The Morphological and Thermal Characteristics of Hollow-Glass-Microsphere-Coated Phase Change Material–Cow Pie Embedded Recycled Plastic Tiles for Cool Roofs

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Processing and Preparation of the Roof Tile Specimens

2.3. Scanning Electron Microscopy (SEM)

2.4. Differential Scanning Calorimetry (DSC)

2.5. Coefficient of Thermal Expansion (CTE), Volumetric Heat Capacity, and Thermal Conductivity

3. Results and Discussion

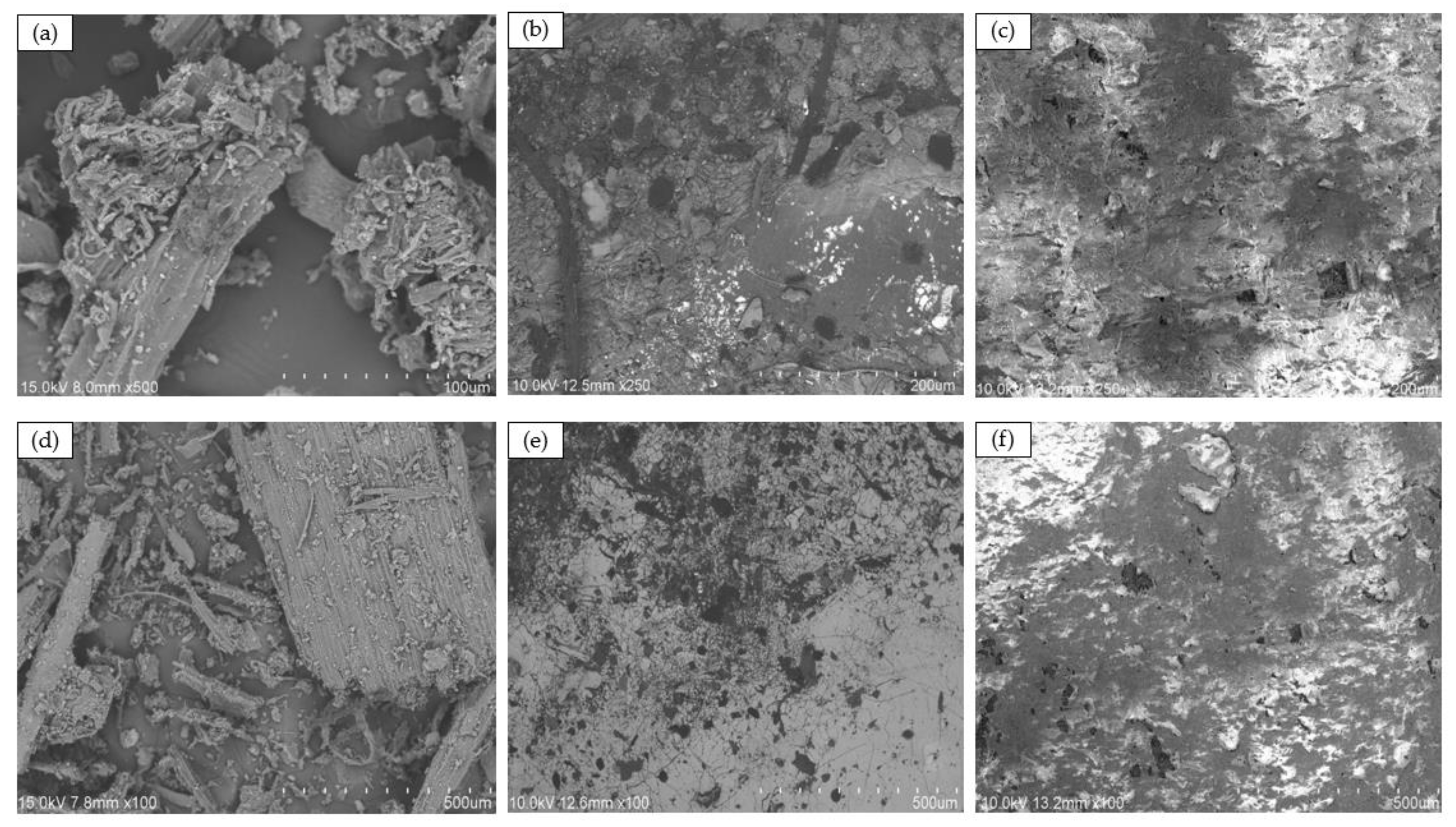

3.1. Morphological Investigations

