Abstract

With the worldwide awareness of sustainability, biomass-derived carbon electrode materials for supercapacitors have attracted growing attention. In this research, for the first time, we explored the feasibility of making use of the carbon byproduct from hydrothermal liquefaction (HTL) of microalgae, termed herein as algae-derived carbon (ADC), to prepare sustainable carbon electrode materials for high-performance supercapacitor development. Specifically, we investigated carbon activation with a variety of activating reagents as well as N- and Fe-doping of the obtained ADC with the intention to enhance its electrochemical performance. We characterized the structure of the activated and doped ADCs using scanning electron microscope (SEM), Raman spectroscopy, Fourier transform infrared spectroscopy (FTIR), X-ray photoelectron spectroscopy (XPS), and BET surface area and pore analysis, and correlated the ADCs’ structure with their electrochemical performance as evaluated using cyclic voltammetry (CV), galvanostatic charge/discharge (GCD), impedance, and cycle stability through an assembled symmetric two-electrode cell with 1 M H2SO4 as electrolyte. It was found that the ADC that is activated using KOH (KOH-ADC) showed the best electrochemical performance, and its specific capacitance was 14.1-fold larger with respect to that of the raw ADC and reached 234.5 F/g in the GCD test at a current density of 0.5 A/g. The KOH-ADC also demonstrated excellent capacitance retention (97% after 10,000 cycles at a high current density of 10 A/g) for stable long-term operations. This research pointed out a promising direction to develop sustainable electrode materials for supercapacitors from the carbon byproduct produced after HTL processing of algae.

1. Introduction

With the awareness of sustainable development, increasing research efforts have been channeled towards developing clean, efficient, and sustainable sources of energy and energy storage devices to meet the energy demand of the human society in the 21st century [1]. Among the various energy storage devices that are being explored, supercapacitors have attracted great attention owing to their high power density, cycle stability, and fast charge and discharge rates [2]. Supercapacitors can be broadly classified into two main categories: electrochemical double layer capacitors (EDLC) and pseudocapacitors. The mechanism of charge storage in EDLC is based on a non-faradaic reversible electrical charge transfer and storage at the electrode–electrolyte interface, while that of the pseudocapacitor is based on a faradaic redox reaction process [3]. Although the latter shows good electrochemical performance, it often suffers from issues of high manufacturing costs and toxicity [4]. On the contrary, EDLC supercapacitors have relatively lower manufacturing cost and environmental benignity. Additionally, EDLC supercapacitors exhibit a high cycle stability and can maintain their electrochemical performance even up to 106 cycles or more [5].

A wide range of electrode materials have been suggested for the development of supercapacitors. Carbon has been widely used for supercapacitor electrode materials because of its low cost, excellent electrical conductivity, and high chemical stability. Due to the drive towards sustainability, biomass-derived carbon electrode materials have become a direction of current research [6]. Hydrothermal liquefaction (HTL) is an important thermochemical process that generates bio-crude oil from biomass [7]. Along with the bio-crude oil product, it is noteworthy that the HTL processing of biomass also generates a significant amount of solid carbon residue (2–70 wt.% of the total product depending on feedstock) [8]. Up to date, these carbon residue byproducts are mostly being utilized for the purpose of carbon sequestering and wastewater treatment [9,10,11]. In a recent report, Shell et al. (2021) utilized the HTL process to develop carbon electrode materials from corn stover and obtained a specific capacitance of 242 F/g at 5 mV/s in the cyclic voltammetry test and an energy density of 9.9 W h/kg in 2 M KOH [12]. The findings from this study indicated the possibility of acquiring carbon electrode materials from the HTL processing of biomass for supercapacitor applications. However, current studies in developing sustainable carbon electrode materials for supercapacitor use lie in plant and animal biomass [13] and little attention has been given to algae, which represent a distinctive class of biomass. There is no report yet to employ carbon residue particles from the HTL processing of algae (termed as algae-derived carbon (ADC) herein) as a value-added product for supercapacitor electrodes, even though HTL is an important thermochemical process to generate bio-crude oil from algal biomass [14]. It is well known that carbon sources and processing techniques impact the quality of carbon electrode materials for supercapacitors [12,15,16,17]. The ADC could possess a rich supply of heteroatoms like nitrogen which comes from the protein component of algae and thus could contribute to pseudocapacitance as an electrode material for supercapacitors.

In this research, for the first time, we seek to specifically explore the potential of ADC as an electrode material for supercapacitor application. With the intention to enhance the electrochemical performance of the obtained ADC, we further performed carbon activation and doping studies, which are popular ways to improve the electrochemical performance of carbon electrode materials and has been proved in our previous research [18,19]. For the carbon activation study, we investigated H2SO4, H3PO4, HNO3, and KOH according to their different activation mechanisms. Specifically, H2SO4 and HNO3 can improve the amount of functional groups on the surface of ADC through the oxidation and nitration of aromatic rings in the ADC [20]; H3PO4 can perform a depolymerization, dehydration, and redistribution of constituent biopolymers to develop porous structures in biochar [21]; KOH can etch the carbon surface to create a porous carbon structure using a decarburization mechanism. It is well known that introducing heteroatoms, especially N, can improve the electrochemical performance of carbon electrode materials [22] and melamine is a good N source for doping purposes [23], while iron-doped carbon electrode materials also demonstrated enhanced electrochemical performance [24]. For the carbon doping study, we thus investigated the N-doping effect using melamine and the Fe-doping effect using iron (III) chloride. Overall, we correlated the electrochemical performance of our ADC electrode materials with the ADC structure from various activations and doping processes and revealed a feasible way to make use of the ADC from HTL processing as a value-added product for energy storage applications.

2. Materials and Methods

2.1. Materials

Algal biomass (Chrollela vulgaris) was acquired from nuts.com (Cranford, NJ, USA). Potassium hydroxide (85%), sulfuric acid (98%), carbon black, iron (III) chloride hexahydrate (99+%), melamine, N-methyl-2-pyrrolidone (NMP), and polyvinylidene fluoride (PVDF) were purchased from Sigma-Aldrich (St. Louis, MO, USA). Phosphoric acid (pure, 85+%) was purchased from Cole-Parmer (Vernon Hills, IL, USA) and nitric acid was bought from Thermo Fisher Scientific (Waltham, MA, USA). All the chemicals were used as purchased without any further purification.

2.2. Preparation of Algae-Derived Carbon (ADC)

In a typical HTL process to prepare ADC, 73 mg of raw algae was mixed with 700 mL DI water and placed in a pressure Parr reactor (model: 4843). The algae system was subjected to a reaction temperature of 300 °C at a pressure of 1500 psi for 30 min. After the reaction, the solid residue, i.e., ADC particles, was separated from the HTL product, washed, and dried in an oven at 60 °C.

To prepare activated and doped ADCs, in the case of H2SO4, H3PO4, and HNO3, the raw ADC particles were immersed in the corresponding acid overnight and then the particles were filtered, washed, and dried for heat treatment; in the case of melamine (N source), iron (III) chloride hexahydrate (Fe source), and KOH, the raw ADC particles were mixed with these chemicals at a mixing ratio of 1:1 (w/w), respectively. All the ADCs were subsequently heated in a furnace at 800 °C for 1 h in a nitrogen environment. The obtained respective activated and doped ADCs were washed with deionized water until neutrality and then dried in oven at 60 °C. The as-prepared ADCs were then used for electrode preparation, respectively. In the following part, individual ADC samples are correspondingly labeled as Raw-ADC, H2SO4-ADC, H3PO4-ADC, HNO3-ADC, N-ADC, Fe-ADC, and KOH-ADC, respectively.

2.3. Material Characterization

The surface morphology of all the ADC materials was revealed by using a field emission SEM (Zeiss Auriga FIB FESEM, White Plains, NY, USA). Raman spectroscopy was performed to characterize the carbon structure of the ADCs using a Horiba Raman confocal microscope (Piscataway, NJ, USA) with an excitation wavelength of 532 nm. FTIR spectroscopy was carried out by employing an Agilent 670 FTIR spectrometer w/ATR (Santa Clara, CA, USA) to identify functional groups and covalent bonds that are present in ADCs. Specific surface area and porosity characteristics of the ADCs were investigated using a Micrometrics ASAP 2020 surface area and porosity system analyzer (Norcross, GA, USA). Surface elemental information of the ADCs was characterized using a Thermo Scientific Escalab Xi+ X-ray photon spectrometer (XPS, Waltham, MA, USA). In the XPS measurements, surface charge effects were minimized and all XPS spectra were charge-corrected using C1s binding energy of 284.8 eV.

2.4. Electrode Preparation and Characterization

The supercapacitor electrodes were prepared by mixing respective as-prepared ADC particles, carbon black, and polyvinylidene fluoride (PVDF) at a mixing ratio of 80:10:10. A few drops of N-methyl-2-pyrrolidone (NMP) solution were added to the ADC mixture to form a slurry. The slurry was cast onto a stainless steel mesh and dried in an oven at 60 °C overnight. This dried paste was then pressed using a 1.5 metric ton load to obtain a flat electrode for the supercapacitor test. A symmetric two-electrode cell, which consisted of the respective electrode material, the separator (filter paper), and 1 M H2SO4 electrolyte, was used to carry out electrochemical analyses including cyclic voltammetry (CV), galvanostatic charge/discharge (GCD), impedance, and cycle stability tests using a CHI660E electrochemical workstation to evaluate the electrochemical performance of the respective electrode materials. The impedances of the cell were carried out in the frequency range of 100 kHz and 0.1 Hz.

