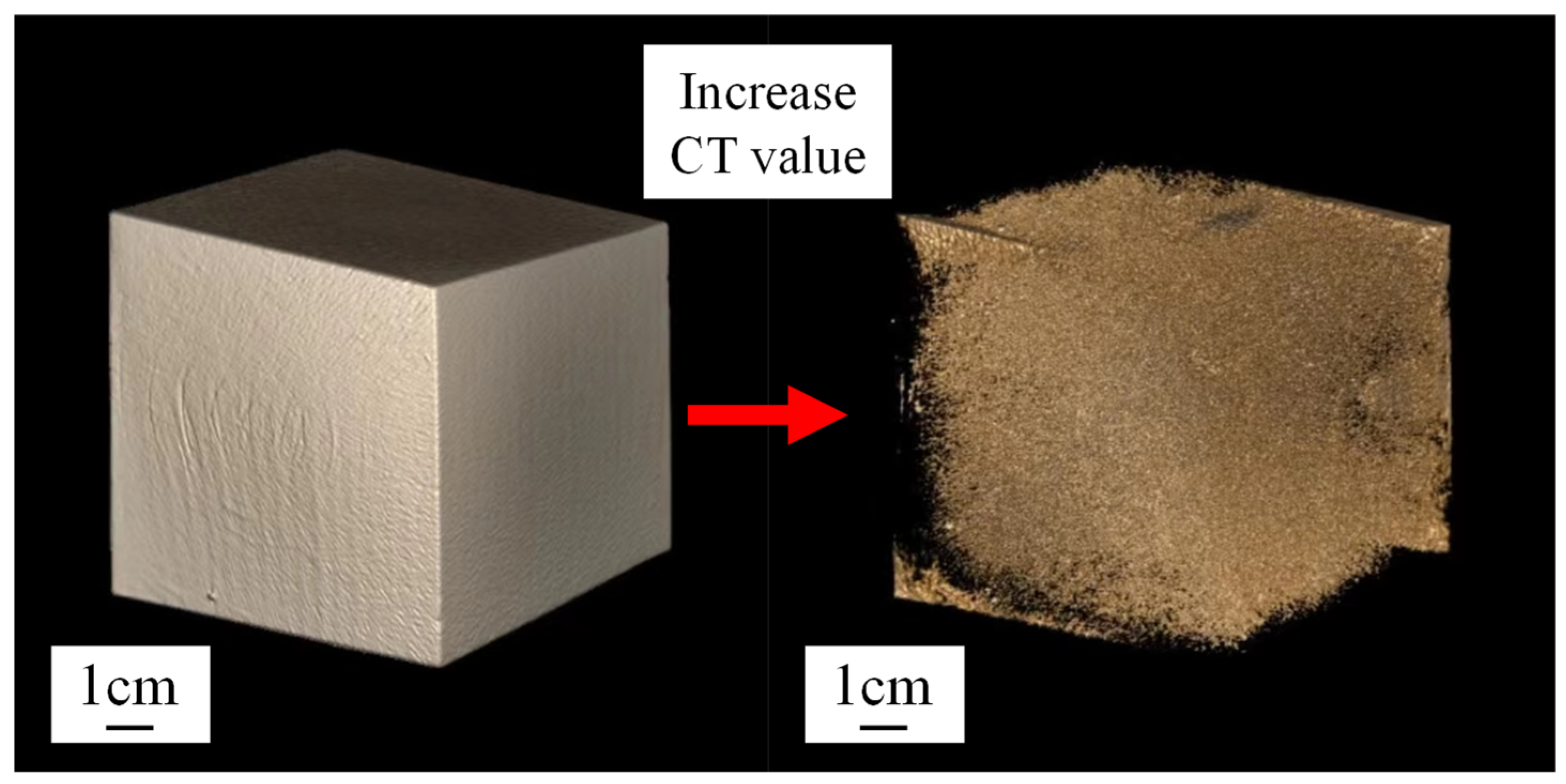

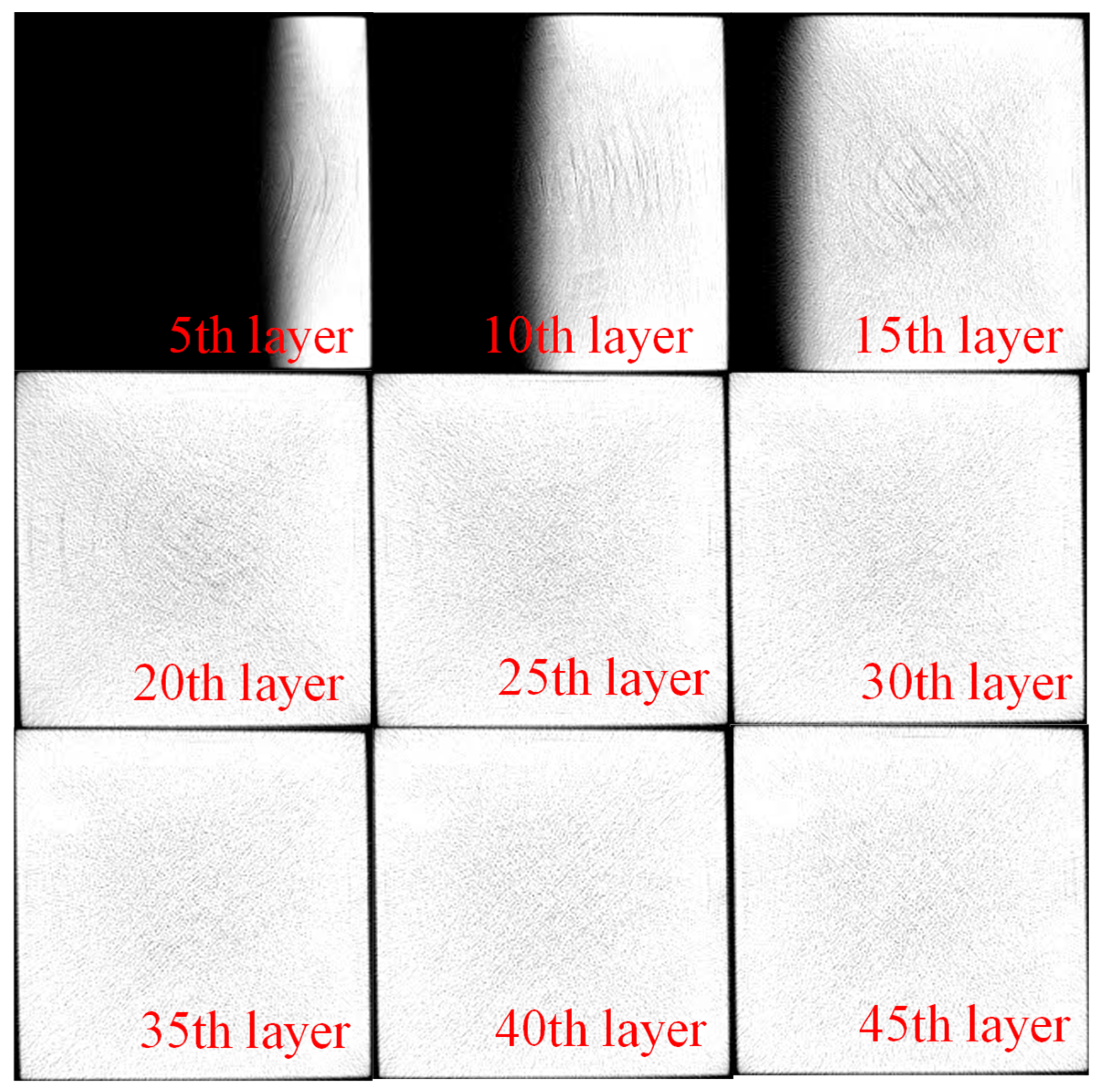

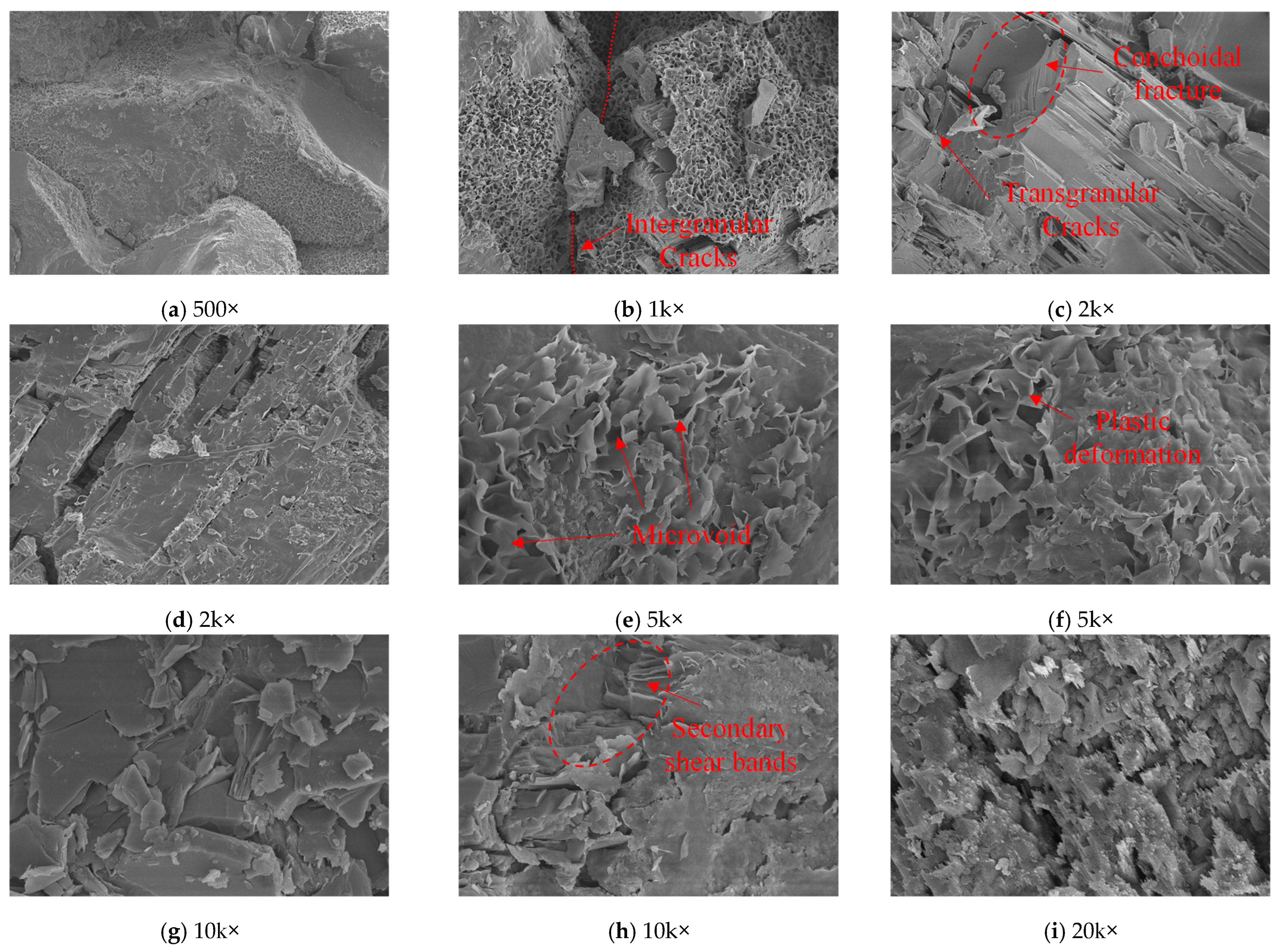

- Mineralogical heterogeneity (quartz-dominated transgranular fractures) and geometric asymmetry jointly regulate damage evolution. CT scans identify microcrack nucleation in high-stress gradient zones (23.4 MPa/mm) on the right flank, while SEM characterization confirms microvoid initiation (1–5 μm) at weakly cemented grain boundaries. Acoustic emission monitoring demonstrates increased crack network complexity (42% higher microcrack density in 20° specimens versus 0°).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kang, H.P.; Gao, F.Q.; Xu, G.; Ren, H.W. Mechanical behaviors of coal measures and ground control technologies for China’s deep coal mines—A review. J. Rock Mech. Geotech. Eng. 2022, 15, 37–65. [Google Scholar] [CrossRef]

