Use of Different O/W or W/O Emulsions as Functional Ingredients to Reduce Fat Content and Improve Lipid Profile in Spanish Cured Processed Meat Product (‘Chorizo’)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Oil Emulsion Formulation

2.3. Meat Product Reformulation

2.4. Physical Analysis

Color

Texture

2.5. Proximate Analysis

2.6. Fatty Acid Profile, Vitamin E Determination and Thiobarbituric Acid

2.7. Sensory Evaluation

2.8. Statistical Analysis

3. Results and Discussion

3.1. Texture of Oil Emulsions

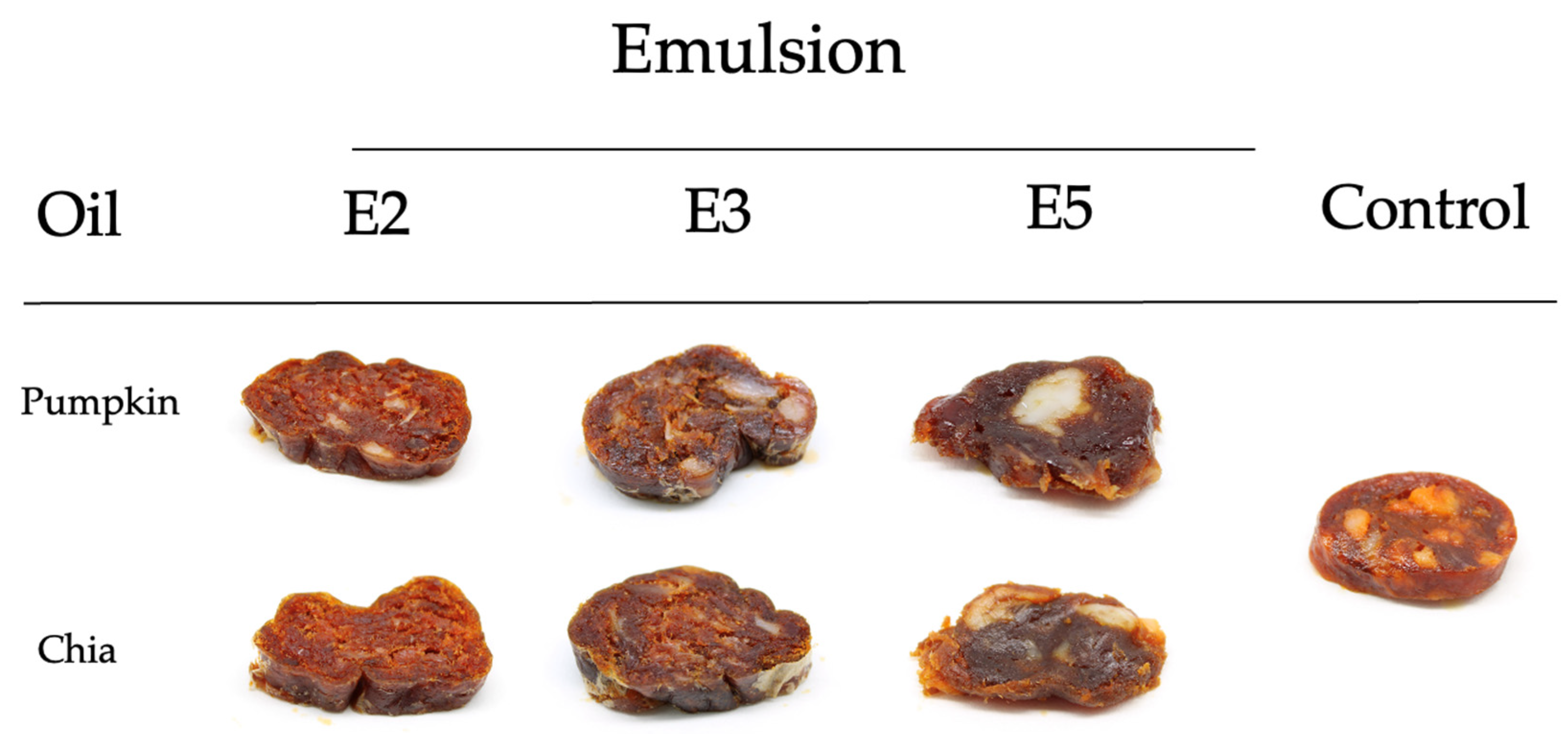

3.2. Physical Characteristics of Different ‘Chorizo’ Formulas

3.3. Nutritional Composition

3.4. Fatty Acid Profile, Vitamin E and TBA Content