The specific capacitance was computed using Equations (1) and (2).

In Equation (1), C (F/g) is the specific capacitance; m (g) is the mass of active material loaded in the working electrode; v (V/s) is the scan rate; I (A) is the current; Vb and Va (V) are the upper and lower potential limits of the chosen potential window. In Equation (2), I (A) is the discharge current; ∆t (s) is the discharge time; ∆V (V) is the potential window; and m (g) is the active mass of a single electrode.

The energy density of the cell (E, W h/kg) was computed using Equation (3):

where C is the specific capacitance of the electrode material from the GCD test and ΔV is the potential window.

The power density of the cell (P, W/kg) was computed using Equation (4):

where E is the energy density of the cell and t is the discharge time.

3. Results and Discussion

3.1. Morphology

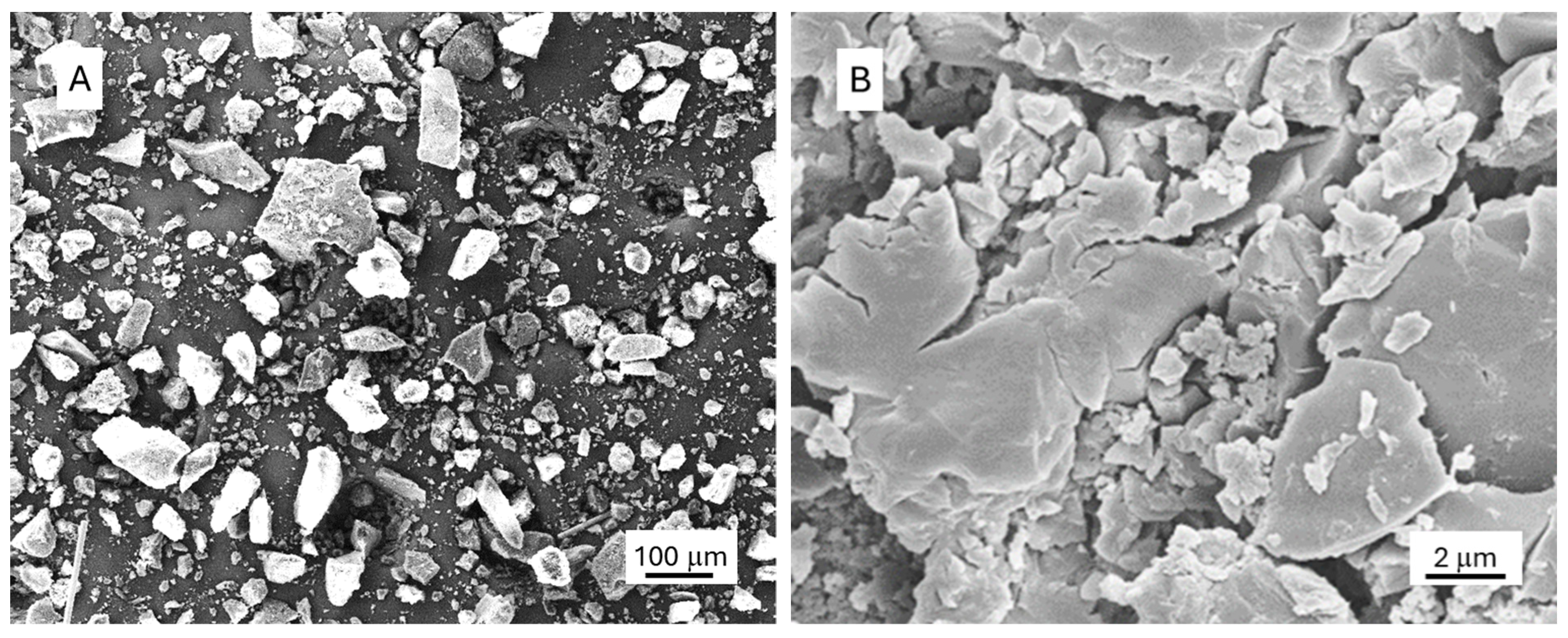

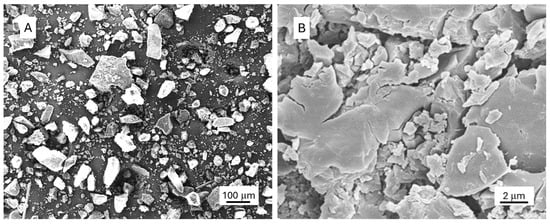

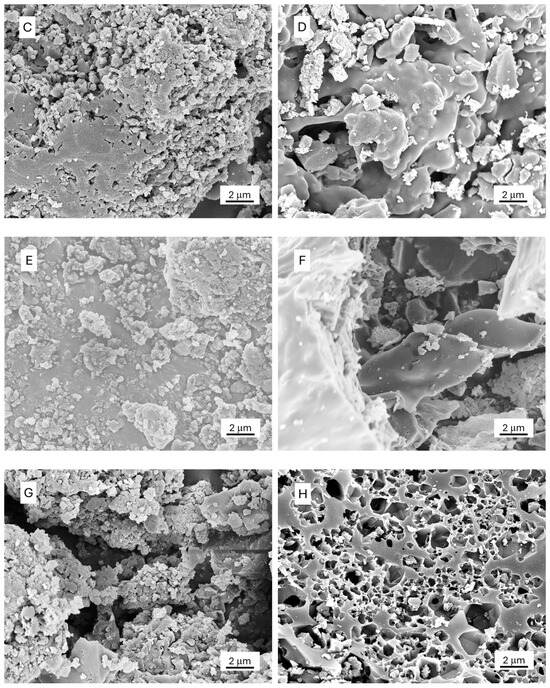

The obtained Raw-ADC comprised of particles with sizes from a few micrometers to hundreds of micrometers (Figure 1A). The surface of the Raw-ADC particles was relatively smooth (Figure 1B). All the activated and doped ADCs showed a relatively rough surface with broken and finer particles (Figure 1C–H). It is noteworthy that KOH-ADC presented the most surface roughness with well-developed porosity (Figure 1H). This is a result of the high carbon etching effect that is associated with KOH.

Figure 1.

SEM images of Raw-ADC (low magnification (A) and high magnification (B)), H2SO4-ADC (C), H3PO4-ADC (D), HNO3-ADC (E), N-ADC (F), Fe-ADC (G), and KOH-ADC (H).

