Hydrodynamic Characterization of Particle–Bubble Aggregate Transport: Bubble Load Dynamics During Vertical Ascent

Abstract

1. Introduction

2. Mineralogical Characteristics and Processing Flowsheet

2.1. Mineralogical Characteristics

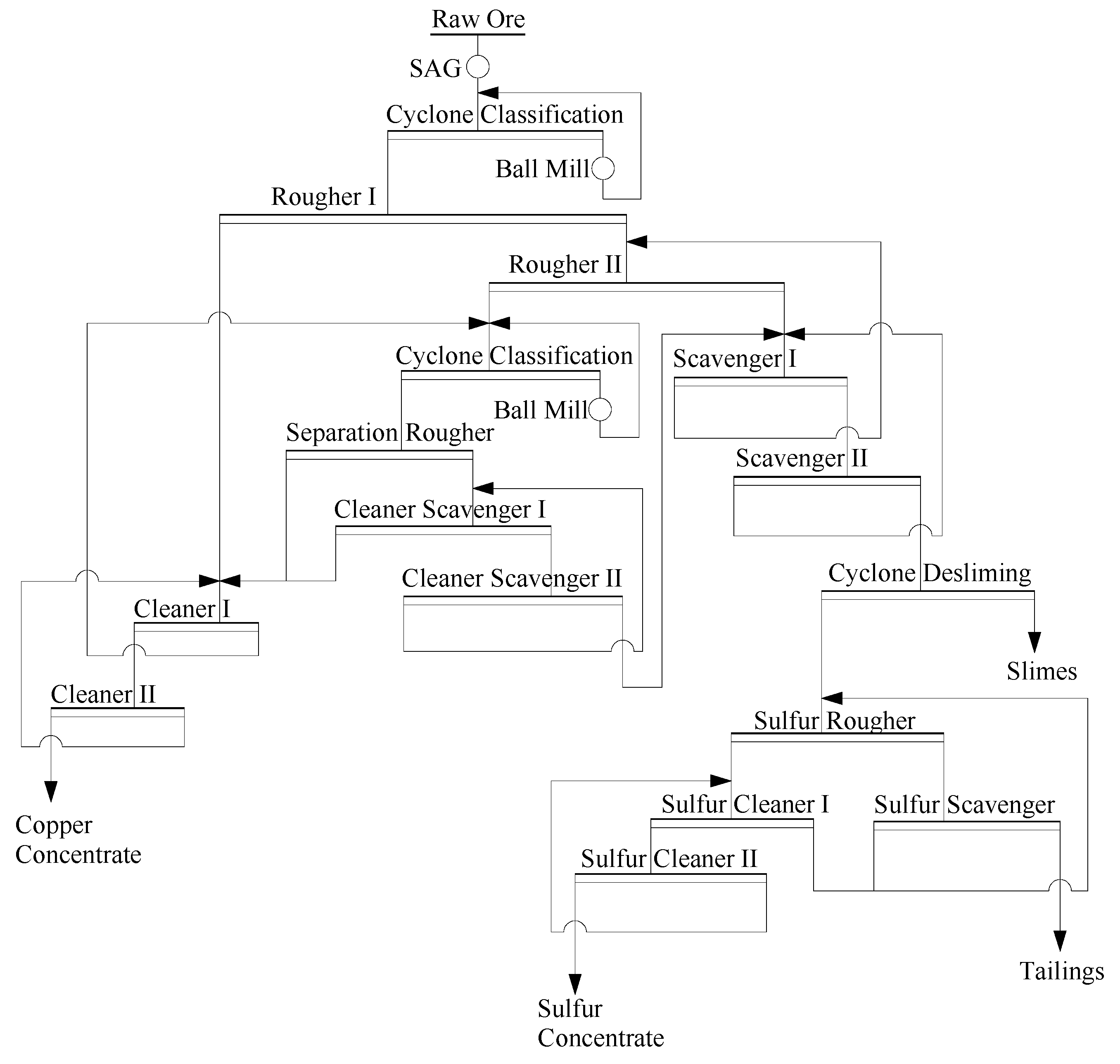

