Electronic Packaging Materials and Technology Applications

A special issue of Materials (ISSN 1996-1944). This special issue belongs to the section "Electronic Materials".

Deadline for manuscript submissions: 31 August 2024 | Viewed by 3987

Special Issue Editors

Interests: electronic packaging; solder joint; twinned cu film; transient liquid phase bonding; metal-metal direct bonding; 3dic interconnection; power device packaging; low-temperature alloys; high-entropy alloys; materials characterization; reliability issue

Interests: electronic packaging; electroplating; solar cell; solder joint; metal bonding; low-temperature alloy

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

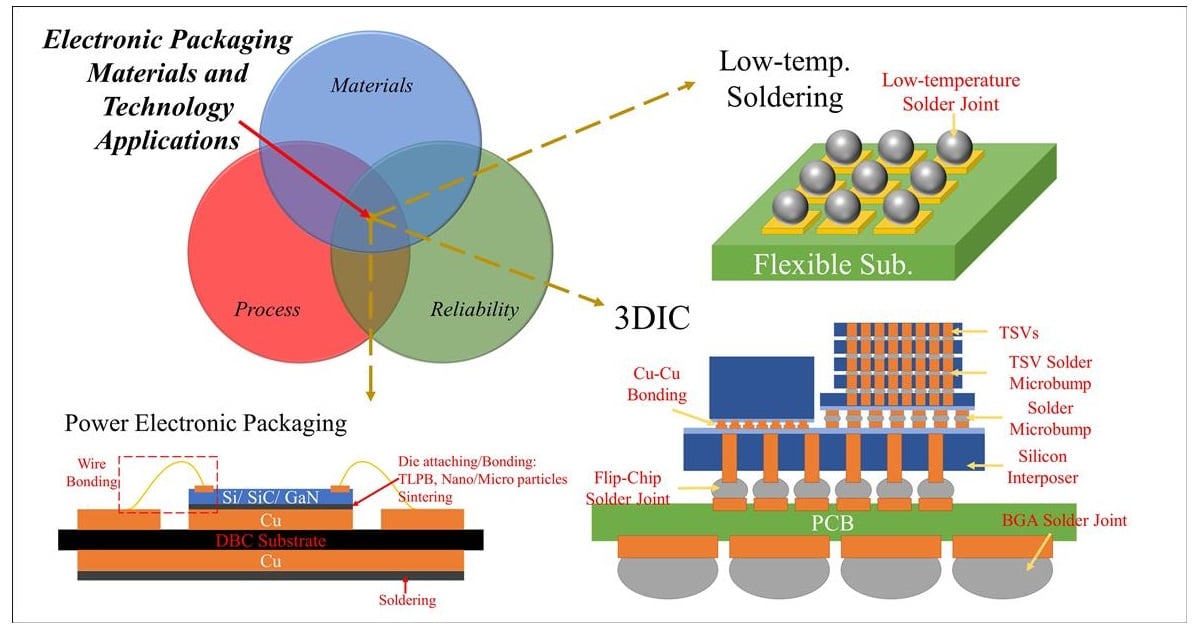

In light of the escalating demand for advanced electronic devices, the domains of 2.5D/3DIC packaging, power device packaging, and low-temperature application packaging have acquired significant attention. These packaging techniques find application in cutting-edge electronic products such as smart devices, electric vehicles, solar energy converters, 5G equipment, and flexible electronics. Consequently, the development of packaging materials, processes, and applications holds critical importance in addressing human well-being, energy concerns, advanced communication equipment, and biomedical products.

We hereby introduce a Special Issue on "Electronic Packaging Materials and Technology Applications". Our collection contains a wide spectrum of research issues, including electronic packaging, solder joint, twinned Cu film, transient liquid phase bonding, metal-metal direct bonding, 3DIC interconnection, power device packaging, low-temperature alloys, materials characterization, and reliability issues—all relevant to advanced packaging technology. We eagerly anticipate the support and contributions of experts in these fields.

Dr. Yu-An Shen

Prof. Dr. Chih-Ming Chen

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- packaging process

- 2.5D/3DIC packaging

- power electronic packaging

- low-temperature application packaging

- packaging materials

- solder joint

- electroplated film for electronic packaging

- transient liquid phase bonding

- metal&ndash

- metal direct bonding

- reliability analysis in electronic packaging

Planned Papers

The below list represents only planned manuscripts. Some of these manuscripts have not been received by the Editorial Office yet. Papers submitted to MDPI journals are subject to peer-review.

Title: Suppressed effect of alkanethiol self-assembly monolayers on the electrochemical migration of fine-pitch nano-sized Ag interconnects prepared by direct-printing technology

Authors: Chia-Hung Tsou; Wan-Hsuan Lin; Chien-Cheng Chiang; Fan-Yi Ouyang

Affiliation: Department of Engineering and System Science, National Tsing Hua University, Hsinchu, Taiwan 30013

Abstract: This paper proposes a method to modify the surface of Ag nanoparticles by introducing self-assembly monolayers (SAMs) to suppress the electrochemical migration (ECM) of fine-pitch Ag interconnects in the humid and biased environment for electronic devices. SAMs on surfaces of Ag nanoparticles are pretreated by immersion in 10 mM 1-dodecanethiol ethanolic solution at different times. The samples with surface treatment exhibit 3 ~ 5 times better ECM resistance than as-printed ones, and the sample immersed for 18 h of thiolate surface treatment exhibits the best ECM performance. It was found that Ag-SR bonding of chelating complexes was formed on the Ag surface after surface treatment. Because the neutral charge of the Ag-SR pair is more difficult to be driven by the electric field in the aqueous electrolyte, the surface-treated samples possess a lower solubility in the electrolyte and a higher activation energy of migration than as-printed ones and thus further improve the ECM resistance of Ag.