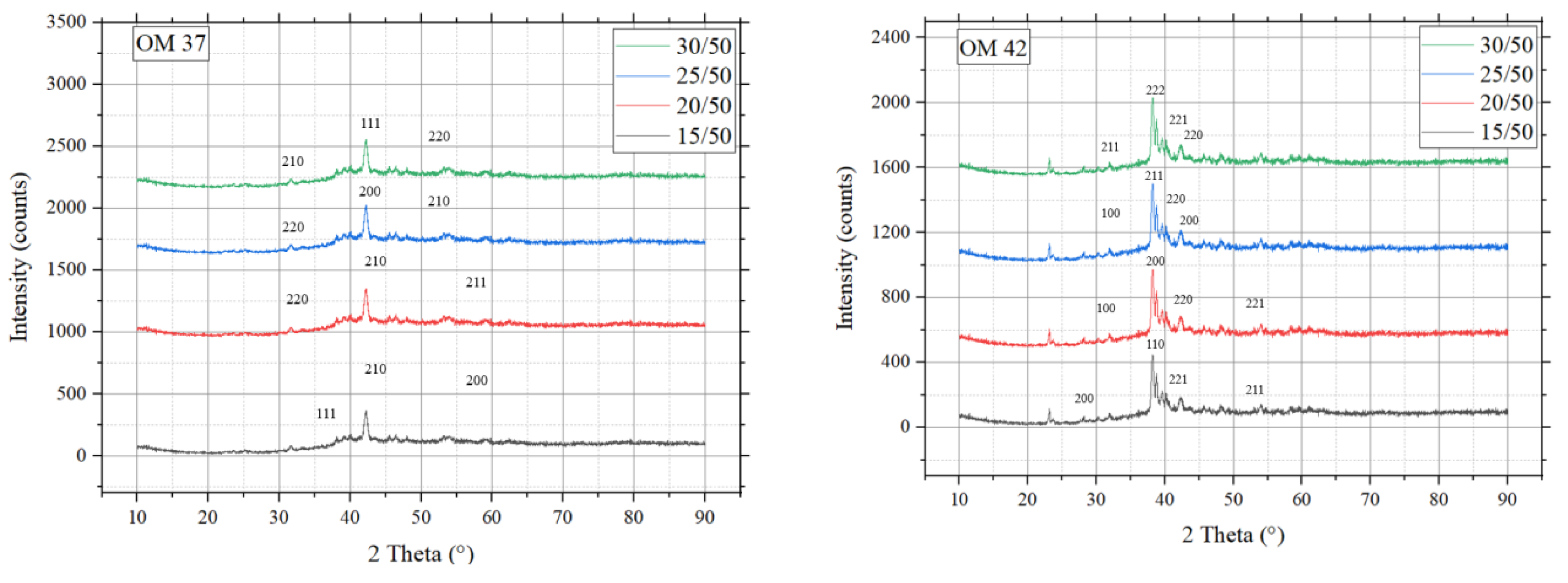

3.2. XRD Analysis

3.3. Thermal Analysis

3.3.1. Differential Scanning Calorimetry (DSC)

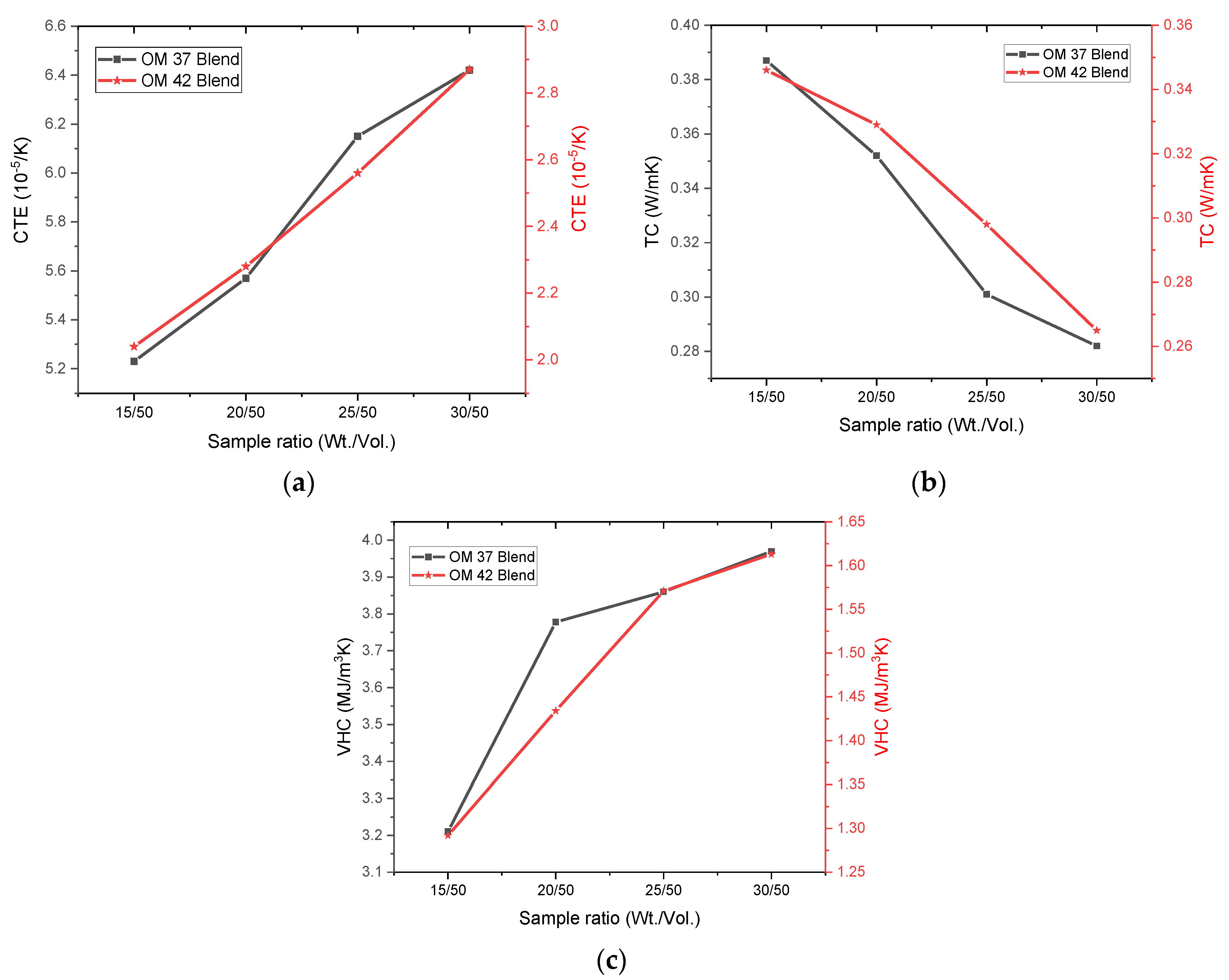

3.3.2. Coefficient of Thermal Expansion (CTE), Thermal Conductivity (TC), and Volumetric Heat Capacity (VHC)

3.4. Real-Time Temperature Distribution on the Roof Tiles

4. Conclusions

- Good bonding was observed during the SEM analysis. PCM, along with cow pie fibers, at a 20/50 (wt./vol.) ratio blend showed the best adhesive bonding for OM37 and OM42.

- The mixing of cow pie fibers into the PCM increased the heat storage capacity of the blends due to a shift in the melting point for the OM37 and OM42 composites.

- The thermal conductivity was reduced with an increase in the cow pie fiber percentage due to the material’s increased porosity. In contrast, the volumetric heat capacity increased with an increase in the cow pie fibers. This further enhanced the thermal storage capacity of the material.

- In the summer season, it was observed that there is a temperature reduction of 6–8 °C indoors in the afternoon, reduced to a 2–3 °C reduction at night, under the test conditions.