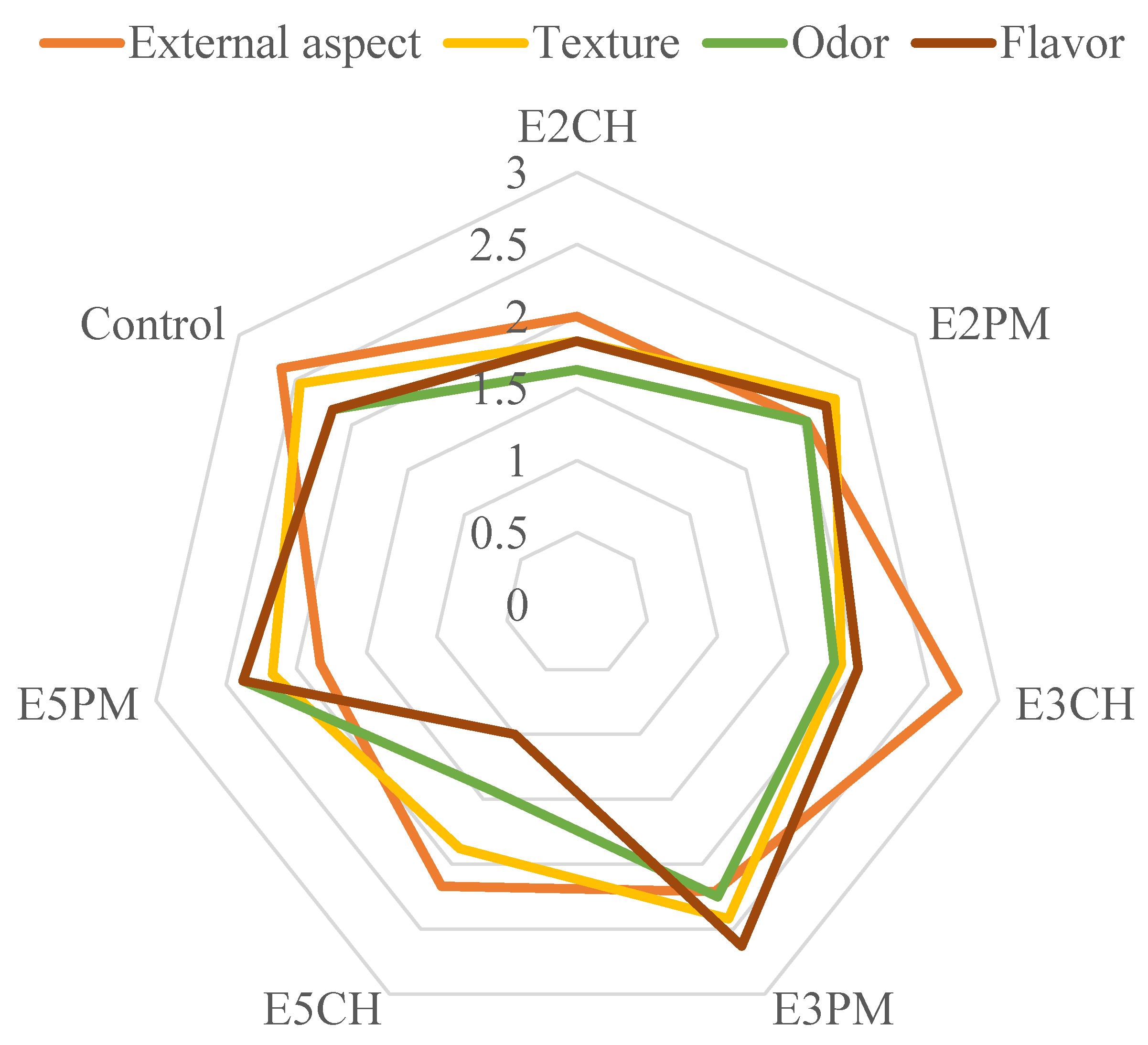

3.5. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hleap-Zapata, J.I.; Romero-Quintana, L.; Botina-Cárdenas, J.; Martínez-Martínez, C.A.; Valenciano-Pulido, Y.; Higuita-Diaz, K. Effect of the partial replacement of wheat flour with tumeric flour (Curcuma longa) on the physicochemical and sensory properties of a common chorizo. DYNA 2020, 214, 46–52. [Google Scholar] [CrossRef]

- BOE. Real Decreto 474/2014, de 13 de Junio, Por el Que se Aprueba la Norma de Calidad de Derivados Cárnicos. 2014. Obtained from boe.es. Available online: https://www.boe.es/boe/dias/2014/06/18/pdfs/BOE-A-2014-6435.pdf (accessed on 13 June 2024).