3.2. Structure

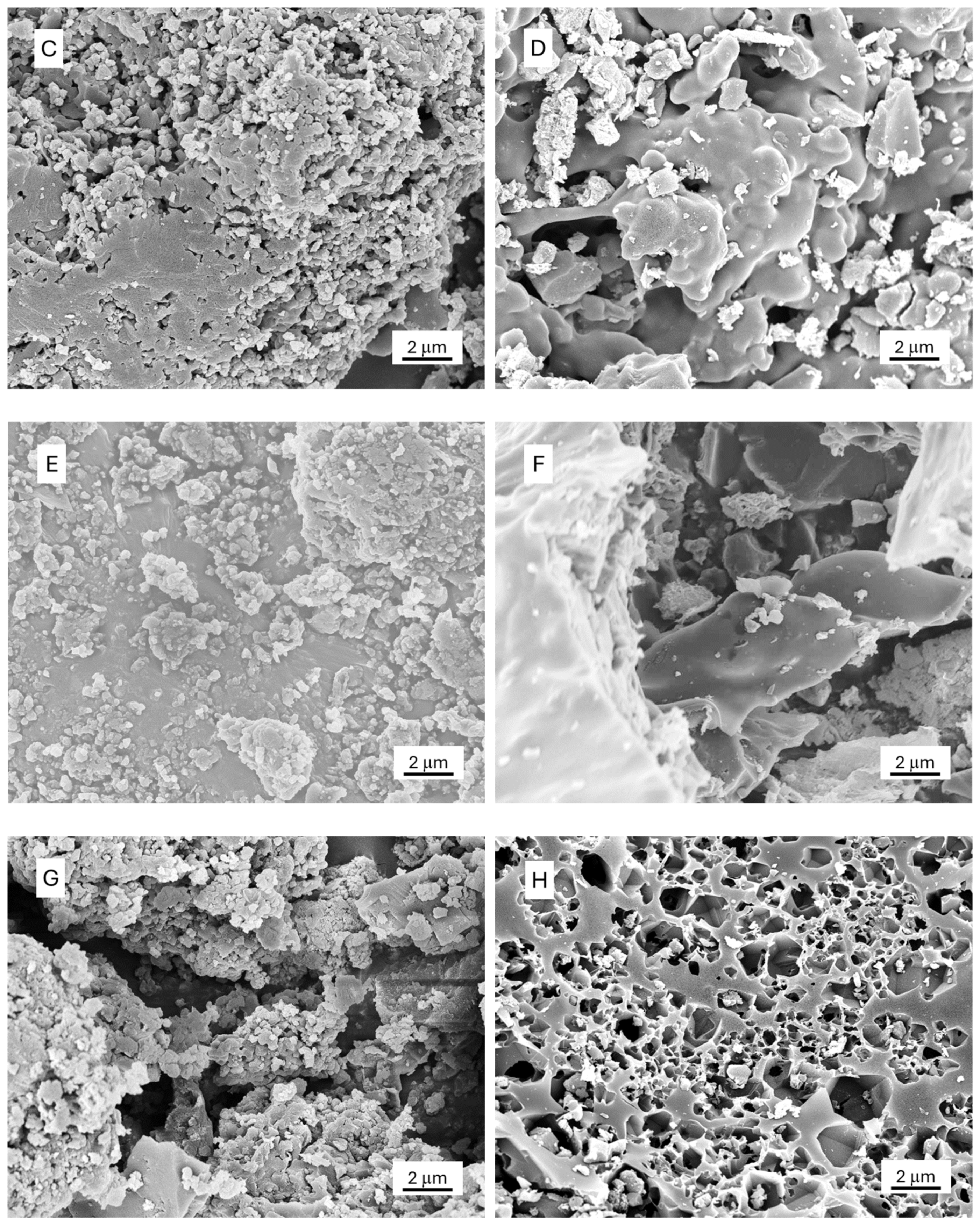

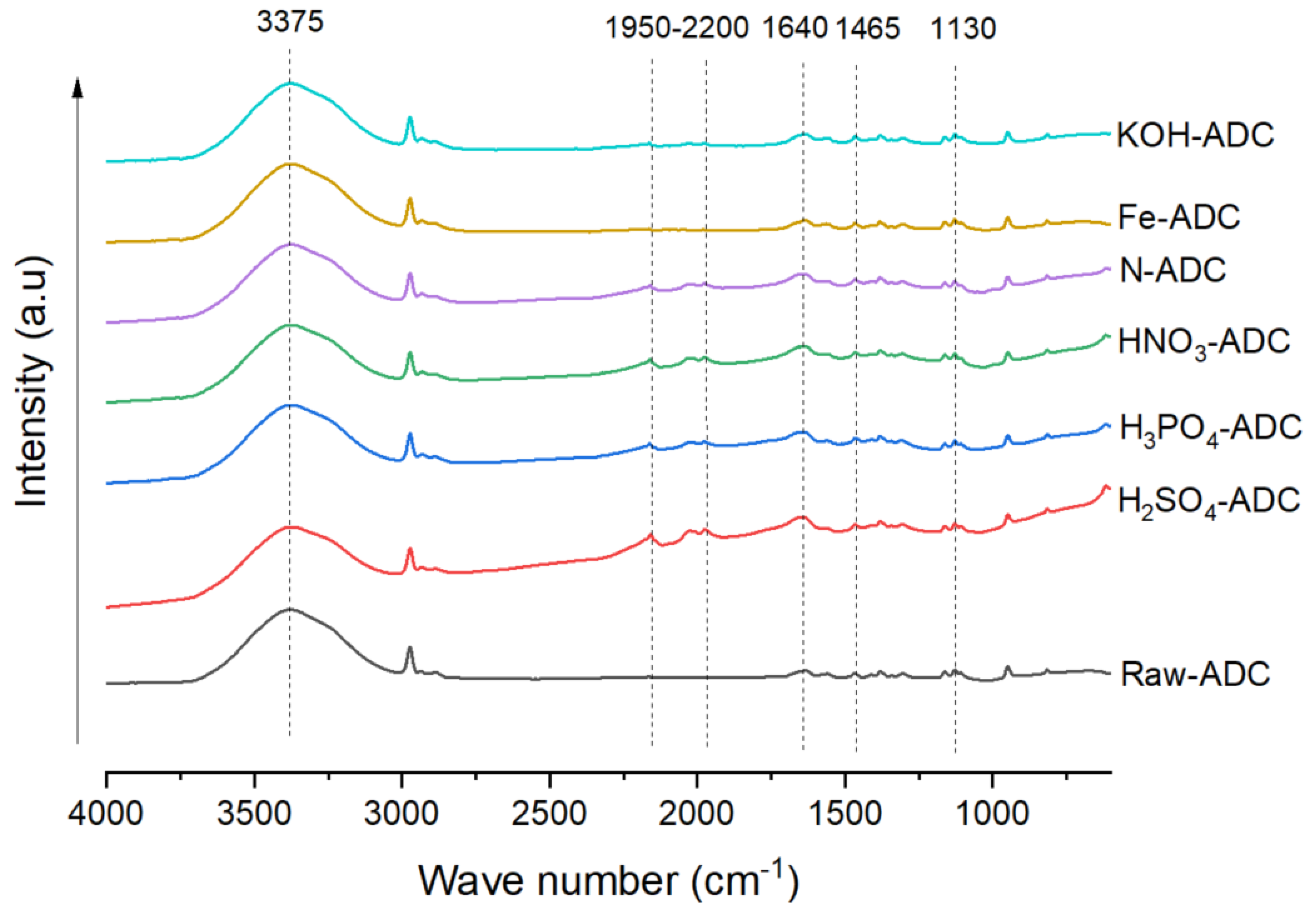

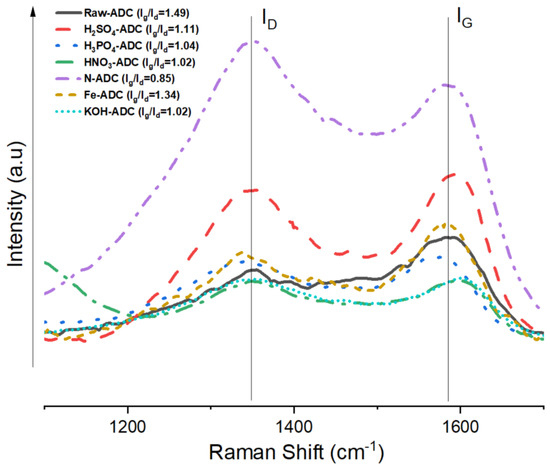

Raman spectroscopy was used to study the carbon structure of all the ADC samples (Figure 2). In Raman spectroscopy, the band between 1598 and 1575 cm−1 (G-band) is attributed to the organized carbon structure, while the band between 1355 and 1330 cm−1 (D-band) is attributed to the disordered carbon structure. Thus, a higher intensity ratio of IG/ID indicates more sp2 hybridized ordered carbon structures in corresponding carbon materials. Among all the studied ADCs, the Raw-ADC exhibited the highest IG/ID ratio of 1.47, implying the presence of the highest level of the ordered graphitic phase in the Raw-ADC. Compared to the Raw-ADC, the activation and doping resulted in reduced IG/ID ratios, i.e., more defective carbon structures, with N-ADC having the lowest IG/ID ratio of 0.85, showing the most defective carbon structure. Basically, the defective carbon structure is a result of carbon etching caused by activation and doping.

Figure 2.

Raman spectroscopy of all the ADC materials.