2.2. Process Flowsheet

3. Sampling and Testing

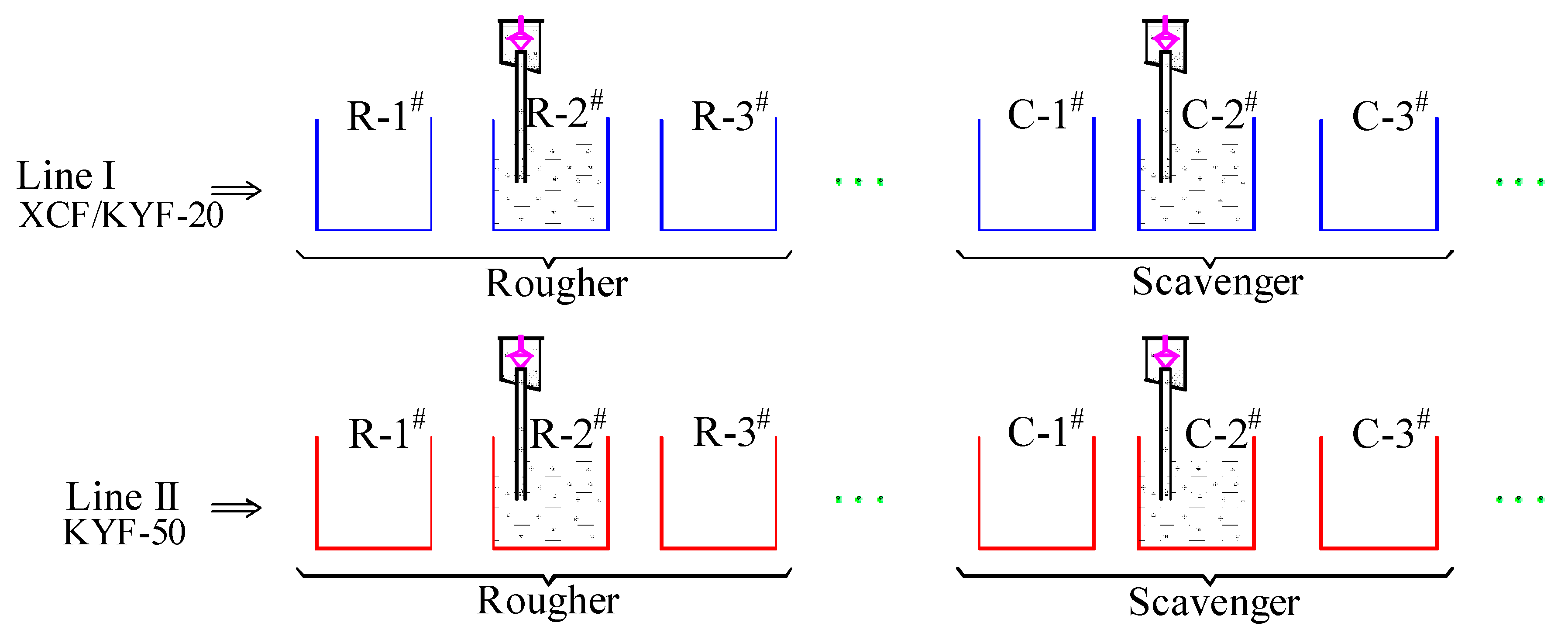

3.1. Testing Apparatus

3.2. Sampling

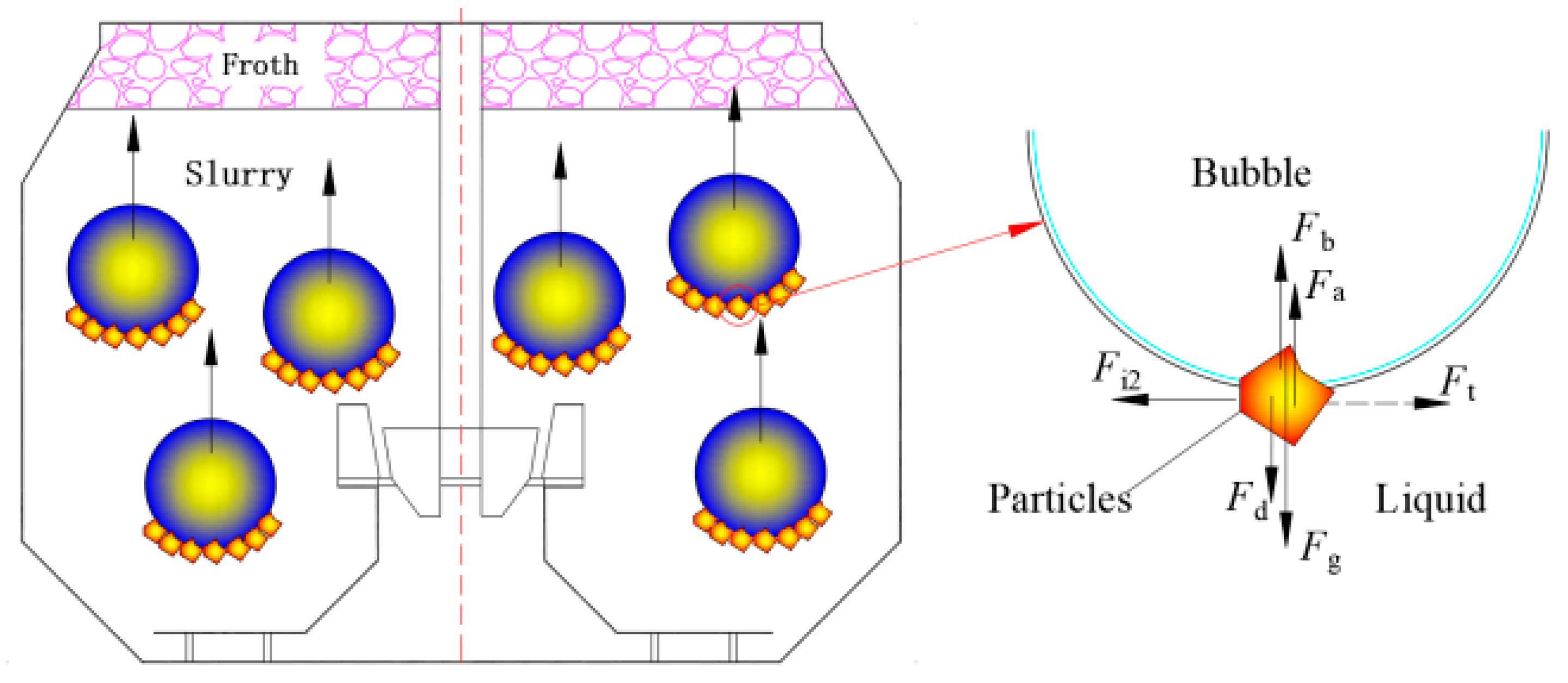

3.3. Stability Analysis of Particle–Bubble Aggregates (PBAs) During Ascension

- Fb—Buoyancy force (N);

- Fa—Adhesive force (N);

- Fd—Viscous drag force (N);

- Fg—Gravitational force;

- Ft—Turbulent force (N);

- Fi—Inertial force (N);

- mp—Particle mass (kg);

- a—Acceleration (m/s2).

- [μm]

- (particle-fluid density difference) [kg/m3]

- ]

- [°]