- Pérez-Palacios, T.; Ruiz-Carrascal, J.; Solomando, J.C.; Antequera, T. Strategies for enrichement in w-3 fatty acids aiming for healthier meat products. Food Rev. Int. 2019, 35, 485–503. [Google Scholar] [CrossRef]

- Ospina-E, J.C.; Sierra-C, A.; Ochoa, O.; Pérez-Álvarez, J.A.; Fernández-López, J. Substitution of Saturated Fat in Processed Meat Products: A Review. Crit. Rev. Food Sci. Nutr. 2011, 52, 113–122. [Google Scholar] [CrossRef] [PubMed]

- Martínez, E.; Pardo, J.E.; Álvarez-Ortí, M.; Rabadán, A.; Pardo-Giménez, A.; Alvarruiz, A. Substitution of Pork backfat by Emulsified Seed Oils in Fresh Deer Sausage (‘Chorizo’) and Its Impact on the Physical, Nutritional, and Sensory Properties. Foods 2023, 12, 828. [Google Scholar] [CrossRef] [PubMed]

- Zettel, V.; Hitzmann, B. Applications of chia (Salvia hispanica L.) in food products. Tr. Food Sci. Technol. 2018, 80, 45–50. [Google Scholar] [CrossRef]

- Procida, G.; Stancher, B.; Cateni, F.; Zacchigna, M. Composición química y caracterización funcional del aceite comercial de semillas de calabaza. Rev. Cienc. Aliment. Agric. 2012, 93, 1035–1041. [Google Scholar]

- Lemus-Mondaca, R.; Marin, J.; Rivas, J.; Sanhueza, L.; Soto, Y.; Vera, N.; Puente-Díaz, L. Pumpkin seeds (Cucurbita maxima). A review of functional attributes and by-products. Rev. Chil. De Nutr. 2019, 46, 783–791. [Google Scholar] [CrossRef]

- Kim, T.K.; Yong, H.I.; Kim, Y.B.; Choi, Y.S. Effects of replacing pork back fat with grape seed oil and gel on quality properties of reduced-fat frankfurters. Meat Sci. 2019, 149, 73–79. [Google Scholar]

- Zhang, W.; Xiao, S.; Samaraweera, H. Use of plant-based oils in emulsion-type sausage: Impact on product quality and physicochemical properties. J. Food Process. Preserv. 2020, 44, e14455. [Google Scholar]

- Freire, M.; Cofrades, S.; Serrano-Casas, V.; Pintado, T.; Jimenez, M.J.; Jimenez-Colmenero, F. Gelled double emulsions as delivery systems for hydroxytyrosol and n-3 fatty acids in healthy pork patties. J. Food Sci. Technol. 2017, 54, 3959–3968. [Google Scholar] [CrossRef]

- Öztürk, B.; Serdaroğlu, M.; Kavuşan, H.S. The effects of different types of emulsions prepared with olive oil on technological and sensory properties of model system sausages. Korean J. Food Sci. Anim. Resour. 2018, 38, 713–724. [Google Scholar]

- CIE. Colorimetry. In Vienne: Central Bureau of the Commission International de L’Eclairage, 2nd ed.; CIE: Vienna, Austria, 1986. [Google Scholar]

- Anzaldúa, A. La Evaluación Sensorial de los Alimentos en la Teoría y la Práctica; Editorial Acribia, S.A.: Zaragoza, España, 1994; pp. 70–79. [Google Scholar]

- Sala, G.; de Wijk, R.A.; van de Velde, F.; van Aken, G.A. Matrix properties affect the sensory perception of emulsion-filled gels. Food Hydrocoll. 2008, 22, 353–363. [Google Scholar] [CrossRef]

- Muñoz, A.M.; Pangborn, R.M.; Noble, A.C. Sensory and mechanical attributes of gel texture: I. effect of gelatin concentration. J. Texture Stud. 1986, 17, 1–16. [Google Scholar] [CrossRef]