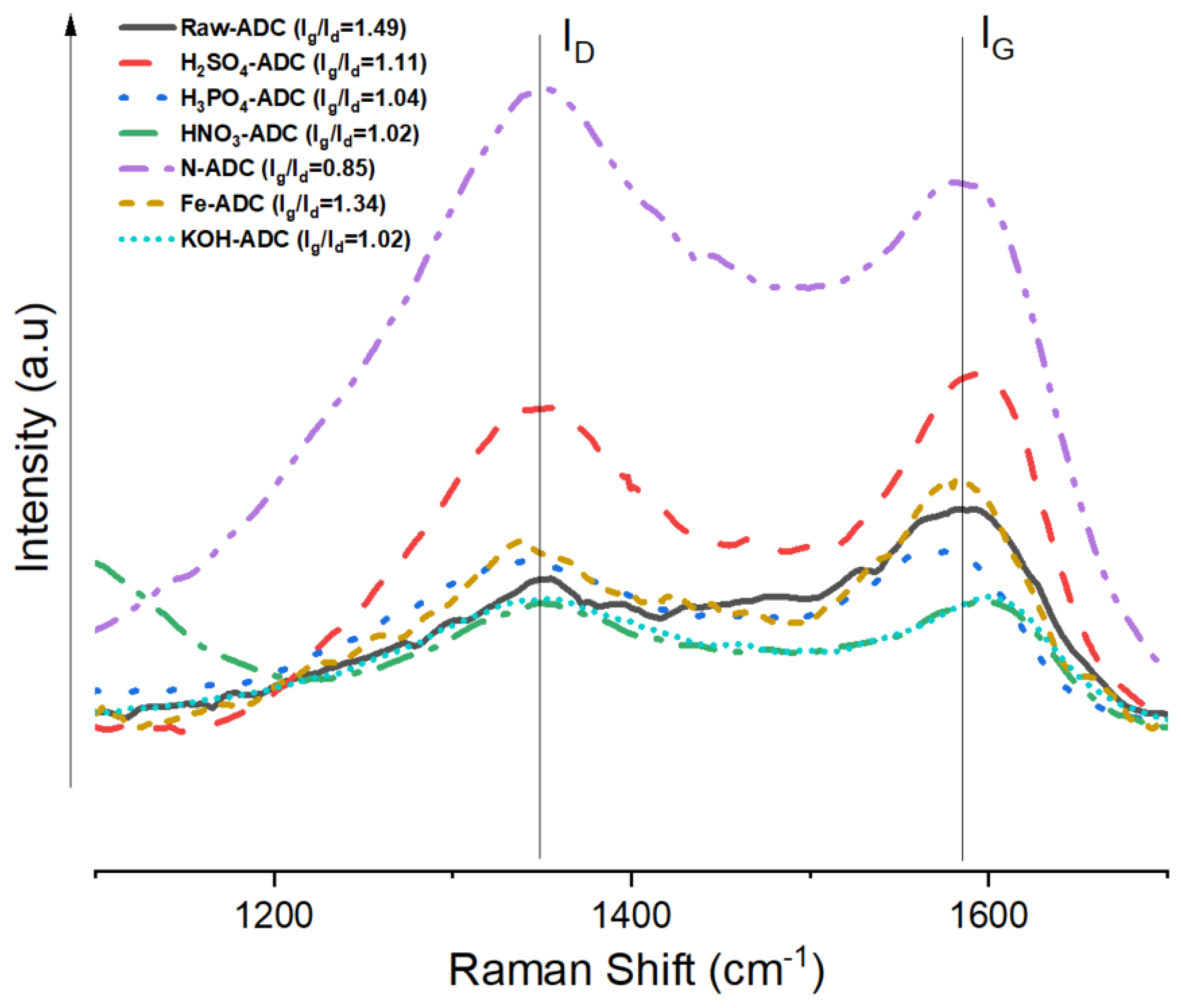

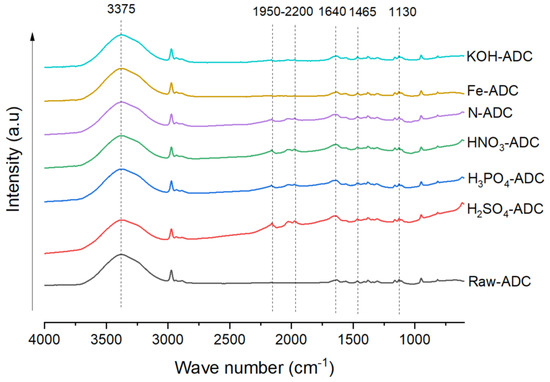

FTIR analysis was carried out to study the chemical functional groups of the as-synthesized ADC (Raw-ADC in Figure 3). The Raw-ADC showed a broad and strong IR peak around 3375 cm−1, which can be attributed to the stretching vibrations of O–H and/or N–H. The peaks observed between 2800 and 3000 cm−1, as well as 1460 and 1380 cm−1, represent C–H vibrations. The relative broad peaks observed around 1630 cm−1 and 1560 cm−1 could be attributed to Amide I and II and/or aromatic C=C stretching vibrations. The peaks in the range of 1100 and 1170 cm−1 could be attributed to C–O–C and/or C–O stretching vibrations. The peaks in the range of 1300 and 1350 cm−1 could be attributed to aromatic C–N stretching and/or O–H bending. After activation and doping, except for Fe-ADC, all the ADC materials showed new peaks in the range of 1950–2200 cm−1 (Figure 3), indicating oxidized functional groups like C≡C, C=C=C, C=C=O, and C=C=N, as well as aromatic compounds. This could be attributed to the oxidation and removal of amorphous carbon structures.

Figure 3.

FTIR spectroscopy of all the ADC materials.

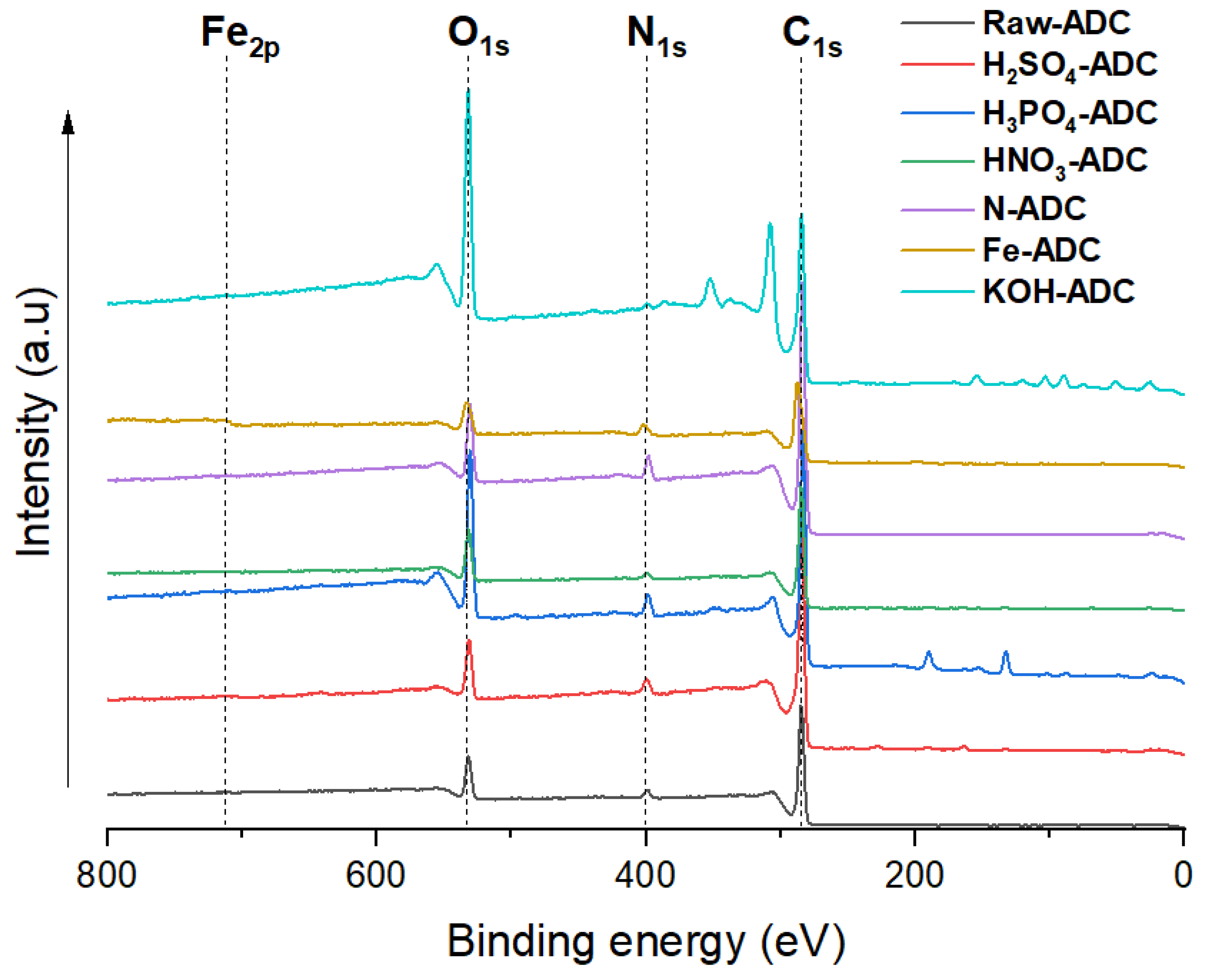

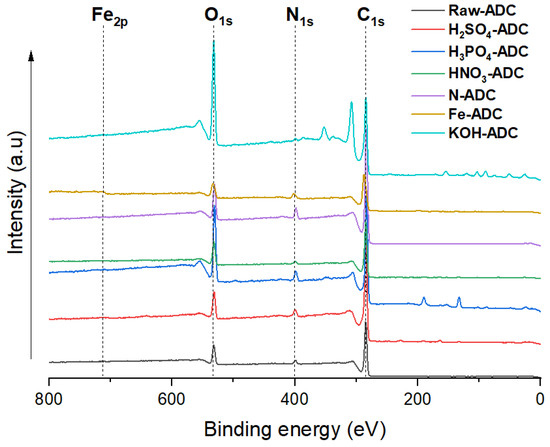

XPS was further carried out to analyze the surface element composition and bonding of all the ADC materials (Figure 4 and Table 1). The full XPS survey indicated that Raw-ADC already contained a significant amount of the N element. Activation and doping generally increased the amount of the N element, except for HNO3 and KOH. Interestingly, Fe doping resulted in the largest amount of the N element. Particularly, KOH activation led to the smallest amount of the N element, the largest amount of the O element, and the smallest amount of the C element. Since N bonding, including pyridinic N, pyrrolic N, quaternary N, and oxidized N, can have significant effects on the electrochemical performance of the carbon electrode material in supercapacitors [18], high-resolution N1s XPS spectra were obtained and analyzed (Table 2 and Figure S1). The N1s peak of ADCs can be deconvoluted into four peaks at 398.5 ± 0.5, 399.5 ± 0.5, 400.5 ± 0.5, and 403 ± 0.5 eV, which correspond to pyridinic N, pyrrolic N, quaternary N, and oxidized N, respectively [18]. It was found that the Raw-ADC did not contain any pyrrolic N, while KOH-ADC demonstrated the highest relative proportion of pyrrolic-N (85%), followed by HNO3-ADC.

Figure 4.

XPS spectra of all the ADC materials.

Table 1.

Relative atomic percentage of selected elements present in the ADC materials.

Table 2.

Area percentage of the deconvoluted high-resolution XPS N1s peaks of the ADC materials.