- In the rainy season, there is a 7–9 °C reduction during afternoons and a 2 °C reduction at night. During winter, there is no significant change in the temperatures during the day, but the indoor temperatures are cozy at night.

- The selection of the PCM will be crucial to energy-saving applications and is based on geographical location.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nayak, A.; Rama Sreekanth, P.S.; Sahu, S.K.; Sahu, D. Structural tuning of low band gap intermolecular push/pull side-chain polymers for organic photovoltaic applications. Chin. J. Polym. Sci. 2017, 35, 1073–1085. [Google Scholar] [CrossRef]

- Gilani, I.E.; Sayadi, S.; Zouari, N.; Al-Ghouti, M.A. Plastic waste impact and biotechnology: Exploring polymer degradation, microbial role, and sustainable development implications. Bioresour. Technol. Rep. 2023, 24, 101606. [Google Scholar] [CrossRef]

- Sahu, S.K.; Rama Sreekanth, P.S. Mechanical, thermal and rheological properties of thermoplastic polymer nanocomposite reinforced with nanodiamond, carbon nanotube and graphite nanoplatelets. Adv. Mater. Process. Technol. 2022, 8 (Suppl. S4), 2086–2096. [Google Scholar] [CrossRef]

- Satya, S.K.; Sreekanth, P.R. An experimental study on recycled polypropylene and high-density polyethylene and evaluation of their mechanical properties. Mater. Today Proc. 2020, 27, 920–924. [Google Scholar] [CrossRef]

- Colwell, J.; Pratt, S.; Lant, P.; Laycock, B. Hazardous state lifetimes of biodegradable plastics in natural environments. Sci. Total Environ. 2023, 894, 165025. [Google Scholar] [CrossRef] [PubMed]

- Sahu, S.K.; Badgayan, N.D.; Samanta, S.; Sreekanth, P.R. Experimental investigation on multidimensional carbon nanofiller reinforcement in HDPE: An evaluation of mechanical performance. Mater. Today Proc. 2020, 24, 415–421. [Google Scholar] [CrossRef]

- Li, M.; Pan, Y.; Hou, Z.; Wu, Z.; Zeng, Z.; Wang, B. Plastic or plastic-free life: From formation to removal. Sci. Total Environ. 2023, 890, 164359. [Google Scholar] [CrossRef]

- McCann, J. Preparation for smart clothing production. In Smart Clothes and Wearable Technology; Wood Head Publishing: Sawston, UK, 2023; pp. 371–404. [Google Scholar]

- Plastic Pollution. Available online: https://www.oecd.org/environment/plastic-pollution-is-growing-relentlessly-as-waste-management-and-recycling-fall-short.htm (accessed on 22 September 2023).

- Li, H.; Aguirre-Villegas, H.A.; Allen, R.D.; Bai, X.; Benson, C.H.; Beckham, G.T.; Bradshaw, S.L.; Brown, J.L.; Brown, R.C.; Cecon, V.S.; et al. Correction: Expanding plastics recycling technologies: Chemical aspects, technology status and challenges. Green Chem. 2023, 25, 791–792. [Google Scholar] [CrossRef]

- López de Dicastillo, C.; Velásquez, E.; Rojas, A.; Guarda, A.; Galotto, M.J. The use of nanoadditives within recycled polymers for food packaging: Properties, recyclability, and safety. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1760–1776. [Google Scholar] [CrossRef]

- Ayre, D. Technology advancing polymers and polymer composites towards sustainability: A review. Curr. Opin. Green Sustain. Chem. 2018, 13, 108–112. [Google Scholar] [CrossRef]

- Satya, S.K.; Sreekanth, P.R. Morphological, thermal and viscoelastic behavior of recycled high density polyethylene nanocomposite incorporated with 1D/2D nanofillers. Iran. Polym. J. 2022, 31, 629–640. [Google Scholar] [CrossRef]

- Ganesan, A.; Preetha, H.; Subathara, S.; Bhowmik, S. Comparative analysis of carbon emission from products of virgin plastics and recycled plastics and their environmental benefits. Int. J. Environ. Sci. Technol. 2023, 20, 6713–6722. [Google Scholar] [CrossRef]