4. Results and Discussion

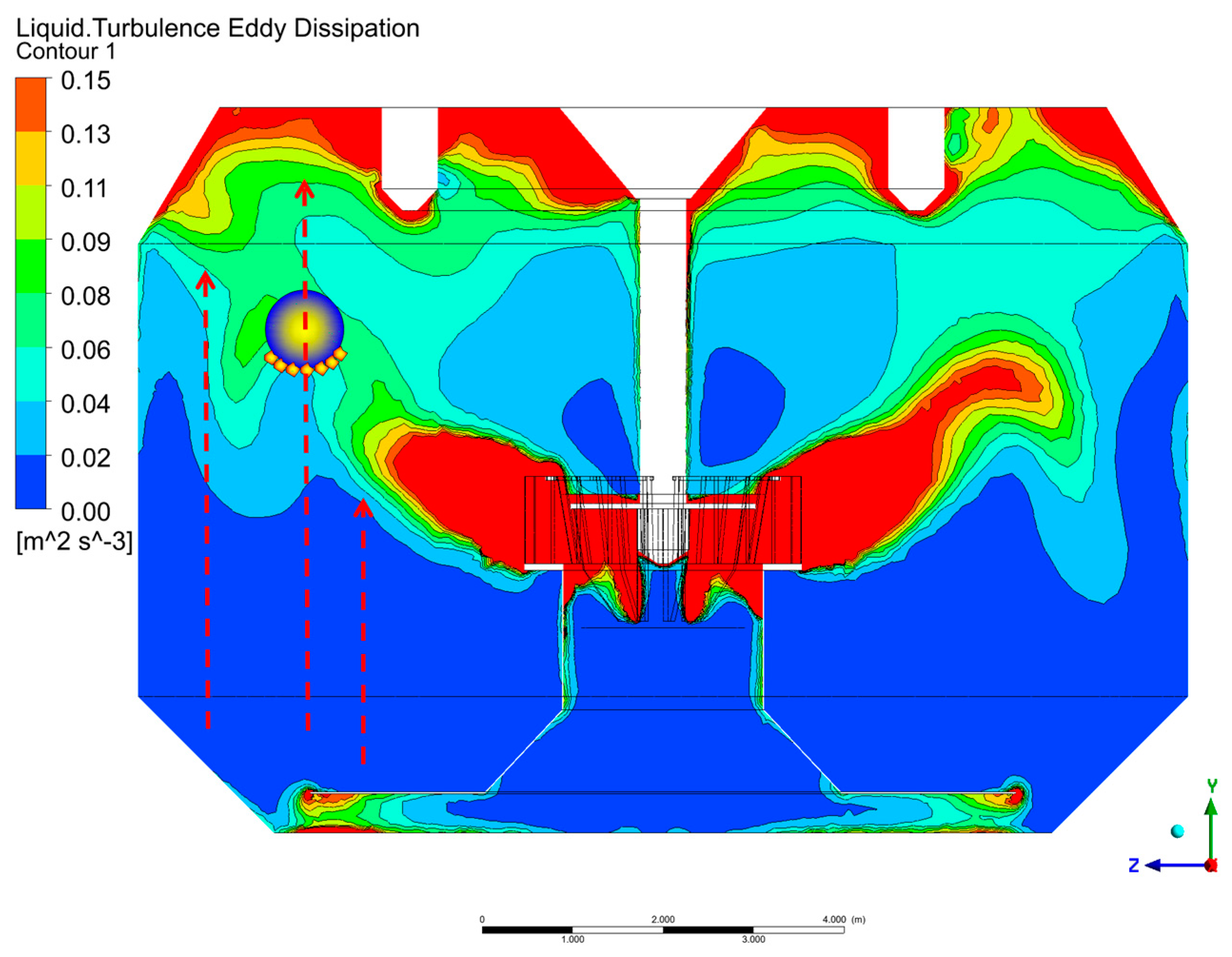

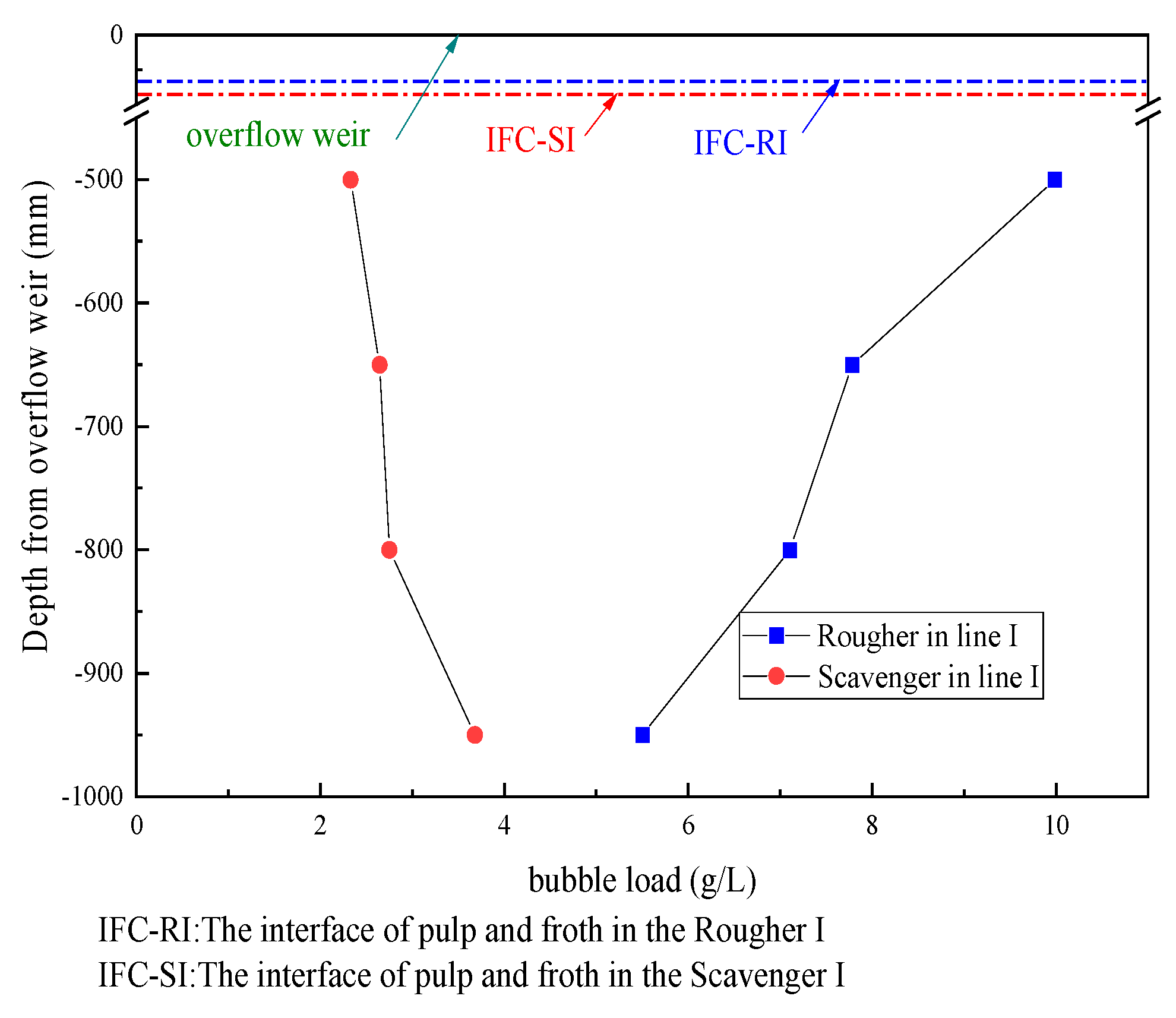

4.1. Trend Analysis of Bubble Load Dynamics

4.2. Characterizing Particle Size Distribution in Flotation Bubble Loads

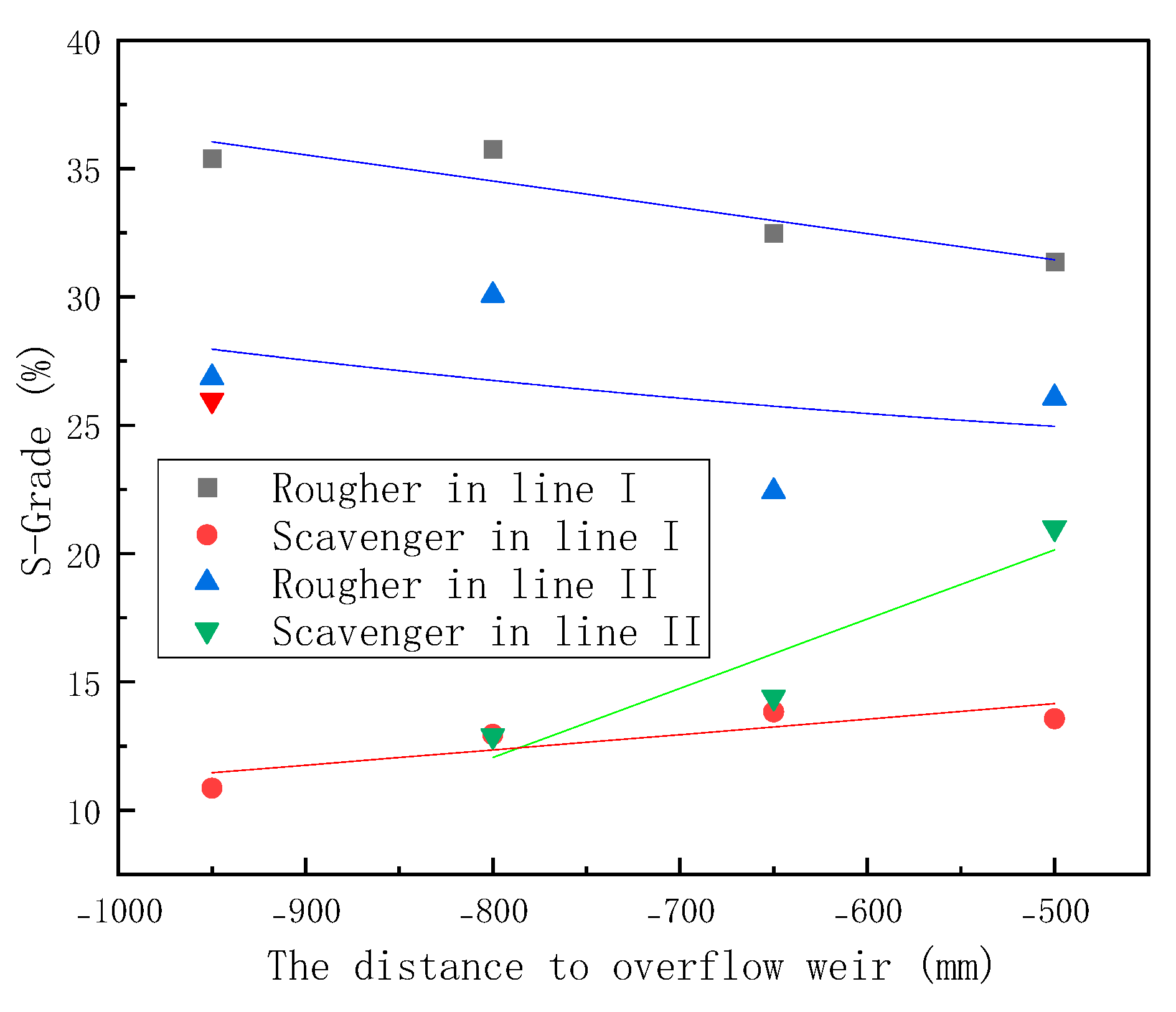

4.3. Quantitative Analysis of Metallic Components in Flotation Bubble Loads

- During vertical movement through sampling tubes, particle–bubble aggregates undergo partial shedding that remains unquantified.

- Data collection was restricted to fixed vertical planes within flotation cells neglects critical heterogeneous hydrodynamic field dynamics. Edge vortices and impeller zone turbulence significantly influence bubble load distribution patterns but remain undocumented.