- Jiang, J.; Xiong, Y.L. Role of interfacial protein membrane in oxidative stability of vegetable oil substitution emulsions applicable to nutritionally modified sausage. Meat Sci. 2015, 109, 56–65. [Google Scholar] [CrossRef]

- Pușcaș, A.; Mureșan, V.; Socaciu, C.; Muste, S. Oleogels in food: A review of current and potential applications. Foods 2020, 9, 70. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Jin, W.; Zhou, B.; Li, B. Application of micronized konjac gel for fat analogue in mayonnaise. Food Hydrocoll. 2014, 35, 375–382. [Google Scholar] [CrossRef]

- Spence, C. On the manipulation, and meaning (s), of color in food: A historical perspective. J. Food Sci. 2023, 88 (Suppl. S1), A5–A20. [Google Scholar] [CrossRef]

- Álvarez, D.; Delles, R.M.; Xiong, Y.L.; Castillo, M.; Payne, F.A.; Laencina, J. Influence of canola-olive oils, rice bran and walnut on functionality and emulsion stability of frankfurters. LWT-Food Sci. Technol. 2011, 44, 1435–1442. [Google Scholar] [CrossRef]

- Nieto, G.; Martínez, L.; Castillo, J.; Ros, G. Hydroxytyrosol extracts, olive oil and walnuts as functional components in chicken sausages. J. Sci. Food Agric. 2017, 97, 3761–3771. [Google Scholar] [CrossRef]

- Tarjuelo, L.; Rabadán, A.; Álvarez-Ortí, M.; Pardo-Giménez, A.; Pardo, J.E. Analysis of Nutritional Characteristics and Willingness to Pay of Consumers for Dry-Cured Sausages (Salchichón) Made with Textured Seed Oils. Foods 2023, 12, 3118. [Google Scholar] [CrossRef]

- Crehan, C.M.; Hughes, E.; Troy, D.J.; Buckley, D.J. Effects of fat level and maltodextrin on the functional properties of frankfurters formulated with 5, 12 and 30% fat. Meat Sci. 2000, 55, 463–469. [Google Scholar] [CrossRef] [PubMed]

- Akhtar, M.J.; Jacquot, M.; Arab-Tehrany, E.; Gaïani, C.; Linder, M.; Desobry, S. Control of salmon oil photo-oxidation during storage in HPMC packaging film: Influence of film colour. Food Chem. 2010, 120, 395–401. [Google Scholar] [CrossRef]

- Onopiuk, A.; Kołodziejczak, K.; Szpicer, A.; Marcinkowska-Lesiak, M.; Wojtasik-Kalinowska, I.; Stelmasiak, A.; Poltorak, A. The Effect of Partial Substitution of Beef Tallow on Selected Physicochemical Properties, Fatty Acid Profile and PAH Content of Grilled Beef Burgers. Foods 2022, 11, 1986. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Choi, I.; Shin, W.K.; Kim, Y. Effects of HPMC (Hydroxypropyl methylcellulose) on oil uptake and texture of gluten-free soy donut. LWT-Food Sci. Technol. 2015, 62, 620–627. [Google Scholar] [CrossRef]

- Liu, X.; Mu, T.; Sun, H.; Zhang, M.; Chen, J.; Fauconnier, M.L. Influence of different hydrocolloids on dough thermo-mechanical properties and in vitro starch digestibility of gluten-free steamed bread based on potato flour. Food Chem. 2018, 239, 1064–1074. [Google Scholar] [CrossRef] [PubMed]

- Maghsoud, M.; Heshmati, A.; Taheri, M.; Emamifar, A.; Esfarjani, F. The influence of carboxymethyl cellulose and hydroxypropyl methylcellulose on physicochemical, texture, and sensory characteristics of gluten-free pancake. Food Sci. Nutr. 2024, 12, 1304–1317. [Google Scholar] [CrossRef] [PubMed]

- Laguna, L.; Primo-Martín, C.; Varela, P.; Salvador, A.; Sanz, T. HPMC and inulin as fat replacers in biscuits: Sensory and instrumental evaluation. LWT-Food Sci. Technol. 2014, 56, 494–501. [Google Scholar] [CrossRef]