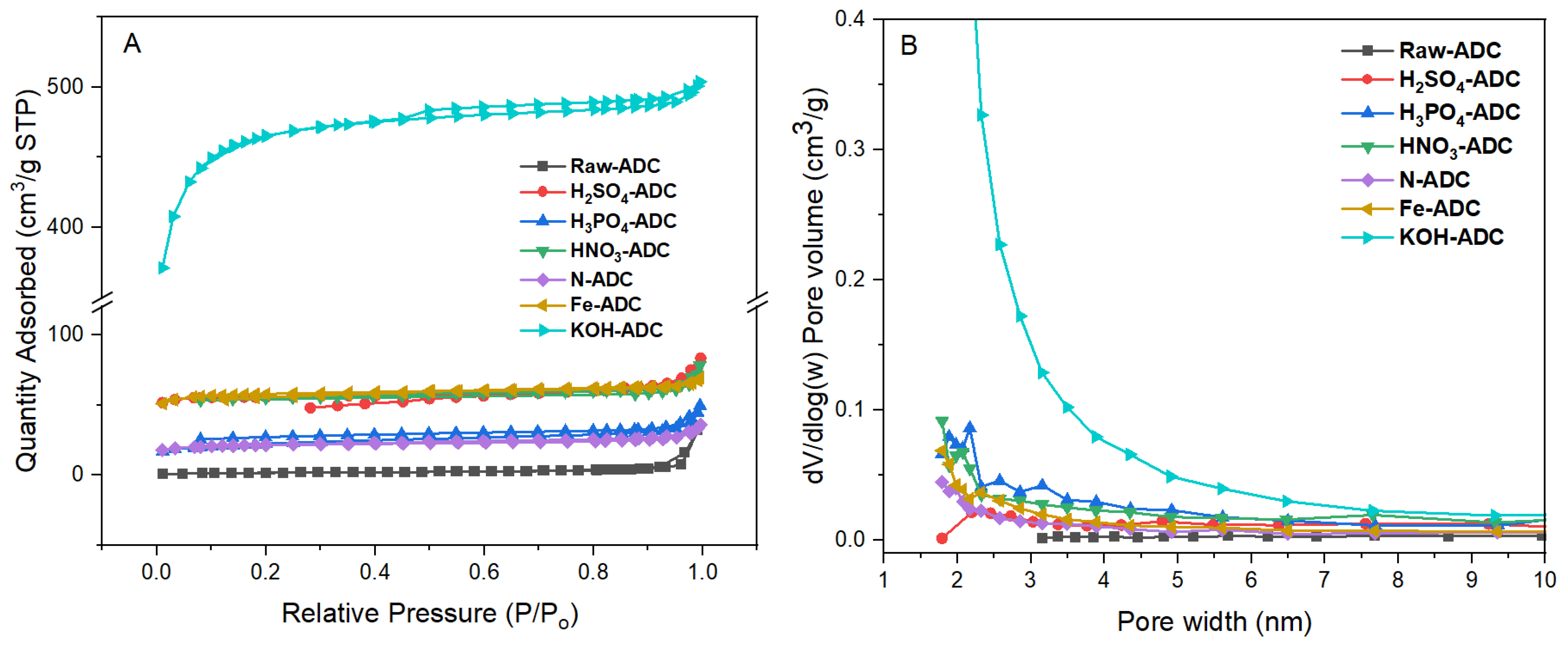

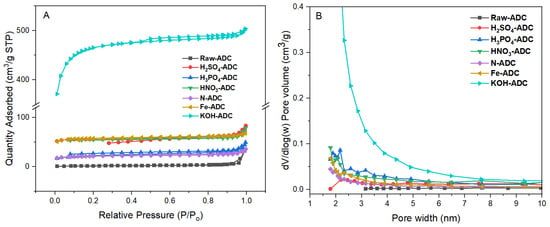

The specific surface area and porosity characteristics of all the ADCs were obtained from the BET surface area analysis (Figure 5 and Table 3). All the ADCs displayed type H4 hysteresis loops, implying the existence of micro- and meso-porous structures. The Raw-ADC, however, did not contain any micropores and showed a low specific surface area of 5.85 m2/g, indicating limited porous structure. Compared to the Raw-ADC, the processes of activation and doping increased micropore and mesopore volumes, as well as the specific surface area, which is consistent with the break of particles and surface roughness as observed from SEM. Among all the ADC materials, H3PO4 activation and melamine treatment for N doping resulted in the least pore development, while KOH-ADC exhibited a marvelous pore structure development with the smallest average pore size (2.20 nm), the largest pore volume (0.1716 cm3/g), and the largest specific surface area (1418 m2/g), indicating the most efficient carbon etching and consequent pore formation. The largest micropore and mesopore volume from KOH activation could be attributed to the CO or CO2 generation [25], as well as the intercalation mechanism by metallic K within the carbon framework, leading to the widening of pores during the high temperature decomposition process [26].

Figure 5.

N2 adsorption/desorption isotherms (A) and pore size distribution (B) of all the ADC materials.

Table 3.

BET surface area and porosity of all the ADC materials.

3.3. Electrochemical Properties

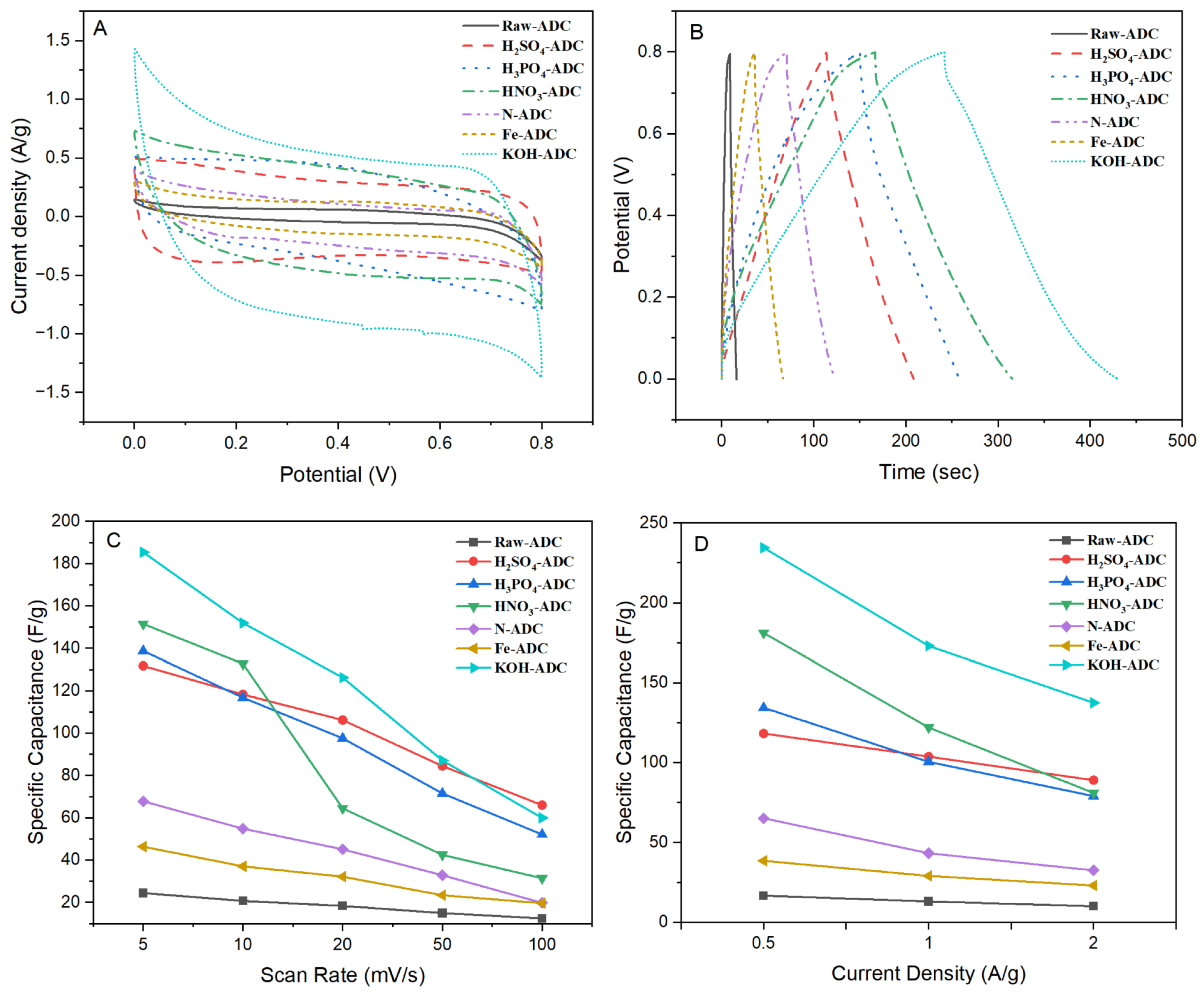

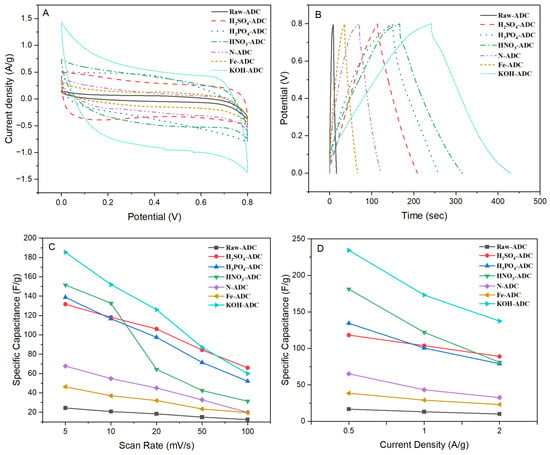

Electrochemical studies including CV and GCD were carried out to assess the performance of the prepared ADC materials as electrodes for supercapacitor uses (Figure 6). The quasi-rectangular CV curves as well as the isosceles shape of the charge/discharge profile of the device indicated good capacitive performance of the ADC materials. The specific capacitances of these ADC electrode materials from the CV test and the GCD test matched each other, which decreased with the increase of the scan rate in the CV test and with the increase of current density in the GCD test.

Figure 6.