- Tests were conducted under identical sampling depths but divergent production scales and equipment specifications obscure relative trend interpretations. Observed differences in separation characteristics across stages and production lines lack validated optimization frameworks.

5. Conclusions

- The improved device enables continuous and stable bubble load measurements through real-time liquid-level adjustment in the sampling chamber, significantly enhancing measurement accuracy and operational efficiency. Its systematic application across both rougher and scavenger stages has provided robust datasets for dynamic process characterization.

- In the rougher stage, bubble load demonstrates progressive accumulation during vertical ascent, whereas the scavenger stage exhibits a proportional decline. This contrasting behavior underscores the hydrodynamic interplay between particle attachment and detachment mechanisms, directly governed by the stability of bubble–particle aggregates.

- The progressive bubble load accumulation in the rougher stage predominantly originates from the attachment of coarse- and medium-grained fractions, whereas the scavenger stage undergoes preferential detachment of fines. Size distribution shifts within ascending bubble loads emerge as a critical determinant of scavenger circuit efficiency. Furthermore, dynamic metallurgical grade variations during vertical transport reveal differential separation efficiencies between line I and line II, highlighting targeted optimization potential through turbulence modulation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kyzas, G.Z.; Matis, K.A. Flotation in Water and Wastewater Treatment. Processes 2018, 6, 116. [Google Scholar] [CrossRef]