- Domínguez, R.; Pateiro, M.; Agregán, R.; Lorenzo, J.M. Effect of the partial replacement of pork backfat by microencapsulated fish oil or mixed fish and olive oil on the quality of frankfurter type sausage. J. Food Sci. Technol. 2017, 54, 26–37. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, F.A.L.; Munekata, P.E.; Pateiro, M.; Campagnol, P.C.; Domínguez, R.; Trindade, M.A.; Lorenzo, J.M. Effect of replacing backfat with vegetable oils during the shelf-life of cooked lamb sausages. LWT 2020, 122, 109052. [Google Scholar] [CrossRef]

- Peng, L.; Xiang, L.; Xu, Z.; Gu, H.; Zhu, Z.; Tang, Y.; Zhao, X. Association between low-fat diet and liver cancer risk in 98,455 participants: Results from a prospective study. Front. Nutr. 2022, 9, 1013643. [Google Scholar] [CrossRef]

- Mei, J.; Qian, M.; Hou, Y.; Liang, M.; Chen, Y.; Wang, C.; Zhang, J. Association of saturated fatty acids with cancer risk: A systematic review and meta-analysis. Lipids Health Dis. 2024, 23, 32. [Google Scholar] [CrossRef] [PubMed]

- Jiménez-Colmenero, F. Healthier lipid formulation approaches in meat-based functional foods. Technological options for replacement of meat fats by non-meat fats. Trends Food Sci. Technol. 2007, 18, 567–578. [Google Scholar] [CrossRef]

- Hasanpour, M.; Rezaie, A.; Iranshahy, M.; Yousefi, M.; Saberi, S.; Iranshahi, M. 1H NMR-based metabolomics study of the lipid profile of omega-3 fatty acid supplements and some vegetable oils. J. Pharm. Biomed. Anal. 2024, 238, 115848. [Google Scholar] [CrossRef]

- Di Marco, A.E.; Tomás, M.C.; Ixtaina, V.Y. Improved accelerated stability of starch-chia oil fatty acid inclusion complexes formed under mild reaction conditions. Carbohydr. Polym. 2024, 331, 121887. [Google Scholar] [CrossRef] [PubMed]

- Hagos, M.; Yaya, E.E.; Chandravanshi, B.S.; Redi-Abshiro, M. Determination of fatty acids composition by GC-MS and physicochemical parameters of pumpkin (Cucurbita maxima) seed oil cultivated in Ethiopia. Bull. Chem. Soc. Ethiop. 2023, 37, 565–577. [Google Scholar] [CrossRef]

- Botella-Martínez, C.; Gea-Quesada, A.; Sayas-Barberá, E.; Pérez-Álvarez, J.A.; Fernández-López, J.; Viuda-Martos, M. Improving the lipid profile of beef burgers added with chia oil (Salvia hispanica L.) or hemp oil (Cannabis sativa L.) gelled emulsions as partial animal fat replacers. LWT 2022, 161, 113416. [Google Scholar] [CrossRef]

- Loi, M.; Paciolla, C. Plant antioxidants for food safety and quality: Exploring new trends of research. Antioxidants 2021, 10, 972. [Google Scholar] [CrossRef] [PubMed]

- Abeyrathne, E.D.N.S.; Nam, K.; Ahn, D.U. Analytical methods for lipid oxidation and antioxidant capacity in food systems. Antioxidants 2021, 10, 1587. [Google Scholar] [CrossRef]

- Roselló-Soto, E.; Barba, F.J.; Lorenzo, J.M.; Dominguez, R.; Pateiro, M.; Mañes, J.; Moltó, J.C. Evaluating the impact of supercritical-CO2 pressure on the recovery and quality of oil from “horchata” by-products: Fatty acid profile, α-tocopherol, phenolic compounds, and lipid oxidation parameters. Food Res. Int. 2019, 120, 888–894. [Google Scholar] [CrossRef]

- Zingg, J.M. Vitamin E: Regulatory role on signal transduction. IUBMB Life 2019, 71, 456–478. [Google Scholar] [CrossRef]

- Claycombe, K.J.; Meydani, S.N. Vitamin E and genome stability. Mutat. Res./Fundam. Mol. Mech. Mutagen. 2001, 475, 37–44. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Q. Natural forms of vitamin E: Metabolism, antioxidant, and anti-inflammatory activities and their role in disease prevention and therapy. Free Radic. Biol. Med. 2014, 72, 76–90. [Google Scholar] [CrossRef] [PubMed]