CV curves at scan rate of 5 mV/s (A), GCD profiles at current density of 0.5 A/g (B), specific capacitances from CV at various scan rates (C), and specific capacitances from GCD at various current densities (D) of all the ADC electrode materials.

The Raw-ADC showed relatively poor electrochemical performance as supercapacitor electrode material. It showed a specific capacitance of 24.4 F/g in the CV test at a scan rate of 5 mV/s and a specific capacitance of 16.6 F/g in the GCD test at a current density of 0.5 A/g. All the activation and doping processing resulted in ADCs with larger specific capacitances, but the N-doping and Fe-doping processing led to less improvement than that of the activation. Compared to the Raw-ADC, the Fe-ADC and N-ADC exhibited 2.3-fold and 3.9-fold specific capacitances, respectively, while the H2SO4-ADC, H3PO4-ADC, and HNO3-ADC demonstrated 7.1-fold, 8.1-fold, and 10.9-fold specific capacitances, respectively. Particularly, the KOH-ADC presented the greatest improvement in specific capacitance, which reached 234.5 F/g during the GCD test at a current density of 0.5 A/g, i.e., 14.1-fold specific capacitance with respect to that of Raw-ADC. This result is better than the reported electrochemical performance of related carbon electrode materials from hydrothermal liquefaction processing of other biomass such as corn stover [12], pine wood [16], and larch wood [17]. It is noteworthy that the KOH-ADC exhibited 50% more specific capacitance than that of the carbon electrode materials from pyrolysis of the same microalgae [15].

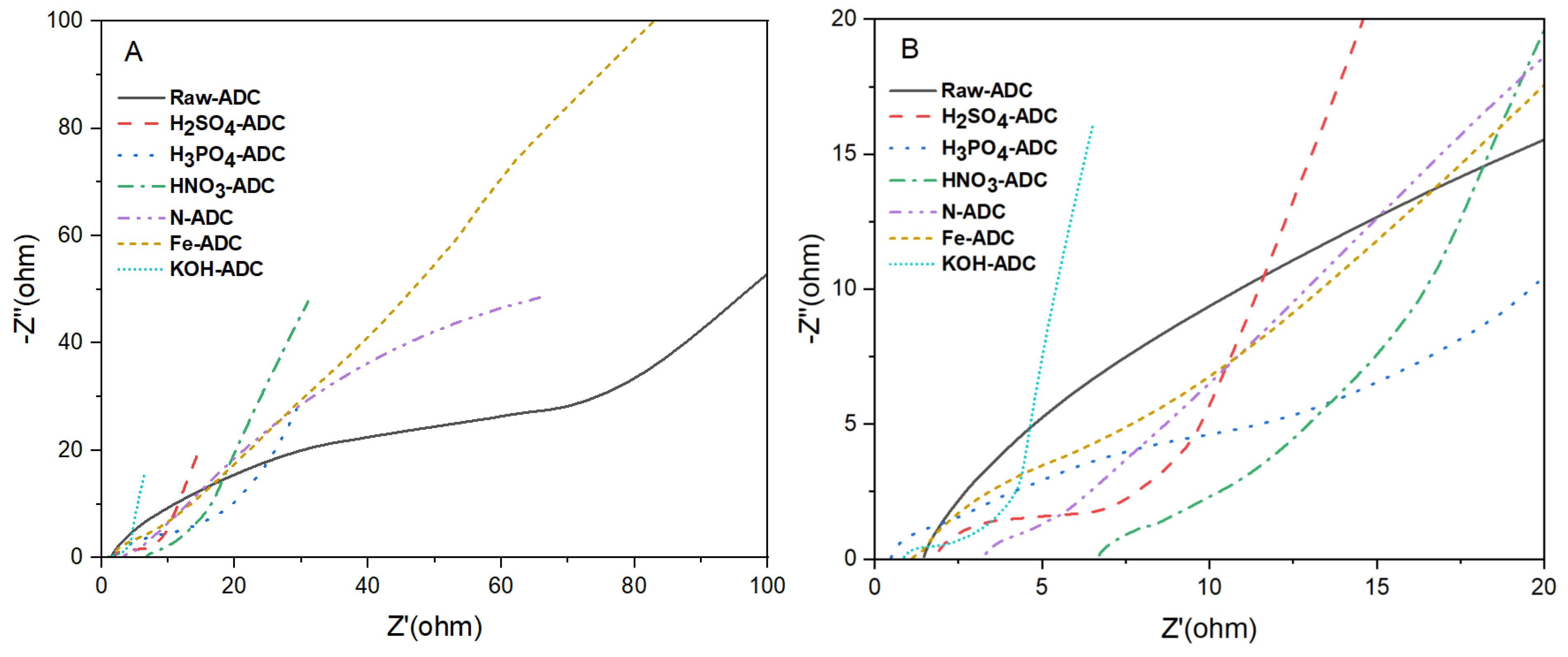

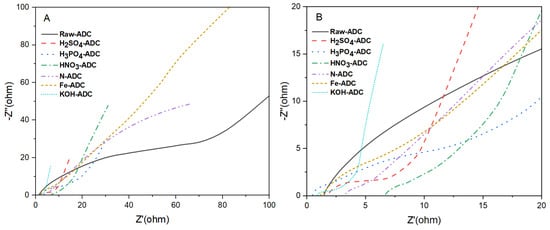

To further characterize the electrochemical behavior of the ADC electrode materials, electrochemical impedance spectroscopy (EIS) was performed (Figure 7). The diameter of the semi-circle of the Nyquist plot in the high frequency region can be ascribed to electrolyte resistance, while the intercept of the Nyquist plot at the axis of the real part of complex impedance in the high frequency region is associated with the electrode resistance, which together make up the internal resistance of the electrode [27]. The angle between the straight line of the Nyquist plot and the axis of the real part of complex impedance indicates capacitive behavior of the electrode material. According to the Nyquist plots of all the ADC electrode materials, KOH-ADC showed the least electrolyte resistance, the second least electrode resistance, and the best capacitive behavior among all the ADC electrode materials, which is consistent with its best electrochemical performance.

Figure 7.

Nyquist plots of all the ADC electrode materials (A) and their views in a high frequency region (B).

3.4. Discussion

The electrochemical performance of all the ADC electrode materials can be correlated with their structure including specific surface area, pore structure, carbon structure, and surface properties. The final electrochemical performance of ADC electrode materials is a combination of all these factors.

KOH-ADC demonstrated the best electrochemical performance, which can be first attributed to its well-developed pore structure and consequently large specific surface area. The presence of the largest specific surface area (1418 m2/g) and the biggest micropore volume (0.0587 cm3/g) may have created the largest active sites for electrochemical activity to take place. In the meantime, the biggest mesopore volume has not only contributed to the specific surface area, but also created more accessible channels for the transport of ions to those micropore sites [28]. Overall, KOH-ADC electrode materials possessed the greatest capability for charge transport paths and storage sites.

Furthermore, KOH-ADC had the smallest average pore size (~2.2 nm) among all the ADC electrode materials, which is closest to the average SO42− electrolytic ionic radius (~0.258 ± 0.004 nm) [29]. Research has shown that a smaller average pore size allows for maximal ion interaction with pore walls, resulting in an increase in the EDL charge capacity without impeding the electro- adsorption and desorption kinetics [30,31,32].

The degree of ordered carbon structures in electrode materials influences the final supercapacitor performance. A relatively high degree of IG/ID implies a high level of graphitization in the electrode material, which can improve its electrical conductivity by reducing the charge transfer resistance to electrolyte ions [33], whereas a high level of a defective phase (low IG/ID) results in a high degree of electrolyte wetting of the electrode surface, which can lead to an enhancement in the electrochemical activity. The final electrochemical performance of carbon electrode materials for supercapacitors is a composite effect of both defective and graphitic phases that are present in the electrode material. From the Raman spectroscopy, KOH-ADC possessed a moderate IG/ID ratio (1.02) and therefore benefitted from the composite effect of both wetting and graphitization, resulting in the best electrochemical performance.

Additionally, KOH-ADC exhibited the largest atomic percentage of pyrrolic-N (85.13% from the XPS analysis), as well as the largest amount of O-containing functional groups (Table 2). It is established that pyrrolic-N improves electrochemical performance by enhancing the surface wettability properties of the carbon electrode as well as improving its pseudocapacitance [34]. Pyrrolic-N sites are located at the edge of carbon structure, and they consist of five-member rings that are bonded to the adjacent carbon atoms from the phenolic/carbonyl groups. The pyrrolic-N could contribute two π electrons to the aromatic system. The high proportion of pyrrolic-N on the surface of KOH-ADC may improve electrolyte wetting and facilitate the diffusion of electrolyte ions through the pores of the electrode material, as well as induce pseudocapacitive effects. The surface O-containing functional groups of KOH-ADC may further improve the electrolyte wetting properties. Overall, the well-developed porous structure and surface properties of KOH-ADC, in turn, resulted in a very low electrode resistance, rapid electrolyte diffusion, and good accessibility of the electrolyte ions to the electrode as evidenced by the Nyquist plot. The best specific capacitance 234.5 F/g among all the ADC electrode materials was thus acquired from KOH-ADC.