- McQuillan, A.; Canbulat, I.; Payne, D.; Oh, J.J. New risk assessment methodology for coal mine excavated slopes. Int. J. Min. Sci. Technol. 2018, 28, 583–592. [Google Scholar] [CrossRef]

- Lindberg, T.T.; Bernhardt, E.S.; Bier, R.; Helton, A.M.; Merola, R.B.; Vengosh, A.; Di Giulio, R.T. Cumulative impacts of mountaintop mining on an Appalachian watershed. Proc. Natl. Acad. Sci. USA 2011, 108, 20929–20934. [Google Scholar] [CrossRef]

- Wang, G.F.; Xu, Y.X.; Ren, H.W. Intelligent and ecological coal mining as well as clean utilization technology in China: Review and prospects. Int. J. Min. Sci. Technol. 2019, 29, 161–169. [Google Scholar] [CrossRef]

- Simpson, G.B.; Badenhorst, J.; Jewitt, G.P.W.; Berchner, M.; Davies, E. Competition for land: The water-energy-food nexus and coal mining in Mpumalanga Province, South Africa. Front. Environ. Sci. 2019, 7, 86. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E. Underground Excavations in Rock; CRC Press: Boca Raton, FL, USA, 1980. [Google Scholar]

- Gutierrez-Ch, J.G.; Senent, S.; Graterol, E.P.; Zeng, P.; Jimenez, R. Rock shear creep modelling: DEM—Rate process theory approach. Int. J. Rock Mech. Min. Sci. 2022, 161, 105295. [Google Scholar] [CrossRef]

- Liu, L.A.; Fang, K.; Zhao, T.B.; Meng, Q.Z.; Zhang, C.G. Characterization and influence analysis of constraint stiffness in rock indentation test. Rock Mech. Rock Mech. Rock Eng. 2025, 1–16. [Google Scholar] [CrossRef]

- Wu, G.S.; Yu, W.J.; Pan, B.; Liu, Y.Q.; Fang, C.F.; Liu, X. Investigate on the mechanical properties and microscopic three-dimensional morphology of rock failure surfaces under different stress states. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 125. [Google Scholar] [CrossRef]

- Wu, J.N.; Yang, X.B.; Song, Y.M.; Sun, Q.D.; Pei, Y.Y. Study on a new inversion method for non-uniform distribution of rock material parameters. Bull. Eng. Geol. Environ. 2022, 81, 280. [Google Scholar] [CrossRef]

- Ai, Z.Y.; Ye, Z.K.; Huang, H.W.; Hu, K.X. Stress analysis of elliptical tunnels in an orthogonally anisotropic elastic full-space under non-uniform in-situ stress. Int. J. Numer. Anal. Methods Geomech. 2024, 48, 517–537. [Google Scholar] [CrossRef]

- Yu, W.J.; Pan, B.; Li, K.; Wu, G.S. Investigation on mechanical properties and dilatancy behavior of deeply buried mudstone: A comprehensive study. Constr. Build. Mater. 2025, 466, 140032. [Google Scholar] [CrossRef]

- Wang, S.; Xu, K.Z.; Zhao, W.C.; Fu, X.F.; Lu, X.S.; Song, Z.L. A New Model to Predict Mudstone Failure Behavior from Brittle to Ductile Caused by Confining Pressures. Processes 2025, 13, 308. [Google Scholar] [CrossRef]

- Liu, Z.L.; Yu, W.J.; Wu, G.S.; Zhang, Z.Z.; Wang, P. Investigate on dynamic mechanical and mesoscopic damage characteristics of high-temperature treated granite based on SPH-FEM coupling algorithm. J. Mater. Res. Technol. 2025, 36, 1891–1911. [Google Scholar]

- Wu, G.S.; Yu, W.J.; Pan, B.; Fang, C.F.; Guo, H.X.; Zhang, C. Failure mechanics mechanisms and permeability stage evolution of limestone considering wave velocity and failure surface characteristics. Soils Found. 2025, 65, 101577. [Google Scholar] [CrossRef]

- Ju, Y.; Xie, H.P.; Zheng, Z.M.; Lu, J.B.; Mao, L.T.; Lingtao, G.; Gao, F.; Peng, R.D. Visualization of the complex structure and stress field inside rock by means of 3D printing technology. Chin. Sci. Bull. 2014, 59, 5354–5365. [Google Scholar] [CrossRef]