- Zaaboul, F.; Liu, Y. Vitamin E in foodstuff: Nutritional, analytical, and food technology aspects. Compr. Rev. Food Sci. Food Saf. 2022, 21, 964–998. [Google Scholar] [CrossRef] [PubMed]

- Mora-Gallego, H.; Serra, X.; Guàrdia, M.D.; Miklos, R.; Lametsch, R.; Arnau, J. Effect of the type of fat on the physicochemical, instrumental and sensory characteristics of reduced fat non-acid fermented sausages. Meat Sci. 2013, 93, 668–674. [Google Scholar] [CrossRef] [PubMed]

- Pires, M.A.; Rodrigues, I.; Barros, J.C.; Carnauba, G.; de Carvalho, F.A.; Trindade, M.A. Partial replacement of pork backfat by Echium oil in reduced sodium bologna sausages: Technological, nutritional and stability implications. J. Sci. Food Agric. 2020, 100, 410–420. [Google Scholar] [CrossRef] [PubMed]

- Heck, R.T.; Vendruscolo, R.G.; de Araújo Etchepare, M.; Cichoski, A.J.; de Menezes, C.R.; Barin, J.S.; Campagnol, P.C.B. Is it possible to produce a low-fat burger with a healthy n − 6/n − 3 PUFA ratio without affecting the technological and sensory properties? Meat Sci. 2017, 130, 16–25. [Google Scholar] [CrossRef]

- Vargas-Ramella, M.; Munekata, P.E.; Pateiro, M.; Franco, D.; Campagnol, P.C.; Tomasevic, I.; Lorenzo, J.M. Physicochemical composition and nutritional properties of deer burger enhanced with healthier oils. Foods 2020, 9, 571. [Google Scholar] [CrossRef]

| Sample | Oil (g) | Water (g) | Emulsifier |

|---|---|---|---|

| E1 | 100 | 100 | 6 g of beewax and 0.6 g of xanthan gum |

| E2 | 114 | 52.5 | 2.5 g guar gum and 5.25 g of inulin |

| E3 | 100 | 60 | 10 g of deffated chia flour and 30 g of inulin |

| E4 | 95 | 95 | 1.6 g of guar gum, 8 g maltodextrin and 1 g of xanthan gum |

| E5 | 120 | 78.6 | 2 g of hydroxypropyl methylcellulose (HPMC) and 1.2 g of xanthan gum |