For comparison, the Raw-ADC performs poorly as an electrode material for supercapacitors (specific capacitance, 16.6 F/g) due to its poor porous structure, i.e., the largest average pore size of 33.51 nm, no micropores, and the lowest specific surface area. Fe-doping and N-doping did not significantly improve the electrochemical performance as anticipated, which could be contributed to the not-well-developed porous structure as evidenced by the lowest total pore volumes among all the prepared ADC electrode materials. Furthermore, their not-so-good electrochemical performance could also be ascribed to the relatively low amount of Fe atoms (Table 1) in the case of Fe-ADC and the 100% pyridinic-N structure in the case of N-ADC.

3.5. Practical Evaluation

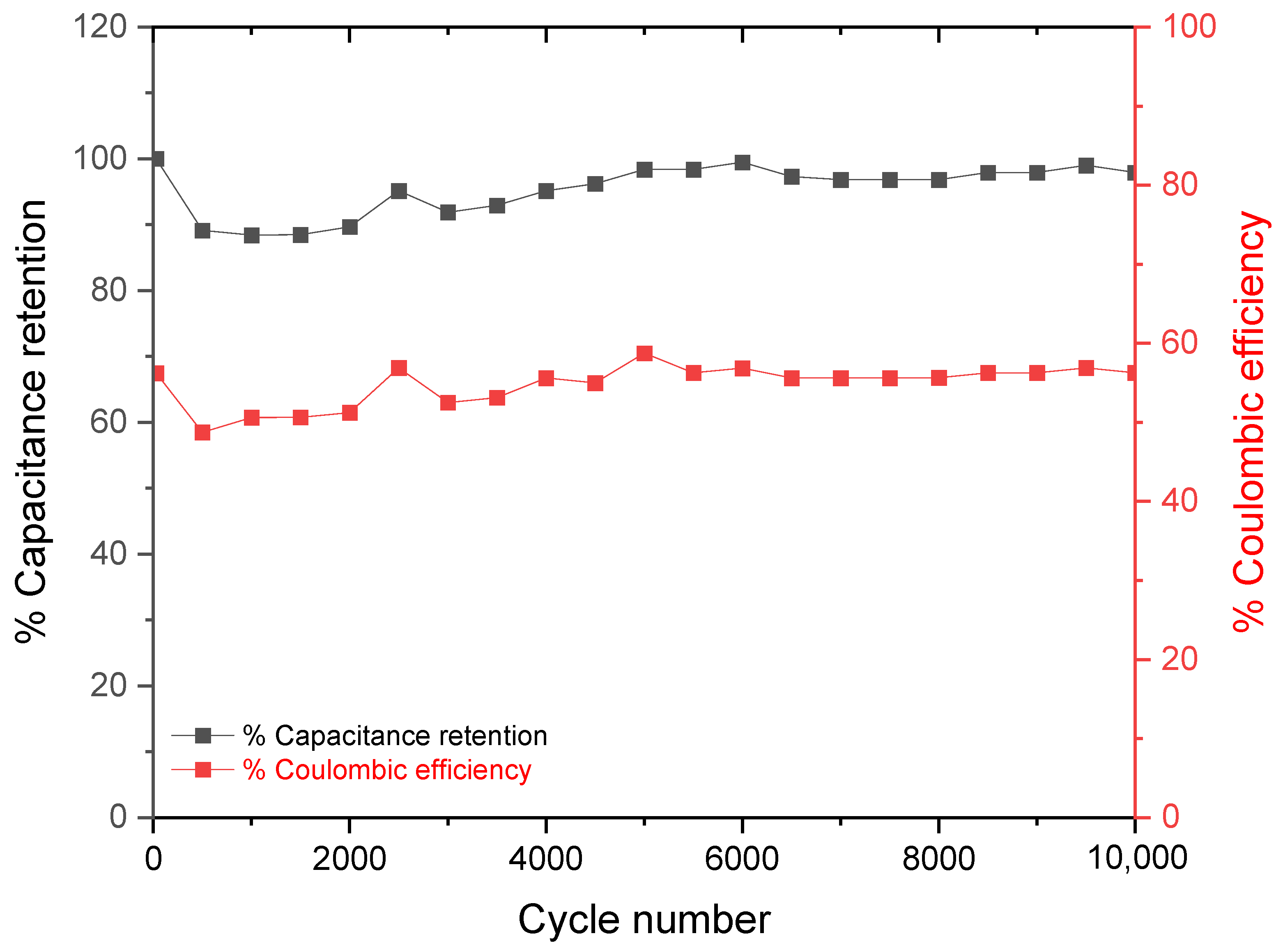

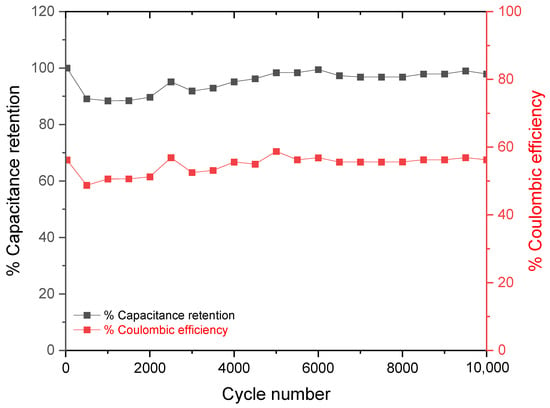

The cycle stability test of a supercapacitor device is of prime importance as it provides the ground information for the practical use of the device. An outstanding capacitance retention of about 97% was attained for the high-performance KOH-ADC electrode material after 10,000 cycles at a current density of 10 A/g (Figure 8). The high capacitance retention of this electrode material could be attributed to the superior structural advantages of KOH-ADC, i.e., the large mesopore volume that created easily accessible channels to the micropores as well as its ultra-large specific surface area and abundant open pores on the surface for EDL formation. In addition, the device showed a stable coulombic efficiency (~55%) for stable long-term operation. The KOH-ADC electrode material also possessed an energy density of 5.1 W h/kg and a power density of 97.6 W/kg, indicating an overall good electrode material for supercapacitor use.

Figure 8.

Cycle stability and coulomb efficiency of KOH-ADC electrode material up to 10,000 cycles of charging-discharging at current density of 10 A/g.

4. Conclusions

In this research, we demonstrated a successful attempt to acquire sustainable carbon electrode materials for supercapacitor use from the carbon byproduct after hydrothermal liquefaction processing of renewable algal biomass. With the intention to enhance the electrochemical performance of the obtained algae-derived carbon (ADC), we performed carbon activation with H2SO4, H3PO4, HNO3, and KOH according to their different activation mechanisms, as well as N-doping with melamine and Fe-doping with iron (III) chloride. Compared to the original Raw-ADC, all the activation and doping processing resulted in ADCs with greater specific capacitances, but the N-doping and Fe-doping processing led to less improvement than that of the activation. Among all the activated and doped ADC electrode materials, KOH-ADC showed the best electrochemical performance and its specific capacitance reached 234.5 F/g through the galvanostatic charge-discharge (GCD) test at a current density of 0.5 A/g, which is a 14.1-fold increase with respect to that of the Raw-ADC. The electrochemical performance of KOH-ADC is better than that of the reported carbon electrode materials from the hydrothermal liquefaction processing of other biomass. This excellent electrochemical performance was supported by the least electrolyte resistance, the second least electrode resistance, and the best capacitive behavior among all the ADC electrode materials from the results of electrochemical impedance spectroscopy (EIS) test. The best electrochemical performance of the KOH-ADC can be attributed first to its well-developed pore structure with the smallest average pore size (2.2 nm), the biggest micropore volume (0.0587 cm3/g), and the largest specific surface area (1418 m2/g). Furthermore, the moderate IG/ID ratio of KOH-ADC warranted both good electrolyte wetting and electrical conductivity, while the largest atomic percentage of pyrrolic-N (88.13% from XPS) and the largest amount of O-containing functional groups in KOH-ADC also improved electrolyte wetting and diffusion of the electrolyte ions and facilitated pseudocapacitive effect. KOH-ADC further showed an outstanding capacitance retention (97%) after 10,000 cycles at a high current density of 10 A/g and a stable coulombic efficiency (~55%) for stable long-term operation. The KOH-ADC electrode material possessed an energy density of 5.1 W h/kg and a power density of 97.6 W/kg. This research points out a promising direction to expand use and add value to the carbon byproduct from the hydrothermal liquefaction of algae. In the meantime, this carbon byproduct is a sustainable carbon source, and its use will facilitate the sustainable development of supercapacitor electrode materials.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/c10020051/s1, Figure S1: High resolution N1s XPS spectra of the ADCs with deconvoluted peaks of oxidized N, quaternary N, pyrrolic N, and pyridinic N: (A) Raw-ADC; (B) H2SO4-ADC; (C) H3PO4-ADC; (D) HNO3-ADC; (E) N-ADC; (F) Fe-ADC; (G) KOH-ADC.

Author Contributions

Conceptualization: L.Z. and A.S.; data curation: K.A. and A.M.; formal analysis: K.A. and M.F.H.; funding acquisition and resources: A.S. and L.Z.; investigation and validation: K.A., A.M., M.F.H. and P.A.; methodology: K.A., A.M., M.F.H. and L.Z.; project administration and supervision: L.Z.; writing —original draft: K.A.; writing—review and editing: L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was partially supported by the United States Department of Agriculture/National Institute of Food and Agriculture (USDA/NIFA) Evans-Allen Fund (NC. X331-5-21-130-1). The authors also thank the support from the Joint School of Nanoscience and Nanoengineering of North Carolina A&T State University, a member of the Southeastern Nanotechnology Infrastructure Corridor (SENIC) and the National Nanotechnology Coordinated Infrastructure (NNCI), which is financially supported by the National Science Foundation (ECCS-2025462).