- Kyzas, G.Z.; Mitropoulos, A.C.; Matis, K.A. From Microbubbles to Nanobubbles: Effect on Flotation. Processes 2021, 9, 1287. [Google Scholar] [CrossRef]

- Tao, D.; Sobhy, A. Nanobubble effects on hydrodynamic interactions between particles and bubbles. Powder Technol. 2019, 346, 385–395. [Google Scholar] [CrossRef]

- Wills, B.A.; Finch, J.A. Wills’ Mineral Processing Technology; Butterworth-Heinemann: Oxford, UK, 2016; ISBN 978-0-08-097053-0. [Google Scholar]

- Wang, G.; Nguyen, A.V.; Mitra, S.; Joshi, J.; Jameson, G.J.; Evans, G.M. A review of the mechanisms and models of bubble-particle detachment in froth flotation. Sep. Purif. Technol. 2016, 170, 155–172. [Google Scholar] [CrossRef]

- Bournival, G.; Ata, S.; Jameson, G.J. Bubble and Froth Stabilizing Agents in Froth Flotation. Min. Proc. Ext. Met. Rev. 2017, 38, 366–387. [Google Scholar] [CrossRef]

- Seaman, D.R.; Franzidis, J.P.; Manlapig, E.V. Bubble load measurement in the pulp zone of industrial flotation machines—A new device for determining the froth recovery of attached particles. Int. J. Miner. Process. 2004, 74, 1–13. [Google Scholar] [CrossRef]

- Bhondayi, C. Use of bubble load to interpret particle transport across the pulp-froth interface in a flotation cell. Physicochem. Probl. Mi 2019, 56, 54–63. [Google Scholar] [CrossRef]

- Koh, P.; Schwarz, M. CFD modelling of bubble-particle attachments in flotation cells. Min. Eng. 2006, 19, 619–626. [Google Scholar] [CrossRef]

- Ostadrahimi, M.; Gharibi, K.; Dehghani, A.; Farrokhpay, S. Estimating Bubble Loading in Industrial Flotation Cells. Minerals 2019, 9, 222. [Google Scholar] [CrossRef]

- Hemmati Chegeni, M.; Abdollahy, M.; Khalesi, M.R. Bubble loading measurement in a continuous flotation column. Min. Eng. 2016, 85, 49–54. [Google Scholar] [CrossRef]

- Eskanlou, M.; Khalesi, M.R.; Abdollahy, M. Bubble loading profiles in a flotation column. Physicochem. Probl. Miner. Process. 2018, 54, 355–362. [Google Scholar] [CrossRef]

- Bhondayi, C.; Moys, M.H. Determination of sampling pipe (riser) diameter for a flotation bubble load measuring device. Min. Eng. 2011, 24, 1664–1676. [Google Scholar] [CrossRef]

- Bhondayi, C.; Moys, M.H. Measurement of a proxy for froth phase bubble sizes as a function of froth depth in flotation machines Part 1. Theoretical development and testing of a new technique. Int. J. Miner. Process. 2014, 130, 8–19. [Google Scholar] [CrossRef]

- King, L.; Evans, G.; Moreno-Atanasio, R. Computational analysis of bubble loading. In Chemeca 2018; Institution of Chemical Engineers: Queenstown, New Zealand, 2018. [Google Scholar]

- Xing, Y.; Gui, X.; Pan, L.; Pinchasik, B.-E.; Cao, Y.; Liu, J.; Kappl, M.; Butt, H.-J. Recent experimental advances for understanding bubble-particle attachment in flotation. Adv. Colloid. Interfac. 2017, 246, 105–132. [Google Scholar] [CrossRef] [PubMed]

- Seaman, D.R.; Manlapig, E.V.; Franzidis, J.P. Selective transport of attached particles across the pulp–froth interface. Min. Eng. 2006, 19, 841–851. [Google Scholar] [CrossRef]

- Yianatos, J.B.; Moys, M.H.; Contreras, F.; Villanueva, A. Froth recovery of industrial flotation cells. Min. Eng. 2008, 21, 817–825. [Google Scholar] [CrossRef]

- Dyer, C. An investigation into the Properties of the Froth Phase in the Flotation Process. Master’s Thesis, University of the Witwatersrand, Johannesburg, South Africa, 1995. [Google Scholar]