- Yin, Z.; Liu, Z.; Liu, X.; Zheng, W.; Yin, L. Urban heat islands and their effects on thermal comfort in the US: New York and New Jersey. Ecol. Indic. 2023, 154, 110765. [Google Scholar] [CrossRef]

- Yang, T.; King, W.P.; Miljkovic, N. Phase change material-based thermal energy storage. Cell Rep. Phys. Sci. 2021, 2, 100540. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Incorporation of phase change materials into building envelope for thermal comfort and energy saving: A comprehensive analysis. J. Build. Eng. 2021, 36, 102122. [Google Scholar] [CrossRef]

- Baniassadi, A.; Sailor, D.J.; Bryan, H.J. Effectiveness of phase change materials for improving the resiliency of residential buildings to extreme thermal conditions. Sol. Energy 2019, 188, 190–199. [Google Scholar] [CrossRef]

- Sheikh, Y.; Orhan, M.F.; Umair, M.; Mehaisi, E.; Azmeer, A. Variation in cooling performance of a bio-based phase change material by adding graphene nanoplatelets with surfactants. Int. J. Thermofluids 2022, 16, 100201. [Google Scholar] [CrossRef]

- Paul, J.; Samykano, M.; Pandey, A.K.; Kadirgama, K.; Tyagi, V.V. Nano Engineered Paraffin-Based Phase Change Material for Building Thermal Management. Buildings 2023, 13, 900. [Google Scholar] [CrossRef]

- Why Indians Put Cow Dung on the Walls of Their Home?|Go Smart Bricks. Available online: https://gosmartbricks.com/why-indians-put-cow-dung-on-the-walls-of-their-home/ (accessed on 22 September 2023).

- Fasake, V.; Dashora, K. A sustainable potential source of ruminant animal waste material (dung fiber) for various industrial applications: A review. Bioresour. Technol. Rep. 2021, 15, 100693. [Google Scholar] [CrossRef]

- Li, K.; Yang, Z.; Zhang, Y.; Li, Y.; Lu, L.; Niu, D. Effect of pretreated cow dung fiber on mechanical and shrinkage properties of cementitious composites. J. Clean. Prod. 2022, 348, 131374. [Google Scholar] [CrossRef]

- Xue, X.; Qiu, M.; Li, Y.; Zhang, Q.M.; Li, S.; Yang, Z.; Feng, C.; Zhang, W.; Dai, J.G.; Lei, D.; et al. Creating an eco-friendly building coating with smart subambient radiative cooling. Adv. Mater. 2020, 32, 1906751. [Google Scholar] [CrossRef] [PubMed]

- Pluss Technologies, savE® PCMs Product Range. Available online: https://plussat.eu/save-pcm-product-range/?_paged=3 (accessed on 22 September 2023).

- Fasake, V.; Dashora, K. Characterization and morphology of natural dung polymer for potential industrial application as bio-based fillers. Polymers 2020, 12, 3030. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Wu, S.; Zhuang, J.; Tong, J.; Qi, H. Tribological and physio-mechanical characterization of cow dung fibers reinforced friction composites: An effective utilization of cow dung waste. Tribol. Int. 2019, 131, 200–211. [Google Scholar] [CrossRef]

- Luo, H.; Xiong, G.; Ma, C.; Chang, P.; Yao, F.; Zhu, Y.; Zhang, C.; Wan, Y. Mechanical and thermo-mechanical behaviors of sizing-treated corn fiber/polylactide composites. Polym. Test. 2014, 39, 45–52. [Google Scholar] [CrossRef]

- Li, Y.; Samad, Y.A.; Polychronopoulou, K.; Alhassan, S.M.; Liao, K. From biomass to high performance solar–thermal and electric–thermal energy conversion and storage materials. J. Mater. Chem. A 2014, 2, 7759–7765. [Google Scholar] [CrossRef]