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author/s.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bilgen, S.; Kaygusuz, K.; Sari, A. Renewable energy for a clean and Sustainable future. Energy Sources 2004, 26, 1119–1129. [Google Scholar] [CrossRef]

- Olabi, A.G.; Abbas, Q.; Al Makky, A.; Abdelkareem, M.A. Supercapacitors as next generation energy storage devices: Properties and applications. Energy 2022, 248, 123617. [Google Scholar] [CrossRef]

- Yu, Z.; Tetard, L.; Zhai, L.; Thomas, J. Supercapacitor electrode materials: Nanostructures from 0 to 3 dimensions. Energy Environ. Sci. 2015, 8, 702–730. [Google Scholar] [CrossRef]

- Abruna, H.D.; Yasuyuki, K.; Henderson, J.C. Batteries and electrochemical capacitors. Phys. Today 2008, 61, 43–47. [Google Scholar] [CrossRef]

- Fic, K.; Platek, A.; Piwek, J.; Frackowiak, E. Sustainable materials for electrochemical capacitors. Mater. Today 2018, 21, 437–454. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, Y.; Song, N.; Li, X. Biomass-derived renewable carbon materials for electrochemical energy storage. Mater. Res. Lett. 2017, 5, 69–88. [Google Scholar] [CrossRef]

- Akhtar, J.; Amin, N.A.S. A review on process conditions for optimum bio-oil yield in hydrothermal liquefaction of biomass. Renew. Sustain. Energy Rev. 2011, 15, 1615–1624. [Google Scholar] [CrossRef]

- Ponnusamy, V.K.; Nagappan, S.; Bhosale, R.R.; Lay, C.-H.; Nguyen, D.D.; Pugazhendhi, A.; Chang, S.W.; Kumar, G. Review on sustainable production of biochar through hydrothermal liquefaction: Physico-chemical properties and applications. Bioresour. Technol. 2020, 310, 123414. [Google Scholar] [CrossRef]

- He, S.; Barati, B.; Hu, X.; Wang, S. Carbon migration of microalgae from cultivation towards biofuel production by hydrothermal technology: A review. Fuel Process. Technol. 2023, 240, 107563. [Google Scholar] [CrossRef]

- Leng, L.; Yuan, X.; Zeng, G.; Shao, J.; Chen, X.; Wu, Z.; Wang, H.; Peng, X. Surface characterization of rice husk bio-char produced by liquefaction and application for cationic dye (Malachite green) adsorption. Fuel 2015, 155, 77–85. [Google Scholar] [CrossRef]

- Salehi, B.; Wang, L. Critical Review on Nanomaterials for Enhancing Bioconversion and Bioremediation of Agricultural Wastes and Wastewater. Energies 2022, 15, 5387. [Google Scholar] [CrossRef]

- Shell, K.M.; Rodene, D.D.; Amar, V.; Thakkar, A.; Maddipudi, B.; Kumar, S.; Shende, R.; Gupta, R.B. Supercapacitor performance of corn stover-derived biocarbon produced from the solid co-products of a hydrothermal liquefaction process. Bioresour. Technol. Rep. 2021, 13, 100625. [Google Scholar] [CrossRef]

- Gao, Y.; Sun, R.; Li, A.; Ji, G. In-situ self-activation strategy toward highly porous biochar for supercapacitors: Direct carbonization of marine algae. J. Electroanal. Chem. 2021, 882, 114986. [Google Scholar] [CrossRef]

- Kandasamy, S.; Bhuvanendran, N.; Narayanan, M.; He, Z. Chapter 13—Thermochemical conversion of algal biomass. In Handbook of Algal Biofuels; Elsevier Inc.: Amsterdam, The Netherlands, 2022; pp. 281–302. [Google Scholar]

- Yardim, Y.; Saka, C. Oxygen and nitrogen-doped carbon particles derived from pyrolysis of Chlorella vulgaris and Spirulina platensis microalgae as an efficient electrode material for supercapacitor application. Full. Nanotub. Carbon Nanostructures 2023, 31, 713–723. [Google Scholar] [CrossRef]

- Amar, V.S.; Houck, J.D.; Shende, R.V. Catalytic HTL-derived biochar and sol-gel synthesized (Mn, Ti)-oxides for asymmetric supercapacitors. Int. J. Energy Res. 2020, 44, 12546–12558. [Google Scholar] [CrossRef]

- Hwang, H.; Lee, J.-H.; Ahmed, M.A.; Choi, J.W. Evaluation of pyrochar and hydrochar derived activated carbons for biosorbent and supercapacitor materials. J. Environ. Manag. 2021, 298, 113436. [Google Scholar] [CrossRef]

- Hasan, M.F.; Mantripragada, S.; Gbewonyo, S.; Xiu, S.; Shahbazi, A.; Zhang, L. Carbon nanofibrous electrode material from electrospinning of chlorella (microalgae) with polyacrylonitrile for practical high-performance supercapacitor. Int. J. Energy Res. 2022, 46, 22867–22882. [Google Scholar] [CrossRef]

- Hasan, M.F.; Asare, K.; Mantripragada, S.; Charles, V.; Shahbazi, A.; Zhang, L. Meso-microporous carbon nanofibrous aerogel electrode material with fluorine-treated wood biochard for high-performance supercapacitor. Gels 2024, 10, 82. [Google Scholar] [CrossRef]

- Nzediegwu, C.; Naeth, M.A.; Chang, S.X. Feedstock type drives surface property, demineralization and element leaching of nitric acid-activated biochars more than pyrolysis temperature. Bioresour. Technol. 2022, 344 Pt B, 126316. [Google Scholar] [CrossRef]

- Yorgun, S.; Yıldız, D. Preparation and characterization of activated carbons from Paulownia wood by chemical activation with H3PO4. J. Taiwan Inst. Chem. Eng. 2015, 53, 122–131. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, J.; Kuang, S.; Zhou, J.; Xing, W.; Zhuo, S. Nitrogen-doped hierarchical porous carbon as an efficient electrode material for supercapacitors. Eletrochimica Acta 2015, 153, 273–279. [Google Scholar] [CrossRef]

- Li, M.; Xue, J. Integrated synthesis of nitrogen-doped mesoporous carbon from melamine resins with superior preformance in supercapacitors. J. Phys. Chem. C 2014, 118, 2507–2517. [Google Scholar] [CrossRef]

- Wu, D.; He, T.; Albashir, A.I.M.; Tan, Y.; Ran, F. Iron-doped carbon electrode materials derived from polyethersulfone. J. Energy Storages 2021, 33, 102099. [Google Scholar] [CrossRef]

- Wang, J.; Kaskel, S. KOH activation of carbon-based materials for energy storage. J. Mater. Chem. 2012, 22, 23710–23725. [Google Scholar] [CrossRef]

- Zhu, L.; Zhao, N.; Tong, L.; Lv, Y. Structural and adsorption characteristics of potassium carbonate activated biochar. RSC Adv. 2018, 8, 21012–21019. [Google Scholar] [CrossRef]

- Mei, B.-A.; Munteshari, O.; Lau, J.; Dunn, B.; Pilon, L. Physical Interpretations of Nyquist Plots for EDLC Electrodes and Devices. J. Phys. Chem. C 2018, 122, 194–206. [Google Scholar] [CrossRef]

- Asare, K.; Hasan, F.; Shahbazi, A.; Zhang, L. A comparative study of porous and hollow carbon nanofibrous structures from electrospinning for supercapacitor electrode material development. Surf. Interfaces 2021, 26, 101386. [Google Scholar] [CrossRef]

- Jenkins, H.D.B.; Thakur, K.P. Reappraisal of Thermochemical Radii for Complex Ions. J. Chem. Educ. 1979, 56, 576–577. [Google Scholar] [CrossRef]

- Vicentini, R.; Nunes, W.G.; Costa, L.H.; Pascon, A.; da Silva, L.M.; Baldan, M.; Zanin, H.G. Environmentally friendly functionalization of porous carbon electrodes for aqueous based electrochemical capacitors. IEEE Trans. Nanotechnol. 2018, 18, 73–82. [Google Scholar] [CrossRef]

- Eliad, L.; Pollak, E.; Levy, N.; Salitra, G.; Soffer, A.; Aurbach, D. Assessing optimal pore-to-ion size relations in the design of porous poly(vinylidene chloride) carbons for EDL capacitors. Appl. Phys. A Mater. Sci. Process. 2006, 82, 607–613. [Google Scholar] [CrossRef]

- Largeot, C.; Portet, C.; Chmioia, J.; Taberna, P.-L.; Gogotsi, Y.; Simon, P. Relation between the Ion Size and Pore Size for an Electric Double-Layer Capacitor. J. Am. Chem. Soc. 2008, 130, 2730–2731. [Google Scholar] [CrossRef] [PubMed]

- Ranaweera, C.K.; Kahol, P.K.; Ghimire, M.; Mishra, S.R.; Gupta, R.K. Orange-Peel-Derived Carbon: Designing Sustainable and High-Performance Supercapacitor Electrodes. C 2017, 3, 25. [Google Scholar] [CrossRef]

- Hulicova-Jurcakova, D.; Seredych, M.; Lu, G.Q.; Bandosz, T.J. Combined Effect of Nitrogen- and Oxygen-Containing Functional Groups of Microporous Activated Carbon on its Electrochemical Performance in Supercapacitors. Adv. Funct. Mater. 2009, 19, 438–447. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).