- Moys, M.H.; Yianatos, J.; Larenas, J. Measurement of particle loading on bubbles in the flotation process. Min. Eng. 2010, 23, 131–136. [Google Scholar] [CrossRef]

- Ata, S. Phenomena in the froth phase of flotation—A review. Int. J. Miner. Process. 2012, 102–103, 1–12. [Google Scholar] [CrossRef]

- Nissinen, A.; Lehikoinen, A.; Mononen, M.; Lähteenmäki, S.; Vauhkonen, M. Estimation of the bubble size and bubble loading in a flotation froth using electrical resistance tomography. Min. Eng. 2014, 69, 1–12. [Google Scholar] [CrossRef]

- Ge, L.; Evans, G.M.; Moreno-Atanasio, R. CFD-DEM investigation of the interaction between a particle swarm and a stationary bubble: Particle-bubble collision efficiency. Powder Technol. 2020, 366, 641–652. [Google Scholar] [CrossRef]

- Mesa, D.; Quintanilla, P.; Reyes, F. Bubble Analyser—An open-source software for bubble size measurement using image analysis. Min. Eng. 2022, 180, 107497. [Google Scholar] [CrossRef]

- Junbo, P. The Practice of Improving the Recovery of Sulfur in Chengmenshan Copper Mine. Hunan Nonferrous Met. 2011, 27, 5–8. [Google Scholar] [CrossRef]

- Eskanlou, A.; Chegeni, M.H.; Khalesi, M.R.; Abdollahy, M.; Huang, Q. Modeling the bubble loading based on force balance on the particles attached to the bubble. Colloids Surf. A Physicochem. Eng. Asp. 2019, 582, 123892. [Google Scholar] [CrossRef]

- Schulze, H.J. Hydrodynamics of Bubble-Mineral Particle Collisions. Min. Proc. Ext. Met. Rev. 1989, 5, 43–76. [Google Scholar] [CrossRef]

- Bloom, F.; Heindel, T.J. Modeling flotation separation in a semi-batch process. Chem. Eng. Sci. 2003, 58, 353–365. [Google Scholar] [CrossRef]

- Yianatos, J.; Vinnett, L.; Carrasco, C.; Alvarez-Silva, M. Effect of entrainment in bubble load measurement on froth recovery estimation at industrial scale. Miner. Eng. 2015, 72, 31–35. [Google Scholar] [CrossRef]

| Element | Cu | S | SiO2 | Al2O3 | Fe | Au | Ag |

|---|---|---|---|---|---|---|---|

| Content | 1.11 | 5.12 | 62.52 | 8.43 | 8.57 | 0.046 | 6.12 |

| Phase | Total Copper | Primary Copper Sulfide | Secondary Copper Sulfide | Copper Oxide |

|---|---|---|---|---|

| Content | 1.116 | 0.251 | 0.717 | 0.148 |

| Proportion | 100 | 22.49 | 64.25 | 13.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, D.; Sun, C.; Sun, T.; Zhao, J.; Shi, S. Hydrodynamic Characterization of Particle–Bubble Aggregate Transport: Bubble Load Dynamics During Vertical Ascent. Processes 2025, 13, 1218. https://doi.org/10.3390/pr13041218

Han D, Sun C, Sun T, Zhao J, Shi S. Hydrodynamic Characterization of Particle–Bubble Aggregate Transport: Bubble Load Dynamics During Vertical Ascent. Processes. 2025; 13(4):1218. https://doi.org/10.3390/pr13041218

Chicago/Turabian StyleHan, Dengfeng, Chuanyao Sun, Tichang Sun, Jingpeng Zhao, and Shuaixing Shi. 2025. "Hydrodynamic Characterization of Particle–Bubble Aggregate Transport: Bubble Load Dynamics During Vertical Ascent" Processes 13, no. 4: 1218. https://doi.org/10.3390/pr13041218

APA StyleHan, D., Sun, C., Sun, T., Zhao, J., & Shi, S. (2025). Hydrodynamic Characterization of Particle–Bubble Aggregate Transport: Bubble Load Dynamics During Vertical Ascent. Processes, 13(4), 1218. https://doi.org/10.3390/pr13041218