| Sample | Type of Oil | Emulsifier |

|---|---|---|

| E2CH | Chia | Guar gum + inulin |

| E2PM | Pumpkin | Guar gum + inulin |

| E3CH | Chia | Deffated chia flour + inulin |

| E3PM | Pumpkin | Deffated chia flour + inulin |

| E5CH | Chia | HPMC + xanthan gum |

| E5PM | Pumpkin | HPMC + xanthan gum |

| Sample | Firmness (N) | Consistency | Cohesiveness (N) | Viscosity Index |

|---|---|---|---|---|

| E1CH | 3.85 b ± 0.4 | 118.16 c ± 3.9 | −4.94 b ± 0.2 | −13.05 b ± 1.1 |

| E1PM | 8.44 b ± 0.5 | 107.6 cd ± 4.1 | −10.62 c ± 0.4 | −11.88 b ± 0.8 |

| E2CH | 6.46 b ± 0.3 | 209.7 b ± 5.5 | −8.26 c ± 0.4 | −21.47 b ± 1.2 |

| E2PM | 7.61 b ± 0.7 | 175.7 bc ± 6.7 | −9.00 c ± 0.3 | −18.04 b ± 1.3 |

| E3CH | 10.28 b ± 0.5 | 377.26 a ± 9.3 | −17.2 c ± 0.2 | −50.24 c ± 2.1 |

| E3PM | 11.34 b ± 0.7 | 344.75 a ± 2.5 | −17.35 c ± 1.4 | −49.26 c ± 2.7 |

| E4CH | 1.67 b ± 0.6 | 52.01 d ± 3.2 | −1.89 b ± 1.3 | −5.24 b ± 0.3 |

| E4PM | 1.79 b ± 0.4 | 65.15 d ± 3.7 | −2.81 b ± 0.4 | −8.02 b ± 0.6 |

| E5CH | 618 a ± 2.3 | 108 cd ± 3.9 | 2.05 a ± 0.2 | 50.73 a ± 4.1 |

| E5PM | 619 a ± 3.5 | 139 c ± 4.1 | 1.32 a ± 0.3 | 47.36 a ± 3.5 |

| Control | 613 a ± 4.1 | 267 ab ± 8.3 | 5.95 a ± 0.6 | 52.63 a ± 2.9 |

| Sample | L* | a* | b* | C* |

|---|---|---|---|---|

| E2CH | 32.89 b ± 2.03 | 18.31 b ± 2.37 | 19.42 b ± 2.85 | 26.72 b ± 3.55 |

| E2PM | 35.33 b ± 1.84 | 19.44 b ± 1.71 | 21.04 b ± 1.95 | 28.64 b ± 3.01 |

| E3CH | 33.52 b ± 2.35 | 16.59 c ± 1.63 | 19.28 b ± 2.87 | 25.43 b ± 2.44 |

| E3PM | 33.79 b ± 1.69 | 16.82 c ± 1.45 | 20.08 b ± 2.88 | 26.23 b ± 3.00 |

| E5CH | 33.74 b ± 1.68 | 12.37 d ± 3.40 | 12.81 c ± 1.93 | 17.96 c ± 3.04 |

| E5PM | 34.31 b ± 2.39 | 14.79 d ± 2.51 | 14.31 c ± 2.48 | 20.64 c ± 3.12 |

| Control | 43.87 a ± 1.78 | 23.52 a ± 1.77 | 29.10 a ± 3.09 | 37.44 a ± 3.19 |

| Sample | Hardness (N) | Cohesiveness | Elasticity (mm) | Masticability (N·mm) |

|---|---|---|---|---|

| E2CH | 278.79 b ± 21.45 | 0.46 ab ± 0.03 | 130.83 b ± 14.93 | 83.17 ab ± 9.98 |

| E2PM | 248.96 b ± 11.38 | 0.41 b ± 0.04 | 123.17 b ± 12.27 | 71.37 b ± 7.32 |

| E3CH | 359.39 a ± 11.09 | 0.48 a ± 0.03 | 172.89 a ± 15.86 | 95.38 a ± 13.43 |

| E3PM | 341.93 a ± 24.48 | 0.44 b ± 0.04 | 160.87 a ± 22.48 | 92.00 a ± 15.74 |

| E5CH | 206.06 c ± 25.16 | 0.44 b ± 0.02 | 92.23 c ± 14.69 | 44.59 c ± 8.48 |

| E5PM | 188.78 c ± 11.33 | 0.41 b ± 0.02 | 86.7 c ± 7.95 | 32.31 c ± 6.15 |

| Control | 207.48 c ± 11.3 | 0.51 a ± 0.02 | 107.4 c ± 7.72 | 65.73 b ± 20.47 |

| Sample | E2CH | E2PM | E3CH | E3PM | E5CH | E5PM | Control |

|---|---|---|---|---|---|---|---|

| Moisture (%) | 23.5 a ± 2.2 | 24.0 a ± 1.8 | 20.1 b ± 1.5 | 20.2 b ± 2.9 | 21.8 ab ± 2.6 | 22.5 ab ± 2.3 | 22.4 ab ± 2.0 |

| Protein (g) | 32.1 a ± 2.8 | 31.3 a ± 2.1 | 25.2 b ± 2.3 | 27.0 ab ± 1.8 | 28.2 ab ± 2.0 | 29.0 ab ± 1.7 | 26.2 b ± 2.9 |

| Total fats (g) | 31.6 c ± 3.1 | 30.8 c ± 1.7 | 33.6 c ± 2.0 | 30.3 c ± 2.3 | 39.1 b ± 2.1 | 37.0 b ± 1.8 | 49.3 a ± 2.8 |

| Saturated fat (g) | 7.1 b ± 0.9 | 9.1 b ± 0.7 | 8.0 b ± 1.0 | 8.9 b ± 0.9 | 8.1 b ± 0.5 | 9.1 b ± 1.1 | 18.6 a ± 1.2 |

| Carbohydrates (g) | 8.1 b ± 0.7 | 7.3 b ± 0.6 | 15.8 a ± 1.1 | 12.9 ab ± 1.1 | 3.7 c ± 0.5 | 2.9 c ± 0.6 | 2.7 c ± 0.2 |