- Wu, S.; Guo, M.; Zhao, J.; Wu, Q.; Zhuang, J.; Jiang, X. Characterization of the Mechanical and Morphological Properties of Cow Dung Fiber-Reinforced Polymer Composites: A Comparative Study with Corn Stalk Fiber Composites and Sisal Fiber Composites. Polymers 2022, 14, 5041. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Tian, S.; Xiao, D. Experimental study on the phase change behavior of phase change material confined in pores. Sol. Energy 2007, 81, 653–660. [Google Scholar] [CrossRef]

- Wu, W.; Wu, W.; Wang, S. Form-stable and thermally induced flexible composite phase change material for thermal energy storage and thermal management applications. Appl. Energy 2019, 236, 10–21. [Google Scholar] [CrossRef]

- Mahamat, A.D.; Ali, A.; Tanguier, J.L.; Donnot, A.; Benelmir, R. Mechanical and thermophysical characterization of local clay-based building materials. In Proceedings of the 2020 5th International Conference on Renewable Energies for Developing Countries (REDEC), Marrakech, Morocco, 29–30 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6. [Google Scholar]

- Ling, Z.; Chen, J.; Xu, T.; Fang, X.; Gao, X.; Zhang, Z. Thermal conductivity of an organic phase change material/expanded graphite composite across the phase change temperature range and a novel thermal conductivity model. Energy Convers. Manag. 2015, 102, 202–208. [Google Scholar] [CrossRef]

| Properties | Units | OM37 | OM42 |

|---|---|---|---|

| Specific heat (Cp) | (kJ/kg K) | 2.63 | 2.78 |

| Density (ρ) | (kg/m3) | 860 | 863 |

| Thermal conductivity (k) | (W/mK) | 0.13 | 0.10 |

| Latent heat (L) | (kJ/kg) | 186 | 199 |

| Melting temp. (t) | (°C) | 38 | 44 |

| Composite | wt./vol. | 2Ө—Peak 1 | 2Ө—Peak 2 | 2Ө—Peak 3 | 2Ө—Peak 4 |

|---|---|---|---|---|---|

| OM37 + Cow Pie Powder | 30/50 | 320 | 430 | 540 | |

| 25/50 | 32.50 | 42.50 | 540 | ||

| 20/50 | 32.50 | 42.50 | 540 | ||

| 15/50 | 330 | 42.50 | 540 | ||

| OM42 + Cow Pie Powder | 30/50 | 320 | 380 | 400 | 430 |

| 25/50 | 32.50 | 390 | 400 | 430 | |

| 20/50 | 32.50 | 390 | 430 | 540 | |

| 15/50 | 330 | 38.50 | 430 | 540 |

| SNo. | Season | Test Condition |

|---|---|---|

| 1 | Summer (May) | Doors and windows were kept closed in the morning and open at night |

| 2 | Rainy (August) | Doors and windows were kept open during morning and night |

| 3 | Winter (December) | Doors and windows were kept open during the morning and closed during night-time |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Satya, S.K.; Rama Sreekanth, P.S. The Morphological and Thermal Characteristics of Hollow-Glass-Microsphere-Coated Phase Change Material–Cow Pie Embedded Recycled Plastic Tiles for Cool Roofs. J. Compos. Sci. 2024, 8, 148. https://doi.org/10.3390/jcs8040148

Satya SK, Rama Sreekanth PS. The Morphological and Thermal Characteristics of Hollow-Glass-Microsphere-Coated Phase Change Material–Cow Pie Embedded Recycled Plastic Tiles for Cool Roofs. Journal of Composites Science. 2024; 8(4):148. https://doi.org/10.3390/jcs8040148

Chicago/Turabian StyleSatya, S. Krishna, and P. S. Rama Sreekanth. 2024. "The Morphological and Thermal Characteristics of Hollow-Glass-Microsphere-Coated Phase Change Material–Cow Pie Embedded Recycled Plastic Tiles for Cool Roofs" Journal of Composites Science 8, no. 4: 148. https://doi.org/10.3390/jcs8040148

APA StyleSatya, S. K., & Rama Sreekanth, P. S. (2024). The Morphological and Thermal Characteristics of Hollow-Glass-Microsphere-Coated Phase Change Material–Cow Pie Embedded Recycled Plastic Tiles for Cool Roofs. Journal of Composites Science, 8(4), 148. https://doi.org/10.3390/jcs8040148