- Gomes, G.J.C.; Forero, J.H.; Vargas, E.A., Jr.; Vrugt, J.A. Bayesian inference of rock strength anisotropy: Uncertainty analysis of the Hoek–Brown failure criterion. Int. J. Rock Mech. Min. Sci. 2021, 148, 104952. [Google Scholar] [CrossRef]

- Song, Z.Y.; Zhao, Y.; Dang, W.G.; Zhang, M. Mechanical responses of sandstone exposed to triaxial diferential cyclic loading with distinct unloading rates of confning stress: A particle-based numerical investigation. Rock Mech. Rock Eng. 2025, 58, 4159–4184. [Google Scholar] [CrossRef]

- Jin, J.; Cao, P.; Zhang, J.; Wang, Y.C.; Miao, C.X.; Li, J.; Bai, X.H. Damage evolution and failure precursor of rock-like material under uniaxial compression based on strain rate field statistics. Appl. Sci. 2025, 15, 686. [Google Scholar] [CrossRef]

- Cui, L.; Sheng, Q.; Zheng, J.J.; Luo, S.; Miao, C. Strain-softening model for granite and sandstone based on experimental and discrete element methods. Sci. Reports. 2024, 14, 24308. [Google Scholar] [CrossRef]

- Meng, Y.Y.; Yu, L.Y.; Yuan, L.; Hua, X.Z.; Ma, Y.K.; Zhuang, J.T.; Jing, H.W.; Liu, X.W. Effects of bedding angle and confining pressure on the mechanical behavior, energy dissipation and micro damage evolution mechanism of layered rock mass under triaxial compression conditions. J. Mater. Res. Technol. 2025, 36, 1259–1272. [Google Scholar] [CrossRef]

- Khazaei, C.; Hazzard, J.; Chalaturnyk, R. Damage quantification of intact rocks using acoustic emission energies recorded during uniaxial compression test and discrete element modeling. Comput. Geotech. 2015, 67, 94–102. [Google Scholar] [CrossRef]

| Parameter | |||||||

|---|---|---|---|---|---|---|---|

| Contact Modulus/GPa | Contact Stiffness Ratio | Parallel Bond Modulus/GPa | Parallel Bond Stiffness Ratio | Normal Bond Strength/MPa | Shear Bond Strength/MPa | Friction Coefficient | |

| Ball-ball | 3.8 | 1.5 | 3.8 | 1.5 | 90.0 | 28.0 | 0.60 |

| Facet-ball | 10.0 | 1.5 | - | - | - | - | 0.10 |

| Model Mechanical Parameters | Laboratory Test Parameters | ||||||

| Elastic Modulus/GPa | Uniaxial Compressive Strength/MPa | Elastic Modulus/GPa | Uniaxial Compressive Strength/MPa | ||||

| 3.86 | 63.98 | 3.94 | 63.5 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, B.; Yu, W.; Li, K.; Liu, Z.; Huang, T.; Yang, J. Mechanical Characteristics and Mechanisms of Destruction of Trapezoidal Sandstone Samples Under Uneven Loading. Processes 2025, 13, 1169. https://doi.org/10.3390/pr13041169

Pan B, Yu W, Li K, Liu Z, Huang T, Yang J. Mechanical Characteristics and Mechanisms of Destruction of Trapezoidal Sandstone Samples Under Uneven Loading. Processes. 2025; 13(4):1169. https://doi.org/10.3390/pr13041169

Chicago/Turabian StylePan, Bao, Weijian Yu, Ke Li, Zilu Liu, Tao Huang, and Jie Yang. 2025. "Mechanical Characteristics and Mechanisms of Destruction of Trapezoidal Sandstone Samples Under Uneven Loading" Processes 13, no. 4: 1169. https://doi.org/10.3390/pr13041169

APA StylePan, B., Yu, W., Li, K., Liu, Z., Huang, T., & Yang, J. (2025). Mechanical Characteristics and Mechanisms of Destruction of Trapezoidal Sandstone Samples Under Uneven Loading. Processes, 13(4), 1169. https://doi.org/10.3390/pr13041169