| Sugars (g) | 4.1 b ± 0.1 | 3.3 b ± 0.2 | 8.9 a ± 0.1 | 5.8 a ± 0.4 | 1.6 c ± 0.2 | 0.6 c ± 0.1 | 0.5 c ± 0.0 |

| Crude fiber (g) | 1.9 b ± 0.2 | 2.1 b ± 0.1 | 2.5 b ± 0.3 | 2.6 b ± 0.4 | 2.8 b ± 0.0 | 1.8 b ± 0.3 | 5.8 a ± 0.1 |

| Energy value (Kcal) | 445 b ± 24 | 432 b ± 22 | 466 b ± 31 | 432 b ± 17 | 480 b ± 18 | 464 b ± 20 | 558 a ± 21 |

| E2CH | E2PM | E3CH | E3PM | E5CH | E5PM | Control | |

|---|---|---|---|---|---|---|---|

| Myristic acid | 0.51 c ± 0.04 | 0.53 c ± 0.04 | 0.66 b ± 0.03 | 0.62 b ± 0.02 | 0.51 c ± 0.03 | 0.53 c ± 0.04 | 1.45 a ± 0.05 |

| Palmitic acid | 13.70 c ± 1.2 | 18.60 b ± 0.9 | 14.80 c ± 1.5 | 18.7 b ± 1.1 | 12.5 c ± 0.9 | 18.8 b ± 1.4 | 24.1 a ± 2.1 |

| Stearic acid | 7.39 c ± 0.9 | 9.68 b ± 1.1 | 7.71 c ± 0.8 | 9.39 b ± 1.2 | 6.76 c ± 1.3 | 9.9 b ± 1.2 | 11.7 a ± 1.4 |

| Oleic acid | 20.80 c ± 2.4 | 33.80 b ± 2.8 | 24.50 c ± 3.1 | 36.2 b ± 4.1 | 19.3 c ± 2.9 | 35.5 b ± 4.3 | 50.1 a ± 5.2 |

| Linoleic acid | 20.20 b ± 1.7 | 34.70 a ± 2.9 | 17.20 b ± 3.1 | 30.8 a ± 2.7 | 18.4 b ± 2.0 | 32.2 a ± 3.1 | 7.97 c ± 3.2 |

| Linolenic acid | 35.10 a ± 3.2 | 0.55 b ± 0.15 | 32.50 a ± 4.1 | 1.92 b ± 0.09 | 40.5 a ± 2.1 | 0.76 b ±0.04 | 0.52 b ± 0.06 |

| Sample | TBA (mg MDA/kg) | Vitamin E (mg/kg) |

|---|---|---|

| E2CH | 2.97 a ± 0.2 | 3.33 c ± 0.2 |

| E2PM | 0.70 b ± 0.1 | 5.75 b ± 0.2 |

| E3CH | 2.03 a ± 0.0 | 3.64 c ± 0.4 |

| E3PM | 0.49 b ± 0.0 | 7.39 a ± 0.3 |

| E5CH | 3.04 a ± 0.3 | 2.05 c ± 0.1 |

| E5PM | 0.66 b ± 0.1 | 10.6 a ± 0.4 |

| Control | 0.42 b ± 0.2 | 3.81 c ± 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez, E.; Vieira Júnior, W.G.; Álvarez-Ortí, M.; Rabadán, A.; Pardo, J.E. Use of Different O/W or W/O Emulsions as Functional Ingredients to Reduce Fat Content and Improve Lipid Profile in Spanish Cured Processed Meat Product (‘Chorizo’). Foods 2024, 13, 2262. https://doi.org/10.3390/foods13142262

Martínez E, Vieira Júnior WG, Álvarez-Ortí M, Rabadán A, Pardo JE. Use of Different O/W or W/O Emulsions as Functional Ingredients to Reduce Fat Content and Improve Lipid Profile in Spanish Cured Processed Meat Product (‘Chorizo’). Foods. 2024; 13(14):2262. https://doi.org/10.3390/foods13142262

Chicago/Turabian StyleMartínez, Elena, Wagner Goncalves Vieira Júnior, Manuel Álvarez-Ortí, Adrián Rabadán, and José Emilio Pardo. 2024. "Use of Different O/W or W/O Emulsions as Functional Ingredients to Reduce Fat Content and Improve Lipid Profile in Spanish Cured Processed Meat Product (‘Chorizo’)" Foods 13, no. 14: 2262. https://doi.org/10.3390/foods13142262